MTD 300 Owner’s Manual

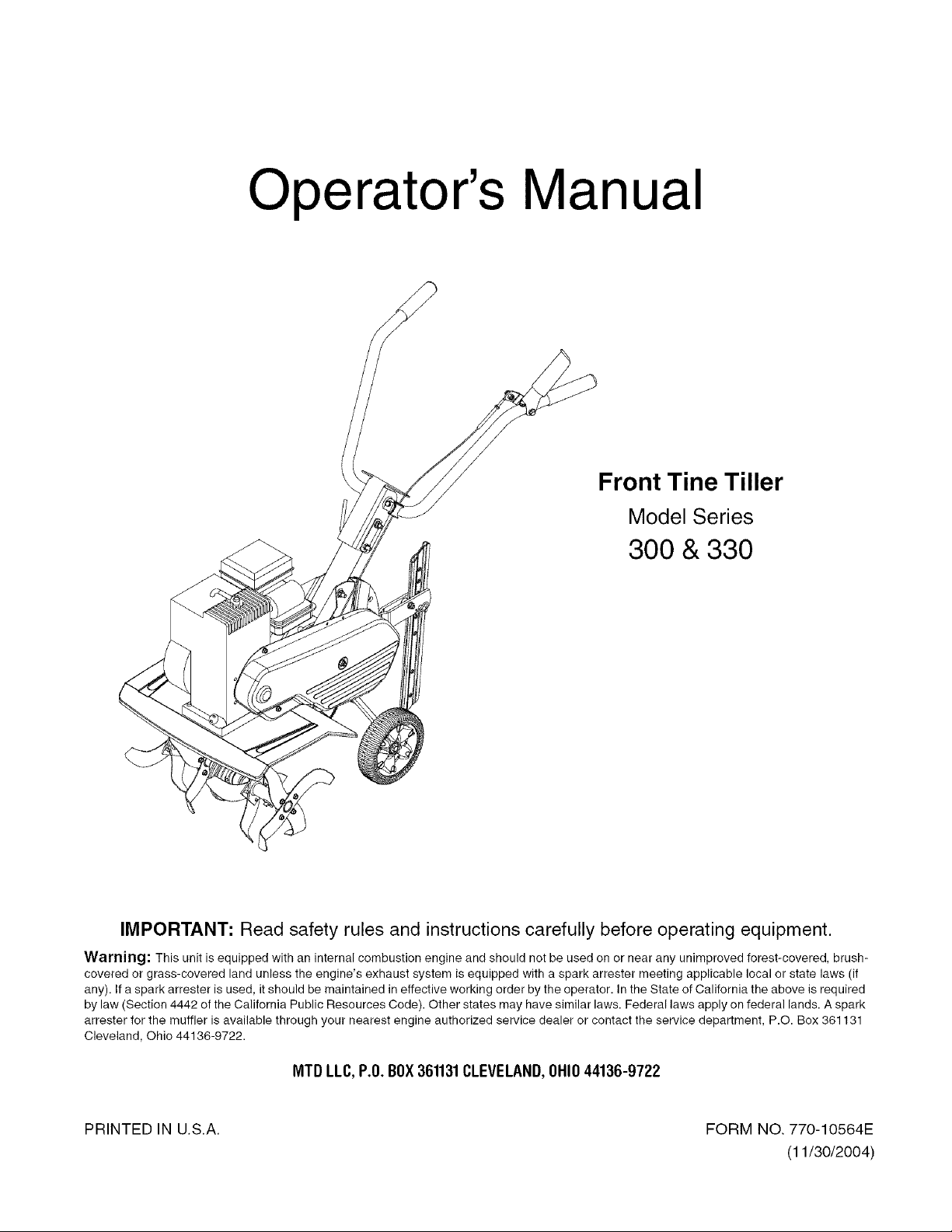

Operator's Manual

Front Tine Tiller

Model Series

300 & 330

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if

any). If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required

by law (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark

arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131

Cleveland, Ohio 44136-9722.

MTDLLC,P.O.BOX361131CLEVELAND,OHIO44136-9722

PRINTED IN U.S.A. FORM NO. 770-10564E

(11/30/2004)

TABLEOFCONTENTS

Content

ImportantSafeOperationPractices

AssemblingYourTiller

KnowYourTiller

OperatingYourTiller

MakingAdjustments

Page Content Page

3 Maintaining You rTiller 10

5 Troubleshooting 11

6 Illustrated Parts List 12

7 Warranty 16

9

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new tiller. It will help you assemble, prepare and maintain the

unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment

and copy the information from it in the space provided below. A sample model plate is also given below.

