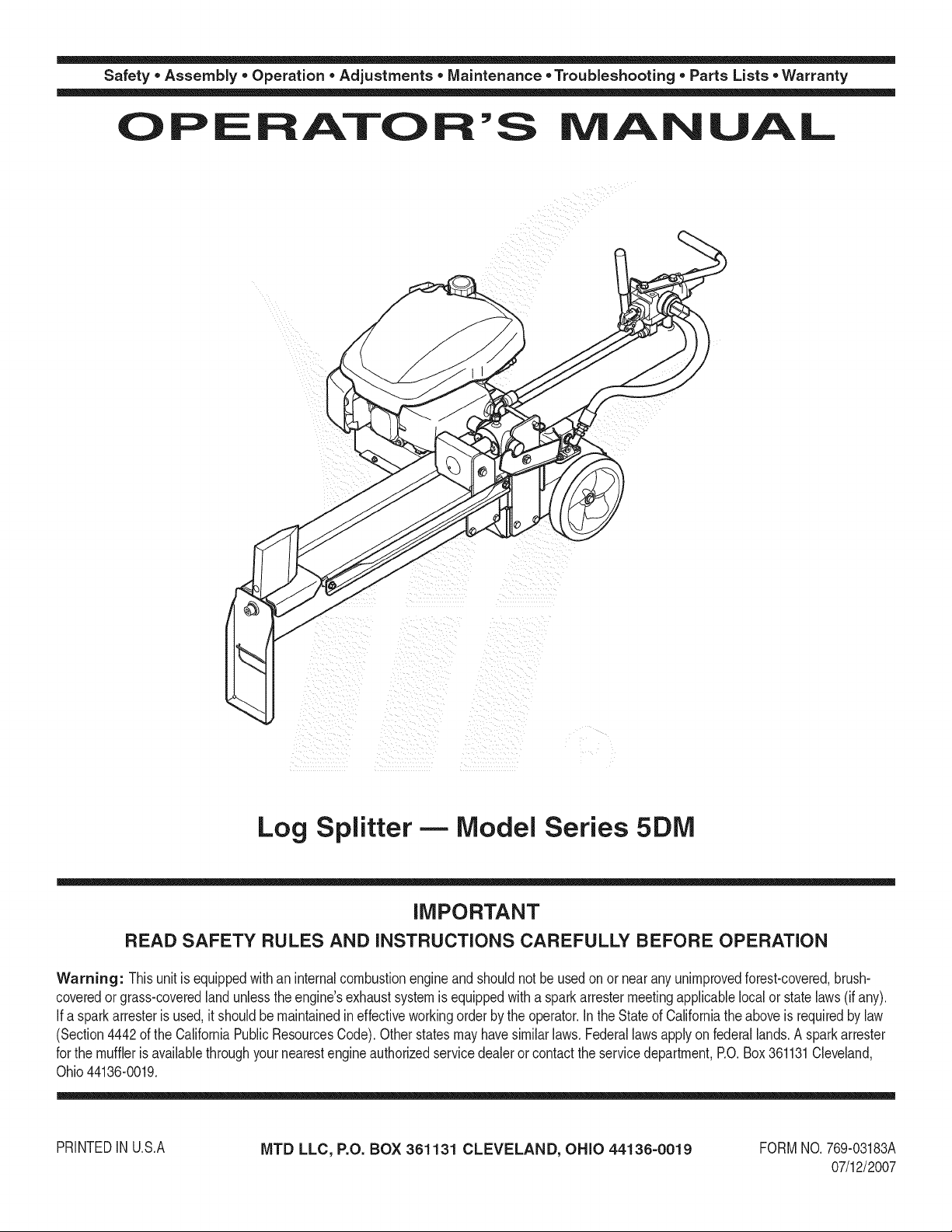

MTD 24AA5DMK029 Owner’s Manual

Safety • Assembly • Operation • Adjustments • Maintenance • Troubleshooting • Parts Lists • Warranty

OF A O AL

Log Splitter- Model Series 5DIVl

iMPORTANT

READ SAFETY RULES AND iNSTRUCTiONS CAREFULLY BEFORE OPERATION

Warning: Thisunitisequippedwithan internalcombustionengineandshouldnotbeusedonor nearanyunimprovedforest-covered,brush-

coveredor grass-coveredlandunlesstheengine'sexhaustsystemisequippedwitha sparkarrestermeetingapplicablelocalor statelaws(if any).

If a sparkarresterisused,it shouldbemaintainedineffectiveworkingorderby theoperator.IntheStateofCaliforniatheaboveis requiredbylaw

(Section4442oftheCaliforniaPublicResourcesCode).Otherstatesmayhavesimilarlaws.Federallawsapplyonfederallands.A sparkarrester

forthemufflerisavailablethroughyournearestengineauthorizedservicedealeror contacttheservicedepartment,RO.Box361131Cleveland,

Ohio44136-0019.

PRINTEDINU.S.A

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136=0019

FORMNO.769-03183A

07/12/2007

This Operator's Manual is an important part of your new log splitter, it will help you assemble,

prepare and maintain the unit for best performance. Please read and understand what it says.

Table of Contents

Safety Labels ............................................. Page 3

Safe Operation Practices .......................... Page 4

Setting UpYour Log Splitter ..................... Page 6

Operating Your Log Splitter ...................... Page 8

Maintaining Your Log Splitter ................ Page 12

Troubleshooting ....................................... Page 14

Finding and Recording Model Number

BEFOREYOUSTARTASSEMBLING

YOURNEW EQUIPMENT

Pleaselocatethe model plate on theequipment andcopy the

informationto the sample model plate providedto the right.

You can locatethe model plate bystanding behind the unit

and lookingdown at the hydraulictank.This informationwillbe

necessaryto usethe website or obtain assistancefromyour

MTDdealer.

Engine Appendix .............................................. 16

Engine Safe Operation Practices ................. 16

Operating Your Engine .................................. 18

Maintaining Your Engine ............................... 20

illustrated Parts List ................................ Page 24

Warranty ............................................. Back Cover

Model Number

wv,nN,mtdproducts,corn

Serial Number

MTD LLC

P.O. BOX 361131

CLEVELAND, OH 44136

330-220-4683

800-800-73102

Customer Support

Please do IVOTreturn the unit to the retailer from which it was

purchased, without first contacting Customer Support.

Ifyou have difficulty assemblingthis product or have any questions regardingthe controls,operation,or maintenanceofthis unit,

you canseek helpfromthe experts.Choosefromthe options below:

1. Visit mtdproducts.com. Click on Yardmachinesand then the Customer Support menu option.

2. Phonea CustomerSupport Representativeat 1.800.800.7310.Spanish speaking agents are available.

2

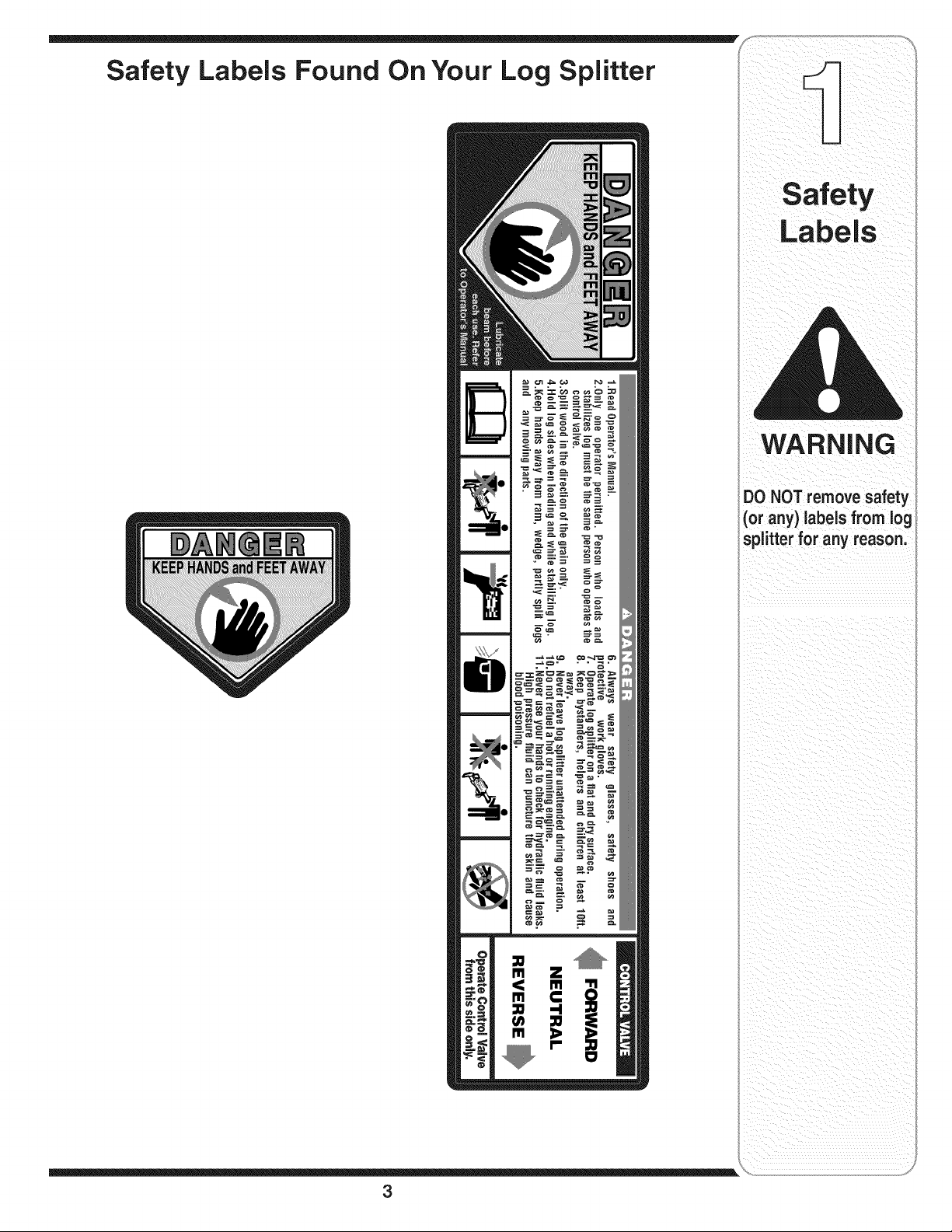

Safety Labels Found On Your Log Splitter

/T_ ¸¸ _!_

ii i i i i i ii

oo.oT_emovo,_foty

(or any)labels from log

splitter for any reason,

3

WARNING: EngineExhaust,some of its constituents,andcertain vehicle compo-

nentscontain or emit chemicals knownto Stateof Californiato cause cancer and

birth defects or other reproductiveharm.

