Page 1

Safety • Setp Up • Operation • Adjustments • Maintenance • Troubleshooting • Parts Lists • Warranty

A O A AL

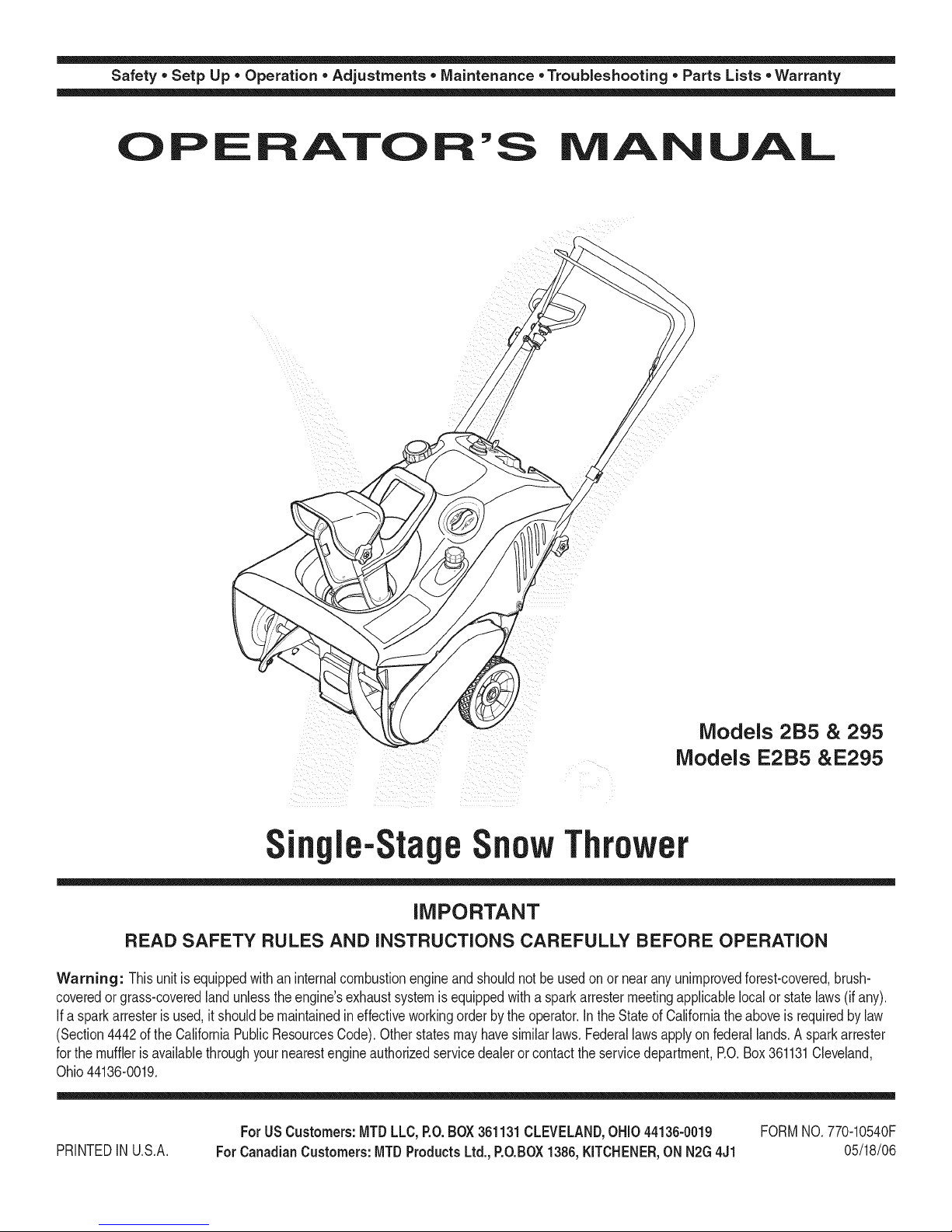

Models 2B5 & 295

Models E2B5 &E295

n le-StageSnowThrower

iMPORTANT

READ SAFETY RULES AND iNSTRUCTiONS CAREFULLY BEFORE OPERATION

Warning: Thisunitis equippedwithaninternalcombustionengineandshouldnotbeusedon or nearanyunimprovedforest-covered,brush-

coveredor grass-coveredlandunlesstheengine'sexhaustsystemisequippedwitha sparkarrestermeetingapplicablelocalor statelaws(if any).

If a sparkarresterisused,it shouldbemaintainedineffectiveworkingorderby theoperator.IntheStateof Californiathe aboveisrequiredbylaw

(Section4442ofthe CaliforniaPublicResourcesCode).Otherstatesmayhavesimilarlaws.Federallawsapplyonfederallands.A sparkarrester

forthe mufflerisavailablethroughyour nearestengineauthorizedservicedealeror contacttheservicedepartment,RO.Box361131Cleveland,

Ohio44136-0019.

FORMNO.770-10540F

05/18/06

PRINTEDIN U.S.A.

ForUSCustomers:MTDLLC,P.O.BOX361131CLEVELAND,OHiO44136-0019

ForCanadianCustomers:MTDProductsLtd.,P.O.BOX1386,KJTCHENER,ONN2G4J1

Page 2

This Operator's Manual is an important part of your new snow thrower, it will help you assemble,

prepare and maintain the unit for best performance. Please read and understand what it says.

Table of

Safety Labels ...................................................... 3

Safe Operation Practices ................................... 4

Setting Up Your Snow Thrower .......................... 6

Know Your Snow Thrower .................................. 7

Operating Your Snow Thrower ........................... 8

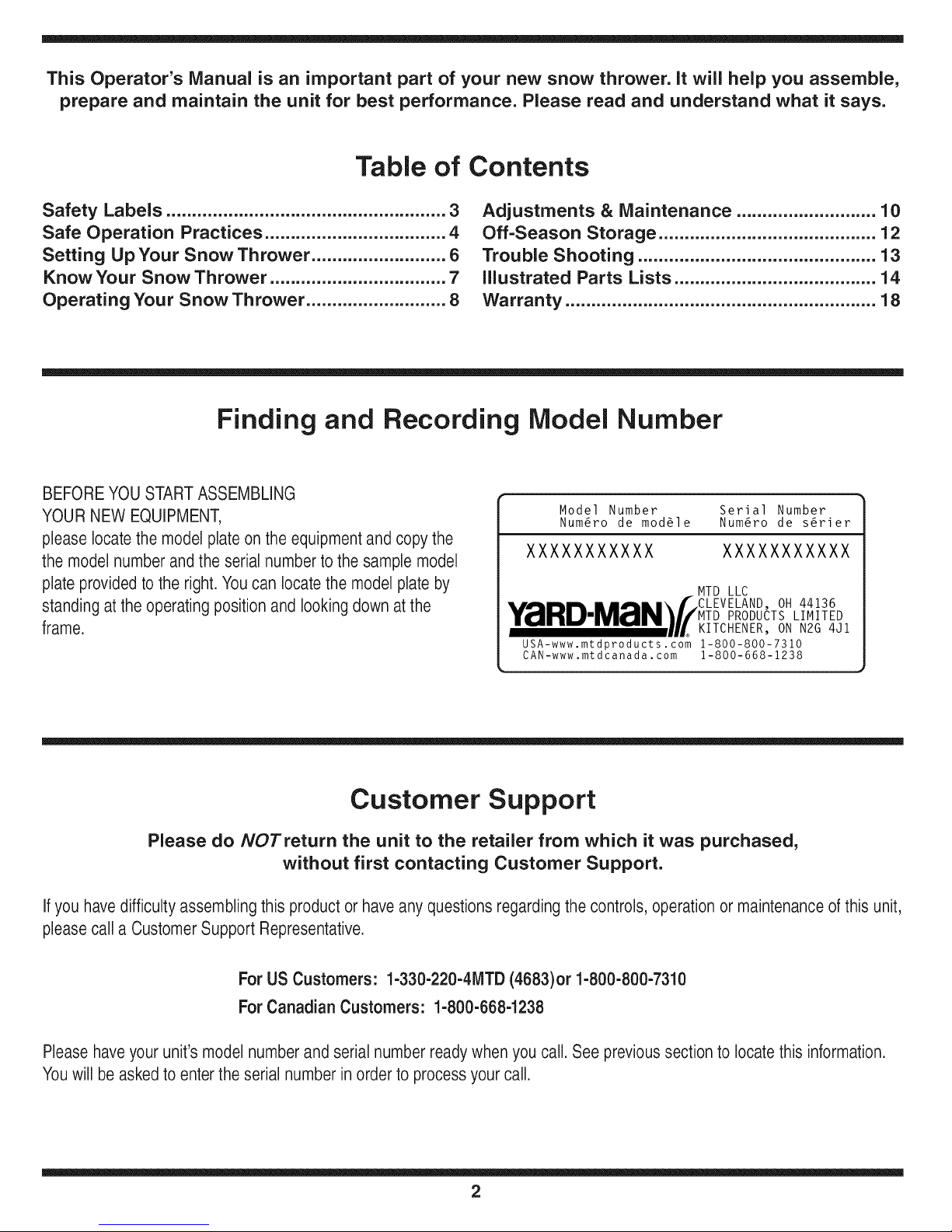

Finding and Recording Model Number

BEFOREYOU STARTASSEMBLING

YOURNEW EQUIPMENT,

please locatethe modelplate on the equipmentand copythe

the modelnumber andthe serial number to the sample model

plate provided to the right.You can locatethe model plate by

standing atthe operatingposition and looking down atthe

frame.

