Page 1

Service Manual

2005 - 250 Series - World Tiller

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outdoor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accurate as possible at the time of publication. However, due to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2005 MTD Products Inc. All Rights Reserved

MTD Products Inc - Product Training and Education Department

FORM NUMBER - 769-02094

10/2005

Page 2

Page 3

TABLE OF CONTENTS

Introduction ............................................................................................................................1

Tines ......................................................................................................................................3

Clutching Mechanism ............................................................................................................4

Gearbox Removal and Replacement. ...................................................................................7

Gearbox Maintenance and Repair. .......................................................................................9

Seal Replacement ...............................................................................................................15

Page 4

Page 5

Vertical Crankshaft Front Tine Tiller

Vertical Crankshaft Front Tine Tiller

1. INTRODUCTION

1.1. Disclaimer: This service manual was intended

for use by trained technicians. The information

contained in this manual is current and accurate

at the time of writing, but is subject to change

without notice.

1.2. Purpose: The vertical crankshaft front tine tiller

was designed to provide a high value tool for

homeowners and gardeners who do not need a

large rear-tine tiller but require something larger

than a cultivator. This product is small enough to

be handy yet large enough to get the job done.

Standard rotating tine tillers excel at turning soil

that has previously been broken. This means

turning-over and introducing compost into existing flower beds and gardens. While it is capable

of breaking untilled soil, a counter-rotating tine

tiller is better suited to that task. The vertical

crankshaft design yields savings in engine cost.

See Figure 1.2.

1.4. Other Versions: The tiller depicted here is just

one of a variety of vertical crankshaft front-tine

tillers currently in production. See Figure 1.4.

Figure 1.4

1.5. Versions of this tiller are distributed in Europe.

Features on export tillers vary slightly from

domestic tillers. See Figure 1.5.

Figure 1.2

1.3. Description: The standard (forward) rotating

tines are driven by a set of worm gears within

the transmission. The tines can be adjusted to till

a swath that varies from 13” (33cm) to 24”

(61cm). The clutching media is a belt that is tensioned between two halves of a split sheave.

One half is attached to the engine, and the other

half is attached to the worm shaft. The friction of

the belt between the two sheave halves transfers power from the engine to the worm shaft at

a 1:1 ratio.

