Page 1

OWWirS GUIDE

• ASSEMBLY • OPERATION • MAINTENANCE • PARTS •

33" SNOW

THROWER

$1.00

Model Number

312-980I000

IMPORTANT!

Record the Model No. and Mfg. Code which

appear on your unit in the space below. You

must have these numbers, along with the date

of purchase, in order to receive warranty or ser

vice.

MEETS ANSI SAFETY STANDARDS

MODEL NO. MFG. CODE

Important:

Made ^

in

AMERICA

Read Safety Rules and Instructions Carefully

FORM NO. 770-5901G

Page 2

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFETY I^STRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL

SAFETY AND/OR PROPERTY OF YOURSELF AND CTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE

A

AHEMPTING TO OPERATE YOUR SNOWTHROWEIL FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PER

SONAL INJURY. WHEN YOU SEE THIS SYMBOL— A HEED ITS WARNING.

Your snow thrower was t uilt to be operated according to the rules for safe operation in this manual.

DANGER; As with any type of power equipment, careiessness or error on the part of the operator can result in

A

serious injury. If you violi ite any of these rules, you may cause serious injury to yourself or others.

SAFE OPERATION PRACTICES

A

A'

TRAINING

A

A

A

1. Read this owner’s guide carefully. Be thorc ughly famil

2. Never allow children to operate equipment. Never allow

3. No one should operate this unit while in oxicated or

4. Keep the area of operation clear of all peisons, espe

5. Exercise caution to avoid slipping or fallinn, especially

PREPARATION

1. Thoroughly inspect the area where the eqt ipment is to

2. Disengage all clutches and shift into ne Jtral before

3. Do not operate equipment without wearing adequate

4. Check the fuel before starting the engine. Gasoline is

5. Use a grounded three wire plug-in for all un ts with elec

6. Adjust collector housing height to clear gravel or

7. Never attempt to make any adjustments wh He engine is

8. Let engine and machine adjust to outdoor :emperature

9. Always wear safety glasses or eye shields Juring oper

OPERATION

1. Do not put hands or feet near rotating parts. Keep clear

2. Exercise extreme caution when operating in or cross

3. After striking a foreign object, stop the enc ine, remove

4. If the snow thrower should start to vibrate abnormally,

iar with the controls and proper use of the equipment.

Know how to stop the unit and disengage the controls

quickly.

adults to operate equipment without proper nstructions.

while taking medication that impairs the senses or reac

tions.

cially small children and pets.

when operating in reverse.

be used and remove all door mats, sleds, bDards, wires

and other foreign objects.

starting engine.

winter outer garments. Wear footwear which will

improve footing on slippery surfaces.

an extremely flammable fuel. Do not fill tie gasoline

tank indoors, while the engine is running, or while the

engine is still hot. Replace gasoline cap securely and

wipe off any spilled gasoline before startinci the engine

as it may cause a fire or explosion.

tric drive motors or electric starting motors.

crushed rock surface.

running (except where specifically recorr mended by

manufacturer).

before starting to clear snow.

ation or while performing an adjustment or repair, to

protect eyes from foreign objects that ma r be thrown

from the machine in any direction.

of discharge opening at all times.

ing gravel drives, walks, or roads. Stay ale 1 for hidden

hazards or traffic. Do not carry passengers.

wire from spark plug, and thoroughly inspect the snow

thrower for any damage. Repair the damage before

restarting and operating the snow thrower.

stop the engine and check immediately fo ■ the cause.

Vibration is generally a warning of trouble.

5. Stop engine whenever you leave the operating position,

before unclogging the collector/impeller housing or dis

charge guide, and making any repairs, adjustments, or

inspections.

6. Take all possible precautions when leaving the unit

unattended. Disengage the collector/impeller, shift into

neutral, stop the engine, and remove the key.

7. When cleaning, repairing, or inspecting, make certain

collector/impeller and all moving parts have stopped.

Disconnect spark plug wire and keep away from plug to

prevent accidental starting.

8. Do not run engine indoors, except when starting engine

and transporting snow thrower in or out of building.

Open doors. Exhaust fumes are dangerous.

9. Do not clear snow across the face of slopes. Exercise

extreme caution when changing direction on slopes. Do

not attempt to clear steep slopes.

10. Never operate snow thrower without guards, plates, or

other safety protection devices in place.

11. Never operate snow thrower near glass enclosure,

automobiles, window wells, drop off, etc., without prop

er adjustments of snow thrower discharge angle. Keep

children and pets away.

12. Do not overload machine capacity by attempting to

clear snow at too fast a rate.

13. Never operate the machine at high transport speeds on

slippery surfaces. Look behind and use care when

backing.

14. Never direct discharge at bystanders or allow anyone in

front of unit.

15. Disengage power to collector/impeller when transport

ing or not in use.

16. Use only attachments and accessories approved by the

manufacturer of snow thrower (such as wheel weights,

counter weights, cabs, etc.).

17. Never operate the snow thrower without good visibility

or light. Always be sure of your footing and keep a firm

hold on the handles. Walk, never run.

MAINTENANCE AND STORAGE

1. Check shear bolts, engine mounting bolts, etc., at fre

A

quent intervals for proper tightness to be sure equip

ment is in safe working condition.

2. Never store the machine with fuel in the fuel tank inside

a building where ignition sources are present, such as

hot water and space heaters, clothes dryers, and the

like. Allow engine to cool before storing in any enclo

sure.

3. Always refer to owner’s guide instructions for important

details if snow thrower is to be stored for an extended

period.

4. Run machine a few minutes after throwing snow to pre

vent freeze up of collector/impeller.

Page 3

ASSEMBLY

NOTE: This unit is shipped WITHOUT GAS-

OLiNE or OIL After assembly, see separate engine

manual for proper fuel and engine oil recommenda

tions.

Lockout Rod

Chute Crank Assembly

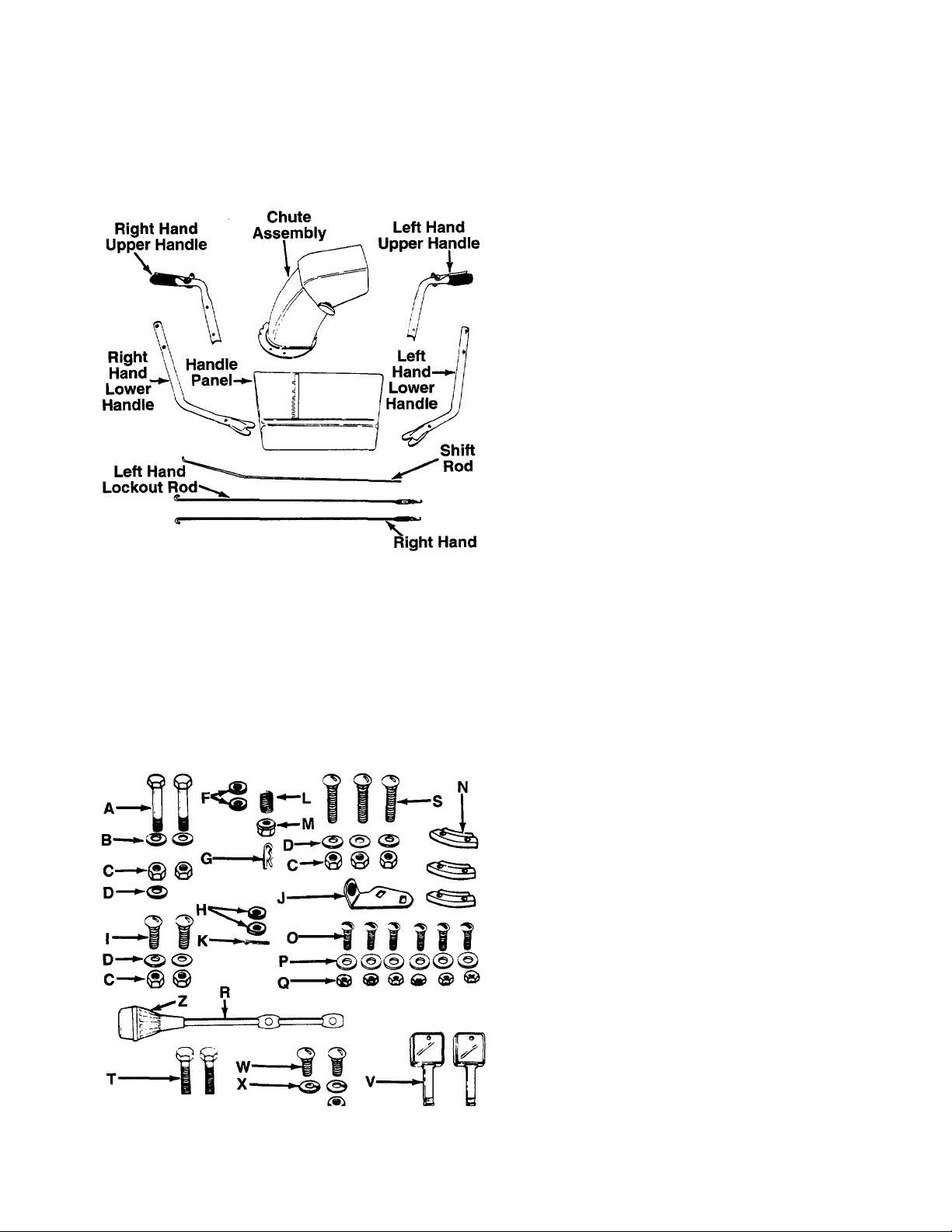

FIGURE 1.

Y

--------

^

FIGURE 2.

Tools Required for Assembly:

Screwdriver

9/16” Wrench

1/2” Wrench

7/16” Wrench

3/8” Wrench

or One Adjustable Wrench

Loose Parts in Carton (see figure 1):

(1) Upper Handle Assembly—L.H.

(1) Lower Handle—L.H.

(1) Upper Handle Assembly—R.H.

(1) Lower Handle—R.H.

(1) Handle Panel

(1) Chute Assembly

“(1) Parts taped together which include;

(1) Right Hand Lockout Rod

(1) Left Hand Lockout Rod

(1) Shift Rod

(1) Chute Crank Assembly

Contents of Hardware Pack (see figure 2):

(Hardware pack may contain extra items which are

not used on your unit.)

A (2) Hex Bolts 3/8-16x2” Long

B (2) Belleville Washers 3/8” I.D.

C (7) Hex Nuts 5/16-18 Thread

D (6) Belleville Washers 5/16” I.D.

F (2) Flat Washers 5/16” I.D.

G (1) Hairpin Clip

H (2) Flat Washers 3/8” I.D. X 5/8” O.D.