Contents

Adjustments & Maintenance ........................... 10

Off-Season Storage .......................................... 12

Trouble Shooting .............................................. 13

illustrated Parts Lists ....................................... 14

Warranty ............................................................ 18

Model Number Serial Number

Num6ro de mod61e Num6ro de s6rier

XXXXXXXXXXX XXXXXXXXXXX

•,,A .... m,,,.\f CLEVELAND, OH 44136

Y_IIHUIMZrIN_//MTD PRODUCTS LIMITED

........... UL KITCHENER, ON N2G 4Jl

USA-www.mtdproducts.com 1-800-800-7310

CAN-www.mtdcanada. com 1-800-668-1238

MTD LLC

Customer Support

Please do NOTretum the unit to the retailer from which it was purchased,

without first contacting Customer Support.

Ifyou havedifficultyassembling this productor haveany questionsregardingthecontrols, operationor maintenanceof this unit,

pleasecall a CustomerSupport Representative.

For US Customers: 1-330-220-4MTD (4683)or 1-800-800-7310

For Canadian Customers: 1-800-668-1238

Pleasehaveyour unit's modelnumber andserial number readywhenyou call. See previoussection to locate this information.

Youwill be asked to entertheserial number inorderto processyour call.

2

Page 3

i i l_I ii_ _ i _iii_!i _ _ii_ ii

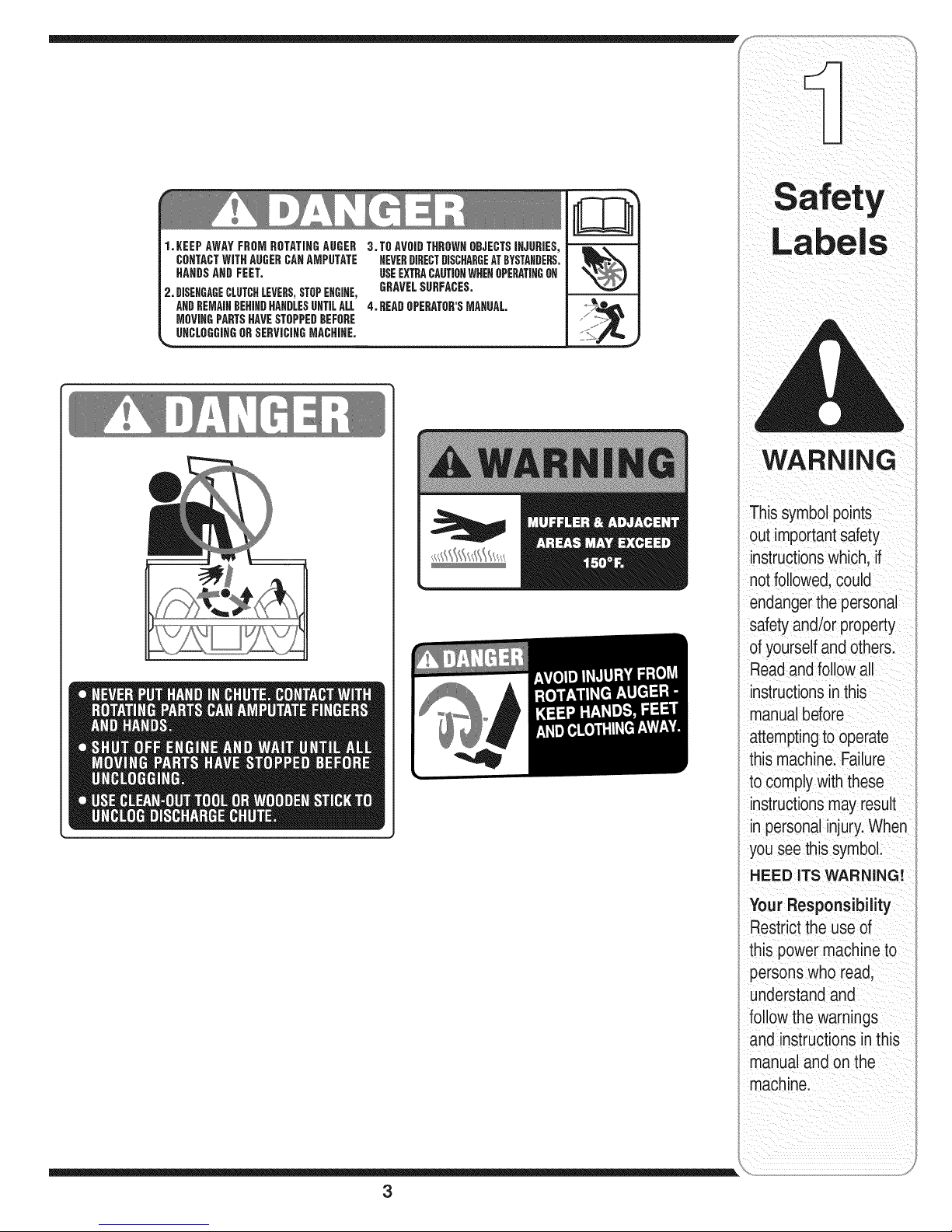

1.KEEPAWAYFROMROTATINGAUGER

CONTACTWiTHAUGERCAHAMPUTATE

HAHOSAND FEET.

2. DISEHGAGECLUTCHLEVERS,STOPEHGIHE,

ANDREMAINDEHIHDHAHBLESUNTILALL

MOVIHGPARTSHAVESTOPPEDBEFORE

UHCLOGGiHGORSERViCIHGMACHiHE.

3.TO AVOIDTHROWNOBJECTSIHJURIES,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHEHOPERATINGOH

GRAVELSURFACES.

4. BEADOPERATOR'SMAHUAL

WARNING

Thissymbolpoints

out importantsafety

instructionswhich,if

notfollowed,could

endangerthepersonal

safetyand/or property

ofyourselfandothers.

Readandfollowall

instructionsinthis

manualbefore

attemptingto operate

this machine.Failure

to complywiththese

instructionsmayresult

in personalinjury.When

youseethis symbol.

HEED ITS WARNING!

Your Responsibility

Restrictthe use of

this power machineto

personswho read,

understandand

followthe warnings

and instructionsin this

manualand onthe

machine.

