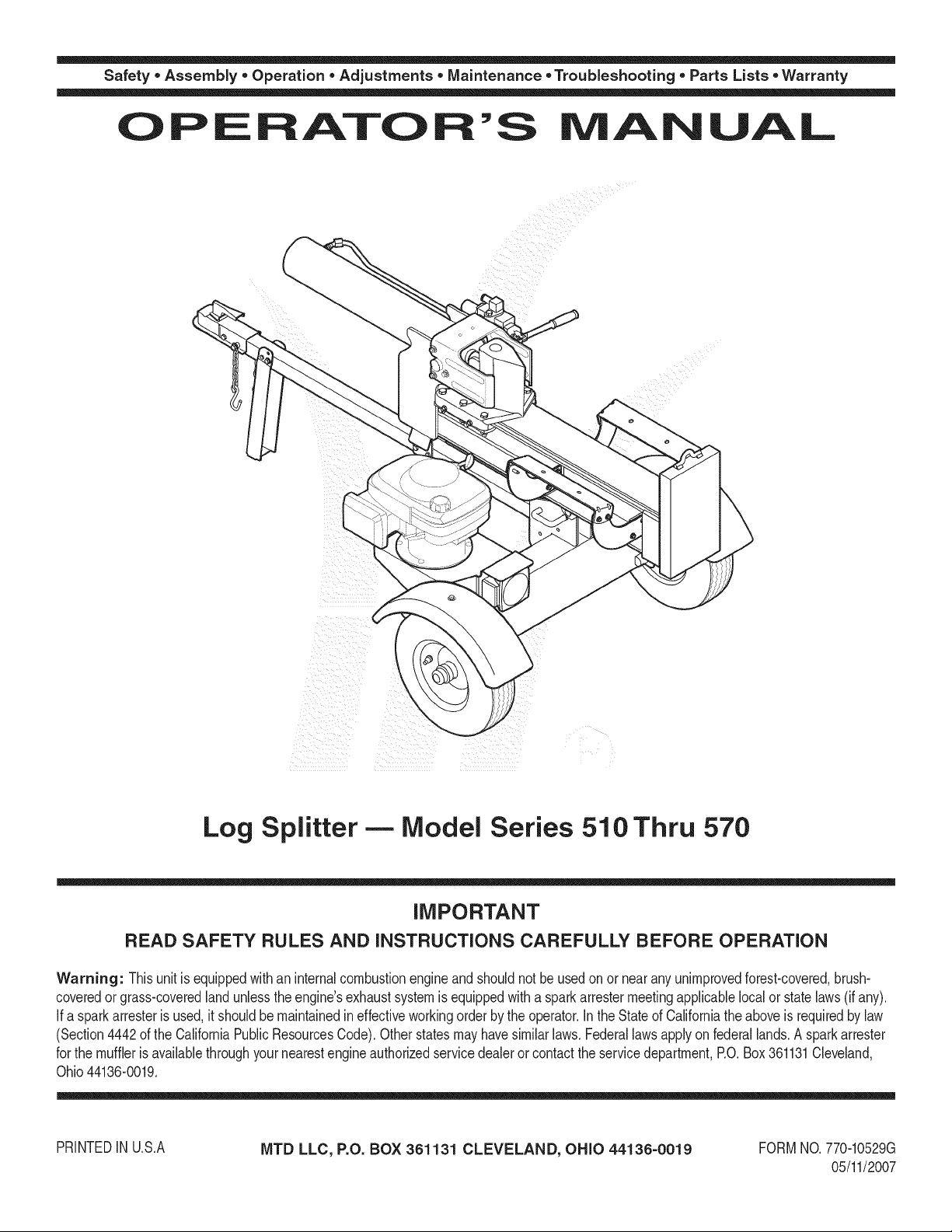

MTD 24BF550B000 Owner’s Manual

Safety • Assembly • Operation • Adjustments • Maintenance • Troubleshooting • Parts Lists • Warranty

OF A O A AL

Log Splitter -- Model Series 510 Thru 570

iMPORTANT

READ SAFETY RULES AND iNSTRUCTiONS CAREFULLY BEFORE OPERATION

Warning: Thisunitisequippedwithan internalcombustionengineandshouldnotbeusedonor nearanyunimprovedforest-covered,brush-

coveredor grass-coveredlandunlesstheengine'sexhaustsystemisequippedwitha sparkarrestermeetingapplicablelocalor statelaws(if any).

If a sparkarresterisused,it shouldbemaintainedineffectiveworkingorderbythe operator.IntheStateofCaliforniatheaboveis requiredbylaw

(Section4442oftheCaliforniaPublicResourcesCode).Otherstatesmayhavesimilarlaws.Federallawsapplyonfederallands.A sparkarrester

forthemufflerisavailablethroughyournearestengineauthorizedservicedealeror contacttheservicedepartment,RO.Box361131Cleveland,

Ohio44136-0019.

PRINTEDINU.S.A

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136=0019

FORMNO.770-10529G

05/11/2007

This Operator's Manual is an important part of your new log splitter, it will help you assemble,

prepare and maintain the unit for best performance. Please read and understand what it says.

Table of Contents

Safety Labels ......................................... Page 3

Safe Operation Practices ...................... Page 4

Setting UpYour Log Splitter ................. Page 6

Operating Your Log Splitter .................. Page 8

Maintaining Your Log Splitter ............ Page 12

Finding and Recording IVlodel Number

BEFOREYOUSTARTASSEMBLING

YOURNEW EQUIPMENT

Pleaselocatethe model plate on the equipment andcopy the

informationto the sample model plate providedto the right.

You can locatethe model plate bystanding behind the unit

and lookingdown at the hydraulictank.This informationwillbe

necessaryto usethe website or obtain assistancefromyour

MTDdealer.

Troubleshooting ................................... Page 16

illustrated Parts List ............................ Page 18

Warranty ............................................... Page 20

Spanish Section ........................... Pages 21-40

F

Model Number

, www, rntdproducts.com

Serial Number

MTD LLC

P.O. BOX 361131

CLEVELAND, OH 44136

330-220-4683

800-800-731 0 /

Customer Support

Please do IVOTreturn the unit to the retailer from which it was

purchased, without first contacting Customer Support.

Ifyou have difficulty assemblingthis product or have any questions regardingthe controls,operation,or maintenanceofthis

unit,youcanseek help fromthe experts.Choosefrom the options below:

1. Visit mtdproducts.com. Clickon the CustomerSupport menu option.

2. Phonea CustomerSupport Representativeat 1-800-800-7310. Spanishspeakingagentsare available.

3. The engine manufacturer is responsiblefor all engine-relatedissueswith regardsto performance,power-rating,specifica-

tions,warranty andservice. Pleasereferto theengine manufacturer'sOwner's/Operator's Manual,packedseparatelywith

your unit, for more information.

2

Safety Labels Found On Your Log Splitter

oREVERSE

=NEUTRAL

='FORWARD

LOG

DISLODGER

Retract wedge,

lodged wood will be

automatically removed.

WARNING

DO NOT remove safety

(or any) labels from log

_plitter for any reason.

I_B_MOVING LOG SPLITTER BY HAND = coup er a jus men i_ nee e, re er o

* Lock jack stand in down position, position.

" DO not attempt to move log splitter = Attach safety chai.s to tow vehicle.

up or down a slope by hand = Do not tow faster than 45 mph.

TOWING LOG SPLITTER High speed may cause Ios_ of control.

Lock beam i. horizontal osition. = Check local, state a.d federal .

I_ _. Lock beam in horizontal position. = Raise jack stand and latch securely iM full up

h,_ ,eq........ b.... tow,.g.... ypub..... d.

3

WARNING: EngineExhaust,some of its constituents,andcertain vehiclecompo-

nentscontain or emit chemicals knownto Stateof Californiato cause cancer and

birth defects or other reproductiveharm.

DANGER: This machinewas builtto beoperatedaccordingto the rulesfor safe operation in this

manual.As with anytype of power equipment,carelessness or error on the part ofthe operatorcan

result in seriousinjury.This machineiscapable of amputatinghands andfeet andthrowing objects.

