MTD 24B570F299 Owner’s Manual

Operator's Manual

CRRF[SM ®

675 Series

LOG SPLITTER

Model No. 247.77641

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our web site: www.sears.com/craftsman FORMNO.769-03988A

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

Spanish

2/4/2009

Warranty Statement .................................. Pac

Safe Operation Practices .......................... Pac

Safety Labels ............................................ Pac

Assembly .................................................. Pac

Operation .................................................. Pac

Service & Adjustments ............................. Pac

Maintenance ............................................. Pac

Limited Warranty on Craftsman Log Splitter

Forone(1)yearfromthedateofpurchase,ifthisCraftsmanEquipmentismaintained,lubricated,andtuned upaccordingtotheinstructionsto

theoperator'smanual,Searswill repairor replacefreeofchargeany partsfoundto bedefectiveinmaterialorworkmanship.Warrantyserviceis

availablefreeofchargeby returningCraftsmanequipmenttoyournearestSearsServiceCenter.In-homewarrantyserviceisavailablebuta trip

chargewillapply.ThisWarrantyappliesonlywhilethisproductisintheUnitedStates.

This warranty does not cover:

• Expendableitemswhichbecomewornduringnormaluse,suchassparkplugs,aircleaners,belts,andoil filters.

• Tire replacementorrepaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedto,damagecausedbyobjects,suchasstonesormetaldebris,

oversizedstock,impactingobjectsthat bendthe frameor crankshaft,orover-speedingtheengine.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethe propergradeandamountofengineoil,or failureto maintainthe equipmentaccordingtotheinstructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningor repairscausedbyfueldeterminetobecontaminatedor oxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

• Equipmentusedforcommercialorrentalpurposes.

WARRANTYSERVICEISAVAILABLEBYRETURNINGTHECRAFTSMANLOGSPLITTERTOTHENEAREST

SEARSPARTS& REPAIRCENTERINTHEUNITEDSTATES.

Thiswarrantyappliesonlywhilethisproductisin useintheUnitedStates.

TOLOCATETHE NEARESTSEARSPARTS&REPAIRCENTERORTOSCHEDULESERVICE,

SIMPLYCONTACTSEARSAT1-800-4-MY-HOME®.

Thiswarrantygivesyouspecificlegalrightsand youmayalsohaveotherrightswhichmayvaryfromstateto state.

SEARS,ROEBUCKANDCO.,D/817WA,HOFFMANESTATES,IL 60179

e2

es 3-5

e6

es 7-8

es 9-12

es 13-14

es 15-17

Off Season Storage .................................. Page 18

Trouble Shooting ....................................... Page 19-21

Parts List ................................................... Page 22-29

Repair Protection Agreement ................... Page 33

Espa_ol ..................................................... Page 34

Service Numbers ...................................... Back Cover

Engine Series: 126L02-0531

Engine Oil: SAE 30

Engine Oil Capacity: 20 Ounces

Fuel Capacity: 1.5 Quarts

Spark Plug (.030" Gap): Champion® RJ19LM

Hydraulic Fluid/Capacity: Dexron Ill/3.0 gal.

Model Number .............................................................

Serial Number ..............................................................

Date of Purchase ..........................................................

Record the model number, serial number

and date of purchase above

2

instructions which, if not followed, could

This symbol points out important safety

endanger the personal safety and/or property of

yourself and others. Read and follow all

instructions in this manual before attempting to

operate this machine. Failure to comply with

these instructions may result in personal injury.

When you see this symbol, HEED ITSWARNING!

This machine was built to be operated according to the

safe operation practices in this manual. As with any type of

power equipment, carelessness or error on the part of the

operator can result in serious injury. This machine iscapable

of amputating fingers, hands, toes and feet and throwing

debris. Failure to observe the following safety instructions

could result in serious injury or death.

CALIFORNIA PROPOSITION 65

Engine Exhaust, some of its constituents, and certain vehicle

Your Responsibility--Restrict the use of this power

the warnings and instructions in this manual and on the

components contain or emit chemicals known to State

of California to cause cancer and birth defects or other

reproductive harm.

Training lo.

1. Read, understand, and follow all instructions on the machine

and in the manual before attempting to assemble and

operate. Keep this manual in a safe place for future and regular

reference and for ordering replacement parts.

2. Read the Operator's Manual and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the

operator and/or bystanders. For questions call, 1-800-659-5917.

3. Be familiar with all controls and their proper operation. Know

how to stop the machine and disengage them quickly.

4. Never allow children under 16 years of age to operate this

machine. Children 16 and over should read and understand the

instructions and safe operation practices in this manual and on

the machine and be trained and supervised by an adult.

5. Never allow adults to operate this machine without proper

instruction.

6.

Many accidents occur when more than one person operates

the machine. Ifa helper is assisting in stacking logs, never

activate the control until the helper is a minimum of 10 feet

from the machine.

Z Keep bystanders, pets, and children at least 20 feet from the

machine while it is in operation.

8. Never allow anyone to ride on this machine.

9. Never transport cargo on this machine.

10. Leaks can be detected by passing cardboard or wood,

11. If injured by escaping fluid, see a doctor immediately. Serious

12. Keep the operator zone and adjacent area clear for safe, secure

13. If your machine is equipped with an internal combustion

14. This machine should be used for splitting wood only, do not

15. Follow the instructions in the manual(s) provided with any

machine to persons who read, understand and follow

machine.

SAVETHESEINSTRUCTIONS!

Hydraulic log splitters develop high fluid pressures during

operation. Fluid escaping through a pin hole opening can

penetrate your skin and cause blood poisoning, gangrene, or

death. Give attention to the following instructions at all times:

a. Do not check for leaks with your hand.

b. Do not operate machine with frayed, kinked, cracked, or

damaged hoses, fittings, or tubing.

c. Stop the engine and relieve hydraulic system pressure

before changing or adjusting fittings, hoses, tubing, or

other system components.

d. Do not adjust the pressure settings of the pump or

valve.

while wearing protective gloves and safety glasses, over the

suspected area. Look for discoloration of cardboard or wood.

infection or reaction can develop if proper medical treatment

is not administered immediately.

footing.

engine and is intended for use near any unimproved forest,

brush, or grass covered land, the engine exhaust should be

equipped with a spark attester. Make sure you comply with

applicable local, state, and federal codes. Take appropriate

firefighting equipment with you.

use it for any other purpose.

attachment(s) for this machine.

3

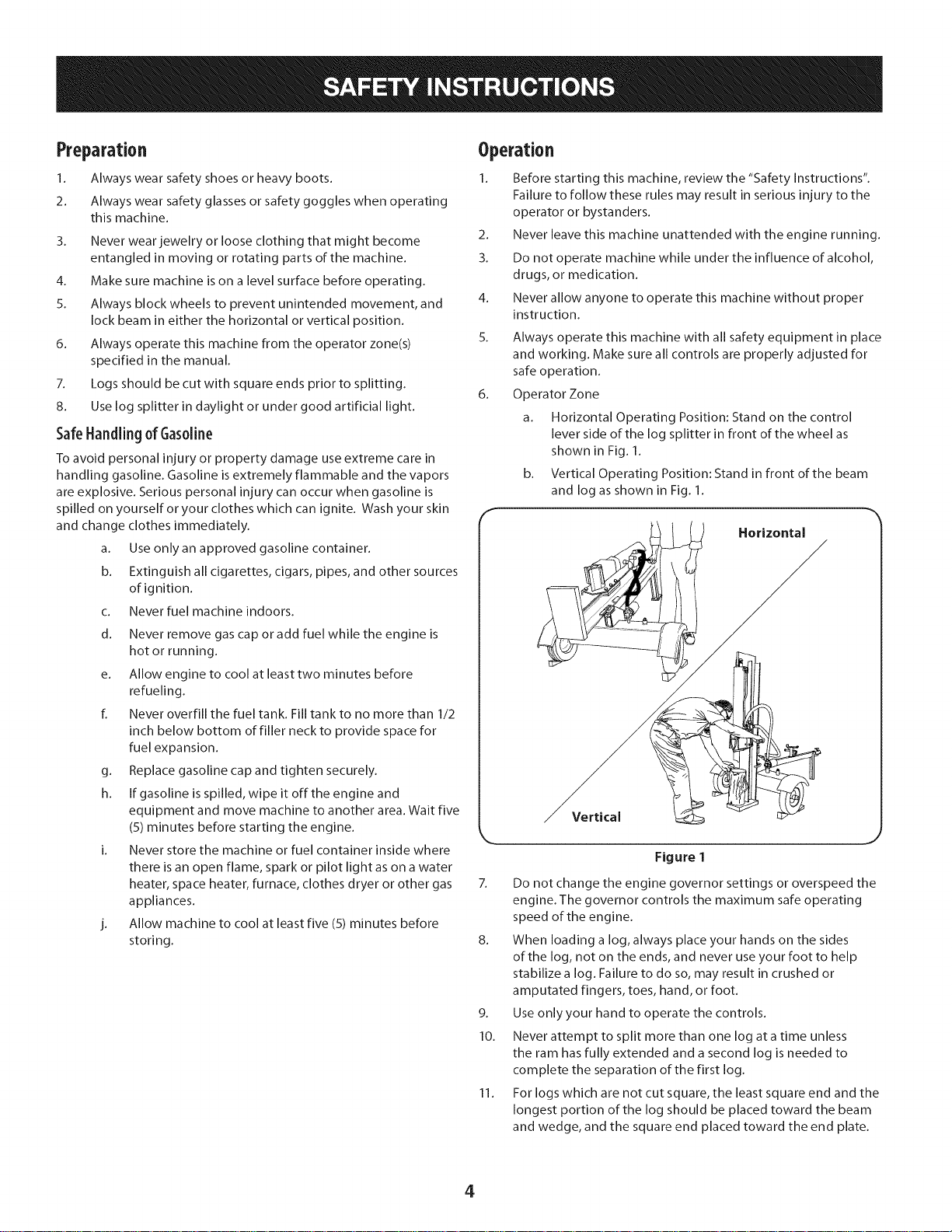

Preparation Operation

1. Always wear safety shoes or heavy boots.

2. Always wear safety glasses or safety goggles when operating

this machine.

3. Never wear jewelry or loose clothing that might become

entangled in moving or rotating parts of the machine.

4. Make sure machine is on a level surface before operating.

5. Always block wheels to prevent unintended movement, and

lock beam in either the horizontal or vertical position.

6. Always operate this machine from the operator zone(s)

specified in the manual.

7. Logs should be cut with square ends prior to splitting.

8. Use log splitter in daylight or under good artificial light.

SafeHandlingofGasoline

To avoid personal injury or property damage use extreme care in

handling gasoline. Gasoline is extremely flammable and the vapors

are explosive. Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite. Wash your skin

and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and other sources

of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the engine is

hot or running.

e. Allow engine to cool at least two minutes before

refueling.

fl Never overfill the fuel tank. Fill tank to no more than 1/2

inch below bottom of filler neck to provide space for

fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment and move machine to another area. Wait five

(5) minutes before starting the engine.

i. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light as on a water

heater, space heater, furnace, clothes dryer or other gas

appliances.

j. Allow machine to cool at least five (5) minutes before

storing.

1. Before starting this machine, review the "Safety Instructions".

Failure to follow these rules may result in serious injury to the

operator or bystanders.

2. Never leave this machine unattended with the engine running.

3. Do not operate machine while under the influence of alcohol,

drugs, or medication.

4. Never allow anyone to operate this machine without proper

instruction.

5_

Always operate this machine with all safety equipment in place

and working. Make sure all controls are properly adjusted for

safe operation.

6_

Operator Zone

a. Horizontal Operating Position: Stand on the control

b. Vertical Operating Position: Stand in front of the beam

7. Do not change the engine governor settings or overspeed the

engine. The governor controls the maximum safe operating

speed of the engine.