3

Page 4

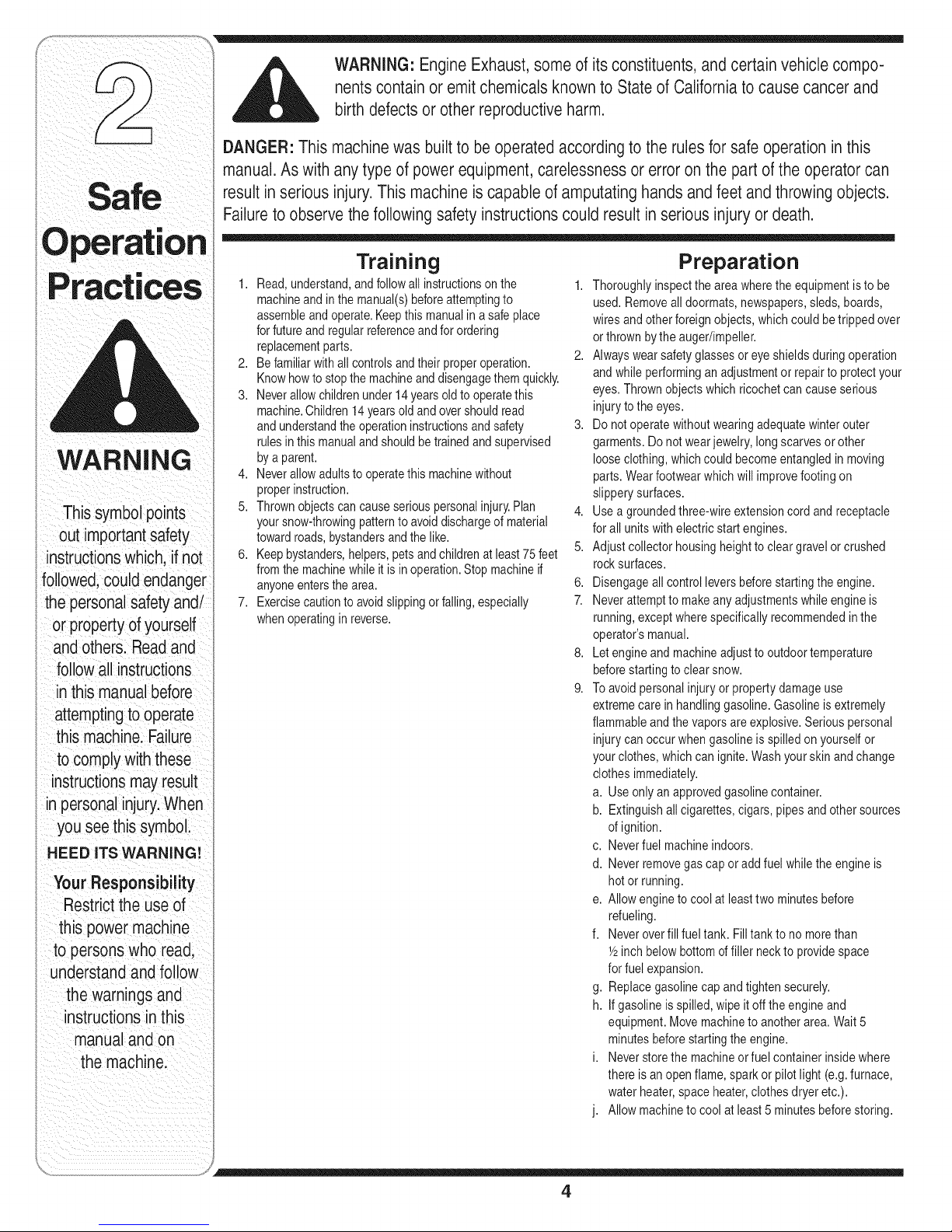

WARNING: EngineExhaust,some of itsconstituents,andcertain vehicle compo-

nentscontain or emitchemicals knownto State of Californiato causecancer and

birth defectsor otherreproductiveharm.

DANGER: This machinewas builtto beoperatedaccording to the rulesfor safe operationin this

manual.As with any type of power equipment,carelessnessor erroronthe part ofthe operatorcan

result inseriousinjury.This machine iscapableof amputatinghands andfeet andthrowing objects.

Failureto observethe followingsafety instructionscould resultinserious injuryor death.

WARNING

Thissymbolpoints

outimportantsafety

instructionswhich,ifnot

followed,could endanger

the personalsafetyand/

i or propertyofyourself

andothers. Readand

followall instructions

inthis manualbefore

attemptingtooperate

this machine.Failure

to complywiththese

instructionsmayresult

in personalinjury.When

youseethis symbol.

i HEED iTS WARNING!

Your Responsibility

i Restrictthe useof

this power machine

i to personswho read,

understandandfollow

the warnings and

instructionsin this

manualand on

the machine.

Training

1. Read,understand,andfollowallinstructionsonthe 1.

machineandin themanual(s)beforeattemptingto

assembleand operate.Keepthis manualinasafe place

forfutureand regularreferenceandfor ordering

replacementparts. 2.

2. Befamiliarwithall controlsandtheir properoperation.

Knowhowto stopthemachineanddisengagethem quickly.

3. Neverallowchildrenunder14yearsoldto operatethis

machine.Children14yearsoldandovershouldread

andunderstandtheoperationinstructionsandsafety 3.

rulesin thismanualandshouldbetrainedandsupervised

bya parent.

4. Neverallowadultsto operatethis machinewithout

properinstruction.

5. Thrownobjectscancauseseriouspersonalinjury.Plan 4.

yoursnow-throwingpatternto avoiddischargeof material

towardroads,bystandersandthe like.

6. Keepbystanders,helpers,petsandchildrenatleast75feet 5.

fromthe machinewhileit isin operation.Stopmachineif

anyoneentersthearea. 6.

7. Exercisecautiontoavoidslippingor falling,especially 7.

whenoperatingin reverse.

Preparation

Thoroughlyinspecttheareawheretheequipmentisto be

used.Removealldoormats,newspapers,sleds,boards,

wiresand otherforeignobjects,whichcouldbetripped over

orthrownbythe auger/impeller.

Alwayswearsafetyglassesor eyeshieldsduringoperation

andwhile performinganadjustmentorrepairto protectyour

eyes.Thrownobjectswhichricochetcancause serious

injurytothe eyes.

Do notoperatewithoutwearingadequatewinterouter

garments.Donotwearjewelry,longscarvesorother

looseclothing,whichcould becomeentangledin moving

parts.Wearfootwearwhich willimprovefootingon

slipperysurfaces.

Useagroundedthree-wireextensioncordand receptacle

forall unitswithelectricstartengines.

Adjustcollectorhousingheighttocleargravelorcrushed

rocksurfaces.

Disengageallcontrolleversbeforestartingthe engine.

Neverattemptto makeanyadjustmentswhileengineis

running,exceptwherespecificallyrecommendedinthe

operator'smanual.

8,

Letengineandmachineadjusttooutdoortemperature

beforestartingtoclearsnow.

9.

Toavoidpersonalinjuryorpropertydamageuse

extremecarein handlinggasoline.Gasolineis extremely

flammableand thevaporsare explosive.Seriouspersonal

injurycanoccurwhengasolineis spilledon yourselfor

yourclothes,whichcanignite.Washyourskin andchange

clothesimmediately.

a. Useonlyan approvedgasolinecontainer.

b. Extinguishallcigarettes,cigars,pipesandothersources

ofignition.

c. Neverfuelmachineindoors.

d. Neverremovegascap oraddfuelwhilethe engineis

hotor running.

e. Allowengineto coolat leasttwo minutesbefore

refueling.

f. Neveroverfill fueltank. Filltankto nomorethan

Y2inchbelowbottomoffiller neckto providespace

forfuel expansion.

g. Replacegasolinecap andtightensecurely.

h. If gasolineis spilled,wipeitoff theengineand

equipment.Movemachineto anotherarea.Wait5

minutesbeforestartingthe engine.

i. Neverstorethe machineorfuel containerinsidewhere

there isan openflame, sparkor pilot light(e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

j. Allowmachinetocoolat least5 minutesbeforestoring.

4

Page 5

Operation

1. Do notput handsor feet nearrotatingparts,inthe

auger/impellerhousingorchuteassembly.Contactwiththe

rotatingpartscanamputatehandsand feet.

2. Theauger/impellercontrolleveris a safetydevice.Never

bypassits operation.Doingso makesthemachineunsafe

andmaycausepersonalinjury.

3. Thecontrolleversmustoperateeasilyin bothdirections

andautomaticallyreturntothe disengagedpositionwhen

released.

4. Neveroperatewithamissingordamagedchuteassembly.

Keepallsafetydevicesinplaceandworking.

5. Neverrunanengineindoorsor ina poorlyventilatedarea.

Engineexhaustcontainscarbonmonoxide,an odorlessand

deadlygas.

6. Do notoperatemachinewhileunderthe influenceofalcohol

or drugs.

7. Mufflerandenginebecomehotandcan causea burn.Do

nottouch.

8. Exerciseextremecautionwhenoperatingonor crossing

gravelsurfaces.Stayalertfor hiddenhazardsortraffic.

9. Exercisecautionwhenchangingdirectionandwhile

operatingon slopes.

10.Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageor personalinjurycausedbyaricochet.

11.Neverdirectdischargeatchildren,bystandersandpetsor

allowanyoneinfront of the machine.

12.Donotoverloadmachinecapacityby attemptingtoclear

snowattoofastof a rate.

13.Neveroperatethis machinewithoutgoodvisibilityor light.

Alwaysbe sureofyourfootingand keepafirmhold onthe

handles.Walk,neverrun.

14.Disengagepowerto theauger/impellerwhentransporting

or not inuse.

15.Neveroperatemachineathightransportspeedsonslippery

surfaces.Lookdownand behindandusecarewhen

backingup.

16.Ifthe machineshouldstarttovibrateabnormally,stopthe

engine,disconnectthespark plugwireandgroundit against

the engine.Inspectthoroughlyfor damage.Repairany

damagebeforestartingandoperating.

17.Disengageallcontrolleversand stopenginebeforeyou

leavetheoperatingposition(behindthe handles).Wait

untilthe auger/impellercomestoa completestopbefore

uncloggingthechuteassembly,makinganyadjustments,or

inspections.

18.Neverput yourhandinthe dischargeorcollectoropenings.

Alwaysuse theclean-outtool providedto unclogthe

dischargeopening.Do notunclogchuteassemblywhile

engineis running.Shutoffengineand remainbehind

handlesuntilallmovingparts havestoppedbefore

unclogging.

19.Useonlyattachmentsandaccessoriesapprovedbythe

manufacturer(e.g.wheelweights,tirechains,cabsetc.).

20. Ifsituationsoccurwhicharenotcoveredinthis manual,

usecareand goodjudgment.Contactyourdealerorcall

(800) 800-7310for assistanceandthenameof yournearest

servicingdealer..