Failureto observethe followingsafetyinstructionscould resultin serious injury or death.

i WARNING

Thissymbol points

outimportant safety

instructionswhich, if

notfollowed,could

endangerthe personal

Soafetyand/or property

f yourself and others.

i Readandfollow all

I instructionsinthis man-

ualbeforeattempting to

operatethis machine.

Failureto complywith

i these instructionsmay

I resultin personalinjury.

Whenyou see this

symbol -

HEED ITS WARNING

Your

I = = w

i Responsubuluty

Restrictthe use

i of this power machine

i to personswho read,

understand

and followthe warnings

and instructions

inthis manual.

General Practices

1. Read,understand,andfollowallinstructionson the

machineand inthemanual(s)beforeattempting

toassembleandoperate.Keepthismanualin a

safeplaceforfutureandregularreferenceandfor

orderingreplacementparts.

2. Befamiliarwithall controlsandproperoperation.

Knowhowtostopthemachineanddisengagethem

quickly.

3. Neverallowchildrenunder16yearstooperatethis

machine.Children,16yearsandover,shouldread

andunderstandinstructionsandsafetyrulesinthis

manualandshouldbetrainedandsupervisedbya

parent.

4. Neverallowadultstooperatethismachinewithout

properinstruction.

5. Manyaccidentsoccurwhenmorethanoneperson

operatesthemachine.Ifa helperisassistinginload-

inglogs,neveractivatethecontroluntilthehelperis

a minimumof 10feetfromthemachine.

6. Keepbystanders,helpers,pets,andchildrenat least

20feetfromthe machinewhileitisinoperation.

7. Neverallowanyonetorideon thismachine.

8. Nevertransportcargoonthis machine.

9. Hydrauliclogsplittersdevelophighfluidpressures

duringoperation.Fluidescapingthrougha pin hole

openingcanpenetrateyourskinandcauseblood

poisoning,gangrene,ordeath.Giveattentiontothe

followinginstructionsatalltimes:

a. Do notcheckforleakswithyourhand.

b. Do notoperatemachinewithfrayed,kinked,

cracked,or damagedhoses,fitting,ortubing.

c. Stopthe engineand relievehydraulicsystem

pressurebeforechangingoradjustingfittings,

hoses,tubing,orothersystemcomponents.

d. Do notadjustthepressuresettingsofthepumpor

valve.

10.Leakscanbedetectedbypassingcardboardor

wood,whilewearingprotectiveglovesand safety

glasses,overthesuspectedarea.Lookfordiscolor-

ationof cardboardorwood.

11.

If injuredbyescapingfluid,seea doctorimmediately.

Seriousinfectionor reactioncandevelopifproper

medicaltreatmentisnotadministeredimmediately.

12.Keeptheoperatorzoneandadjacentareaclear for

safe,securefooting.

13.Ifyourmachineisequippedwithaninternalcom-

bustionengineanditisintendedfor usenearany

unimprovedforest,brush,or grasscoveredland,

theengineexhaustshouldbeequippedwithaspark

arrester.Makesureyoucomplywithapplicablelocal,

state,andfederalcodes.Takeappropriatefirefighting

equipmentwithyou.

14.Thismachineshouldbe usedfor splittingwoodonly,

donotuseitforanyotherpurpose.

15.Followtheinstructionsinthemanual(s)providedwith

anyattachment(s)forthismachine.

Preparation

1. Alwayswearsafetyshoesorheavyboots.

2. Alwayswearsafetyglassesorsafetygogglesduring

operatingthismachine.

3. Neverwearjewelryorlooseclothingthatmight

becomeentangledinmovingor rotatingpartsof the

machine.

.

Makesuremachineison levelsurfacebeforeoperat-

ing.

5.

Alwaysblockmachineto preventunintendedmove-

ment,andlockineitherhorizontalor verticalposition.

6.

Alwaysoperatethis machinefromtheoperator

zone(s)specifiedinthemanual.

Z

Logsshouldbecutwith squareendspriortosplitting.

8.

Uselogsplitterindaylightorundergoodartificiallight.

9.

Toavoidpersonalinjuryorpropertydamageuse

extremecareinhandlinggasoline.Gasolineis

extremelyflammableandthe vaporsareexplosive.

Seriouspersonalinjurycanoccurwhengasolineis

spilledonyourselforyourclotheswhichcanignite.

Washyourskinandchangeimmediately.

a. Useonlyanapprovedgasolinecontainer.

b. Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

c. Neverfuelmachineindoors.

d. Neverremovegascaporaddfuelwhiletheengine

ishot or running.

e. Allowenginetocoolatleasttwo minutesbefore

refueling.

4

f. Neveroverfillthefuel tank.Filltankto no more

than1/2inch belowbottomoffillerneckto provide

spaceforfuelexpansion.

g. Replacegasolinecapandtightensecurely.

h. Ifgasolineisspilled,wipeit offtheengineand

equipment,movemachinetoanotherarea.Wait5

minutesbeforestartingthe engine.

i. Neverstorethemachineor fuelcontainerinside

wherethereisan openflame,sparkor pilot lightas

on a waterheater,spaceheater,furnace,clothes

dryeror othergasappliances.

j. Allow machinetocool5 minutesbeforestoring.

Operation

1. Beforestartingthismachine,reviewthe"Safety

instructions".Failuretofollowtheserulesmayresultin

seriousinjurytotheoperatororbystanders.

2. Neverleavethismachineunattendedwiththeengine

running.

3. Donotoperatemachinewhileundertheinfluenceof

alcohol,drugs,or medication.

4. Neverallowanyonetooperatethismachinewithout

properinstruction.

5. Alwaysoperatethismachinewithall safetyequipment

inplaceandworking.Makesureallcontrolsare

properlyadjustedforsafeoperation.

6. Donotchangetheenginegovernorsettingsor

overspeedtheengine.Thegovernorcontrolsthe

maximumsafeoperatingspeedoftheengine.

7. Whenloadinga log,alwaysplaceyourhandsonthe

sidesofthelog,notontheends,andneveruseyour

footto helpstabilizea log.Failuretodo so,mayresult

incrushedoramputatedfingers,toes,hand,or foot.

8. Useonly yourhandto operatethecontrols.

9. Neverattemptto splitmorethanonelogata time

unlesstheramhasfullyextendedanda secondlogis

neededtocompletetheseparationofthefirst log.

10.Forlogswhicharenotcutsquare,theleastsquare

endandthe longestportionofthelogshouldbe

placedtowardthe beamandwedge,andthe square

end placedtowardtheendplate.

11.Whensplittingintheverticalposition,stabilizethelog

beforemovingthecontrol.Splitasfollows:

a. Placelog ontheendplateandturnuntilitleans

againstthebeamandis stable.

b. Whensplittingextralargeorunevenlogs,thelog

mustbestabilizedwithwoodenshimsor splitwood

betweenthelogandendplateorground.

12.Alwayskeepfingersawayfromany cracksthatopen

inthelogwhilesplitting.Theycanquicklycloseand

pinchoramputateyourfingers.

13.Keepyourworkareaclean,immediatelyremovesplit

woodaroundthe machinesoyoudonotstumbleover

it.

14.Nevermovethismachinewhiletheengineisrunning.

15.Thismachineshouldnotbetowedon anystreet,

highwayor publicroadwithoutcheckingtheexisting

federal,state,or localvehiclerequirements.Any

licensingor modificationssuchas taillights,etc.,

neededtocomply,is thesoleresponsibilityofthe

purchaser.Ifa"Statementof Origin"isrequiredin

yourstate,seeyourlocaldealer.

16.Donottow machinefasterthan45mph.

17.SeeTransportingtheLogSplittersectioninthis

manualforpropertowinginstructionsonceall

federal,local,or staterequirementsare met.

Maintenance and Storage

1. Stoptheengine,disconnectthesparkplugand

grounditagainstthe enginebeforecleaning,or

inspectingthemachine.