8. When loading a log, always place your hands on the sides

of the log, not on the ends, and never use your foot to help

stabilize a log. Failure to do so, may result in crushed or

amputated fingers, toes, hand, or foot.

9. Use only your hand to operate the controls.

10. Never attempt to split more than one log at a time unless

the ram has fully extended and a second log is needed to

complete the separation of the first log.

11. For logs which are not cut square, the least square end and the

longest portion of the log should be placed toward the beam

and wedge, and the square end placed toward the end plate.

lever side of the log splitter in front of the wheel as

shown in Fig. 1.

and log as shown in Fig. 1.

Horizontal

Vertical

Figure 1

4

12.

When splitting in the vertical position, stabilize the log before

moving the control. Split as follows:

a. Place log on the end plate and turn until it leans against

the beam and is stable.

b. When splitting extra large or uneven logs, the log must

be stabilized with wooden shims or split wood between

the log and end plate or ground.

12. Always keep fingers away from any cracks that open in the log

while splitting. They can quickly close and pinch or amputate

your fingers.

13. Keep your work area clean. Immediately remove split wood

around the machine so you do not stumble over it.

14. Never move this machine while the engine is running.

15. This machine should not be towed on any street, highway or

public road without checking the existing federal, state, or

local vehicle requirements. Any licensing or modifications such

as taillights, etc., needed to comply, is the sole responsibility

of the purchaser. If a "Statement of Origin" is required in your

state, see your local dealer.

16. Do not tow machine over 45 mph.

17. See Transporting the Log Splitter section in this manual for

proper towing instructions once all federal, local, or state

requirements are met.

Maintenanceand Storage

This machine is equipped with an internal combustion engine and

should not be used on or near any unimproved forest-covered,

brush-covered or grass-covered land unless the engine's exhaust

system is equipped with a spark arrester meeting applicable local

or state laws (if any)

1. Stop the engine, disconnect the spark plug and ground it

against the engine before cleaning, or inspecting the machine.

2. Stop the engine and relieve hydraulic system pressure before

repairing or adjusting fittings, hoses, tubing, or other system

components.

3. To prevent fires, clean debris and chaff from the engine

and muffler areas. If the engine is equipped with a spark

attester muffler, clean and inspect it regularly according to

manufacturers instructions. Replace if damaged.

4. Periodically check that all nuts and bolts, hose clamps, and

hydraulic fittings are tight to be sure equipment is in safe

working condition.

5. Check all safety guards and shields to be sure they are in the

proper position. Never operate with safety guards, shields, or

other protective features removed.

6_

The pressure relief valve is preset at the factory. Do not adjust

the valve.

7.

Never attempt to move this machine over hilly or uneven

terrain without a tow vehicle or adequate help.

8.

For your safety, replace all damaged or worn parts immediately

with original equipment manufacturer's (O.E.M.) parts only.

"Use of parts which do not meet the original equipment

specifications may lead to improper performance and

compromise safety!"

Do not alter this machine in any manner, alterations such as

attaching a rope or extension to the control handle, or adding

to the width or height of the wedge may result in personal

injury.

10.

According to the Consumer Products Safety Commission

(CPSC) and the U.S. Environmental Protection Agency (EPA),

this product has an Average Useful Life of seven (7) years, or

130 hours of operation. At the end of the Average Useful Life

have the machine inspected annually by an authorized service

dealer to ensure that all mechanical and safety systems are

working properly and not worn excessively. Failure to do so

can result in accidents, injuries or death.

SparkArrestor

Ira spark arrester is used, it should be maintained in effective

working order by the operator. In the State of California the above

is required by law (Section 4442 of the California Public Resources

Code). Other states may have similar laws. Federal laws apply on

federal lands.

A spark attester for the muffler is available through your nearest

Sears Parts and Repair Service Center.

SafetySymbols

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the

machine before attempting to assemble and operate.

° I °_ READ THE OPERATOR'S MANUAL(S)

I

I

I

II

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- CRUSHING HAZARD

Keep hands away from wedge, end plate, partly split wood and moving parts.

BYSTANDARDS

Keep bystanders, helpers and children at least 10feet away.

SINGLE OPERATOR

Only one person should operate the machine at a time. The adult who loads and holds log must be

the one who operates control handle.

i/

WARNING-- PRESSURIZED FLUID

Never check for hose leaks with your hands. High pressure fluid can escape through a pin hole leak

and cause serious injury by puncturing the skin and causing blood poisoning.

EYEPROTECTION

Always wear safety glasses or safety goggles when operating this machine.

WARNING-- MOVING WEDGE

Keep hands away from wedge and moving parts.

6

Figure 3=1

IMPORTANT:Yourlogsplitterisshippedwithmotoroil intheengine.

However,you MUSTchecktheoil levelbeforeoperating.Becareful

nottooverfill.

NOTE:All referencesinthis manualtotheleftor rightsideof thelog

splitterarefromtheoperatingpositiononly.

REMOVING THE LOG SPLITTER FROM THE

CARTON

1. Prythe top,sidesandendsoffofthecrate.

2. Setthepanelsasidetoavoidtire puncturesorpersonalinjury.

3. Removeanddiscardtheplasticbagthatcoversthelogsplitter.

4. Removeany loosepartsincludedwithwiththelogsplitter(i.e.,

operator'smanual,etc.)

_J

5. Cutand removethestrapswhichsecurethepartsto the bottomof

thecrate.Unboltany remainingpartswhichmaybe boltedtothe

bottomof the crate.

Useextremecautionunpackingthismachine.Somecomponentsare

veryheavyandwill requireadditionalpeopleor mechanicalhandling

equipment.

LOOSE PARTS IN CARTON

\

... j

Figure 3=2

1. TongueAssembly

Disconnectthe sparkplugwireandgroundit againsttheengineto

preventunintendedstarting.

ASSEMBLING THE TONGUE

Attaching the Jack Stand

Thejackstandisshippedinthetransportposition.

1. Removethe springclipandclevispinandpivotthejackstand

towardsthegroundtotheoperatingposition.

2. Securethejackstandinpositionwiththeclevispinandspringclip.

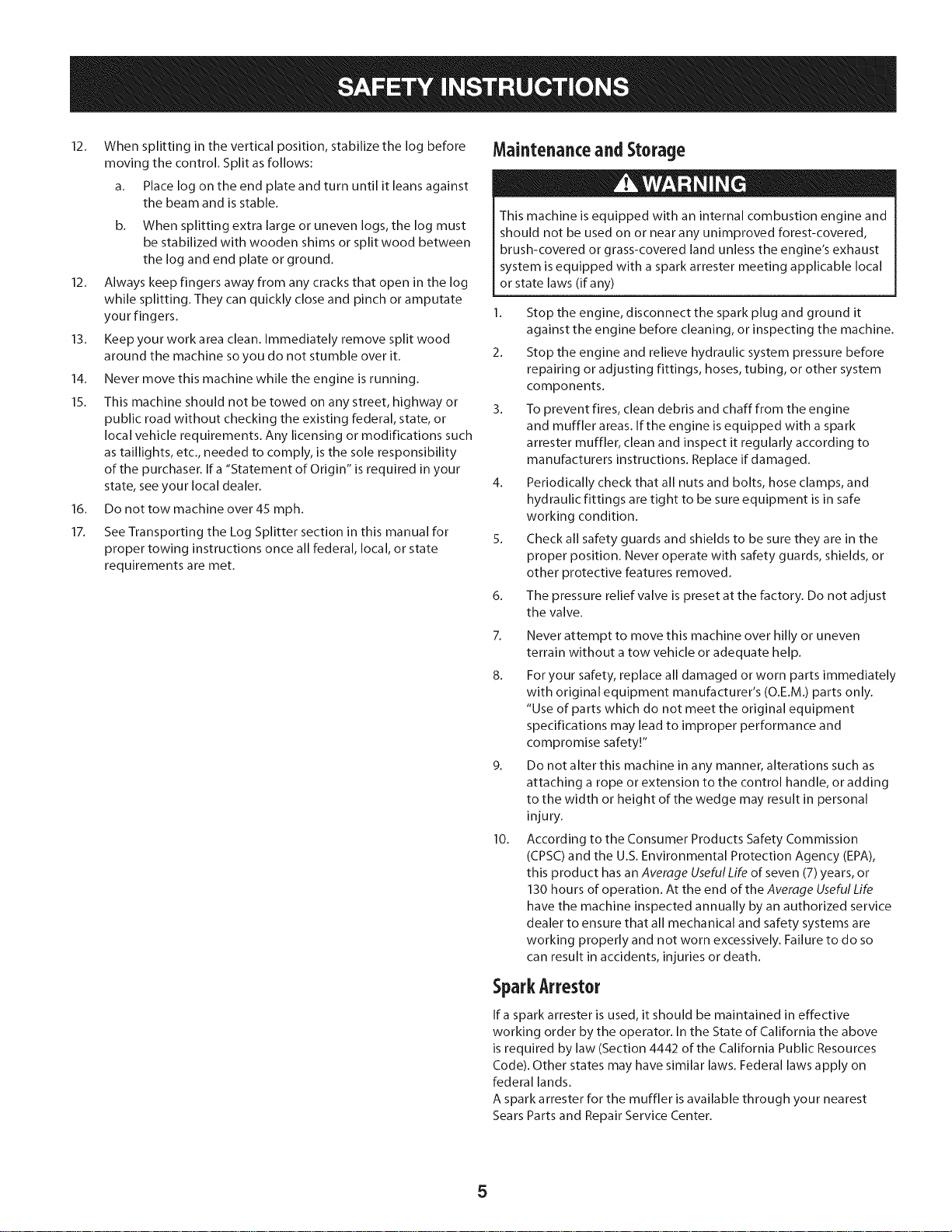

See Figure3-1.

