Page 1

10*

Model Nos.

20’’SN0W THROWER

For one year from date of purchase, MTD Products Inc ,

will replace for the original purchaser, free of charge, F.O.B.

factory or authorized service firm, any part or parts found to

be defective in material or workmanship. All transportation

charges on parts submitted for replacement under this war

ranty must be paid by the purchaser. This warranty does not

include replacement of parts which become inoperative

through misuse, excessive use, accident, neglect, improper

maintenance or alterations by unauthorized persons. This

warranty does not include the engine, motor, battery, bat

tery charger or any component parts thereof. For service on

these units refer to the applicable manufacturer's warranty.

The above warranty will apply only to the original owner

and will be effective only if the warranty card has been pro

perly processed. It will not apply where the unit has been

used commercially.

Warranty service is available through your local author

ized service dealer or distributor. UNDER NQ CIRCUM

STANCES WILL THE RETURN OF A COMPLETE UNIT

BE ACCEPTED BY THE FACTORY UNLESS PRIOR

WRITTEN PERMISSION HAS BEEN EXTENDED.

313-205 & 313-230

1.2.Know the controls and how to stop quickly—READ

THE OWNER'S MANUAL.

Disengage power and stop motor before cleaning dis

charge, removing obstacles, making adjustments, or

when leaving operation position.

Never direct discharge at bystanders nor allow anyone

in front of machine—debris may be hidden in the snow.

Keep children and pets a safe distance away.

Do not allow children to operate machine nor allow

adults to operate it without proper instruction.

Adjust height to clear gravel or crushed rock surface.

7. Exercise caution to avoid slipping or falling, especi

when operating in reverse.

Handle gasoline with care — it is highly flammable.

8.

A. Use approved gasoline container^

B. Never add gasoline to a running motor — fill tank

out of doors and wipe up spilled gasoline.

C. Replace gasoline cap securely.

D. Open door if motor is run in garage — exhaust

gases are dangerous.

Disengage all clutches and shift into neutral before

9.

starting motor. Keep hands, feet and clothing away

from power driven parts.

Use a grounded three wire extension cord for all plug

10.

in electric units.

Keep machine in good operating condition and keep

11

safety devices in place.