2. Stoptheengineand relievehydraulicsystem

pressurebeforerepairingoradjustingfittings,hoses,

tubing,orothersystemcomponents.

3. Topreventfires,cleandebrisandchafffromthe

engineandmufflerareas,iftheengineisequipped

withasparkarrestermuffler,cleanand inspectit

regularlyaccordingtomanufacturersinstructions.

Replaceifdamaged.

4. Periodicallycheckthatall nutsandbolts,hose

clamps,and hydraulicfittingsaretightto besure

equipmentisinsafeworkingcondition.

5. Checkall safetyguardsandshieldsto besure

theyareintheproperposition.Neveroperatewith

safetyguards,shields,orotherprotectivefeatures

removed.

6. The pressurereliefvalveis presetatthefactory.Do

notadjustthevalve.

7. Neverattemptto movethismachineoverhillyor

uneventerrainwithouta towvehicleor adequate

help.

8. Foryoursafety,replaceall damagedorwornparts

immediatelywithoriginalequipmentmanufacturer's

(O.E.M.)partsonly."Useof partswhichdonotmeet

theoriginalequipmentspecificationsmayleadto

improperperformanceandcompromisesafety!"

9. Do notalter thismachineinanymanner,alterations

suchasattachingaropeor extensiontothecontrol

handle,oraddingtothe widthor heightof thewedge

mayresultinpersonalinjury.

Your Responsibility

Restricttheuseofthispowermachinetopersonswho

read,understandandfollowthe warningsandinstruc-

tionsinthismanualandonthe machine.Alwaysfollow

directionsonsafetylabelsfoundon yourequipment.

Safe.

o,o,a.,,oo

Practices

WARNING

Thissymbol points

out importantsafety

instructionswhich, if

notfollowed,could

endangerthe personal

safety and/or property

of yourself and others.

Readand followall

instructions inthis man-

ual before attemptngto

operatethis machine.

Failureto comply with

these instructionsmay

result in personalinjury.

Whenyou see this

symbol-

HEED ITS WARNING

Your

Responsibility

Restrictthe use

ofthis powermachine

to personswho read,

understand

and followthe warnings

and instructions

in this manual.

5

,__ WARNING:Useextreme caution

__ components areveryheavyand will

NOTE:Allreferencesinthismanualtotheleft or right

sideof thelog splitterisfromtheoperatingpositiononly.

Exceptions,ifany,willbespecified.

unpacking this machine.Some

requireadditional people or mechanical

handlingequipment.

YourLog

Splitter

i

WARNING

tion unpackingthis

mach[liei Some

componentsare,ery

heavy and will require

additional people or

mechanical handling

equipmenL

Manual coversa range

of pr0ductspecifications

for Variousmodels:

Characteristicsand

featUresdiscussed

and/or illustratedin

this manual

applicableto a!l models:

MTD LLC reSerVesthe

Assembling the Tongue

Attaching the Jack Stand

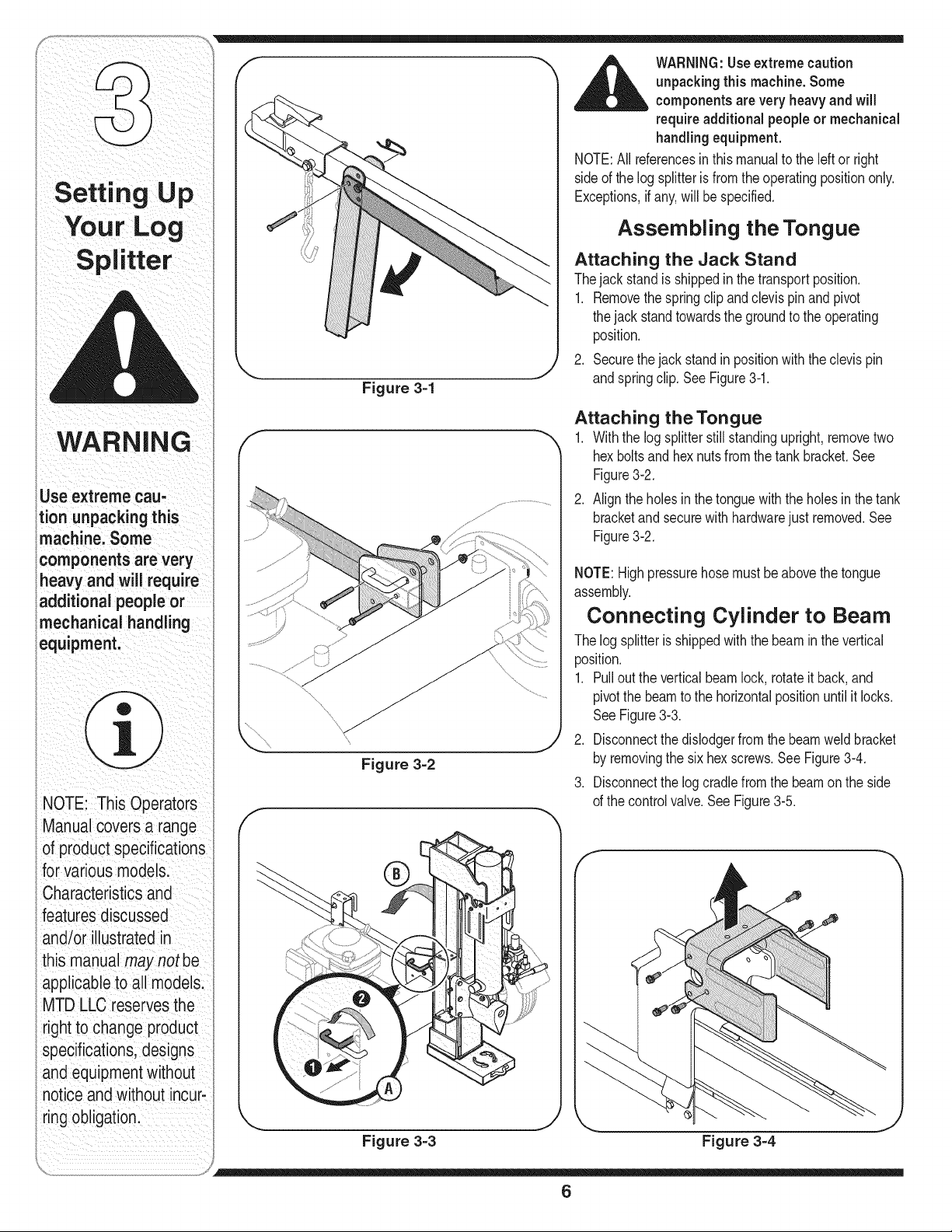

Thejackstandisshippedinthe transportposition.

1. Removethespringclipandclevispinand pivot

thejackstandtowardsthegroundto theoperating

position.

2. Securethejackstandinpositionwiththeclevispin

Figure 3-1

andspringclip.SeeFigure3-1.

