Page 1

YARDMACHINES

OPERATOR'S MANUAL

LOG SPLITTER

VERTICAL

SHAFT

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit isequipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 368022 Cleveland, Ohio 44136-9722.

MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A.

FORM NO. 770-10055A

(5/99)

Page 2

SECTION 1: FINDING YOUR MODEL NUMBER

This Operator's Manual is an important part of your new log splitter. It will help you assemble, prepare and

maintain your log splitter. Please read and understand what it says.

Before you start to prepare your log splitter for its first use, please locate the model plate and copy the

information from it in this Operator's Manual. The information on the model plate is very important if you need

help from your dealer or the MTD customer support department.

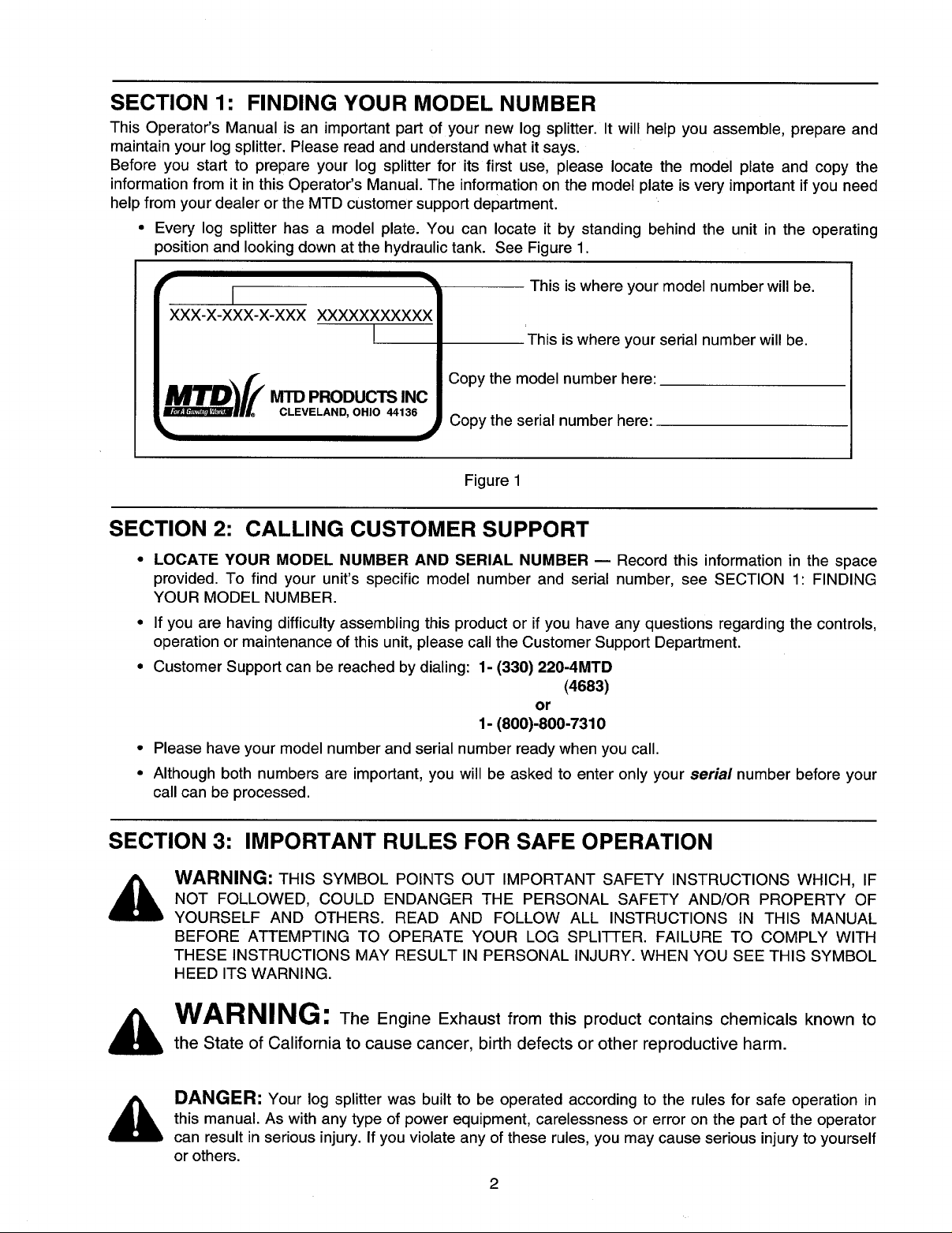

• Every log splitter has a model plate. You can locate it by standing behind the unit in the operating

position and looking down at the hydraulic tank. See Figure 1.

I

XXX-X-XXX-X-XXX XXXXXXXXXXX

CLEVELAND, OHIO 44136 •

Copy the model number here:

Copy the serial number here:

Figure 1

This is where your model number will be.

This is where your serial number will be.

SECTION 2: CALLING CUSTOMER SUPPORT

• LOCATE YOUR MODEL NUMBER AND SERIAL NUMBER m Record this information in the space

provided. To find your unit's specific model number and serial number, see SECTION 1: FINDING

YOUR MODEL NUMBER.

• If you are having difficulty assembling this product or if you have any questions regarding the controls,

operation or maintenance of this unit, please call the Customer Support Department.

• Customer Support can be reached by dialing: 1- (330) 220-4MTD

(4683)

or

1- (800)-800-7310

• Please have your model number and serial number ready when you call.

• Although both numbers are important, you will be asked to enter only your serial number before your

call can be processed.

SECTION 3: IMPORTANT RULES FOR SAFE OPERATION

WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF

NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF

YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE YOUR LOG SPLITTER. FAILURE TO COMPLY WITH

THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL

HEED ITS WARNING.

WARNING: The Engine Exhaust from this product contains chemicals known to

the State of California to cause cancer, birth defects or other reproductive harm.

DANGER: Your log splitter was built to be operated according to the rules for safe operation in

this manual. As with any type of power equipment, carelessness or error on the part of the operator

can result in serious injury. If you violate any of these rules, you may cause serious injury to yourself

or others.

2

Page 3

1. TRAINING

• Before operating this splitter, read and understand

this operator's manual completely. Become famil-

iar with it for your own safety. To fail to do so may

cause serious injury. Do not allow anyone to oper-

ate your splitter who has not read this manual.

Keep this manual in a safe place for future and reg-

ular reference and for ordering replacement parts.

• Never use your splitter for any other purpose than

splitting wood. It is designed for this use and any

other use may cause an injury. Your log splitter is a

precision piece of power equipment, not a toy.

Therefore, exercise extreme caution at all times.

• Never allow children to operate your log splitter. Do

not allow adults to operate it without proper instruc-

tion. Only persons well acquainted with these rules

of safe operation should be allowed to use your log

splitter.

• Only the operator is to be near your log splitter dur-

ing use. Keep all others, including pets and chil-

dren, a minimum of 20 feet away from your work

zone. Flying wood can be hazardous. If a helper is

assisting in loading logs, never activate the control

until the helper is clear of the area. More accidents

occur when more than one person operates the log

splitter than at any other time.

• No one should operate this unit while intoxicated or

while taking medication that impairs the senses or

reactions. A clear mind is essential for safety.

Never allow a person who is tired or otherwise not

alert to use your splitter.

=

PREPARATION

• Never wear loose clothing or jewelry that can be

caught by moving parts of your log splitter and pull

you into it. Keep clothing away from all moving

parts of your log splitter.

• Wear proper head gear to keep hair away from

moving parts. Always wear protective hearing

devices as needed.

• Always wear safety shoes. A dropped log can seri-

ously injure your foot.

• Always wear safety glasses or goggles while oper-

ating your splitter. A piece of splitting log could fly

off and hit your eyes.

• Wear leather work gloves. Be sure they are tight fit-

ting without loose cuffs or draw strings.

• Use your log splitter in daylight, or under good arti-

ficial light.

• Never operate your splitter on slippery, wet, muddy

or icy surfaces. Safe footing is essential in prevent-

ing accidents.

• Never operate your splitter while it's still attached to

a towing vehicle.

• Only operate your splitter on level ground and not

on the side of a hill. It could tip, or rolling logs or

poor footing could cause an accident. Operating

the splitter on level ground also prevents the spill-

age of gasoline from the fuel tank.

Never attempt to move the log splitter over hilly or

uneven terrain without a tow vehicle or adequate

help.

Always block the wheels to prevent movement of

log splitter while in operation.