Attaching the Tongue

1. Withthelogsplitterstillstandingupright,removethetwohexbolts

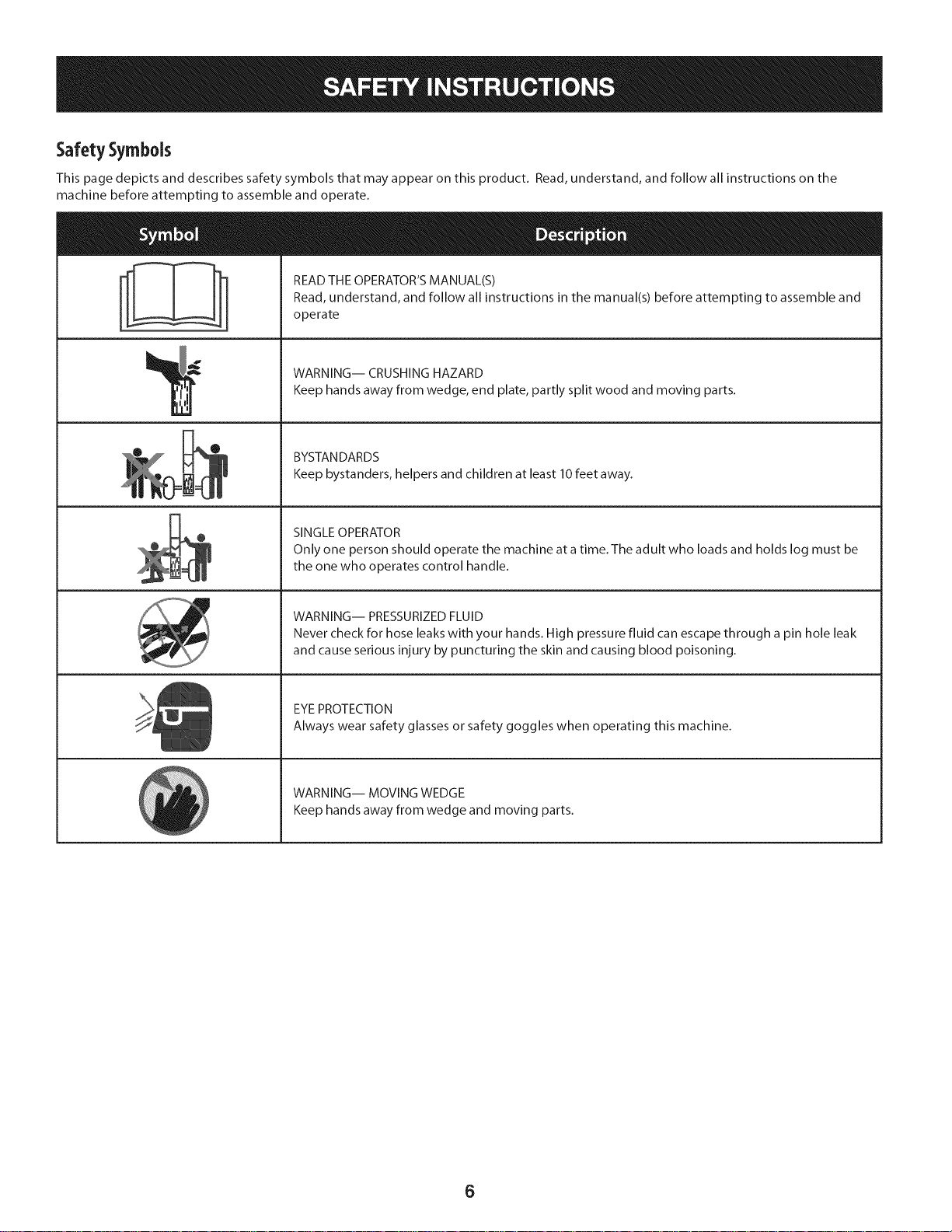

and hexnutsfromthe tankbracket.SeeFigure3-2.

2. Aligntheholesinthetonguewiththeholesinthetankbracketand

securewiththehardwarejustremoved.See Figure3-2.

NOTE:Thehighpressurehosemustbe abovethetongueassembly.

CONNECTING CYLINDER TO BEAM

Figure 3=3

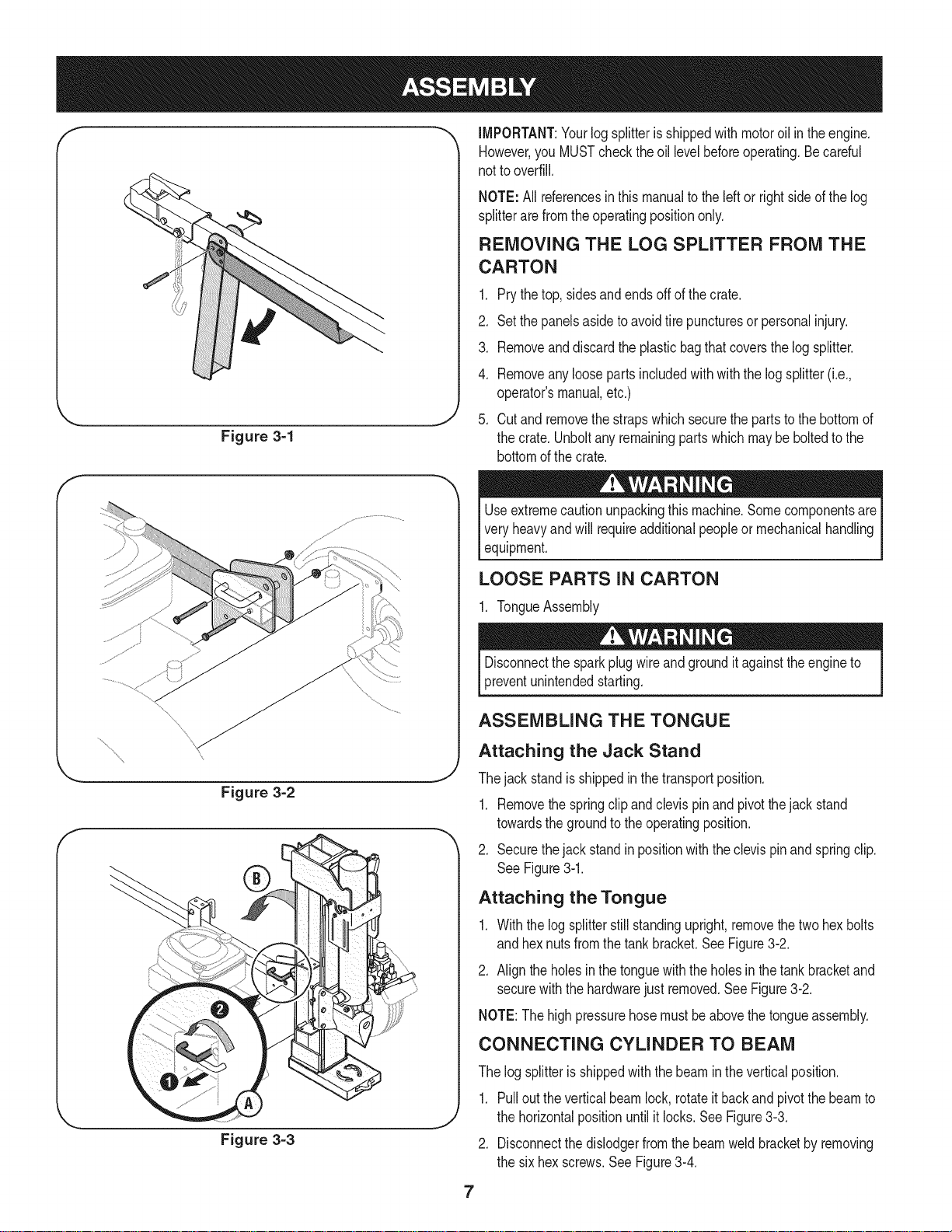

Thelogsplitterisshippedwiththe beamin theverticalposition.

1. Pullouttheverticalbeamlock,rotateitbackandpivotthe beamto

thehorizontalpositionuntilitlocks.SeeFigure3-3.

2. Disconnectthe dislodgerfromthebeamweldbracketby removing

thesix hexscrews.SeeFigure3-4.

7

.

Disconnectthelogcradlefromthe beamonthe sideofthecontrol

valve.SeeFigure3-5.

.

Liftand slidethecylinderup tothe topof beamandintotheweld

brackets.

5. Attachthedislodgeroverthewedgeassemblyandsecureit tothe

weldbracketswiththe previouslyremovedhardware.

NOTE:Oncethesixhex screwsaretightened,theremaybea slight

gapbetweenthedislodgerandtheweldbrackets.Thisgapisnormal.

6. Reattachthelogcradletothesideofthebeamwiththe control

valve,aligningtheendsofthecradlewiththebeamflanges.

7. Rollthelog splitteroffthebottomcrate.

PREPARING THE LOG SPLITTER

1. Lubricatethebeamarea(wherethesplittingwedgewillslide)with

engineoil.Donotuse grease.

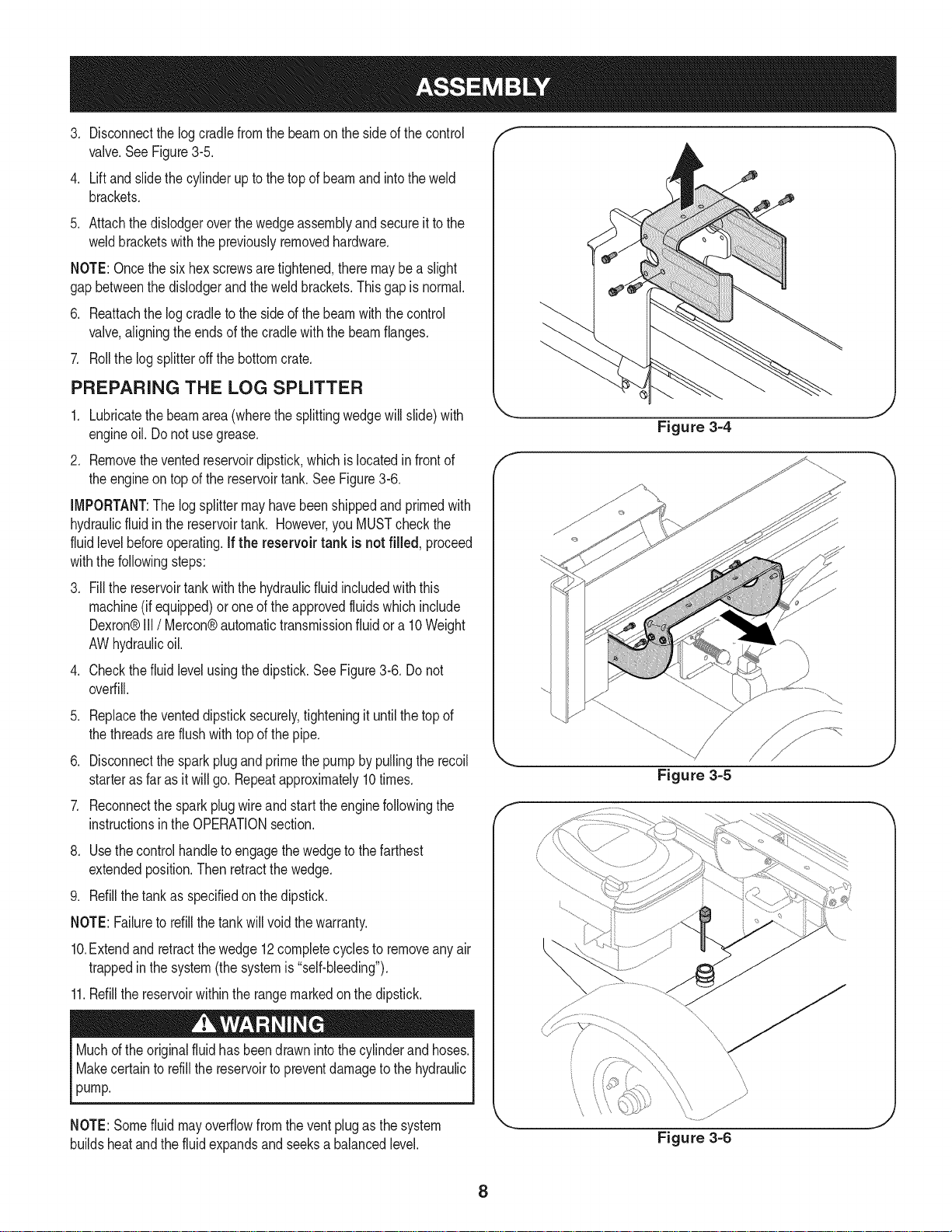

2. Removetheventedreservoirdipstick,whichislocatedinfrontof

theengineontopofthereservoirtank.SeeFigure3-6.

IMPORTANT:The logsplittermayhavebeenshippedandprimedwith

hydraulicfluidin thereservoirtank. However,youMUSTcheckthe

fluidlevelbeforeoperating.If the reservoir tank is not filled, proceed

withthefollowingsteps:

.

Fillthereservoirtankwiththe hydraulicfluidincludedwiththis

machine(if equipped)or oneoftheapprovedfluidswhichinclude

Dexron®III/ Mercon®automatictransmissionfluidora 10Weight

AWhydraulicoil.

.

Checkthefluidlevelusingthedipstick.SeeFigure3-6. Donot

overfill.

.

Replacetheventeddipsticksecurely,tighteningit untilthetopof

thethreadsareflushwithtopofthepipe.

6. Disconnectthe sparkplugand primethepumpby pullingthe recoil

starteras faras itwillgo.Repeatapproximately10times.

7. Reconnectthesparkplugwireandstarttheenginefollowingthe

instructionsin theOPERATIONsection.