Attaching the Tongue

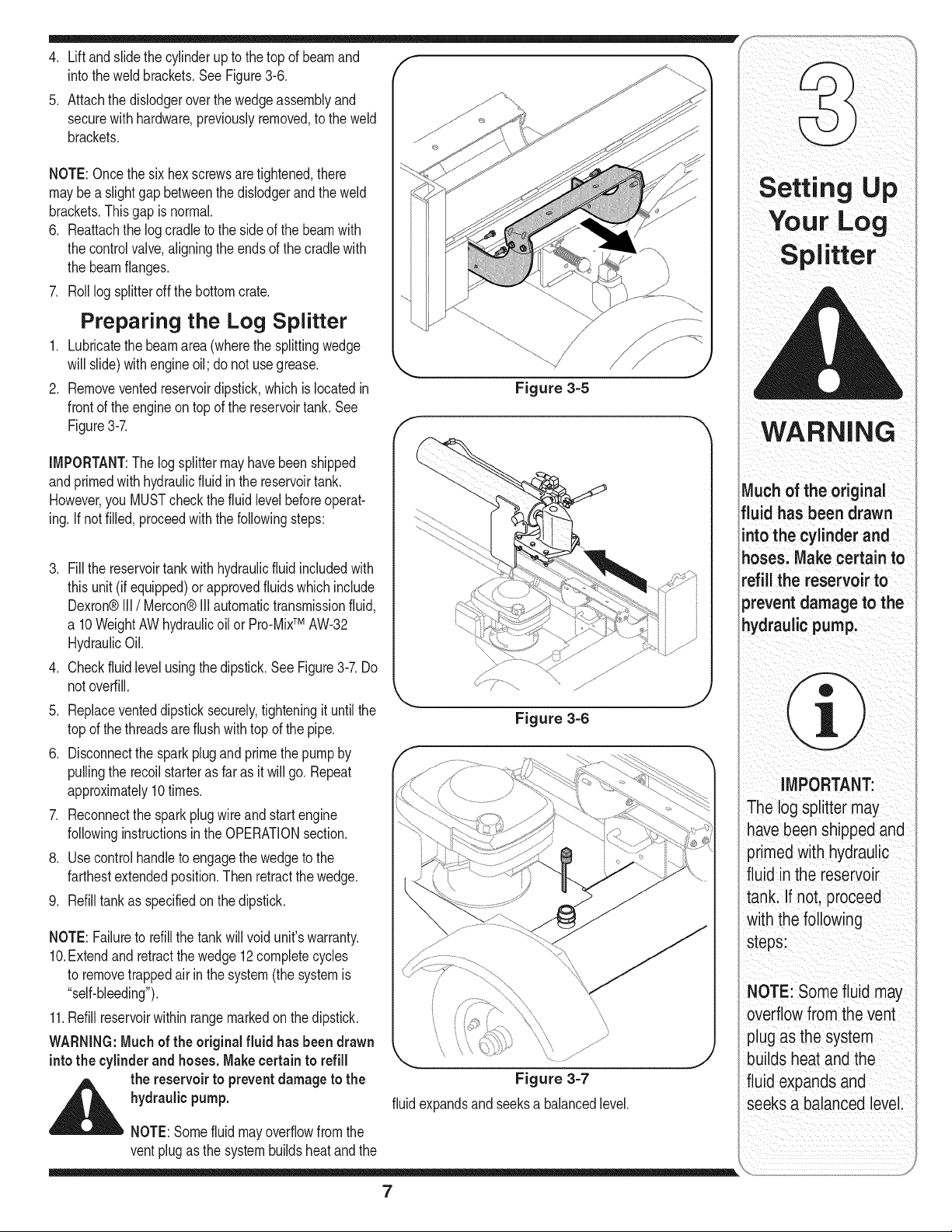

_'X 1. Withthelogsplitterstillstandingupright,removetwo

..................................2. Aligntheholesinthetonguewiththe holesin the tank

hexboltsandhexnutsfromthetankbracket.See

Figure3-2.

bracketandsecurewithhardwarejustremoved.See

Figure3-2.

NOTE:Highpressurehosemustbeabovethetongue

assembly.

Connecting Cylinder to Beam

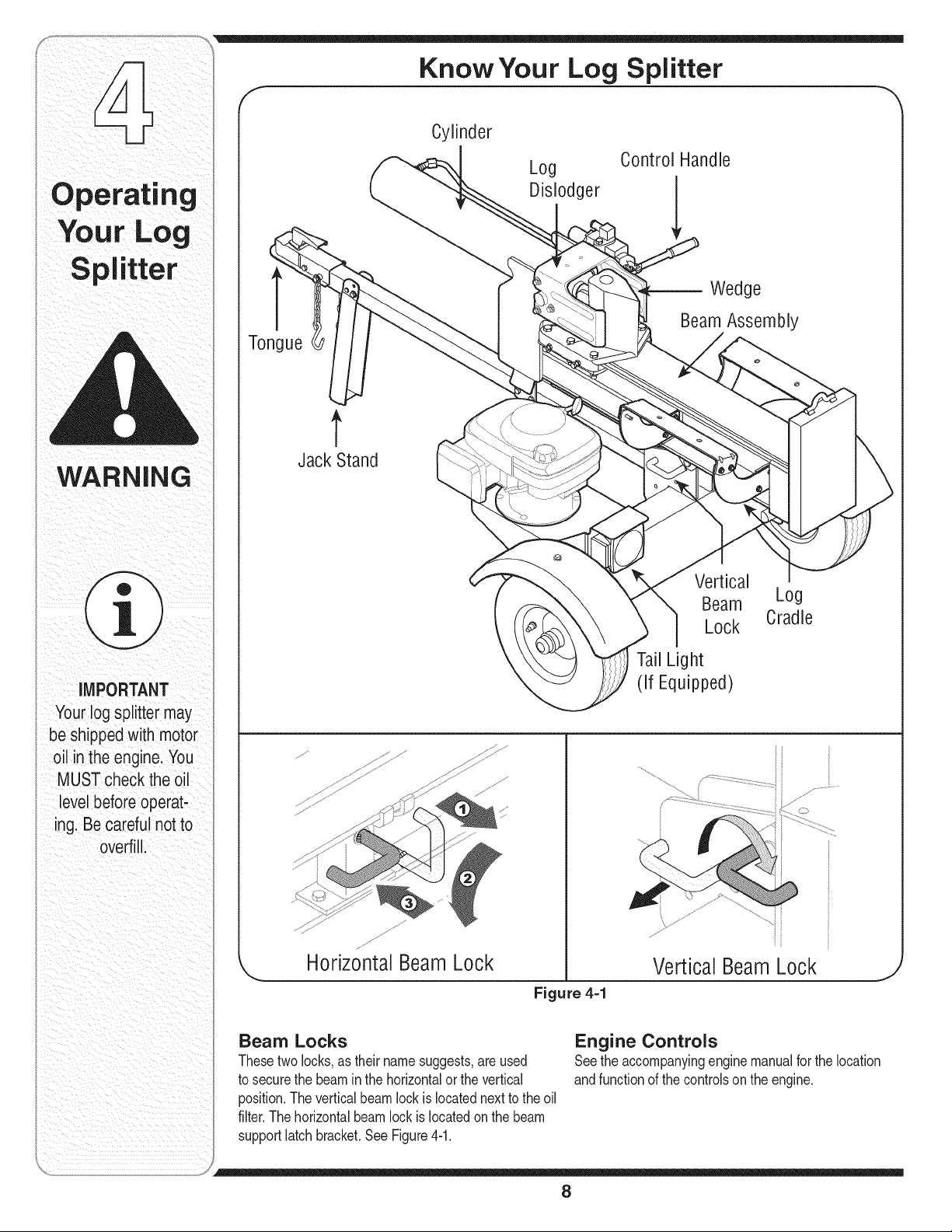

Thelog splitterisshippedwiththe beamin thevertical

position.

1. Pullouttheverticalbeamlock,rotateitback,and

pivotthebeamtothehorizontalpositionuntilitlocks.

SeeFigure3-3.

