Page 1

Safety • Assembly • Operation • Adjustments • Maintenance • Troubleshooting • Parts Lists • Warranty

OF A O A AL

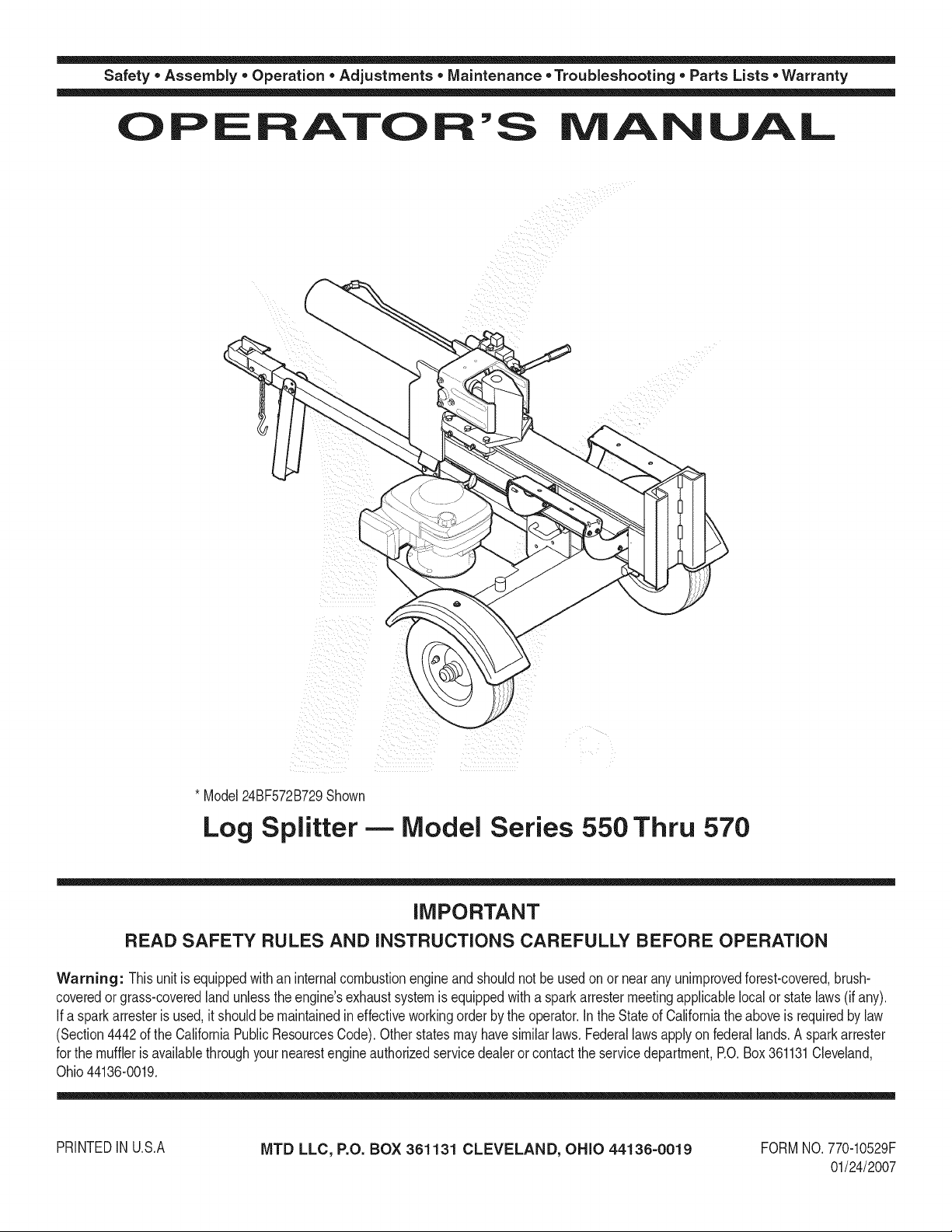

* Model24BF572B729Shown

Log Splitter -- Model Series 550 Thru 570

IMPORTANT

READ SAFETY RULES AND iNSTRUCTiONS CAREFULLY BEFORE OPERATION

Warning: Thisunitisequippedwithan internalcombustionengineandshouldnot beusedon ornearany unimprovedforest-covered,brush-

coveredorgrass-coveredlandunlesstheengine'sexhaustsystemisequippedwitha sparkarrestermeetingapplicablelocalor statelaws(if any).

If a sparkarresterisused,itshouldbemaintainedineffectiveworkingorderbytheoperator.IntheStateofCaliforniatheaboveisrequiredbylaw

(Section4442oftheCaliforniaPublicResourcesCode).Otherstatesmayhavesimilarlaws.Federallawsapplyonfederallands.A sparkarrester

forthemufflerisavailablethroughyournearestengineauthorizedservicedealeror contactthe servicedepartment,RO.Box361131Cleveland,

Ohio44136-0019.

PRINTEDIN U.S.A

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136=0019

FORMNO.770-10529F

01/24/2007

Page 2

This Operator's Manual is an important part of your new log splitter, it will help you assemble,

prepare and maintain the unit for best performance. Please read and understand what it says.

Table of Contents

Safety Labels ......................................... Page 3

Safe Operation Practices ...................... Page 4

Setting UpYour Log Splitter ................. Page 6

Operating Your Log Splitter .................. Page 8

Finding and Recording Model Number

BEFOREYOU STARTASSEMBLING

YOURNEW EQUIPMENT

Pleaselocatethe modelplate on the equipment andcopy the

informationto the sample modelplate provided to the right.

You can locatethe modelplate bystanding behind the unit

and lookingdown at the hydraulictank. This informationwill be

necessaryto use the website or obtain assistance from your

MTDdealer.

Maintaining Your Log Splitter ............ Page 12

Troubleshooting ................................... Page 16

illustrated Parts List ............................ Page 18

Warranty ......................................... Back Cover

F

Model Number

, www, rntdproducts.com

Serial Number

MTD LLC

P.O. BOX 361131

CLEVELAND, OH 44136

330-220-4683

800-800-731 0 /

Customer Support

Please do IVOTreturn the unit to the retailer from which it was

purchased, without first contacting Customer Support.

Ifyou have difficultyassemblingthis product or have any questions regardingthe controls,operation,or maintenance ofthis

unit,you can seek helpfrom the experts.Choosefrom the options below:

1. Visit mtdproducts.com. Click on Yardmachinesand then the CustomerSupport menu option.

2. Phonea Customer Support Representative at 1 (800) 800-7310.

3. The engine manufacturer is responsiblefor allengine-relatedissueswith regardsto performance,power-rating,specifica-

tions,warranty andservice. Pleasereferto the engine manufacturer'sOwner's/Operator's Manual,packedseparatelywith

your unit, for more information.