MTD PRODUCTS INC •

5389 WEST 130th STREET • P. 0. BOX 2741 CLEVELAND OHIO 44111

FORM NO. 770-4790

Page 2

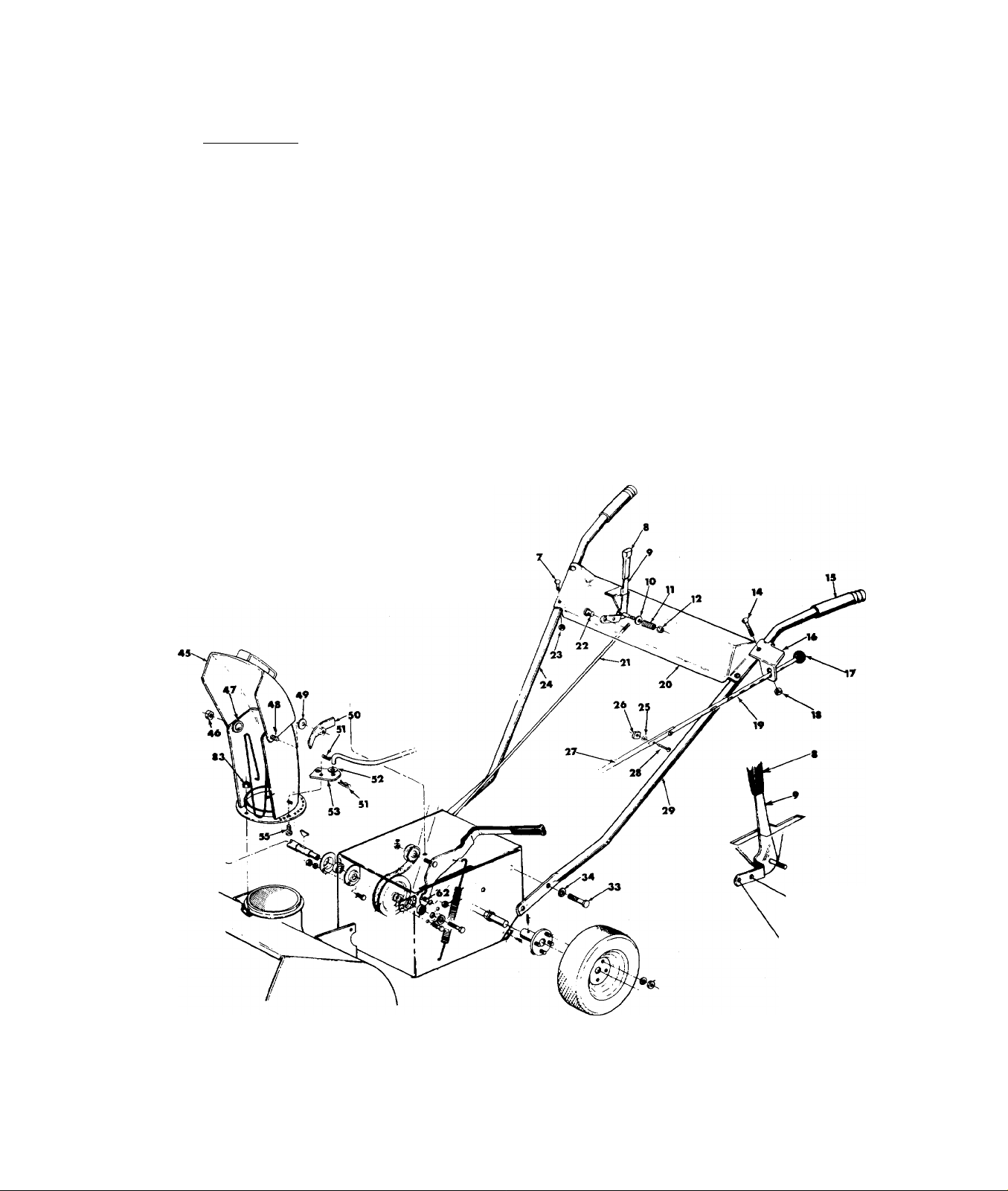

ASSEMBLY INSTRUCTIONS

Right hand (R.H.) and left hand (L.H.) are as observed

from the operating position.

1. Assemble chrome handles (Ref. No. 24 and 29) to

the frame with four hex head cap screws %-16x %

long and four lock washers DO NOT TIGHTEN.

2. Assemble handle panel (Ref. No. 20) to the handles

with the four carriage bolts 14-20 x IVa Ig. and hex

locknuts 14-20 thd. Assemble handle panel so you

can read the instructions on the handle panel from

the operating position. LIFT HANDLE UP AS YOU

TIGHTEN ALL BOLTS AND NUTS ON THE HANDLE

ASSEMBLY.

NOTE: Model 313-205 has no Reverse.

3. The linkage arm (Ref. No. 21) for the transmission is

located on the R.H. side of the frame. Pull the arm

back into reverse. (Towards the operator.) It may be

necessary to roll the snow thrower slightly until it

engages in the reverse position. Assemble the fer

rule to the shift lever handle use hole marked "20"

\ on the handle panel and screw in the shifting rod.

Adjust the rod by screwing it in or out until it fits

into the linkage arm on the side of the frame. Se

cure it with a cotter pin.

4. Chute Crank. Assemble the chute crank (two parts)

into the two holes in the handle panel being sure

the rod passes through the chute control bracket.

Push the rod all the way through and assemble it

to the chute bracket with two cotter pins and flat

washers.

5. Remove the wing nut, washer, and carriage bolt

5/16-18 x% Ig. from the chute assembly. Lift the

deflector and reassemble. If the deflector will not

move, loosen the screw and nut slightly so it pivots

freely.