I (2) Carriage Bolts 5/16-18 X 3/4” Long

J (1) Chute Crank Bracket

K (1) Cotter Pin

L (1) Compression Spring

M (1) Hex Insert Lock Nut 5/16-18 Thread

N (3) Chute Flange Keepers

O (6) Truss Machine Screws 1/4-20 x 3/4” Long

P (6) Flat Washers 1/4” I.D.

Q (6) Hex Lock Nuts 1/4-20 Thread

“R (1) Shift Lever

S (3) Carriage Bolts 5/16-18 x 2” Long

T (2) Hex Bolts 5/16-18x13/4” Long*

U (2) Hex Insert Lock Nuts 5/16-18 Thread*

V (2) Ignition Keys (May be Attached to Engine)

W (2) Carriage Bolts 5/16-18 X 5/8” Longt

X (2) Lock Washers 5/16” I.D.t

Y (2) Hex Nuts 5/16-18 Threadt

Z (1) Shift Knob

tOptional Parts

*The augers are secured to the spiral shaft with two

hex bolts and hex insert lock nuts (see ref. nos. 40

and 50 on page 22). If you hit a foreign object or ice

jam, the snow thrower is designed so that the hex

bolts will shear. Two replacement hex bolts and nuts

are provided in the hardware pack for your conve

nience. Store in a safe place until needed.

Page 4

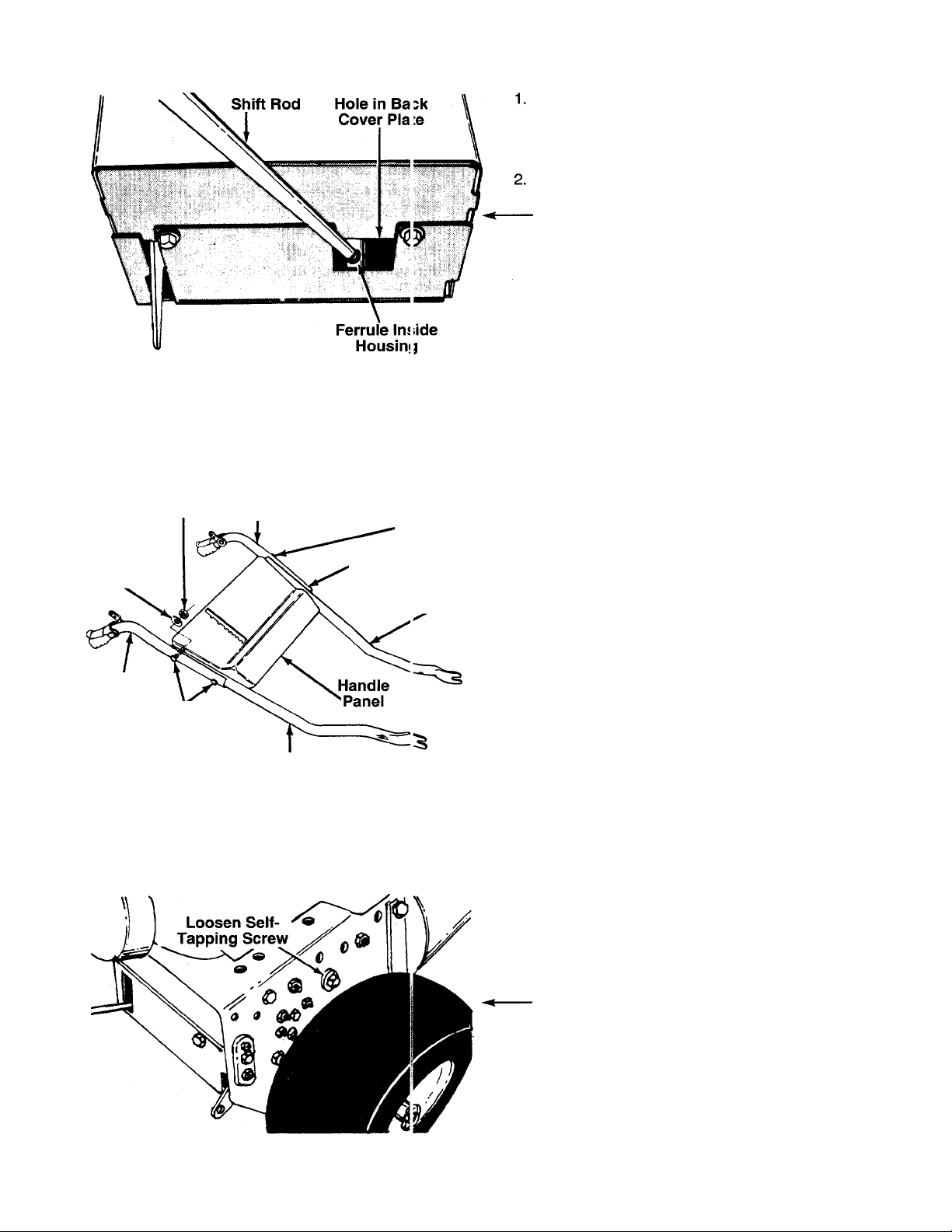

FIGURE 3.

Remove snow thrower and all parts from the car

ton. Check all carton inserts to be certain that all

loose parts and literature have been removed

before the carton is discarded.

Attach the shift rod to the shifting mechanism,

located inside the snow thrower frame, as follows.

■See figure 3.

a. Place the threaded end of shift rod into the

hole in the back cover.

b. Thread the shift rod into the ferrule which is

attached to the shifting mechanism until the

ferrule is approximately halfway down the

threaded end of the rod. Adjustment of shift

rod will be made in step 17.

NOTE: The shift mechanism is a movabie assembly.

It may be helpful to pull the linkage (and ferrule) clos

er to the opening in the back cover when assembling

the shift rod.

Hex Nut

Belleville

Washer (D)

Right

Hand

Upper

Handle

FIGURE 4.

(C)

Carriage

Bolt (S)

Left Hand

Upper Handle

Right Hand

Lower Handle

Carriage

Bolts (S)

Leave Open

Left I-land

Lower Handle

Preassemble the handles to the handle panel as

follows. See figure 4.

a. Place two carriage bolts (S) through the right

hand upper and lower handles (both carriage

bolts go through both handles).

Attach right hand handles to handle panel by

b.

placing carriage bolts through the holes in the

handle panel.

Secure with two belleville washers (D) (cupped

c.

side of washer against the handle panel) and

hex nuts (C). Do not tighten at this time.

Attach the left hand upper and lower handles

-d.

in the same manner, using only one carriage

bolt, belleville washer and hex nut in the upper

hole on the handle panel. Leave bottom hole

open.

FIGURE 5.

4. To attach the handle assembly to the unit, loosen

one self-tapping screw and belleville washer on

each side of the unit. See figure 5. A 9/16”

wrench or adjustable wrench is required.

Page 5

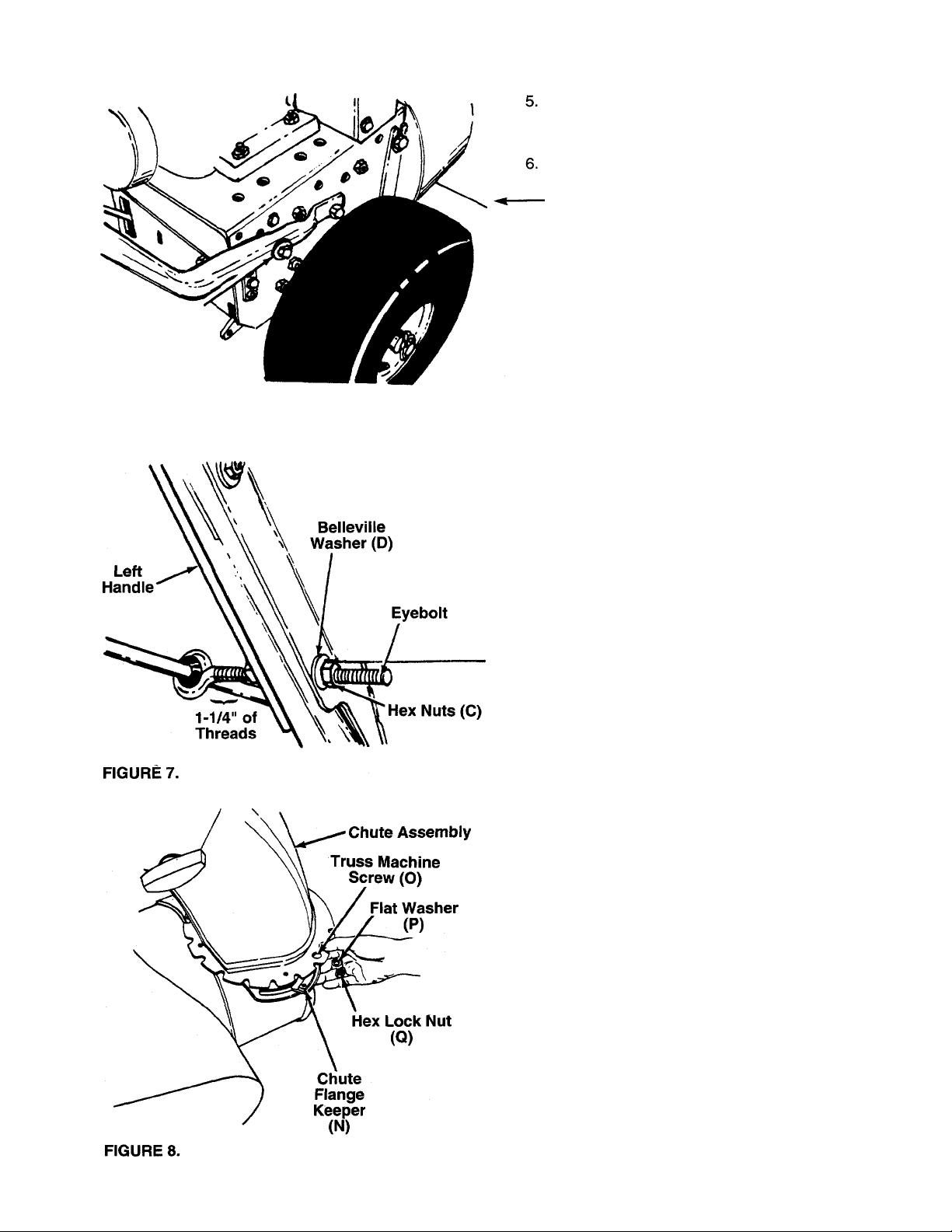

Hex Bolt (A)

Belleville

Washer (B)

FIGURE 6.

Slide the slotted end of the handles under the

belleville washers on the self-tapping screws

which were loosened in step 4.

Secure the upper hole in the handles with belle

ville washers (B) (cupped side against the han

dles) and hex bolts (A). See figure 6. Do not tight

en at this time.