8. Usethecontrolhandletoengagethewedgeto the farthest

extendedposition.Thenretractthewedge.

9. Refillthetankasspecifiedonthedipstick.

NOTE:Failuretorefillthe tankwillvoidthe warranty.

10.Extendand retractthewedge12completecyclesto removeanyair

trappedinthesystem(thesystemis"self-bleeding").

11.Refillthereservoirwithintherangemarkedonthe dipstick.

Muchd the originalfluid hasbeendrawnintothecylinderand hoses.

Makecertainto refillthe reservoirtopreventdamagetothehydraulic

pump.

Figure 3=4

Figure 3=5

\\\

"x

,J

\

\

NOTE:Somefluidmayoverflowfromtheventplugas the system

buildsheatandthe fluidexpandsandseeksa balancedlevel.

Figure 3=6

8

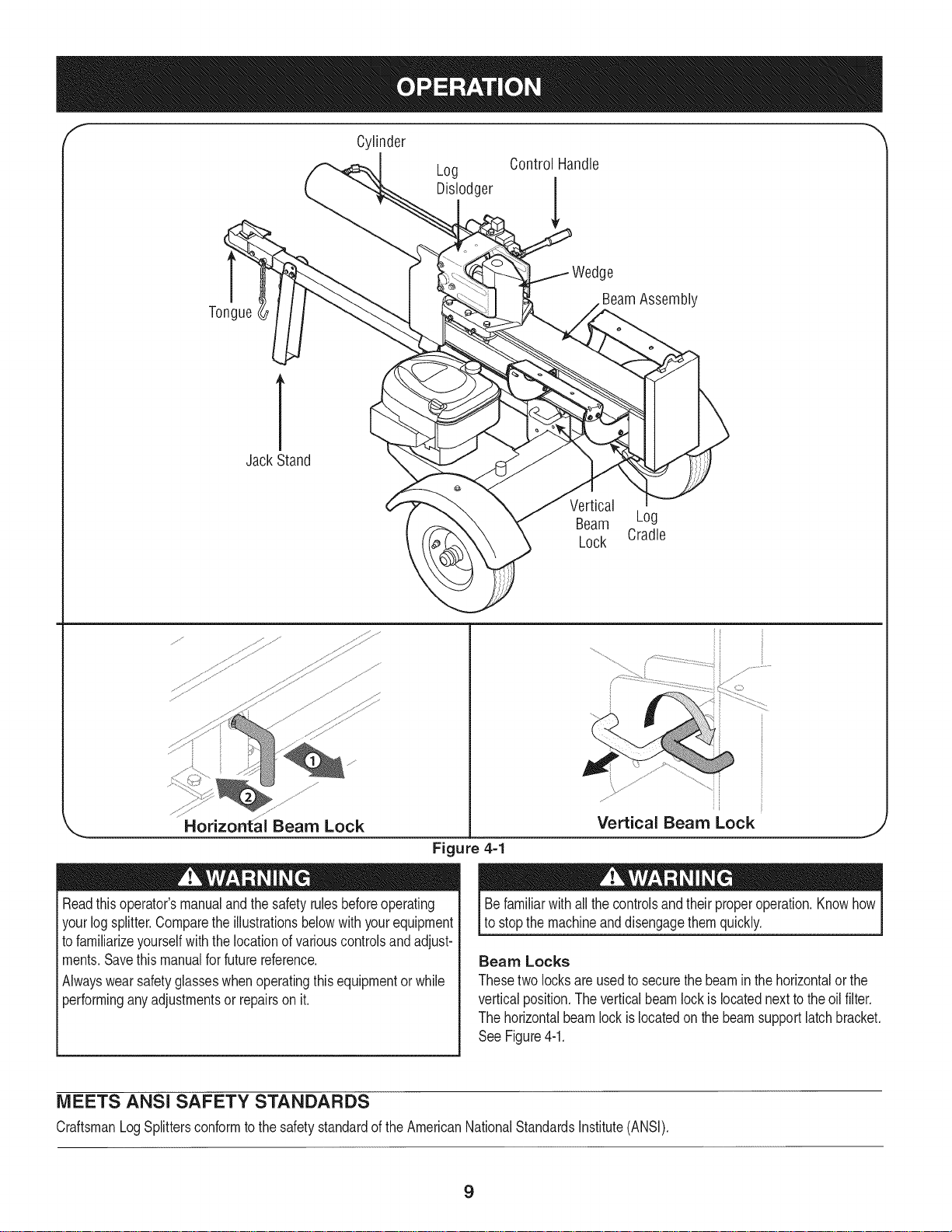

Cylinder

Log

Dislodger

Control Handle

e

Tongue

BeamAssembly

1

JackStand

Vertical

Beam Log

Lock Cradle

,_ Horizontai Beam Lock

Figure 4=1

Readthisoperator'smanualandthesafetyrulesbeforeoperating

yourlogsplitter.Comparetheillustrationsbelowwithyourequipment

tofamiliarizeyourselfwiththelocationofvariouscontrolsandadjust-

ments.Savethismanualforfuturereference.

Alwayswearsafetyglasseswhenoperatingthisequipmentorwhile

performinganyadjustmentsor repairson it.

MEETS ANSI SAFETY STANDARDS

CraftsmanLogSplittersconformtothesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

Befamiliarwithall thecontrolsandtheir properoperation.Knowhow

tostopthemachineanddisengagethemquickly.

Beam Locks

Thesetwo locksareusedto securethebeamin the horizontalor the

verticalposition.Theverticalbeamlockis locatednexttotheoil filter.

Thehorizontalbeamlockislocatedonthebeamsupportlatchbracket.

See Figure4-1.

9

Vertical Beam Lock

J

ENGINE CONTROLS

Stop Switch

Pushthe switchto ON priorto chokingfor the enginestart;pushto

OFFto shuttheenginedown.

Choke Control

Thechokecontrolisusedto chokeoff thecarburetorandassistin

startingtheengine.

Starter Handle

Thestarterhandleis locatedon theengine.Pullthestarterhandleto

startengine.

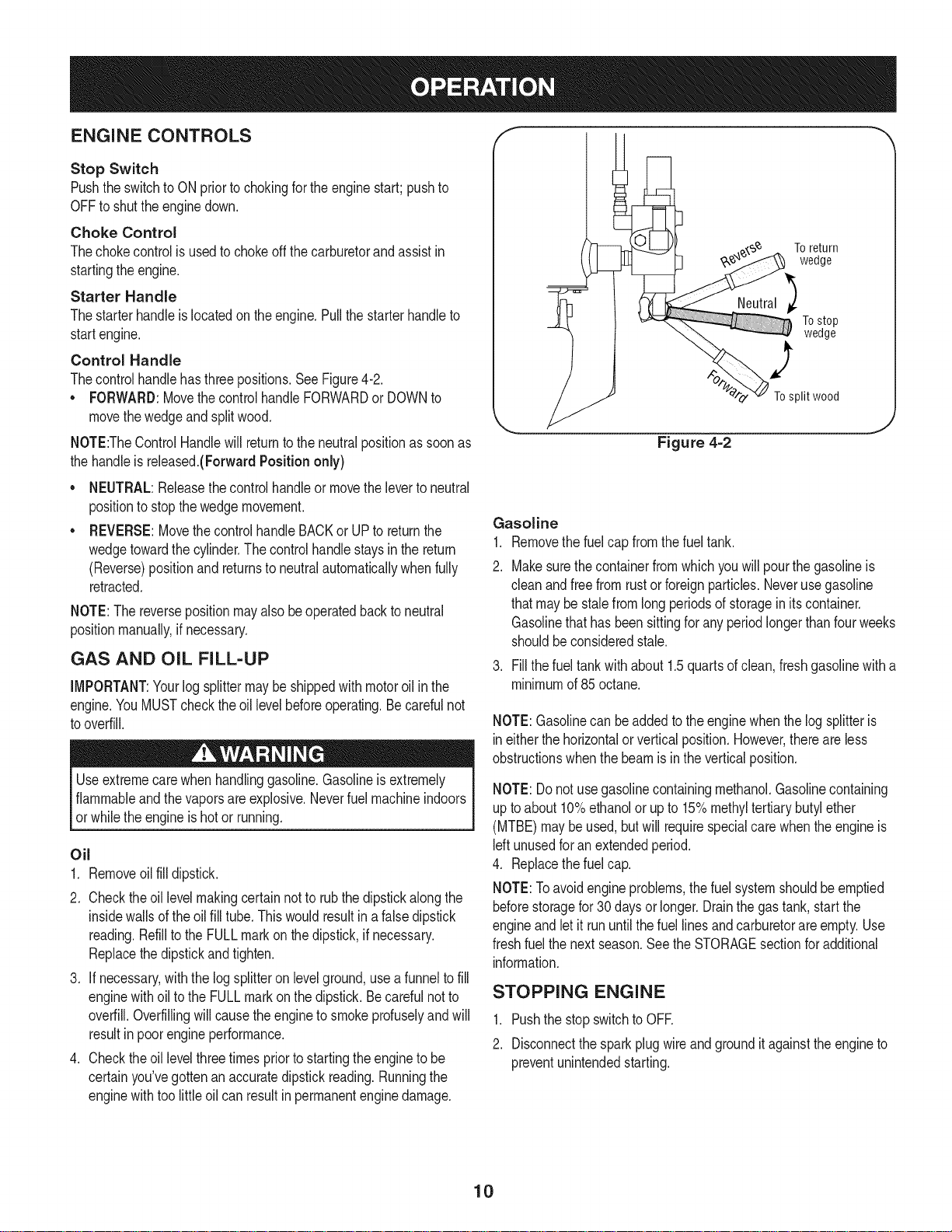

Control Handle

Thecontrolhandlehasthreepositions.SeeFigure4-2.

• FORWARD:MovethecontrolhandleFORWARDorDOWNto

movethewedgeandsplitwood.

NOTE:TheControlHandlewillreturnto theneutralpositionassoonas

thehandleisreleased.(ForwardPosition only)

NEUTRAL:Releasethecontrolhandleor movethelevertoneutral

positiontostopthewedgemovement.

REVERSE:MovethecontrolhandleBACKorUPto returnthe

wedgetowardthecylinder.The controlhandlestaysinthereturn

(Reverse)positionand returnsto neutralautomaticallywhenfully

retracted.

NOTE:The reversepositionmayalsobeoperatedbacktoneutral

positionmanually,if necessary.

GAS AND OiL FILL-UP

iMPORTANT:Yourlogsplittermaybeshippedwithmotoroil inthe

engine.YouMUSTcheckthe oillevelbeforeoperating.Becarefulnot

tooverfill.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthe vaporsareexplosive.Neverfuelmachineindoors

or whiletheengineishotor running.

Oil

1. Removeoilfill dipstick.

2. Checktheoil levelmakingcertainnottorubthe dipstickalongthe

insidewallsofthe oil filltube.Thiswouldresultina falsedipstick

reading.Refillto the FULLmarkon thedipstick,ifnecessary.

Replacethedipstickandtighten.

3. If necessary,withthelogsplitteronlevelground,usea funneltofill

enginewithoilto the FULLmarkon thedipstick.Becarefulnotto

overfill.Overfillingwillcausetheenginetosmokeprofuselyandwill

resultinpoorengineperformance.

4. Checktheoil levelthreetimespriortostartingtheengineto be

certainyou'vegottenan accuratedipstickreading.Runningthe

enginewithtoolittleoilcanresultinpermanentenginedamage.

To return

wedge

Tostop

wedge

2

To split wood

Figure 4=2

Gasoline

1. Removethe fuelcapfromthefueltank.

2. Makesurethe containerfromwhichyou will pourthegasolineis

cleanandfreefromrustorforeignparticles.Neverusegasoline

thatmaybe stalefromlongperiodsof storageinitscontainer.