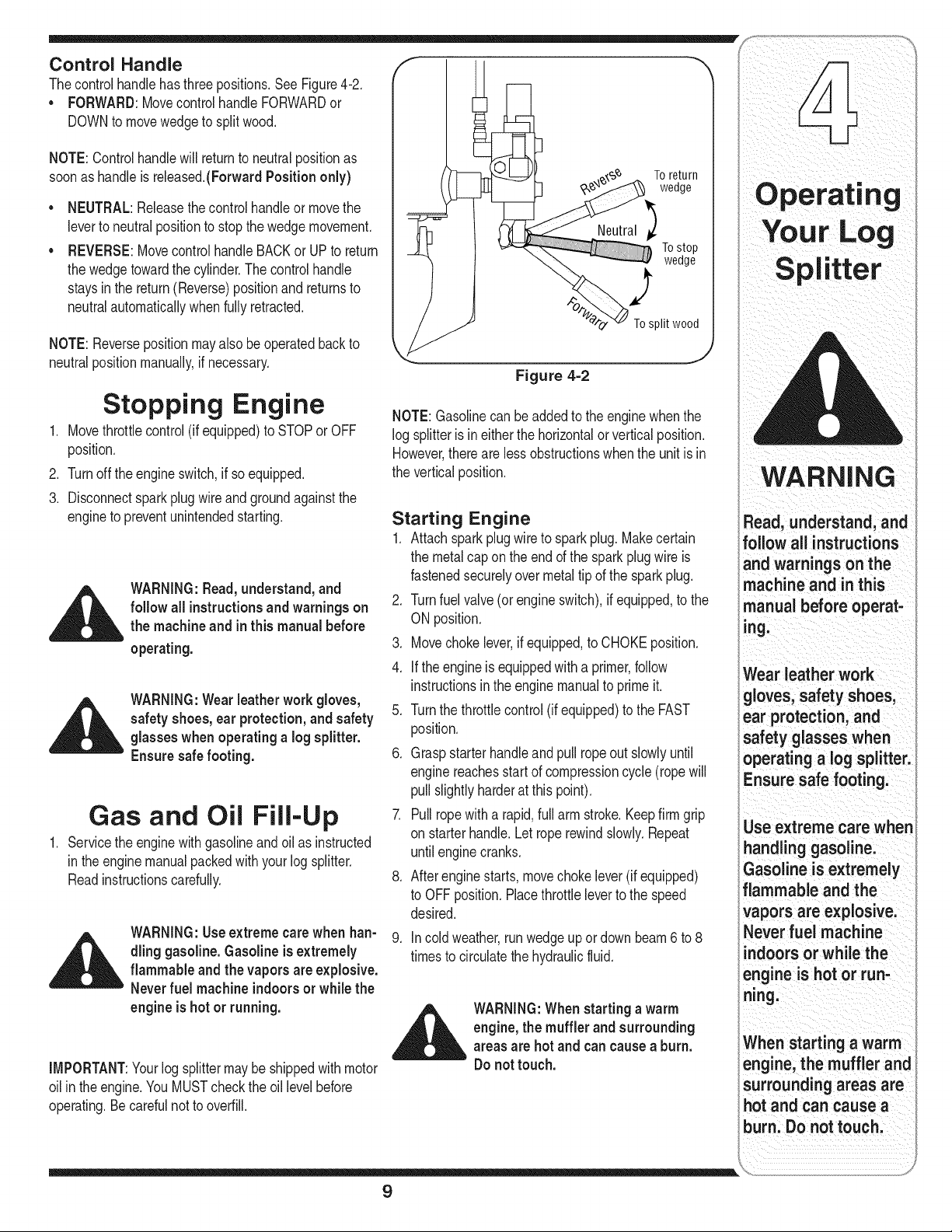

2. Disconnectthedislodgerfromthebeamweldbracket

Figure 3=2 byremovingthesixhexscrews.SeeFigure3-4.

3. Disconnectthelogcradlefromthe beamontheside

ofthecontrolvalve.SeeFigure3-5.

/

right to ChangeProduct

specifiCati0ns:designs

and equipment Without

notice andwith0ut inCur:

ring obligation:

,.. j \

Figure 3-3 Figure 3-4

6

4. Liftandslidethe cylinderuptothetopof beamand

intotheweldbrackets.SeeFigure3-6.

5. Attachthedislodgeroverthewedgeassemblyand

securewith hardware,previouslyremoved,to theweld

brackets.

NOTE:Oncethesix hexscrewsaretightened,there

maybeaslightgapbetweenthedislodgerandthe weld

brackets.Thisgapisnormal.

6. Reattachthelogcradletothesideofthebeamwith

thecontrolvalve,aligningtheendsofthecradlewith

thebeamflanges.

7. Rolllogsplitteroff thebottomcrate.

Preparing the Log Splitter

,

Lubricatethebeamarea(wherethe splittingwedge

willslide)withengineoil;donotusegrease.

2.

Removeventedreservoirdipstick,whichislocatedin

frontoftheengineon topofthe reservoirtank.See

Figure3-7.

IMPORTANT:The logsplittermayhavebeenshipped

and primedwithhydraulicfluidinthe reservoirtank.

However,you MUSTcheckthe fluidlevelbeforeoperat-

ing.If notfilled,proceedwiththefollowingsteps:

3. Fillthereservoirtankwithhydraulicfluidincludedwith

this unit(if equipped)orapprovedfluidswhichinclude

Dexron®III/ Mercon®IIIautomatictransmissionfluid,

a 10WeightAWhydraulicoilor Pro-MixTM AW-32

HydraulicOil.

4. Checkfluidlevelusingthedipstick.SeeFigure3-7.Do

notoverfill.

5. Replaceventeddipsticksecurely,tighteningit untilthe

topofthe threadsareflushwithtopof thepipe.

6. Disconnectthesparkplugandprimethepumpby

pullingthe recoilstarterasfar asit willgo. Repeat

approximately10times.

7. Reconnectthesparkplugwireandstartengine

followinginstructionsintheOPERATIONsection.

8. Usecontrolhandleto engagethewedgeto the

farthestextendedposition.Thenretractthe wedge.

9. Refilltankasspecifiedonthedipstick.

NOTE:Failureto refillthetankwillvoidunit'swarranty.

10.Extendandretractthewedge12completecycles

to removetrappedair inthesystem(the systemis

"self-bleeding").

11.Refillreservoirwithinrangemarkedonthedipstick.

WARNING:Much of the original fluid hasbeendrawn

intothe cylinderandhoses.Makecertainto refill

hydraulic pump.

the reservoir to preventdamageto the

NOTE:Somefluidmayoverflowfromthe

ventplugasthesystembuildsheatandthe

Figure 3=5

f

Figure 3-6

Figure 3=7

fluidexpandsandseeksa balancedlevel.

Much of the original

fluid has been drawn

intothecylinder and

hoses: Make certain to

refill the reservoir to

prevent damage to the

hydraulic pump:

ii _i_i _ii_!iii_iiiii_ TM iii_

IMPORTANT:

The logsplitter may

have been shipped and

primedWithhydraulic

fluid inthe reservoir

tan If noL proceed

with the following

steps:

NOTE!Some fluid may

overflow from the vent

plugas the system

builds heat andthe

fluid expandsand

seeks abalanced level:

i_ ii i

7

i_i_i_iii_i iiii _iiii_i__ii_i_!i_

f

Tongue

t

Jack Stand

Know Your Log Splitter

Cylinder

Log

Dislodger

Control Handle

I

BeamAssembly

Wedge

IMPORTANT

i Yourlogsplitter may

be shippedwith motor

I oil inthe engine.You

MUSTcheck the oil

levelbeforeoperat-

ing.Be careful notto

overfill.

Horizontal Beam Lock

Figure 4=1

Vertical

Beam Log

Lock Cradle

TailLight

(If Equipped)

Vertical Beam Lock

J_

J

Beam Locks

Thesetwolocks,astheirnamesuggests,areused

tosecurethebeaminthehorizontalorthe vertical

position.Theverticalbeamlockis locatednextto theoil

filter.Thehorizontalbeamlockis locatedonthebeam

supportlatchbracket.SeeFigure4-1.

Engine Controls

Seetheaccompanyingenginemanualforthe location

andfunctionofthe controlsontheengine.

8

Control Handle

Thecontrolhandlehasthreepositions.SeeFigure4-2.

• FORWARD:MovecontrolhandleFORWARDor

DOWNtomovewedgeto splitwood.

NOTE:Controlhandlewill returntoneutralpositionas

soonashandleisreleased.(ForwardPositiononly)

NEUTRAL:Releasethecontrolhandleormovethe

leverto neutralpositionto stopthewedgemovement.

REVERSE:MovecontrolhandleBACKor UPto return

thewedgetowardthecylinder.Thecontrolhandle

staysinthe return(Reverse)positionand returnsto

neutralautomaticallywhenfullyretracted.

NOTE:Reversepositionmayalsobeoperatedbackto

neutralpositionmanually,if necessary.

Stopping Engine

1. Movethrottlecontrol(ifequipped)to STOPor OFF

position.