DANGER: This machinewas builtto be operated accordingto the rulesfor safe operation inthis

manual.As with anytype of powerequipment,carelessness or error on the part ofthe operator

can resultinserious injury.This machine iscapable of amputatinghands and feet and throwing

objects. Failureto observethe following safety instructionscouldresult in seriousinjury ordeath.

WARNING

Thissymbo points

out importantsafety

instructionswhich, if

notfollowed, could

endangerthe personal

safetyand/or property

of yourself and others.

Readand followall

instructionsinthis man-

ual before attemptingto

operatethis machine.

Failureto complywith

these instructionsmay

i resultin personal injury.

Whenyou seethis

symbol -

i HEED ITSWARNING

Your

i Responsibility

Restrictthe use

ofthis powermachine

to personswho read,

understand

andfollow the warnings

and instructions

inthis manualand on

themachine.

General Practices

1. Read,understand,andfollowallinstructionson the

machineand inthemanual(s)beforeattempting

toassembleandoperate.Keepthismanualin a

safeplaceforfutureandregularreferenceandfor

orderingreplacementparts.

2. Befamiliarwithall controlsandproperoperation.

Knowhowtostopthemachineanddisengagethem

quickly.

3. Neverallowchildrenunder16yearstooperatethis

machine.Children,16yearsandover,shouldread

andunderstandinstructionsandsafetyrulesinthis

manualandshouldbetrainedandsupervisedbya

parent.

4. Neverallowadultstooperatethismachinewithout

properinstruction.

5. Manyaccidentsoccurwhenmorethanoneperson

operatesthemachine,if a helperisassistinginload-

inglogs,neveractivatethecontroluntilthe helperis

a minimumof 10feetfromthemachine.

6. Keepbystanders,children,andpetsatleast20 feet

fromthemachinewhileit isinoperation.

7. Neverallowanyonetorideonthismachine.

8. Nevertransportcargoonthis machine.

9. Hydrauliclogsplittersdevelophighfluidpressures

duringoperation.Fluidescapingthrougha pin hole

openingcanpenetrateyourskinandcauseblood

poisoning,gangrene,ordeath.Giveattentiontothe

followinginstructionsatalltimes:

a. Do notcheckforleakswithyourhand.

b. Do notoperatemachinewithfrayed,kinked,

cracked,or damagedhoses,fitting,ortubing.

c. Stopthe engineand relievehydraulicsystem

pressurebeforechangingoradjustingfittings,

hoses,tubing,orothersystemcomponents.

d. Do notadjustthepressuresettingsofthepumpor

valve.

10.Leakscanbedetectedbypassingcardboardor

wood,whilewearingprotectiveglovesand safety

glasses,overthesuspectedarea.Lookfordiscolor-

ationof cardboardorwood.

11.

If injuredbyescapingfluid,seea doctorimmediately.

Seriousinfectionor reactioncandevelopifproper

medicaltreatmentisnotadministeredimmediately.

12.Keeptheoperatorzoneandadjacentareaclear for

safe,securefooting.

13.Ifyourmachineisequippedwithaninternalcom-

bustionengineandit isintendedforusenearany

unimprovedforest,brush,or grasscoveredland,

theengineexhaustshouldbeequippedwithaspark

arrester.Makesureyoucomplywithapplicablelocal,

state,andfederalcodes.Takeappropriatefirefighting

equipmentwithyou.

14.Thismachineshouldbe usedfor splittingwoodonly,

donotuseitfor anyother purpose.

15.Followtheinstructionsin the manual(s)providedwith

anyattachment(s)forthismachine.

Preparation

1. Alwayswearsafetyshoesorheavyboots.

2. Alwayswearsafetyglassesorsafetygogglesduring

operatingthismachine.

3. Neverwearjewelryor looseclothingthatmight

becomeentangledinmovingor rotatingpartsofthe

machine.

4. Makesure machineison levelsurfacebeforeoperat-

ing.

5. Alwaysblockmachineto preventunintendedmove-

ment.

e.

Alwaysoperatethis machinefromtheoperator

zone(s)specifiedinthemanual.

.

Logsshouldbecutwith squareendspriortosplitting.

8.

Uselogsplitterin daylightor undergoodartificiallight.

9.

Toavoidpersonalinjuryorpropertydamageuse

extremecareinhandlinggasoline.Gasolineis

extremelyflammableandthe vaporsareexplosive.

Seriouspersonalinjurycanoccurwhengasolineis

spilledonyourselforyourclotheswhichcanignite.

Washyourskinandchangeimmediately.

a. Useonlyanapprovedgasolinecontainer.

b. Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

c. Neverfuelmachineindoors.

d. Neverremovegascaporaddfuelwhiletheengine

ishotor running.

e. Allowenginetocoolatleasttwo minutesbefore

refueling.

f. Neveroverfillthefueltank.Filltankto nomore

than1/2inchbelowbottomoffillernecktoprovide

spaceforfuelexpansion.

4

g. Replacegasolinecapandtightensecurely. 3. Topreventfires,clean debrisandchafffromthe

h. Ifgasolineisspilled,wipeit offtheengineand

equipment,movemachinetoanotherarea.Wait5

minutesbeforestartingthe engine.

i. Neverstorethemachineor fuelcontainerinside

wherethereisan openflame,sparkor pilot lightas

on a waterheater,spaceheater,furnace,clothes

dryeror othergasappliances.

j. Allow machinetocool5 minutesbeforestoring.

Operation

1. Beforestartingthismachine,reviewthe"Safety

instructions".Failuretofollowtheserulesmayresultin

seriousinjurytotheoperatororbystanders.

2. Neverleavethismachineunattendedwiththeengine

running.

3. Donotoperatemachinewhileundertheinfluenceof

alcohol,drugs,or medication.

4. Neverallowanyonetooperatethismachinewithout

properinstruction.

5. Alwaysoperatethismachinewithall safetyequipment

inplaceandworking.Makesureallcontrolsare

properlyadjustedforsafeoperation.

6. Donotchangetheenginegovernorsettingsor

overspeedtheengine.Thegovernorcontrolsthe

maximumsafeoperatingspeedoftheengine.

7. Whenloadinga log,alwaysplaceyourhandsonthe

sidesofthelog,notontheends,andneveruseyour

footto helpstabilizea log.Failuretodo so,mayresult

incrushedoramputatedfingers,toes,hand,or foot.

8. Useonly yourhandto operatethecontrols.

9. Neverattemptto splitmorethanonelogata time

unlesstheramhasfullyextendedanda secondlogis

neededtocompletetheseparationofthefirst log.

10.Forlogswhicharenotcutsquare,theleastsquare

endandthe longestportionofthelogshouldbe

placedtowardthe beamandwedge,andthe square

end placedtowardtheendplate.

11.Alwayskeepfingersawayfromany cracksthatopen

inthelogwhilesplitting.Theycanquicklycloseand

pinchoramputateyourfingers.

12.Keepyourworkareaclean,immediatelyremovesplit

woodaroundthe machinesoyoudonotstumbleover

it.

13.Nevermovethismachinewhiletheengineisrunning.

14.Thismachineshouldnotbe towedonanystreet,

highway,orpublicroadbehinda vehicle.

Maintenance and Storage

1. Stop theengine,disconnectthesparkplugand

grounditagainsttheenginebeforecleaning,or

inspectingthemachine.

2. Stop theengineand relievehydraulicsystempressure

beforerepairingoradjustingfittings,hoses,tubing,or

othersystemcomponents.

engineandmufflerareas,iftheengineisequipped

withasparkarrestermuffler,cleanand inspectit

regularlyaccordingtomanufacturersinstructions.

Replaceifdamaged.

.

Periodicallycheckthatall nutsandbolts,hose

clamps,and hydraulicfittingsaretightto besure

equipmentisinsafeworkingcondition.

.

Checkallsafetyguardsandshieldsto besure

theyareintheproperposition.Neveroperatewith

safetyguards,shields,orotherprotectivefeatures

removed.

6. The pressurereliefvalveis presetatthefactory.Do

notadjustthevalve.

7. Neverattemptto movethismachineoverhillyor

uneventerrainwithoutadequatehelp.

8. Foryoursafety,replaceall damagedorwornparts

immediatelywithoriginalequipmentmanufacturer's

(O.E.M.)partsonly."Useof partswhichdonotmeet

theoriginalequipmentspecificationsmayleadto

improperperformanceandcompromisesafety!"

9. Do notalter thismachineinanymanner,alterations

suchasattachingaropeor extensiontothecontrol

handle,oraddingtothe widthor heightof thewedge

mayresultinpersonalinjury.

Spark Arrestor

with an internalcombustionengine

__k ARNING: This machineisequipped

coveredorgrass-coveredlandunless the engine's

exhaustsystemisequippedwith a sparkarrestor

meetingapplicable local or statelaws (if any).

If a sparkarresterisused,it shouldbemaintainedin

effectiveworkingorderbytheoperator.IntheStateof

Californiatheaboveisrequiredbylaw(Section4442

oftheCaliforniaPublicResourcesCode).Otherstates

mayhavesimilarlaws.Federallawsapplyonfederal

lands.

