Page 1

FIFTY CENTS

Model No.

310-430A

OWNER

MANUAL

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

PRINTED IN U.S.A.

Important:

Read Safety Rules and

Instructions Carefully

NOTE

This snow thrower has provisions

for optional 110V starter (390-986).

FORM NO. 770-8918

\

Page 2

INDEX

Limited Warranty

Safe Operation Practices..................................... 3

Assembly Instructions.......................................... 4

Operation............................................................11

Adjustments........................................................14

.................................................

♦

♦

LIMITED WARRANTY

♦

♦

♦

♦

♦

♦

♦

♦

For one year from the date of original retail purchase, MTD PRODUCTS INC. will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm,

any part or parts found to be defective in material or workmanship. Transportation charges

for any parts submitted for replacement under this warranty must be paid by the purchaser

unless such return is requested by MTD PRODUCTS INC.

This warranty will not apply to any part which has become inoperative due to misuse,

excessive use, accident, neglect, improper maintenance, alterations, or unless the unit

has been operated and maintained in accordance with the instructions furnished. This

warranty does not apply to the engine, motor, battery, battery charger or component parts

thereof. Please refer to the applicable manufacturer’s warranty on these items.

This warranty will not apply where the unit has been used commercially.

2

Lubrication

Maintenance...................................................... 17

Iliustrated Parts

Parts List ............................................

Parts Information

..........................................................

........................................

............ .....................

20, 22, 24

21,23,25,26

Back Cover

16

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

Warranty service is available through your local authorized service dealer or distributor. If

you do not know the dealer or distributor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will not be accepted by the factory unless prior written

permission has been extended by MTD.

This warranty gives you specific legal rights. You may also have other rights which vary

frnm .«statfi to

♦

♦

♦

♦

♦

Page 3

SAFE OPERATION PRACTICES FOR SNOW

THROWERS

TRAINING

1. Read the Owner’s guide instruction manual

carefully. Be thoroughly familiar with the

controls and proper use of the equipment.

Know how to stop the unit and disengage the

controls quickly.

2. Never allow children to operate equipment.

Never allow adults to operate equipment

without proper instructions.

3. Keep the area of operation clear of all

persons, especially small children and pets.

4. Exercise caution to avoid slipping or falling,

especially when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the

equipment is to be used and remove all door

mats, sleds, boards, wires and other foreign

objects.

2. Disengage all clutches and shift into neutral

before starting engine.

3. Do not operate equipment without wearing

adequate winter outer garments. Wear

footwear which will improve footing on

slippery surfaces.

4. Handle fuel with care. It is highly flammable.

(A) Use approved fuel container.

(B) Never add fuel to a running engine or hot

engine.

(C) Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors.

(D) Replace gasoline cap securely and wipe

up spilled fuel.

5. Use a grounded three wire plug-in for all units

with electric drive motors or electric starting

motors.

6. Adjust collector housing height to clear gravel

or crushed rock surface.

7. Never attempt to make any adjustments while

engine is running (except where specifically

recommended by manufacturer).

8. Let engine and machine adjust to outdoor

temperature before starting to clear snow.

OPERATION

1. Do not put hands or feet near rotating parts.

Keep clear of discharge opening at all times.

2. Exercise extreme caution when operating on

or crossing a gravel drive, walks, or roads.

Stay alert for hidden hazards or traffic. Do not

carry passengers.

3. After striking a foreign object, stop the

engine, remove wire from spark plug,

thoroughly inspect the snow thrower for any

damage, and repair the damage before

restarting and operating the snow thrower.

4. If the snow thrower should start to vibrate

abnormally, stop the engine and check

immediately for the cause. Vibration is

generally a warning of trouble.

5. Stop engine whenever you leave the operating

position, before unclogging the collector/

impeller housing or discharge guide, and

making any repairs, adjustments, or inspec

tions.

6. Take all possible precautions when leaving

the vehicle unattended. Disengage the power

take-off, lower the attachment, shift into

neutral, set the parking brake, stop the

engine, and remove the key.

7. When cleaning, repairing, or inspecting make

certain collector/impeller, and all moving

parts have stopped. Disconnect spark plug

wire and keep away from plug to prevent

accidental starting.

8. Do not run engine indoors, except when

starting engine and for transporting snow

thrower in or out of building. Open doors.

Exhaust fumes are dangerous.

9. Do not clear snow across the face of slopes.

Exercise extreme caution when changing

direction on slopes. Do not attempt to clear

steep slopes.

10. Never operate snow thrower without guards,

plates, or other safety protection devices in

place.

11. Never operate snow thrower near glass

enclosure, automobiles, window wells, drop

off, etc. without proper adjustments of snow

thrower discharge angle. Keep children and

pets away.

12. Do not overload machine capacity by

attempting to clear snow at too fast a rate.

13. Never operate machine at high transport

speeds on slippery surfaces. Use care when

backing.

14. Never direct discharge at bystanders or allow

anyone in front of unit.

15. Disengage power to collector/impeller when

transporting or not in use.

16. Use only attachments and accessories

approved by the manufacturer of snow

thrower (such as wheel weights, counter

weights, cabs, etc.).

17. Never operate the snow thrower without good

visibility or light. Always be sure of your

footing and keep a firm hold on the handles.

Walk, never run.

MAINTENANCE AND STORAGE

1. Check shear bolts, engine mounting bolts,

etc. at frequent intervals for proper tightness

to be sure equipment is in safe working

condition.

2. Never store machine with fuel in the fuel tank

Inside a building where open flame or spark

are present. Allow engine to cool before

storing in any enclosure.

3. Always refer to owner's guide instructions for

important details if snow thrower is to be

stored for an extended period.

4. Run machine a few minutes after throwing

snow to prevent freeze up of collector/

impeller.

Page 4

Æ

The snow thrower is shipped with

out gas or oil. See operating section

of this manual after assembly.

Reference to right hand or left hand

side of machine are observed from

the operating position.

CAUTION

NOTE

ASSEMBLY

INSTRUCTIONS

Tools Required for Assembly

9/16” Wrench

1/2” Wrench

7/16” Wrench or

or One Adjustable Wrench

Screwdriver

Hammer

Block of Wood

Remove from Carton

FIGURE 1.

Snow Thrower

~^lli

J ■■■ f.

Hiindlp

Assembly

(M

Chute- Assombly

1. Remove snow thrower and all parts from the

carton. Make certain that all loose parts and

literature have been removed before the

----

carton is discarded.

2. Extend throttle control assembly which is

attached to engine at rear of the snow thrower

and place on floor.

A CAUTION

Do not bend or kink control wire.

Loose

(1)

(1)

(1) Chute Crank Assembly

(1) Shifting Rod

(1) Clutch Rod Assembly

(1)

FIGURE 2.

R.irtr. T.ipnd

Together

Page 5

c-

D-

1

FIGURES.

F-~^

G—^ M

A

K V T—**

-K .tlr'

i. .^W

-»-AB

Contents of Hardware Pack

A (2) Ignition Keys

B (3) Chute Flange Keepers

C (6) Hex Cent. Lock Nut 1/4-20 Thd.

D (2) Self-Tapping Screws #8 x .50” Lg.

E (1) Auger Clutch Grip Assembly—L.H.

F (1) Belleville Washer .34 I.D. X .88 0.D.

— G (1) Hex Nut 5/16-18 Thd.

H (1) Carriage Bolt 5/16-18 X 1.75” Lg.

I (1) Belleville Washer

J (1) Hex Nut 5/16-18 Thd.

K (1) Clevis Pin

L (1) Push Cap

M (2) Cotter Pins 3/32” Dia.x 1.00” Lg.

N (1) Ferrule

O 0) Flat Washer.344 I.D.x.88 0.D.

P (2) Hex Jam Nut 5/16-24 Thd.