Maintenance & Storage

1. Nevertamperwithsafetydevices.Checktheir proper

operationregularly.Refertothe maintenanceand

adjustmentsectionsofthismanual.

2. Beforecleaning,repairing,orinspectingmachine

disengageall controlleversandstopthe engine.Wait until

theauger/impellercometo acompletestop.Disconnectthe

sparkplugwireandgroundagainsttheengineto prevent

unintendedstarting.

3. Checkbolts andscrewsforpropertightnessatfrequent

intervalstokeepthe machinein safeworkingcondition.

Also,visuallyinspectmachinefor anydamage.

4. Do notchangethe enginegovernorsettingorover-speed

theengine.The governorcontrolsthemaximumsafe

operatingspeedoftheengine.

5. Snowthrowershaveplatesandskidshoesaresubjectto

wearanddamage.Foryoursafetyprotection,frequently

checkallcomponentsandreplacewith originalequipment

manufacturer's(OEM)partsonly."Useof partswhich do

notmeetthe originalequipmentspecificationsmayleadto

improperperformanceandcompromisesafety!"

6. Checkcontrolsperiodicallytoverify theyengageand

disengageproperlyandadjust,if necessary.Referto the

adjustmentsection inthisoperator'smanualforinstructions.

7. Maintainor replacesafetyandinstructionlabels,as

necessary.

8. Observeproperdisposallawsandregulationsfor gas,oil,

etc.toprotectthe environment.

9. Priorto storing,runmachineafew minutestoclearsnow

frommachineandpreventfreezeupof auger/impeller.

10.Neverstorethemachineorfuel containerinsidewhere

thereisan openflame,sparkor pilotlightsuchasa water

heater,furnace, clothesdryeretc.

11.Alwaysreferto theoperator'smanualforproperinstructions

onoff-seasonstorage.

Do not modify engine

Toavoidseriousinjuryordeath,donot modifyengineinany

way.Tamperingwiththegovernorsettingcan leadto a runaway

engineandcauseit to operateatunsafespeeds.Nevertamper

withfactorysettingofenginegovernor.

Notice regarding Emissions

Engineswhicharecertifiedto complywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOff RoadEquipment)

arecertifiedto operateonregularunleadedgasoline,and

mayincludethefollowingemissioncontrolsystems:Engine

Modification(EM)andThreeWayCatalyst(TWO)ifsoequipped.

Your Responsibility

Restrictthe useofthis powermachineto personswhoread,

understandandfollowthewarningsandinstructionsinthis

manualandonthe machine.

WARNING

Thissymbolpoints

outimportantsafety

instructionswhich,ifnot

followed,couldendanger

the personalsafetyand/

orpropertyof yourself

and others.Readand

followall instructions

in this manualbefore

attemptingtooperate

this machine.Failure

to complywiththese

instructionsmayresult

in personalinjury.When

youseethissymbol.

HEED iTS WARNING!

Your Responsibility

Restrictthe use of

this power machine

to personswho read,

understandand follow

the warnings and

instructions inthis

manualand on

the machine.

5

Page 6

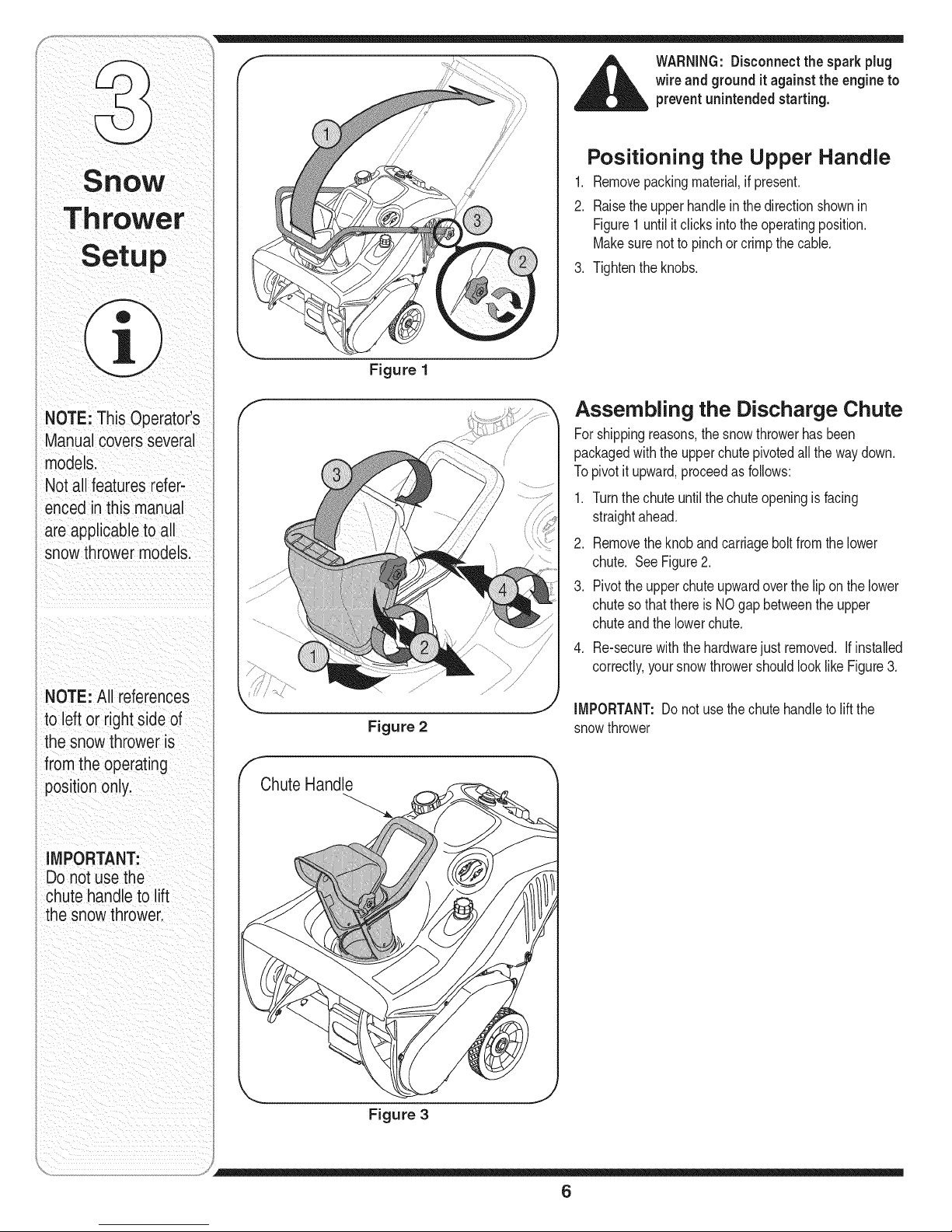

Figure 1

Positioning the Upper Handle

1. Removepackingmaterial,ifpresent.

2. Raisethe upperhandleinthedirectionshownin

Figure1 untilitclicksintotheoperatingposition.

Makesurenottopinchor crimpthecable.

3. Tightenthe knobs.

NOTE:This Operator's

Manualcoversseveral

models.

Notall features refer-

encedinthis manual

are applicableto all

snow throwermodels.

I NOTE: All references

i to leftor rightside of

the snowthrower is

fromthe operating

I positiononly.

i IMPORTANT:

i Donot use the

chute handleto lift

thesnow thrower.

f

Chute Handle

Figure 2

Assembling the Discharge Chute

Forshippingreasons,thesnowthrowerhasbeen

packagedwiththe upperchutepivotedall thewaydown.

Topivotit upward,proceedasfollows:

1. Turnthechuteuntilthechuteopeningis facing

straightahead.

2. Removetheknob andcarriageboltfromthelower

chute. SeeFigure2.

3. Pivotthe upperchuteupwardovertheliponthelower

chutesothatthere isNOgap betweentheupper

chuteandthelowerchute.

4. Re-securewiththe hardwarejust removed. If installed

correctly,yoursnowthrowershouldlooklike Figure3.

IMPORTANT:Do notusethechutehandleto liftthe

snowthrower

Figure 3

6

Page 7

Recoil Starter

Primer

GasolineCap Button (if equipped)

ChuteAssembly_

ShavePlate Spark PlugAccess

Auger

Figure 4

Choke Lever

Activatingchokecontrolclosesthechokeplateon

carburetorandaids in startingengine.Refertotheengine

manualpackedwithunitformoredetailedinstructions.

Primer

Depressingprimerforcesfueldirectlyintoengine's

carburetorto aid incold-weatherstarting.Refertoengine

manualpackedwithunitformoredetailedinstructions.

Ignition Key

Theignitionkeymustbeinsertedandsnappedin place

in orderforthe engineto start.Removetheignitionkeyto

preventunauthorizeduseofequipment.DoNOTattempt

toturn thekey.

Recoil Starter

Thestarterhandleisusedtomanuallystarttheengine.

Electric Starter (if Equipped)

Usedtostartenginewitha 120Vpowersource.