2

Page 3

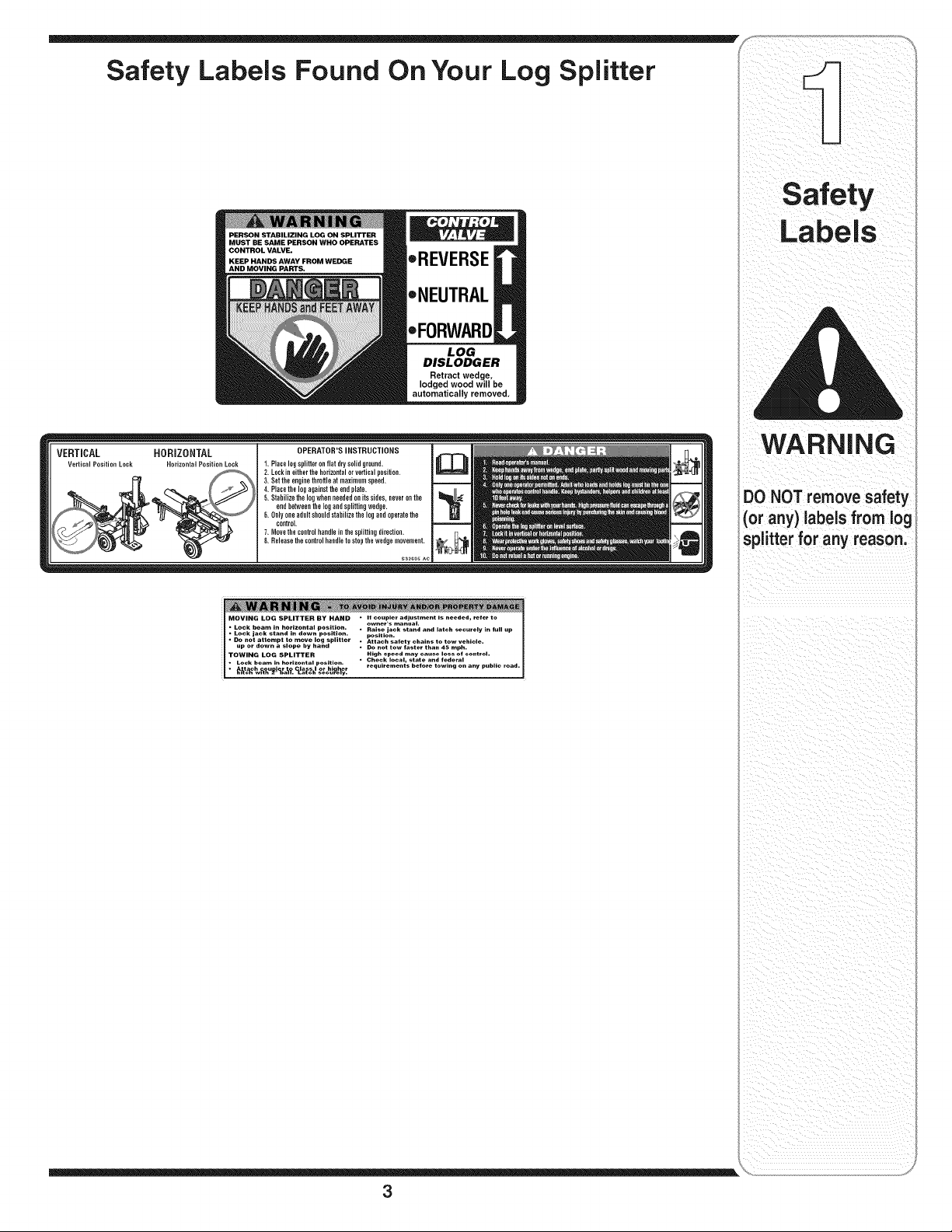

Safety Labels Found On Your Log Splitter

oREVERSE

INEUTRAL

IFORWARD

LOG

DISLODGER

Retract wedge,

lodged wood will be

automatically removed.

WARNING

DO NOT remove safety

{orany) labelsfromlog

;plitterfor any reason.

m_AIMOVING LOG SPLITTER BY HAND • coup er a jus men is nee e , re er o

• oc jac s an n own pus on, position,

• Do not attempt to move log splitter . Attach safety ohains to tow vehiole,

up or down a slope by hand . Do not tow faster than 45 mph.

TOWING LOG SPLITTER High speed may cause loss of control.

Lock beam in horizontal osition. " Check Iooal, state and federal .

J__" Lock beakh _ _" hd°;iz _ ........ _t]i_ ........ j ................................

_/_" requirements be ore towing on any pub io road.

3

Page 4

WARNING: EngineExhaust,some of its constituents, andcertain vehicle compo-

nentscontain or emit chemicals knownto Stateof Californiato cause cancer and

birth defects or otherreproductiveharm.

DANGER: This machinewas builtto beoperatedaccordingto the rulesfor safe operation in this

manual.As with any type of power equipment,carelessnessor error on the part ofthe operator can

result in serious injury.This machineis capableof amputatinghands andfeet andthrowing objects.

Failureto observethe followingsafety instructionscould resultin serious injury or death.

i WARNING

Thissymbol points

outimportant safety

instructionswhich, if

notfollowed,could

endangerthe personal

Soafetyand/or property

f yourselfand others.

i Readand follow all

I instructionsinthis man-

ualbeforeattempting to

operatethis machine.

Failureto complywith

i these instructionsmay

I resultin personalinjury.

Whenyou seethis

symbol -

HEED ITS WARNING

Your

I = = w

i Responsubuluty

Restrictthe use

i of this power machine

i to personswho read,

understand

and followthe warnings

and instructions

inthis manual.

General Practices

1. Read,understand,andfollowall instructionson the

machineandinthe manual(s)beforeattempting

toassembleandoperate.Keepthismanualin a

safeplaceforfutureandregularreferenceandfor

orderingreplacementparts.

2. Befamiliarwithall controlsandproperoperation.

Knowhowtostopthemachineanddisengagethem

quickly.

3. Neverallowchildrenunder16yearstooperatethis

machine.Children,16yearsandover,shouldread

andunderstandinstructionsandsafetyrulesinthis

manualandshouldbetrainedandsupervisedbya

parent.

4. Neverallowadultstooperatethismachinewithout

properinstruction.

5. Manyaccidentsoccurwhenmorethanoneperson

operatesthe machine.If a helperisassistinginload-

inglogs,neveractivatethecontroluntilthehelperis

a minimumof 10feetfromthe machine.

6. Keepbystanders,helpers,pets,andchildrenat least

20feetfromthe machinewhileitisinoperation.

7. Neverallowanyoneto rideon thismachine.

8. Nevertransportcargoonthis machine.

9. Hydrauliclogsplittersdevelophighfluidpressures

duringoperation.Fluidescapingthrougha pin hole

openingcanpenetrateyourskinandcauseblood

poisoning,gangrene,or death.Giveattentiontothe

followinginstructionsatalltimes:

a. Donotcheckfor leakswithyourhand.

b. Donotoperatemachinewithfrayed,kinked,

cracked,ordamagedhoses,fitting,ortubing.

c. Stopthe engineand relievehydraulicsystem

pressurebeforechangingoradjustingfittings,

hoses,tubing,orothersystemcomponents.

d. Donotadjustthepressuresettingsofthe pumpor

valve.

10.Leakscanbedetectedbypassingcardboardor

wood,whilewearingprotectiveglovesand safety

glasses,overthesuspectedarea.Lookfordiscolor-

ationof cardboardorwood.

11.

If injuredby escapingfluid,seea doctorimmediately.

Seriousinfectionor reactioncandevelopifproper

medicaltreatmentis not administeredimmediately.

12.Keeptheoperatorzoneandadjacentareaclearfor

safe,securefooting.

13.If yourmachineisequippedwithan internalcom-

bustionengineanditisintendedfor usenearany

unimprovedforest,brush,or grasscoveredland,

theengineexhaustshouldbeequippedwitha spark

arrester.Makesureyoucomplywithapplicablelocal,

state,andfederalcodes.Takeappropriatefirefighting

equipmentwithyou.

14.Thismachineshouldbeusedforsplittingwoodonly,

donotuseitfor anyotherpurpose.

15.Followtheinstructionsinthe manual(s)providedwith

anyattachment(s)forthismachine.

Preparation

1. Alwayswearsafetyshoesorheavyboots.

2. Alwayswearsafetyglassesorsafetygogglesduring

operatingthismachine.

3. Neverwearjewelryor looseclothingthatmight

becomeentangledinmovingor rotatingpartsofthe

machine.

.

Makesuremachineis on levelsurfacebeforeoperat-

ing.

5.

Alwaysblockmachineto preventunintendedmove-

ment,andlockineitherhorizontalor verticalposition.

6.

Alwaysoperatethis machinefromtheoperator

zone(s)specifiedinthemanual.

Z

Logsshouldbecutwith squareendspriorto splitting.

8.

Uselogsplitterindaylightor undergoodartificiallight.

9.

Toavoidpersonalinjuryor propertydamageuse

extremecareinhandlinggasoline.Gasolineis

extremelyflammableandthevaporsareexplosive.

Seriouspersonalinjury canoccurwhengasolineis

spilledonyourselforyourclotheswhichcanignite.

Washyourskinandchangeimmediately.

a. Useonlyan approvedgasolinecontainer.

b. Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

c. Neverfuelmachineindoors.

d. Neverremovegascaporaddfuel whiletheengine

ishot or running.

e. Allowenginetocoolat leasttwo minutesbefore

refueling.

4

Page 5

f. Neveroverfillthefueltank.Filltanktono more

than1/2inch belowbottomof filler neckto provide

spaceforfuelexpansion.

g. Replacegasolinecapandtightensecurely.

h. Ifgasolineis spilled,wipeit offtheengineand

equipment,movemachinetoanotherarea.Wait5

minutesbeforestartingtheengine.

i. Neverstorethemachineor fuelcontainerinside

wherethereisan openflame,sparkor pilotlightas

on a waterheater,spaceheater,furnace,clothes

dryeror othergasappliances.

j. Allow machinetocool5 minutesbeforestoring.