Q (1) Lock Washer 5/16” Scr.

S (1) Shift Lever

T (2) Vinyl Tape

U (1) Elastic Lock Nut 3/8-24 Thd.

V (1) Compression Spring

W (1) Belleville Washer .40 I.D. x .88 O.D.

X (2) Carriage Bolts 5/16-18 X.62” Lg.

Y (2) Lock Washers 5/16” Scr.

Z (2) Hex Nuts 5/16-18 Thd.

AA (2) Hex Screws 3/8-16 X.88” Lg.

AB (2) Lock Washer 3/8” Scr.

FIGURE 4.

FIGURES.

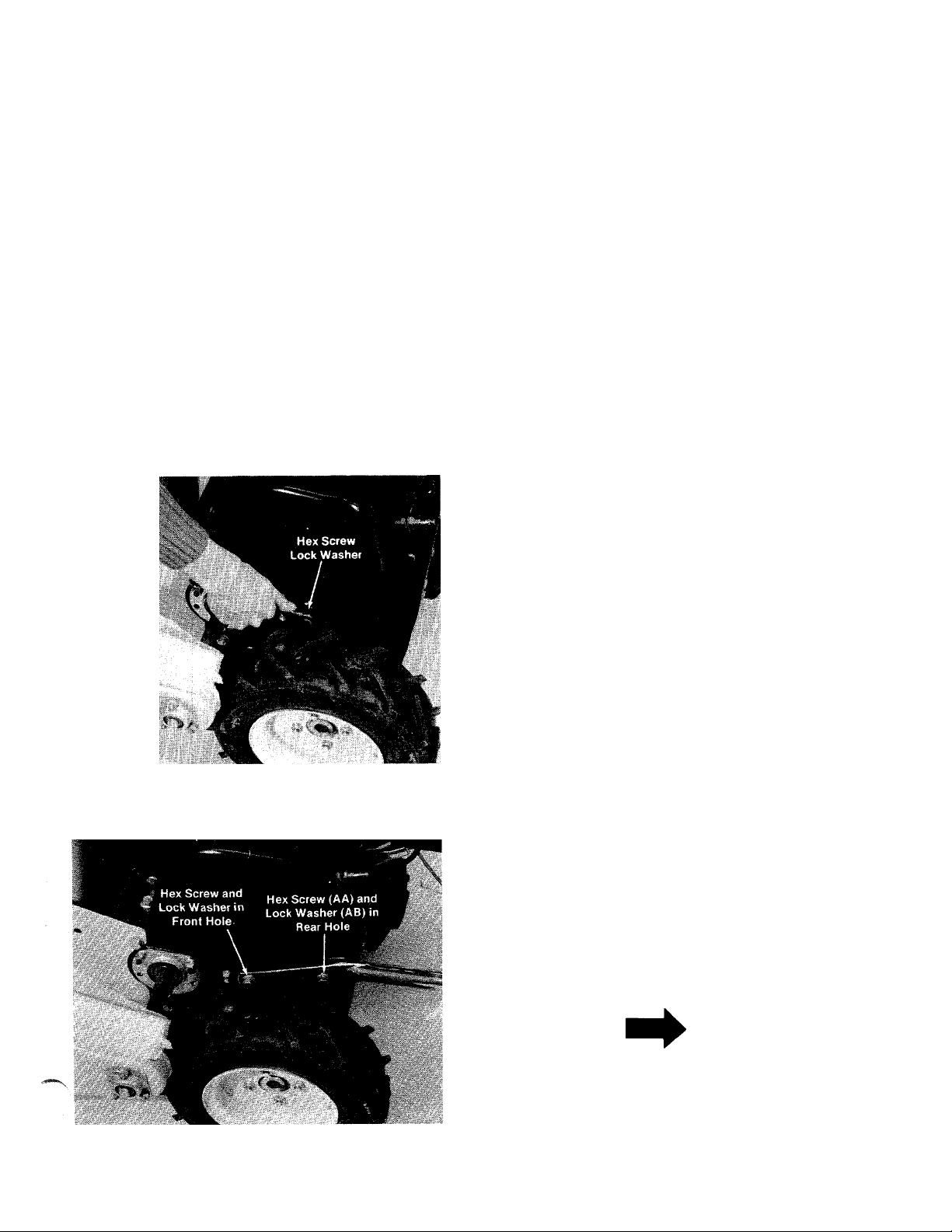

3. To attach handle assembly to the snow

— thrower, first remove the hex screw and lock

washer from each side of snow thrower

housing. A 9/16” wrench is required. See

figure 4.

4. Fasten handle assembly to snow thrower

housing. Place lock washer (AB) on hex screw

(AA). Line up holes in handle with holes in

sides of snow thrower housing. Start hex

— screws into rear holes by hand. Replace hex

screw and lock washer in front hole. See

figure 5. Do not tighten at this time.

NOTE

Loosen the three hex nuts which

hold the handle panel to the handle.

This will permit handle to move

freely so it can be assembled to the

housing with greater ease. Leave

hex nuts loose.

Page 6

FIGURES.

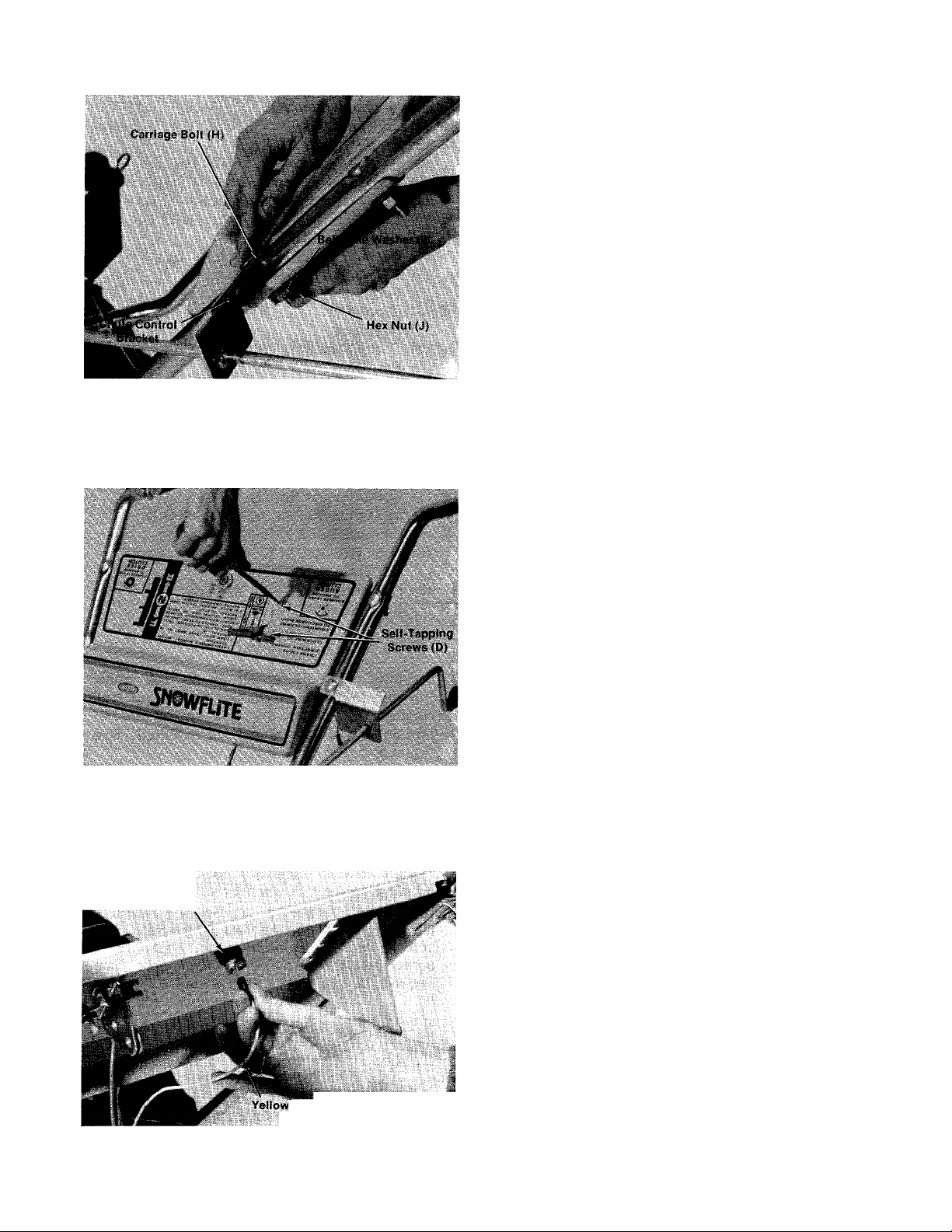

5.--Attach chute crank assembly to unit. Line up

hole in chute control bracket with hole in

handle. Secure with carriage bolt (H),

belleville washer (I) and hex nut (J) as shown

----

in figures.