Plug for Electric Start

Requiresuseofa three-prongoutdoorextensioncord

anda 120Vpowersource.

Spark Plug Cover

Removesparkplugcovertoaccesssparkplug.

Oil Fill

Auger

Whenengaged,the augersrotationdrawssnowinto the

augerhousingandthrowsitout thedischargechute.

Rubberpaddleson the augersalsoaidin propellingthe

unitas theycomeincontactwiththe pavement.

Auger Control Handle

Locatedon the upperhandle,theaugercontrolhandle

isusedtoengageanddisengagedriveto theauger.

Squeezethecontrolhandleagainsttheupperhandleto

engageauger;releaseitto disengage.

Discharge Chute / Chute Handle

Rotatethedischargechuteto theleftor rightusing

chutehandle.Theangleofthe dischargechutecontrols

thedistancethatthesnowis thrown.Tiltthe discharge

chuteupforgreaterdistance;tiltdownfor lessdistance.

Loosenthehandknobonthe sideof thedischarge

chutetoadjust.Tilt thechuteto thedesiredposition,

andtightentheknob.

Shave Plate

Theshaveplatemaintainscontactwithpavementas

thesnowthroweris propelled,allowingsnowcloseto

pavement'ssurfaceto bedischarged.

WARNING

Be familiar with

allthe controls on

tahesnowthrower

ndtheir proper

operation. Knowhow

to stop the machine

anddisengage them

quickly.

7

Page 8

Before Starting

1. Thesparkplugwirewasdisconnectedforsafety.

Attachsparkplugwireto sparkplugbeforestarting.

IMPORTANT:Forcompleteanddetailedengine

starting,stoppingand storinginstructions,it is

recommendedthatyoureadthe enginemanualalso

includedwiththis unit.

Gas and Oil Fill-Up

1. Checkoilandgasolinelevelandadd ifnecessary.

Followrelatedinstructionsinthe separateengine

manualpackedwithyoursnowthrower.

f

_,ugerControlHandle

RecoilStarter

Primer

Gasoline_

Cap

\

Key

Ele( Starter |

Button if equipped)l

WARNING

Read, understand,

and follow all instruc-

tions and warnings

onthe machine and

in this manual before

operating.

Use extreme care

when handling

gasoline. Gasoline is

extremely flammable

and the vapors are

i explosive. Neverfuel

the machine indoors

or while the engine

i is hot or running.

i Extinguish cigarettes,

cigars,pipes and

other sources of

ignition.

The electric starter

must be used with a

properly grounded

three-prong

receptacle at all

times to avoid the

i possibilityof electric

i shock. Follow all

i instructionscarefully

prior to operating the

electric starter.

_ ARNING:Useextremecarewhen

handlinggasoline. Gasolineis

extremely flammableand the vapors

are explosive. Neverfuel the machine

indoorsor while the engineis hot or

running.Extinguish cigarettes, cigars,

pipesand other sources of ignition.

To Start Engine

1. Insertignitionkeyintoslot.

2. Nowfollowthe instructionsbelowasitpertainsto

yourunit.SeeFigure4forlocationof controls

Electric Starter (if so equipped)

WARNING:Theelectricstartermust

be usedwitha properly groundedthree-prong receptacleat all times to

avoidthe possibilityof electric shock.

Follow all instructionscarefullyprior

to operating the electric starter.

1. Theelectricstarterisequippedwitha grounded

three-wirepowercordandplug,andisdesignedto

operateon120voltAC householdcurrent.

2. Determinethatyour housewiringisa three-wire

groundedsystem.Aska licensedelectricianif you

arenotcertain.

3. If your home wiringsystem isnot a three-wire

grounded system, do notusethiselectricstarter

underanyconditions.

4. If your home electricalsystemisgrounded, but

a three-holereceptacleis notavailable,oneshould

beinstalledbya licensedelectricianbeforeusingthe

electricstarter.

5. If you have a grounded three-prong receptacle,

proceedasfollows:

6. MoveChokeControlto "Full"position.

7. Pushprimerslowly,three(3) times,makingsureto

coverventholewhenpushing.

8. Connectpowercordtoswitchboxondashpanel.

Plugtheotherendof powercordintoa three-prong

120-volt,grounded,ACreceptacle.

Cap Plug j)

Figure 5

9. Pushstarterbuttonto crankengine.Asyoucrankthe

engine,movechokeleverto FULLchokeposition.

10.Whenenginestarts,releasestarterbutton,andmove

chokegraduallytoOFRif enginefalters,movechoke

immediatelyto FULLandthengraduallytoOFR

11.Whendisconnectingthepowercord,alwaysunplug

from thethree-prong receptaclefirst, and then

from thesnow thrower.

Recoil Starter

1. Movechokeleverto FULLchokeposition(coldengine

start).

2. If engineiswarm,placechokeinOFFpositioninstead

ofFULL.

3. Pushprimerbuttonslowlytwoorthreetimes forcold

enginestart.

4. If engineiswarm,pushprimerbuttononlyonce.

NOTE:Alwayscoverventholein primerbuttonwhen

pushing.Additionalprimingmaybe necessaryforfirst

startif temperatureisbelow150F(-90C).

5. Graspstarterhandleandpullropeout slowly,untilit

pullsslightlyharder.Letroperewindslowly.

6. Pullstarterhandlerapidly.Donotallowhandleto snap

back.Allowitto rewindslowlywhilekeepinga firm

holdonthestarterhandle.

7. As enginewarmsupandbeginstooperateevenly,

rotatechokeleverslowlytoOFFposition.If engine

falters,returnto FULLchoke,thenslowlymoveto OFF

position.

8

Page 9

To Stop Engine Operating Tips

1. To stopengine,turnignitionkeycounter-clockwise.

Disconnectthesparkplugwirefromthesparkplug

to preventaccidentalstartingwhileequipmentis

unattended.

Tohelppreventpossiblefreeze-upof starter,

proceedas follows:

1. Runengineforafew minutesbeforestoppingtohelp

dryoff anymoistureonthe engine.

2. Electric Starter (optional}: Connectpowercordto

switchboxon engine,thento 120voltACreceptacle.

Withtheenginerunning,pushstarterbuttonandspin

thestarterforseveralseconds.Theunusualsound

madeby spinningthestarterwill notharmengineor

starter.Disconnectthepowercordfrom receptacle

first,andthenfromswitchbox.

3. RecoilStarter: Withenginerunning,pullstarterrope

witha rapid,continuousfullarmstrokethreeorfour

times.Pullingthestarterropewillproducea loudclatter-

ingsound,whichisnotharmfultotheengineorstarter.

4. Wipeall snowand moisturefromthe carburetorcover

intheareaof thecontrollevers.Also,movecontrol

leversbackandforthseveraltimes.Leavechoke

controlintheFULLchokeposition.

5. Removeignitionkeyanddisconnectsparkplugwireto

preventaccidentalstarting.

1. Dischargesnowdownwindwheneverpossible.

Slightlyoverlapeachpreviouslyclearedpath.

2. Liftinguponthe handlewillallowthe rubberon the

augersto propelthesnowthrowerforward.Pushing

downwardon the handlewillraisetheaugersoffthe

groundandstopforwardmotion.

NOTE:Excessiveupwardpressureon the handlewill

resultinprematurewearontherubberaugerblades

whichwouldnot becoveredbywarranty.

3. Runtheenginefor a fewminutesbeforestoppingto

helpdryanymoistureonthe engine.

4. Cleanthesnowthrowerthoroughlyaftereachuse.

WARNING

Muffler,engineand

surroundingareas

become hot and

causeaburn:

Do not touch,

Operating the Snow Thrower

Thepitchof thechuteassemblycontrolstheangleat

whichthesnowisthrown.Adjustthe chuteassemblyby

followingtheinstructionsbelow.

1. Loosenthewing knobfoundontheleftsideof the

chuteassemblyandpivotthe upperchuteupwardor

downwardto thedesiredpitch.Retightenthe wing

knobbeforeoperatingthesnowthrower.

2. Positionthechuteassemblyopeningby usingthe

ChuteHandletothrowthe snowinthedesireddirec-

tion.See Figure6.

.._ J

Figure 6

IMPORTANT:

Forcomplete and

detailed engine

starting, stoppingand

storing instructions,

it isrecommended

that you read the

_=nginemanual also

includedwith

this unit.

NOTE:

Excessiveupward

pressure on the

handlewillresult in

premature wear

on the rubber

auger blades which

would not be covered

by warranty.

9

Page 10

MaintenanCe

WARNING

Disconnect the

spark plugwire

and ground it against

the engine to prevent

unintended starting.

NEVERattempt

to make any

adjustments while

I the engine is

running, except

where specified in

the operator's

manual.

Before servicing,

repairing, or

inspecting,

disengage the

control bail and

stop engine. Wait

i until all moving

i parts havecome to a

complete stop.

_ ARNING:NEVERattemptto make

any adjustments whilethe engineis

running,exceptwherespecified inthe

operator'smanual.