A sparkarresterforthe mufflerisavailablethroughyour

nearestengineauthorizedservicedealerorcontactthe

servicedepartment,RO.Box361131Cleveland,Ohio

44136-0019.

and shouldnot beusedon or near any

unimproved forest-covered, brush-

Average Useful Life

AccordingtotheConsumerProductsSafetyCommis-

sion(CPSC)andtheU.S.EnvironmentalProtection

Agency(EPA),thisproducthasanAverageUsefulLifeof

seven(7)years,or 130hoursofoperation.Attheendof

theAverageUsefulLife,buyanewmachineorhavethe

machineinspectedannuallybyanauthorizedservice

dealertoensurethatallmechanicalandsafetysystems

areworkingproperlyandnotwornexcessively.Failure

todo socan resultinaccidents,injuriesor death.

i _ _ i _ iii iI ii _iiiii _

Operation

Practices

WARNING

Thissymbolpoints

out importantsafety

instructionswhich, if

not followed, could

endangerthe personal

safetyandlor propertyof

yourselfand others.Read

and follow all instructions

inthis manual before

attempting to operate

this math ine.Failure

to complywiththese

instructionsmayresult

in personalinjury.When

you seethis symbol -

HEED ITS WARNING

5

,_1 WARNING:Useextremecaution

__ componentsarevery heavyand will

unpacking thismachine.Some

requireadditional peopleor mechanical

handlingequipment.

Setting Up

Your Log

Splitter

NOTE:Allreferencesinthismanualtotheleft or right

sideof thelog splitterisfromtheoperatingpositiononly.

Exceptions,ifany,willbespecified.

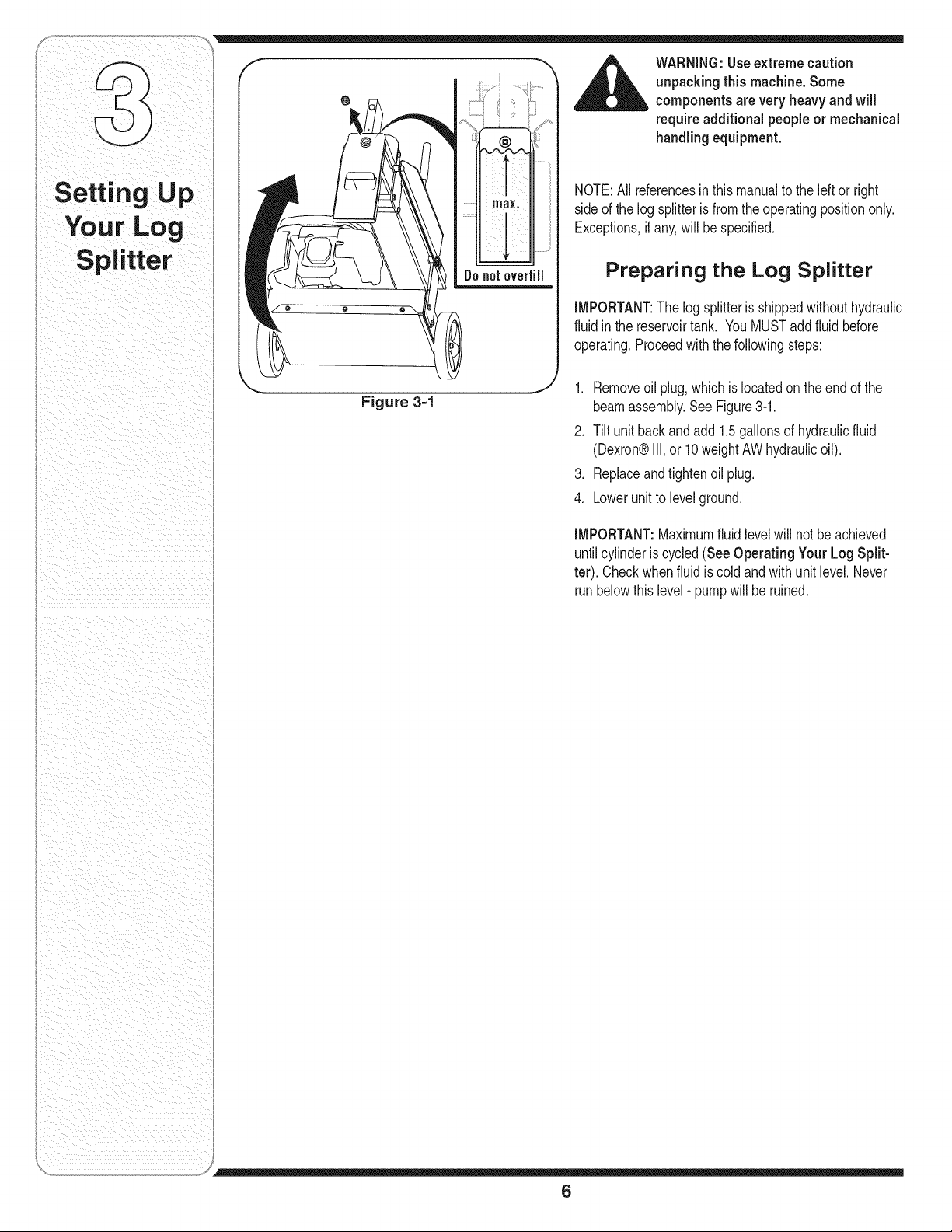

Preparing the Log Splitter

iMPORTANT:Thelogsplitterisshippedwithouthydraulic

fluidin the reservoirtank. YouMUSTaddfluidbefore

operating.Proceedwiththe followingsteps:

1. Removeoilplug,whichislocatedontheendofthe

Figure 3-1 beamassembly.SeeFigure3-1.

2. Tiltunit backandadd1.5gallonsofhydraulicfluid

(Dexron®III,or 10weightAWhydraulicoil).

3. Replaceandtightenoil plug.

4. Lowerunitto levelground.

IMPORTANT:Maximumfluidlevelwillnot beachieved

untilcylinderiscycled(SeeOperating Your LogSplit-

ter). Checkwhenfluidiscold andwithunitlevel.Never

runbelowthislevel- pumpwillbe ruined.

6

IMPORTANT:This unitisshippedwithoutgasolineoroil

in theengine.Fillupgasolineandoil BEFOREpriming

pumpor operatingyourlogsplitter.

5. Addoil providedbeforeprimingpumporstartingunit

forthefirsttimeoutofthebox.SeeEngineOperation

sectionfor thisandforlocationoftheoilfill.

6. Servicethe enginewith gasolineasinstructedinthe

EngineOperationsection.See EngineOperation

sectionfor locationofgasfill.

_ ARNING:Useextremecarewhenhan-

flammableand thevaporsareexplosive.

Neverfuel the machineindoorsor while

the engineis hot or running.Extinguish cigarettes,

cigars,pipesand other sourcesof ignition.

dlinggasoline.Gasolineisextremely

.

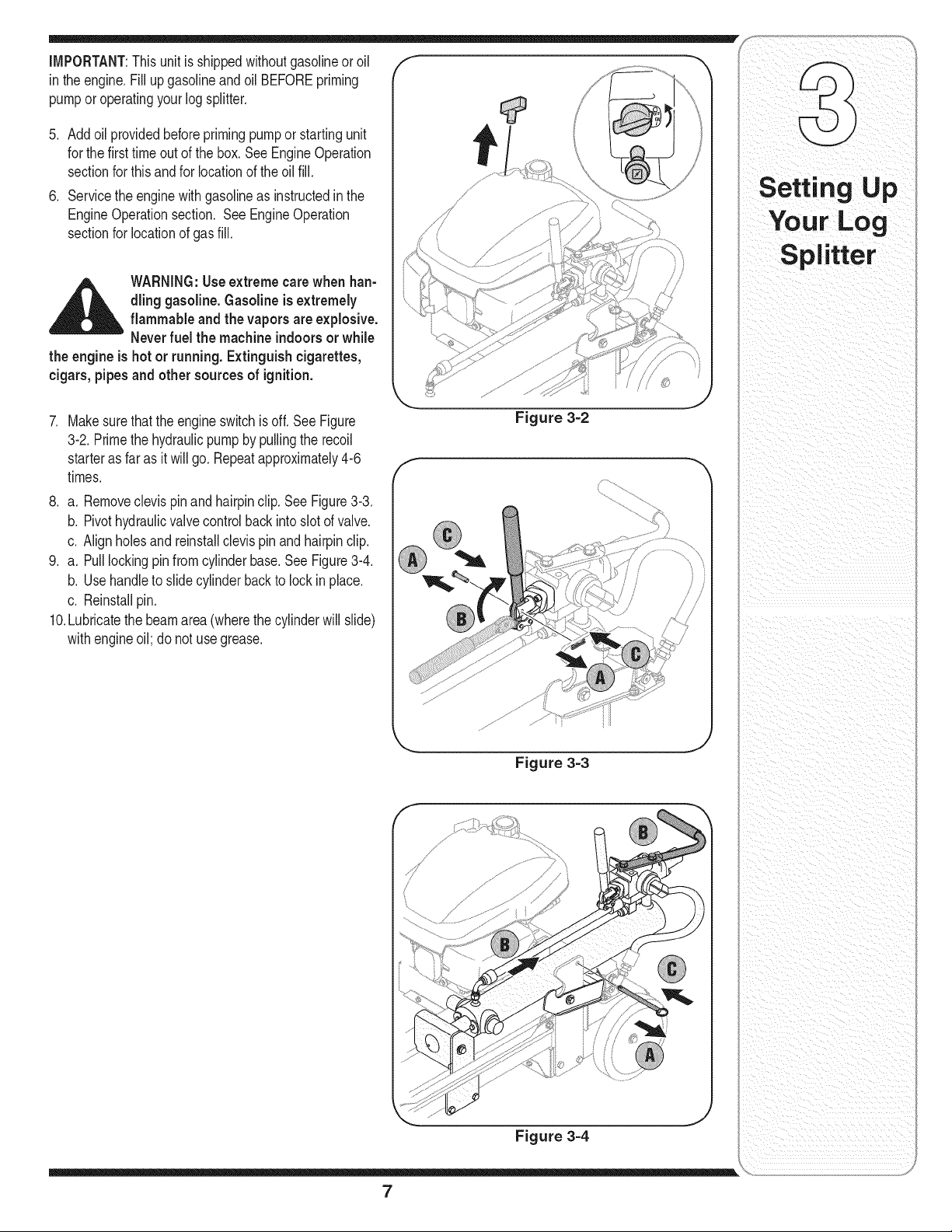

Makesurethattheengineswitchis off.SeeFigure

3-2.Primethehydraulicpumpbypullingthe recoil

starteras farasit willgo.Repeatapproximately4-6

times.

8. a. Removeclevispinandhairpinclip.SeeFigure3-3.

b. Pivothydraulicvalvecontrolbackintoslotofvalve.

c. Alignholesand reinstallclevispinandhairpinclip.