Operation

1. Beforestartingthismachine,reviewthe"Safety

instructions".Failuretofollowtheserulesmayresultin

seriousinjurytothe operatoror bystanders.

2. Neverleavethismachineunattendedwiththeengine

running.

3. Donotoperatemachinewhileundertheinfluenceof

alcohol,drugs,or medication.

4. Neverallowanyonetooperatethismachinewithout

properinstruction.

5. Alwaysoperatethismachinewithall safetyequipment

inplaceandworking.Makesureallcontrolsare

properlyadjustedforsafeoperation.

6. Donotchangetheenginegovernorsettingsor

overspeedthe engine.Thegovernorcontrolsthe

maximumsafeoperatingspeedofthe engine.

7. Whenloadingalog,alwaysplaceyourhandsonthe

sidesofthelog,noton theends,andneveruseyour

footto helpstabilizea log.Failuretodo so,mayresult

incrushedoramputatedfingers,toes,hand,orfoot.

8. Useonly yourhandto operatethecontrols.

9. Neverattemptto splitmorethanonelogat a time

unlesstheramhasfullyextendedanda secondlogis

neededtocompletetheseparationofthe first log.

10.Forlogswhicharenot cutsquare,theleastsquare

endandthe longestportionofthelogshouldbe

placedtowardthe beamand wedge,andthe square

end placedtowardtheendplate.

11.Whensplittingintheverticalposition,stabilizethe log

beforemovingthecontrol.Splitasfollows:

a. Placelog ontheendplateandturnuntilit leans

againstthebeamandis stable.

b. Whensplittingextralargeor unevenlogs,thelog

mustbestabilizedwithwoodenshimsor splitwood

betweenthe logandendplateor ground.

12.Alwayskeepfingersawayfromanycracksthatopen

inthelogwhilesplitting.Theycanquicklycloseand

pinchoramputateyourfingers.

13.Keepyourworkareaclean,immediatelyremovesplit

woodaroundthe machineso youdo notstumbleover

it.

14.Nevermovethismachinewhiletheengineisrunning.

15.Thismachineshouldnotbetowedon anystreet,

highwayorpublicroadwithoutcheckingtheexisting

federal,state,or localvehiclerequirements.Any

licensingor modificationssuchastaillights,etc.,

neededtocomply,is thesoleresponsibilityofthe

purchaser.If a"Statementof Origin"isrequiredin

yourstate,seeyourlocaldealer.

16.Donottowmachinefasterthan45mph.

17.SeeTransportingthe LogSplittersectionin this

manualforpropertowinginstructionsonceall

federal,local,or staterequirementsare met.

Maintenance and Storage

1. Stoptheengine,disconnectthe sparkplugand

grounditagainstthe enginebeforecleaning,or

inspectingthemachine.

2. Stoptheengineand relievehydraulicsystem

pressurebeforerepairingor adjustingfittings,hoses,

tubing,orothersystemcomponents.

3. Topreventfires,cleandebrisandchafffromthe

engineandmufflerareas,if theengineis equipped

witha sparkarrestermuffler,cleanand inspectit

regularlyaccordingtomanufacturersinstructions.

Replaceifdamaged.

4. Periodicallycheckthatall nutsandbolts,hose

clamps,andhydraulicfittingsaretightto besure

equipmentisinsafeworkingcondition.

5. Checkall safetyguardsandshieldsto besure

theyareintheproperposition.Neveroperatewith

safetyguards,shields,orotherprotectivefeatures

removed.

6. The pressurereliefvalveispresetatthefactory.Do

notadjustthevalve.

7. Neverattemptto movethismachineoverhillyor

uneventerrainwithouta towvehicleor adequate

help.

8. Foryoursafety,replaceall damagedor wornparts

immediatelywithoriginalequipmentmanufacturer's

(O.E.M.)partsonly."Useof partswhichdo notmeet

theoriginalequipmentspecificationsmayleadto

improperperformanceandcompromisesafety!"

9. Do notalterthismachineinany manner,alterations

suchasattachinga ropeor extensiontothecontrol

handle,oraddingtothe widthor heightofthewedge

mayresultin personalinjury.

Your Responsibility

Restricttheuseofthispowermachinetopersonswho

read,understandandfollowthe warningsandinstruc-

tionsinthis manualandonthemachine.Alwaysfollow

directionsonsafetylabelsfoundon yourequipment.

Safe.

o,o,a.,,oo

Practices

WARNING

Thissymbol points

out importantsafety

instructionswhich, if

notfollowed, could

endangerthe personal

safety and/or property

of yourself and others.

Readand followall

instructions inthis man-

ual before attempt ngto

operatethis machine.

Failureto comply with

these instructionsmay

result in personalinjury.

Whenyou seethis

symbol-

HEED ITS WARNING

Your

Responsibility

Restrictthe use

ofthis powermachine

to personswho read,

understand

and followthe warnings

and instructions

in this manual.

5

Page 6

YourLog

Splitter

i

Figure 3-1

"_ ,_ WARNING:Useextreme caution

unpacking this machine.Some

__ components arevery heavy and will

require additional people or mechanical

handlingequipment.

NOTE:Allreferencesin thismanualtotheleft or right

sideof thelog splitterisfromtheoperatingpositiononly.

Exceptions,ifany,willbespecified.

Assembling the Tongue

Attaching the Jack Stand

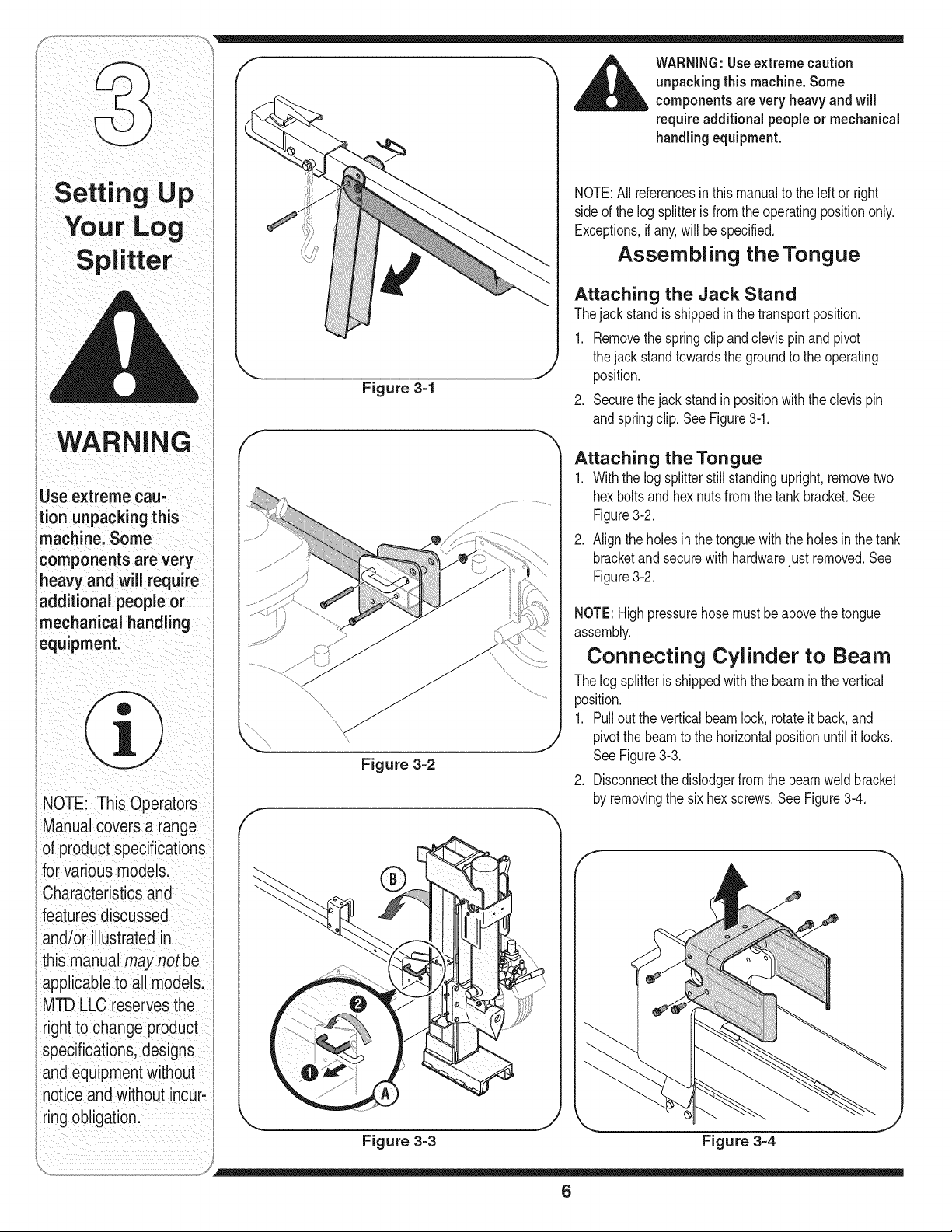

Thejackstandisshippedinthetransportposition.