You can locate the model plate by looking at the rear of the tine shield. This information will be necessary

to use the manufacturer's web site and/or help from the Customer Support Department or an authoriJed

service dealer.

" -_ Copy the model number here:

MT,D _ P._TDo._OXLL_'3_3_] Copy the serial number here:

www.mtdproducts.com 8_Q-8_O-731Q

CLEVELAND,OH 44136

330_220-4683

CUSTOMERSUPPORT

PleasedoNOTretum the unit to theretailer without first contactingCustomerSupport.

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, you can seek help from the experts. Choose from the options below:

Visit mtdproducts.com for many useful suggestions. Click on Customer Support button andyou will get the four options reproduced here. Click on the appropriate button and help is

immediately available.

v

EAn_dAnswers

The answe_ _ you am

_lle_lif_ yeIH i_l _ll[_ies e[ _[ _81e yell _e_$e_a_

_ice gooato[

If you prefer to reach a Customer Support Representative, please call (330) 220-4MTD or

1(800) 800-7310.

a mouse_c#ck away!

\En ine

The engine manufacturer is responsible for all engine-related issues with regard to

performance, power-rating, specifications, warranty and service. Please refer to the engine

manufacturer's Owner's/Operator's Manual, packed separately with your unit, for more

information.

SECTION1: IMPORTANTSAFEOPERATIONPRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could

endanger the personal safety and/or property of yourself and others, Read and follow all instructions in

this manual before attempting to operate this machine, Failure to comply with these instructions may

result in personal injury, When you see this symbol-- heed its warning,

WARNING: Engine exhaust, some of its constituents, and certain vehicle components contain or

emit chemicals known to State of California to cause cancer and birth defects or other reproductive

harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this

manual, As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury, This machine is capable of amputating hands and feet. Failure to observe the

following safety instructions could result in serious injury or death,

Training

1, Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in asafe

place for future and regular reference and for

ordering replacement parts,

2, Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 14years old to operate

this machine, Children 14years old and over should

read and understand the operation instructions and

safety rules in this manual and should be trained

and supervised by a parent,

4. Never allow adults to operate this machine without

proper instruction,

5. Keep bystanders, helpers, pets and children at least

75 feet from the machine while it is in operation,

Stop machine if anyone enters the area.

Preparation

1, Thoroughly inspect the areawhere the equipment is

to be used, Remove all stones, sticks, wire, and

other foreign objects which could be tripped over

and cause personal injury,

2, Wear sturdy, rough-soled work shoes and close

fitting slacks and shirt. Loose fitting clothes or

jewelry can be caught in movable parts, Never

operate this machine in bare feet or sandals,

3, Disengage clutch levers and shift (if provided) into

neutral CN") before starting the engine.

4, Never leave this machine unattended with the

engine running.

5, Never attempt to make any adjustments while

engine is running, except where specifically

recommended in the operator's manual,

6, To avoid personal injury or property damage use

extreme care in handling gasoline, Gasoline is

extremely flammable and the vapors are explosive,

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite,

Wash your skin and change clothes immediately,

7, Use only an approved gasoline container,

8, Extinguish all cigarettes, cigars, pipes and other

sources of ignition,

9, Never fuel machine indoors.

10, Never remove gas cap or add fuel while the engine

is hot or running.

11, Allow engine to cool at least two minutes before

refueling,

12, Never over fill fuel tank. Fill tank to no more than 1/2

inch below bottom of filler neck to provide space for

fuel expansion.

13, Replace gasoline cap and tighten securely,

14, Ifgasoline is spilled, wipe it off the engine and

equipment, Move machine to another area. Wait 5

minutes before starting the engine.

15, Never store the machine or fuel container inside

near an open flame, spark or pilot light (e.g,

furnace, water or space heater, clothes dryer etc,),

16, Allow machine to cool 5 minutes before storing,

Operation

1. Donot put hands or feet near rotating parts. Contact

with the rotating parts can amputate hands and feet.

2. Do not operate machine while under the influence

of alcohol or drugs.

3, Never operate this machine without good visibility

or light.Always be sure of your footing and keep a

firm hold on the handles.