Gasolinethathas beensittingforanyperiodlongerthanfourweeks

shouldbeconsideredstale.

3. Fillthefueltankwithabout1.5quartsof clean,freshgasolinewitha

minimumof85 octane.

NOTE:Gasolinecanbeaddedto theenginewhenthelog splitteris

ineitherthe horizontalorverticalposition.However,thereare less

obstructionswhenthebeamis inthe verticalposition.

NOTE:Donotusegasolinecontainingmethanol.Gasolinecontaining

uptoabout10%ethanolor upto 15%methyltertiarybutylether

(MTBE)maybe used,but will requirespecialcarewhentheengineis

Idt unusedforanextendedperiod.

4. Replacethefuelcap.

NOTE:Toavoidengineproblems,thefuel systemshouldbeemptied

beforestoragefor30 daysor longer.Drainthegastank,startthe

engineand let it rununtilthe fuel linesandcarburetorareempty.Use

freshfuelthenextseason.SeetheSTORAGEsectionforadditional

information.

STOPPING ENGINE

1. Pushthestopswitchto OFE

2. Disconnectthe sparkplugwireandgroundit againsttheengineto

preventunintendedstarting.

10

STARTING ENGINE

1. Attachthe sparkplugwireto the sparkplug.Makecertainthe metal

capon theendofthesparkplugis fastenedsecurelyoverthemetal

tiponthesparkplug.

2. Pushthe stopswitchtoON.

3. MovethechokecontroltotheCHOKEposition.

4. Graspthe starterhandleand pullthe ropeout slowlyuntilthe

enginereachesitsstartofcompressioncycle(ropewillpullslightly

harderatthispoint).

5. Pulltheropewitha rapid,continuous,full armstroke.Keepa firm

griponthe starterhandle.Letthe roperewindslowly.

6. Repeat,if necessary,untilthe enginestarts.Slowlyadjustthe

choketowardtheRUNposition.Waituntiltheenginerunssmoothly

beforeeachchokeadjustment.

7. Iftheenginefalters,movethecontrolleverto theCHOKEposition,

thenslowlybackto the RUNposition.

8. Ifweatheriscold, runthewedgeupor downthe beam6 to 8 times

tocirculatethe

Whenstartinga warmengine,themufflerandsurroundingareasare

hotandcancausea burn. Donottouchtheseareas.

USING THE LOG SPLITTER

.

Placethe logsplitterondry,levelground.

2.

Placethe beamineitherthehorizontalorverticalpositionandlock

itin placewiththe appropriatelockingrod.

.

Blockthefrontandbackofbothwheels.

4.

Placethe logagainsttheend plateandonly splitwoodin the

directionofthegrain.

5. Tostabilizethelog,placeyourhandonlyonthe sidesofthelog.

Neverplaceyourhandon the endbetweenthe log and the

splittingwedge.

6. Onlyoneadultshouldstabilizethelogandoperatethecontrol

handle,sotheoperatorhasfullcontroloverthelogand thesplitting

wedge.

Control Handle

1. MovethecontrolhandleFORWARDor DOWNtosplitwood.

2. Releasethecontrolhandletostopthewedgemovement.

3. MovethecontrolhandleBACKorUPto returnthewedge.

Log Dislodger

Thelogdislodgerisdesignedto removeanypartiallysplitwoodfrom

thewedge.Thismayoccurwhilesplittinglargediameterwoodor

freshlycutwood.

Neverremovepartiallysplitwoodfromthewedgewithyourhands.

Fingersmaybecometrappedbetweenthesplitwood.

1. Toremovepartiallysplitwoodfromthewedge,movethecontrol

handletothe REVERSEpositionuntilthewedgeisfullyretractedto

allowthe splitwoodportiontocontactthelogdislodger.

2. Onceremovedfromthewedgewiththelogdislodger,splitthe

woodfromtheoppositeendorin anotherlocation.

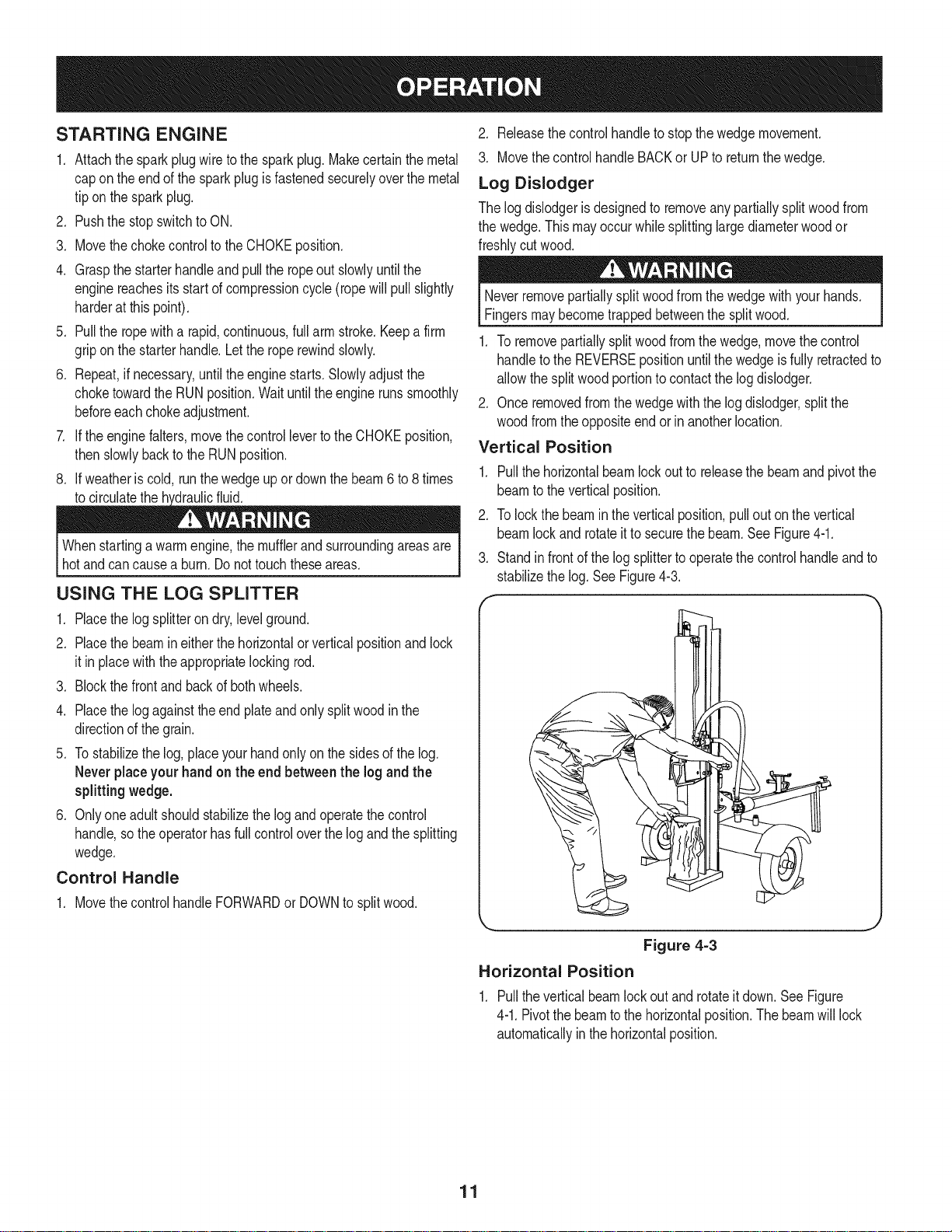

Vertical Position

1. Pullthehorizontalbeamlockouttoreleasethebeamandpivotthe

beamto the verticalposition.

2. Tolockthebeamin theverticalposition,pulloutonthe vertical

beamlockand rotateit to securethe beam.See Figure4-1.

3. Standin frontofthelogsplittertooperatethecontrolhandleandto

stabilizethelog.SeeFigure4-3.

Figure 4=3

Horizontal Position

1. Pulltheverticalbeamlockout androtateitdown.SeeFigure

4-1.Pivotthe beamtothehorizontalposition.Thebeamwilllock

automaticallyinthe horizontalposition.

11

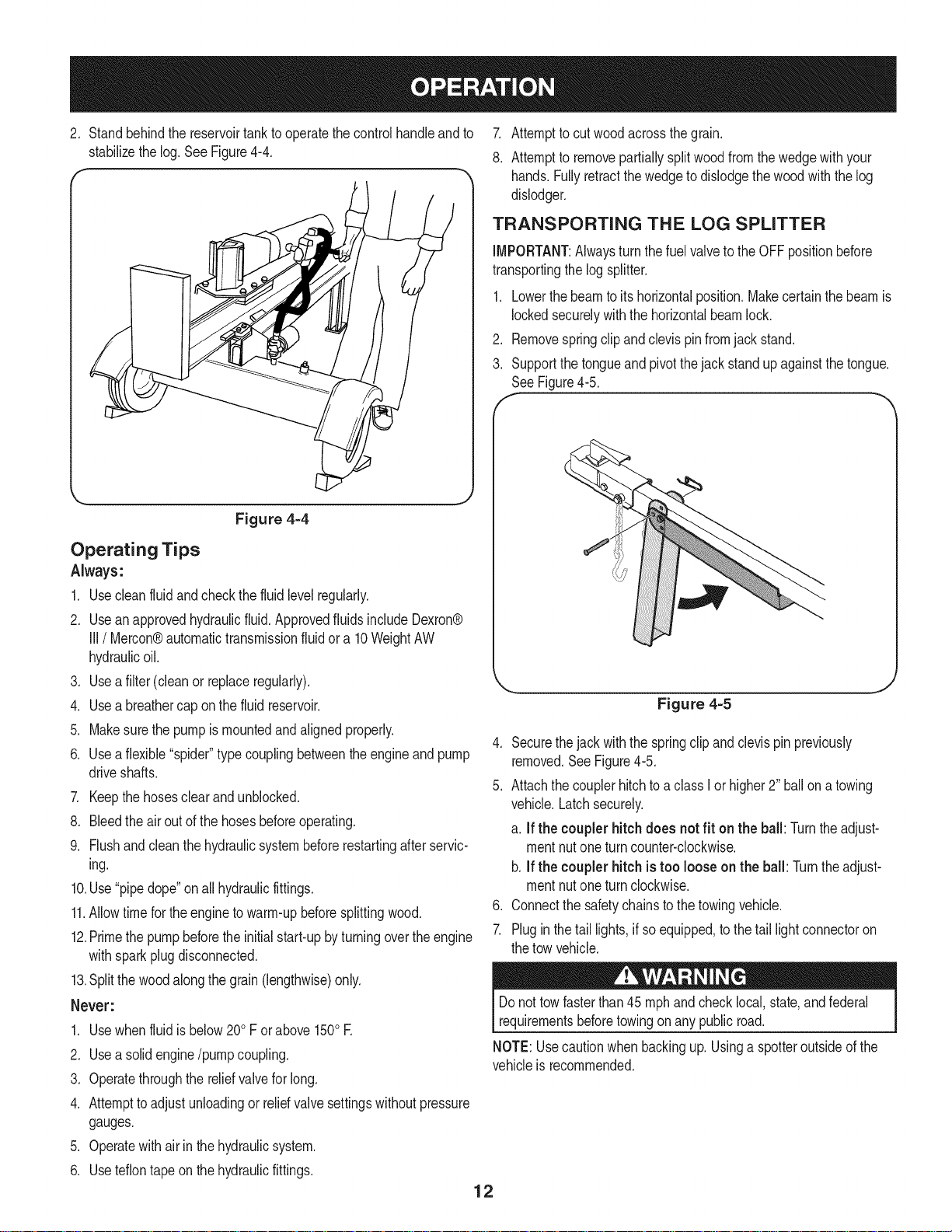

2, Standbehindthe reservoirtankto operatethecontrolhandleandto 7.

stabilizethelog,See Figure4-4, 8,

TRANSPORTING THE LOG SPLITTER

transportingthelogsplitter.