2. Turnofftheengineswitch,if soequipped.

3. Disconnectsparkplugwireand groundagainstthe

engineto preventunintendedstarting.

,_ WARNING:Read,understand,and

__ WARNING:Wearleather work gloves,

follow all instructions andwarnings on

the machineand in this manual before

operating.

safetyshoes, ear protection,and safety

glasseswhen operating a log splitter.

Ensuresafe footing.

Gas and Oil Fill=Up

1. Servicethe enginewith gasolineandoilas instructed

in theenginemanualpackedwithyourlog splitter.

Readinstructionscarefully.

WARNING:Useextremecarewhenhan-

dling gasoline.Gasolineis extremely

flammableand thevapors are explosive.

Neverfuel machine indoorsor while the

engine ishot or running.

IMPORTANT:Yourlogsplittermaybeshippedwithmotor

oil in theengine.YouMUSTchecktheoillevelbefore

operating.Becarefulnottooverfill.

To return

wedge

To stop

wedge

)

To split wood

Figure 4=2

NOTE:Gasolinecanbe addedto theenginewhenthe

logsplitterisin eitherthehorizontalorverticalposition.

However,therearelessobstructionswhenthe unitis in

theverticalposition.

Starting Engine

1. Attachsparkplugwireto sparkplug. Makecertain

themetalcapontheendofthe sparkplugwireis

fastenedsecurelyovermetaltip ofthe sparkplug.

2. Turnfuelvalve(or engineswitch),ifequipped,tothe

ONposition.

3. Movechokelever,ifequipped,toCHOKEposition.

4. If theengineisequippedwithaprimer,follow

instructionsintheenginemanualtoprimeit.

5. Turnthethrottlecontrol(ifequipped)totheFAST

position.

6. Graspstarterhandleandpullropeoutslowlyuntil

enginereachesstartof compressioncycle(ropewill

pullslightlyharderatthispoint).

7. Pullropewitha rapid,fullarmstroke.Keepfirmgrip

on starterhandle.Letroperewindslowly.Repeat

untilenginecranks.

8. Afterenginestarts,movechokelever(ifequipped)

toOFFposition.Placethrottlelevertothe speed

desired.

9. In coldweather,runwedgeupor downbeam6to 8

timesto circulatethehydraulicfluid.

_ WARNING:Whenstarting awarm

engine,the muffler and surrounding

areasare hot andcan causea burn.

Donottouch.

WARNING

Read, understand, and

follow all instructions

and warnings on the

machine and inthis

manual before operat-

ing.

Wear leather work

gloves,safety shoes,

ear protection,and

safety glasseswhen

operating a log splitter.

Ensure safe footing.

Use extreme carewhen

handlinggasoline.

Gasoline isextremely

flammable and the

vapors are explosive.

Never fuel machine

indoorsor while the

engine is hot or run-

ning.

When starting a warm

engine, the muffler and

surrounding areas are

hot and can cause a

burn. Do not touch.

9

Coo,ro,.and,o

// I 1. MovecontrolhandleFORWARDor DOWNtosplit

Z_I 1_1 , wood.

2. Releasethecontrolhandleto stopthewedgemove-

ment.

3. MovecontrolhandleBACKorUPto returnthewedge.

Log Dislodger

Thelog dislodgerisdesignedtoremoveanypartially

splitwoodfromthewedge.Thismayoccurwhilesplitting

largediameterwoodorfreshlycutwood.

Neverremove partially

split wood from the

wedgewith your

hands. Fingers may be-

come trapped between

split wood.

Figure 4=3

Before Each Use

1. Removethedipstickand checkhydraulicfluidlevel.

Refillifnecessary.ApprovedfluidsincludeDexron®

III/ Mercon®III automatictransmissionfluid,a

10WeightAWhydraulicoilor Pro-MixTM AW-32

HydraulicOil.

2. Check engineoil level.Refillifnecessary.

3. Fill upgasolineifnecessary.

4. Lubricatethebeamareawheresplittingwedgewill

slidewithengineoil. Donotusegreaseto lubricate.

Makesureto lubricateboththe frontandthebackof

thebeamface.

5. Attachsparkplugwireto thesparkplug.

_ ARNING:Neverremove partiallysplit

1. Toremovepartiallysplitwoodfromwedge,move

controlhandleto REVERSEpositionuntilwedgeis

fullyretractedtoallowsplitwoodportionto contactthe

logdislodger.

2. Onceremovedfromwedgewith logdislodger,split

woodfromoppositeendor inanotherlocation.

Vertical Position

1. Pullthehorizontalbeamlockoutto releasethebeam

andpivotthe beamtotheverticalposition.

2. Tolockthebeamin theverticalposition,pullout

ontheverticalbeamlockandrotateit tosecurethe

beam.SeeFigure4-1.

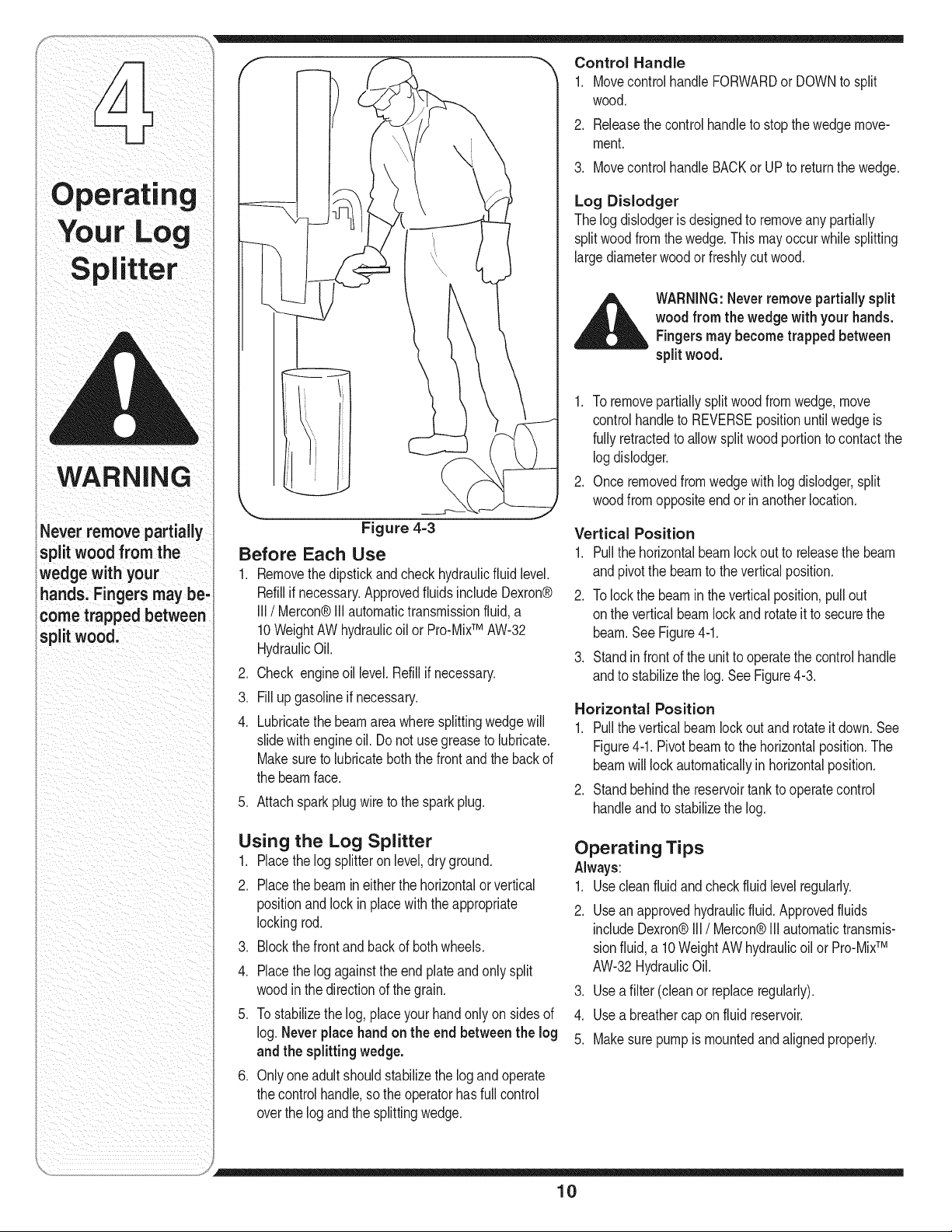

3. Standinfrontoftheunittooperatethecontrolhandle

andtostabilizethelog.SeeFigure4-3.