6. At this point, tighten secureiy all nuts and

bolts.

7. Hold throttle control underneath handle

panel. Bring throttle control knob through the

slot in handle panel. Line up the two holes in

the throttle control with the two holes in

handle panel. Secure with self-tapping screws

(D). A screwdriver is required. See figure 7.

FIGURE 7.

FIGURES.

Safety

Switch

8. Plug yellow electric wire into safety switch

— beneath handie panei. See figure 8.

Electric

Wire

Page 7

FIGURES.

Shift Lever

(Flared Edge

Facing Detents

in Handle Panel)

Washer (W)

fl Compression

Spring (V)

Handle Panel

Weld Bolt

Belleville

9. Place shift lever (S) through slot in handle

panel, making sure flared edge of shift lever

faces the detents on handle panel. See figure

9.

10. Place shift lever on handle panel weld bolt.

------

Secure with belleville washer (W) (cupped

side goes against shift lever), compression

spring (V) and elastic lock nut (U). See figure

9. Tighten lock nut until compression spring

holds the shift lever into detent slots on

handle panel.

FIGURE 10.

ê

i

V

Ék/

11. Place bent end of shifting rod up through

shifting bracket located on right side of unit

(see figure 10). Secure with flat washer (0)

and cotter pin (M).

12. Move shifting bracket to middle (neutral)

position. Roll the unit back and forth. It

should move freely.

13. Place shift lever in neutral position. Thread

ferrule (N) onto shifting rod and place into

shift lever. Roll unit back and forth, checking

to be sure it is in neutral gear. If it does not

move freely, remove the ferrule and thread in

___

or out as necessary. Replace the ferrule and

move the unit again. Repeat procedure as

needed until neutral position is reached.

¡

14. After unit is set in neutral, secure ferrule to

shift lever with cotter pin (M) as shown in

figure 11.

FIGURE 11.

Page 8

FIGURE 12.

“Z” End of Control

Wire Hooked in

Clutch Grip

I

/

Drive Clutch

Grip

15. Thread hex jam nut (P) onto drive clutch

___

control cable which is attached to the snow

thrower housing. See figure 12.

16. Thread end of clutch control cable through

cable support bracket on right handle. Place

lock washer (Q) and hex jam nut (P) over

clutch control cable. Start nut on cable

housing by hand.

17. Hook “Z” end of control wire through hole in

drive clutch grip assembly. See figure 13.

Hex Jam

Nut (P)

FIGUREIS.

■M

\

Control Wire is

straight

Lock Washer (Q)

.'W

*t, I™/

Z” End of Clutch

Rod Assembly

18. Hold clutch grip so that the grip is against the

_

handle as shown in figure 13. Adjust the

clutch control cable so that the slack is taken

out of the control wire. Tighten the two hex

nuts at the cable support bracket. Control

wire should now be straight.

A

CAUTION

Do not overtighten control wire.

Too much tension may cause it to

break.

19. Auger clutch rod assembly and lockout rod

are preassembled. Place “Z” end of clutch rod

assembly into hole in clutch bracket on left

side of unites shown in figure 14.

FIGURE 14.

Page 9

■íi'ít .

Lockout

Rod

FIGUREIS.

A

Auger Clutch

Grip

Auger Clutch

Grip Assembly

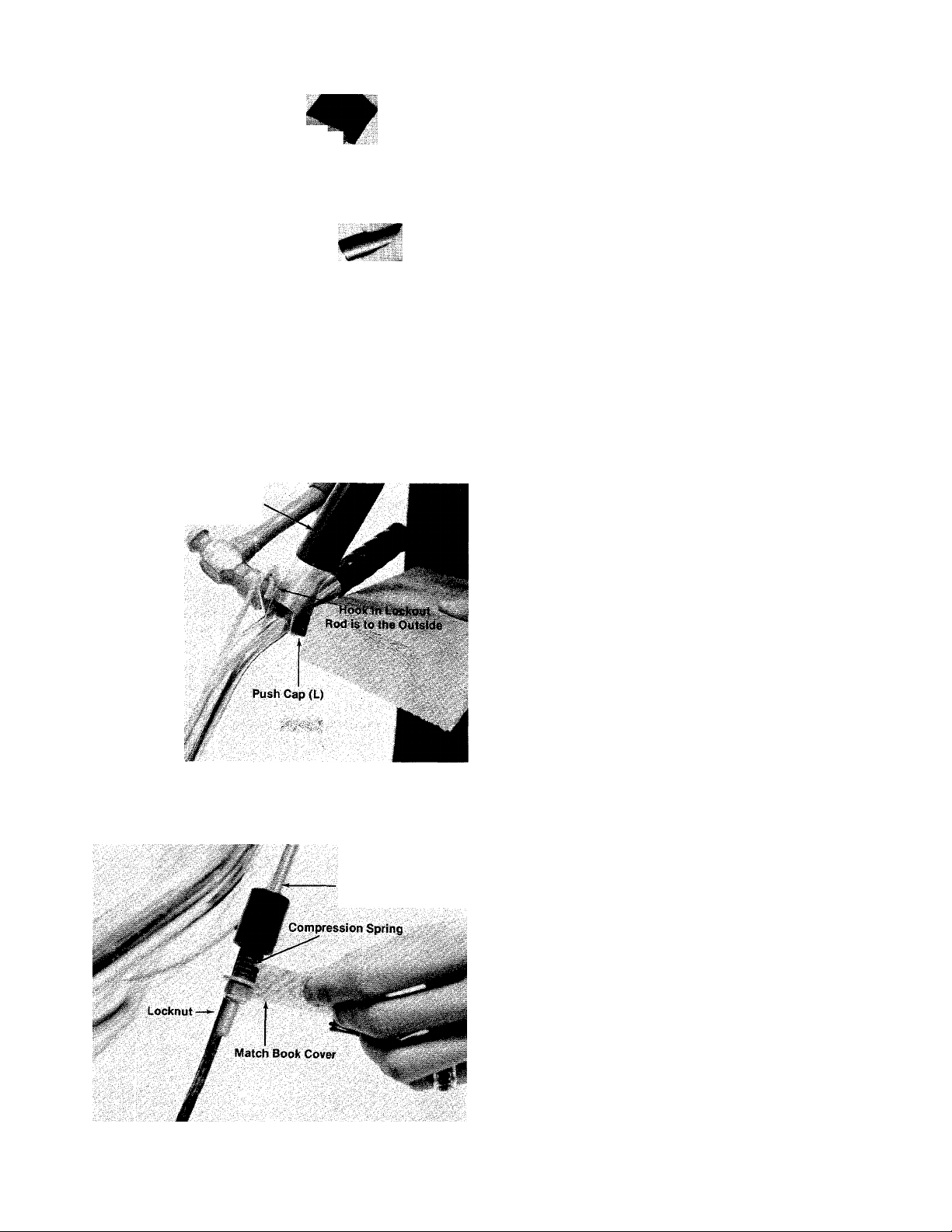

20. Hook lockout rod into auger clutch

------

assembly (E) as shown in figure 15.

grip

21. Place auger clutch grip on left handle (hook in

lockout rod is to the outside). Secure with

clevis pin (K) and push cap (L), using a

-----

hammer and a block of wood as shown in

figure 16.

mm

FIGURE 16.