1. Removethespringclipandclevispinand pivot

thejack standtowardsthegroundto the operating

position.

2. Securethejackstandin positionwiththeclevispin

andspringclip.SeeFigure3-1.

WARNING

tion unpackingthis

machinei Some

componentsare,e y

heavy and will require

additional people or

mechanical handling

equipmenL

Manual coversa range

of productspecifications

for Variousmodels:

Characteristicsand

featUresdiscussed

and/or illustratedin

this manual

applicableto a!l models:

MTD LLC reSerVesthe

Figure 3=2

Attaching the Tongue

1. Withthelogsplitterstillstandingupright,removetwo

hexboltsandhexnutsfromthetankbracket.See

Figure3-2.

2. Aligntheholes inthetonguewiththe holesin thetank

bracketandsecurewithhardwarejust removed.See

Figure3-2.

NOTE:Highpressurehosemustbeabovethetongue

assembly.

Connecting Cylinder to Beam

Thelogsplitterisshippedwiththebeaminthevertical

position.

1. Pulloutthe verticalbeamlock,rotateit back,and

pivotthebeamto the horizontalpositionuntilitlocks.

SeeFigure3-3.

2. Disconnectthedislodgerfromthe beamweldbracket

byremovingthe sixhexscrews.SeeFigure3-4.

right to ChangeProduct

specifiCatiOns:designs

and equipment Without

notice andwith0ut inCur:

ring obligation:

,... j k,,

Figure 3=3 Figure 3-4

6

Page 7

3. Disconnectthelogcradlefromthe beamontheside

ofthecontrolvalve.SeeFigure3-5.

4. Liftandslidethe cylinderuptothetopofbeamand

intotheweld brackets.SeeFigure3-6.

5. Attachthedislodgeroverthewedgeassemblyand

securewith hardware,previouslyremoved,to the weld

brackets.

NOTE:Oncethesix hexscrewsaretightened,there

maybea slightgapbetweenthedislodgerandtheweld

brackets.Thisgapis normal.

6. Reattachthelogcradletothesideof the beamwith

thecontrolvalve,aligningtheendsofthecradlewith

thebeamflanges.

7. Rolllogsplitteroff the bottomcrate.

Preparing the Log Splitter

,

Lubricatethe beamarea(wherethe splittingwedge

willslide)withengineoil;donotusegrease.

2.

Removeventedreservoirdipstick,whichislocatedin

frontoftheengineon topofthe reservoirtank.See

Figure3-7.

IMPORTANT:Thelogsplittermayhavebeenshipped

and primedwithhydraulicfluidinthe reservoirtank.

However,you MUSTcheckthefluidlevelbeforeoperat-

ing.If notfilled,proceedwiththefollowingsteps:

3. Fillthereservoirtankwith hydraulicfluid includedwith

this unit(if equipped)orapprovedfluidswhichinclude

Dexron®III/ Mercon®IIIautomatictransmissionfluid,

a 10WeightAWhydraulicoilor Pro-MixTM AW-32

HydraulicOil.

4. Checkfluidlevelusingthedipstick.SeeFigure3-7.Do

notoverfill.

5. Replaceventeddipsticksecurely,tighteningit untilthe

topofthe threadsareflushwithtopof the pipe.

6. Disconnectthesparkplugandprimethepumpby

pullingthe recoilstarterasfarasit willgo.Repeat

approximately10times.

7. Reconnectthesparkplugwireandstart engine

followinginstructionsin the OPERATIONsection.

8. Usecontrolhandleto engagethewedgeto the

farthestextendedposition.Thenretractthe wedge.

9. Refilltankasspecifiedonthe dipstick.

Figure 3=5

f

Muchofthe original

fluidhas beendrawn

intothe cylinder

hoses: Make certain to

refillthe reservoirto

preventdamage to the

hydraulicpump.

Figure 3-6

ii _i_i _ii_!iii_iiiii_ TM iii_

IMPORTANT:

The logsplitter may

have been shipped and

primedWithhydraulic

fluid inthe reservoir

tan If noL proceed

with the following

steps:

NOTE:Failureto refillthetankwillvoidunit'swarranty.

10.Extendandretractthewedge12completecycles

to removetrappedairinthesystem(thesystemis

"self-bleeding").

11.Refillreservoirwithinrangemarkedonthe dipstick.

_ ARNING:Muchof the original

fluid has beendrawn into the cylinder

and hoses. Makecertainto refill the

reservoirto preventdamageto the

hydraulicpump.

Figure 3=7

NOTE:Somefluidmayoverflowfromtheventplugas

thesystembuildsheatandthe fluidexpandsandseeks

a balancedlevel.

7

NOTE!Some fluid may

overflow from the vent

plugas the system

builds heat andthe

fluid expandsand

seeks abalanced level:

i_ ii i

Page 8

i_i_i_iii_i iiii _iiii_i__ ii_i_!i_

Know Your Log Splitter

Cylinder

Control Handle

fislod

BeamAssembly

IMPORTANT

i Yourlogsplitter may

be shippedwith motor

I oil inthe engine. You

MUSTcheckthe oil

levelbefore operat-

ing.Be careful notto

overfill.

/

JackStand

Tongue

Vertical

Beam

Lock

TailLight

(If Equipped)

LogCradle

Horizontal Beam Lock

Figure 4=1

Beam Locks

Thesetwolocks,astheirnamesuggests,areused

tosecurethebeaminthe horizontalorthevertical

position.Theverticalbeamlockis locatednextto theoil

filter.Thehorizontalbeamlockis locatedon the beam

supportlatchbracket.See Figure4-1.

J_

VerticalBeamLock

Engine Controls

Seetheaccompanyingenginemanualforthe location

andfunctionofthecontrolsontheengine.

8

J

Page 9

Control Handle

Thecontrolhandlehasthreepositions.See Figure4-2.

• FORWARD:MovecontrolhandleFORWARDor

DOWNtomovewedgeto splitwood.

NOTE:Controlhandlewill returntoneutralpositionas

soonashandleisreleased.(ForwardPosition only)

NEUTRAL:Releasethecontrolhandleor movethe

leverto neutralpositiontostopthewedgemovement.

REVERSE:MovecontrolhandleBACKorUPto return

thewedgetowardthecylinder.Thecontrolhandle

staysinthe return(Reverse)positionand returnsto

neutralautomaticallywhen fullyretracted.

NOTE:Reversepositionmayalsobeoperatedbackto

neutralpositionmanually,if necessary.

Stopping Engine

1. Movethrottlecontrol(ifequipped)to STOPor OFF

position.

2. Turnoffthe engineswitch,if soequipped.

3. Disconnectsparkplugwireand groundagainstthe

engineto preventunintendedstarting.

,_ WARNING:Read,understand,and

__ WARNING:Wearleather work gloves,

follow all instructions and warnings on

the machineand in this manual before

operating.

safetyshoes, ear protection,and safety

glasseswhen operating a log splitter.

Ensuresafe footing.

Gas and Oil Fill=Up

1. Servicethe enginewith gasolineandoilas instructed

in the enginemanualpackedwithyourlog splitter.

Readinstructionscarefully.

WARNING:Useextremecarewhenhan-

dling gasoline.Gasolineis extremely

flammableand the vapors are explosive.

Neverfuel machine indoorsor while the

engine is hot or running.

IMPORTANT:Yourlogsplittermaybeshippedwithmotor

oil in theengine.YouMUSTcheckthe oil levelbefore

operating.Becarefulnottooverfill.

To return

wedge

To stop

wedge

)

To split wood

Figure 4=2

NOTE:Gasolinecanbe addedtotheenginewhenthe

logsplitterisin eitherthehorizontalorverticalposition.

However,thereare lessobstructionswhenthe unitis in

theverticalposition.