2. Removespringclipandclevispinfromjack stand.

3. Supportthetongueandpivotthejack standup againstthetongue.

Figure 4=4

Operating Tips

Always:

1. Usecleanfluidandcheckthe fluid levelregularly.

2. Useanapprovedhydraulicfluid.ApprovedfluidsincludeDexron®

III/ Mercon®automatictransmissionfluidora 10WeightAW

hydraulicoil.

3. Useafilter(cleanor replaceregularly).

4. Usea breathercaponthe fluid reservoir.

5. Makesurethe pumpis mountedandalignedproperly.

6. Useaflexible"spider"typecouplingbetweentheengineandpump

driveshafts.

7. Keepthehosesclearandunblocked.

8. Bleedtheairoutofthehosesbeforeoperating.

9. Flushandcleanthehydraulicsystembeforerestartingafterservic-

ing.

10.Use"pipedope"onall hydraulicfittings.

11.Allowtimefortheenginetowarm-upbeforesplittingwood.

12.Primethe pumpbeforetheinitialstart-upbyturningovertheengine

withsparkplugdisconnected.

13.Splitthewoodalongthe grain(lengthwise)only.

Never:

1. Usewhenfluidis below200For above1500E

2. Usea solidengine/pumpcoupling.

3. Operatethroughthereliefvalvefor long.

4. Attempttoadjustunloadingor relid valvesettingswithoutpressure

gauges.

5. Operatewithairin thehydraulicsystem.

6. Useteflontapeon the hydraulicfittings.

4. Securethejack withthe springclipandclevispinpreviously

5. Attachthe couplerhitchtoa classI or higher2" ballona towing

6. Connectthe safetychainsto the towingvehicle.

vehicleis recommended.

12

Attempttocutwoodacrossthe grain.

Attemptto removepartiallysplitwoodfromthewedgewithyour

hands.Fullyretractthewedgetodislodgethewoodwiththelog

dislodger.

IMPORTANT:AlwaysturnthefuelvalvetotheOFFpositionbefore

1. Lowerthebeamtoitshorizontalposition.Makecertainthebeamis

lockedsecurelywiththe horizontalbeamlock.

SeeFigure4-5.

Figure 4=5

removed.SeeFigure4-5.

vehicle.Latchsecurely.

a. If the couplerhitchdoes notfit on the ball: Turntheadjust-

mentnutone turncounter-clockwise.

b.If the couplerhitch is too loose onthe ball: Turntheadjust-

mentnutone turnclockwise.

7. Plugin thetail lights,if so equipped,tothetaillightconnectoron

thetowvehicle.

Donot towfasterthan45mph andchecklocal,state,and federal

requirementsbeforetowingonanypublicroad.

NOTE:Usecautionwhenbackingup.Usinga spotteroutsideofthe

f

Adjustment

Bolt

.Gib

Jam Nut

Lock Nut

Figure 5=1

Donotat any timemakeanyadjustmentswithoutfirststopping

theengine,disconnectingsparkplugwireandgroundingitagainst

theengine.Alwayswearsafetyglassesduringoperationor while

[performng anyadjustmentsor repars.

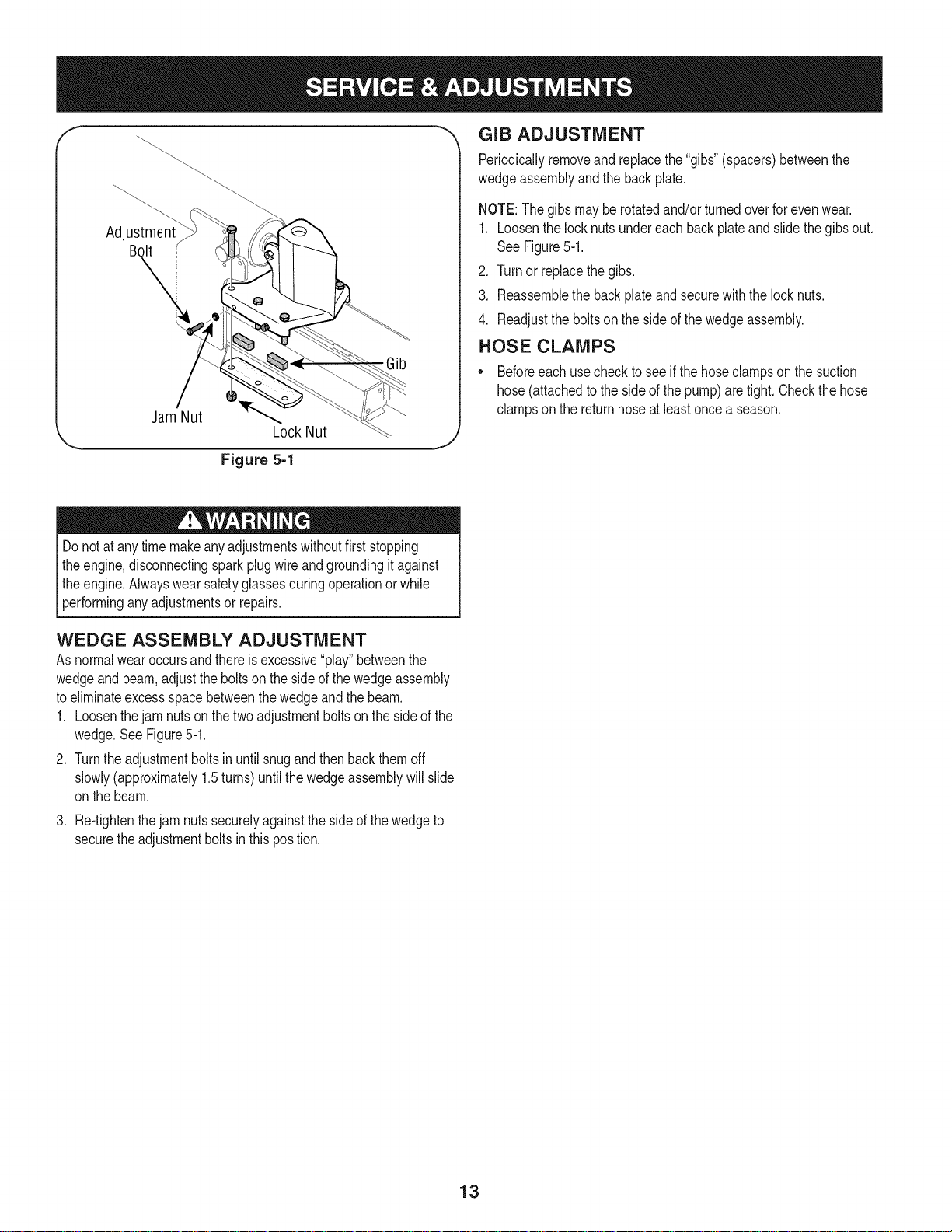

"_ GIB ADJUSTMENT

Periodicallyremoveandreplacethe"gibs"(spacers)betweenthe

wedgeassemblyandthe backplate,

NOTE:The gibsmaybe rotatedand/orturnedoverforevenwear.

1. Loosenthelocknutsundereachbackplateandslidethe gibsout.

See Figure5-1.

2. Turnor replacethegibs.

3. Reassemblethe backplateandsecurewiththelocknuts.

4. Readjustthe boltsonthesideofthewedgeassembly.

HOSE CLAMPS

• Beforeeachusecheck toseeif thehoseclampsonthe suction

hose(attachedtothesideofthepump)aretight.Checkthehose

clampsonthereturnhoseatleastoncea season.

WEDGE ASSEMBLY ADJUSTMENT

Asnormalwearoccursandthereis excessive"play"betweenthe

wedgeandbeam,adjusttheboltsonthe sideofthewedgeassembly

toeliminateexcessspacebetweenthewedgeandthe beam.

1. Loosenthejam nutson the twoadjustmentboltson the sideofthe

wedge.SeeFigure5-1.

2. Turntheadjustmentboltsinuntil snugandthenbackthemoff

slowly(approximately1.5turns)untilthe wedgeassemblywillslide

onthebeam.

.

Re-tightenthejamnutssecurelyagainstthesideofthewedgeto

securetheadjustmentboltsin thisposition.

13

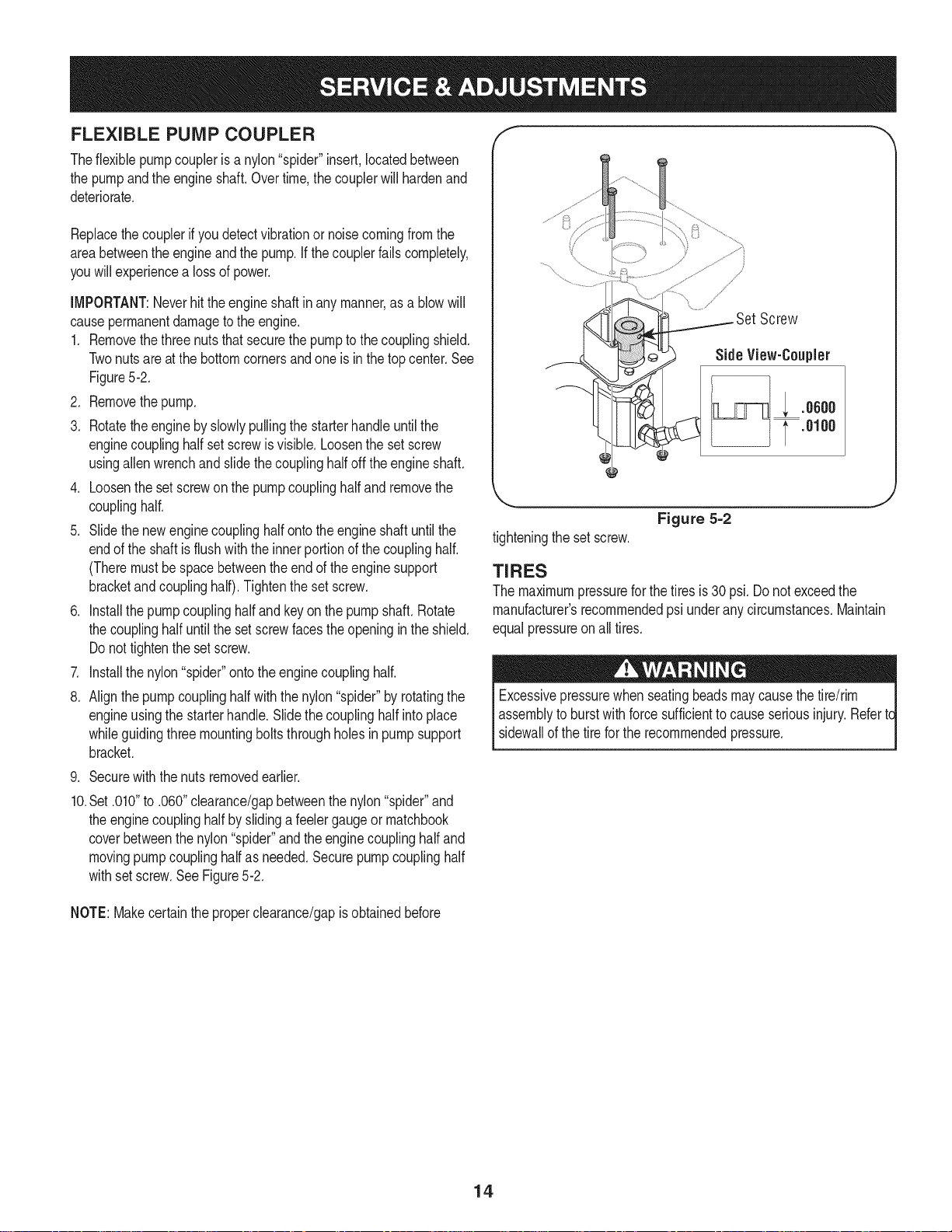

FLEXIBLE PUMP COUPLER

Theflexiblepumpcouplerisa nylon"spider"insert,locatedbetween

thepumpandthe engineshaft.Overtime,thecouplerwillhardenand

deteriorate.