Use This Hole

20" Models

Use This Hole

26" Models

Page 3

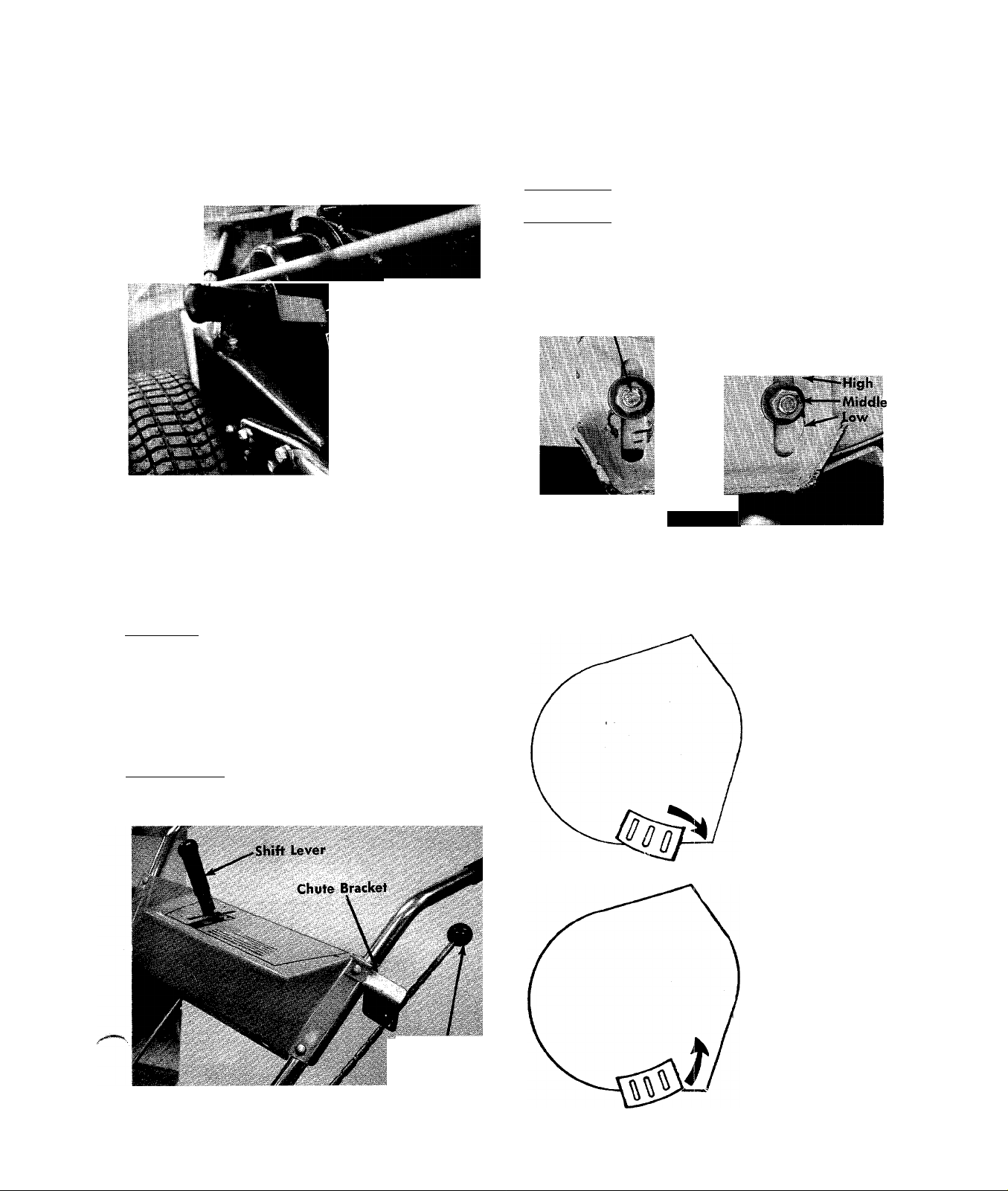

CONTROLS

SKID SHOES

/•^MAIN Clutch. This clutch shuts off the power to the

/heels and auger. When the handle is up it is in the

disengaged position. It is shown in the disengaged

position in the photo. (See figure 1.)