Figure 1.5

1

Page 6

Vertical Crankshaft Front Tine Tiller

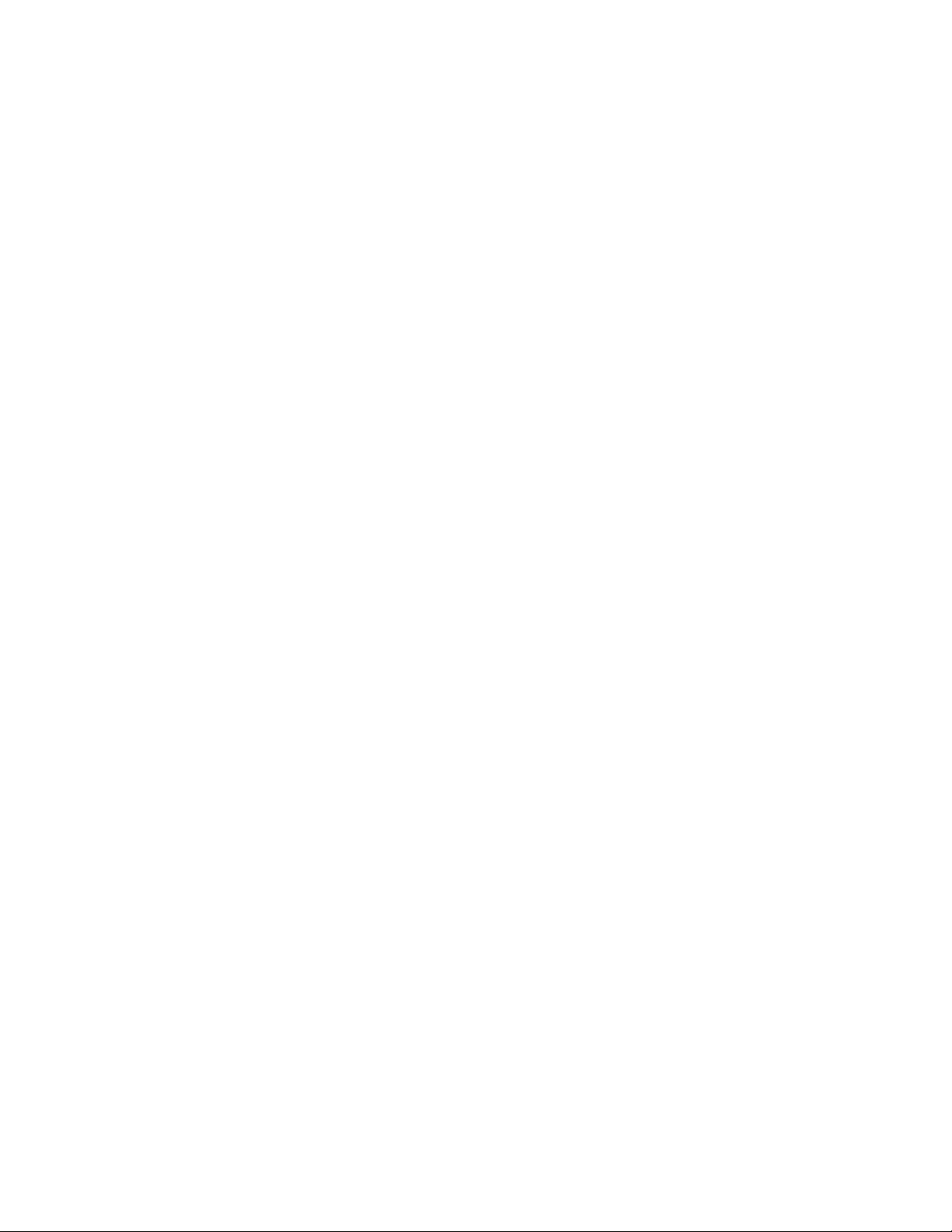

1.6. Different widths and tine configurations are in

production. The T-250 44cm/61cm version has a

disc on the end of the tine shaft to confine trailings. See Figure 1.6.

Figure 1.6

1.7. The disc can be removed. See Figure 1.7.

1.8. The tines can be reconfigured. See Figure 1.8.

Figure 1.8

1.9. There is also a T-210 35cm/40cm version,

roughly 50% larger than a mini cultivator.

See Figure 1.9.

Figure 1.7

Figure 1.9

2

Page 7

Vertical Crankshaft Front Tine Tiller

2. TINES

2.1. Disconnect and ground the spark plug wire

before servicing or adjusting the tines.

2.2. The tines are easily removed or adjusted using

the hairpin clips and clevis pins that fasten them

to the tine shaft. See Figure 2.2.

Long hub

Hairpin

Short hub

Figure 2.2

clips

2.4. There are left and right side tines, each has a

different angle of attack. The tines must sweep

away from the dirt as they enter it. If the tines are

reversed left/right, they will hook into the dirt too

aggressively. See Figure 2.4.

Right hand tine

Rotation Rotation

Figure 2.4

Left hand tine

2.3. The tines have two types of hub tube: long, and

short.

2.5. Keep the tine shaft clear of wire fencing, monofilament, clothesline and other material that may

wrap around the shaft.

2.6. Penetrating oil may be used to loosen tines that

are corroded to the tine shaft.

• Lubricating the tine shaft before storage will help

prevent this condition.

• A small amount of anti-seize between the tine

hub tubes and the tine shaft will help prevent this

condition.

2.7. Replace the tines and the hardware that secures

them to the tine shaft when they become visibly

worn.