Check the fuel before starting the engine. Gasoline

is an extremely flammable fuel. Do not fill the gaso-

line tank indoors, when the engine is running, or

while the engine is still hot. Replace gasoline cap

securely and wipe off any spilled gasoline before

starting the engine as it may cause a fire or explo-

sion.

• Both ends of each log must be cut as square as

possible to help prevent the log from riding out of

the splitter during operation.

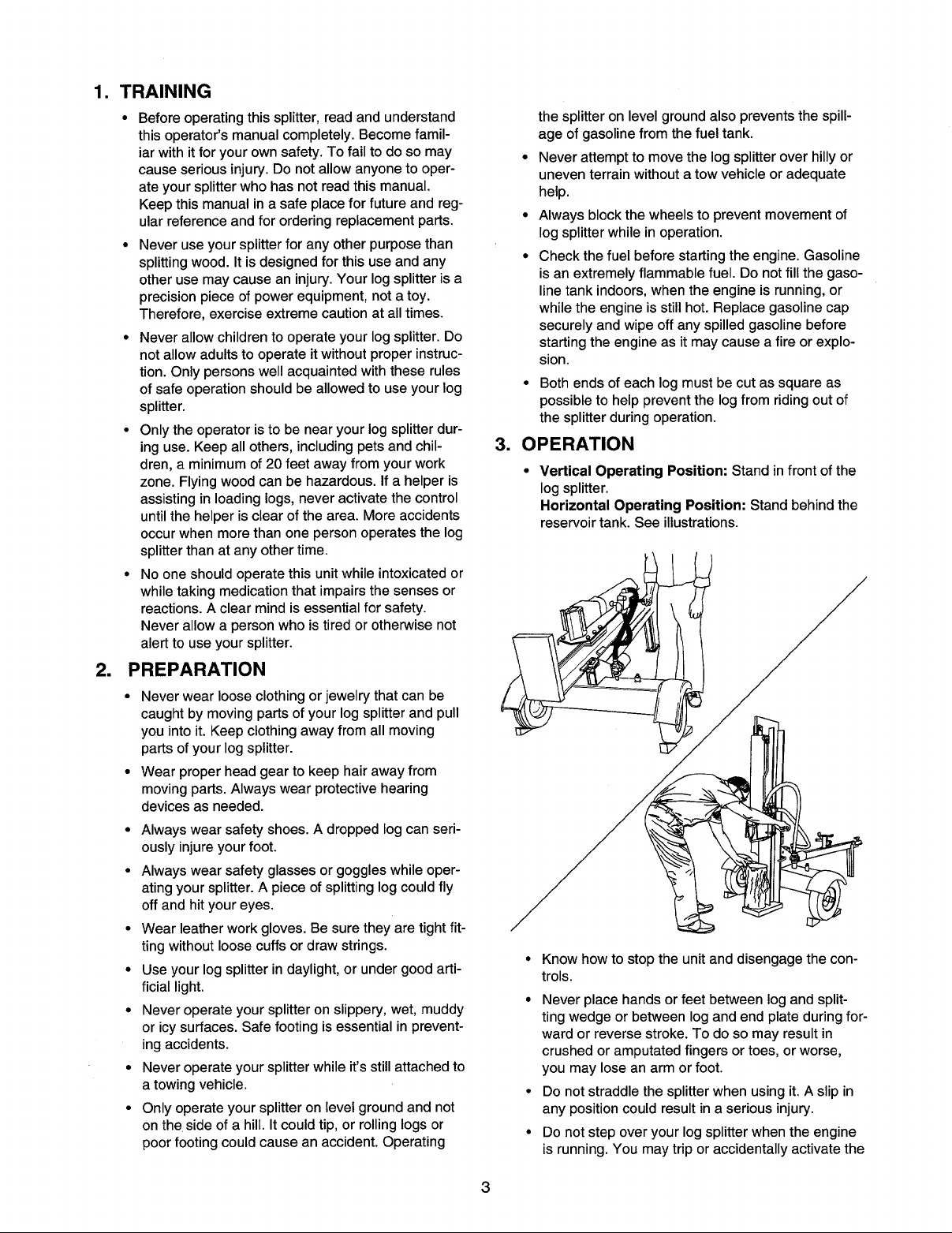

3. OPERATION

Vertical Operating Position: Stand in front of the

log splitter.

Horizontal Operating Position: Stand behind the

reservoir tank. See illustrations.

Know how to stop the unit and disengage the con-

trols.

• Never place hands or feet between log and split-

ting wedge or between log and end plate during for-

ward or reverse stroke. To do so may result in

crushed or amputated fingers or toes, or worse,

you may lose an arm or foot.

• Do not straddle the splitter when using it. A slip in

any position could result in a serious injury.

• Do not step over your log splitter when the engine

is running. You may trip or accidentally activate the

3

Page 4

splitting wedge if you step over. If you need to get

to the other side, walk around.

• Never try to split two logs on top of each other. One

may fly out and injure you.

• When loading the log splitter, place your hands on

the side of the log, not at the ends. Never attempt

to load your splitter while the splitting wedge is in

motion. You may get caught by the wedge and

injured.

• Only use your hand to operate the splitting wedge

or control lever. Never use your foot or a rope or

any other extension device. This could result in

your inability to stop your splitter quickly enough to

avoid injury.

• Always keep fingers away from any cracks that

open in the log during splitting operation. They can

quickly close and pinch or amputate your fingers.

• Never attempt to split woods across the grain.

Some types of wood may burst or fly out of your

splitter and result in injury to you or a bystander.

• For logs that are not cut square, the longest por-

tion of the log should be rotated down and the most

square end placed against the splitting wedge.

• Keep your work area clean. Immediately remove

split wood around your splitter so that you do not

stumble over it. Clean chips and dirt off end plate

(wood platform) after each log is split, or whenever

necessary to maintain flat contact between wood

and end plate (platform).

• Never move the log splitter while the engine is run-

ning.

• Never leave your log splitter unattended with the

engine running. Shut off the engine if you are leav-

ing your splitter, even for a short period of time.

Someone could accidentally activate the splitting

wedge and be injured.

• Do not run engine in an enclosed area. Exhaust

gases contain carbon monoxide. This odorless gas

can be deadly when inhaled.

• Be careful not to touch the muffler after the engine

has been running. It will be HOT!

• If the equipment should start to vibrate abnormally,

stop the engine and check immediately for the

cause. Vibration is generally a warning of trouble.

• When cleaning, repairing or inspecting, make cer-

tain all moving parts have stopped. Disconnect the

spark plug wire and keep the wire away from the

plug to prevent accidental starting.

4. CUSTOMER RESPONSIBILITIES

Do not operate your splitter in poor mechanical

condition or when in need of repair.

Periodically check that all nuts, bolts, screws, hose

clamps and hydraulic fittings are tight to be sure

equipment is in safe working condition. Where

appropriate, check all safety guards and shields to

be sure they are in the proper position. Never oper-

ate your splitter with safety guards, shields or other

protective features removed. These safety devices

are for your protection.

• Replace all damaged or worn parts such as

hydraulic hoses and fittings immediately with manu-

facturer approved replacement parts.

• Do not change the engine governor settings or

overspeed the engine. This increases the hazard of

personal injury. The maximum engine speed is pre-

set by the manufacturer and is within safety limits.

• Do not alter your splitter in any manner such as

attaching a rope or extension to the control lever or

adding to the width or height of the wedge. Such

alterations may cause your splitter to be unsafe.

• Perform all recommended maintenance proce-

dures before you use your splitter.

• Do not service or repair your log splitter without dis-

connecting the spark plug wire and moving it away

from the spark plug.

• Never store the equipment with gasoline in the tank

inside of a building where ignition sources are

present, such as hot water and space heaters,

clothes dryers and the like. Allow the engine to cool

before storing in any enclosure.

• Always store gasoline in an approved, tightly

sealed container. Store the container in a cool, dry

place. Do not store in a building where ignition

sources are present.

• To reduce fire hazard, keep engine free of grass,

leaves, wood chips, and excessive grease and oil.

• The hydraulic system of your log splitter requires

careful inspection, along with the mechanical parts.

Be sure to replace frayed, kinked, or otherwise

damaged hydraulic components.

• Fluid escaping from a very small hole can be

almost invisible. Do not check for leaks with your

hand. Escaping fluid under pressure can have suffi-

cient force to penetrate skin, causing serious per-

sonal injury. Leaks can be located by passing a

piece of cardboard or wood over the suspected

leak and looking for discoloration.