Starting Engine

1. Attachsparkplugwireto sparkplug. Makecertain

themetalcapontheendofthesparkplugwire is

fastenedsecurelyovermetaltipofthe sparkplug.

2. Turnfuelvalve(or engineswitch),ifequipped,tothe

ONposition.

3. Movechokelever,ifequipped,toCHOKEposition.

4. If theengineisequippedwitha primer,follow

instructionsin the enginemanualtoprimeit.

5. Turnthethrottlecontrol(if equipped)to the FAST

position.

6. Graspstarterhandleandpullropeout slowlyuntil

enginereachesstartof compressioncycle(ropewill

pullslightlyharderatthispoint).

7. Pullropewitha rapid,fullarm stroke.Keepfirmgrip

on starterhandle.Let roperewindslowly.Repeat

untilenginecranks.

8. Afterenginestarts,movechokelever(ifequipped)

toOFFposition.Placethrottlelevertothe speed

desired.

9. In coldweather,runwedgeupor downbeam6 to 8

timesto circulatethehydraulicfluid.

_ WARNING:Whenstarting awarm

engine,the muffler and surrounding

areasare hot and can causea burn.

Donottouch.

WARNING

Read, understand, and

follow all instructions

and warnings on the

machine and inthis

manual before operat-

ing.

Wear leather work

gloves,safety shoes,

ear protection,and

safety glasseswhen

operating a log splitter.

Ensure safe footing.

Use extreme carewhen

handlinggasoline.

Gasoline isextremely

flammable and the

vapors are explosive.

Never fuel machine

indoorsor while the

engine is hotor run-

ning.

When starting a warm

engine, the muffler and

surrounding areas are

hot and can cause a

burn. Do not touch.

9

Page 10

Coo,ro,.and,o

// I 1. MovecontrolhandleFORWARDor DOWNtosplit

Z_I 1_1 , wood.

2. Releasethecontrolhandleto stopthewedgemove-

ment.

3. MovecontrolhandleBACKorUPto returnthewedge.

Log Dislodger

Thelog dislodgerisdesignedtoremoveanypartially

splitwoodfromthewedge.Thismayoccurwhilesplitting

largediameterwoodorfreshlycutwood.

Neverremove partially

split wood from the

wedgewith your

hands. Fingers may be-

come trapped between

split wood.

Figure 4=3

Before Each Use

1. Removethedipstickand checkhydraulicfluidlevel.

Refillifnecessary.ApprovedfluidsincludeDexron®

III/ Mercon®IIIautomatictransmissionfluid,a

10WeightAWhydraulicoilor Pro-MixTM AW-32

HydraulicOil.

2. Check engineoil level.Refillifnecessary.

3. Fill upgasolineifnecessary.

4. Lubricatethebeamareawheresplittingwedgewill

slidewithengineoil. Donotusegreasetolubricate.

Makesureto lubricateboththe frontandthebackof

thebeamface.

5. Attachsparkplugwireto thesparkplug.

_ ARNING:Neverremove partiallysplit

1. Toremovepartiallysplitwoodfromwedge,move

controlhandleto REVERSEpositionuntilwedgeis

fullyretractedtoallowsplitwoodportiontocontactthe

logdislodger.

2. Onceremovedfromwedgewithlogdislodger,split

woodfromoppositeendor inanotherlocation.

Vertical Position

1. Pullthehorizontalbeamlockout to releasethebeam

andpivotthe beamtothe verticalposition.

2. Tolockthe beamin theverticalposition,pullout

ontheverticalbeamlockandrotateittosecurethe

beam.SeeFigure4-1.

3. Standinfrontoftheunit to operatethecontrolhandle

andtostabilizethelog.SeeFigure4-3.

Horizontal Position

1. Pulltheverticalbeamlockoutand rotateit down.See

Figure4-1.Pivotbeamtothehorizontalposition.The

beamwill lockautomaticallyinhorizontalposition.

2. Standbehindthereservoirtanktooperatecontrol

handleandtostabilizethelog.

wood from the wedge with your hands.

Fingersmaybecometrapped between

split wood.

Using the Log Splitter

1. Placethelogsplitteronlevel,dry ground.

2. Placethebeamineitherthe horizontalorvertical

positionandlockinplacewiththeappropriate

lockingrod.

3. Blockthe frontandbackof bothwheels.

4. Placethelogagainsttheendplateandonlysplit

woodinthedirectionof the grain.

5. Tostabilizethelog,placeyourhandonlyon sidesof

log.Neverplacehandon theend betweenthe log

and the splittingwedge.

6. Onlyoneadult shouldstabilizethelogandoperate

thecontrolhandle,sotheoperatorhasfullcontrol

overthe logandthesplittingwedge.

Operating Tips

Always:

1. Usecleanfluidandcheckfluidlevelregularly.

2. Useanapprovedhydraulicfluid.Approvedfluids

includeDexron®III/Mercon®IIIautomatictransmis-

sionfluid,a 10WeightAWhydraulicoilor Pro-MixTM

AW-32HydraulicOil.

3. Useafilter (cleanorreplaceregularly).

4. Usea breathercapon fluidreservoir.

5. Makesure pumpismountedandalignedproperly.

10

Page 11

6. Usea flexible"spider"typecouplingbetweenengine

and pumpdriveshafts.

7. Keephosesclearand unblocked.

8. Bleedairoutof hosesbeforeoperating.

9. Flushandcleanhydraulicsystembeforerestarting

afterservicing.

10.Use"pipedope"onall hydraulicfittings.

11.Allowtimeforwarm-upbeforesplittingwood.

12.Primethepumpbeforeinitialstart-upbyturningover

theenginewithsparkplugdisconnected(ifnotalready

doneatfactory).

13.Splitwoodalongthe grain(lengthwise)only.

Never:

1. Usewhenfluidisbelow200Forabove1500R

2. Usea solidengine/pumpcoupling.

3. Operatethroughreliefvalveforlong.

4. Attemptto adjustunloadingor reliefvalvesettings

withoutpressuregauges.

5. Operatewithair in hydraulicsystem.

6. Useteflontapeon hydraulicfittings.

7. Attemptto cutwoodacrossthegrain.

8. Attemptto removepartiallysplitwoodfromthewedge

withyourhands.Fullyretractwedgetodislodgewood

withlog dislodger.

Raising and Lowering Beam

1. Usecontrolhandleto runwedgeupanddownbeam

6 to 8 timestocirculatethehydraulicfluid,whichwill

warmandthinthefluid.

2. Placelog splitteron a firm,levelsurface.

Toraisethe beamforverticaloperation:

3. Pullout the horizontalbeamlockonthetongue.

4. Pivotbeamlockdowntoreleasethebeam.

5. Move thebeamto theverticalposition.Secureitwith

thebeamlockonthe reservoirtankassembly.

Figure 4-4

Transporting the Log Splitter

IMPORTANT:Alwaysturnfuelvalveto OFFposition

beforetransportingthe logsplitter.

.

Lowerthebeamto its horizontalposition.Makecer-

tainthe beamislockedsecurelywiththehorizontal

beamlock.

2. Removespringclipandclevispin fromjack stand.

3. Supportthetongueandpivotthejackstandup

againstthetongue.See Figure4-4.

4. Securewiththespringclipandclevispinpreviously

removed.See Figure4-4.

5. Attachcouplerhitchtoa class I orhigher2" ballon a

towingvehicle;latchsecurely.

a. If couplerhitchdoesnotfit on ball:Turn

adjustmentnutoneturn counter-clockwise.

b. If couplerhitch istoo loose on ball: Turn

adjustmentnutoneturn clockwise.

6. Connectthesafetychainsto thetowingvehicle.

7. Pluginthetaillights,ifso equipped,tothe tail light

connectoron the towvehicle.

Operatin

Do not tow faster than

45mph and check

local, state, and federal

requirements before

towing on any public

road.

_ ARNING:Alwaysusethe logsplitter

Tolowerthebeam:

1. Pullout the verticalbeamlockonthereservoirtank.

2. Pivotbeamlockdowntoreleasethebeam.

3. Carefullypullbackon beamandlowerit tothe

horizontalposition.Thehorizontalbeamlockwilllock

automatically.SeeFigure4-1.

inthe verticalpositionwhen splitting

heavy logs.

,__i= WARNING:Do not tow faster than

NOTE:Usecautionwhen backingup.It isrecom-

mendedtousea spotteroutsidethevehicle.