4, Keep bystanders, helpers, pets, and children at

least 75 feet from the machine while it is in

operation, Stop the machine if anyone enters the

area,

5, Be careful when tilling in hard ground, The tines

may catch in the ground and propel the tiller

forward, If this occurs, let go of the handle bars and

do not restrain the machine.

6. Exercise extreme caution when operating on or

crossing gravel surfaces, Stay alert for hidden

hazards or traffic, Do not carry passengers,

7. Never operate the machine at high transport

speeds on hard or slippery surfaces,

8. Exercise caution to avoid slipping or falling,

9, Lookdownandbehindandusecarewhenin

reverseorpullingmachinetowardsyou,

10, Starttheengineaccordingtotheinstructionsfound

inthismanualandkeepfeetwellawayfromthe

tinesatalltimes,

11, Afterstrikingaforeignobject,stoptheengine,

disconnectthesparkplugwireandgroundagainst

theengine,Thoroughlyinspectthemachineforany

damage,Repairthedamagebeforestartingand

operating,

12, Disengageallclutchleversandstopenginebefore

youleavetheoperatingposition(behindthe

handles),Waituntilthetinescometoacomplete

stopbeforeuncloggingthetines,makingany

adjustments,orinspections.

13, Neverrunanengineindoorsorinapoorly

ventilatedarea.Engineexhaustcontainscarbon

monoxide,anodorlessanddeadlygas.

14, Mufflerandenginebecomehotandcancausea

burn.Donottouch,

15, Usecautionwhentillingnearfences,buildingsand

undergroundutilities,Rotatingtinescancause

propertydamageorpersonalinjury.

16, Donotoverloadmachinecapacitybyattemptingto

tillsoiltodeepattofastofarate.

17, Ifthemachineshouldstartmakinganunusualnoise

orvibration,stoptheengine,disconnectthespark

plugwireandgrounditagainsttheengine.Inspect

thoroughlyfordamage,Repairanydamagebefore

startingandoperating,

18, Keepallshields,guardsandsafetydevicesinplace

andoperatingproperly.

19, Neverpickuporcarrymachinewhiletheengineis

running,

20, Useonlyattachmentsandaccessoriesapprovedby

themanufacturer.Failuretodoso,canresultin

personalinjury.

21, Ifsituationsoccurwhicharenotcoveredinthis

manual,usecareandgoodjudgment.Contactyour

dealerortelephone1-800-800-7310forassistance

andthenameofyournearestservicingdealer.

Maintenance& Storage

1. Never tamper with safety devices, Check their

proper operation regularly.

2. Check bolts and screws for proper tightness at

frequent intervals to keep the machine in safe

working condition, Also, visually inspect machine for

any damage,

3. Before cleaning, repairing, or inspecting, stop the

engine and make certain the tines and all moving

parts have stopped, Disconnect the spark plug wire

and ground it against the engine to prevent

unintended starting.