• Should it become necessary to loosen or remove

any hydraulic fitting or line, be sure to relieve all

pressure by shutting off the engine and moving the

control handle back and forth several times.

• Do not remove the cap from the hydraulic tank or

reservoir while your log splitter is running. Hot oil

under pressure could cause injury.

• The pressure relief valve on your splitter is preset

at the factory. Do not adjust the valve. Only a quali-

fied service technician should perform this adjust-

ment.

Completely drain fuel tank prior to storage. This

guards against accumulation of fuel fumes which

could result in a fire hazard.

Never store log splitter outside without a water-

proof cover. Rain will cause rust on the inside of

the cylinder.

4

Page 5

5. TOWING

This unit should not be towed on any street, high-

way or public road without checking the existing

federal, local or state vehicle requirements. Any

licensing or modifications such as taillights, etc.,

needed to comply with the existing federal, local or

state vehicle requirements is the sole responsibility

of the purchaser.

*If a "Statement of Origin" is required in your state,

see your local dealer to receive one.

• Before towing, be certain the log splitter is cor-

rectly and securely attached to the towing vehicle,

and the safety chains are in place. Leave slack in

chains for turning allowance.

• Use a class I or higher hitch ball with a 1-7/8" ball.

Keep ball socket and clamp face lubricated with

chassis grease.

• Be sure the coupler is secured to the hitch ball and

the lock lever is down tight and locked.

• Check vehicle hitch, ball and coupler for signs of

wear or damage. Replace any parts that are worn

or damaged before towing.

• The coupler must be secured to the log splitter

tongue tube with the original equipment bolts and

nuts. See your local dealer for replacement parts.

Coupler nuts should be tightened securely (23 foot

pounds).

• Make sure beam assembly is securely latched in

the horizontal position and jack stand (if provided)

is pivoted and secured in the UP position before

towing the log splitter. Never tow with the beam in

the vertical position.

• Do NOT tow the log splitter faster than 45 MPH.

Higher speeds may damage the log splitter. Exces-

sive speeds may cause the log splitter to "fishtail"

or otherwise become unstable.

• Check the tire pressure on log splitter tires. 30 PSI

is the maximum for highway travel.

• When parking, storing or operating your log split-

ter, keep the coupler off the ground so dirt will not

build up in the ball socket.

• Do not allow anyone to sit or ride on your splitter.

They can easily fall off and be seriously injured.