FIGURE 17.

Lockout Rod

22. Squeeze the auger clutch grip to engage

lockout rod so you can check for correct

adjustment. With the lockout rod engaged,

you should be able to get a match book cover

------

between the coils of the compression spring

(spring should not be compressed tightly). If

there is not space between spring coils,

adjust the locknut using a 7/16” wrench until

correct adjustment is reached. See figure 17.

Page 10

Keeper (B) Beneath Lip *

FIGUREIS.

liex Lock Nuts (C)

V

Chute Flange

j

Grease the chute opening.

Place chute assembly over chute opening.

Place chute flange keepers (B) beneath lip of

chute assembly. Secure with hex lock nuts

(C) as shown in figure 18. Tighten with a

7/16” wrench, then back off 1/4 turn to allow

easier movement.

25. Grease the teeth on the chute assembly.

26. Place the end of chute crank assembly into

slot provided. Slide worm and bracket on

chute crank assembly into teeth on chute

assembly. Fasten in position with belleville

washer (F) (cupped side up) and hex nut (G).

See figure 19. Tighten finger tight.

Belleville Washer (F)

Hex Nut (G)

FIGURE 19.

Drift Cutli r

27. Turn chute crank to see that chute moves

freely. If adjustment is necessary, slide worm

and bracket in or out. Then tighten hex nut

securely with a|HB|wrench.

'A"

28. Loosen hex nut holding drift cutter to unit.

■

\

■

Pivot into position. Insert carriage bolt (X)

------

through snow thrower housing and drift cutter

with head to the inside of housing. Secure

with lock washer (Y) and hex nut (Z). Tighten

securely. See figure 20.

FIGURE 20.

10

Page 11

Throttle Control

Cable

FIGURE 21.

OPERATION

CONTROLS

29. Secure yellow electric wire to throttle control

•cable with the vinyl tape (T) provided. See

figure 21.

Shift Lever (See Figures 22 and 23)

The shift lever is located on the right hand side of

the handle panel. The shift lever may be moved

into forward, neutral or reverse position.

A. Center Position (N) is Neutral.

B. Forward Position (F) is Forward.

C. Rear Position (R) is Reverse.

Auger Clutch

i

F

t

0

1

FIGURE 22.

FIGURE 23.

11

Page 12

Safety Ignition Switch (See figures 22 and 24)

The ignition key must be in the switch and turned

to the on position before the unit will start.

Auger Clutch (See figures 22 and 27)

The auger clutch is located on the left handle.

Squeeze the clutch grip to engage the augers.

Release to stop the snow throwing action.

FIGURE 24.

Throttle Control (See figures 22 and 25)

The throttle control is located on the left hand

side of handle panel..It regulates the speed of the

engine.

THROTTLE

FIGURE 25.

Drive Clutch (See figures 22 and 26)

The drive clutch is located on the right handle

Squeeze the clutch grip to engage drive. Release

to stop.

'squeeze lever

TO ENGAGE

AUGER

CLUTCH

FIGURE 27.

Chute Crank (See Figure 22)

The chute crank is located on left hand side of the

snow thrower.

To change the direction in which snow is thrown,

turn chute crank as follows:

1. Crank clockwise to discharge to the ieft.

2. Crank counterclockwise to discharge to the

right.

STARTING INSTRUCTIONS

1. Remove oil fill cap. Add oil until reaching

point of overflowing. See figure 28.

SQUEEZE LEVER’

FIGURE 26.

O'

TO ENGAGE

DRIVE

CLUTCH

FIGURE 28.

12

Page 13

Above Freezing Temperatures: Use oil with

viscosity grade SAE 30 or SAE 10W-30 or SAE

10W-40.

Below Freezing Temperatures: Use oil with

viscosity grade SAE 5W-30 or SAE 10W.

2. Fill fuel tank with fresh, clean unleaded or

regular gasoline.

I WARNING \

Never fill fuel tank indoors, with en

gine running or while engine is hot.

3. Attach spark plug wire to spark plug.

4. Insert ignition key and turn to “ON” position.

5. Place shift lever in “NEUTRAL” (N) position.

6. Place throttle control in “START” (fast)

position.

2. Push primer two (2) or three (3) times.

See figure 30.

NOTE

Additional priming may be required

(for initial start only) if temperature

is below 15°F.

J WARNIN^

Never run engine indoors or in en

closed poorly vented area. Engine

exhaust gases contain carbon mon

oxide: an odorless and deadly gas.

7. Start engine, following appropriate instruc

tions:

A. Cold engine start (engine has not been run

recently)

1. Pull choke wire out to “ON” position.

See figure 29.

FIGURE 30.

3. Grasp the starter rope handle and pull

out rapidly. Return rope handle slowly.

Repeat until engine starts. If engine

fails to start, repeat steps 2 and 3 as

necessary until engine starts.

4. After engine starts, push choke wire in

gradually (to “OFF” position).

B. Warm engine start (engine still warm from

recent running)

1. Grasp the starter rope handle and pull

out rapidly. Return rope handle slowly.

Repeat until engine starts.

2. If engine fails to start after a number of

attempts, pull choke wire out. Repeat

step one until engine starts. After

engine starts, push choke wire in

gradually.

WARNING \

FIGURE 29.

Once the snow blower has been in

operation, caution should be exer

cised in the area of the muffler

and surrounding surfaces. See fig

ure 31.

13

Page 14

FIGURE 31.

TO STOP ENGINE

ADJUSTMENTS

^ WARNING J

NEVER attempt to clean chute or

make any adjustments while engine

is running.

CHUTE ASSEMBLY ADJUSTMENT

The distance snow is thrown can be adjusted by

adjusting the angle of the chute assembly. The

sharper the angle, the shorter the distance snow

is thrown.

NOTE

Run engine for a few minutes before

stopping to help dry off any mois

ture which may have accumulated

on the recoil starter.

1. Move throttle control lever to “STOP” posi

tion.

2. Turn ignition key to “OFF” position.

3. Remove ignition key to prevent accidental

starting.

A

Disconnect spark plug wire from

spark plug and secure it so that

it cannot accidentally contact spark

plug. This will reduce the possibility

of unauthorized starting of engine

while equipment is unattended.

TO ENGAGE DRIVE

CAUTION

To adjust chute assembly, loosen the hand knob.

Pivot the top of the chute assembly to position

desired. Retighten the hand knob.

SKID SHOE ADJUSTMENT

The space between the shave plate and the ground

can be adjusted. For close snow removal, place

skid shoes in the low position. Use middle or high

position when area to be cleared is uneven. See

figure 32.

To adjust skid shoes, loosen the four hex nuts and

carriage bolts. Move skid shoes to desired

position. Retighten nuts and bolts securely.

1. With the engine running near top speed, move

shift lever into forward (F) or reverse (R)

position. (If the lever does not shift easily,

move the unit back and forth to align gears as

you shift the lever.)

2. Squeeze the drive clutch grip (located on the

right handle) and the snow thrower will move.

Release it and the drive motion will stop.

CAUTION

A

NEVER move shift lever without first

releasing the drive clutch.

' High Position

' Middle Position

- Low Position

Skid Shoe

FIGURE 32.