45mphand checklocal, state,and

federal requirementsbefore towing on

any publicroad.

11

Page 12

WARNING

Donotat anytime

make any adjustments

without first stopping

engine, disconnecting

spark plugwire, and

grounding it against

,the engine. Always

iwear safety glasses

during operation or

while performing any

iadjustments or repairs.

Before cleaning,

i!ubricating, repair=

rag,or inspecting,

,disengage the control

ileverand stop engine.

iDisconnect the spark

plugwire and ground

itagainst the engine

to prevent unintended

starting. Always wear

safety glasses during

operation or while

iperforming any adjust-

iments or repairs.

Lock Nut

Figure 5=1

__i WARNING:Donot at any time make

any adjustmentswithout first stopping

engine,disconnecting sparkplug wire,

and groundingit against the engine.

Alwayswear safety glassesduring

operationor while performingany

adjustments or repairs.

Wedge Assembly Adjustment

Asnormalwearoccursandthereisexcessive"play"

betweenthe wedgeandbeam,adjustthe boltsonthe

sideof thewedgeassemblytoeliminateexcessspace

betweenthe wedgeandthe beam.

1. Loosenthejam nutson thetwoadjustmentboltson

thesideof the wedge.SeeFigure5-1.

2. Turntheadjustmentboltsin untilsnugandthenback

themoffslowly(approximately1.5turns)untilthe

wedgeassemblywillslideonthebeam.

3. Re-tightenthejam nutssecurelyagainsttheside

ofthewedgeto securetheadjustmentboltsin this

position.

Gib Adjustment

Periodicallyremoveand replacethe "gibs"(spacers)

betweenthe wedgeassemblyandthebackplate.

NOTE:Thegibsmayberotatedand/orturnedoverfor

evenwear.

1. Loosenthelocknutsundereach backplateand slide

thegibsout.See Figure5-1.

2. Turnor replacethegibs.

3. Reassemblethebackplateandsecurewiththe lock

nuts.

4. Readjusttheboltson the sideofthewedgeassembly.

WARNING:Beforecleaning,lubricating,

repairing,or inspecting,disengage

the control lever and stop engine.

Disconnectthe spark plug wire and

ground itagainst theengine to prevent

unintended starting. Always wear

safety glassesduring operation orwhile

performingany adjustments or repairs.

Conditions that Will Void Warranty

1. Failuretomaintainproperfluidlevel inreservoir

2. Changingthe reliefvalvesettingorpressureadjust-

mentofcontrolvalvewithoutproperknowledgeand

instructionfromthefactory

__ WARNING:Nigher pressurecould

3. Disassemblingthepump

4. Useofincorrecthydraulicfluid

5. Allowingtheflexiblepumpcouplertodeteriorate

withoutproperandregularinspection

6. Lackoflubricationor improperlubricationof the beam

orunit

7. Improperadjustmentofsplittingwedge

8. Excessiveheatingof the hydraulicsystem

9. Attemptingtostartunitin temperaturesunder20°F

withoutpre-heatingfluidin reservoir

10.Unattendedleaksinhydraulicsystem

cause the hoses to burst, cylinder

to rupture,and intensefluid to be

released,which could resultinserious

personalinjury.

iHigher pressurecould

icause the hoses to

burst, cylinderto rup-

iture, and intensefluid

to be released, which

could result inserious

ipersonal injury.

12

Page 13

Hydraulic Fluid and Inlet Filter

• Checkthehydraulicfluidlevelinthelogsplitter

reservoirtankbeforeeachuse.Maintainfluidlevel

withintherangespecifiedonthedipstickat alltimes.

• Changethe hydraulicfluidinthereservoirevery100

hoursof operation.Followthe stepsbelow:

1. Disconnectthesuctionhosefromthebottomof the

reservoirtank.

2. Carefullyunthreadtheinletfilterandcleanitwith

penetratingoil. SeeFigure5-2.

3. Allowthefluidto drainintoa suitablecontainer.

4. Reinsertthefilterand refillthereservoirwiththree(3)

gallonsof oil. ApprovedfluidsincludeDexron®III/

Mercon®IIIautomatictransmissionfluid,a 10Weight

AWhydraulicoilor Pro-MixTM AW-32HydraulicOil.

• Maintainfluidlevelwithintherangespecifiedonthe

dipstickat alltimes.Whencheckingthefluid,always

makesuretotightenthe dipstickuntilthetopofthe

threadsareflushwiththe topof the pipe.

NOTE:Alwaysdisposeofused hydraulicfluidandengine

oil at approvedrecyclingcentersonly.

Contaminantsinfluidmaydamagethehydraulic

components.Flushingthe reservoirtankandhoses

withkerosenewheneverserviceisperformedon

thetank,hydraulicpumpor valveisrecommended.

Contactan authorizedservicedealer.

Figure 5=2

• Makecertainto readjusttheadjustmentboltsso

wedgemovesfreely,butnoexcessspaceexists

betweenthe wedgeplateandthebeam.

Hose Clamps

• Check,beforeeachuse,ifhoseclampsonthe

suctionhose(attachedtothesideofthepump)are

tight.Checkthehoseclampson the returnhoseat

leastoncea season.

WARNING

Hydraulic Filter

• Changethe hydraulicfilterevery50hoursofopera-

tion. Useonly a 10micronhydraulicfilter.Orderpart

number723-0405.

Beam and Splitting Wedge

• Lubricatebothsidesof the beam(whereitcomesinto

contactwiththesplittingwedge),beforeeachuse,

withengineoil.Thewedgeplateon the logsplitteris

designedsothegibson the sideof thewedgeplate

canbe removedand rotatedand/orturnedoverfor

evenwear.

Engine

Refertotheseparateenginemanualforallmaintenance

instructions.

Flexible Pump Coupler

Theflexiblepumpcouplerisa nylon"spider"insert,

locatedbetweenthe pumpandthe engineshaft.Over

time,the couplerwillhardenanddeteriorate.

Replacethecouplerifyoudetectvibrationor noise

comingfromtheareabetweentheengineandthe

pump.If the couplerfailscompletely,youwillexperience

a lossofpower.

NOTE:Alwaysdispose

of used hydraulic

fluidand engineoil at

approvedrecycling

centersonly.

IMPORTANT

Neverhit the engine

shaft inany manner,

as a blowwill cause

permanentdamageto

the engine.

13

Page 14

Figure 5=3

6. Installpumpcouplinghalfand keyon pumpshaft.

Rotatecouplinghalfuntil setscrewfacesopeningin

shield.Donottightensetscrew.

7. Installnylon"spider"ontoenginecouplinghalf.

8. Alignpumpcouplinghalfwith nylon"spider"byrotat-

ingengineusingstarterhandle.Slidecouplinghalf

intoplacewhileguidingthreemountingboltsthrough

holesin pumpsupportbracket.

9. Securewithnuts removedearlier.

10.Set.010"to.060"clearance/gapbetweenthe nylon

"spider"andtheenginecouplinghalfbyslidinga

feelergaugeor matchbookcoverbetweenthenylon

"spider"andtheenginecouplinghalfand moving

pumpcouplinghalfas needed.Securepumpcoupling

halfwith setscrew.SeeFigure5-3.

NOTE:Makecertainproperclearance/gapisobtained

beforetighteningsetscrew.

WARNING

'Excessive pressure

when seating beads

_maycausetire/rim

_assembly to burst

with force sufficientto

cause serious injury.

Referto sidewall of

,tire for recommended

;pressure.

IMPORTANT:Neverhittheengineshaftinanymanner,

asa blowwillcausepermanentdamagetotheengine.

1. Removethreenutsthat securethepumptothe

couplingshield.Twonutsareat the bottomcorners

andoneisin thetopcenter.SeeFigure5-3.

2. Removethepump.

3. Rotatetheenginebyslowlypullingstarterhandle

untilenginecouplinghalfset screwisvisible.Loosen

setscrewusingallenwrenchandslidecouplinghalf

offengineshaft.

4. Loosenset screwon pumpcouplinghalfand remove

couplinghalf.

5. Slidenewenginecouplinghalfontothe engine

shaftuntil theendofthe shaftisflushwiththe inner

portionof the couplinghalf.(Theremustbespace

betweenthe endoftheenginesupportbracketand

couplinghalf).Tightensetscrew.

Tires

Seesidewalloftireforrecommendedpressure.Under

anycircumstancesdo notexceedmanufacturer'srecom-

mendedpsi.Maintainequalpressureonalltires.