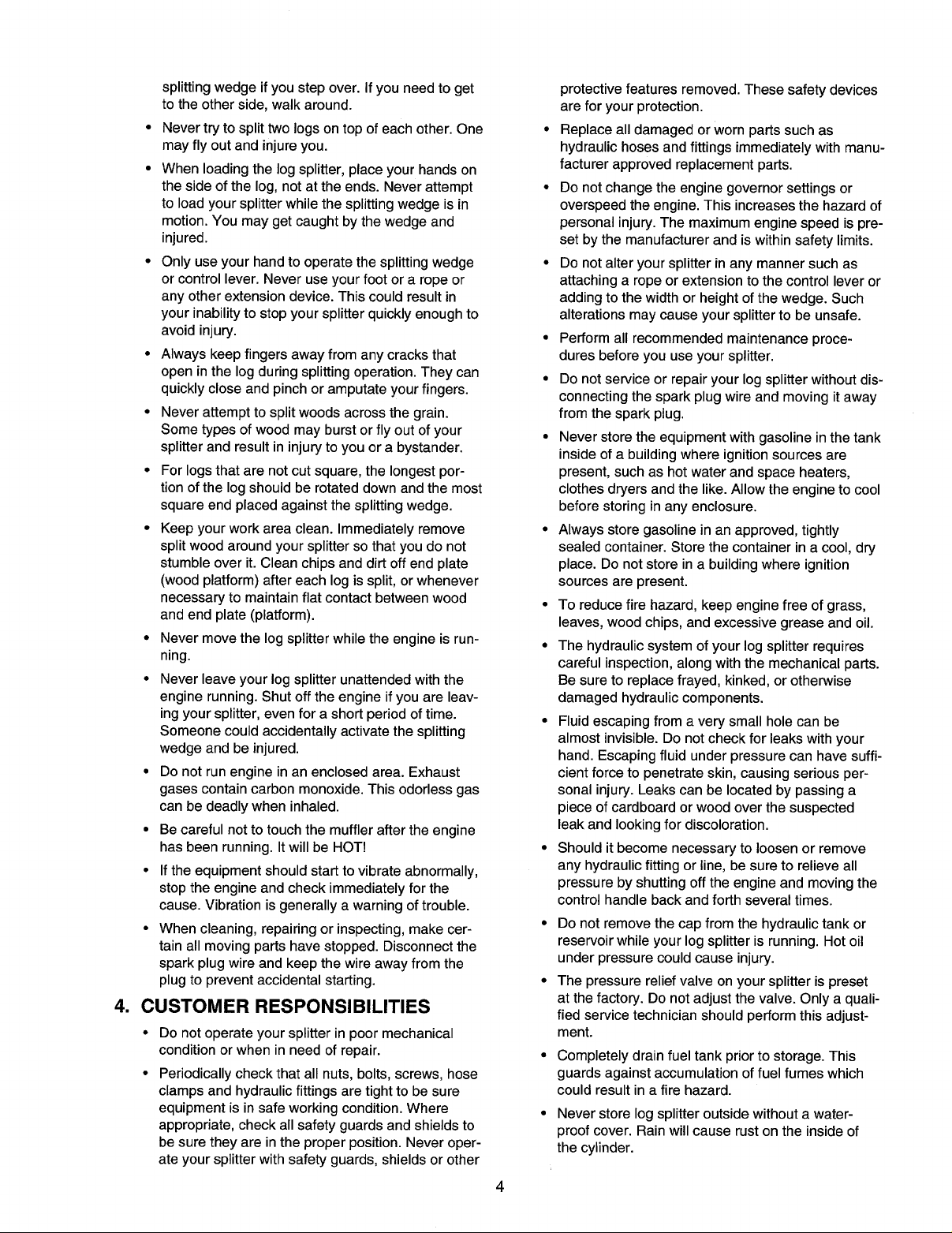

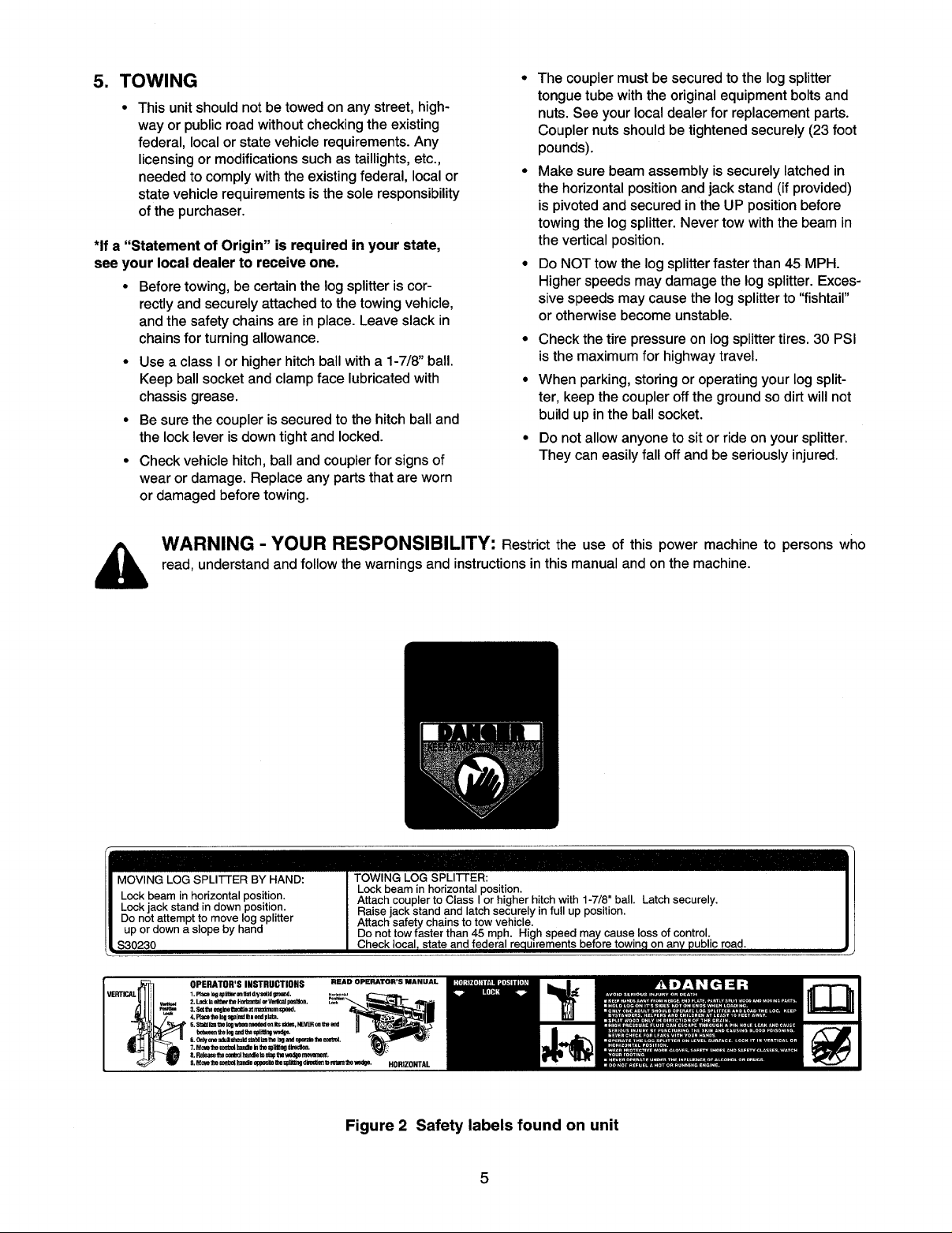

,_ WARNING - YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who

i $30230

I _ OPERATOR'S INSTRUCTIONS

I VERTICALII IIII 1.m_l_ _,_r onr=l_d g.,_. _:._.,

I _ill _ 2.L0_o_H_DnUtorV0_ap_on. _, "__,,,U_iid

I ,_l:#f--- -j HI b_,q_0_spmngwo_. • _--_l_,_,_,

read, understand and follow the warnings and instructions in this manual and on the machine.

MOVING LOG SPLITTER BY HAND:

Lock beam in horizontal position.

Lock jack stand in down position.

Do not attempt to move log splitter

up or down a slope by hand

3.S_thee_lneI[l_lZieatms,humspeed. _"._ . •

Lock beam in horizontal position.

Attach coupler to Class I or higher hitch with 1-7/8" ball. Latch securely.

Raise jack stand and latch securely in full up position.

Attach safety chains to tow vehicle.

I TOWING LOG SPLITTER:

Do not tow faster than 45 mph. High speed may cause loss of control.

Check local Tstate and federal requirements before towin,_ on any public road.

READ OPERATOR S MANUAL

L _ 1' 9.Movear_er'eebotha_e °PPOSPO_ spl_ngdize_l°_t° '_'_z'd_ew4ge. HORIZONTAL

Figure 2 Safety labels found on unit

5

Page 6

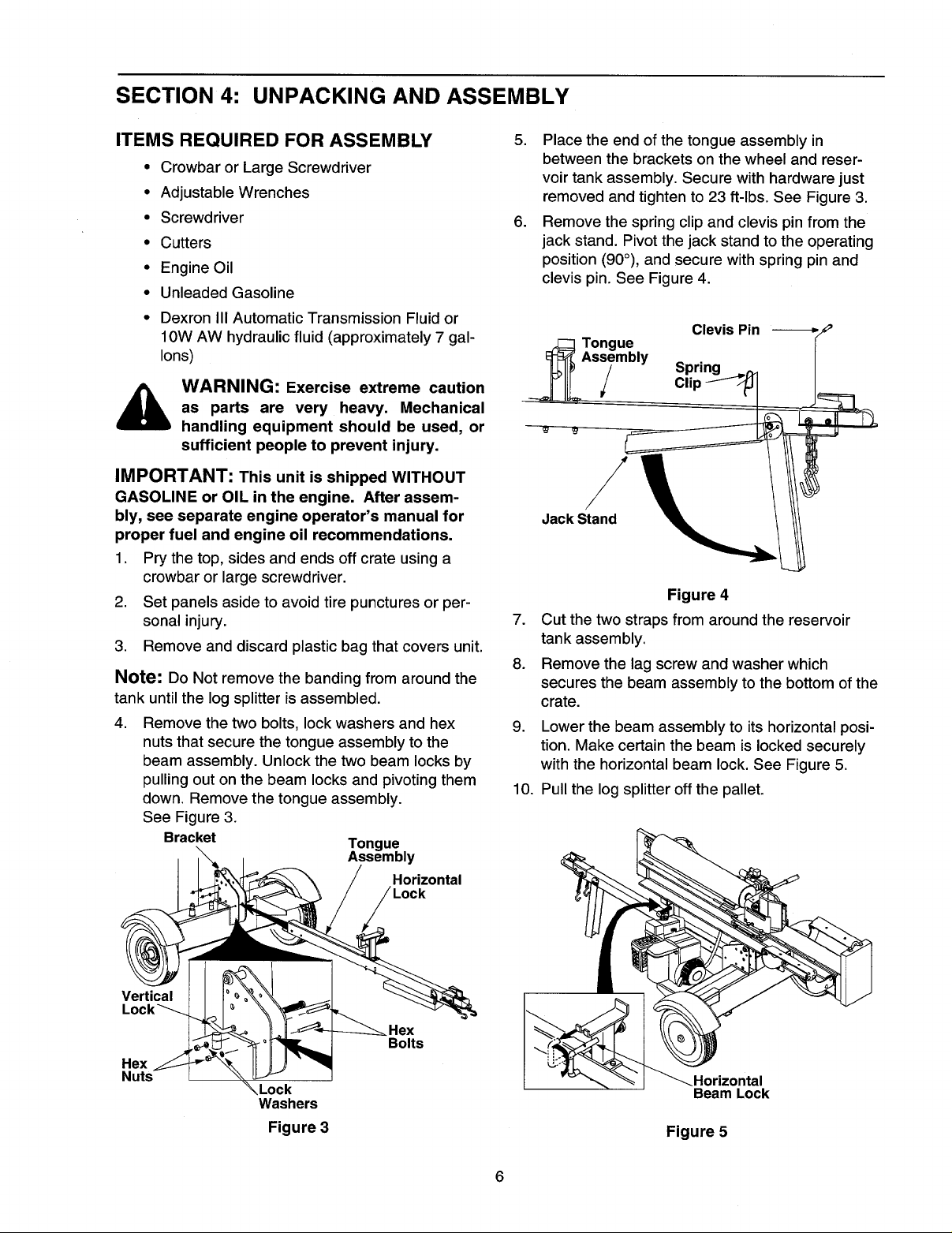

SECTION 4: UNPACKING AND ASSEMBLY

ITEMS REQUIRED FOR ASSEMBLY

• Crowbar or Large Screwdriver

• Adjustable Wrenches

• Screwdriver

• Cutters

• Engine Oil

• Unleaded Gasoline

• Dexron III Automatic Transmission Fluid or

10W AW hydraulic fluid (approximately 7 gal-

lons)

WARNING: Exercise extreme caution

as parts are very heavy. Mechanical

handling equipment should be used, or

sufficient people to prevent injury.

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL in the engine. After assem-

bly, see separate engine operator's manual for

proper fuel and engine oil recommendations.

1. Pry the top, sides and ends off crate using a

crowbar or large screwdriver.

2. Set panels aside to avoid tire punctures or per-

sonal injury.

3. Remove and discard plastic bag that covers unit.

Note: Do Not remove the banding from around the

tank until the log splitter is assembled.

4. Remove the two bolts, lock washers and hex

nuts that secure the tongue assembly to the

beam assembly. Unlock the two beam locks by

pulling out on the beam locks and pivoting them

down. Remove the tongue assembly.

See Figure 3.

Bracket Tongue

Assembly

Horizontal

5. Place the end of the tongue assembly in

between the brackets on the wheel and reser-

voir tank assembly. Secure with hardware just

removed and tighten to 23 ft-lbs. See Figure 3.

6. Remove the spring clip and clevis pin from the

jack stand. Pivot the jack stand to the operating

position (90°), and secure with spring pin and

clevis pin. See Figure 4.

Tongue

Assembly

Jack Stand

Clevis Pin

Cli

Spring

Figure 4

.

Cut the two straps from around the reservoir

tank assembly.

8.

Remove the lag screw and washer which

secures the beam assembly to the bottom of the

crate.

9. Lower the beam assembly to its horizontal posi-

tion. Make certain the beam is locked securely

with the horizontal beam lock. See Figure 5.