14

Page 15

AUGER CHAIN ADJUSTMENT

If the drive chain to the auger is loose, it may be

adjusted using a 9/16” wrench. Loosen the hex

nut on the outside of the chain guard on the left

hand side of the unit. Slide the bolt down as

necessary. Tighten the hex nut securely. See

figure 33.

Loosen the two hex nuts at the wheel axle on the

right hand side of snow thrower housing. Lift up

on the right wheel to take the slack out of the

chain as you retighten the nuts. See figure 34.

SHIFTING ROD ADJUSTMENT

To adjust the shifting rod, refer to step number 13

under assembly instructions.

DRIVE CLUTCH CONTROL ADJUSTMENT

To adjust the drive clutch control, refer to step

number 18 underassembly instructions.

Hex Nut

Chain Guard

FIGURE 33.

REAR AXLE CHAIN ADJUSTMENT

To adjust the rear axle chain, first tip the snow

thrower forward so it rests on the auger housing

and drift cutters.

Lift Right

Hand Wheel

AUGER CLUTCH CONTROL ADJUSTMENT

To adjust the auger clutch control, refer to step

number 22 under assembly instructions.

FIGURE 34.

15

Page 16

LUBRICATION

SPECIFICATIONS:

Lubricate once a season or after every 25 hours of

operation.

Oil—Use SAE 30 or equivalent.

Grease—Use automotive multi-purpose grease.

Lubricate chain once a season with engine oil.

Engine—Remove oil fill plug and add oil until it

reaches point of overflowing.

Grease Worm On Chute

Crank Once a Season

Change Oil—After first two (2) hours of operation

and every twenty-five (25) hours thereafter. Drain

oil from oil drain plug.

Above Freezing Temperature: Use oil with

viscosity grade SAE 30, or SAE 10W-30, or SAE

10W-40.

Below Freezing Temperature: Use oil

viscosity grade SAE 5W-30 or SAE 10W.

Capacity—Approximately VA pints.

with

Grease Chute Opening Once

A Season

Oil all chains, bearings, gears and the shifting

mechanism at least once a season , Use engine

oil. Avoid getting oil on V-belts and pulleys.

16

Page 17

,-<^^***'*N

MAINTENANCE

SHAVE PLATE AND SKID SHOES

The shave plate and skid shoes on the bottom of

the snow thrower are subject to wear. They should

be checked periodically and replaced when

necessary.

To remove shave plate, remove the csrriage bolts,

lock washers and hex nuts which attach it to the

snow thrower housing. Reassemble new shave

plate, making sure heads of the carriage bolts are

to the inside of the housing. Tighten securely.

To remove skid shoes, remove the four carriage

bolts, belleville washers and hex nuts which

attach them to the snow thrower. Reassemble

new skid shoes with the four carriage bolts,

belleville washers (cupped side goes against skid

shoes) and hex nuts.

BELT REMOVAL AND REPLACEMENT

^ WARNING {

Remove the spark plug wire from the

spark plug and ground. Drain gaso

line from the fuel tank, or place a

piece of plastic film underneath

the gas cap to prevent gasoline from

leaking.

Remove the belt keeper by removing the self

tapping screw shown in figure 36. A 9/16”

wrench is required.

FIGURE 36.

3. Tip the snow thrower forward so that it rests

on the auger housing and drift cutters.

4. Remove bottom cover. First remove the two

self-tapping screws shown in figure 36 with a

Va” wrench. Then lift cover out from the slots

in the frame. See figure 37.

To remove and replace either the auger drive belt

or the drive belt, proceed with the following

instructions.

1. Remove the three self-tapping screws from

the belt cover using a 7/16” wrench. See

figure 35.

I§elf -Tapping

' Screw

Belt Cover

FIGURE 35.

FIGURE 37.

5. Remove the large shoulder bolt which acts as

a belt keeper by removing the hex nut and lock

washer on the outside of the frame assembly.

A 9/16” wrench is required. See figure 38.

17

Page 18

FIGURE 38.

6. Remove the belt guard plate by removing the

self-tapping screw shown in figure 38. Hold

one hand underneath the frame to catch the

plate so it does not fall. A Vz" wrench is

required. See figure 39.

me:»

Auger Drive ■

Belt

Large Bottom

Pulleys

Drive Belt ^

Se^-Tappirjg

c. Slide the belt off the bottom pulley and out

the bottom of the chain case.

Auger Drive

Bell Idler Pulleys'^

FIGURE 40.

9. To Reinstall Drive Belt:

a. Slip belt over engine pulley.

b. Place belt between belt guard pin and idler

pulley. See figure 40.

c. Feed belt over large bottom pulley.

10. To Reinstall Auger Belt:

a. Slide belt in from bottom.

b. Slip belt over engine pulley.

c. Place between belt guard pin and idler

pulley. See figure 40.

d. Feed belt over large bottom pulley.

11. Reinstall belt guard plate. Hold It in place

beneath frame In one hand. Secure with self

tapping screw, using a 1/2” wrench. See

figure 41.

r

FIGURE 39.

7. To Remove Auger Drive Belt:

a. Slip auger drive belt off engine pulley. See

figure 40.

b. Lift belt out of the sheave of the bottom

pulley.

c. Slide belt out the bottom of the chain case.

8. To Remove Drive Belt:

a. First slip the auger drive belt off the engine

pulley as shown in figure 40.

b. Slip the drive belt over the double engine

pulley.

Belt Guard

Plate

FIGURE 41.

18

Page 19

12. Reinstall shoulder bolt (which acts as a belt

keeper) at the base of the two large pulleys. A

9/16” wrench is required. Tighten securely.

13. Reinstall bottom cover by slipping it into the

two slots in frame provided. Secure with two

self-tapping screws, using a Vz" wrench.

If unit is to be stored over 30 days, prepare for

storage as follows;

1. Remove all gasoline from fuel tank to prevent

gum deposits from forming on these parts

and causing possible malfunction of engine.

14. Tip unit into operating position.

15. Reinstall belt guard and belt cover.

16. Remove plastic film from gas cap.

A

Check engine and snow thrower fre

quently for loose nuts, bolts, etc.,

and keep these items tightened.

CAUTION

OFF SEASON STORAGE

^ WARNING I

NEVER STORE ENGINE WITH FUEL IN TANK

INDOORS OR IN ENCLOSED, POORLY VENTI

LATED, ENCLOSURES, WHERE FUEL FUMES

MAY REACH AN OPEN FLAME, SPARK OR

PILOT LIGHT AS ON A FURNACE, WATER

HEATER, CLOTHES DRYER, ETC.

I WARNING \

DRAIN FUEL INTO APPROVED CONTAINER

OUTDOORS, AWAY FROM OPEN FLAME.

Run engine until engine starts to falter, then use

choke to continue engine operation until all fuel in

tank and carburetor is exhausted. Remove fuel

line at tank or carburetor and drain any remaining

gasoline from system.

CAUTION

A

FUEL LEFT IN ENGINE DURING WARM

WEATHER DETERIORATES AND WILL CAUSE

SERIOUS STARTING PROBLEMS.

2. Remove spark plug and pour one (1) ounce of

engine oil through spark plug hole into

cylinder. Crank engine several times to

distribute oil. Replace spark plug.

3. Clean unit by removing any dirt from exterior

of engine and equipment.

4. Follow lubrication recommendations on page

16.

19

Page 20

310-430A

IF YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL 4 SERIAL NO

MODEL

Page 21

PARTS LIST FOR MODEL 310-430A

REF.

NO.

1

05506 Drive Clutch Grip Ass’y.

2

01166

4

711-0415 Clevis Pin .375 Dia. x 1.62

PART

NO.

COLOR

CODE

DESCRIPTION

Grip 33 736-0231

NEW REF.

PART

Lg.