3

Page 8

Vertical Crankshaft Front Tine Tiller

3. CLUTCHING MECHANISM

3.1. Disconnect and ground the spark plug wire

before performing a service or adjustments to

the clutching mechanism. If the engine has been

recently been run allow it to cool before service

is performed.

3.2. The clutching mechanism consists of the clutch

control lever, clutch cable, belt, upper and lower

sheaves, and belt tensioner.

3.3. Service to most of these components require the

removal of the engine.

3.4. Removal of engine and clutch housing.

See Figure 3.4.

3.5. To remove the cable, detach the cable from the

handlebars by pushing the barbed bracket out of

the hole. See Figure 3.5.

Clutch control

lever

Figure 3.5

3.6. Disconnect the Z-fitting from the lever.

3.7. Turn the engine upside-down to gain access to

the cable connection inside the clutch housing.

See Figure 3.7.

Z-fitting

Figure 3.4

NOTE: Removal steps

• Remove the 6 bolts and locking nuts that hold

the clutch housing to the rest of the tiller, using a

pair of 9/16” wrenches.

• Lift the engine and clutch housing from the tiller

and place them on a flat level surface without

constraining the cable.

• If the engine is to be inverted, drain the gasoline

from the fuel tank.

Idler

bracket

Figure 3.7

NOTE: The orientation of spring is hooking from

the bottom.

4

Page 9

Vertical Crankshaft Front Tine Tiller

3.8. Remove snap ring that attaches the cable to the

clutch housing.

3.9. Disconnect the cable from the idler bracket.

See Figure 3.9.

Snap ring

Figure 3.9

3.10. Install the cable by reversing the order of

removal.

3.11. To remove the belt, it will be necessary to

remove the idler bracket

3.14. Lift the idler bracket and belt out of housing.

See Figure 3.14.

Figure 3.14

3.15. Remove the lock nut from the stud by using a

9/16” wrench. See Figure 3.15.

Belt keeper

tabs

3.12. Disconnect the return spring from the idler

bracket.

3.13. Remove the 3/4 “ hex shoulder bolt and 9/16

lock nut on top side of clutch housing.

See Figure 3.13.

Idler

return

spring

Shoulder bolt

Figure 3.13

Figure 3.15

NOTE: Belt keeper tabs perform a braking func-

tion when the belt is released.

NOTE: Belt pt# 754-04061 Use of a non-standard belt may result in poor performance or loss

of braking feature creating a unsafe condition.

5

Page 10

Vertical Crankshaft Front Tine Tiller

3.16. If it is necessary to remove the top half of the

sheave from the engine crankshaft, apply heat to

the socket head cap screw to release the thread

locking compound. See Figure 3.16.

Figure 3.16

3.17. Remove the socket head cap screw with a 3/16”

allen wrench. See Figure 3.17.

3.20. With the engine and clutch housing removed,

the tine shield can be lifted off of the tiller.

See Figure 3.20.

Figure 3.20

NOTE: There are two dowels that locate the tine

shield to the tiller transmission.

3.21. If it is necessary to remove the lower half of the

sheave from the transmission worm shaft, apply

heat to release the thread locking compound.

See Figure 3.21.

Figure 3.17

NOTE: It may be necessary to stop the engine

from turning with either a piston stop or a flywheel holder.

NOTE: The sheave half that is attached to the

crank shaft provides fly weight for the engine.

3.18. At this point the clutch housing can be removed

from the engine using a 9/16” wrench.

3.19. On installation, apply thread locking compound

such as Loctite 242 (blue) the threads and

tighten to torque of 250-270 in-lbs (28-30 n-m)

RTV

sealant

Dowels

Figure 3.21

NOTE: There is a thin bead of RTV sealant

beneath the tine shield to help exclude dust from

the clutch housing. It does not necessarily seal

to the tine shield.

6

Page 11

Vertical Crankshaft Front Tine Tiller

3.22. Remove the socket head cap screw and heavy

washer that secure the lower half of the sheave

to the transmission worm shaft using a 3/16”

allen wrench. See Figure 3.22.