7. Thread one hex nut (C) onto the eyebolt on the

chute crank assembly until there is approximately

1-1/4" of threads showing between the nut and

—the head of the eyebolt. See figure 7.

8. Place the eyebolt into the lower hole in the left

handle and handle panel. See figure 7. Secure

with belleville washer (D) (cupped side against

the handle panel) and hex nut (C). Do not tighten

until after attaching the other end of the chute

crank (step 14).

9. Tighten securely all bolts and nuts on the handle

panel and all four bolts which secure the handles

to the frame.

10. Grease the chute opening using a multi-purpose

automotive grease or equivalent.

11. Place chute assembly over chute opening, with

the opening in the chute assembly facing the front

of the unit. Place chute flange keepers (N)

beneath lip of chute assembly. Secure with truss

machine screws (O), flat washers (P) and hex

-------

lock nuts (Q) as shown in figure 8. Tighten with a

7/16" wrench, then back off 1/4 turn to allow

easier movement.

Page 6

Flat

Washers

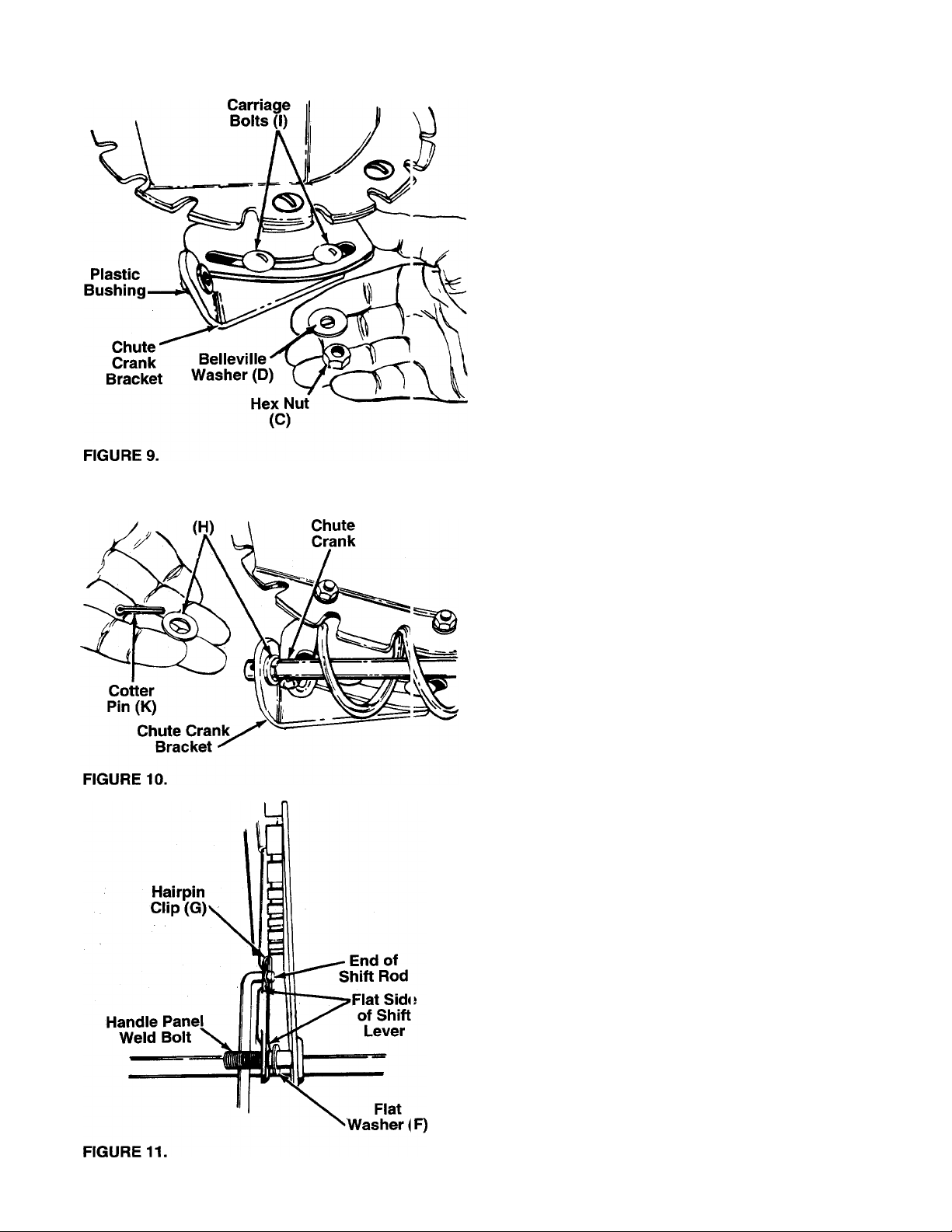

Attach chute crank bracket to the extension on

12.

the left side of the chute opening (bracket goes

beneath the extension) as shown in figure 9.

Secure with carriage bolts (I), belleville washers

(D) (cupped side of washers goes against the

bracket) and hex nuts (C). Tighten finger tight

only at this time.

13. Place one flat washer (H) on the end of the chute

crank, then insert the end of the crank into the

hole in the plastic bushing in the chute crank

------

bracket. See figure 10. Place the other flat wash

er (H) on the end of the chute crank, and insert

cotter pin (K) into hole in the end of crank. Secure

by bending the ends of cotter pin in opposite

directions.

14. Adjust the chute bracket so that the spiral on the

chute crank fully engages the teeth on the chute

assembly. Tighten the nuts on the chute crank

bracket securely. Tighten the hex nuts on the

eyebolt at the handle panel.

15. Thread shift knob (Z) onto the shift lever (R).

16. Place one flat washer (F) over the weld bolt on

the handle panel. Place shift lever (R) through

slot in handle panel, with the flat side of shift lever

against bracket on handle panel. Place the hole

in the end of the shift lever over the handle panel

------

weld bolt. See figure 11.

17. Place the shift lever in the fastest forward position

(5th speed). Push the shift rod all the way forward

(assembled to the ferrule in step 3). Thread the

shift rod in or out of the ferrule as necessary until

the end of the rod lines up with the hole in the

shift lever. Insert end of rod into hole in shift lever

and secure with hairpin clip (G). See figure 11.

Page 7

FIGURE 12.

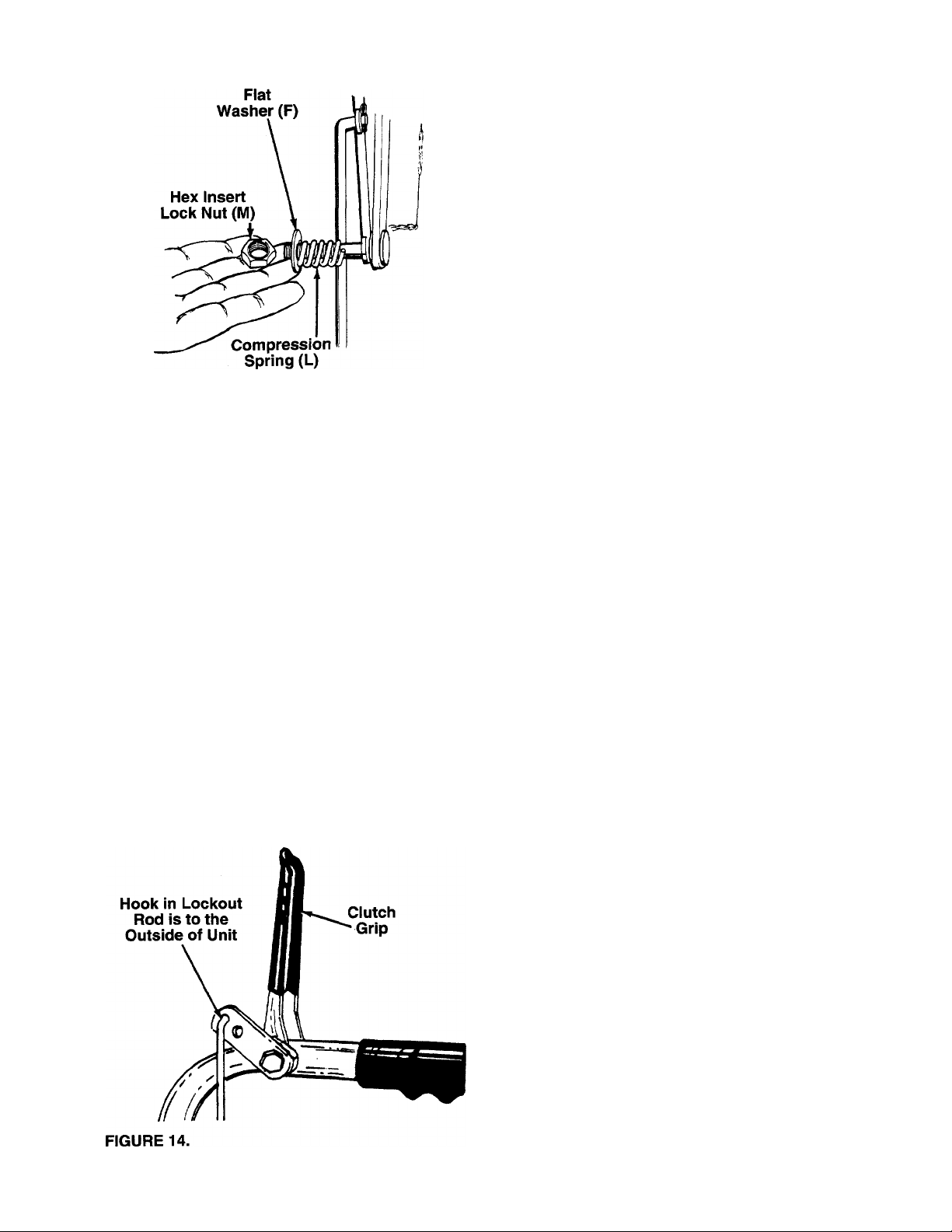

18. Secure with flat washer (F), compression spring

--------(L) and hex insert lock nut (M). See figure 12.

Tighten lock nut until compression spring returns

the shift lever into detent slots on handle panel.

NOTE: The adjustment of the shift rod must be

checked as described in step 23 before the unit is

operated.

Left Hand

Lockout

Rod

1-1/2"

Thread

FIGURE 13.

' Right Hand

Lockout

Rod

} 1/4” of

Thread

19. There is a left and a right hand lockout rod. The

left hand lockout rod is label “L”.

Approximate initial settings for the lockout rods

are as follows: The left hand lockout rod for the

drive clutch should have approximately 1-1/2

inches of thread showing below the nut. The right

hand lockout rod for the auger clutch should have

approximately 1/4 inch of thread showing below

------

the nut. See figure 13.