5 711-0677

6

725-0201

7

725-0464 ignition Switch 36 05811

Adjustment Ferrule

Ignition Key

8 736-0225 Internal L-Wash. 5/8” Scr.*

9 746-0312

10

710-0227

11

T«-5yi

12

05507

13

726-0110 Push Cap .375” Rod—Black

14 736-0242

15 712-0267

16

736-0140 FI-Wash. .385I.D. X.62

Throttle Control Ass’ySelf Tap. Scr. #8x .50” Lg.

Curved Carriage Bolt

5/16-18x«BI/-75lia-

Auger Clutch Grip Ass’y.

Belleville Wash.

Hex Nut 5/16-18 Thd.*

O.D. X .060 45 725-0480

17 720-0171

18

726-0100 Push Nut 3/8” Rod

19 747-'0t53^1w

20

05567

21

05516

22

732-0337

23

749-0203 Handle—L.H.

24

05816 Handle Panel Ass’y.

25

747-0154 Lockout Rod .214 Dia. x

Black Knob—3/8” Dia. Hole 46 725-0476

Chute Crank

Auger Clutch Rod Ass’y.

Chute Control Bracket

Compression Spring .39 O.D.

X .75” Lg.

N

32.0” Lg.

26

27

73^1^ L-Wash.3/8” Scr.*

28

732-0320

Pilot Scr. 3/8-16 xBl’Lg.

Extension Spring .38 O.D.

X3.25 Lg.

29 710-0600 Hex Wash. Hd. Self Tap Scr.

5/16-24 X .50” Lg.

30 05790

710-0322

31

Frame Cover

Hex Sems Scr. 5/16-18 x

N

1.00” Lg.*

NO.

32

COLOR NEW

NO.

748-0233

CODE

DESCRIPTION

Shoulder Spacer

PART

FI-Wash. .34I.D. xl.12

O.D. X .125

34

736-0119

35 712-0158

L-Wash. 5/16” Scr.*

Hex Cent. L-Nut 5/16-18

Thd.

Shifting Bracket

37 714-0111

Cotter Pin 3/32” Dia. x 1.00

Lg.

38 736-0159

FI-Wash. .344I.D.X.88

O.D. X .063

749-0204

39

40 05559

712-0324 Hex Ins. L-Nut V4-20 Thd.

41

42 736-0173

43 747-0175

746-0374 Drive Clutch Control Cable

44

Handle—R.H.

Thrower Clutch Bracket

FI-Wash. .28 I.D. x .75 O.D.

Shifting Rod

Vinyl Sealing Tape

Electric Wire

47

710-0458

Carriage Bolt 5/16-18 x

1.75” Lg.*

48 712-0116

Hex Ins. Jam L-Nut 3/8-24

Thd.*

49

732-0193

Compression Spring .60

O.D. X .88” Lg.

50

736-0105

Belleville Wash. .40 I.D. x

.88 O.D.

05694 Shift Handle Ass’y.

52

53

05^

55 tTOb

Cable Support Bracket

He)^el^^^c^7W^

.75” Lg.

56 726-0195

57

“U”-Nut 3/8-16 Thd.

Hex Jam Nut 5/16-24 Thd.

PART

N

N

N

'For faster service obtain standard nuts, boits and washers localiy. if these items cannot be obtained locaiiy, order by part

number and size as shown on parts list.

(488—Mack Truck Yellow)

When ordering parts if color or finish is important, use color code shown at left. (e.g. Mack

Truck Yellow Finish—05546 (488).)

The engine is not under warranty by the Snow Thrower

manufacturer. If repairs or service is needed on the

engine, please contact your nearest authorized engine

service outlet. Check the “Yellow Pages” of your

telephone book under “Engines—Gasoline.”

NOTE

This instruction manual covers various

models and all specifications shown do not

necessarily apply to your model. Specifica

tions subject to change without notice or

obligation.

21

Find It Fast

In The

Yellow Pages

Page 22

310-430A

/ 2

h./ /

22

Page 23

PARTS LIST FOR MODEL 310-430A

COLOR

REF.

PART

NO.

NO.

1 734-0988

CODE

DESCRIPTION

Wheel Ass’y.—Comp. 12.50

X3.50—R.H.

734-0987

Wheel Ass’y.—Comp. 12.50 x

3.50—L.H. (Not Shown)

710-0409

2

Hex Scr. 5/16-24x1.75” Lg.

H.T.

05811

3

4 738-0140

712-0158

5

Shifting Bracket

Shid. Scr. .438” Dia. x .180

Lg-

Hex Cent. L-Nut 5/16-18

6 Shifting Bracket Support

7 710-0600

Hex Wash. Hd. Self-Tap Scr.

5/16-24 X .50

714-0111

8

Cotter Pin 3/32” Dia. x

1.00” Lg.

736-0187

9

10

11

748-0229

715-0114

FI-Wash. .64 I.D. X 1.25 O.D.

X .060

Hex Flange Brg. .63 I.D.

H-Spring Pin Spri. V4” Dia.

xl.50 Lg.

05792

12

Drive Housing Bracket—

R.H.

714-0104

13

14 748-0163

15 748-0161

05054

16

738-0315

17

748-0164

18

713-0263

19

Internal Cotter Pin 3/8” Dia.*

Spur Gear—21 Teeth

Clutch Collar

Shifting Yoke

Rod

Sprocket—10 Teeth

#41 Chain—V2” Pitch x33

Links

20

713-0723

05093

Master Link

28 Teeth—Sprocket Hub

Ass’y.

21

750-0229

Spacer—.62 I.D. x .88 O.D.

1.030

736-0237

22

FI-Wash. .64 I.D. X 1.25

O.D. X .100

738-0459

23

24

714-0137

Shifting Shaft

Hi-Pro Key 3/16 X 3/4” Dia. x

1.062

05137

25

26 710-0506

27 756-0325

32 Teeth Sprocket Hub Ass’y.

Hex Scr. V2-20 X 5.50” Lg.

5.25” O.D. Pulley with 9

Teeth Sprocket

738-0314 Shaft

28

NEW

PART

N

N

REF.

NO.

29

713-0265

713- 0723

30

714- 0126

31

714-0129

32

05789

33

741-0133

34

05034

35

736-0329

36

712- 0287

37

750-0295

38

736-0250

39

748-0162

40

738-0460

41

713- 0261

42

736-0921

43

712-0200

.44

10470

716-0104

45

46

47

736-0287

48

712-0267

49

736-0119

50

710-0451

51

748 085»

52

710-0190

53

750-0324

54

736-0119

55

712- 0267

56

713- 0264

713-0723

57

712-0273

PART

COLOR

NO.

CODE

7/3'-OZ7B

DESCRIPTION

#41 Chain 1/2 Pitch x 47

Links

Master Link

Hi-Pro Key—3/16 X 3/4” Dia.

Hi-Pro Key—3/32x5/8”

Dia.

Drive Housing Bracket

Ass’y- —L.H.

Ball Bearing .500 I.D. x 1.38

O.D. x .438

Bearing Housing

L-Wash. 1/4 Scr.*

Hex Nut 1/4-20 Thd.*

Spacer—.52 I.D. x .62 O.D.

X2.69

FI-Wash. 1.06 I.D. X 1.75

O.D. X .100

Spur Gear—62 Teeth

Wheel Axle

32 Teeth—Sprocket Hub

Ass’y.

L-Wash. for 1/2” Scr.*

Hex Ins. Jam L-Nut V2-2O

Thd.

Bearing Plate

E-Ring for .500” Dia. Shaft

Flange Bearing w/Flats

.753

FI-Wash. .81 I.D. X 1.25

O.D. X .060

Hex Nut 5/16-18 Thd.*

L-Wash. 5/16” Scr.*

Carriage Bolt 5/16-18 x .75”

Lg.