9. a. Pulllockingpinfromcylinderbase.SeeFigure3-4.

b. Usehandleto slidecylinderbackto lockinplace.

c. Reinstallpin.

10.Lubricatethebeamarea(wherethecylinderwillslide)

withengineoil; donotusegrease.

Figure 3=2

i i i i i i ii

Figure 3=3

Figure 3=4

7

Operating

/

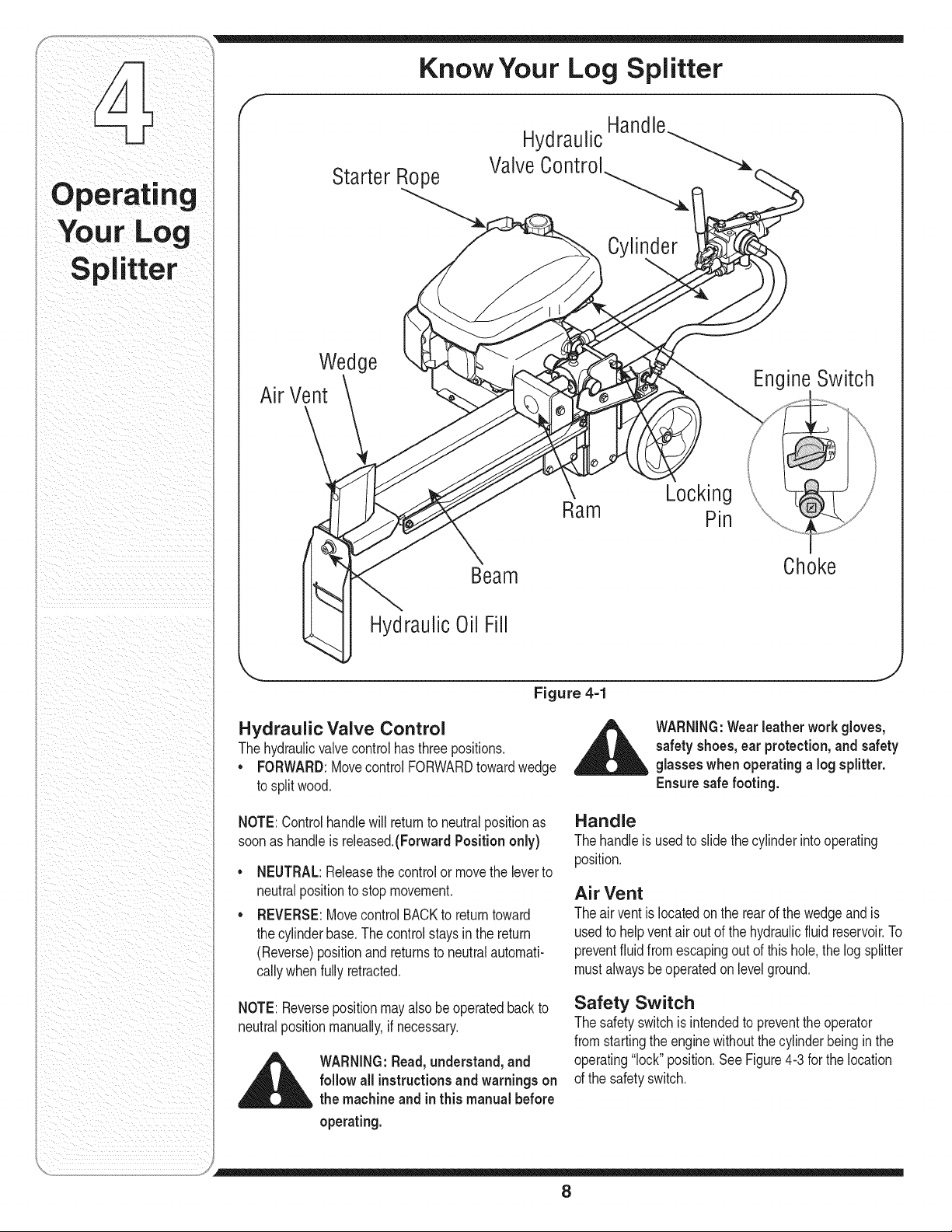

Know Your Log Splitter

HydraulicHandle,.,_

StarterRope

ValveControl._._

Your Log

Splitter

Air Vent

Wedge

Hydraulic Oil Fill

Beam

Ram

Cylinder

Engine Switch

Locking ,,,

Pin

Choke

Figure 4=1

Hydraulic Valve Control

Thehydraulicvalvecontrolhas threepositions.

• FORWARD:MovecontrolFORWARDtowardwedge

tosplitwood.

NOTE:Controlhandlewill returnto neutralpositionas

soonas handleis released.(ForwardPosition only)

NEUTRAL:Releasethecontrolormovethe leverto

neutralpositionto stopmovement.

REVERSE:MovecontrolBACKto returntoward

thecylinderbase.Thecontrolstaysinthereturn

(Reverse)positionandreturnsto neutralautomati-

callywhenfullyretracted.

NOTE:Reversepositionmayalsobeoperatedbackto

neutralpositionmanually,ifnecessary.

__L WARNING:Read,understand, and

follow all instructionsand warnings on

the machineand inthis manualbefore

operating.

__i ARNING:Wearleather work gloves,

Handle

Thehandleisusedtoslidethecylinderintooperating

position.

Air Vent

Theair ventislocatedontherearofthe wedgeandis

usedto helpventairout ofthehydraulicfluidreservoir.To

preventfluidfromescapingoutof thishole,thelog splitter

mustalwaysbeoperatedon levelground.

Safety Switch

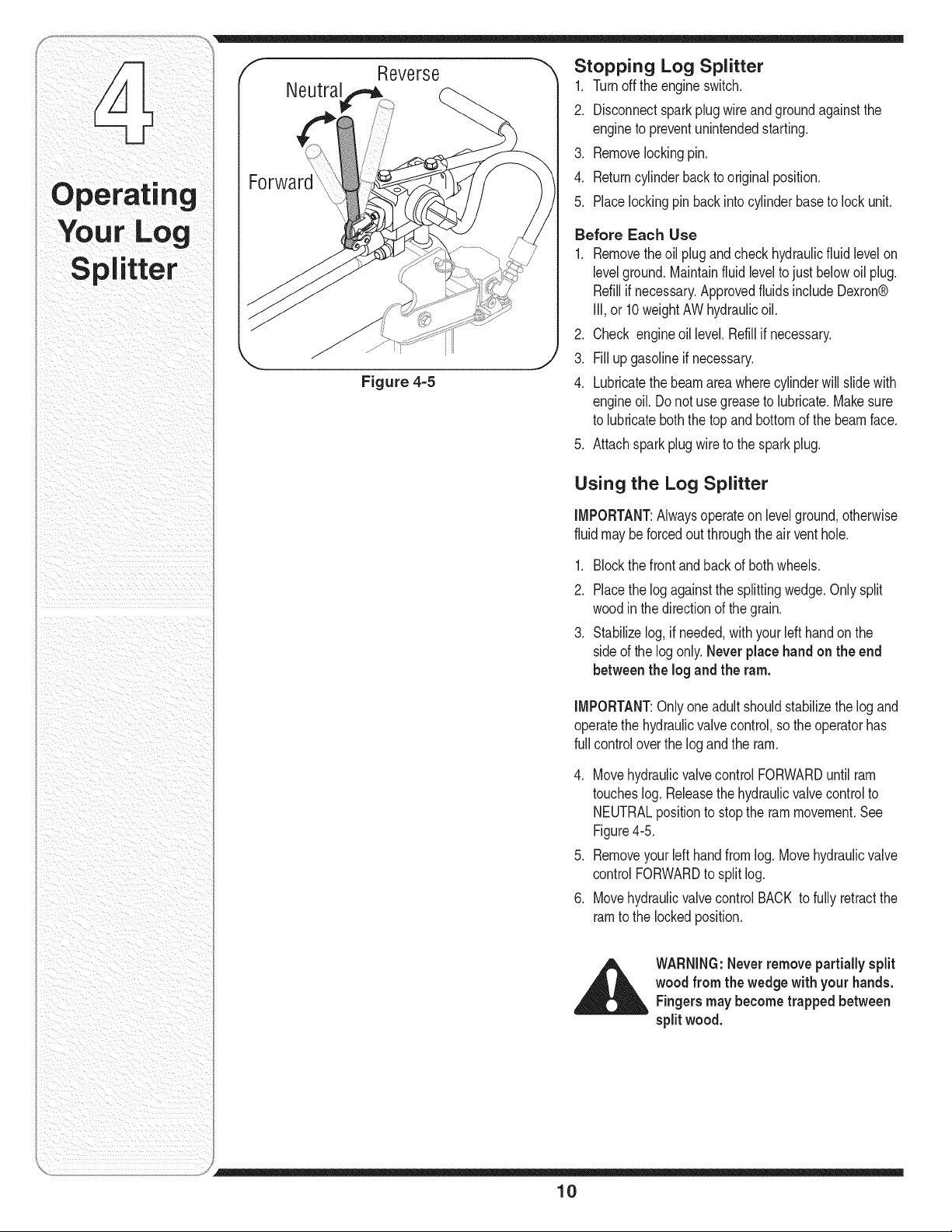

Thesafetyswitchisintendedtopreventtheoperator

fromstartingtheenginewithoutthecylinderbeingin the

operating"lock"position.SeeFigure4-3 forthelocation

ofthesafetyswitch.

safetyshoes,earprotection,and safety

glasses when operating a log splitter.

Ensuresafefooting.