10. Pull the log splitter off the pallet.

Vertical

Hex

Nuts

Lock

Washers

Figure 3

Hex

Bolts

Horizontal

Beam Lock

Figure 5

6

Page 7

PREPARING THE ENGINE

.

Place the log splitter on a firm, level surface.

2.

Fill engine with gasoline and oil as instructed in

the separate engine manual packed with your

log splitter.

PREPARING THE LOG SPLITTER

.

Lubricate the beam area where splitting wedge

will slide with engine oil (DO NOT USE

GREASE). Make certain to oil both front and

back of the beam face.

2. Remove reservoir vent plug. See Figure 6.

Reservoir

Vent Plu

+

3"to3 /2"

+

Maintain fluid

level within 3"

to 3 1/2" from

top at all times.

Do not overfill.

Check fluid level using scale. Never run

below this level. Pump will be ruined.

Figure 7

4. Disconnect the spark plug wire. Prime the pump

by pulling the recoil starter, to turn the engine

over, approximately 10 times.

5. Reconnect the spark plug wire.

6. Start engine. (See Starting The Engine in

OPERATION SECTION)

7. Use the control handle to engage the wedge to

the far extended position.

8. Retract the wedge.

9. Refill tank to within 3" to 3 1/2" from the top of

the fill tube.

10.

Extend and retract the wedge 12 complete

cycles to remove trapped air in the system (sys-

tem is "self-bleeding").

Refill the reservoir to within 3" to 3 1/2" from the

11.

top of the fill tube. Much of the original fluid has

been drawn into the cylinder and hoses. Make

certain to refill the reservoir, to prevent extreme

damage to the hydraulic pump. Failure to refill

the tank will void your warranty.

i20739

Figure 6

.

Fill the reservoir tank to the within 3" to 3 1/2"

from the top of fill tube with Dexron III automatic

transmission fluid, or 10W AW hydraulic fluid.

Check fluid level using a scale. Do not overfill.

Replace vent plug securely.

See Figure 7.

NOTE: The reservoir tank has a capacity of

approximately 4 gallons.

NOTE: Some fluid may overflow from the vent plug

as the system builds heat and the fluid expands and

seeks a balanced level.

_ WARNING: Do not operate the log

7

splitter without the proper amount of

hydraulic oil in the reservoir tank.

Page 8

SECTION 5: CONTROLS

ENGINE CONTROLS

See the separate engine operator's manual that was

packed with your log splitter.

LOG SPLITTER CONTROLS

CONTROL HANDLE

Handle

Control= _

Figure 8

The control handle has three positions.

See Figure 8.

Splitting: Push the control handle forward or

down. Splitting wedge moves toward the end plate.

Neutral: Control handle will return to neutral posi-

tion when handle is released. Splitting wedge stops

in place.

Disengage: Pull the control handle up or back.

Splitting wedge moves toward the cylinder. The con-

trol handle will lock in the disengage position. It will

return to neutral automatically when the disengage

stroke is complete.

BEAM LOCKS

Vertical

Beam

Beam Lock

Figure 9

There are two beam locks one for each operating

position. See Figure 9.

Vertical: The vertical beam lock is located next to

the oil filter.

Horizontal: The horizontal beam lock is part of

the beam support latch bracket.

SECTION 6: OPERATION

Always:

• Use clean fluid and check fluid level regularly

• Use Dexron III Automatic Transmission Fluid

or 10W AW hydraulic fluid.

• Use a filter (clean or replace regularly)

• Use a breather cap on fluid reservoir

• Keep end of reservoir return tube below fluid

level

• Make certain pump is mounted and aligned

properly

• Use a flexible "spider" type coupling between

engine and pump driveshafts

• Keep hoses clear and unblocked

• Bleed air out of hoses before operating

• Flush and clean hydraulic system before start-

up after any malfunction or servicing

• Use "pipe dope" on all hydraulic fittings

Allow time for warm-up before splitting wood

Prime the pump before initial start-up by turn-

ing over the engine with spark plug discon-

nected

Split wood with the grain (lengthwise) only

Never:

• Use when fluid is below 20° F,,

or above 150° F.

• Use a solid engine/pump coupling

• Operate through relief valve for more than

several seconds

• Attempt to adjust unloading or relief valve set-

tings without pressure gauges

• Operate with air in hydraulic system

• Use teflon tape on hydraulic fittings

• Attempt to cut wood across the grain

Page 9

TO STOP ENGINE

1. Move the engine shut-off switch to the OFF posi-

tion or move throttle control to the STOP posi-

tion.

2. After engine has stopped, disconnect spark plug

wire from spark plug to prevent accidental start-

ing while equipment is unattended.

STARTING THE ENGINE

IMPORTANT: Refer to the separate engine man-

ual for detailed starting instructions.

1. Place the engine shut-off switch to ON position

or move throttle control lever to FAST position.

2. Make sure fuel shut-off located under gasoline

tank is open (if so equipped).

Engines with choke lever: Placechoke lever

in CHOKE position (a warm engine may not require

choking).

Engines with primer: Prime engine as instruct-

ed inseparate engine manual.

3. Grasp starter handle and pullrope out slowly

until engine reaches start of compression cycle

(rope will pull slightly harder at this point). Let

the rope rewind slowly.

_ ARNING: When restarting a warm

4. Pull rope with a rapid, continuous, full arm

5. Repeat instructions until engine fires. When

6. Gradually move choke lever to RUN position as

7. If weather is cold, run wedge up and down beam

engine, keep away from muffler and

other heated surfaces on the engine.

stroke. Keep a firm grip on the starter handle.

Let the rope rewind slowly. Do not let starter

handle snap back against starter.

engine starts, move choke lever halfway

between CHOKE and RUN.

engine warms up.

6 to 8 times to circulate the hydraulic fluid.

USING THE LOG SPLITTER

Never attempt to cut a log in half sideways. Always

split the log lengthwise. Maximum log length is 24".

,_ WARNING: When splitting heavy logs,

always use the log splitter in the verti-

cal position.

WARNING: Wear leather work gloves,

safety shoes and safety glasses when

operating log splitter. Ensure safe foot-

ing.

1. Place the log splitter on level, dry and solid

ground.

2. Place the beam in either the horizontal or verti-

cal position and lock in place with the appropri-

ate locking rod.

3. Block the front and back of both wheels.

4. Set the engine throttle to maximum speed.

5. Place the log against the end plate. Only split

wood in the direction of the grain.

6. When necessary to stabilize the log, place your

hand only on sides of log, NEVER on the end

between the log and splitting wedge.

7. ONLY ONE ADULT SHOULD STABILIZE THE

LOG AND OPERATE THE CONTROL HAN-

DLE so the operator has full control over stabiliz-

ing the log and movement of the splitting wedge.

OPERATING POSITIONS

CONTROL HANDLE POSITIONS

• Move control handle FORWARD or DOWN to

split wood.

• Release the control handle to stop the wedge

movement.

• Move control handle BACK or UP to return the

wedge.

TRANSPORTING THE LOG SPLITTER

1. Lower the beam to its horizontal position. Make

certain the beam is locked securely with the hori-

zontal beam lock.

.

Unhook the spring clip and remove the clevis pin

from the jack stand. Support the tongue, and

pivot the jack stand up against the tongue.

Secure with the clevis pin and spring clip just

removed.

3. Attach the hitch to a towing vehicle, making cer-

tain to latch securely.

4. Attach the safety chains to the towing vehicle.

5. Plug in the taillights as instructed in the taillight

kit manual included with your log splitter.

Page 10

VERTICAL

• For vertical operation, pull the horizontal beam

lock out and pivot it down to release the

beam. Pivot the beam to the vertical position.

• Lock the beam in the vertical position, by pull-

ing out on the vertical beam lock and pivoting

it to the left.

• Stand in front of the log splitter to operate the

control handle and to stabilize the log.

See Figure 10.

VERTICAL

HORIZONTAL

• For horizontal operation, pull the vertical beam

lock out and pivot it down. Pivot the beam to

the horizontal position.

° Lock the beam in the horizontal position; by

pulling out on the horizontal beam lock and

pivoting it to the left.

• Stand behind the reservoir tank to operate the

control handle and to stabilize the log.

See Figure 11.

HORIZONTAL

Figure 10

SECTION 7: ADJUSTMENTS

_ WARNING: Always stop the engine

WEDGE PLATE ADJUSTMENT

As normal wear occurs, periodically adjust the bolts

on the side of the wedge plate as follows to elimi-

nate the excess space between the wedge plate and

the beam. See Figure 12.