8 Teeth Sprocket #41 Chain

Hex Scr. 5/16-18x4.00” Lg.

Spacer .50 O.D. x .34 I.D. x

3.25” Lg.

L-Wash. 5/16” Scr.*

HexNut5/16-18Thd.*

#41 Chain 1/2 Pitch x 37 Links

Master Link

Hex Jam L-Nut 5/16-24 Thd.

NEW

PART

N

N

N

N

N

'For faster service obtain standard nuts, bolts and washers locally. If these items cannot be obtained locally, order by part

number and size as shown on parts list.

(488—Mack Truck Yellow) When ordering parts if color or finish is important, use color code shown at left. (e.g. Mack

Truck Yellow Finish—05546 (488).)

The engine is not under warranty by the Snow Thrower

manufacturer. If repairs or service is needed on the

engine, please contact your nearest authorized engine

service outlet. Check the “Yellow Pages” of your

telephone book under “Engines—Gasoline.”

23

Find It Fast

In the

Yellow Pages

Page 24

310-430A

40 ö

60 59 ®

24

Page 25

REF

NO

PART

COLOR

NO.

CODE

1

_

2 710-0599

05621

3

4 714-0105

5 710-0600

6 05810

05821

7

8 736-0119

9 710-0237

10 746-0374

11 736-0234

12

712-0116

13 754-0205

14 756-0257

15 736-0235

16 736-0169

17 710-0152

18

710-0723

756-0137

19

712-0107

20

21

05823

05556

22

712-0266

23

714-0111

24

747-0174

25

748-0233

26

05559

27

710-0322

28

29 738-0281

30

712-0158

31 736-0231

32 712-0266

33

34

35 710-0606^

05156

36

37

741-0155

38 713-0266

39 713-0723

40 712-0267

41

710-0600

05244

42

74^17^^^

43

44

45 71^79^^"

46 756-0258

47 756-0325

738-0117

48

PARTS LIST FOR MODEL 310-430A

DESCRIPTION

Engine

Hex Self-Tap Scr. V4-20 x .50”

Lg-

Belt Cover N

Sq. Key 3/16x1.00” Lg.

Hex Wash. Hd. Self-Tap Scr.

5/16-24 X.50” Lg.

Belt Guard N

Engine Plate Ass’y. N

L-Wash. 5/16” Scr.*

Hex Scr. 5/16-24 X ;62” Lg.

Drive Clutch Control Cable N

FI-Wash. .391.D. X 1.50

O.D. X .060

Hex Ins. Jam L-Nut 3/8-24

Thd.

3V-Belt31.5” Lg.

Engine Pulley

FI-Wash. .40 I.D. X 1.25 O.D.

X .157

L-Wash; 3/8” Scr.*

Hex Scr. 3/8-24x1.00” Lg.*

Hex Scr. 3/8-.^iJx1.25” Lg.*

Flat Idler 2.25 O.D. , , i u, v

Drive Idler Brkt. Ass’y.

Thrower Idler Brkt. Ass’y.

Hex Cent. L-Nut 3/8-16 Thd.

Cotter Pin 3/32” Dia. x 1.00”

Lg.*

Clutch Rod 5/16” Dia. x

2.88 Lg.

Shoulder Spacer

Thrower Clutch Bracket

Hex Sems Scr. 5/16-18 x

1.00” Lg.*

Shid. Scr. .625” Dia. X.170”

Hex Cent. L-Nut 5/16-18

Thd.

FI-Wash. .34 I.D. xl.12

O.D. X .125

Hex Cent. L-Nut 3/8-16 Thd.

Woodruff Key 5/32 x 5/8 Dia.

jUirower Shaft

Hex Scr. V4-20x1.50” Lg.*

14 Teeth Sprocket Hub Ass’y.

Ball Brg. .625 I.D. X 1.38

O.D. X .438

#41 Chain —V2” Pitch X 83

Links

#41 Master Link Va” Pitch

Type II

Hex Nut 5/16-18 Thd.*

Hex Wash. Hd. Self-Tap Scr.

5/16-18 X .50” Lg.

Bearing Housing

Self Aligning Brg. .750 I.D.

~

.. .......

. .. ... .. . .. ... .. . .. ... .. . 7 ”ee ^

Hex Nut 3/8-16 Thd

1/2” V-Pulley .753 I.D.

5.25” O.D. Pulley with 9

Teeth Sprocket

ShId. Scr. .498” Dia. x 2.475”

Lg.

NEW

PART

N

25

REF.

NO.

49

710-0623

50

736-0231

51

712-0254

710-0538

52

736-0242

53

54

05561

55

710-0260

56

05139

57

07386

58

710-0371

59

712-0798

60

736-0105

05571

61

62

710-0389

63

05540 —488

64

05001

741-0170

65

66

738-0227

67

05018

68

05515

05482 —488

69

70

710-0276

71

05225 —488

72

736-0179

736-0242

73

74

09966

75

712-0158

76

715-0103

77

736-0179

78

717-0301

79

747-0153

80

05783

736-0242

81

82

05785

83

05673

84

710-0726

85

710-0442

732-0264

86

87

710-0560

88

736-0235

89

750-0252

90

736-0219

756-0192

91

92

712- 0130

93

713- 0177

PART

NO.

COLOR

CODE

DESCRIPTION

Hex Self-Tap Scr. 3/8-16 x

.75” Lg.

FI-Wash. .341” I.D. xl.12”

O.D.

Hex Jam Nut 5/16-24 Thd.*

Hex Lock Screw 5/16-18 x

.62” Lg.

Bell. Wash. .34I.D. X.88

O.D. X .060

Chain Guard

Carr. Bolt 5/16-18 X .62” Lg.*

Drift Cutters

FI-Wash.

Hex Scr. 5/16-18 X .88” Lg.

Hex Nut 3/8-16 Thd.*

Bell. Wash. .40 I.D. x.88

0. D.

Slide Shoe

Carr. Bolt3/8-16x.75”Lg.*

Spiral Housing Ass’y. 21”

Shave Plate

Flange Brg. w/Flats 1.0”

1. D.

Spiral Shaft

Spiral Ass’y.—L.H.

Chute Brkt.

Chute Ass’y.

Carr. Bolt 5/16-18x1.00”

Lg.*

Top Chute Ass’y.

FI-Wash. .53 I.D. X 1.25 O.D.

X .100

Bell. Wash. .34 I.D. x.88

O.D.

Handle Knob Ass’y.

Hex Cent. L-Nut 5/16-18

Thd.

Spring Pin Roll 1/8” Dia. x

.75” Lg.

FI-Wash. .531 I.D. X 1.25

O.D.

Worm—R.H. with Three

Thread

Chute Crank

Chute Flange Keeper Ass’y.

Bell. Wash. .34 I.D. x.88

O.D.

Frame Ass’y.

Belt Guard Plate

Hex Wash. Self-Tap Scr.

5/16-18 X .75” Lg.

Hex Scr. 5/16-18x1.50” Lg.*

Extension Spring .38 O.D. x

2.50” Lg.

Carriage Bolt 3/8-16 x 1.75”

Lg.

FI-Wash. .40 I.D. X 1.25 O.D.

Idler Spacer

Bell. Wash. .40 I.D. x 1.12

O.D.

Plastic Idler

Hex Ins. L-Nut 3/8-16 Thd.

40 Tooth Sprocket Hub Ass’y.

NEW

PART

N

N

N

Page 26

PARTS LIST FOR MODEL 310-430A (Continued)

REF.

NO.

PART

NO.

94 715-0118

COLOR

CODE

DESCRIPTION

Spring Pin Spiral 5/16 x

NEW

PART

1.75” Lg.

05136

95

05023

96

05017

97

05360 Bearing Hsg. Ass’y-

98

716-0121

99

Plastic Bushing

Spiral Plate

Spiral Ass’y.—R-H.