4, Do not change the engine governor settings or over-

speed the engine, The governor controls the

maximum safe operating speed of the engine,

5, Maintain or replace safety and instruction labels, as

necessary,

6, Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

7, Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

such as a water heater, furnace, clothes dryer etc,

8, Always refer to the operator's manual for proper

instructions on off-season storage,

9, If the fuel tank has to be drained, do this outdoors,

10, Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

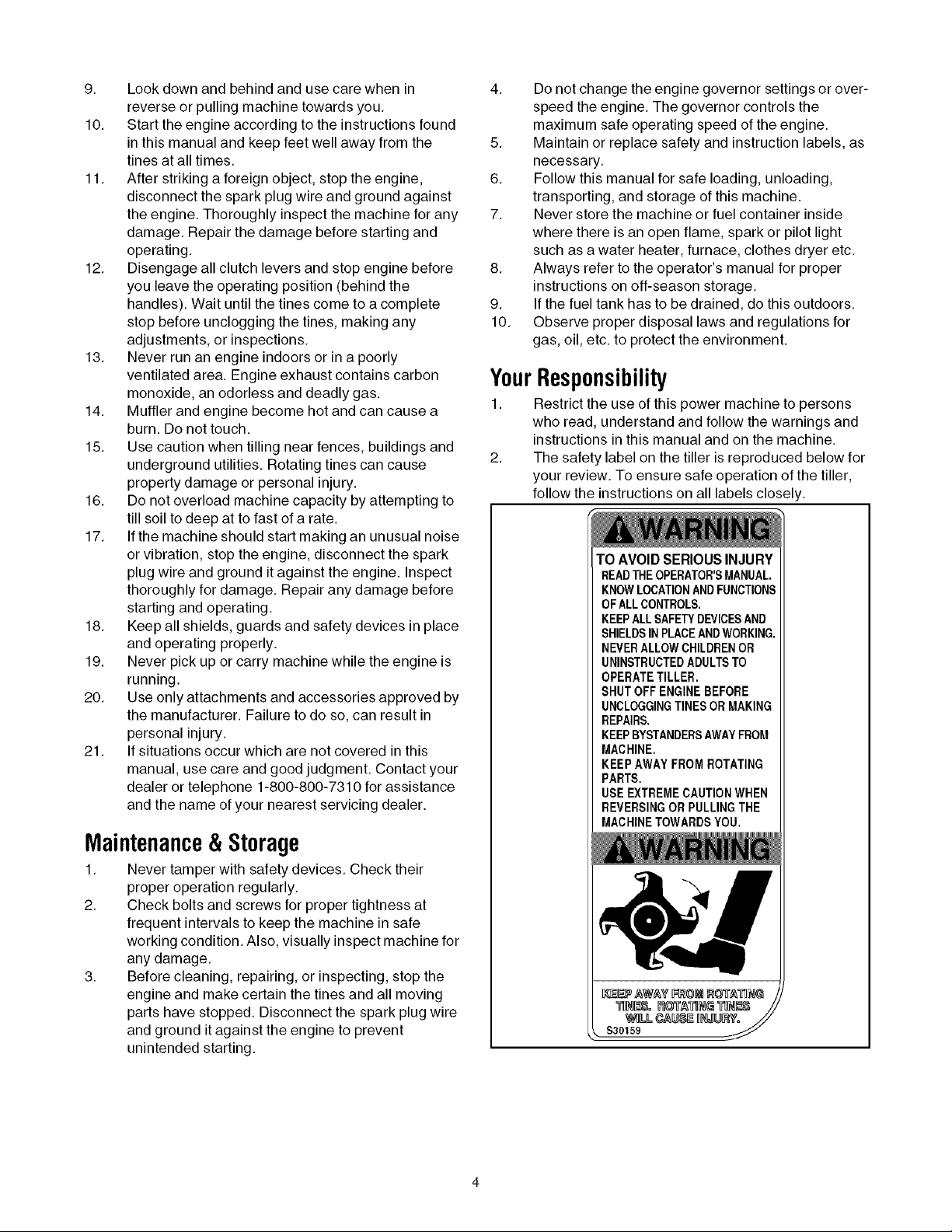

YourResponsibility

1. Restrict the use of this power machine to persons

who read, understand and follow the warnings and

instructions in this manual and on the machine.

2. The safety label on the tiller is reproduced below for

your review. To ensure safe operation of the tiller,

follow the instructions on all labels closely,

TO AVOID SERIOUS INJURY

READTHEOPERATOR'SMANUAL.

KNOWLOCATIONANDFUNCTIONS

OFALLCONTROLS.

KEEPALLSAFETYDEVICESAND

SHIELDSINPLACEANDWORKING.

NEVERALLOWCHILDRENOR

UNINSTRUCTEDADULTSTO

OPERATETILLER.

SHUTOFFENGINEBEFORE

UNCLOGGINGTINESORMAKING

REPAIRS.

KEEPBYSTANDERSAWAYFROM

MACHINE.

KEEPAWAYFROMROTATING

PARTS.

USEEXTREMECAUTIONWHEN

REVERSINGORPULLINGTHE

MACHINETOWARDSYOU.

, S30159

SECTION2: ASSEMBLINGYOURTILLER

NOTE: This operator's manual covers various models

of riflers. The units illustrated may vary slightly from

your unit. Follow only those instructions which pertain

to your model number.

NOTE: References to right or left side of the tiller are

determined from behind the unit in the operating

position.

IMPORTANT:This unit is shipped without gasoline or oil

in the engine. Be certain to service engine with gasoline

and oil as instructed in the separate engine manual

before operating your machine.

LoosePartsInCarton

Tailpiece and Depth Stake

NOTE: All hardware needed for assembly is attached

to the loose parts or the tiller.

BeforeAssembly

WARNING: Disconnect the spark plug wireand ground it against the engine to prevent

unintended starting.