.Main Clutch

FIGURE 1

CAUTION

The skid shoes on each side of the thrower are adjust

able by loosening the bolts and nuts.

low Position—Close snow removal.

Middle or High Position—Use when road is uneven.

The skid shoes and shave plate should be replaced

when worn.

Bolt and Nut

Skid Shoe

FIGURE 3.

Main Clutch must be disengaged when

starting.

Shift Lever. Move the shift lever into either forward or

reverse rapidly on model 313-230 only. Engaging

slowly causes wear on the clutch collars. There is no

clutch to engage the drive wheels.

To stop the snow thrower move the shift lever into

neutral (N). Move this control only when the engine is

operating. (See figure 2.)

Chute Controls. Raise the chute control knob and push

or pull to rotate the chute. Loosen the wing nut to

adjust the deflector. (See figure 2.)

The skid shoes may be tipped for better operation.

Tip front of skid shoe

down when operat

ing in hard packed

snow.

FIGURE 2.

Chute Control

Tip front of skid shoe

up when operating in

loose stone or soft

areas.

Page 4

STARTING YOUR SNOW THROWER

1. Follow your engine instructions for lubrication and

gasoline.

2. Disengage the main clutch (Lever UP).

3. Put the shift lever in neutral position (N).

4. Start the engine in accordance with the engine

manual.

OPERATION

1. SLOWLY engage the main clutch.

2. Move the shift lever into FORWARD (F) position.

3. To stop the forward drive of the snow thrower pull

the shift lever into NEUTRAL (N).

NOTE

NOTE

This instruction manual covers various models

and all accessories shown do not necessarily

apply to your model snow thrower.

If repairs or service is needed on the engine

or engine controls such as

the primer, choke or throt

tle control, contact your

nearest authorized engine

service outlet. Check the

"Yellow Pages" of your

telephone book under "Eng i nes—Gasol i ne".

Find It Fait

In Th*

'Yellow Pages'

For more traction, chains are

mended.

Order Model

of Chains

313-205 and 230

393-988

Part No.

recom-

Tire Size

10 X 2.75

LUBRICATION

Refer to the parts drawings. Lubricate after each 25

hours of operation the parts indicated. Use multipur

pose

automotive grease on parts marked

SAE 30 engine oil on parts marked

and

Page 5

Ol

USE THIS HOLE

26"MODEL$

Page 6

Page 7

PARTS LIS

SNOW THROWER MODELS 313-205 AND 313-230

REF.

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13 ,

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

32

33

34

PART

NO.

5228

714-105

756-170

5230

736-235

710-262

720-142

5131

736-105

732-193

712-116

5258—435

710- 256

1166

5266—435

722-115

712-107

5269

5125—435

711- 374

711- 179

712- 158

5124

736-147

712-425

5268

710-467

5123

734-468

734-296

734-297

710-216

736-169

COLOR

CODE

DESCRIPTION

Engine

Belt Guard Assembly

Square Key 3/16x3/16x

1" Lg.*

2% Pulley

Top Belt Guard Assembly

Flat Washer

Carriage Bolt 5/16-18 x

1.50" Lg.

Flat Bar End Grip

Shift Grip

Belleville Washer

Compression Spring

Hex Elastic Stop Nut %-24

Thd.

Spirol Housing Assembly

Carriage Bolt 14-20x1’/2"

Lg.*

Grip

Chute Control Bracket

Ball—Knob

Center Lock Nut '/4-20 Thd.

Chute Control Rod

Handle Panel Ass'y.

Shifting Rod

Adjustment Ferrule

Center Lock Nut 5/16-18 Thd

Handle—R.H.

Ext. Lock Washer #10-24

Screw*

Square Nut 10-24 Thd.*

Chute Rod

Truss Hd. Mach. Screw 10-24

X 1" Lg.*

Handle—L.H.