Snap Ring for 1.50” Dia.

Shaft

736-0163

100

FI-Wash. 1.0” I.D. xOHi

0.^.K,030

736-0250

101

FI-Wash. 1.06 I.D. X 1.75

O.D.

loz .3*i S. fi le. i% &» X .ofc

/Q% 73(s~ ^23S' . 7VJ^/’/ /Z^ Cff Tej^s^/c/x

26

Page 27

PARTS INFORMATION

POWER EQUIPMENT PARTS AND SERVICE

Parts and service for all MTD manufactured power equipment are

available through the authorized service firms listed below. All orders

should specify the model number of your unit, parts number,

desc'ription of ports ond the quontity of each part required.

ALABAMA BIRMINGHAM

Auto Electric & Carburetor Co

ARKANSAS FORT SMITH

Mity Mite Motors, Inc.................................4515 South 16th Street 72901

Sutton’s Lawn Mower Shop

CALIFORNIA PORTERVILLE

Billious.......................................................75 North D Street.... 93257

Lawn Mower Supply Co

J.W. Jewett Co.............................................981 Folsom St

COLORADO DENVER

South Denver Lawn Equip.........................527 West Evans

FLORIDA JACKSONVILLE

Radco Distributors

Small Eng. Dist..........................................2351 N.W. 147th St.... 33054

GEORGIA EAST POINT

East Point Cycle & Key.........................................2834 Church St.30344

ILLINOIS LYONS

Keen Edge Co.............................................8615 Ogden Ave

INDIANA ELKHART

Parts & Sales Inc

IOWA DUBUQUE

Power Lawn & Garden Equip

LOUISIANA NEW ORLEANS

Suhren Engine Co

MARYLAND TAKOMA PARK

Center Supply Co

MASSACHUSETTS SPRINGFIELD

Morton B. Collins Co

MICHIGAN LANSING

Lorenz Service Co........................................2500 S. Pennsylvania . 48910

Power Equipment Dist

MINNESOTA HOPKINS

Hance Distributing Inc

PowerTools Inc

MISSISSIPPI BILOXI

Biloxi Sales & Service, Inc

MISSOURI KANSAS CITY

Automotive Equip. Service.......................................3117 Holmes St 64109

Ross-Frazier Supply Co

Henzier, Inc..................................................2015 Lemay Ferry Rd.. 63125

NEW JERSEY BELLMAWR

Lawnmower Parts Inc.................................717 Creek Rd

Feld Distributor...........................................28 Glen Rd

NEW YORK CARTHAGE

Gamble Dist., Inc

................................................

......................................

................................................

..............................

..................................

.............................

.....................................................................

...................

NORTH LITTLE ROCK

......................

............................

...................

.....................

................................

.........................

.............................

SAN BERNARDINO

SAN FRANCISCO

OPA LOCKA

6867 New Hampshire Ave.. 20012

MOUNT CLEMENS

36463 South Gratiot.. 48043

ST. PAUL

3771 Sibley Memorial Hwy. . 55122

ST. JOSEPH

ST. LOUIS

RUTHERFORD

2625 4th Ave. S

Rt. 4 Box 368

25608 E. Baseline .... 92410

2403 Market St.32206

2101 Industrial Pkwy.. 46514

2551 J.F. Kennedy.... 52001

8330 Earhart Blvd.70118

300 Birnie Ave

420 Excelsior Ave. W.. 55343

506 Caillavet St

8th and Monteray .... 64503

...............

...................

.................

..............

............

................

..............

.................

.....................

West End Ave.13619

35233

72117

94107

80223

60534

01107

39533

08030

07070

BRIGGS AND STRATTON, TECUMSEH AND PEERLESS PARTS AND

SERVICE

Briggs & Stratton, Tecumseh and peerless parts and service should be

handled by your nearest authorized engine service firm. Check the

yellow pages of your telephone directory under the listing

Engines—Gasoline, Briggs & Stratton or Tecumseh Lauson.

GTP Leisure Products Inc

NORTH CAROLINA GOLDSBORO

Smith Hardware Co...............................r. 515 N. George St. .. 27530

Dixie Sales Company

OHIO CARROLL

Stebe’s Mid-State Mower Supply ... Box 366-71 High St. ..43112

Bleckrie, Inc

National Central

Burton Supply Co

OKLAHOMA ADA

Ada Auto Supply

Victory Motors, Inc

Forest Sales Inc......................................... 1039 NW 63rd St

OREGON PORTLAND

Kenton Supply Co

PENNSYLVANIA CHESTER

Stull Equipment Corp

EECOInc.....................................................4021 N.ethSt

Thompson RubberCo................................5222-24 N. Fifth St.... 19120

Bluemont Co

TENNESSEE KNOXVILLE

Master Repair Service................................2000 Western Ave. ... 37921

Memphis Cycle & Supply Co.....................421 Monroe Ave

American Sales & Service, Inc

TEXAS DALLAS

Marr Brothers, Inc......................................423 E. Jefferson

Woodson Sales Corp................................. 1702 N. Syivania............76111

Bullard SuDply Co

Catto & Putty, Inc

UTAH SALT LAKE CITY

A-1 Engine & Mower Co

VERMONT BURLINGTON

Vermont Hdwe. Co. Inc

VIRGINIA RICHMOND

RBI Corp....................................................963 Myers St

WASHINGTON SEATTLE

Bailey’s Inc

WEST VIRGINIA CHARLESTON

Young’s, Inc

WISCONSIN APPLETON

Automotive Supply Co

..............................................

........................................

.............................................

................................................

...............................................

........................

....................................

............................

.......................................

....................................

...................................

................................

....................................

.......................................

............................

.............................

...............................

SYRACUSE

420 Marcellus St

GREENSBORO

327 Battleground Ave. 27402

CLEVELAND

7900 Lorain Ave

WADSWORTH

687 Seville Rd

YOUNGSTOWN

1301 Logan Ave. Box 929 . .44501

301 E. 12th St

MUSKOGEE

605 S. Cherokee

OKLAHOMA CITY

8216 N. Denver Ave. .. 97217

742 W. Front St

HARRISBURG

PHILADELPHIA

PITTSBURGH

11125 Frankstown Rd. 15235

MEMPHIS

..................

1922 Lynnbrook

FORT WORTH

HOUSTON

2409 Commerce St.... 77003

SAN ANTONIO

414 Live Oak

437 E. 9th St

180 Flynn Ave

1414 14th Ave

233 Virginia St., E

123 S. Lin wood Ave... 54911

...............

..................

..................

...............

...............

...................

...................

.................

...................

.................

...............

............

...........

..............

..............

.............

...........

13204

44102

44281

74820

74401

73116

19013

17110

38103

38116

75203

78298

84111

05401

23260

98102

25301

WARRANTY PARTS AND SERVICE POLICY

The purpose of warranty is to protect the customer from defects in workmanship and materials, defects which are NOT detected at the time of

manufacture. It does not provide tor the unlimited and unrestricted replacement of parts. Use and maintenance ore the responsibility of the

customer, The manufacturer cannot assume responsibility for conditions which it has no control. Simply put, if it's the manufacturer's fault, it's

the manufacturer's responsibility: if it's the customer's fault, it's the customer's responsibility.

CLAIMS AGAINST THE MANUFACTURER'S

WARRANTY INCLUDES

1. Replacement of Missing Parts on new equipment.

2. Replacement of Defective Partswithin the warranty period.

3. Repair of Defects within the warranty period.

All claims MUST be substantiated with the following information:

1. Model Number of unit involved.

2. Date unit was purchased or first put into service.

3. Date of failure.

4. Nature of failure.

MTD PRODUCTS INC • 5965 GRAFTON ROAD • P.O. BOX 36900 • CLEVELAND OHIO 44136

Loading...

Loading...