Lower

Pulley

Double-D

Shaft

Figure 3.22

3.23. The pulley adapter will slip off of the transmission worm shaft. It drives the shaft through a

double-D profile.

Pulley adaptor

4. GEARBOX REMOVAL AND REPLACEMENT.

NOTE: The tiller gear box is subject to the like

kind exchange program, providing that the failure is warrantable.

NOTE: Outside of warranty.the repair vs.

replacement will be at the discretion of the enduser and the repair shop.

4.1. Begin the transmission removal process by

Removing the engine and clutch housing. See

Figure 4.1.

NOTE: Some 2005 and later tillers may have a

low profile hex-head cap screw in place of the

socket head cap screw. It may be removed using

a 9/16” wrench.

3.24. On installation, apply thread locking compound

such as Loctite 242 (blue) to the threads and

tighten to a torque of 250-270 in-lbs (28-30 n-m).

Figure 4.1

• Remove the 6 bolts and locking nuts that hold

the clutch housing to the rest of the tiller, using a

pair of 9/16” wrenches.

• Lift the engine and clutch housing from the tiller

and place them on a flat level surface without

straining the cable.

• If the engine is to be inverted, drain the gasoline

from the fuel tank.

4.2. Lift the tine shield off transmission.

7

Page 12

Vertical Crankshaft Front Tine Tiller

4.3. Take note of the tine orientation, then remove

the tines. See Figure 4.3.

Figure 4.3

4.4. Remove the nut and bolt that hold the front

wheel bracket and tension spring to the transmission using a pair of 7/16” wrenches. See Figure 4.4.

4.7. To install the replacement gearbox simply

reverse the removal process.

See Figure 4.7.

NOTE: When Making service-or-replace decision about the gearbox, carefully evaluate the

value of the tiller.

Figure 4.7

Wheel bracket

bolt

Figure 4.4

NOTE: Tighten the wheel bracket bolt to a

torque of 90-120 in/lbs (10-13 n-m) on installation.

4.5. Remove 2 through-bolts that secure the handle

bars to the gearbox, using a pair of 1/2”

wrenches.

• If any major damage is discovered to the case,

the bronze gear, or the worm shaft, repair costs

will likely exceed the value of the transmission.

• Beyond warranty, confirm the amount that the

customer is willing to spend before commencing

any internal transmission repairs.

4.6. Remove 2 bolts that hold the depth bar bracket

on the gearbox, using a pair of 9/16” wrenches.

8

Page 13

Vertical Crankshaft Front Tine Tiller

5. GEARBOX MAINTENANCE AND REPAIR.

5.1. Gearbox contains 12 fl/oz. of 85w-140 gear lube.

NOTE: In normal service it should not be neces-

sary to change the gear lube on a regular basis.

The gear lube can be drained and replaced if the

transmission is to be opened for repair, or if the

fluid becomes contaminated, for example by

pressure washing.

NOTE: Damage caused by water in the transmission is NOT warrantable.

5.2. To check the fluid level clean the surface surrounding the fill plug. See Figure 5.2.

Gear lube

fill plug

5.4. When filling the gear box with the gear lube be

sure that the gear box is upright position, the oil

level will come up halfway on the tine shaft.

5.5. Drain and properly dispose of the gear lube if the

transmission is to be serviced. Refill it to the

proper level upon completion.

5.6. Before attempting to split the housing, clean the

tine shaft. Remove all dirt, rust, and scale using

emery cloth or a wire wheel.

NOTE: Wear eye protection.

5.7. Remove the 12 perimeter bolts that hold the two

case halves together using a 3/8” wrench, and

separate the housing.

See Figure 5.7.

Figure 5.2

5.3. Remove the fill plug with a 7/16” open end

wrench. See Figure 5.3.

Figure 5.3

NOTE: A bent piece of wire can be used as an

improvised dipstick.

Figure 5.7

NOTE: When assembling the gear box:

• Clean all components.

• Apply gear lube to the surfaces that rotate

against a seal.