Adjust wedge plate as follows:

1. Loosen the jam nuts on the two adjustment bolts

2. Tighten the jam nuts securely against the gib

and disconnect the spark plug wire

before performing any adjustments.

on the side of the gib plate, located beneath the

splitting wedge. Turn the adjustment bolts in until

snug, then back them off slowly until the wedge

assembly will slide on the beam.

plate to hold the adjustment bolts in this position.

Hex

Bolts

Adju.=

Bolts

Attached

To Cylinder

Figure 11

Gib Plate

Figure 12

..Wedge

Back

Plate

Plate

10

Page 11

GIB PLATE ADJUSTMENT

Periodically remove and replace the "gibs" (spacers)

between the wedge plate and the back plate as fol-

lows. See Figure 12.

NOTE: If desired, the gibs may be rotated and/or

turned over for even wear.

SECTION 8: MAINTENANCE

_ WARNING: Always stop the engine

and disconnect the spark plug wire

before performing any maintenance or

repairs.

Adjust Gib Plate as follows:

1. Remove the center bolt on top of the wedge

plate. Slide the gib plate out.

2. Remove and replace the gibs. Reassemble the

gib plate, making certain flat washers are in

place under the gib plate.

3. Readjust the bolts on the side of the wedge

plate as instructed above.

even wear. Make certain to readjust the adjustment

bolts so wedge moves freely, but no excess space

exists between the wedge plate and beam.

HOSE CLAMPS

RESERVOIR FLUID

Check the hydraulic fluid level in the log splitter res-

ervoir tank before each use. Maintain fluid level

within 3" to 3 1/2" from top at all times. Change

the hydraulic fluid in the reservoir every 100 hours of

operation. Disconnect the suction hose from the bot-

tom of the reservoir tank, and drain the fluid into a

suitable container. Refill using only Dexron III auto-

matic transmission fluid or 10W AW hydraulic fluid.

Be aware of the environment when disposing of

used petroleum products. Please dispose of

used hydraulic fluid, engine oil and any by prod-

ucts from the maintenance of you log splitter at

approved recycling centers.

NOTE: Drain the fluid and flush the reservoir tank

and hoses with kerosene whenever any repair work

is performed on the tank, hydraulic pump or valve.

Contaminants in the fluid will damage the hydraulic

components. (Should be performed by an autho-

rized service dealer.)

WARNING: Use extreme caution when

working with kerosene, as it is an

extremely flammable fluid.

Check the hose clamps on the suction hose

(attached to side of the pump) for proper tightness

before each use. Check the hose clamps on the

return hose at least once a season.

ENGINE

Refer to the separate engine manual for all engine

maintenance instructions.

FLEXIBLE PUMP COUPLER

The flexible pump coupler is a nylon "spider" insert,

located between the pump and engine shaft. Over a

period of time, the coupler will harden and deterio-

rate.

Replacement is needed if you detect vibration or

noise coming from the area between the engine and

the pump. If the coupler fails completely, you will

experience a loss of power.

IMPORTANT: Never hit the engine shaft in any

manner, as a blow will cause permanent damage to

the engine.

When replacing the flexible pump coupler, proceed

as follows. Follow the instructions carefully as the

alignment is critical.

HYDRAULIC FILTER

Change the hydraulic filter every 50 hours of opera-

tion. Use only a 10 micron hydraulic filter. Order part

number 723-0405.

BEAM AND SPLITTING WEDGE

Lubricate both sides of the beam (where it comes into

contact with the splitting wedge) before each use with

engine oil. The wedge plate on the log splitter is

designed so the gibs on the side of the wedge plate

can be removed and rotated and/or turned over for

1. Disconnect the spark plug wire from the spark

plug, and secure it away from the spark plug.

2. Remove three nuts and lock washers which

secure the pump to the coupling shield. Two

nuts are at the bottom corners and one is in the

top center.

3. Remove the pump.

4. Rotate the engine by pulling starter handle until

engine coupling half set screw is at bottom.

Loosen set screw using allen wrench. Slide cou-

pling half off of engine shaft.

11

Page 12

5. Loosensetscrewonpumpcouplinghalf,and

removecouplinghalf.

6. Slidenewenginecouplinghalfontotheengine

shaftuntiltheendoftheshaftisflushwiththe

innerportionofthecouplinghalf.(Theremustbe

spacebetweenendoftheenginesupport

bracketandcouplinghalf.)Tightensetscrew.

7. Installpumpcouplinghalfandkeyonpump

shaft.Rotatecouplinghalfuntilsetscrewfaces

down.Donottightensetscrew.

8. Installnylon"spider"ontoenginecouplinghalf.

9. Alignpumpcouplinghalfwithnylon"spider"by

rotatingengineusingstarterhandle.Slidecou-

plinghalfintoplacewhileguidingthreemount-

ingboltsthroughholesinpumpsupportbracket.

10.Securewithnutsandwashersremovedearlier.

11.Set.010inchto.060inchclearancebetween

thenylon"spider"andtheenginecouplinghalf

byslidingamatchbookcoverbetweenthenylon

"spider"andtheenginecouplinghalfandmov-

ingpumpcouplinghalfasneeded.Securepump

couplinghalfwithsetscrew.SeeFigure13.

NOTE: Make certain proper clearance is obtained

before tightening set screw.

12. Reattach spark plug wire to spark plug.

PUMP

Set

Screw_l____

Nylon I__ Steel

"Spider"--__._.__.

Insert _es

Clearance_ ENGINE

TIRES

See sidewall of tire for recommended pressure.

Maximum tire pressure under any circumstances is

30 p.s.i. Equal tire pressure should be maintained on

all tires.

LIII J_o _Coupling

Figure 13

WARNING: Excessive pressure (over

30 p.s.i.) when seating beads may cause

tire/rim assembly to burst with force

sufficient to cause serious injury.

SECTION 9:

If the log splitter will not be used for a period longer

than 30 days, the following steps should be taken to

prepare the log splitter for storage.

1. Clean the engine and the entire log splitter thor-

oughly.

2. Refer to the engine manual for correct engine

storage instructions.

OFF-SEASON STORAGE

3.

Wipe unit with an oiled rag to prevent rust, espe-

cially wedge and beam.

.

Store unit in a clean, dry area. Do not store next

to corrosive materials, such as fertilizer.

NOTE: When storing any type of power equipment

in an unventilated or metal storage shed, care

should be taken to rustproof the equipment by coat-

ing with a light oil or silicone.

12

Page 13

SECTION 10: CONDITIONS WHICH WILL VOID YOUR WARRANTY

1. Failure to maintain proper fluid level in reservoir

will void your warranty, causing permanent dam-

age to pump by allowing air to be drawn into

pump. Fluid will become foamy.

2. Changing the relief valve setting or pressure

adjustment of control valve without proper

knowledge and instruction from the factory will

void your warranty. A very minor adjustment

could destroy the structural and safety limits for

which the unit was designed. The system will

produce more power than the structure will with-

stand. Higher pressure could cause the hoses to

burst, cylinder to rupture and intense fluid

releases, which could result in serious personal

injury.

3. Disassembling the pump will void your warranty.

If replacement is necessary, merely disconnect

and replace. Do not attempt to adjust pump set-

tings, as they are adjusted by the manufacturer

at the factory.

4. Use of incorrect hydraulic fluid will void your war-

ranty. Use only Dexron III automatic transmis-

sion fluid or 10W AW hydraulic fluid.

5. The flexible pump coupler must be inspected

regularly. Allowing the coupler to deteriorate will

void your warranty. Deterioration of spider insert

and prolonged use after its deterioration will

destroy pump bearings, engine bearings and the

coupler hubs.

6. Improper beam lubrication will cause premature

wear and looseness. Lubricate the beam regu-

larly. Lack of lubrication will void your warranty.

7. Improper adjustment of splitting wedge will void

your warranty. If wedge is too loose, cylinder

beam and wedge wear will result. Allowing the

wedge to loosen and be used under operating

stress will cause damage which will not be cov-

ered under warranty. If wedge is too tight,

severe beam damage will result which will not be

covered under warranty.

8. Do not overheat the hydraulic system. Exces-

sive heat will destroy the hydraulic system with

hardened O-rings and excessive friction.

9. Do not attempt to start in temperatures under

20° F. without pre-heating fluid in reservoir.

Excessively cold fluid cannot circulate and draw

into pump.