8

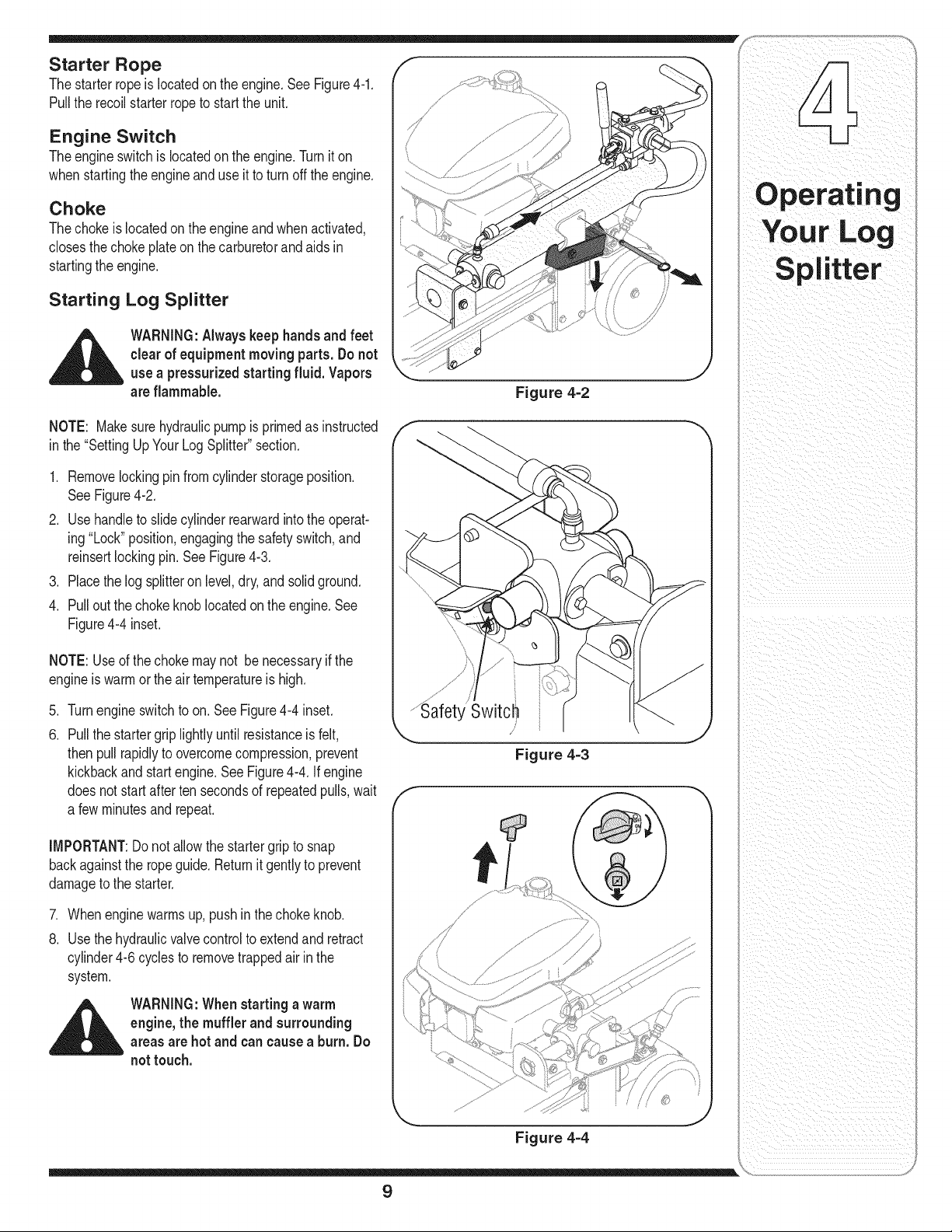

Starter Rope

Thestarterropeislocatedontheengine.SeeFigure4-1.

Pulltherecoilstarterropetostarttheunit.

Engine Switch

Theengineswitchis locatedontheengine.Turniton

whenstartingtheengineanduseittoturn offtheengine.

Choke

Thechokeislocatedon theengineandwhenactivated,

closesthe chokeplateon thecarburetorandaidsin

startingthe engine.

r Log

Starting Log Splitter

WARNING:Alwayskeephandsandfeet

clearof equipmentmovingparts.Donot

usea pressurizedstartingfluid. Vapors

areflammable.

NOTE: Makesurehydraulicpumpisprimedasinstructed

inthe"SettingUpYourLogSplitter"section.

1. Removelockingpin fromcylinderstorageposition.

See Figure4-2.

2. Usehandleto slidecylinderrearwardintotheoperat-

ing"Lock"position,engagingthe safetyswitch,and

reinsertlockingpin.See Figure4-3.

3. Placethelog splitteronlevel,dry,andsolidground.

4. Pullout thechokeknoblocatedontheengine.See

Figure4-4inset.

NOTE:Useofthe chokemaynot benecessaryifthe

engineiswarmor theairtemperatureishigh.

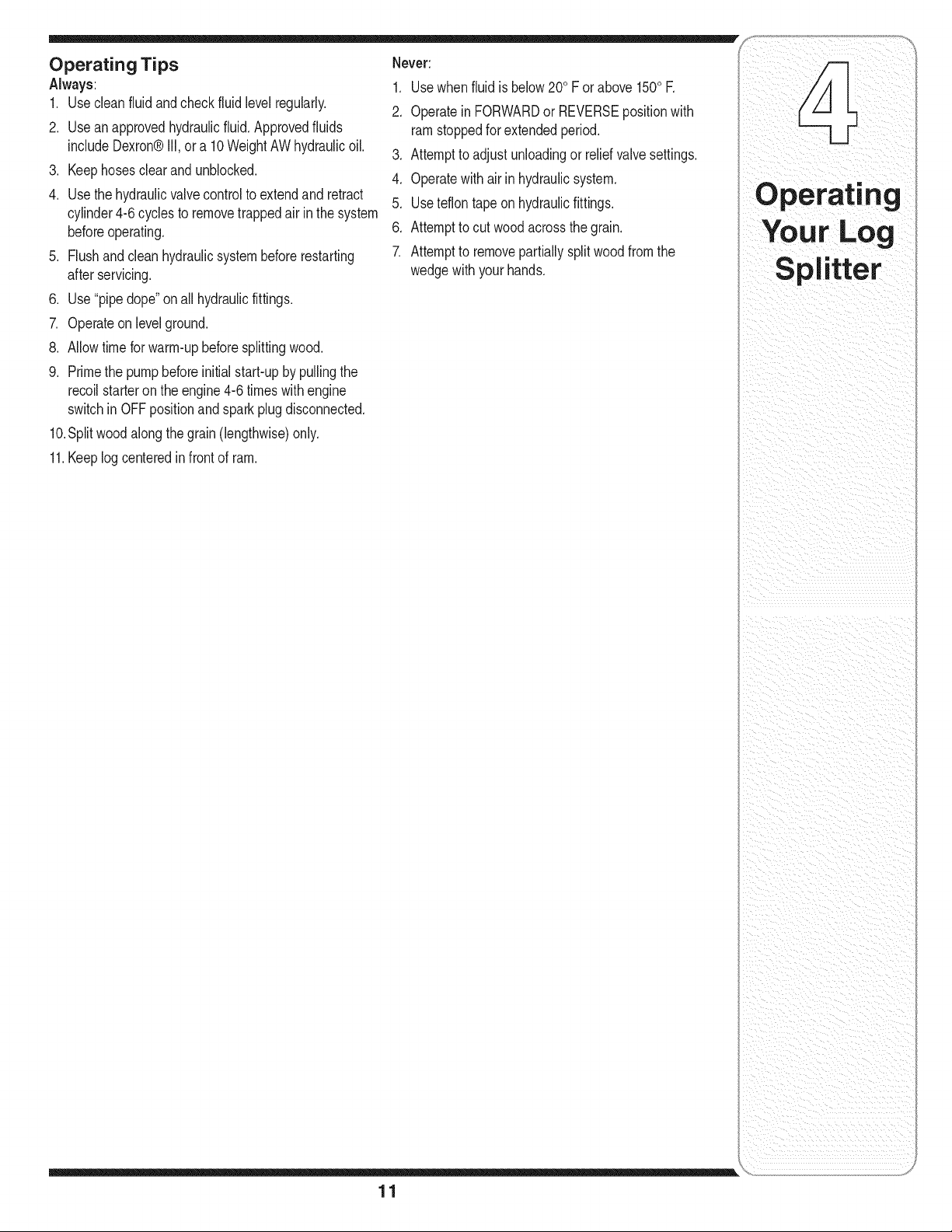

5. Turnengineswitchtoon.SeeFigure4-4inset.

6. Pullthe startergriplightlyuntilresistanceisfelt,

thenpullrapidlyto overcomecompression,prevent

kickbackandstartengine.SeeFigure4-4.If engine

doesnotstartaftertensecondsofrepeatedpulls,wait

a fewminutesand repeat.

ii i_ _i_ii_ii!ii_ _!_

Figure 4-2

i i i i i i ii

ii i _iI_ ii

/

Figure 4-3

IMPORTANT:Donotallowthestartergriptosnap

backagainsttheropeguide.Returnitgentlyto prevent

damagetothe starter.

7. Whenenginewarmsup,pushinthechokeknob.

8. Usethe hydraulicvalvecontroltoextendandretract

cylinder4-6 cyclesto removetrappedair inthe

system.

__i ARNING:Whenstartingawarm

engine,the muffler and surrounding

areasare hot andcancauseaburn.Do

not touch.