Handle

Adjustment Lever

\

\

Handle

Adjustment Lever

\

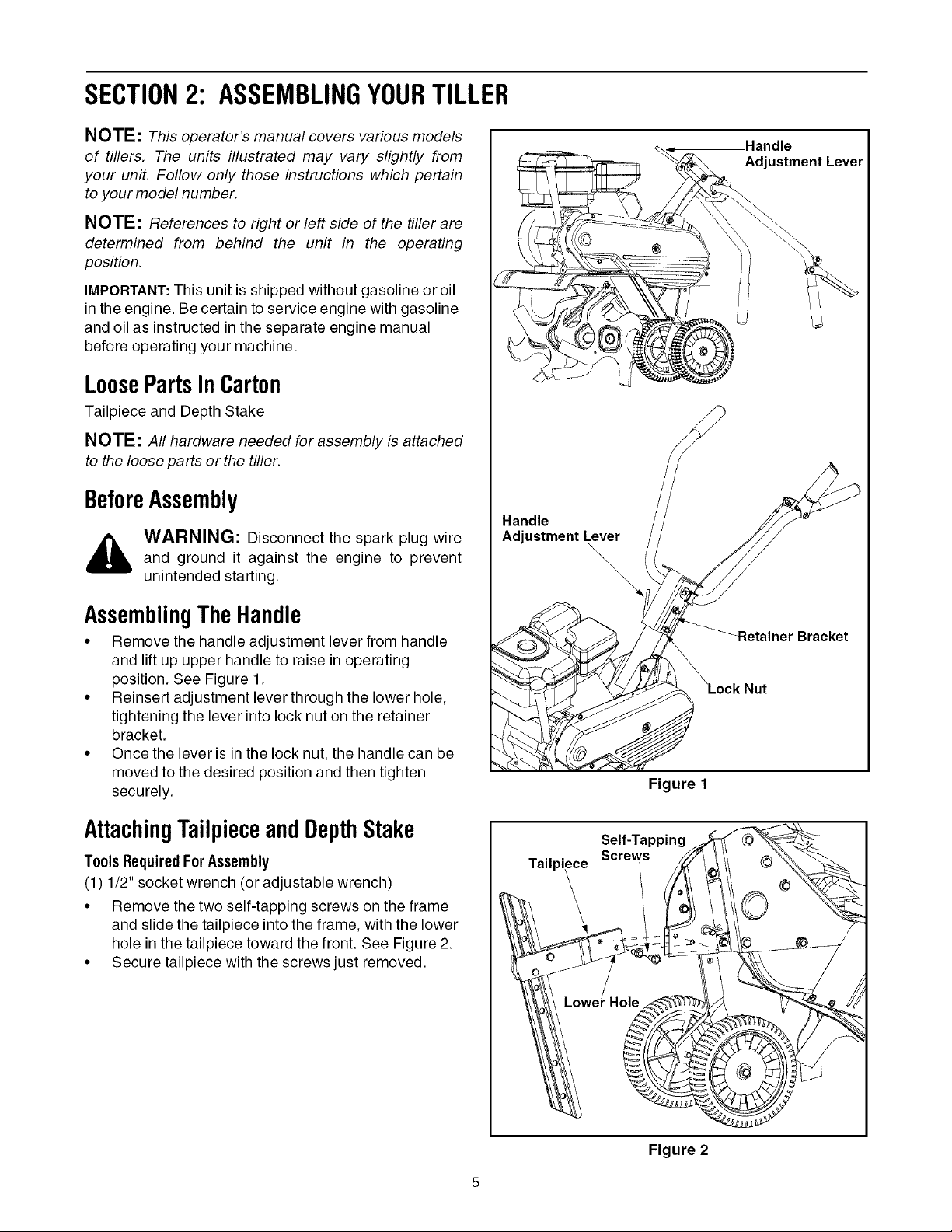

AssemblingTheHandle

• Remove the handle adjustment lever from handle

and lift up upper handle to raise in operating

position. See Figure 1.

• Reinsert adjustment lever through the lower hole,

tightening the lever into lock nut on the retainer

bracket.

• Once the lever is in the lock nut, the handle can be

moved to the desired position and then tighten

securely.

AttachingTailpieceandDepthStake

ToolsRequiredForAssembly

(1) 1/2" socket wrench (or adjustable wrench)

• Remove the two self-tapping screws on the frame

and slide the tailpiece into the frame, with the lower

hole in the tailpiece toward the front. See Figure 2.

• Secure tailpiece with the screws just removed.

Tailpiece

-Retainer Bracket

Figure 1

Self-Tapping

Screws

Figure 2

Loading...

Loading...