Figure 7

/

Figure 8

Shave Plate

1. Tocheckthe adjustmentofthe shaveplate,placethe

uniton a levelsurface.Thewheels,shaveplateand

augersshouldallcontactlevelsurface.Notethatif the

shaveplateis adjustedtoohigh,snowmayblowunder

thehousing.Ifthe shaveplatewearsout excessively,

ortheunit doesnot self-propel,theshaveplatemay

betoolowand needsto beadjusted.

NOTE:On newunitsorunitswitha newshaveplate

installed,theaugersmaybeslightlyoff theground.

2. Toadjust,tip thesnowthrowerbacksothat it restson

thehandle.Loosenthefourlocknutsand boltswhich

securetheshaveplatetothe housing.See Figure7.

Movetheshaveplatetodesiredpositionand retighten

thenutsandboltssecurely.

Replacing Shave Plate

Theshaveplate isattachedtothe bottomof theauger

housingandis subjecttowear.It shouldbechecked

periodically.Therearetwo wearingedgesandthe shave

platecan bereversed.RefertoFigure7.Toreplaceor

reversethe shaveplateproceedasfollows.

,

Removethecarriageboltsand hexlocknutswhich

attachit tothe snowthrowerhousing.

2.

Installnewshaveplate(or reverse),makingsurethe

headsof thecarriageboltsare ontheinsideofthe

housing.

,

Adjusttheshaveplateaccordingto instructionsabove

4. Tightensecurely.

Control Cable

Asa resultof boththecontrolcableandthedrive belt

stretchingdueto wear,periodicadjustmentsmaybe

necessary.

If theaugerseemsto hesitatewhenrotatingwhilethe

enginemaintainsa constantspeed,an adjustmentis

necessary.Proceedasfollows:

Theupperholeinthe controlhandleprovidesfor an

adjustmentincabletension.Toadjust,disconnectthe

endofcontrolcablefromthebottomholeinthecontrol

handleand reinsertit intheupperhole.Insertthecable

fromtheoutsideas shownin Figure8.Testthe snow

throwerto seeif thereisa noticeabledifference.

Carburetor

,__ WARNING:If any adjustments needto

be madeto the enginewhile the engine

isrunning(e.g. carburetor), keep

clear of all moving parts.Becareful of

muffler, engine and other surrounding

heatedsurfaces.

1. Referto theseparateenginemanual,packedwith

yourunit,for carburetoradjustmentinformation.

10

Page 11

Replacing Belt

_il ARNING:Before servicing,repairing,

Removethebeltcoverbyremovingfivehexscrews.See

Figure9.Thensimplypullthebeltoff bygraspingitfrom

thebottomofthe augerpulleyandpullingoff. Onceyou

removethe beltfromthe pulleys,youcanpushdownon

theidlerpulleytoreleasethebelt fromunderbeltkeeper.

Toreplacethebeltfollowtheseinstructionsandreferto

Figure10:

1. Pushdownon theIdlerpulley.

2. Putbelton top oftheaugerpulleyunderbeltkeeper.

3. Threadbeltaroundenginepulley.

4. Pushbeltoverbottomof augerpulley.

Reinstallthebelt coverremovedearlier.

or inspecting,disengagethe control

bail and stop engine.Waituntil all

moving partshavecome to a complete

stop. Disconnect spark plug wire and

ground itagainst the engine to prevent

unintended starting.

Engine

1. Referto theseparateenginemanualforaNengine

maintenanceprocedures.

2. Checkengineand snowthrowerfrequentlyforloose

hardware,andtightenas needed.

Lubrication

Lubricatepivotpointsonthe controlhandleandthe

extensionspringatthe endofthe controlcable witha

lightoilonce everyseasonandbeforestorageofthe

snowthrowerat theendof theseason.

Replacing Auger Paddies

Thesnowthrowerauger'srubberpaddlesaresubjectto

wearandshouldbe replacedifanysignsof excessive

wearis present.

IMPORTANT:DoNOTallowtheauger'srubberpaddles

towearto the pointwhereportionsofthemetalauger

itselfcancomeincontactwiththepavement.Doingso

canresultinseriousdamagetoyour snowthrower.

Tochangetherubberpaddles,proceedasfollows:

1. Removethe existingrubberpaddlesbyunthreadingthe

self-tappingscrewswhichsecurethemtotheauger.

SeeFigure11.

2. Securethereplacementrubberpaddlestothe auger

usingthe hardwareremovedearlier.

Figure 9

\

Figure 10

/

/ /

Maintenance

Before servicing,

repairing,or nspect,

ing, disengage the

controlbailandstop

engine; Wait until

moving parts have

i

/

come to a complete

stop;Disconnect

and

ground it against the

engine tO prevent

unintended starting:

IMPORTANT:DONOT

allow the augerlsrubber

paddles to weartothepoint

wheie portio0softhemetal

auger itselfcan Comein

contact withthepavement.

Doing SOCanresultin

serious damagetOyour

Figure 11

11

Page 12

WARNING

Never store snow

i thrower with fuel

in tank indoorsor

in poorly ventilated

areas, where fuel

fumes may reach an

open flame, spark

or pilot light as on a

furnace, water heater,

i clothes dryer or gas

, appliance.

Drain fuel intoan

approved container

outdoors,away from

any open flame. Be

certain engine is

i cool. Do not smoke.

Fuel left in engine

during warm weather

deteriorates and

will cause serious

starting problems.

Observethe following,whenpreparingyour snow

throwerfor off-seasonstorage:

• Drainfuelintoanapprovedcontaineroutdoors,away

fromanyopenflame.Allowengineto cool.Extin-

guishcigarettes,cigars,pipesandother sources

ofignitionpriortodrainingfuel. Fuelleft inengine

duringwarmweatherdeterioratesandwillcause

seriousstartingproblems.

If unitis tobestoredover30 days,preparefor

storageasinstructedinthe separateenginemanual

packedwithyourunit.

Runengineuntilfueltankis emptyandenginestops

duetolackof fuel.

Removegasolinefromcarburetorandfuel tankto

preventgum depositsfromformingontheseparts

andcausingpossiblemalfunctionof engine.

Draincarburetorbypressingupwardon bowldrain,

locatedbelowthecarburetorcover.

• Fuelstabilizers,suchasSTA-BIL®,areanaccept-

ablealternativein minimizingtheformationoffuel

gumdepositsduringstorage.Donotdraincarburetor

ifusinga fuelstabilizer.

• Wipeequipmentwithanoiled ragto preventrust.

• Removesparkplugandpouroneounceofengine

oilthroughsparkplugholeinto cylinder.Coverspark

plugholewithrag.Crankengineseveraltimesto

distributeoil.Replacesparkplug.

• Followthelubricationrecommendationsfoundinthe

MaintenanceSection.

Alwaysstorethe snowthrowerina clean,dryarea.

Do not drain

carburetor if using

fuel stabilizer.

Never use engine or

carburetor cleaning

i products inthe fuel

tank or permanent

damage may occur.

12

Page 13

Problem Cause Remedy

Fn_ n_fn _tn _tnd [ 11 ChOkenotinON position: 1 MoveChoketo ONposton

_-= " " "!" "" Sparkplugwiredisconnected. 2: Connectwlreto sparkplug.

Fue!tankemptyor stalefuel. &Fill tankwithcleanlfreShgaSoiinel

4 Enginenotprimed. ,Primeengineas instructedin

op ia,ngYouiSniwTh!o ei

5 FaultySparkplug Clean;adjustgap,or replace:

61Blocked fuellinei 6. Cleanfuel !inel

safetykeynotin ignitiononengine, 7 !nser!keyfu! Yint° ,heswitch:

8. Fue Shut-offvave cosed.(f 8. Openrue shut-df vare:

Engineruns erratic

1. UnitrunningonCHOKE.

2. Blockedfuellineor stalefuel.

3. Wateror dirtin fuelsystem.

4. Carburetoroutof adjustment.

1. Movechokeleverto OFFposition.

2. Cleanfuelline; filltankwithclean,

freshgasoline.

3. Drainfueltank. Refillwith

freshfuel.

4. ContactServiceCenter.

Engne overheats 1 Carburetornotadjustedpropery 1 ContactServce Center

Excessive 1. Loosepartsor damagedauger. 1. Stopengineimmediatelyand

Vibration disconnectsparkplugwire.Tighten

all boltsand nuts.Ifvibration

continues,haveunitservicedbya

ServiceCenter.

Lossof power 1, Sparkplugwire loose. 1. Connectandtightensparkplug

wire.

2. Gas capventholeplugged. 2. Removeice andsnowfromgas

I cap.Becertanventholeisclear.

• 3 Exhaustportplugged ". 3 ContactServiceCenter

NOTEi ThiSsection

addressesminor

service issues: For

further details,contact

customerassistancel

ii i _iI_ ii

Unit fails 1. Drivecontrolcane in needof adjust- 1. Adjustdrivecontrolcane. Referto

to propelitself merit. "Adjustments".