Wheel Assembly Complete

Rim Assembly Only

Tire—Only 10. X 2.75

Hex Hd. Cap Scr. 54-16 x %'

Lg.*

Spring Lock Washer 54" Scr.*

REF.

NO.

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

PART

NO.

720-142

5058

710-152

736-169

712-287

736-329

710-237

736-119

710-442

710-289

5225—435

712-158

736-179

710-260

736-105

5140-

714-111

736-300

5265732-211

710- 289

714- 126

711- 519

741-162

754-133

712- 1 16

756-137

738-147

732-185

712-375

748-151'

715- 107

COLOR

CODE

-435

-435

DESCRIPTION

Flat Bar End Grip

Idler Bracket Assembly

Hex Hd. Cap Scr, %-24 x 1"

Lg.*

Spring Lock Washer %" Scr.*

Hex Nut '/4-20 Thd.*

Spring Lock Washer Va" Scr.*

Hex Hd. Cap Screw 5/16-24

%" Lg.*

Spring Lock Washer 5/16"

Screw*

Hex Hd. Cap Screw 5/16-18

X l'/2" Lg.*

Hex Hd. Cap Screw 'A-20 x

'/2" Lg.*

Top Chute Assembly

Hex Center Lock Nut 5/16-

18 Thd.

Flat Washer

Carriage Bolt 5/16-18 x%"

Lg.*

Belleville Washer

Chute Wing Assembly

Cotter Pin 3/32 Dia. x 1"

Lg.*

Flat Washer .406 i.D. x .734

O.D.

Chute Bracket

Chute Guard

Hex Hd, Cap Scr. 'A-20 x '/2"

Lg.*

Hi Pro Key #606

Drive Shaft

Ball Bearing

3 V-Belt 31.5

Hex Elastic Stop Nut %-24

Thd.

Flat Idler

Shoulder Bolt %-16 Thd.*

Tension Spring

Hex Center Lock Nut %-16

Thd.*

Flange Bearing %" Dia.

Spirol Pin

REF.

NO.

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

PART

NO.

710-224

5051

5041

710-289

736-264

741-133

5245

736-192

756-136

710-555

5244

736-119

712-267

5031-

712-107

712-107

5156

736-192

741-133

5267736-329

710-289

710-538

736-264

712- 267

736-119

710-606

710-152

736-169

6605-

713- 106

5251-

COLOR

CODE

-435

-435

-435

-435

DESCRIPTION

Sems Hex Hd. Self Tap Scr.

Type A #10-32x'/2" Lg.

Gear—Housing Assembly

Frame Assembly

Hex Hd. Cap Scr. Vi-20 x

'/2" Lg.*

Flat Washer 5/16 Scr.*

Ball Bearing '/2" I.D.

Bearing Housing Assembly

Flat Washer

5" Dia. Pulley with Sprocket

Pilot Scr. %-16 x .88" Lg.

Housing

Spring Lock Washer 5/16" Scr.

Hex Nut 5/16-18 Thd.*

Chute Flange Keeper Ass'y.

Hex Center Lock Nut 'A-20

Thd.

Hex Center Lock Nut '/i-20

Thd.

10 Tooth Sprocket

Flat Washer .530 I.D. x .930

O.D.

Ball Bearing '/2" I.D. x 1%

O.D.

Chain Guard

Spring Lock Washer Scr.*

Hex Hd. Cap Screw 'A-20 x

'/2" Lg.*

Hex Hd. Cap Screw with

Lock 5/16-18 X .62" Lg.

Flat Washer

Hex Nut 5/16-18 Thd.*

Spring Lock Washer 5/16

Screw*

Hex Hd. Cap Screw 'A-20 x

l'/2" Lg.*

Hex Hd. Cap Screw %-24 x

V' Lg.*

Spring Lock Washer %Scr.*

Chain Adjuster

Roller Chain #41 x31.5 Lg.

without Master Link

Spiral Assembly

Page 8

o

70

z

p

VI

V|

0

'O

O

z

-H

PARTS LIST FOR SNOW THROWER MODELS 313-205 AND 313-230

REF.