Replacethecouplerifyoudetectvibrationornoisecomingfromthe

areabetweentheengineandthe pump.If thecouplerfailscompletely,

youwill experiencealossofpower.

]i!ill

iMPORTANT:Neverhitthe engineshaftin anymanner,asa blowwill

causepermanentdamagetotheengine.

1. Removethethreenutsthatsecurethepumptothecouplingshield.

Twonutsareat the bottomcornersandoneis inthetopcenter.See

Figure5-2.

2. Removethepump.

3. Rotatetheenginebyslowlypullingthestarterhandleuntilthe

enginecouplinghalfsetscrewisvisible.Loosenthesetscrew

usingallenwrenchand slidethecouplinghalfoff theengineshaft.

4. Loosenthesetscrewonthe pumpcouplinghalfandremovethe

couplinghalf.

5. Slidethenewenginecouplinghalfontotheengineshaftuntil the

endoftheshaftisflushwiththe innerportionofthecouplinghalf.

(Theremustbespacebetweentheendoftheenginesupport

bracketandcouplinghalf).Tightenthesetscrew.

6. Installthe pumpcouplinghalfandkeyon thepumpshaft.Rotate

thecouplinghalfuntilthesetscrewfacestheopeningin the shield.

Donottightenthe set screw.

7. Installthe nylon"spider"ontotheenginecouplinghalf.

8. Alignthepumpcouplinghalfwiththenylon"spider"byrotatingthe

engineusingthe starterhandle.Slidethecouplinghalfinto place

whileguidingthreemountingboltsthroughholesinpumpsupport

bracket.

9. Securewiththe nutsremovedearlier.

10.Set.010"to .060"clearance/gapbetweenthenylon"spider"and

theenginecouplinghalfbyslidinga feelergaugeor matchbook

coverbetweenthenylon"spider"andthe enginecouplinghalfand

movingpumpcouplinghalfas needed.Securepumpcouplinghalf

withsetscrew.SeeFigure5-2.

/

Screw

Side View-Coupler

; .oooo

.0100

J

Figure 5=2

tighteningtheset screw.

TIRES

Themaximumpressureforthetiresis30 psi.Donotexceedthe

manufacturer'srecommendedpsiunderanycircumstances.Maintain

equalpressureonall tires.

Excessivepressurewhenseatingbeadsmaycausethetire/rim

assemblyto burstwithforcesufficienttocauseseriousinjury.Refertc

sidewallofthetirefor the recommendedpressure.

NOTE:Makecertainthe properclearance/gapisobtainedbefore

14

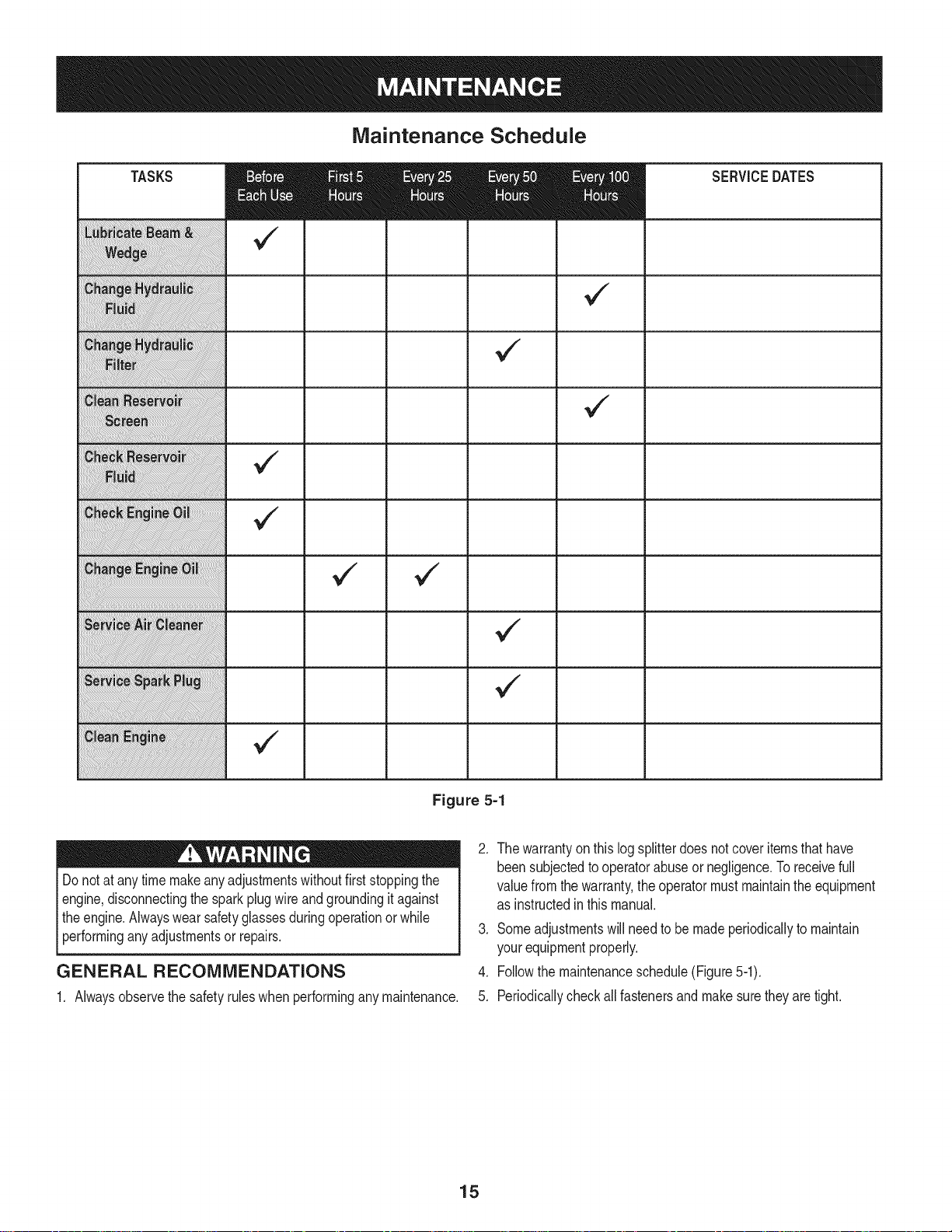

Maintenance Schedule

TASKS

SERVICEDATES

v

Figure 5=1

Donotat any timemakeanyadjustmentswithoutfirststoppingthe

engine,disconnectingthe sparkplugwireandgroundingitagainst

theengine.Alwayswearsafetyglassesduringoperationor while

performinganyadjustmentsor repairs.

GENERAL RECOMMENDATIONS

1. Alwaysobservethesafetyruleswhenperforminganymaintenance.

.

Thewarrantyonthis logsplitterdoesnotcoveritemsthathave

beensubjectedtooperatorabuseornegligence.Toreceivefull

valuefromthewarranty,theoperatormustmaintaintheequipment

asinstructedinthis manual.

3. Someadjustmentswillneedto bemadeperiodicallytomaintain

yourequipmentproperly.

4. Followthemaintenanceschedule(Figure5-1).

5. Periodicallycheckallfastenersandmakesuretheyaretight.

15

HYDRAULIC FLUID AND iNLET FILTER

Checkthehydraulicfluidlevelinthelogsplitterreservoirtank

beforeeachuse.Maintainthefluidlevelwithinthe rangespecified

onthedipstickatall times.

Changethehydraulicfluidinthe reservoirevery100hoursof

operation.Followthestepsbelow:

Disconnectthesuctionhosefromthe bottomofthereservoirtank.

2. Carefullyunthreadtheinletfilterandcleanitwithpenetratingoil.

SeeFigure5-2.

3. Allowthefluidtodrainintoa suitablecontainer.

4. Reinsertthefilterandrefillthe reservoirwiththree(3) gallonsofoil.

ApprovedfluidsincludeDexron®III/Mercon® automatictransmis-

sionfluid ora 10WeightAWhydraulicoil.

• Maintainthefluidlevelwithintherangespecifiedonthedipstickat

alltimes.

NOTE:Alwaysdisposeofusedhydraulicfluidandengineoilat

approvedrecyclingcentersonly.

• Contaminantsinfluidmaydamagethehydrauliccomponents.

Flushingthereservoirtankand hoseswithkerosenewhenever

serviceisperformedonthe tank, hydraulicpumporvalveis

recommended.Anyrepairtothehydrauliccomponentsshouldbe

performedbya SearsServiceCenter.

USE EXTREMECAUTIONWHEN WORKING WITH KEROSENE. IT IS AN EXTREMELY

FLAMMABLEFLUID.

Hydraulic Filter

• Changethehydraulicfilterevery50 hoursof operation.Useonlya

10micronhydraulicfilter.Orderpart number723-0405.

BEAM AND SPLITTING WEDGE

Beforeeachuse,lubricatebothsidesofthebeam(whereit comes

intocontactwiththe splittingwedge)withengineoil.Thewedge

plateonthelog splitterisdesignedsothegibsonthesideof the

wedgeplatecanbe removedandrotatedand/orturnedoverfor

evenwear.

• Makecertaintoreadjusttheadjustmentboltssothewedgemoves

freely,butnoexcessspaceexistsbetweenthewedgeplateandthe

beam.

/

Figure 5=2

ENGINE

Check Engine Oil

1. Stoptheengineandwait severalminutesbeforecheckingtheoil

level.

2. Removethe oilfilldipstick.

3. Checktheoillevelon thedipstick.Withtheengineon levelground,

theoil mustbeto the FULLmarkon thedipstick.