FINAL ADJUSTMENT MUST BE MADE AS

DESCRIBED IN STEPS 21 AND 22. If the left

hand lockout rod is not adjusted correctly, the

shift lever cannot be shifted past neutral. If the

right hand lockout rod is not adjusted correctly,

the augers will not stop rotating.

20. Hook the right hand lockout rod into the top hole

provided in the right hand clutch grip (auger

-------clutch). See figure 14. Hook the left hand lockout

rod (labeled “L”) into the top hole in the left hand

clutch grip (drive clutch). The hook is to the out

side of the unit.

Page 8

FIGURE 15.

Drive

Bracket

FIGURE 16.

FIGURE 17.

Left Hand

Lockout Rod

Drive Brncket

Auger <

Bracket

Hook i ri

Sprint I

Hole: n

Hich

Middle

Low

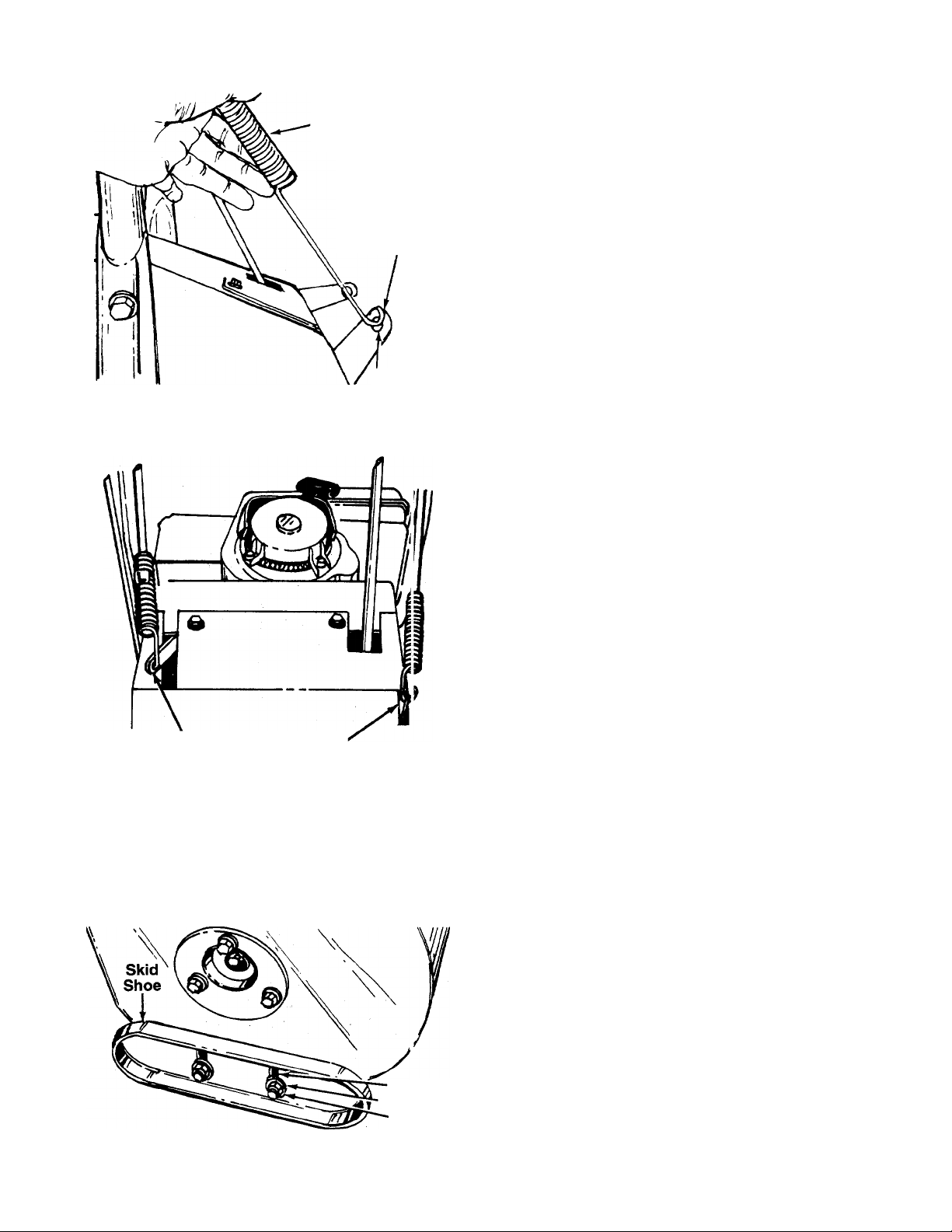

21. Swing the left hand lockout rod down and simply

hold it beside the drive bracket. Do not pull on

spring. Do not move bracket. The hook on the

end of the spring must line up with the center of

the hole in the drive bracket. See figure 15.

If it does not, adjust the nut on the lockout rod by

sliding the spring up and using a 7/16” wrench to

move the nut on the end of the rod up or down as

necessary until the hook on the spring aligns with

the center of the hole in the bracket as shown in

-------

figure 15.

Hook spring into drive bracket. See figure 16.

22. Adjust the right hand lockout rod in the same

manner as the left hand lockout rod. Refer to

Step 21. When adjustment is correct, hook the

-------

spring into the auger bracket. See figure 16.

WARNING: There must not be any ten

sion on either clutch rod spring with the

A

drive or auger clutch grip in the disen

gaged (up) position. These clutches are a

safety feature, and their function can be

overridden if there is tension on either

spring with the clutches disengaged.

23. Check for correct adjustment of the shift rod as

follows.

a. Disconnect and ground the spark plug wire

against the engine.

b. Place the shift lever in the neutral position.

Push the unit back and forth. It should move

freely.

c. Engage the drive clutch grip (located on the

left handle) by squeezing the clutch grip

against the handle. Push the unit back and

forth. It should still move freely. If the wheels

tend to lock up, adjustment is necessary.

To adjust the shift lever, place the shift lever in the

fastest forward position (5th speed). Remove the hair

pin clip which secures the shift rod to the shift lever

(refer to figure 11), and remove the rod from the lever.

Push the shift rod all the way forward. Thread the shift

rod in or out of the ferrule one or two turns as neces

sary, until the end of the rod lines up with the hole in

the shift lever. Insert end of rod into hole in shift lever

and secure with hairpin clip. Recheck the adjustment.

24. The space between the shave plate and the

ground can be adjusted. For close snow removal,

place skid shoes in the low position. Use middle

or high position when area to be cleared is

-------

uneven. See figure 17.

Adjust skid shoes by loosening the four hex nuts

and carriage bolts and moving skid shoes to

desired position. Make certain the entire bottom

surface of skid shoe is against the ground to

avoid uneven wear on the skid shoes. Retighten

nuts and bolts securely.

Page 9

Ridge

FIGURE 18.

OPTIONAL EQUIPMENT

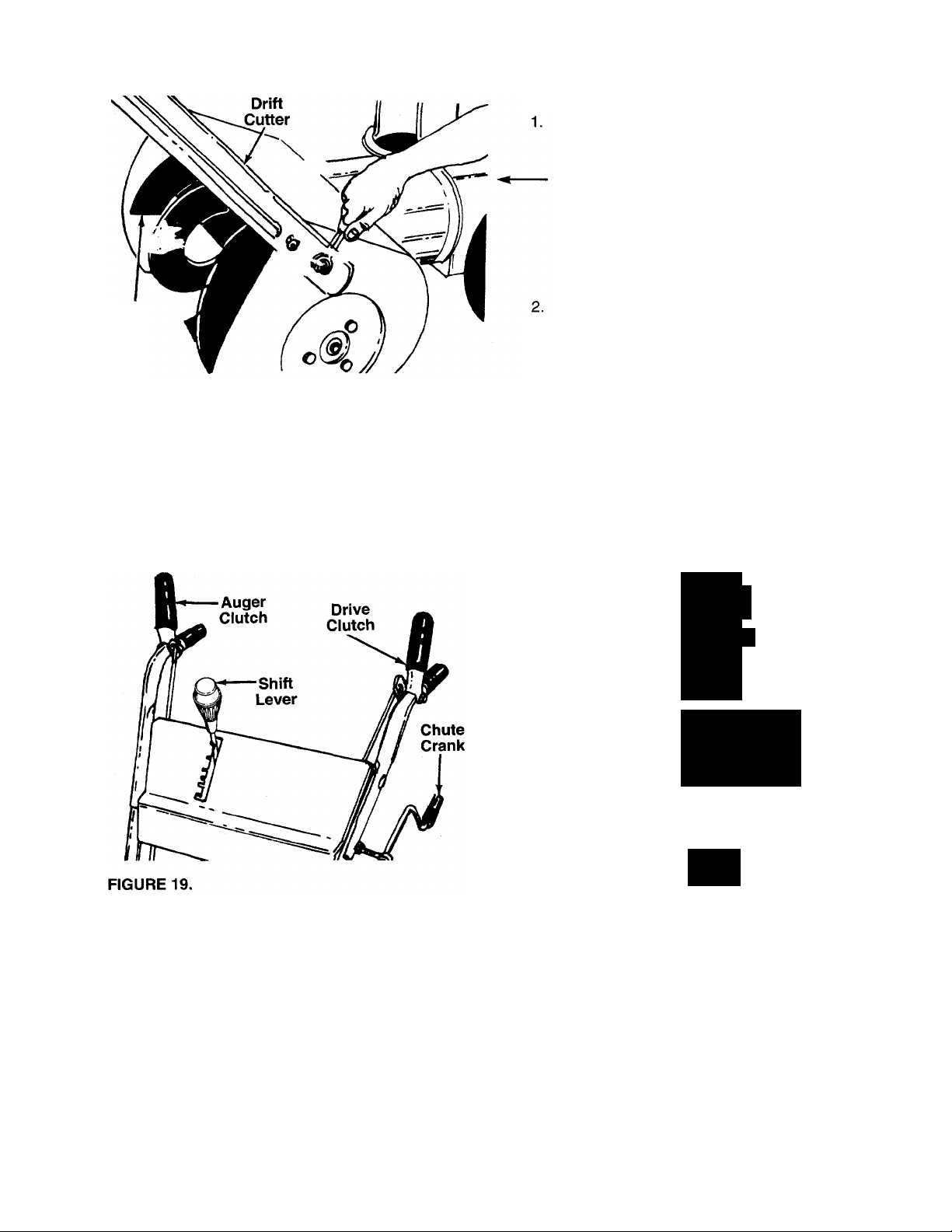

If your unit is equipped with optional drift cutters,

use a 1/2" wrench to remove the carriage bolts,

lock washers and hex nuts holding the drift cut

ters to the auger housing. See figure 18. Turn

and place the drift cutters in position (ridges on

drift cutters go toward the outside of the unit).