NO.

100 748-110

1

101 710-260

PART

NO.

COLOR

CODE

DESCRIPTION

Flange Bearing % I.D. 129 711-355 Shaft

Carriage Bolt 5/16-18 x%" 130

Lg.*

102

710-260

Carriage Bolt 5/16-18 x%"

Lg.*

103

736-119

Spring Lock Washer 5/16"

Scr.*

104

105

106

712-267

5001—435

710-389

Hex Nut 5/16-18 Thd.*

Shave Plate

Carriage Bolt %-16x%"

Lg.*

107

108 736-105

109

no 710-152

5002—435

712-798

Slide Shoe

Belleville Washer

Hex Nut %-16 Thd.*

Hex Hd. Cap Screw %-24 x

1" Lg.*

111

112

113

114

115

116

736-169

711-520

726-100

5057

5051

710-259

Spring L-Wash. %" Scr.*

Spiral Axle

Push Nut % Rod Pal Nut

Rod

Gear Housing Assembly

Sems Hex Hd. Cap Scr. 5/16-

18 X %" Lg.*

117

118

119

120

121

714-111

5053

738-140

5054

710-259

Cotter Pin 3/32 X 1" Lg.*

Shifting Bracket

Shoulder Bolt 5/16-18 Thd.

Shifting Yoke

Sems Hex Hd. Cap Screw

5/16-18 x%" Lg.*

122

712-429

Hex Elastic Stop Nut 5/16-

18 Thd.

123

124

125

126

127

748-227

711-354

715-114

5137

713-129

Flange Bearing % Dia.

Shifting Shaft

Spirol Pin '/4" Dia. X 1" Lg.*

Spacer Hub Assembly

Roller Chain with Master

Link #41 X 24" Lg.

128

716-106

"E"—Ring Truarc #5133-62

%" Dia.*

REF.

NO.

PART

NO.

COLOR

CODE

DESCRIPTION

736-116 Flat Washer .625 I.D. x .937

O.D.

131 713-131 Roller Chain with Master Link

#41 X 17" Lg.

132

133

5093

715-114

134 748-164

Shaft Assembly

Spirol Pin 14" Dia. X 1.50" Lg.*

10 Teeth Spur Gear

135 748-161 Clutch Collar

136

716-106 "E"—Ring Truarc #5133-

62 %" Dia.*

137

748-162

62 Teeth Spur Gear

(313-230 Only)

138

714-137

Key 3/16 Thick x%" Dia.

1.062

139 748-163

21 Teeth Spur Gear

(313-230 Only)

140 736-116

Flat Washer .625 I.D.x .937

O.D.

141

716-106

"E"—Ring Truarc #5133-62

%" Dia.*

142

143 716-104

5090 Wheel Axle Assembly

"E"—Ring Truarc #5133-50

’/2" Dia.*

144 748-852

145

713-131 Roller Chain with Master Link

8 Tooth Sprocket

#41 X 17" Lg.

146

147

148 736-119

714-129

5051

Woodruff Key #503

Gear Housing Assembly

Spring Lockwasher 5/16"

Screw*

149 712-267

150 714-126

151

152

710-322

713-723 Master Link for #41 Chain

Hex Nut 5/16-18 Thd.*

Hi Pro Key #606 (313-230 Onl

Hex Sem.s Scr. 5/16-18 x 1.00"

(Use with Ref. No. 98)

153

154

155

156 -

5049

5223

5055

±726-111

-------------

Gear Hsg. Half Ass'y.

Chute Ass'y.

Frame Cover

-L Push Ca D . 188 Rod

----------------

Lg.

(/»

*For faster service obtain standard nuts, bolts, and washers locally. If these items cannot be obtained locally,

order by part number and size as shown on parts list.

Loading...

Loading...