2. Drivebelt looseordamaged. 2. Replacedrivebelt.

Unit fails 1, Chuteassemblyclogged. 1. Stopengineimmediatelyand

to dscharge snow disconnectsparkplugwire.Clean

2. Foreignobjectlodgedinauger. 2, Stopengineimmediatelyand

3. Augerbeltlooseor damaged. 3, RefertoMaintenancesection

chuteassemblyandinsideof

augerhousingwithclean-outtool

ora stick.

disconnectsparkplugwire.

Removeobjectfromauger.

13

Page 14

iVlodel/iVlodele 2B5-295

NOTE:Snowthrowerfeatures/componentsvary bymodel.NOTall partslistedaboveandpicturedonthe previouspageare standardequipment.

REMARQUE:Lescaract_ristiques/composantsdessouffleusesvarientd'unmodule&unautre.Lespi_ces_num_r_esci-dessuset illustr_essurla

pagepr_c_dentenesontpas TOUTESfourniesen serie.

14

Page 15

Model/Modele 2B5-295

REF PART

NO, NO,

N° DE N° DE

RI_F PI_:CE

1 629-0071

2 710-0409

3 710-0627

4 710-0654A

5 710-0751

6 710-1003

7 712-04064

8 726-0154

9 726-0201

10 726-0205

11 731-2825

12 736-0119

13 736-0242

14 747-04236

15 750-04297B

16 751-0535

17 751-10023

18 751-10278

19 754-0101A

20 756-0416B

21 756-04232

22 790-00216

23 790-00134

24 7511152847

25 7512B1476

26 734-04225

27 684-04168

28 735-04033

29 710-0896

30 735-04032

31 684-04025A

32 710-0642

33 710-0653

34 712-0896

35 710-0352

36 712-04063

37 726-0299

38 736-0326

39 736-0329

40 736-0176

41 741-04188

42 684-04227

43 748-0234

44 738-0924A

45 790-00249

46 790-00283

47 790-00045A

48 710-0106

49 756-0625

50 684-04228

51 750-04571

52 722-3022

Extension Cord 10 Ft.

Hex Bolt 5/16-24 x 1.75

Hex L-Bolt 5/16-24 x .75 Gr. 5

Hex Wash HD Tap Scr 3/8-16 x .88

Hex Bolt 1/4-20 x .62 Gr. 5

Hex Wash B-Tapp Scr #10 x .62" Lg.

Hex L-Flanged Nut 1/4-20 Gr. F Nylon

Push Mount Tie

Push Speed Nut

Hose Clamp

Choke Knob

L-Wash 5/16 ID

Flat Washer .340 ID x .872 OD x .060

Gas Tank Wire Support

Spacer .875 x .320 x 1.10

Fuel Line

Fuel Tank 2 Quart

Cap-Fuel

V-Belt 1/2 x 35.0" Lg.

Pulley Half .625 ID x 2.25 OD

Pulley 1/2 x 6,0" OD

Engine Bracket

Gas Tank Support Bracket

Primer Hose Line

Primer

Wheel, 7.0 x 1.5 Lug

Idler Pulley (1/4" hole)

Rubber Paddle

Hex B-Tap Scr 1/4-28 x .25" Lg

Rubber Spiral-Crescent

Auger Ass'y 21" w/Solid Shaft

Thd Forming Scr. 1/4-20 x .75 Lg.

Hex Wash HD Tapp Scr 1/4-20 x .375

Hex Ins Jam L-Nut 1/4-28

Hex Tap Scr. 1/4-14 x .375" Lg.

Flange Locknut 5/16-18 Gr. F, Nylon

Push Cap x 1/2" Rod

Flat Washer .50 ID x 1.00 OD x .125

L-Wash 1/4 ID

Flat Washer .25 ID x .93 OD x .125

Ball Bearing .625 x 37 x 12.63

Auger Assembly Housing

Shoulder Spacer .25 THK

Hex Shld.Scr.1/4-28 x .375

Bearing Cup

Idler Bracket

Belt Cover

Hex Screw 1/4-20 x 1.25 Gr. 5 Special

Cable Guide Roller

Auger Assembly

Shld. Spacer .260 x .785 x .538

Tape

DESCRIPTION

DESCRIPTION

Corde a ralonge de 10 pi de Ig.

Boulon hex. 5/16-24 x 1,75

Boulon hex 5/16-24 x 0,75 Qual. 5

Vis autotaraudee 3/8-16 x 0,88

Boulon hexagonale 1/4-20 x 0,62 Qual. 5

Vis taraud6e nO. 10 x 0,62 po de Ig.

Contre-ecrou a embase 1/4-20 Qual. F nylon

Tige de poussoir

Ecrou rapide d'enfoncer

Collier

Manette de volet de d6part

Rondelle frein 5/16 DI

Rondelle plate 0,340 DI x 0,872 DE x 0,060

Fil de support - reservoir a carburant

Entretoise 0,875 x 0,320 x 1,10

Ligne d'essence

R6servoir de carburant de 2 quarts

Capuchon d'essence

Courroie trapezdidale 1/2 x 35,0 po de Ig

Moitie poulie 0,625 DI x 2,25 DE

Poulie 1/2 x 6,0" DE

Support du moteur

Support de reservoir de carburant

Ligne d'amorgeur

Amor_:eur

Roue, 7,0 x 1,50 Lug

Poulie du tendeur (trou 1/4 po)

Pale en caoutchouc

Vis taraud6e a t_te hexagonale 1/4-28 x 0,25

Spirale en caoutchouc - croissant

Ens. de la tariere de 21 po avec arbre solide

Vis taraud6e 1/4-20 x 0,75 Ig.

Vis auto-taraudeuse hexagonale 1/4-20 x 0,375

Contre-6crou de blocage 1/4-28

Vis taraud6e 1/4-14 x 0,375 po de Ig.

Contre-ecrou a embase 5/16-18 Qual. F, nylon

l_crou pour tige de 1/2 po

Rondelle plate 0,50 DI x 1,0 DE x 0,125

Rondelle frein 1/4 DI

Rondelle plate 0,25 DI x 0,93 DE x 0,125

Roulement a billes 0,625 x 37,0 x 12,63

Logement de la tariere

Entretoise epaul6e

Visa epaulement 1/4-28 x 0,375

Roulement a cuvette

Support du tendeur

Couvercle de courroie

Visa t_te hex. 1/4-20 x 1,25 Qual. 5 Special

Guide du c&ble

Ensemble de la tariere

Entretoise 0,260 x 0,785 x 0,538

Bande

31A-2951

5.18.06

Forparts and/or

accessories refer to

customer support on

page2.

Adressez-vousau

,,Service apr_s-vente>,

la page 2 pource qui

-oncerne les pi_ces

et/ou accessoires.

NOTE:Fora properworkingmachine,useFactoryApprovedParts.V-beltsaredesignedtoengageanddisen-

gagesafely.A substitute(nonOEM)V-beltcanbe dangerousbynotdisengagingcompletely.

REMARQUE:N'utilisezquedescourroieshomologu_esparI'usine. Lescourroiestrap_zdldalessontcon_ues

pourunembrayageet und_brayagesansdanger.Eemploid'unecourroiederemplacement(sansI'_tiquette

d'_quipementd'origine)peuts'avererdangereuxsi cettecourroienesed_brayepascompl_tement.

15

Page 16

iVlodel/iVlodele 2B5-295

_11)

16

Page 17

REF PART

NO. NO.

N° DE N° DE

R#:F PIt_CE

1 684-04127

2 710-04071

3 710-0451

4 712-04063

6 731-04388A

7 731-04354A

9 710-04532

10 720-04072

11 725-0157

13 747-04159

14 749-04106

15 684-0178

16 684-04032

684-04029

684-04211

684-04030

17 710-0895

18 710-1003

19 710-1090

20 710-1882

21 710-3083

22 712-0252

23 725-2018

24 736-0225

25 736-0400

26 736-0451

27 7510009636

28 710-0134

29 710-3008

30 712-04064

31 731-1033

32 736-0176

33 746-04237

34 749-04114

35 725-0201

36 684-0190

37 731-04127

38 731-04353

39 731-04886

40 732-04111

41 732-0357A

DESCRIPTION

Lower Chute Ass'y (Incl. #37-40)

Carriage Screw 5/16-18 x 1.0

Carriage Bolt 5/16-18 x .75

Flange Locknut 5/16-18 Gr. F, Nylon

Chute Handle

Upper Chute

Carriage Bolt 5/16-18 x 2.0 Gr. 5

Handle Knob Assembly

Cable Tie

Bail-Gull Wing

Upper Handle-Gull Wing

Mitten Grip Bracket Ass'y

Shroud Yellow, Elec. Start

Shroud Black, Elec. Start, 5 HP

Shroud Grey, Elec. Start

Shroud Black, Elec. Start, 7 HP

Hex Tapp Scr 1/4 x .75" Lg.