//

Figure 4-4

9

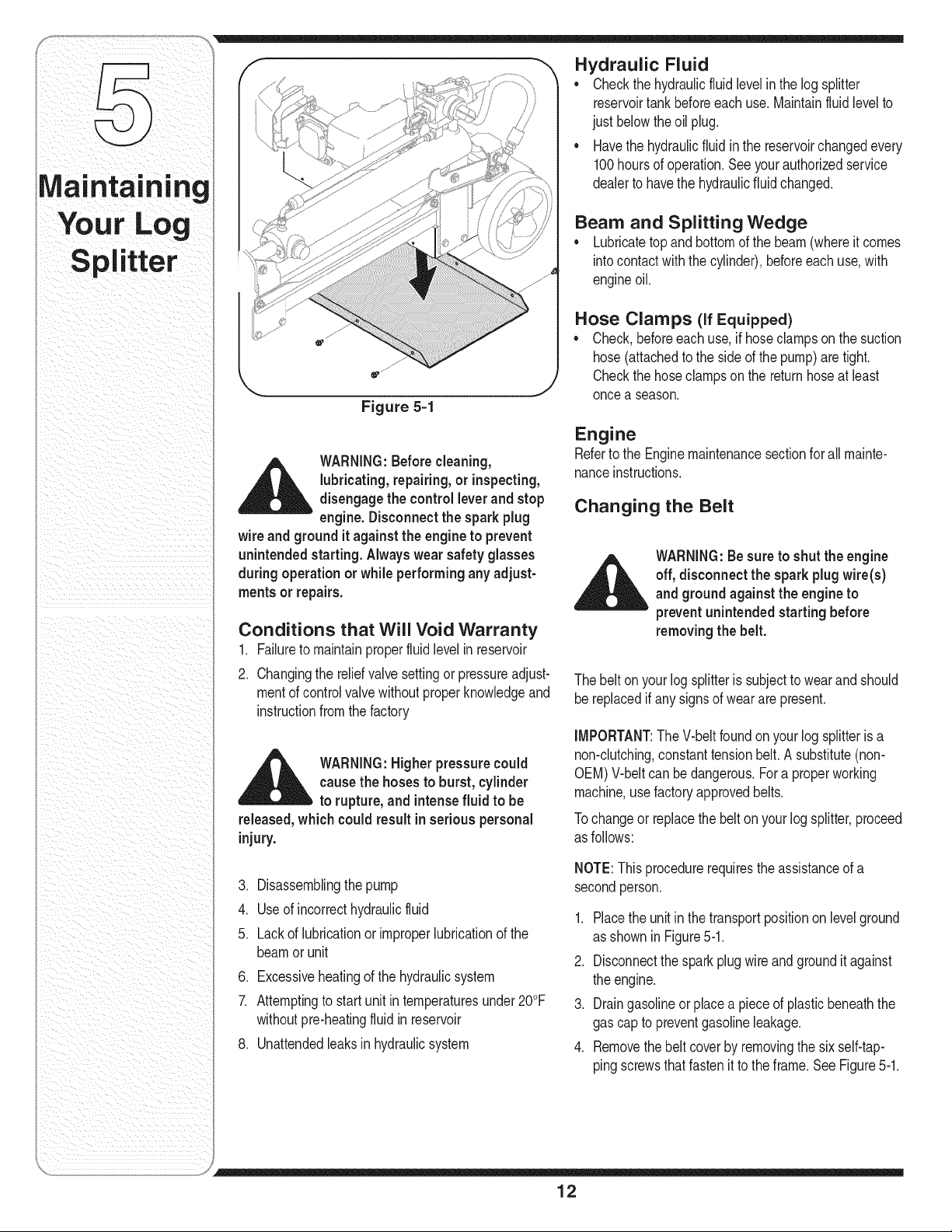

Reverse _ Stopping Log Splitter

Operating

Your Log

Splitter

Neutra 2. Disconnectsparkplugwireandgroundagainstthe

_l_,,jk: 1. Turnoff theengineswitch.

Figure 4=5

|

enginetopreventunintendedstarting.

3. Removelockingpin.

4. Returncylinderbackto originalposition.

5. Placelockingpinbackintocylinderbaseto lockunit.

Before Each Use

1. Removetheoil plugandcheckhydraulicfluidlevelon

levelground.Maintainfluidleveltojustbelowoil plug.

Refillifnecessary.ApprovedfluidsincludeDexron®

III,or10weightAWhydraulicoil.

2. Check engineoil level.Refillifnecessary.

3. Fill upgasolineifnecessary.

4. Lubricatethebeamareawherecylinderwillslidewith

engineoil.Donotusegreaseto lubricate.Makesure

tolubricateboththetopand bottomofthebeamface.

5. Attachsparkplugwireto thesparkplug.

Using the Log Splitter

IMPORTANT:Alwaysoperateonlevelground,otherwise

fluidmaybeforcedoutthroughtheair venthole.

1. Blockthe frontandbackofbothwheels.

2. Placethelogagainstthesplittingwedge.Onlysplit

woodinthedirectionofthegrain.

3. Stabilizelog,ifneeded,withyourlefthandonthe

sideof thelog only.Neverplacehand on the end

between the log and the ram.

IMPORTANT:Onlyoneadultshouldstabilizethelog and

operatethehydraulicvalvecontrol,sotheoperatorhas

fullcontroloverthelogandthe ram.

4. MovehydraulicvalvecontrolFORWARDuntilram

toucheslog.Releasethehydraulicvalvecontrolto

NEUTRALpositionto stopthe rammovement.See

Figure4-5.

5. Removeyourlefthandfromlog.Movehydraulicvalve

controlFORWARDto splitlog.

6. MovehydraulicvalvecontrolBACK tofully retractthe

ramto thelockedposition.

__IL WARNING:Neverremove partiallysplit

wood from the wedgewith your hands.

Fingers maybecometrapped between

split wood.

10

Operating Tips Never:

Always: 1. Usewhenfluidisbelow200For above150oF.

1. Usecleanfluidandcheckfluidlevelregularly. 2. Operatein FORWARDor REVERSEpositionwith

2. Usean approvedhydraulicfluid.Approvedfluids ramstoppedforextendedperiod.

includeDexron®Ill,or a 10WeightAWhydraulicoil. 3. Attemptto adjustunloadingor reliefvalvesettings.

3. Keephosesclearandunblocked.

4. Usethe hydraulicvalvecontroltoextendandretract

cylinder4-6 cyclestoremovetrappedairinthesystem

beforeoperating. 6. Attemptto cutwoodacrossthegrain, r' Log

5. Flushandcleanhydraulicsystembeforerestarting 7. Attemptto removepartiallysplitwoodfromthe

afterservicing, wedgewithyour hands.

6. Use"pipedope"onall hydraulicfittings.

7. Operateon levelground.

8. Allowtimeforwarm-upbeforesplittingwood.

9. Primethepumpbeforeinitialstart-upbypullingthe

recoilstarteron theengine4-6timeswithengine

switchinOFFpositionandsparkplugdisconnected.

10.Splitwoodalongthegrain(lengthwise)only.

11.Keeplogcenteredinfrontofram.

4. Operatewithairinhydraulicsystem.

5. Useteflontapeonhydraulicfittings.

11

S_

Maintaining

Hydraulic Fluid

• Checkthehydraulicfluidlevelinthelogsplitter

reservoirtankbeforeeachuse.Maintainfluidlevelto

just belowtheoilplug.

• Havethehydraulicfluidinthe reservoirchangedevery

100hoursof operation.Seeyourauthorizedservice

dealertohavethehydraulicfluidchanged.

Your Log

Splitter

Figure 5=1

_ ARNING:Beforecleaning,

wireandgroundit againstthe engineto prevent

unintended starting.Alwayswearsafetyglasses

during operationorwhileperforminganyadjust-

ments or repairs.

lubricating,repairing,or inspecting,

disengagethe controlleverand stop

engine.Disconnectthesparkplug

Conditions that Will Void Warranty

1. Failuretomaintainproperfluidlevelinreservoir

2. Changingthe reliefvalvesettingorpressureadjust-

mentofcontrolvalvewithoutproperknowledgeand

instructionfromthefactory

_ WARNING:Higherpressurecould

released,which could resultin serious personal

injury.

cause the hoses to burst, cylinder

to rupture, and intensefluid to be

Beam and Splitting Wedge

• Lubricatetopandbottomof the beam(whereitcomes

intocontactwiththe cylinder),beforeeachuse,with

engineoil.

Hose Clamps (if Equipped)

• Check,beforeeachuse,ifhoseclampsonthesuction

hose(attachedtotheside ofthepump)aretight.

Checkthehoseclampsonthe returnhoseat least

oncea season.

Engine

RefertotheEnginemaintenancesectionforallmainte-

nanceinstructions.

Changing the Belt

off, disconnect the spark plugwire(s)

_ ARNING:Besure to shut the engine

Thebelt onyourlogsplitterissubjecttowearandshould

be replacedif anysignsofweararepresent.

IMPORTANT:TheV-beltfoundonyourlogsplitterisa

non-clutching,constanttensionbelt.Asubstitute(non-

OEM)V-beltcanbe dangerous.Foraproperworking

machine,usefactoryapprovedbelts.

Tochangeor replacethebeltonyourlogsplitter,proceed

asfollows:

and ground against the engineto

preventunintended starting before

removingthebelt.

3. Disassemblingthepump

4. Useof incorrecthydraulicfluid

5. Lackof lubricationor improperlubricationof the

beamor unit

6. Excessiveheatingof thehydraulicsystem

7. Attemptingtostartunitintemperaturesunder20°F

withoutpre-heatingfluidin reservoir

8. Unattendedleaksinhydraulicsystem

NOTE:Thisprocedurerequiresthe assistanceof a

secondperson.

1. Placetheunitinthetransportpositionon levelground

asshownin Figure5-1.

2. Disconnectthesparkplugwireandgrounditagainst

theengine.

3. Draingasolineorplaceapieceofplasticbeneaththe

gascap topreventgasolineleakage.

4. Removethebelt coverbyremovingthesixself-tap-

pingscrewsthatfastenittotheframe.SeeFigure5-1.

12

5. Chockbothwheels,frontandrear,andhaveyour f

helpergraspthefrontofthe unitandcarefullytiltit

backtoexposethebeltdriveunderneath.

IMPORTANT:To preventengineoil fromentering

carburetorand/orhydraulicoilfromescapingthroughthe

air venthole,do not tilt unitto theside.