10. Repair any leaks in hydraulic system immedi-

ately. Unattended leaks will cause air to enter

system and/or decrease fluid level in reservoir,

causing damage to the hydraulic system which

will not be covered by warranty.

SECTION 11: TROUBLE SHOOTING GUIDE

Problem

Engine fails to start

Engine runs erratic

Engine

overheats

Possible Cause(s)

Dirtyaircleaner.

Fuelshut-off valveclosed(ifso

equipped).

Fueltank empty,or stalefuel.

Choke not in ON position.

Blocked fuel line.

Spark plug wire disconnected.

Faulty spark plug.

Unit running on CHOKE.

Spark plug wire loose.

Blocked fuel line or stale fuel.

Water or dirt in fuel system.

Dirty air cleaner.

Carburetor out of adjustment.

Engine oil level low.

Dirty air cleaner.

Air flow restricted.

Carburetor not adjusted properly.

Corrective Action

Refer to the engine manual packed with your unit.

Open fuel shut-off valve.

Fill tank with clean fresh gasoline. Fuel will not last over thirty

days unless a fuel stabilizer is used.

Move switch to ON position.

Clean fuel line.

Connect wire to spark plug.

Clean, adjust gap or replace.

Move choke lever to OFF position.

Connect and tighten spark plug wire.

Clean fuel line; fill tank with clean fresh gasoline. Fuel will not last

over thirty days unless a fuel stabilizer is used.

Drain fuel tank. Refill with fresh fuel.

Refer to the engine manual packed with your unit.

Refer to the engine manual packed with your unit.

Fill crankcase with proper oil.

Refer to the engine manual packed with your unit.

Stop engine and disconnect spark plug wire. Remove blower

housing and clean.

Refer to the engine manual packed with your unit.

13

Page 14

SECTION 12: HYDRAULIC TROUBLE SHOOTING GUIDE

Trouble

Cylinder rod will

not move

Slow cylinder

shaft speed while

extending and

retracting

Leaking cylinder Return unit for authorized repair.

wood will not split,

or wood splits too

slowly

Engine stalls

during

splitting

Engine will not

turn or stalls

under low load

conditions

Will not split logs

]Leaking pump

ishaft seal

Possible Causes

Broken drive shaft.

Shipping plugs left in

hydraulic hoses.

Set screws in coupling not

adjusted properly.

Loose shaft coupling.

Gear sections damaged.

Damaged relief valve.

Hydraulic lines blocked.

Incorrect oil level.

Damaged directional valve.

Blocked directional valve.

Gear sections damaged.

Excessive pump inlet

vacuum.

Slow engine speed.

Damaged relief valve.

Incorrect oil level.

Contaminated oil.

Directional valve leaking

internally.

Internally damaged cylinder, i

Broken seals.

Scored cylinder.

Small gear section

damaged.

Pump check valve leaking.

Excessive pump inlet

vacuum.

Incorrect oil level.

Contaminated oil.

Directional valve leaking

internally.

Overloaded cylinder.

Internally damaged cylinder.

Low horsepower/weak

engine.

Overloaded cylinder.

Engine/pump misalignment.

Frozen or seized pump.

Low horsepower/weak

engine.

Hydraulic lines blocked.

Blocked directional valve.

Reservoir fluid level low.

Broken drive shaft.

Engine/pump misalignment.

Gear sections damaged.

Poorly positioned shaft seal.

Plugged oil breather.

Corrective Action

Return unit for authorized repair.

Disconnect hydraulic hoses, remove shipping plugs, reconnect hoses.

See operator's manual for correct adjustment.

Correct engine/pump alignment as necessary. See operator's manual.

Return unit for authorized repair.

Return unit for authorized repair.

Flush and clean hydraulic system.

Check oil level.

Return unit for authorized repair.

Flush and clean hydraulic system; return unit for authorized repair.

Return unit for authorized repair.

Make certain pump inlet hoses are clear and unblocked-use short, large

diameter inlet hoses.

Return unit for authorized repair.

Return unit for authorized repair.

Check oil level.

Drain oil, clean reservoir, refill, make certain oil return tube is below oil

level.

Return unit for authorized repair.

Return unit for authorized repair.

Return unit for authorized repair.

Return unit for authorized repair.Engine runs but

Return unit for authorized repair.

Make certain pump inlet hoses are clear and unblocked; use short, large

diameter inlet hoses.

Check oil level.

Drain oil, clean reservoir, refill, make certain oil return tube is below oil

level.

Return unit for authorized repair.

Do not attempt to split wood against the grain.

Return unit for authorized repair.

Return unit for authorized repair.

Do not attempt to split wood against the grain. If engine stalls repeatedly,

take unit for authorized repair.

Correct alignment as necessary. See operator's manual.

Return unit for authorized repair.

Return unit for authorized repair.

Flush and clean hydraulic system.

Flush and clean hydraulic system; return unit for authorized repair.

Check and fill reservoir tank as instructed in Operation section of this

manual.

Return unit for authorized repair.

Correct alignment as necessary. See operator's manual.

!Return unit for authorized repair.

Return unit for authorized repair.

Make certain reservoir is properly vented.

Note: For repairs beyond the minor adjustments above, contact your local authorized service dealer.

14

Page 15

15

Page 16

Models 500, 501, & 510

16

\

\

15

11

22

14

21

73

27

28

29

31

A

30 33

32

39

75

69

\

7O

/

72 '\

71

67

56

16

Page 17

REF.

NO.

1

2

3

4

5

6

7

8

,90

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

PART

NO.

781-0323B

712-0239

710-1018

736-0192

710-0459A

781-0356

781-0351

712-3001

750-0743

781-0537

781-0352A

781-0350A

736-0921

781-0168A

681-0093

714-0211

711-1135

718-0307

727-0471

727-0443

712-0130

726-0132

737-0153

737-0192

718-0481

737-0235

737-0306

723-0405

727-0502

714-0470

738-0805

732-0583

726-0214

781-0690

737-0236

681-0092A

710-0654A

DESCRIPTION

Wedge Asm

Lock Nut 1/2-20

Hex Cap Screw 1/2-20 x 2.75

Flat Washer .531 x .93 x .090

Hex Cap Screw 3/8-24 x 1.5

Floating Gib Plate

Adjustable Gib

Hex Jam Nut 3/8-24

Spacer

Back Bracket

Adjustable Gib Shim

Fixed Gib

Lock Washer 1/2

Stripper Side

Beam Asm

Cotter Pin

Clevis Pin

Hydraulic Cylinder

Hydraulic Tube

Return Hose 3/4" I.D. x 44" Lg.

Lock Nut 3/8-16

Hose Clamp 5/8"

Return Elbow

90 ° Solid Male Adapter

Control Valve

3/4" Hose Adapter

Filter Housing

Oil Filter

High Pressure Hydraulic Hose

Cotter Pin 1/8" Dia.

Hinge Pin 1/2 x 4.8" Lg.

Comp. Spring 4" Lg.

Push Cap

Locking Rod

Pipe Plug

Frame Asm

Hex Washer Screw 3/8-16 x 1.0

REF.

NO.

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

75

PART

NO.

735-0256

726-0174

714-0122

718-0686

719-0353

712-0123

736-0119

781-0097

710-1338

718-0683

737-0329

710-0521

712-0798

736-0169

710-0411

681-0110

781-0680A

736-0185

712-0375

711-0813

732-0194

750-0497

710-0944

736-0262

713-0433

727-0311

781-0162

721-0168

741-0987

634-0186

634-0188

736-0351

712-0359

714-0162

734-0873

710-3144

736-0116

DESCRIPTION

Suction Hose

Hose Clamp

Sq.-Key 3/16" x .75"

Flexible Coupling

Coupling Shield

Hex Nut 5/16-24

L-Wash. 5/16" I.D.*

Rear Coupling Support Bracket

Hex Screw 5/16-24 x 3.25

Gear Pump (11 GPM)

45 Degree Elbow

Hex Bolt 3/8-16 x 3" Lg.

Hex Nut 3/8-16 Thd.*

L-Wash. 3/8" I.D.*

Hex Bolt 3/8-16 x 4" Lg.

Support Beam Asm

Tube

Flat Washer 3/8

Hex L-Nut 3/8-16 Thd.

Clevis Pin 5/16 x 2.5" Lg.

Spring Pin

Spacer 3/8" I.D. x .625" O.D.

Hex Bolt 3/8-16 x 4" Lg. (Grd 5)

FI-Wash. 3/8" I.D. x .87" O.D.