Hex Wash B-Tapp Scr #10 x .62" Lg.

Hex Scr..312-18 x 1.250

Hex Scr. 5/16-18 x 1.50 Gr. 5

Hex Scr. 5/16-18 x 1.375 Gr. 5

Hex Nut 5/8-32 x. 12 Special

Key Switch-Electric Start

L-Washer Internal

Flat Washer .218" ID x .62" OD

Saddle Wash..320 ID x .937 OD

Recoil Handle, Mitten

Carriage Bolt 1/4-20 x .62

Hex Bolt 5/16-18 x .75" Lg. Gr. 5

Hex L-Flanged Nut 1/4-20 Gr. F Nylon

Shave Plate

Flat Washer .25 ID x .93 OD x .125

Control Cable

Lower Handle

Ignition Key

Spark Plug Cover

Lower Chute 5" Dia

Ring-Lower Chute

Chute Adapter 5" Dia

Chute Adjustment Spring

Extension Spring .33 OD x 1.12 Lg.

DESCRIPTION

Ensemble de la goulotte inf. comp. les nos. 37 ou 40)

Boulon ordinaire 5/16-18 x 1,0

Boulon ordinaire 5/16-18 x 0,75

Contre-6crou & embase 5/16-18 Qual. F, nylon

Poign6e - goulotte d'6jection

Goulotte d'6jection sup_rieur

Boulon ordinaire 5/16-18 x 2,0 Qual. 5

Bouton

Attache-cAble

Manette de commande de suspension

Guidon sup6rieur

Support - poign6e de d6marreur

Capot jaune, demarreur 61ec.

Capot noir, demarreur 61ec., 5 HP

Capot gris, demarreur 61ec.

Capot noir, demarreur 61ec., 7 HP

Vis taraud6e &t6te hex de 1/4 x 0,75 po de Ig

Vis taraudee no. 10 x 0,62 po de Ig.

Vis hexagonal 0,312-18 x 1,250

Vis hexagonal 5/16-18 x 1,50 Qual. 5

Vis hexagonal 5/16-18 x 1,375 Qual. 5

Ecrou & six pans 5/8-32 x 0,12 sp_ciale

Contacteur d'allumage - d6marreur 61ectrique

Rondelle frein interne

Rondelle plate 0,218" Dt x 0,62" DE

Rondelle selle 0,320 DI x 0,937 DE

Poign6e du demarreur

Boulon ordinaire 1/4-20 x 0,62

Boulon hex. 5/16-18 x 0,75 po de Ig. Qual. 5

Contre-6crou & embase 1/4-20 Qual. F nylon

Grattoir

Rondelle plate 0,25 DIx 0,93 DE x 0,125

CAble de la commande

Guidon inf6rieur

Clavette

Couvercle de bougie

Goulotte d'6jection inf_rieur dia. 5 po

Bague - goulotte d'ejection inf_rieur

Adaptateur de la goulotte 5 po de dia.

Ressort d'ajustement - goulotte d'6jection

Ressort d'extension 0,33 DE x 1,12 po de Ig

31A-2952

5.15.06

Forparts and/or

accessories referto

customer support on

page2.

Adressez-vous au

<<Serviceapr_s-vente_,

& la page2 pource qui

concerne les pi_ces

et/ou accessoires.

17

Page 18

MANUFACTURER'S LiMiTED WARRANTY

Thelimitedwarrantysetforthbelowisgivenby MTDLLCwithrespect

tonewmerchandisepurchasedandusedin theUnitedStatesand/orits

territoriesandpossessions,andbyMTDProductsLimitedwithrespectto

newmerchandisepurchasedandusedin Canadaand/oritsterritoriesand

possessions(eitherentityrespectively,"MTD").

MTDwarrantsthisproduct(excludingitsnormalwearpartsasdescribed

below)againstdefectsinmaterialandworkmanshipfora periodof two

(2) yearscommencingon thedateoforiginalpurchaseandwill,at its

option,repairor replace,free ofcharge,anypartfoundtobe defective

inmaterialsor workmanship.Thislimitedwarrantyshallonlyapplyif

thisproducthasbeenoperatedand maintainedinaccordancewiththe

Operator'sManualfurnishedwiththeproduct,and hasnotbeensubjectto

misuse,abuse,commercialuse,neglect,accident,impropermaintenance,

alteration,vandalism,theft,fire,water,or damagebecauseofother perilor

naturaldisaster.Damageresultingfromthe installationor useofanypart,

accessoryorattachmentnotapprovedbyMTDforusewiththeproduct(s)

coveredby thismanualwillvoidyourwarrantyastoanyresultingdamage.

Normalwearpartsarewarrantedto befree fromdefectsinmaterialand

workmanshipfor a periodofthirty(30)daysfromthedateof purchase.

Normalwearpartsinclude,butare notlimitedto itemssuchas:batteries,

belts,blades,bladeadapters,grassbags,riderdeckwheels,seats,snow

throwerskidshoes,frictionwheels,shaveplates,augerspiralrubberand

tires.

NOWTOOBTAINSERVICE:Warrantyserviceis available,WITH

PROOFOF PURCHASE,throughyourlocalauthorizedservicedealer.To

locatethedealerin yourarea;

Inthe U.S.A.:

CheckyourYellowPages,or contactMTDLLCat RO.Box361131,

Cleveland,Ohio44136-0019,orcall1-800-800-7310or 1-330-220-4683

or logontoourWeb siteat www.mtdproducts.com.

In Canada:

ContactMTDProductsLimited,Kitchener,ON N2G4J1,or call1-800-

668-1238or logon toourWebsiteatwww.mtdcanada.com.

Thislimitedwarrantydoesnotprovidecoveragein the followingcases:

a. Theengineor componentpartsthereof.Theseitemsmaycarrya

separatemanufacturer'swarranty.Refertoapplicablemanufacturer's

warrantyfortermsandconditions.

b. Logsplitterpumps,valves,andcylindershavea separateone-year

warranty.

c. Routinemaintenanceitemssuchas lubricants,filters,blade

sharpening,tune-ups,brakeadjustments,clutchadjustments,deck

adjustments,andnormaldeteriorationof theexteriorfinishdueto use

orexposure.

d. Servicecompletedbysomeoneotherthananauthorizedservice

dealer.

e. MTDdoesnotextendanywarrantyforproductssoldor exported

outsideofthe UnitedStatesand/orCanada,andtheir respectivepos-

sessionsandterritories,exceptthosesoldthroughMTD'sauthorized

channelsofexportdistribution.

f. Replacementpartsthatarenot genuineMTDparts.

g. Transportationchargesand servicecalls.

h. If Productsare usedcommercially.(MTDmayseparatelyoffer Limited

CommercialWarrantiesoncertainselectproducts.Askyourdealeror

retailerfordetailsorcontactMTDServicefor moreinformation.)

No impliedwarranty, includinganyimpliedwarranty of merchant-

ability of fitness for a particularpurpose,applies afterthe applicable

periodof expresswritten warranty aboveas to the partsas identi-

fied. Noother expresswarranty, whether written or oral, except as

mentionedabove,given by anypersonor entity,includinga dealer

or retailer,with respect to anyproduct,shallbind MTD.Duringthe

periodof the warranty,the exclusiveremedyis repairor replacement

of the productas setforth above.

Theprovisionsas setforth inthis warranty providethe soleand

exclusiveremedyarising from the sale.MTDshallnot be liable

for incidentalorconsequentiallossor damageincluding,without

limitation, expensesincurredfor substituteor replacement lawncare

servicesor for rentalexpensesto temporarily replaceawarranted

product.

Somejurisdictionsdonotallowthe exclusionorlimitationof incidentalor

consequentialdamages,or limitationson howlonganimpliedwarranty

lasts,sothe aboveexclusionsor limitationsmaynotapplytoyou.

Innoeventshall recoveryofany kindbegreaterthantheamountofthe

purchasepriceof theproductsold.Alterationof safety features of the

productshall void thiswarranty. Youassumetheriskandliabilityfor

loss,damage,orinjuryto youandyour propertyand/ortoothersandtheir

propertyarisingout ofthe misuseorinabilitytousetheproduct.

Thislimitedwarrantyshallnotextendto anyoneotherthanthe original

purchaseror to thepersonforwhomitwaspurchasedasa gift.

HOWLOCALLAWSRELATETOTHiS WARRANTY:Thislimitedwar-

rantygivesyouspecificlegalrights,andyou mayalsohaveotherrights

thatvary indifferentjurisdictions.

IMPORTANT:OwnermustpresentOriginalProofof Purchaseto obtain

warrantycoverage.

iVlTDLLC, RO.BOX 361131CLEVELAND, OHiO 44136-0019; Phone: 1-800-800-7310

iVlTDProducts Ltd., P.O. BOX1386, KITCHENER, ON N2G 4J1; Phone: 1-800-668-1238

18

Loading...

Loading...