Secure with the hardware just removed, carriage

bolts (W) (heads of bolts are to the inside of the

housing), lock washers (X) and hex nuts (Y).

Tighten securely.

If your unit is equipped with an optional electric

starter which has not been installed at the factory,

install at this time. Follow the instructions packed

with the electric starter for installation.

TIRE PRESSURE (Pneumatic Tires)

The tires are over-inflated for shipping purposes.

Check tire pressure and reduce to 15 to 20 psi.

NOTE: If the tire pressure is not equal in both tires,

the unit may pull to one side or the other.

CONTROLS

SHIFT LEVER (See figures 19 and 20)

The shift lever is located on the right hand side of the

handle panel. The shift lever may be moved into one

of eight positions. Run engine with throttle in the fast

position. Use the shift lever to determine ground

speed.

A. Center Position (N)—NEUTRAL.

B. Forward Position—one of five speeds. Position

number one (1) is the slowest. Position number

five (5) is the fastest.

C. Rear Position—Two REVERSE (R) speeds. “R”

nearest the neutral (N) position is the slower of

the two.

♦ 5

Fs a

□ p

Rp 3

A« 2

DS T

0

R

FAST

FIGURE 20.

DRIVE CLUTCH (See figure 19)

The drive clutch is located on the left handle.

Squeeze the clutch grip to engage drive. Release to

stop.

AUGER CLUTCH (See figure 19)

The auger clutch is located on the right handle.

Squeeze the clutch grip to engage the augers.

Release to stop the snow throwing action.

CHUTE CRANK (See figure 19)

The chute crank is located on left hand side of the

snow thrower.

Page 10

To change the direction in which snow is throw n, turn

chute crank as follows:

1. Crank clockwise to discharge to the left.

2. Crank counterclockwise to discharge to the right.

THROTTLE CONTROL (See figure 21)

The throttle control is located on the engine. It regu

lates the speed of the engine.

SAFETY IGNITION SWITCH (See figure 21)

The ignition key must be inserted in the switch before

the unit will start. Remove the ignition key when snow

thrower is not in use.

OPERATION

FIGURE 21.—Optional Electric Starter Shown

GAS AND OIL FILL-UP

Service the engine with gasoline and oil as ins ructed

in the separate engine manual packed with you' snow

thrower. Read instructions carefully.

NOTE: Your snow thrower is shipped without oi i; how

ever, a small amount of oil may be present from the

factory. Do not overfill.

WARNING: Never fill fuel tank indoors,

with engine running or while engine is

A

hot. Do not smoke when filling fuel tank.

TO START ENGINE

Electric Starter (Optional)

WARNING: The optional electric starter is eq jipped

with a three-wire power cord and plug, and is

designed to operate on 120 volt AC househo d cur

rent. It must be properly grounded at all times to avoid

the possibility of electric shock which may be in urious

to the operator. Follow all instructions carefully.

Determine that your house wiring is a three-wire

grounded system. Ask a licensed electrician if you are

not certain. If your house wiring system is not a threewire grounded system, do not use this electric starter

under any conditions. If your system is grounded and

a three-hole receptacle is not available at tho point

your starter will normally be used, one shojid be

installed by a licensed electrician.

When connecting the power cord, always connect

cord to starter on engine first, then plug the other end

into a three-hole grounded receptacle.

When disconnecting the power cord, always unplug

the end from the three-hole grounded receptacle first.

1. Attach spark plug wire to spark plug.

2. Make certain the auger and drive clutch levers

are in the disengaged (released) position. Place

the shift lever in NEUTRAL (N) position.

3. Move throttle control up to FAST position. Insert

ignition key into slot. See figure 21. Be certain it

snaps into place. Do not turn key.

4. Rotate choke knob to OFF position.

5. Connect power cord to switch box on engine.

Plug the other end of power cord into a threehole, grounded 120 volt AC receptacle.

6. Push starter button to crank engine. See figure

21. As you crank the engine, move choke knob to

FULL choke position.

7. When engine starts, release starter button, and

move choke gradually to OFF. If engine falters,

move choke immediately to FULL and then grad

ually to OFF.

Recoil Starter:

1. Attach spark plug wire to spark plug.

2. Make certain the auger and drive clutch levers

are in the disengaged (released) position. Place

the shift lever in NEUTRAL (N) position.

3. Move throttle control up to FAST position. Insert

ignition key into slot. See figure 21. Be certain it

snaps into place. Do not turn key.

10

Page 11

4. Rotate choke knob to FULL choke position (cold

engine start).

If engine is warm, place choke in OFF position

instead of FULL.

5. Push primer button two or three times. See figure

21.

If engine is warm, push primer button once only.

NOTE: Always cover vent hole in primer button when

pushing. Additional priming may be necessary for first

start if temperature is below 15°F.

6. Grasp starter handle (see figure 21) and pull rope

out slowly, until it pulls slightly harder. Let rope

rewind slowly.

7. Pull starter handle rapidly. Do not allow handle to

snap back. Allow it to rewind slowly while keeping

a firm hold on the starter handle.

8. Repeat steps 6 and 7 until engine starts. If engine

fails to start, repeat steps 5, 6 and 7 until engine

starts.

9. As engine warms up and begins to operate even

ly, rotate choke knob slowly to OFF position. If

engine falters, return to FULL choke, then slowly

move to OFF position.

Optional Electric Starter: Connect power cord

to switch box on engine, then to 120 volt AC

receptacle. With the engine running, push starter

button and spin the starter for several seconds.

The unusual sound made by spinning the starter

will not harm engine or starter. Disconnect the

power cord from receptacle first, and then from

switch box.

Recoil Starter: With engine running, pull starter

rope with a rapid, continuous full arm stroke three

or four times. Pulling the starter rope will produce

a loud clattering sound, which is not harmful to

the engine or starter.

3. To stop engine, remove the ignition key. Do not

turn key. Disconnect the spark plug wire from the

spark plug to prevent accidental starting while

equipment is unattended.

NOTE: Do not lose ignition key. Keep it in a safe

place. Engine will not start without the ignition key.

4. Wipe all snow and moisture from the carburetor

cover in the area of the control levers. Also, move

control levers back and forth several times. Leave

throttle control lever in the STOP or OFF position.

Leave choke control in the FULL choke position.

A DANGER

AVOID INJURY FROM ROTATING

AUGER - KEEP HANDS FEET

AND CLOTHING AV/AY.

TO STOP ENGINE

1. Run engine for a few minutes before stopping to

help dry off any moisture on the engine.

2. To help prevent possible freeze-up of starter, pro

ceed as follows.

A

DANGER

SHUTOFF ENGINE

BEFORE UNCLOG

GING DISCHARGE

CHUTE.

TO ENGAGE DRIVE

1. With the engine running near top speed, move

shift lever into one of the five FORWARD posi

tions or two REVERSE positions. Select a speed

appropriate for the snow conditions that exist.

Use the slower speeds until you are familiar with

the operation of the snow thrower.

2. Squeeze the drive clutch grip (located on the left

handle) and the snow thrower will move. Release

it and the drive motion will stop.

NOTE: NEVER move shift lever without first releasing

the drive clutch.

TIRE CHAINS (Optional Equipment)

Tire chains should be used whenever extra traction is

needed.

11

Page 12

OPERATING TIPS

NOTE: Allow the engine to warm up for a few minutes

as the engine will not develop full power until it reach

es operating temperature.

WARNING: Temperature of muffUir and

surrounding areas may exceed I50°F.

A

1. For most efficient snow removal, remove snow

2. Discharge snow downwind whenever possible.

3. Set the skid shoes 1/4" below the scraper oar for

4. Be certain to follow the precautions listed under

5. Clean the snow thrower thoroughly afte' each

Avoid these areas.

immediately after it falls.

Slightly overlap each previous swath.

normal usage. The skid shoes may be adjusted

upward for hard-packed snow. Adjust dow nward

when using on gravel or crushed rock.

“To Stop Engine” on page 11 to prevent possible

freeze-up.

use.

ADJUSTMENTS

WARNING: NEVER attempt to clean

chute or make any adjustments while

A

CHUTE ASSEMBLY ADJUSTMENT

The distance snow is thrown can be adjusted by

adjusting the angle of the chute assembly. The sharp

er the angle, the shorter the distance snow is tirown.

See figure 22.

To adjust chute assembly, loosen the hand knob.

Pivot the top of the chute assembly to pcsition

desired. Retighten the hand knob.

engine is running.

SKID SHDE ADJUSTMENT

The space between the shave plate and the ground

can be adjusted. Refer to step number 24 of the

Assembly Instructions.

DRIVE AND AUGER CLUTCH ADJUSTMENTS

To adjust the drive or auger clutch, unhook the spring

from the drive or auger bracket. Refer to steps 21 and

22 under Assembly Instructions for proper adjust

ment.

SHIFT RDD ADJUSTMENT

To adjust the shift rod, remove the cotter pin which

secures the shift rod to the shift lever. Adjust as speci

fied in step number 17 under Assembly Instructions.

CARBURETOR ADJUSTMENT

WARNING: If any adjustments are made

to the engine while the engine is running

A

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude

and load.

Refer to the separate engine manual packed with

your unit for carburetor adjustment information.

DRIVE WHEELS

The snow thrower is equipped with a differential which

makes the unit easy to maneuver. It may be adjusted

for two different methods of operation. The adjust

ment is made by placing the klick pins in one of two

different holes on each side of the unit. See figure 23.

1. Differential Action—Place klick pin in the outside

2. Straight Axle Action—Place klick pin in the hole in

(e.g. carburetor), keep clear of all moving

parts. Be careful of heated surfaces and

muffler.

hole in the axle. This position allows easy maneu

vering when blowing light to medium snow.

the hub next to the rim on the right wheel. This

position should be used when blowing heavy

snow or when greater traction is needed (icy sur

faces, etc.). The unit will be more difficult to

maneuver.

FIGURE 22.

Outside Hole

in Axle

FIGURE 23.

12

Page 13

LUBRICATION

CHAINS AND SHIFTING MECHANISM

Lubricate all chains, bearings, hexagonal shaft and

round shaft with engine oil at least once a season or

after every 10 hours of operation. See figure 24.

Avoid getting oil on rubber friction wheel and alu

minum wheel.

Oil Bearings

at Least Once

a Season or

Every 10 Hours

FIGURE 26.

Hexagonal

Shaft

FiGURE 24.

CHUTE OPENING

Grease the chute opening once a season, using an

automotive multi-purpose grease or equivalent. See

figure 25.

GEAR CASE

The gear case is lubricated with 4 ounces of Shell

Alvania grease EPROO (order part number 737-0168).

See figure 27.