Chain--Tow Hitch

Hitch Coupler

Jack Stand

Bearing Seal Only

Bearing Cone

Wheel Assembly

Rim Assembly

FI-Wash..76" I.D. x 1.5" O.D.

Slotted Nut 3/4-16 Thd.

Cotter Pin 5/32" Dia. x 1-1/4" Lg.

Hub Cap

Hex Cap Screw 3/8-16 x 2.0

Flat Washer .635 ID x .93 OD

17

Page 18

Models 530, 550, 560, and 561

40

®

19

18

22

A

33

37_

\

39

38_

46

5

\

15

48

j47

C

55

45

35

74

8O

\

58

"76

77

65

18

78

42

\

79

/

8_

64

;668

57

71

72

Page 19

_EF.

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

3O

31

32

33

34

35

36

37

38

39

40

41

1"If E(

PART

NO.

781-0323B

712-0239

710-1018

736-0192

710-0459A

781-0356

781-0351

712-3001

i750-0750

i781-0537

781-0352A

781-0350A

736-0921

712-0239

781-0168A

712-0130

710-0859

681-0126

714-0211

711-1135

718-0306

727-0471

727-0443

726-0132

737-0153

737-0192

718-0481

737-0235

737-0306

723-0405

727-0502

714-0470

738-0805

726-0214

732-0583

736-0116

781-0690

737-0236

681-0092A

681-0138

710-0157

uipped

DESCRIPTION

Wedge Asm

Lock Nut 1/2-20

Hex Cap Screw 1/2-20 x 2.75

Flat Washer .531 x .93 x .090

Hex Cap Screw 3/8-24 x 1.5

Floating Gib Plate

Adjustable Gib

Hex Jam Nut 3/8-24

Spacer

Back Bracket

Adjustable Gib Shim

Fixed Gib

Lock Washer 1/2

Lock Nut 1/2-20

Stripper Side

Lock Nut 3/8-16

Hex Cap Screw 3/8-16 x 2.5

Beam Asm

Cotter Pin

Clevis Pin

Hydraulic Cylinder

Hydraulic Tube

Return Hose 3/4" ID x 44" Lg

Hose Clamp 5/8"

Return Elbow

90 Degree Solid Male Adapter

Control Valve

3/4" Hose Adapter

Filter Housing

Oil Filter

High Pressure Hydraulic Hose

Cotter Pin 1/8" Dia

Hinge Pin 1/2 x 4.8" Lg.

Push Cap

Comp. Spring 4" Lg.

Flat Washer .635 ID x .93 OD

Locking Rod

Pipe Plug

Frame Asm

Fender Asm 1

Hex Cap Screw 5/16-24 x .75

REF.

NO.

42

43

44

45

46

47

48

49

5O

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

8O

81

PART

NO.

736-0159

736-0119

712-0123

710-0654A

726-0174

735-0256

710-1338

714-0122

718-0686

719-0353

736-0119

712-0123

781-0O97

718-0683

737-0329

710-0521

712-0798

736-0169

710-0411

781-0690

681-0110

781-0680A

736-0185

712-0375

711-0813

732-0194

750-0497

710-0944

736-0262

713-0433

727-0311

781-0162

721-0168

741-0987

634-0186

634-0180

736-0351

712-0359

714-0162

734-0873

DESCRIPTION

5/16 Washer

Lock Washer 5/16

Hex Nut 5/16-24

Hex Washer Screw 3/8-16 x 1.0

Hose Clamp

Suction Hose

Hex Screw 5/16-24 x 3.25

Sq. Key 3/16" x .75

Flexible Coupling

Coupling Shield

L-Washer 5/16" ID

Hex Nut 5/16-24

Rear Coupling Support Bracket

Gear Pump (11gpm)

45 Degree Elbow

Hex Bolt 3/8-16 x 3" Lg.

Hex Nut 3/8-16

L-Washer 3/8" ID

Hex Bolt 3/8-16 x 4" Lg.

Locking Rod

Support Beam Asm

Tube

Flat Washer 3/8

Hex Lock Nut 3/8-16

Clevis Pin 5/16 x 2.5"

Spring Pin

Spacer 3/8" ID x .625' OD

Hex Bolt 3/8-16 x 4" Lg.

Flat Washer 3/8" ID x .87" OD

Chain - Tow Hitch

Hitch Coupler

Jack Stand

Bearing Seal Only

Bearing Cone

Wheel Assembly

Rim Assembly

Flat Washer .76" ID x 1.5" OD

iSIotted Nut 3/4-16

Cotter Pin 5/32" x 1-1/4" Lg.

Hub Cap

19

Page 20

MANUFACTURER'S LIMITED WARRANTY FOR:

YARDMACHINESr)#

The limited warranty set forth below is given by MTD b. Routine maintenance items such as lubricants, filters,

PRODUCTS INC ("MTD") with respect to new merchandise

purchased and used in the United States, its possessions

and territories.

MTD warrants this product against defects in material and

workmanship for a period of two (2) years commencing on

the date of original purchase and will, at its option, repair or

replace, free of charge, any part found to be defective in

material or workmanship. This limited warranty shall only

apply if this product has been operated and maintained in

accordance with the Operator's Manual furnished with the

product, and has not been subject to misuse, abuse, com-

mercial use, neglect, accident, improper maintenance,

alteration, vandalism, theft, fire, water or damage because

of other peril or natural disaster. Damage resulting from the

installation or use of any accessory or attachment not

approved by MTD Products Inc. for use with the product(s)

covered by this manual will void your warranty as to any

resulting damages.

Normal wear parts or components thereof are subject to

separate terms as follows: All normal wear part or compo-

nent failures will be covered on the product for a period of

90 days regardless of cause. After 90 days, but within the

two year period, normal wear part failures will be covered

ONLY IF caused by defects in material or workmanship of

OTHER component parts. Normal wear parts and compo-

nents include, but are not limited to, belts, blades, blade

adapters, grass bags, rider deck wheels, seats, snow

thrower skid shoes, shave plates and tires. Batteries are

covered by a 90-day limited replacement warranty.

HOW TO OBTAIN SERVICE: Warranty service is available,

WITH PROOF OF PURCHASE THROUGH YOUR LOCAL

AUTHORIZED SERVICE DEALER. To locate the dealer in

your area, please check for a listing in the Yellow Pages or

contact the Customer Service Department of MTD PROD-

UCTS INC by calling 1-800-800-7310 or writing to P.O. Box

368022, Cleveland, Ohio 44136-9722. No product returned

directly to the factory will be accepted unless prior written

permission has been extended by the Customer Service

Department of MTD PRODUCTS INC.

blade sharpening and tune-ups, or adjustments such

as brake adjustments, clutch adjustments or deck

adjustments; and normal deterioration of the exterior

finish due to use or exposure.

C.

Log splitter pumps, valves and cylinders have a sepa-

rate one year warranty.

d.

MTD does not extend any warranty for products sold

or exported outside of the United States of America,

its possessions and territories, except those sold

through MTD's authorized channels of export distribu-

tion.

No implied warranty, including any implied warranty of

merchantability or fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty or guaranty, whether written or oral,

except as mentioned above, given by any person or

entity, including a dealer or retailer, with respect to any

product shall bind MTD. During the period of the War-

ranty, the exclusive remedy is repair or replacement of

the product as set forth above. (Some states do not

allow limitations on how long an implied warranty lasts, so

the above limitation may not apply to you.)

The provisions as set forth in this Warranty provide the

sole and exclusive remedy arising from the sales. MTD

shall not be liable for incidental or consequential loss

or damages including, without limitation, expenses

incurred for substitute or replacement lawn care ser-

vices, for transportation or for related expenses, or for

rental expenses to temporarily replace a warranted

product. (Some states do not allow the exclusion or limita-

tion of incidental or consequential damages, so the above

exclusion or limitation may not apply to you.)

In no event shall recovery of any kind be greater than the

amount of the purchase price of the product sold. Alteration

of the safety features of the product shall void this War-

ranty. You assume the risk and liability for loss, damage, or

injury to you and your property and/or to others and their

property arising out of the use or misuse or inability to use

the product.

This limited warranty does not provide coverage in the

following cases:

a.The engine or component parts thereof. These items

carry a separate manufacturer's warranty. Please refer

to the applicable manufacturer's warranty on these

items.

This limited warranty shall not extend to anyone other than

the original purchaser, original lessee or the person for

whom it was purchased as a gift.

How State Law Relates to this Warranty: This limited

warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Loading...

Loading...