Horizontal Position

1. Pulltheverticalbeamlockout and rotateitdown.See

Figure4-1.Pivotbeamtothe horizontalposition.The

beamwill lockautomaticallyinhorizontalposition.

2. Standbehindthereservoirtanktooperatecontrol

handleandtostabilizethelog.

wood from the wedgewith your hands.

Fingersmaybecometrapped between

split wood.

Using the Log Splitter

1. Placethelogsplitteronlevel,dryground.

2. Placethebeamineitherthehorizontalorvertical

positionandlockinplacewiththeappropriate

lockingrod.

3. Blockthe frontandbackof bothwheels.

4. Placethelogagainsttheendplateandonlysplit

woodinthedirectionofthegrain.

5. Tostabilizethelog,placeyourhandonly on sidesof

log.Neverplacehandon theend betweenthe log

and the splittingwedge.

6. Onlyoneadultshouldstabilizethelogandoperate

thecontrolhandle,sotheoperatorhasfullcontrol

overthe logandthesplittingwedge.

Operating Tips

Always:

1. Usecleanfluidandcheckfluid levelregularly.

2. Useanapprovedhydraulicfluid.Approvedfluids

includeDexron®III/Mercon®IIIautomatictransmis-

sionfluid,a 10WeightAWhydraulicoilor Pro-MixTM

AW-32HydraulicOil.

3. Useafilter (cleanorreplaceregularly).

4. Usea breathercapon fluidreservoir.

5. Makesure pumpismountedandalignedproperly.

10

6. Usea flexible"spider"typecouplingbetweenengine

and pumpdriveshafts.

7. Keephosesclearandunblocked.

8. Bleedairoutof hosesbeforeoperating.

9. Flushandcleanhydraulicsystembeforerestarting

afterservicing.

10.Use"pipedope"onallhydraulicfittings.

11.Allowtimeforwarm-upbeforesplittingwood.

12.Primethepumpbeforeinitialstart-upbyturningover

theenginewithsparkplugdisconnected(if notalready

doneatfactory).

13.Splitwoodalongthegrain(lengthwise)only.

Never:

1. Usewhenfluidisbelow200Forabove1500R

2. Usea solidengine/pumpcoupling.

3. Operatethroughreliefvalveforlong.

4. Attemptto adjustunloadingorreliefvalvesettings

withoutpressuregauges.

5. Operatewithairinhydraulicsystem.

6. Useteflontapeonhydraulicfittings.

7. Attemptto cutwoodacrossthegrain.

8. Attemptto removepartiallysplitwoodfromthewedge

withyourhands.Fullyretractwedgetodislodgewood

withlogdislodger.

Raising and Lowering Beam

1. Usecontrolhandletorunwedgeupanddownbeam

6 to8 timestocirculatethehydraulicfluid,whichwill

warmandthinthefluid.

2. Placelog splitterona firm,levelsurface.

Toraisethebeamforverticaloperation:

3. Pullout thehorizontalbeamlockonthetongue.

4. Pivotbeamlockdowntoreleasethebeam.

5. Move the beamto theverticalposition.Secureitwith

thebeamlockonthe reservoirtankassembly.

Figure 4-4

Transporting the Log Splitter

IMPORTANT:Alwaysturnfuelvalveto OFFposition

beforetransportingthelogsplitter.

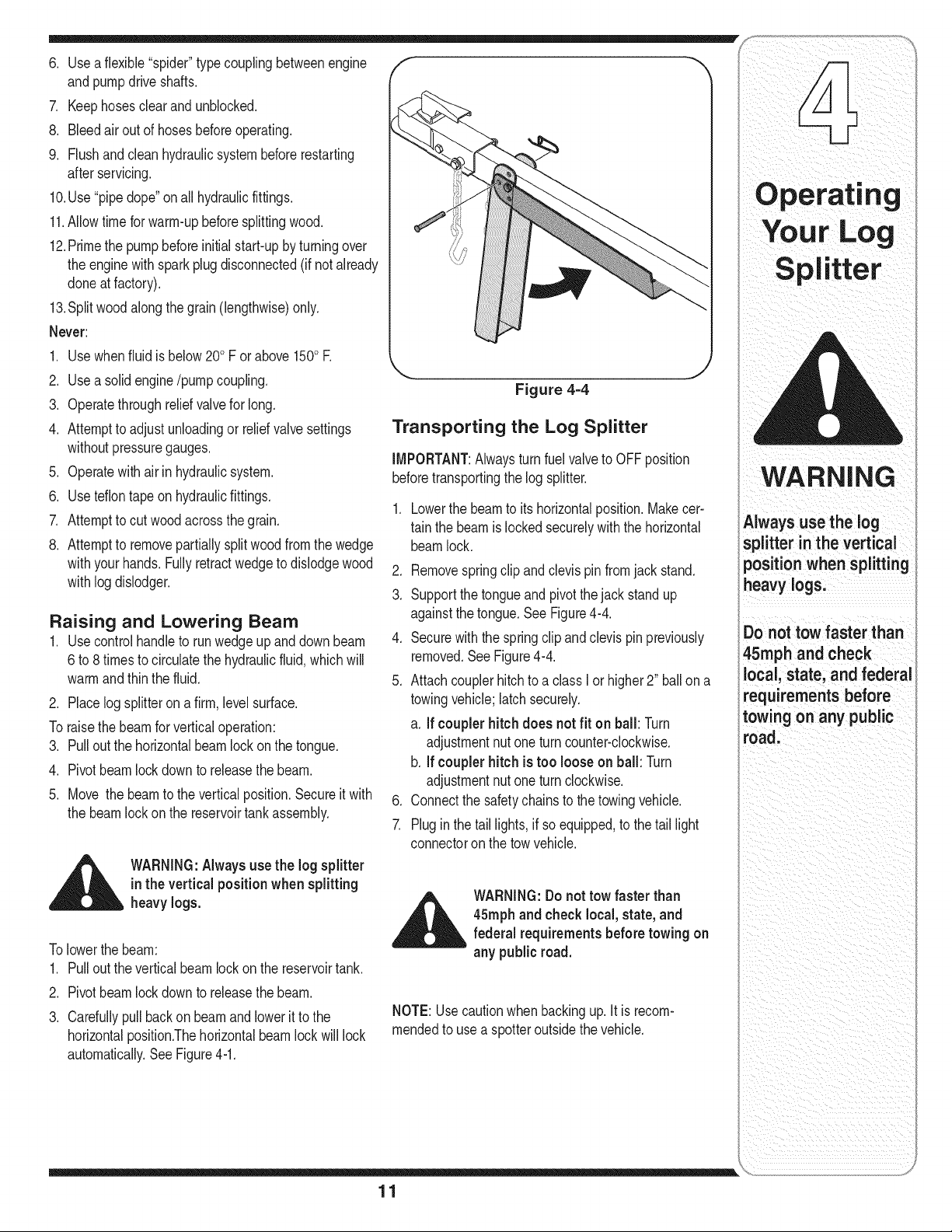

.

Lowerthebeamtoits horizontalposition.Makecer-

tainthe beamislockedsecurelywiththehorizontal

beamlock.

2. Removespringclipandclevispin fromjack stand.

3. Supportthetongueandpivotthe jackstandup

againstthetongue.See Figure4-4.

4. Securewiththespringclip andclevispinpreviously

removed.SeeFigure4-4.