,_l_k,, WARNING:Excessivepressurewhen

seatingbeads may causetire/rim as-

sembly to burst with force sufficient to

cause serious injury.Referto sidewall

of tire for recommendedpressure.

14

Page 15

Storing Your Log Splitter

Prepareyourlog splitterforstorageattheendof the

seasonor ifthelog splitterwillnotbeusedfor30 daysor

more.

_ WARNING:Neverstoremachine with

1. Cleanthelog splitterthoroughly.

NOTE:Wedo notrecommendtheuseof pressurewash-

ersor gardenhosetocleanyourunit.Theymaycause

damageto bearingsortheengine.Theuseofwaterwill

resultinshortenedlifeand reduceserviceability.

2. Wipe unitwithanoiled ragto preventrust,especially

on thewedgeandthebeam.

3. Drainfueltank.Alwaysdrainfuelintoapproved

containeroutdoors,awayfromopenflame.Besure

thatengineiscoolbeforedrainingthefuel. Donot

smokewhilehandlingfuel.

fuel inthe fuel tank insideof building

where fumes may reach an open flame

or spark,or where ignitionsources are

presentsuchas hotwater and space

heaters,furnaces, clothesdryers,

stoves,electricmotors, etc.

4. Starttheengineandletitrununtilthefuellinesand

carburetorareempty.

5. Removesparkplug.Holdingaragoverthecylinder

hole,pourapproximately1/2ounce(approximately

onetablespoon)ofengineoil intocylinderandcrank

slowlyto distributetheoil.

6. Replacesparkplug.

7. Do not storegasolinefromoneseasonto another.

8. Replaceyourgasolinecanif it startsto rust.Rust

and/ordirt inthegasolinewillcauseproblems.

9. Storeunitina clean,dryarea.Donotstorenextto

corrosivematerials,suchasfertilizer.

NOTE:if storinginan unventilatedor metalstorage

shed,becertainto rustprooftheequipmentby coating

witha lighto11orsilicone.

Maintaining

WAR

Neverstor

with fuel in the fuel

tank insideofbuilding

where fumes may

reach an open flame

r sparki 0r where

ignitionsources are

presentsuchashot

water and space heat'

ers, furnaces, clothes

dryers; stoves, electric

motors, etc,

15

NOTEi we do not

recommendtheuse of

pressure washersor

gardenhoseto Clean

your UniLThey may

cause damageto bear,

ngSOrthe engine;The

useof waterwill result

in shortened lifeand

reduce serviceability.

Page 16

For repairsbeyond

the minor ad/ust-

merits listed hem

Problem Cause Remedy

Enginefails to start 1. Sparkplugwiredisconnected. 1. Connectwireto sparkplug.

2. Fueltankemptyor stalefuel. 2. Filltankwithclean,freshgasoline.

3. Choke if equippednotinCHOKE 3. Movechoketo CHOKEposition.

position.

4. Faultysparkplug. 4 Clean,adjustgap,or replace.

5. Blockedfuelline. 5. Cleanfuelline.

6. Engine(if equippedwitha primer)not 6. Primeengine.

primedproperly. 7. Movethrottleleverto FASTposi-

7. Throttlecontrollevernotin correct tion.

startingposition

Engineruns erratic

equipped.

2. Sparkplugwireloose.

3. Blockedfuellineor stalefuel.

4. Waterordirt infuel system.

1. MovechokelevertoOFFposition.1. UnitrunningwithCHOKEapplied,if so

2. Connectandtightenspark

plugwire.

3. Cleanfuelline;fill tankwith clean,

fresh(lessthan30 daysold)

gasoline.

4. Drainfueltank.Refillwith

freshfuel.

I ¸

I i iii_

I i i i i

I_ _ i i

I i i i i

I i i_ i

5. Dirty aircleaner. 5. Cleanorreplaceaircleaner.

6. Carburetornotadjustedproperly. 6. Seeauthorizedservicedealer.

EngneOverheats EngineOillevel owl 11 FillCrankcaseWithproperoil.

2. Dirty aircleaner. 2. Cleanorreplaceair cleaner.

31 carburetornotadjustedproperlyl 3. Seeauthoiizedservicedealeil

Problem

Cylinder rodwill not

move

1. Brokendriveshaft.

2. Shippingplugsleft inhydraulichoses.

3. Set screwsincouplingnotadjusted

properly.

4. Looseshaftcoupling.

5. Gearsectionsdamaged.

6. Damagedreliefvalve.

7. Hydrauliclinesblocked.

8. Incorrectoil level.

9. Damageddirectionalvalve.

10.Blockeddirectionalvalve.

Cause

Remedy

1. Seeauthorizedservicedealer.

2. Disconnecthydraulichoses,

removeshippingplugs,reconnect

hoses.

3. Seeoperator'smanualforcorrect

adjustment.

4. Correctengine/pumpalignmentas

necessary.

5. Seeauthorizedservicedealer.

6. Seeauthorizedservicedealer.

7. Flushandcleanhydraulicsystem.

8. Checkoil level.

9. Seeauthorizedservicedealer.

lO.Flushandcleanhydraulicsystem.

16

Page 17

Problem Cause Remedy

Slowcy indershaft I 1, Gearsectionsdamaged• I 1.Seeauthorizedservicedealer•

speedwhile extending 2. Excessivepumpinletvacuum. 2. Makecertainpumpinlethosesare

and retractng cearandunblocked-useshort,

LeakingCylinder 1. Brokenseals. 1. Seeauthorizedservicedealer.

Engineruns but wood 1. Smallgearsectiondamaged. 1. Seeauthorizedservicedealer.

will not split or wood 2. Pumpcheckvalveleaking. 2. Seeauthorizedservicedealer.

splits too slowly 3. Excessivepumpinletvacuum. 3. Makecertainpumpinlethosesare

Enginestalls during 1. Lowhorsepower/weakengine. 1.

splitting 2. Overloadedcylinder. 2.

I

3. Slowenginespeed

4. Damagedreliefvalve•

5 Incorrectoillevel•

6. Contaminatedoil.

7. Directionalvalveleakinginternally•

I 8. Internallydamagedcylinder.

2. Scoredcylinder. 2. Seeauthorizedservicedealer.

4 Incorrectoillevel. 4. Checkoillevel.

5. Contaminatedoil. 5. Dran o c eanreservor,and ref .

6. Directionalvalveleaknginternally. • i i .

• y . •

I 7 Overloadedc linder I 7 Donotattempttosp twood

8. nternallydamagedcylinder.

!

largediameterinlethoses,

3 Seeauthorzedservcedeaer

4 Seeauthorzedservce deaer

5 ChecKo eve

6 Dran o c eanreservor and ref

7Seeauthorzedservce deaer

8.Seeauthorzedservce deaer.

clearandunblocked

6 Seeauthorzedservcedeaer

I aganstthe gran

8. Seeauthorzedservcedeaer.

Seeauthorizedservicedealer.

Donotattemptto splitwood

againstthegrainor seeauthorized

servicedealer.

ydraulic

Trouble

Shootin

ments listed here,

contact an authorized

service dealer.

Engine wil! not turn Or Engine!PumPmisallgnmenL 1! Collect alignmentas necessa[y!

stalls under low load 2: Frozenorseizedpump. 2 See authorizedservicedealer.

conditions 31 LowhorsepOwer/weakengine, see authorizedservicedealerl

Hydrau!ic!inesbloCk_d Flushandcleanhydrau!icsyste_

5,Blocked directionalvalve: 5: Flush andclean hydraulicsystem.

Leakingpump shaft

seal

1. Brokendriveshaft.

2. Engine/pumpmisalignment.

3. Gearsectionsdamaged.

4. Poorlypositionedshaft seal.

5. Pluggedoilbreather.

1. Seeauthorizedservicedealer.

2. Correctalignmentas necessary.

3. Seeauthorizedservicedealer.

4. Seeauthorizedservicedealer.

5. Makecertainreservoiris properly

vented.

17

Page 18

Model Series 550 Thru 570

i

'L4_, :4_

A

18

To secure

ground wire

Page 19

Ref. PartNo. Description

No.