4. Replacethedipstickandtighten.

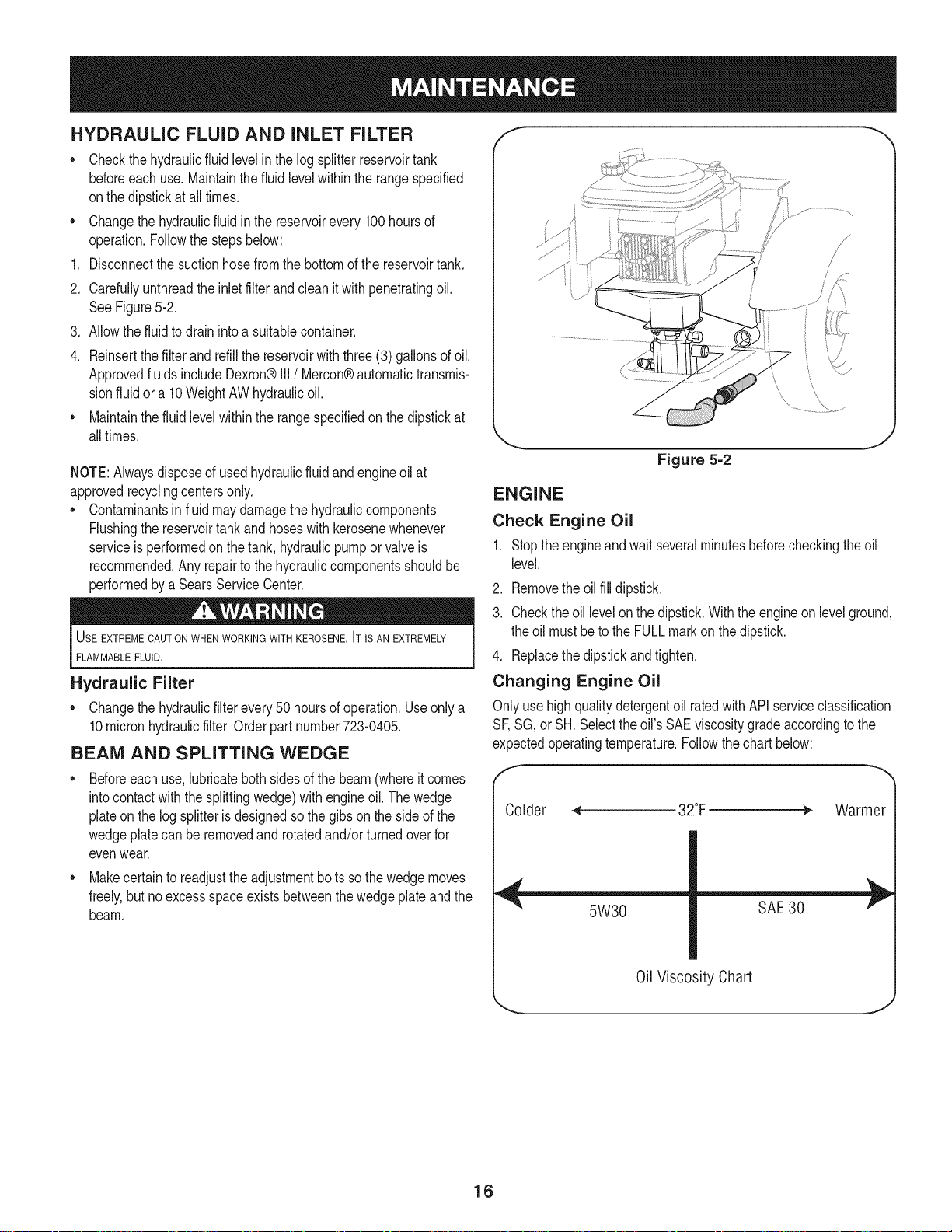

Changing Engine Oil

Onlyusehighqualitydetergentoil ratedwithAPIserviceclassification

SF,SG,or SH.Selecttheoil's SAEviscositygradeaccordingtothe

expectedoperatingtemperature.Followthechartbelow:

Warmer

5W30

SAE 30

16

0il Viscosity Chart

NOTE:Althoughmulti-viscosityoils(5W30,10W30,etc.)improve

startingincoldweather,theywill resultin increasedoilconsumption

whenusedabove32°RCheckyourengineoillevelmorefrequentlyto

avoidpossibleenginedamagefromrunninglowonoil.

Changetheengineoilafterthefirstfivehoursofoperation,andevery

50 hoursthereafter.Changetheoilevery25hoursofoperationifthe

engineisoperatedunderheavyloadorin highambienttemperatures.

To Drain Oil

Drainthe oilwhilethe engineis warm.Followtheinstructionsgiven

below.

.

Removethedrainplugontheengineanddraintheoilintoa

suitablecontainer.

2.

Whentheengineis drainedof alloil, replacethedrainplugand

refillwithapproximately20oz.offreshoil. Referto GasAnd Oil

Fill-upintheOPERATIONsection.

Service Air Cleaner

Theair cleanerpreventsdamagingdirt, dust,etc.,fromenteringthe

carburetorandbeingforcedintotheengineandisimportanttoengine

lifeand performance.

Neverruntheenginewithoutanaircleanercompletelyassembled.

Servicethecartridgeevery25operatinghoursor everyseason.

Servicethecartridgemoreoftenunderdustyconditions.

To Service Air Filter

.

Loosentheaircleanercoverscrew,butdo not removethescrew

fromthecover.Swingthecoverdownto removefromthehinge.

2.

Inspectthefilterfordiscolorationor dirtaccumulation.If eitheris

present,proceedasfollows:

a. Cleanthe insideof bodyandcoverthoroughlyand removethe

cartridge.

b. Reassemblethenewcartridgein thebody.Swingthecover

downandtightenthescrewloosenedearlier.

Temperatureof mufflerandnearbyareasmayexceed150°F(65°C).

Avoidtheseareas.

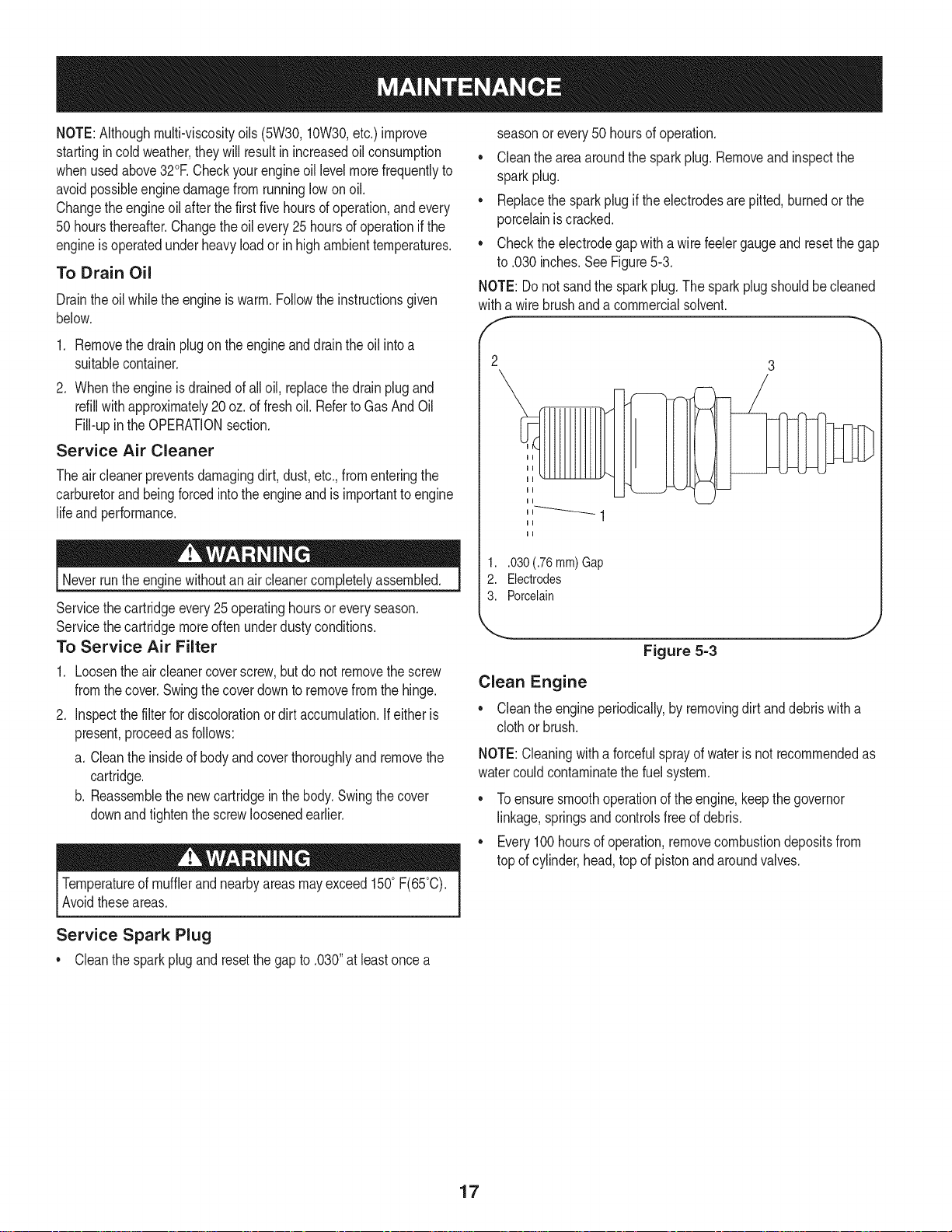

seasonor every50 hoursof operation.

• Cleantheareaaroundthe sparkplug.Removeandinspectthe

sparkplug.

• Replacethesparkplugif theelectrodesarepitted,burnedor the

porcelainiscracked.

• Checktheelectrodegapwitha wire feelergaugeandresetthe gap

to .030inches.SeeFigure5-3.

NOTE:Donot sandthesparkplug.Thesparkplugshouldbecleaned

witha wirebrushanda commercialsolvent.

f

1..030 (.76 mm) Gap

2. Electrodes

3. Porcelain

J

Figure 5=3

Clean Engine

• Cleantheengineperiodically,by removingdirtanddebriswitha

clothor brush.

NOTE:Cleaningwitha forcefulsprayof waterisnotrecommendedas

watercouldcontaminatethefuelsystem.

• Toensuresmoothoperationoftheengine,keepthegovernor

linkage,springsandcontrolsfreeof debris.

• Every100hoursofoperation,removecombustiondepositsfrom

topofcylinder,head,topof pistonandaroundvalves.

Service Spark Plug

* Cleanthesparkplugandresetthegapto .030"at leastoncea

17

Prepareyourlogsplitterforstorageattheendoftheseasonor ifthe

logsplitterwillnotbeusedfor30daysor more.

WARNING:Neverstorethemachinewithfuelinthe fueltank inside

ofbuildingwherefumesmayreachanopenflameor sparkor where

ignitionsourcesarepresentsuchashotwaterandspaceheaters,

furnaces,clothesdyers,stoves,electricmotors,etc.

NOTE:Ayearlycheck-upbyyourlocalSearsservicecenterisa good

waytoensureyourlog splitterwillprovidethemaximumperformance

nextseason.

LOG SPLITTER

1. Cleanthe logsplitterthoroughly.

2. Wipethe logsplitterwithanoiledragtopreventrust,especiallyon

thewedgeandthe beam.

ENGINE

IMPORTANT:Itisimportanttopreventgumdepositsfromforming

intheessentialfuelsystempartssuchas thecarburetor,fuel filter,

fuelhoseortankduringstorage.Also,alcoholblendedfuels(called

gasoholorusingethanolor methanol)canattractmoisturewhichleads

toseparationandformationof acidsduringstorage.Acidicgascan

damagethefuelsystemof anenginewhilein storage.

1. Drainthe fueltank.Alwaysdrainthefuelintoanapprovedcontainer

outdoorsawayfromopenflame.Besuretheengineiscool. Donot

smokewhilehandlingthefuel.

2. Starttheengineandlet it rununtil thefuellinesandcarburetorare

empty.

IMPORTANT:Neveruseengineor carburetorcleanerproductsinthe

fueltankor permanentdamagemayoccur.Usefreshfuelnextseason.

3. Removethe sparkplug,pourapproximately1/2oz.ofengineoilinto

cylinderandcrankit slowlytodistributetheoil.

4. Replacethesparkplug.

NOTE:Fuelstabilizerisan acceptablealternativeinminimizingthe

formationoffuelgumdepositsduringstorage.

Pleasefollowtheinstructionsbelowforstoringyourlogsplitterwith

fuelandstabilizerintheengine:

1. Addstabilizertothegasolineinthefueltankor storagecontainer.

Alwaysfollowthe mixratiofoundonthe stabilizercontainer.

2. Runtheengineat least10minutesafteraddingstabilizerto allow

thestabilizertoreachthecarburetor.

IMPORTANT:Donotdrainthegastankandcarburetorifusingfuel

stabilizer.Drainalltheoil fromthecrankcase(thisshouldbedone

aftertheenginehasbeenoperatedandisstill warm)andrefillthe

crankcasewithfreshoil.

OTHER

• Donotstorethegasolinefromoneseasonto another.

• Replaceyourgasolinecanif itstartstorust.

Storethe logsplitterin a clean,dry area.Donotstoreit nextto

anycorrosivematerials,suchasfertilizer.

• Wipetheequipmentwithan oiledragto preventrust.

18

Loading...

Loading...