5. Attachcouplerhitchtoa class Iorhigher2" ballon a

towingvehicle;latchsecurely.

a. If couplerhitchdoesnotfit on ball:Turn

adjustmentnutoneturncounter-clockwise.

b. If couplerhitch istoo loose on ball: Turn

adjustmentnutoneturnclockwise.

6. Connectthesafetychainsto thetowingvehicle.

7. Pluginthetail lights,ifsoequipped,tothetaillight

connectoronthetowvehicle.

Operatin

Do not tow faster than

45mph and check

local, state, and federal

requirements before

towing on any public

road.

_ ARNING:Alwaysusethe logsplitter

Tolowerthebeam:

1. Pullout theverticalbeamlockonthereservoirtank.

2. Pivotbeamlockdowntoreleasethebeam.

3. Carefullypullbackonbeamandlowerit tothe

horizontalposition.Thehorizontalbeamlockwilllock

automatically.SeeFigure4-1.

inthe verticalpositionwhen splitting

heavy logs.

,__i= WARNING:Do nottow faster than

NOTE:Usecautionwhenbackingup.Itis recom-

mendedtousea spotteroutsidethevehicle.

45mphand checklocal, state,and

federal requirementsbefore towing on

any publicroad.

11

WARNING

Donotat anytime

make any adjustments

without first stopping

engine, disconnecting

spark plugwire, and

grounding it against

,the engine. Always

iwear safety glasses

during operation or

while performing any

iadjustments or repairs.

Before cleaning,

i!ubricating, repair=

rag,or inspecting,

,disengage the control

ilever and stop engine.

iDisconnect the spark

plugwire and ground

itagainst the engine

to prevent unintended

starting. Always wear

safety glasses during

operation or while

iperformingany adjust-

iments or repairs.

Lock Nut

Figure 5=1

__i WARNING:Donot at any time make

any adjustments without first stopping

engine,disconnecting sparkplug wire,

and groundingit against the engine.

Alwayswear safety glassesduring

operationor while performingany

adjustments or repairs.

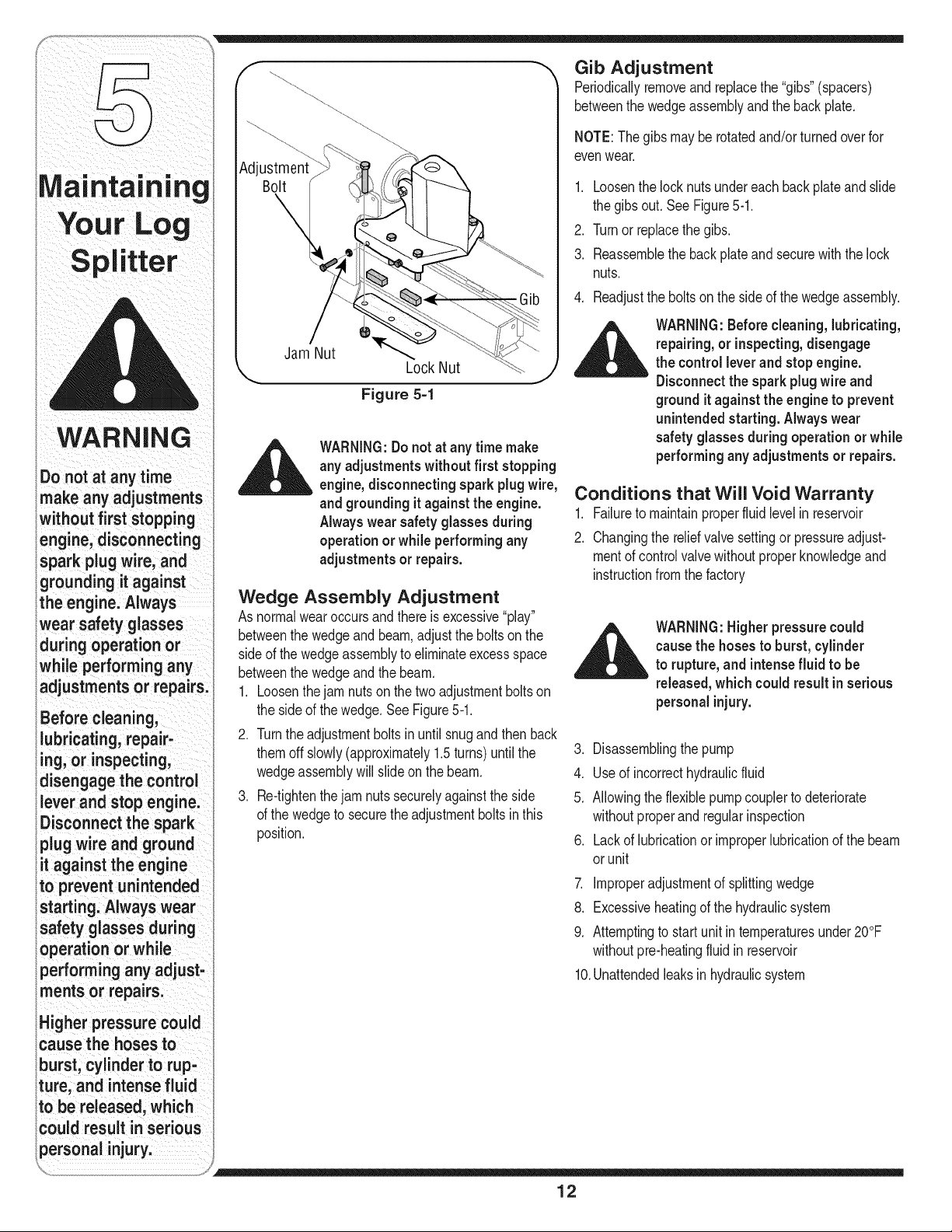

Wedge Assembly Adjustment

Asnormalwearoccursandthereisexcessive"play"

betweenthewedgeandbeam,adjustthe boltsonthe

sideof thewedgeassemblytoeliminateexcessspace

betweenthewedgeandthe beam.

1. Loosenthejam nutson thetwoadjustmentboltson

thesideofthewedge.SeeFigure5-1.

2. Turntheadjustmentboltsin untilsnugandthenback

themoffslowly(approximately1.5turns)untilthe

wedgeassemblywillslideonthebeam.

3. Re-tightenthejam nutssecurelyagainsttheside

ofthewedgeto securetheadjustmentboltsinthis

position.

Gib Adjustment

Periodicallyremoveand replacethe"gibs"(spacers)

betweenthewedgeassemblyandthe backplate.

NOTE:Thegibsmayberotatedand/orturnedoverfor

evenwear.

1. Loosenthelocknutsundereachbackplateand slide

thegibsout.See Figure5-1.

2. Turnor replacethegibs.

3. Reassemblethebackplateandsecurewiththelock

nuts.

4. Readjusttheboltson thesideofthewedgeassembly.

WARNING:Beforecleaning,lubricating,

repairing,or inspecting,disengage

the control lever and stop engine.

Disconnectthe spark plug wire and

ground itagainst the engine to prevent

unintended starting. Always wear

safety glassesduring operation or while

performingany adjustments or repairs.

Conditions that Will Void Warranty

1. Failuretomaintainproperfluidlevelinreservoir

2. Changingthe reliefvalvesettingorpressureadjust-

mentofcontrolvalvewithoutproperknowledgeand

instructionfromthefactory

__ WARNING:Nigher pressurecould

3. Disassemblingthe pump

4. Useof incorrecthydraulicfluid

5. Allowingtheflexiblepumpcouplertodeteriorate

withoutproperandregularinspection

6. Lackoflubricationorimproperlubricationofthebeam

orunit

7. Improperadjustmentofsplittingwedge

8. Excessiveheatingof thehydraulicsystem

9. Attemptingtostartunitin temperaturesunder20°F

withoutpre-heatingfluidin reservoir

10.Unattendedleaksinhydraulicsystem

cause the hoses to burst, cylinder

to rupture,and intensefluid to be

released,which could resultinserious

personalinjury.

iHigher pressure could

icause the hoses to

burst, cylinderto rup-

iture, and intensefluid

to be released, which

could result inserious

ipersonal injury.

12

Loading...

Loading...