FIGURE 27.

FIGURE 25.

WHEELS

Lubricate the bearings at the wheels with light oil at

least once a season or after every 25 hours of opera

tion. See figure 26.

DIFFERENTIAL

The differential is sealed at the factory and does not

require checking. If disassembled for any reason,

lubricate with 3/4 oz. of Sunaplex EP990 grease.

Order part number 737-0120.

ENGINE

Refer to engine manual for engine lubrication instruc

tions.

13

Page 14

MAINTENANCE

WARNING: Disconnect the spark plug

wire and ground against the engine

A

before performing any repairs or mainte

nance.

AUGERS

The augers are secured to the spiral shaft with two

hex bolts and hex lock nuts. See figure 28. If yc u hit a

foreign object or ice jam, the snow thrower is

designed so that the hex bolts will shear.

If the augers will not turn, check to see if the hex bolts

have sheared. Two replacement hex bolts and hex

lock nuts have been provided with the snow tf rower.

For future use, order part number 710-0891 (h-5x bolt

5/16-18 X 1.75” long) and 712-0429 (hex insert lock

nut 5/16-18 thread).

ENGINE

Refer to separate engine manual for all engine

maintenance procedures.

BELT REMOVAL AND REPLACEMENT

WARNING: Disconnect the spark plug

wire from the spark plug and ground.

A

To remove and replace either the auger drive belt or

the drive belt, proceed with the following instructions.

1. Remove the chute crank at the chute assembly

2. Remove the plastic belt cover on the front of the

Drain gasoline from the fuel tank, or

place a piece of plastic film underneath

the gas cap to prevent gasoline from

leaking.

by removing the cotter pin and flat washer.

engine by removing the three self-tapping screws

and flat washers. See figure 29.

FIGURE 28.

SHAVE PLATE AND SKID SHOES

The shave plate and skid shoes on the bottom of the

snow thrower are subject to wear. They should be

checked periodically and replaced when necessary.

Skid shoes are reversible for longer life. The / may

also be inverted to extend their life even further.

To remove skid shoes, remove the four carriage bolts,

belleville washers and hex nuts which attach tf em to

the snow thrower. Reassemble new skid shoes with

the four carriage bolts, belleville washers (cupped

side goes against skid shoes) and hex nuts.

To remove shave plate, remove the carriage bolts,

belleville washers and hex nuts which attach it to the

snow thrower housing. Reassemble new shave plate,

making sure heads of the carriage bolts are to the

inside of the housing. Tighten securely.

3. Remove the large shoulder bolt and spacer on

the right hand side of the engine pulley with an

adjustable wrench. Remove the shoulder bolt and

spacer from the idler bracket assembly with one

hand. Use the other hand to catch the belleville

washer which is on the shoulder bolt between the

idler bracket and engine plate. See figure 30.

14

Page 15

; Belleville

Washer

6. To separate the auger housing from the frame

assembly, two people are required. One person is

in the operating position. Squeeze the auger

clutch grip (right hand) as you raise up on the

handles. See figure 33. The other person is in

front of the unit. Push down on the housing or

optional drift cutters. See figure 33. The unit will

separate into two pieces.

Idler Bracket

Assembly

Shoulder Bolt

Spacer

FIGURE 30.

Engine

Pulley

FIGURE 31.

4. Slip the auger drive belt (the front belt) off the

engine pulley. See figure 31.

5. Remove the top screws and lock washers which

attach the auger housing assembly to the frame

assembly. A 9/16” wrench is required. See figure

32. Loosen (do not remove) the bottom screws.

Lift Up

on Handles

(Auger Clutch

Grip Squeezed)

FiGURE 33.

To Remove Auger Drive Belt:

a. Remove the hex screw and belleville washer

from the center of the pulley on the auger

housing. Remove the pulley. See figure 34. Be

careful not to lose the key.

FIGURE 32.

Loosen

Bottom Screws

15

b.

Remove and replace auger drive belt.

c.

Reassemble pulley to auger housing with hex

screw and belleville washer (cupped side is

toward the pulley). Be certain key is in place

on shaft.

Page 16

8. To Remove Drive Belt:

a. Remove the cotter pin which holds the linkage

rod to the idler bracket assembly. See figure

35.

b. Unhook extension spring from tho engine

plate. See figure 35.

13. Reassemble belt cover and chute crank.

14. Remove plastic film from gas cap.

Changing the Friction Wheel

1. Tip the snow thrower forward and let it rest on the

housing or optional drift cutters.

2. Remove the four self-tapping screws holding the

rear cover.

3. Slide out the rear cover.

4. Using two 1/2" wrenches, loosen and then

remove the three hex nuts and lock washers

holding the friction wheel to the friction wheel

adapter. See figure 36.

FIGURE 35.

c. Remove drive belt from the engine pulley and

bottom drive pulley.

d. Replace belt and reassemble in reverj e order.

9. Reassemble the two halves of the unit, "wo peo

ple are required.

NOTE: If the two halves do not reassemb'e easily,

the idler pulley and/or the brake shoe may t e behind

the large pulley.

10. Secure the two halves with the two sciews and

lock washers.

11. Slip the auger drive belt over engine pulloy.

12. Reassemble the large shoulder bolt, spacer and

belleville washer as shown in figure 30. Belleville

washer goes on shoulder bolt between the idler

bracket assembly and engine plate (cuf ped side

toward engine plate).

NOTE: Shoulder of the bolt must go throjgh both

sides of idler bracket assembly.

FIGURE 36.

5. Slide the friction wheel off the end of the hex

shaft. See figure 37.

NOTE: It may be necessary to strike the friction wheel

with a soft hammer to knock it loose.

6. Assemble the new friction wheel so the cupped

side is towards the friction wheel adapter.

7. Fasten the friction wheel to the friction wheel

adapter with the three lock washers and hex nuts.

Tighten each nut in rotation until they are finger

tight. Spin the wheel to see that it is not cocked on

the hub. Then tighten using two 1/2" wrenches.

16

Page 17

Friction Wheel

FIGURE 37.

If unit is to be stored over 30 days, prepare for stor

age as follows:

1. Remove all gasoline from carburetor and fuel

tank to prevent gum deposits from forming on

these parts and causing possible malfunction of

engine.

a. Run engine until fuel tank is empty and engine

stops due to lack of fuel.

b. Drain carburetor by pressing upward on bowl

drain, located below the carburetor cover.

WARNING: Drain fuel into approved con

tainer outdoors, away from open flame.

Be certain engine is cool. Do not smoke.

A

Fuel left in engine during warm weather

deteriorates and will cause serious start

ing problems.

8. Replace the rear cover.

WARNING: Check engine and snow

thrower frequently for loose nuts, bolts,

A

etc. and keep these items tightened.

OFF-SEASON STORAGE

WARNING: Never store engine with fuel

in tank indoors or in poorly ventilated

▲

areas, where fuel fumes may reach an

open flame, spark or pilot light as on a

furnace, water heater, clothes dryer or

other gas appliance.

NOTE: Fuel stabilizer (such as STA-BIL) is anaccept-

able alternative in minimizing the formation of fuel

gum deposits during storage. Add stabilizer to gaso

line in fuel tank or storage container. Always follow

mix ratio found on stabilizer container. Run engine at

least 10 minutes after adding stabilizer to allow it to

reach carburetor. Do not drain carburetor if using fuel

stabilizer.

2. Remove spark plug and pour one (1) ounce of

engine oil through spark plug hole into cylinder.

Crank engine several times to distribute oil.

Replace spark plug.

3. Remove all dirt from exterior of engine and equip

ment.

4. Follow lubrication recommendations on page 13.

NOTE: When storing any type of power equipment in

an unventilated or metal storage shed, care should be

taken to rust proof the equipment. Using a light oil or

silicone, coat the equipment, especially any chains,

springs, bearings and cables.

17

Page 18

TROUBL.E SHOOTING GUIDE

Trouble

Engine fails to start 1. Fuel tank empty, or stale fuel.

Engine runs erratic 1. Unit running on CHOKE.

Loss of power

Engine overheats 1. Engine oil love! low.

Excessive vibration

Possible Cau!>e(s)

2. Blocked fu€ 1 line.

3. Key not in switch on engine.

4. Spark plug wire disconnected.

5. Faulty spark plug.

2. Blocked fue I line or stale fuel.

3. Water or diit in fuel system.

4. Carburetor Dut of adjustment.

1. Spark plug wire loose.

2. Gas cap ve It hole plugged.

2. Carburetor lot adjusted properly.

Loose parts or damaged impeller.

Corrective Action

1. Fill tank with clean, fresh gasoline.

2. Clean fuel line.

3. Insert key.

4. Connect wire to spark plug.

5. Clean, adjust gap or replace.

1. Turn choke knob to OFF position.

2. Clean fuel line; fill tank with clean

fresh gasoline.

3. Use carburetor bowl drain to drain

fuel tank. Refill with fresh fuel.

4. Adjust carburetor. See separate

engine manual.

1. Connect and tighten spark plug

wire.

2. Remove ice and snow from cap.

Be certain vent hole is clear.

1. Fill crankcase with proper oil.

2. Adjust carburetor. See separate

engine manual.

Stop engine immediately and

disconnect spark plug wire. Tighten

all bolts and nuts. Make all

necessary repairs. If vibration

continues, have unit serviced by

authorized service dealer.

Hard to shift, or will

not shift

Unit fails to propel itself 1. Unit in neut al.

Unit fails to discharge

snow

NOTE: For repairs beyond the minor adjustments listed above, please contact your nearest authorized service dealer.

Shift rod mi sadjusted.

2. Klick pins n 3t in proper position.

3. Incorrect acjustment of drive clutch.

4. Drive belt Ic ose or damaged.

1. Auger shear bolt broken.

2. Discharge c hute clogged.

3. Foreign obj 3ct lodged in auger.

4. Incorrect acjustment of auger drive

clutch.

5. Auger drive belt loose or damaged.

Readjust shift rod. See Adjustment

section of this manual.

1. Move shift lever to one of the

forward speeds or reverse (readjust

shift rod if needed).

2. Place klick pins in wheel hub.

3. Adjust drive clutch. Refer to

Adjustment section.

4. Replace drive belt. Refer to

Maintenance section.

1. Replace auger shear bolt. Refer to

Maintenance section.

2. Stop engine immediately and

disconnect spark plug wire. Clean

discharge chute and inside of auger

housing.

3. Stop engine immediately and

disconnect spark plug wire.

Remove object from auger.

4. Adjust auger clutch. Refer to

Adjustment section.

5. Replace auger drive belt. Refer to

Maintenance section.

18

Page 19

OPTIONAL EQUIPMENT

At the time of manufacture of snow thrower, the fol

lowing optional equipment is available.