1. 718-0769A HydraulicCylinder

2. 727-04166 HydraulicTube

3. 710-1018 HexCapScrew1/2-20x 2.75

4. 737-0192 90 DegreeSolidAdapter

5. 718-0481A ControlValve

6. 737-0153 ReturnElbow

7. 737-0238 NipplePipe1/2-14

8. 710-1806 HexCapScrew1/2-13x 3.25

9. 719-0550A WedgeAssembly

10. 712-3058 HexLockNut,1/2-20

11. 712-0711 HexJamNut3/8-24

12. 710-0459A HexCapScrew3/8-24x 1.5

13. 781-0351 AdjustableGib

14. 736-0116 FlatWasher.635x.93x.06

15. 712-3022 HexLockNut1/2-13

16. 681-04071A BeamAssembly

17. 710-3056 HexScrew,5/16-18x 3.25

18. 710-0654A HexWasherScrew3/8-16x 1.0

19. 781-1048A DislodgerBracket

20. 781-0790 BackPlate

21. 737-04093 inletFilter

22. 727-0443 ReturnHose3/4" IDx44" Lg.

23. 726-0132 HoseClamp5/8"

24. 737-0316 FilterHousing

25. 723-0405 Oil Filter

26. 734-0873 HubCap

27. 714-0162 CotterPin

28. 712-0359 SlottedNut3/4-16

29. 634-0186 WheelAssembly

30. 736-0351 FiatWasher.760IDx.500OD

31. 737-0312 Adapter3/4-14

32. 781-0526At HoseGuard

33. 737-0348A VentedDipstick

34. 711-1587 ClevisPin

35. 781-0690 LockRod

36. 714-0470 CotterPin

37. 726-0214 PushCap

38. 732-0583 CompressionSpring

39. 781-04180 LogTrayBracket

40. 710-0650 TT Screw,5/16-18x.875

41. 712-04065 FlangeLockNut,3/8-16

42. 781-04179 LogTray

Ref. PartNo. Description

No.

43. 681-04040A FrameAssembly

44. 710-0521 HexBolt3/8-16x3"

45. 719-0353 CouplingShield

46. 714-0122 SquareKey3/16"x.75

47. 718-04145 FlexibleCoupling

48. 712-04063 FlangeLockNut,5/16-18

49. 781-0097 RearCouplingSupportBracket

50. 781-1024 FenderMountingBracket

51. 727-04130 Hose

52. 718-04127 GearPump

53. 737-0329 45 DegreeElbowFitting

54. 727-0502 HighPressureHydraulicHose

55. 781-0788 TongueAssembly

56. 747-1261 LatchRod

57. 781-1045 Latch

58. 732-3127 CompressionSpring

59. 736-0371 FiatWasher

60. 781-0538At HoseGuard

61. 710-3085 HexCapScrew,3/8-16x3.50

62. 736-0185 FlatWasher,.375x.738x.063

63. 747-04539 HydraulicValveControl

64. 681-04030 HitchCouplingAssembly

65. 713-0433A Chain

66. 731-2496A Fender(Black)

731-2499A Fender(Red)

67. 711-0813 ClevisPin

68. 720-04088 Grip

69. 732-0194 SpringPin

70. 781-0789 JackStand

71. 715-0120 SpiralPin

72. 710-0650 TT Screw,5/16-18x0.875"

73. 710-0602 TT Screw,5/16-18x 1.00

74. 625-0062t LightKit

75. 681-0164t LightBracket- LH

781-1027At LightBracket- RH

76. 710-0874t Screw,5/16-18x1.25

77. 712-3008t Jam Nut,3/8-16

78. 726-0201t SpeedNut, .3125ID

79. 711-04585 ClevisPin

80. 713-04036 ValveHandleLink

81. 714-0111 CotterPin

82. 710-0376 HexScrew,5/16-18x1.00

t If Equipped

ENUiNE

_FACTORY PARTS

Toorder replacement

parts, call

1-800-800-7310

or visit

www.mtdproducts.com

19

Page 20

MANUFACTURER'S LiMiTED WARRANTY FOR

ThelimitedwarrantysetforthbelowisgivenbyMTDLLCwithrespect

tonewmerchandisepurchasedandusedin theUnitedStates,its

possessionsandterritories.

"MTD"warrantsthisproductagainstdefectsinmaterialandworkman-

shipfor a periodoftwo (2)yearscommencingonthedateoforiginal

purchaseandwill,at itsoption,repairor replace,freeofcharge,any

partfoundto bedefectiveinmaterialsorworkmanship.Thislimitedwar-

rantyshallonlyapplyifthisproducthasbeenoperatedand maintained

inaccordancewiththe Operator'sManualfurnishedwiththeproduct,

andhasnotbeensubjectto misuse,abuse,commercialuse,neglect,

accident,impropermaintenance,alteration,vandalism,theft,fire,water,

ordamagebecauseof otherperilor naturaldisaster.Damageresulting

fromthe installationor useofany part,accessoryor attachmentnot

approvedby MTDforusewiththeproduct(s)coveredbythis manual

willvoid yourwarrantyastoanyresultingdamage.

Normalwearpartsarewarrantedto befreefromdefectsinmaterialand

workmanshipfor a periodofthirty(30)daysfromthe dateof purchase.

Normalwearpartsinclude,butare notlimitedto itemssuchas: batter-

ies,belts,blades,bladeadapters,grassbags,riderdeckwheels,seats,

snowthrowerskidshoes,shaveplates,augerspiralrubberandtires.

HOW TO OBTAINSERVICE: Warrantyservice isavailable,WITH

PROOFOF PURCHASE, through your localauthorized service

dealer.Tolocate the dealer in yourarea, check yourYellowPages,

or contact MTD LLC at RO. Box361131,Cleveland, Ohio 44136-

0019,or call 1-800-800-7310or 1-330-220-4683 or log on to our

Website at www.mtdproducts.com.

Thislimitedwarrantydoesnot providecoverageinthefollowingcases:

a. Theengineor componentpartsthereof.Theseitemsmaycarrya

separatemanufacturer'swarranty.Referto applicablemanufacturer's

warrantyfortermsandconditions.

b. Logsplitterpumps,valves,andcylindershavea separateoneyear

warranty.

c. Routinemaintenanceitemssuchaslubricants,filters,blade

sharpening,tune-ups,brakeadjustments,clutchadjustments,deck

adjustments,andnormaldeteriorationoftheexteriorfinishdueto

useor exposure.

d. Servicecompletedbysomeoneotherthananauthorizedservice

dealer.

e. MTDdoesnotextendanywarrantyforproductssoldor exported

outsideoftheUnitedStates,its possessionsandterritories,except

thosesoldthroughMTD'sauthorizedchannelsofexportdistribution.

f. ReplacementpartsthatarenotgenuineMTDparts.

g. Transportationchargesandservicecalls.

Noimpliedwarranty,includingany impliedwarranty of mer-

chantabilityof fitness for a particular purpose,applies after the

applicable periodof expresswritten warranty aboveasto the

partsasidentified.Nootherexpresswarranty,whetherwrittenor

oral, exceptas mentioned above,givenby any personor entity,

includingadealeror retailer, withrespect to any product,shall

bindMTD.Duringthe periodof the warranty,the exclusiveremedy

isrepairor replacementof the productas setforth above.

Theprovisionsasset forth inthis warrantyprovidethesoleand

exclusiveremedy arising from the sale.MTDshallnot be liable

for incidentalor consequentiallossor damageincluding,without

limitation, expensesincurredfor substituteor replacementlawn

careservicesor for rentalexpensesto temporarily replacea

warranted product.

Somestatesdo notallowthe exclusionor limitationofincidentalor

consequentialdamages,orlimitationsonhowlongan impliedwarranty

lasts,sotheaboveexclusionsorlimitationsmaynotapplytoyou.

Innoeventshallrecoveryofanykindbegreaterthantheamountofthe

purchasepriceof the productsold.Alterationof safetyfeaturesof

the productshallvoid this warranty.Youassumetheriskandliability

forloss,damage,orinjurytoyou andyourpropertyand/ortoothersand

theirpropertyarisingoutofthemisuseorinabilitytousethe product.

Thislimitedwarrantyshallnotextendtoanyoneotherthantheoriginal

purchaserorto the personforwhomitwas purchasedas a gift.

HOWSTATELAWRELATESTOTHISWARRANTY:This limited

warrantygivesyouspecificlegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

IMPORTANT:OwnermustpresentOriginalProofof Purchasetoobtain

warrantycoverage.

IVITDLLC, P.O. BOX 361131 CLEVELAND, OHiO 44136-0019; Phone: 1=800=800-7310, 1-330=220-4683

GDOO-lO0015 REV.A

Loading...

Loading...