• Protects seal lips on installation.

• Apply RTV sealant such as Permatex Ultra Grey

599BR to the mating surfaces of the case

halves.

• Tighten screws to a torque of 90-120 in/lbs (1013 n-m).

9

Page 14

Vertical Crankshaft Front Tine Tiller

5.8. Remove the shim from tine shaft inspect for any

wear to the shaft or gears. See Figure 5.8.

Shim

. 060

Figure 5.8

5.9. Pull Tine shaft through the gear.

See Figure 5.9.

5.10. Lift the bronze gear out of the housing after the

tine shaft has been removed.

See Figure 5.10.

NOTE: Gear tooth profile is concave to mate

with worm gear.

5.11. Inspect the bronze gear, bronze tine shaft bearings, tine shaft, and housings for significant wear

or damage.

Figure 5.10

Hi-Pro

key

Figure 5.9

NOTE: Hi-Pro key between the tine shaft and

the bronze gear.

5.12. Remove and inspect worm input shaft for wear

or damage to bearings.

See Figure 5.12.

Figure 5.12

10

Page 15

Vertical Crankshaft Front Tine Tiller

5.13. To remove the seals, simply pry them up with a

heavy screw driver.

See Figure 5.13.

Figure 5.13

NOTE: Care must be given not to score the

inside of the gear box casting.

5.14. If it is necessary to remove the bushings from

the housing that may be driven-out from the

inside. See Figure 5.14.

5.15. When installing new bushings, press them in so

that the end of the bushing is even with the

inside boss of the housing. See Figure 5.15.

Figure 5.15

NOTE: Bushing part number 741-04139

NOTE: If the tiller is need of tine shaft bearings

and the correct bearing (p/n 741-04139) is not

available, Troy-Bilt p/n GW-1086 may be modified by cutting off 3/8” for a suitable replacement.

Figure 5.14

NOTE: The bushing removal tool from the Troy-

Bilt tiller tine shaft tool kit TWX-4006 is the correct size.

NOTE: If you see that the bushings are in need

of replacement prior to taking out seals you can

press the seals out at the same time your removing the bushing

5.16. Scribe the GW-1086 bearing against the drivenout 741-04139 bearing to mark the length. See

Figure 5.16.

3/8”

Figure 5.16

11

Page 16

Vertical Crankshaft Front Tine Tiller

5.17. The GW-1086 bearing may be cut using a tubing

cutter, and dressed to clean any flash or burrs.

See Figure 5.17.

Figure 5.17

NOTE: When cutting down the bearing, do not

apply enough pressure to distort the bearing. Be

gentle.

5.20. With the screw and heavy washer removed, the

sheave-half can be lifted away, along with the

adapter. See Figure 5.20.

Pulley

Sheave

Adaptor

Figure 5.20

5.21. With the adaptor removed, the shim washers,

seal, and sealed ball bearing will slip off of the

s ha ft . Se e F i gu r e 5 .2 1.

5.18. The sheave half is most easily removed from the

worm shaft after the shaft has been removed

from the housing.

5.19. Fixture the shaft in a bench vise, and apply heat

to the socket head cap screw to release the

t h r e a d l o c k i n g c o m p o u n d . S e e F i g u r e 5 . 1 9 .

Hex head cap

screw

Figure 5.19

Figure 5.21

NOTE: Some tillers may have a hex head cap

screw at this location.

12

Page 17

Vertical Crankshaft Front Tine Tiller

5.22. The tapered roller bearing can be pressed off of

the bottom of the worm shaft. See Figure 5.22.

Figure 5.22

5.23. Inspect the bearings for roughness or obvious

damage. Replace them if necessary.

5.24. Replace the shim washers above the sealed

bearing, followed by a new seal.

See Figure 5.24.

5.26. Test fit the worm shaft assembly in the housing.

Check end-play. End play should be 0. 0-.014”

(.36 mm). See Figure 5.26.