Description

110 Volt Electric Start Kit:

Tire Chains: 16 x 6.5

Snow Shield:

Drift Cutter Kit:

Replacement Skid Shoe Kit:

Headlight Kit:

Kit No.

390-987

390-146

390-674

390-679

390-680

390-255

19

Page 20

Model 9801

20

Page 21

Model 9801

PARTS LIST FOR MODEL 9801 SNOW THROWER

lEF.

NO.

10 710-0487

11 749-0595

12

13

14

15

16

17 741-0475

18 749-0405

19

20 732-0463

21 712-0324

22 732-0184

PART

NO.

1 738-0561

2

738-0560

741-0402

3

CODE

Shid. Nut 1/4-20 Thd. 23

Shid. Bolt .374 Dia. x 1.375" Lg.

Hex Flange Plastic Bearing

DESCRIPTION

.38" I.D.

05987 Clutch Grip Ass’y.—L.H. 26

4

5 720-0220

720-0180

6 747-0461

7 712-0267

8 736-0242

9 731-0496

Grip—Red

Grip—Black 28 736-0105

Lockout Rod 29

Hex Nut 5/16-18 Thd.* 30 784-5133

Bell-Wash. .34" I.D. x .88" O.D. 31 738-0129 Shid. Bolt .498 Dia. x 2.0" Lg.

Plastic Plug

Curved Carriage Bolt

5/16-18x2.0" Lg. 3.18" Lg.

Upper Handle—L.H.

726-0100

Push Nut 3/8" Rod 35

720-0201A Knob 3/8" Rod

715-0138

05980

747-0416A

Roll Pin .12 Dia. X.631" Lg.

Chute Crank Ass’y.

Eye Bolt 5/16-18x5.0“ Lg. 39

Plastic Bushing

Lower Handle—L.H.

784-5451 638

Handle Panel Ass’y.

Extension Spring .75" O.D.

X 5.0" Lg.

Hex Ins. L-Nut 1/4-20 Thd.

Extension Spring .75" O.D.

X 5.0" Lg.

REF.

NO.

PART

NO.

710-0600

CODE DESCRIPTION

Hex Wash. Hd. Self-Tap Scr.

5/16-24 X .50" Lg.

24

25

736-0105

710-0427

Bell-Wash. .40" I.D. x .88" O.D.

Hex Bolt 3/8-16x2.0" Lg.*

784-5131B 638 Frame Cover

27

710-0555

Pilot Hex Scr. 3/8-16 x .88" Lg.

Bell-Wash. .40" I.D. x .88" O.D.

05500

Drive Clutch Brkt. Ass’y.

Shifting Linkage Brkt. Ass’y.

05518B

32

33 732-0303

34

749-0406

Auger Clutch Brkt.

Extension Spring .38" O.D. x

Lower Handle—R.H.

747-0356A Shifting Rod

36 747-0696 Shift Handle

37 749-0596 Upper Handle—R.H.

05988 Clutch Grip Ass’y.—R.H.

38

714-0104 Int. Cotter Pin 5/16" Dia.

40 736-0264

41

732-0193

42

712-0429 Hex Ins. L-Nut 5/16-18 Thd.

FI-Wash. .344" I.D. x .62" O.D.

Compression Spring

43 720-0218 Knob

44 726-0247 Push Cap

45 731-0473

Black Vinyl Grip

‘For faster service obtain standard nuts, bolts and washers locally.

If these items cannot be obtained locally, order by part number

and size as shown on parts list.

CODE: N notates a new part (not previously existing). A three digit

number is the color code. Specify color code as shown below if

color or finish is important when ordering parts, [i.e., 638 for Red

Finish].

Color Codes

456—Radiant Tangerine

460—Green Flake

483—Charcoal Gray

498—Yellow

499—Beige

629—Silver Flake

637—Black

638—Red

640—Green

646—CM Blue

657—Teal

NOTE

Specifications subject to change without notice or

obligation.

21

Page 22

Model 9801

IMPORTANT: Use only Original

Equipment Manufacturer (O.E.M.)

V-belts when replacing belts.

They are of special construction

(type of cord, cord location,

length, etc.). Use of V-belts other

than O.E.M. belts generally will

provide only temporary service.

For best results, use only factory

approved parts.

NOTE: These parts are

part of Blower Housing

Assembly, Part No. 784-

5011.

22

Page 23

Model 9801

PARTS LIST FOR MODEL 9801 SNOW THROWER

tEF.

NO.

10 732-0303

11

12 05491A Engine Brkt. Ass’y13 710-0198

14

15 736-0231

16 710-0395

17 736-0217

18

19 736-0119

20 712-0267

21

22 736-0217

23 738-0143

24 756-0344

25 736-0158

'26

27

28 738-0129

29 756-0243

30 754-0194

31

PART

NO.

1

710-0726

2 731-0321

3 714-0118

4

—

5 712-0267

6 736-0119

CODE

Hex AB-Tap Scr. 5/16 x .75" Lg.

Belt Cover

Sq. Key 1/4" x 1.50" Lg.

Engine 35 756-0240

Hex Nut 5/16-18 Thd.* 36

L-Wash.5/16" I.D.*

DESCRIPTION

7 717-0882 Engine Spacer Ass’y8

736-0105

738-0215A

9

Bell-Wash. .40 I.D. x .88 O.D. 38

Shid. Bolt .498" Dia. x 3.00" Lg. 39 05493

Ext. Spring .38 O.D. x 3.18" Lg. 40

712-0375

Hex Cent. L-Nut 3/8-16 Thd.

Hex Sems Scr. 5/16-18 x

.75" Lg.*

784-5129B

Frame Ass’y.

Fi-Wash. .344" I.D. x 1.125" O.D. 45 754-0131

X .12" 46

Hex Bolt 5/16-18x2.25" Lg.*

L-Wash. 3/8" I.D. H.D.

710-0555

Pilot Scr. 3/8-16 X .88" Lg. 48

L-Wash. 5/16" I.D.*

Hex Nut 5/16-18 Thd.*

712-0798

Hex Nut 3/8-16 Thd.* 50

L-Wash. 3/8" I.D. H.D. 51

ShId. Bolt .498" Dia. x .340" Lg.

V-Pulley .628 I.D. x 7.50 O.D.

L-Wash, for 5/8" I.D.* 53

712-0221

05510

Hex Ins. Jam L-Nut 5/8-18 Thd. 54

Brake Brkt. Ass’y.

Shid. Bolt .498" Dia. x 2.00" Lg. 55

V-Pulley .875 I.D. X 10.12 O.D.

“V”-Belt

712-0116

Hex Ins. Jam L-Nut 3/8-24 Thd.

REF.

NO.

32 756-0240

33 05531

34 712-0116

PART

NO.

CODE

DESCRIPTION

Fl-ldler w/Flanges 3.0 O.D.

Brake Linkage Ass’y.

Hex Ins. Jam L-Nut 3/8-24 Thd.

3.0" O.D. Fl-ldler w/Flanges

714-0507 Int. Cot. Pin 3/32" Dia.

37 738-0282 Shid. Bolt .625" Dia x 2.750"

750-0227 Spacer .75 O.D. x 1.00" Lg.

Lg-

Blower Idler Brkt. Ass’y.

747-0149

41 710-0191

736-0217

42

07386 FI-Wash.

43

Auger Clutch Rod .31" Dia.

X 10.62" Lg.

Hex Bolt 3/8-24 x 1.25" Lg.

L-Wash. 3/8" I.D. H.D.

44 756-0241B Engine Pulley—Double Groove

“V”-Belt

710-0237 Hex Bolt 5/16-24 x .62" Lg.*

47 736-0242 Bell-Wash. .345 I.D. x .88

O.D.X .060

05495 Drive Idler Brkt. Ass’y.

738-0281 Shid. Bolt—.625" Dia. x .170"

49

Lg736-0219

Bell-Wash. .40 I.D. x 1.12 O.D.

736-0117 FI-Wash. .385" I.D. x .620" O.D.

52 737-0130 Pipe Nipple—1/4" Pipe Thd.

X 3.5" Lg.

737-0132

Hex Hd. Cap 1/4-18 Pipe Thd.

736-0264 FI-Wash. .344" I.D. x .62" O.D. x

.63"

714-0104

—

725-0954 Ignition Key (Not Shown)

—

390-987

Int. Cot. Pin 5/16" Dia.

Electric Start Kit (Not Shown)t

tOptional Parts

*For faster service obtain standard nuts, bolts and washers locally.

If these items cannot be obtained locally, order by part number

and size as shown on parts list.

NOTE: The engine is not under warranty by the mower manufacturer.. .If repairs or service is needed on

the engine, please contact your nearest authorized engine service outlet. Check the “Yellow Pages” of

your telephone book under “Engines-Gasoline.”

Find It Fast

In The

Yellow Pages

23

Page 24

Model 9801

Gear Case Lubricant—

4 oz. of Shell Alvania grease, part

number 737-0168.

50

24

Page 25

Model 9801

PARTS LIST FOR MODEL 9801 SNOW THROWER

lEF.

NO.

10

11

12

13

15

16 05980 Chute Crank Ass’y17

18

19 756-0243

20 714-0126

21 712-0267

22 736-0119

23

24 741-0185

25

26

28

29 784-5011

30

31

32

33

34 738-0276

35

36 05812

37

38

39 05461

40 712-0429

41

42

PART

NO.

1 09966

736-0242

2

CODE

Hand Knob Ass’yBell-Wash. .345 I.D. x .88

DESCRIPTION

O.D. X .060

3

736-0231

FI. Wash. .312 I.D. x 1.125

O.D. x .125

731-0846B

5

6 710-0255

7 736-0142

731-0840B Chute

8

710-0276

9

712-0107

731-0851

Top Chute 50

Truss Mach. Scr. 1/4-20 x .75" 51

FI-Wash. 1/4" I.D.

Carr. Bolt 5/16-18 X 1.00" Lg.

Hex Cent. L-Nut 1/4-20 Thd. 55

Chute Flange Keeper

714-0507 Cotter Pin

736-0140

741-0475

FI-Wash. .385" I.D. x .62"

Bushing

710-0371 Hex L-Scr. 5/16-18 x .88" Lg.

736-0242

Bell-Wash. .345 I.D. x .88

V-Pulley .875 I.D. x 10.12 61

#9 Hi-Pro Key 3/16 X 3/4" Dia.

Hex Nut 5/16-18 Thd.* 63 721-0145

L-Wash. 5/16" I.D,*

05244

Bearing Hsg.—Self Aligning Brg.

Self Aligning Brg. .875 I.D.

711-0640

736-0105

Stud 3/8-16x2.75" Lg.