[

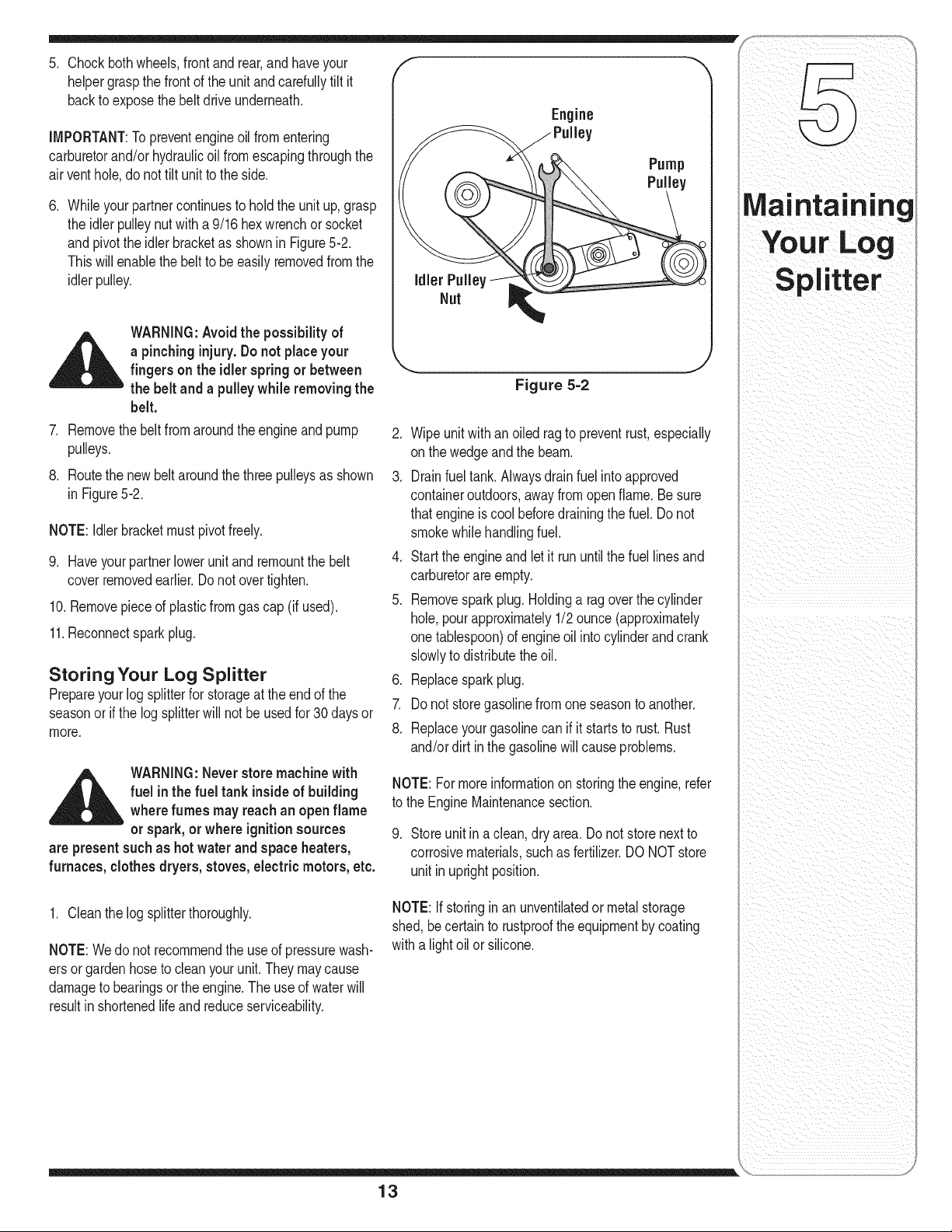

6. Whileyourpartnercontinuestoholdtheunit up,grasp

theidlerpulleynut witha9/16hexwrenchor socket

and pivottheidlerbracketasshowninFigure5-2.

Thiswillenablethebeltto beeasilyremovedfromthe

idlerpulley.

WARNING:Avoidthe possibilityof

a pinchinginjury.Donot placeyour

fingers on the idlerspringor between

the belt and a pulleywhile removingthe

belt.

7. Removethebeltfromaroundthe engineandpump

pulleys.

8. Routethe newbeltaroundthethreepulleysas shown

in Figure5-2.

NOTE:Idlerbracketmustpivotfreely.

9. Haveyourpartnerlowerunitandremountthebelt

coverremovedearlier.Donotovertighten.

10.Removepieceof plasticfromgas cap(ifused).

11.Reconnectsparkplug.

Storing Your Log Splitter

Prepareyourlog splitterforstorageatthe endofthe

seasonor ifthe log splitterwillnotbeusedfor30 daysor

more.

Figure 5=2

2. Wipeunitwith anoiledragtopreventrust,especially

onthewedgeandthebeam.

3. Drainfueltank. Alwaysdrainfuelintoapproved

containeroutdoors,awayfromopenflame. Besure

thatengineiscoolbeforedrainingthefuel.Donot

smokewhilehandlingfuel.

4. Startthe engineandletitrununtilthefuellinesand

carburetorareempty.

5. Removesparkplug.Holdingaragoverthecylinder

hole,pourapproximately1/2ounce(approximately

onetablespoon)ofengineoil intocylinderandcrank

slowlyto distributetheoil.

6. Replacesparkplug.

7. Do notstoregasolinefromoneseasonto another.

8. Replaceyourgasolinecanifit startsto rust.Rust

and/ordirt inthegasolinewillcauseproblems.

Maintaining

ii i_ _i_ii_ii!ii_ _!_

i i i iI i i i i i ii

ii i _iI_ ii

A WARNING:Neverstoremachinewith

are presentsuchas hotwaterandspaceheaters,

furnaces, clothesdryers,stoves,electricmotors,etc.

1. Cleanthelog splitterthoroughly.

NOTE:Wedonot recommendtheuseofpressurewash-

ersor gardenhosetocleanyourunit.Theymaycause

damageto bearingsorthe engine.Theuseofwaterwill

resultinshortenedlifeand reduceserviceability.

fuel inthe fuel tank insideof building

where fumes may reachan open flame

or spark,or where ignitionsources

NOTE:Formoreinformationonstoringthe engine,refer

totheEngineMaintenancesection.

9. Storeunitin a clean,dryarea.Donot storenextto

corrosivematerials,suchasfertilizer.DONOTstore

unitinuprightposition.

NOTE:If storinginan unventilatedor metalstorage

shed,becertainto rustprooftheequipmentbycoating

withalightoilorsilicone.

13

Preblem Cause Remedy

Enginefailsto start Sparkplugwiredisc0nneCted, i Connectwiretosparkplug.

2: FUeltankemPtYor StalefUell tankwith €iean,freshgasoline:

&Choke not inCHOKEposition, 3, Chokeengineas instructedin

!'OperatingYourLogSplitter!!:

4. Trunnionsnotdepressingsafetyswitch 4 Moyecylinderintolocked positOn,

Fauitysparkpiugl

Blockedfuellinel Cleanfuel iine

7, EngineF!o0dedl 7, waitafewminutest0starL

i ill i _ii

i_ _ iii

For repairsbeyond

the minor adjust-

merits listed hem

I_ _ iiiiiiiiiiiiiiiiiii

Engineruns erratic

1. UnitrunningwithCHOKEapplied.

2. Sparkplugwireloose.

3. Blockedfuellineorstalefuel.

4. Waterordirt infuelsystem.

5. Dirty aircleaner, section.

6. Ventingascapplugged. 6. Clearvent.

1. PushCHOKEknobin.

2. Connectandtightenspark

plugwire.

3. Cleanfuelline;filltankwithclean,

fresh(lessthan30 daysold)

gasoline.

4. Drainfueltank.Refillwith

freshfuel.

5. Referto enginemaintenance

Engine Overheats Engineoil!eve Iowl 1 Fi!!Crankiasewithproperoi!.

2: Airf!ow restricted, 2 Removeblowerhousing

i ..... andclean.

Occasionalskips 1. Sparkpluggaptooclose. 1. Adjustgapto .030".

(hesitates)at

highspeed

des poor y Spark p!ugfouled faulty orgap 1: Resetgapto .o30'!orreplace

, toowde Sparkplugl

Dirtyaircleaner. 2 Rder to eng!nemaintenance

' section.

Problem

Cylinder rodwill not

move

Cause

1. Brokenor wornbelt.

2. Shippingplugsleftinhydraulichoses.

3. Set screwsinpumppulleynot

adjustedproperly.

4. Loosepulley.

5. Pumpgearsectionsdamaged.

6. Damagedreliefvalve.

7. Hydrauliclinesblocked.

8. Incorrectoil level.

9. Damageddirectionalvalve.

10.Blockeddirectionalvalve.

11.Unlevelground;hydraulicfluidnot

reachingpump.

14

Remedy

1. Replacebelt.

2. Disconnecthydraulichoses,

removeshippingplugs,reconnect

hoses.

3. Seeauthorizedservicedealer.

4. Correctengine/pumpalignmentas

necessary.

5. Seeauthorizedservicedealer.

6. Seeauthorizedservicedealer.

7. Flushandcleanhydraulicsystem.

8. Checkoil level.

9. Seeauthorizedservicedealer.

lO.Flushandcleanhydraulicsystem.

11.Movelogsplittertolevelground.

Problem Cause Remedy

Slowcy indershaft I 1, Gearsectionsdamaged. I 1. Seeauthorizedservicedealer.

speedwhile extending 2, Excessivepumpinletvacuum. 2. Makecertainpumpinlethosesare

and retracting, clearandunblocked-useshort,

LeakingCylinder 1. Brokenseals. 1. Seeauthorizedservicedealer.

Engine runs butwood 1. Smallgearsectiondamaged. 1. Seeauthorizedservicedealer.

will not split or wood 2. Pumpcheckvalveleaking. 2. Seeauthorizedservicedealer.

splits too slowly 3. Excessivepumpinletvacuum. 3. Makecertainpumpinlethosesare

B

3. Slowenginespeed.

4. Damagedreliefvalve.

5 Incorrectoillevel.

6. Containnatedoil.

7. Directionalvave leakinginternally.

8. Internallydamagedcylinder.

9. Unt noton eve ground.

2. Scoredcylinder. 2. Seeauthorizedservicedealer.

4. Incorrectoillevel. 4, Checkoillevel.

5 Contaminatedoil 5. Drainoil,cleanreservoir,and refill.

6. Directionalvalveleakinginternally. 6. Seeauthorizedservicedealer.

7 Overloadedc linder 7 Do notattemptto sp t wood

I ' Y " I aga'nstthe gra'n

8. nternaydamagedcy nder. 8. Seeauthorzedservcedeaer.

9 Wornbelt. I 9, Replacebelt,

I lO.Unitnotonlevelground. I lO.Movelogsplittertolevelground.

I

largediameterinlethoses.

3 Seeauthorzedservcedeaer

4 Seeauthorzedservcedeaer

5 Checko eve

6 Drano ceanreservor and ref

7 Seeauthorzedservcedeaer

8 Seeauthorzedservcedeaer

9, Movelogsplittertolevelground.