Figure 5.26

NOTE: The closer to zero end play, the better.

5.27. Add or remove shims (p/n 736-0266 and 736-

04186) to achieve correct end-play. Generally,

this will not require adjustment.

Bearing

Shim washers Oil seal

Figure 5.24

NOTE:

Protect the lip of the new seal on installation.

5.25. Secure the pulley adapter and sheave half to the

worm shaft using the heavy washer and cap

screw. Do not torque the screw or apply thread

locking compound.

5.28. Remove the worm shaft from the housing, fixture

it in a bench vise, apply thread-locking compound such as Loctite 242 (blue) to the threads

of the cap screw securing the sheave, and

tighten it to a torque of 250-270 in-lb. (28-30 nm). See Figure 5.28.

Figure 5.28

5.29. Reposition the worm shaft assembly in the housing.

5.30. Position the first tine shaft thrust washer in the

housing.

13

Page 18

Vertical Crankshaft Front Tine Tiller

5.31. Place the bronze gear on top of the thrust

washer, confirming that the holes in the gear, the

thrust washer, and the tine shaft bearing are

aligned. See Figure 5.31.

Figure 5.31

5.32. Install the tine shaft, hi-pro key, and second

thrust washer.

5.34. Position the second half of the housing, and

secure it using the 12 screws previously

removed. Tighten the screws to a torque of 90120 in-lb. (10-13 n-m). See Figure 5.34.

Figure 5.34

5.35. Install the tine shaft seals. See Figure 5.35.

5.33. Apply a thin bead of RTV sealant such as Permatex Ultra Grey 599BR to the mating surfaces

of the case halves. See Figure 5.33.

Figure 5.33

Figure 5.35

5.36. Drive the seals all the way in, so that they seat

against the shoulder in the bore.

5.37. Re-fill the case with 12 fl/oz. of 80w140 gear lube

before operation.

5.38. Install the gearbox in the tiller by reversing the

removal process.

14

Page 19

Vertical Crankshaft Front Tine Tiller

6. SEAL REPLACEMENT

NOTE: Replacement of the seals can be done

without removing or disassembling the transmission.

NOTE: Drain fuel from the fuel tank.

NOTE: If the seal on the left side needs replace-

ment, drain the engine oil as well.

6.1. Position the tiller on its side, with the seal to be

replaced facing up. Remove tines from tine

shaft. See Figure 6.1.

6.3. After the seal is free from the transmission

housing it is possible to slide the seal off by

hand.

See Figure 6.3.

Figure 6.3

6.4. When the old seal has been removed examine

the tine shaft to for damage to the sealing surface. If the shaft is damaged there are two

options:

Figure 6.1

NOTE: It may be necessary to clean the tine

shaft with emery cloth prior to removing the seal.

6.2. Use seal puller tool or heavy screw driver to get

a hold on the old seal.

See Figure 6.2.

Figure 6.2

• Replace the shaft.

• Repair the shaft with a locally purchased “Reddisleeve” or similar product.

6.5. Use old micro fiche or similar material to protect

the seal a s i t slips over t h e tine shaft.

See Figure 6.5.

Figure 6.5

NOTE: Use caution not to score the shaft.

15

Page 20

Vertical Crankshaft Front Tine Tiller

6.6. Slide the seal along with the protective film or

sleeve into the tine shaft bore in the transmission housing.

See Figure 6.6.

NOTE: A light coating of oil on the shaft will aid

the film and seal down to the transmission.

Figure 6.6

6.7. Slide the film out of the seal.

See Figure 6.7.

6.8. Drive the seal home against the with Seal

installer tool from the Troy-Bilt tiller tine shaft tool

kit TWX-4006.

See Figure 6.8.

Figure 6.8

6.9. Install the tines.

6.10. Confirm correct gear lube and engine oil levels.

6.11. Run and test the tiller before delivery to the customer.

Figure 6.7

NOTE: Start the seal in the bore with gentle

thumb pressure.

16

Loading...

Loading...