Bell-Wash. .400 I.D. x .88 68 736-0119 L-Wash. 5/16" I.D.*t

O.D.X .060

712-0267

Hex Nut 5/16-18 Thd.* 70

Blower Hsg. Ass’y.

784-5038A Slide Shoe

736-0105

Bell-Wash. .400 I.D. x .88 73

O.D.X .060

712-0342

710-0790

Hex Jam Nut 3/8-16 Thd.

Carr. Bolt 3/8-16 X .62" Lg. 76

Blower Axle

715-0118

Spring Pin Spiral 5/16" Dia.

X 1.75" Lg.

Blower Fan Ass’y.

717-0297 Complete Gear Hsg. Half—

L.H. (Incl. Bearing) 81

714-0135

#91 Woodruff Key 1/4" x 3/4"

Dia.

Spiral Ass’y.—L.H.

05462

Spiral Ass’y.—R.H.

Hex Ins. L-Nut 5/16-18 Thd.

741-0494

710-0726

Plastic Bushing

Hex Wash. Hd. Self-Tap Scr.

5/16-24 X .62" Lg.

REF.

NO.

46

PART

NO.

CODE DESCRIPTION

741-0192 Flange Brg. w/Flats 1.0" I.D.

47 05845 Bearing Hsg.—Spiral Hsg.

736-0250 FI-Wash. 1.06 I.D. x 1.75"

48

O.D. X .100

49 738-0491 Spiral Axle

710-0891 Hex Bolt 5/16-18 X 1.75" Lg.

721-0146 Oil Seal 1.50" I.D.

52 738-0275

741-0182 Flange Brg. 1.503 I.D.

53

54 736-0266

Worm Gear Shaft

FI-Wash. 1.5 I.D. X 2.0 O.D.

717-0300 Double Threaded Worm Gear

741-0184 Thrust Brg. .88 I.D. x 1.44

56

O.D. X .078

57 736-0291

58 717-0299

741-0217

59

717-0298 Complete Gear Hsg. Half—

60

FI-Wash. .88 I.D. X 1.40 O.D.

Double Threaded Worm—L.H.

Sleeve Brg. .875 I.D.

R.H. (Incl. Ref. Nos. 51 & 53)

710-0376 Hex Bolt 5/16-18 X 1.0" Lg.

62 721-0144 Gasket

Oil Seal .875" I.D.

64 714-0126 #9 Hi-Pro Key 3/16 X 3/4" Dia.

65 716-0111 Snap Ring—.875" Dia.

66 714-0135

67 712-0267

#91 Woodruff Key 1/4 x 3/4" Dia.

Hex Nut 5/16-18 Thd.*t

69 05378 Shave Plate—33"

71

710-0260

05139A

Carr. Bolt 5/16-18 X .62" Lg.t

Drift Cutterf

72 736-0271 Wave Wash. 5/16" I.D.

712-0429 Hex Ins. L-Nut 5/16-18 Thd.

74

784-5075

75 710-0528

Gear Hsg. Support Plate

Hex Bolt 5/16-18 X 1.25"*

710-0726 Hex Wash. Hd. Self-Tap

Scr. 5/16-18 X .75" Lg.

77 736-0291 FI-Wash. .88 I.D. x 1.40 O.D.

78 737-0175

Filler Plug

79 784-5076 Gear Hsg. Support Brkt.

80 710-0451 Carr. Bolt 5/16-18 X .75" Lg.*

784-5123 Chute Crank Bracket

82 736-0242 Bell-Wash. .345 I.D. x .88"

712-0267

83

710-0412

84

736-0270 Bell-Wash. .28" I.D. x .75" O.D.

85

—

717-0296

Hex Nut 5/16-18 Thd.*

Hex Bolt 1/4-28 x .75" Lg.*

Gear Box Ass’y. Comp.

fOptional Parts

*For faster service obtain standard nuts, bolts and washers locally.

If these Items cannot be obtained locally, order by part number

and size as shown on parts list.

25

Page 26

Model 9801

Differential Lubricant—

3/4 oz. of Sunaplex grease,

part number 737-0120.

If these parts are to be disassembled

for any reason, it is necessary to

heat them after driving the spiral pin

out in order to separate as they are

treated with loc-tite.

26

Page 27

Model 9801

PARTS LIST FOR MODEL 9801 SNOW THROWER

lEF.

VJO.

10

11 741-0301

12

13 748-0281

14

15

16

17 710-0195

18

19

20

21 713-0270

22 713-0723

23 713-0199

p4 713-0193

25

26

27

28

29

30

31

32 747-0150

33

34 736-0105

35

36

37

38

39

40

41

42 712-0193

44 734-0255

45

46

47 736-0169

48

49

50

PART

NO.

714-0143

1

716-0115

2

736-0187

3

4 741-0305

CODE

Klick Pin 1/4" Dia. xl.75"

Snap Ring .625" Shaft

FI-Wash. .62" I.D. x 1.25" 53

Sleeve Brg. (Must Be Drilled

After Press Fit)

05637

5

7 741-0192

8 741-0305

05794

9

716-0102

Differential Tubing Ass’y-—Ft.H.

Flange Brg. w/Flats 1" I.D.

Sleeve Brg.

Bearing Housing

Snap Ring—1.00" Dia.

Ball Brg. .25MM x 52MM x

15MMThk.

710-0198

Hex Sems Bolt 5/16-18 x .75"

Lg.*

Friction Wheel Adapter

05080A Friction Wheel Ass’y736-0119

712-0267

L-Wash. 5/16" I.D.*

Hex Nut 5/16-18 Thd.*

Hex Bolt 1/4-28 x .62" Lg.*

736-0329

738-0278

712-0287

L-Wash. 1/4" I.D.*

Sliding Support Axle

Hex Nut 1/4-20 Thd.*

#41 Chain—1/2" Pitch x 43 Links 70

Master Link

#41 Chain—1/2" Pitch x 19 Links

713-0723

Master Link

9 and 14 Teeth Sprocket Hub

Ass’y.

748-0184

05520

736-0217

712-0116

784-5137

05500

714-0104

Flange Brg. .630" I.D.

Chain Support Brkt.

L-Wash. 3/8" I.D.—H.D.

Hex L-Jam Nut 3/8-24 Thd.

Sliding Brkt. Ass’y.

Drive Clutch Brkt. Ass’y.

Inter. Cot. Pin 5/16" Dia.

Drive Clutch Rod 7.38" Lg.

738-0144

Shid. Bolt

Bell-Wash. .44" I.D. x .88“ 85

717-0302

732-0121

784-5129B

710-0538

05820B

736-0264

09262

Aluminum Drive Plate

Extension Spring 4.31" Lg.

Frame Ass’y.

Hex L-Bolt 5/16-18 X .62" 88 738-0281

Differential Shaft Ass’y.

FI-Wash. .345" I.D. x .75"

Rim Only—16"

Cone Nut 3/8-24 Thd.

Tubeless Air Valve

734-1526

734-1525

712-0342

Wheel Ass’y. Comp. 16 x 6.5

Tire Only 16 X 6.5 95

Hex Jam Nut 3/8-16 Thd. 96

L-Wash. 3/8" I.D.*

784-5133

738-0129

Shift Linkage Brkt. Ass’y. 98

ShId. Bolt .498" Dia. x 2.005" 99

Lg.

736-0264

FI-Wash. .344" I.D. x.62"

DESCRIPTION

REF.

NO.

51

52

54 05497

55 738-0279

56 715-0136

PART

NO.

CODE

DESCRIPTION

714-0507 Cotter Pin 3/32" Dia. x .75"*

711-0628A Adjustment Ferrule

747-0356

Shifting Rod

Drive Plate Mtg. Brkt. Ass’y.

Drive Plate Spindle

H-Spring Pin Spiral 3/16"

Dia. X 1.25" Lg.

57 714-0388

712-0138 Hex Nut 1/4-28 Thd.

58

59 736-0329

738-0304 Differential Pin

60

61 738-0280

62 712-0896

714-0129

63

64 748-0204

65 713-0269

#61 Hi-Pro Key 3/16 X 5/8" Dia.

L-Wash. 1/4" I.D.*

Hex Shaft

Hex L-Nut 1/4-28 Thd.

#9 Hi-Pro Key 3/32 x 5/8" Dia.

8 Teeth Sprocket

#420 Chain—.50 Pitch x 37 Links

713-0154 Master Link

713-0194 9 and 32 Teeth Sprocket Hub

66

Ass’y.

67 710-0258

750-0277 Spacer .51"I.D. X.69" O.D.

68

69 741-0133

738-0284

71

710-0559

72 713-0198

748-0222 Differential Housing

73

748-0224 20 Tooth Spur Gear

74

748-0223

75

736-0187

76

748-0222 Differential Housing

77

05484 Differential Hsg. Support Plate

78

08253B Bearing Housing

79

80 741-0919

81 736-0119

712-0267 Hex Nut 5/16-18 Thd.*

82

05491A Engine Brkt. Ass’y.

83

714-0104 Inter. Cotter Pin 5/16" Dia.

84

732-0303

86 747-0149

87 05518B

Hex Bolt 1/4-20 X .62" Lg.*

Ball Bearing

Differential Connecting Shaft

Hex Bolt 1/4-28 X 1.75" Lg.*

28 Teeth Sprocket

9 Tooth Spur Gear

FI-Wash. .62" I.D. x 1.25"

Ball Brg. .787" I.D. x 1.85"

L-Wash. 5/16" I.D.*

Extension Spring 3.18" Lg.

Auger Clutch Rod .31" Dia.

X 10.62" Lg.

Auger Clutch Brkt.

Shid. Bolt .625" Dia. X. 170"

05523 Pivot Axle Brkt.

89

736-0264 FI-Wash. .345" I.D. x .75"

90

91 710-0538

92 710-0258

93 750-0275

94

736-0329

Hex L-Bolt 5/16-18 X .62"

Hex Bolt 1/4-20 X .62" Lg.*

Sprocket Hub Tubing 1.88"

L-Wash. 1/4" I.D.*

712-0375 Hex Cent. L-Nut 3/8-16 Thd.

712-0287 Hex Nut 1/4-20 Thd.*

97

736-0159

FI-Wash. .344" I.D. x .875"

710-0629 Hex Bolt 3/8-24 x 2.75" Lg.*

736-0242 Bell-Wash. .345" I.D. x .88"

390-0146 Tire Chain (Optional)

100

1

*For faster service obtain standard nuts, boits and washers locaiiy.

If these items cannot be obtained iocaily, order by part number

and size as shown on parts list.

27

Page 28

FOR REPLACEMENT PARTS, CONTACT:

SERVICE DEPARTMENT • P.O. BOX 360900 • CLEVELAND, OHIO 44136

Loading...

Loading...