I clearandunblocked.

ydraulic

Trouble

Shootin

For repairs beyond

theminoradjust-

mentslisted here,

contact an authorized

service dealer.

Enginestalls during 1. Lowhorsepower/weakengine. 1. Seeauthorizedservicedealer.

splitting 2. Overloadedcylinder. 2. Donotattemptto splitwood

againstthegrainor seeauthorized

servicedealer.

Enginewill notturnor 1, Engine/pumpmisalignment, 1. Correctalignmentas necessary.

stalls under low load 2. Frozenorseizedpump. 2. Seeauthorizedservicedealer.

conditions 3. Lowhorsepower/weakengine, 3. Seeauthorizedservicedealer.

system

Leakingpumpshaft

seal

I 4 Hydraucnes bocked 4 F ushandcean hydrauc

g

. 5. Blockeddirectionalvalve. I 5, Flushandclean hydraulicsystem,

1. Brokendriveshaft.

2. Engine/pumpmisalignment.

3. Gearsectionsdamaged.

4. Poorlypositionedshaftseal.

5. Pluggedoilbreather.

1. Seeauthorizedservicedealer.

2. Correctalignmentas necessary.

3. Seeauthorizedservicedealer.

4. Seeauthorizedservicedealer.

5. Makecertainreservoiris properly

vented.

15

WARNING: Gasoline and itsvaporsare extremely flammableand explosive.Fireor

explosioncan cause severeburnsor death. Ifgasoline isspilled on yourself or your

clothes,wash yourskin and change clothes immediately.

En line

Safe

Operation

Practices

Gasolineand its vaporsare

extremely flammable and

explosive. Fire or explosion can

cause severe burns or death, if

gasoline isspilled on yourself

or yourclothes, wash your skin

and change clothes immediately.

Whenaddingfuel,turnengineOFFandletengine

coolat least2 minutesbeforeremovinggascap.

o

Fillfueltankoutdoorsor inwellventilatedarea.

o

Useonlyanapprovedgasolinecontainer.

o

Neverfillcontainersinsideavehicleor onatruck or

trailerbedwitha plasticliner.Alwaysplacecontain-

ersonthegroundawayfromyourvehiclebefore

filling.

• If possible,removegas-poweredequipmentfromthe

truckor trailerandrefueliton theground.Ifthisis

notpossible,thenrefuelsuchequipmentona trailer

withaportablecontainer,ratherthanfroma gasoline

dispensernozzle.

• Keepthenozzlein contactwiththerimof thefuel

tankorcontaineropeningat alltimesuntilfuelingis

complete.Donotuseanozzlelock-opendevice.

• Donotoverfillfueltank.Filltanktoapproximately

oneinchbelowlowestportionof necktoallowfor

fuelexpansion.

• Keepgasolineawayfromsparks,openflames,pilot

lights,heat,andotherignitionsources.

• Neverfuelequipmentindoorsbecauseflammable

vaporswillaccumulatein the area.

• Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

• Checkfuelline,tank, cap,andfittingsfrequentlyfor

cracksor leaks.Replaceif necessary.

• Whenstartingengine,makesuresparkplug,muffler,

fuelcap andaircleanerareinplace.

• Donotcrankenginewithsparkplugremoved.

• If fuelspills,wait untilit evaporatesbeforestarting

engine.

• Whenoperatingequipment,donottipengineor

equipmentatanglewhichcausesgasolinetospill.

• Donotchokecarburetorto stopengine.

• Whentransportingequipment,transportwithfueltank

EMPTY.

Whenstoringgasolineorequipmentwithfuelintank,

storeawayfromfurnaces,stoves,waterheatersor

otherappliancesthathavepilotlightorotherignition

sourcebecausetheycanignitegasolinevapors.

,__. Starting engine creates spark-

ing. Sparking can ignite nearby

__ flammable gases. Explosion and

fire could result.

If thereis a naturalorLPgasleakageinarea,donot

startengine.

• Donot usepressurizedstartingfluidsbecausevapors

areflammable.

_ ngines give off carbon mon-

oxide, an odorless, colorless,

poisonous gas.Breathing carbon

monoxide can cause nausea,

fainting, or death.

Startandrunengineoutdoors.

• Donot startor runenginein enclosedarea,evenif

doorsor windowsare open.

_ nintentional sparking can result

infire or electric shock. Unin-

tentional start-up can result in

entanglement, traumatic amputa-

tion, or laceration.

• Beforeperformingadjustmentsor repairs,disconnect

sparkplugwireand keepitawayfromsparkplug.

• Whentestingforspark,useapprovedsparkplug

tester.

Donotcheckforsparkwithsparkplugremoved.

16

Runningengine produces heat.

Engineparts, especially muffler,

become extremely hot. Severe

thermal burns canoccur on

contact. Combustibledebris,

suchas leaves, grass, brush, etc.,

cancatch fire.

• Allowmuffler,enginecylinder,andfinstocoolbefore

touching.

• Keepchildrenawayfromhot or runningengines.They

cansufferburnsfromahot muffler.

Removeaccumulatedcombustiblesfrommufflerand

cylinderarea.

_ Rotating engine partscan

Operateequipmentwithguardsin place.

Keephandsandfeetawayfromrotatingparts.

contactor entangle hands, feet,

hair, clothing,or accessories.

Traumaticamputation or severe

lacerationcan result.

• Tieuplonghairand removejewelry.

Donotwearloose-fittingclothing,danglingdraw-

stringsoritemsthatcouldbecomecaught.

,__ Rapid retraction of starter cord

• Whenstartingengine,pullcordslowlyuntilresis-

tanceisfelt,thenpullrapidly.

• Removeallexternalequipment/engineloadsbefore

startingengine.

• Directcoupledequipmentcomponentssuchas, but

notlimitedtoblades,impellers,pulleys,sprockets,

etc.,mustbesecurelyattached.

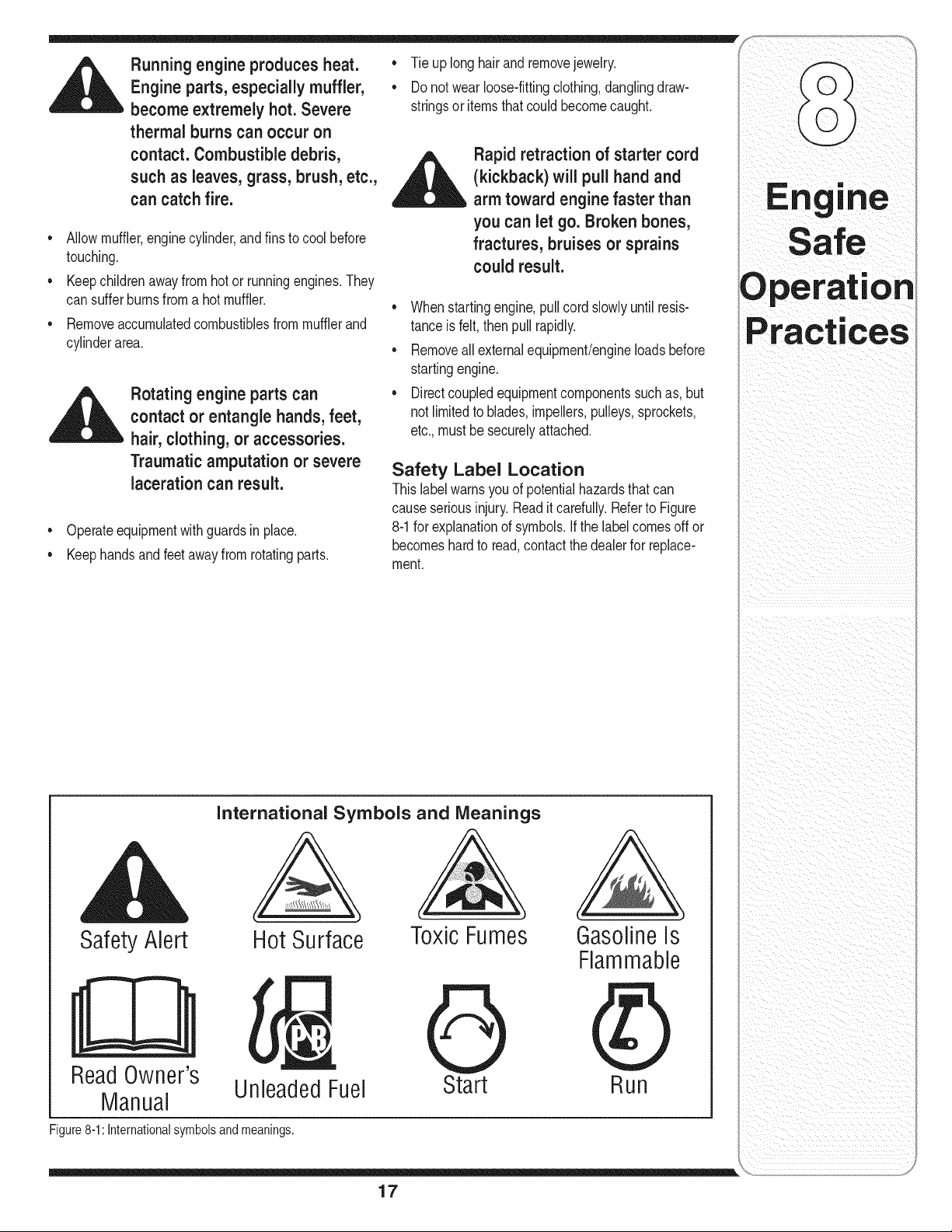

Safety Label Location

Thislabelwarnsyouofpotentialhazardsthat can

causeseriousinjury.Readitcarefully.Referto Figure

8-1forexplanationofsymbols.If thelabelcomesoffor

becomeshardto read,contactthedealerforreplace-

ment.

(kickback) will pull hand and

arm toward engine faster than

you can let go. Brokenbones,

fractures, bruises or sprains

could result.

O,o,a,.o°

ractices

ii i _iI_ ii

International Symbols and Meanings

A

SafetyAlert

ReadOwner's

Manual

Figure8-1:Internationalsymbolsandmeanings.

HotSurface ToxicFumes

UnleadedFuel

17

G

Start

GasolineIs

Flammable

Run

Loading...

Loading...