MTD 24A495D099 Owner’s Manual

Owner's Manual

CRAFTSMAN

8.5 Horse Power

CHIPPER-SHREDDER

Model No.

247.77588O

CAUTION: Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

770-1228A

Printed in U.S.A. (3/98)

Content Page Content Page

Warranty Information 2 Service & Adjustment 14

Safe Operation Practices 3 Off-Season Storage 16

Assembly 5 Trouble-Shooting 17

Operation 8 Repair Parts 18

Maintenance 11

One-Year Warranty on Craftsman Chipper-Shredder

Forone year from thedate ofpurchase,whenthisCraftsmanchipper-shredderis maintained,lubricated,and

tunedupaccordingtothe operatingand maintenance instructionsintheowner'smanual,Sears willrepair,free of

charge, any defect in materialorworkmanship.

Thiswarrantyexcludes blades, chipperblades, flails,aircleaners, spark plugs, catcherbags andtires whichare

expendable parts and become worn dudng normal use.

Ifthis chipper-shredderis used for commercialor rentalpurposes, thiswarranty appliesfor only30 days from the

date ofpurchase.

WARRANTY SERVICE IS AVAILABLE BYCONTACTING THE NEAREST SEARS SERVICE CENTER INTHE

UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS IN USE INTHE UNITED

STATES.

This warranty gives you specific legalrights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., D/817WA, Hoffman Estates, II 60179

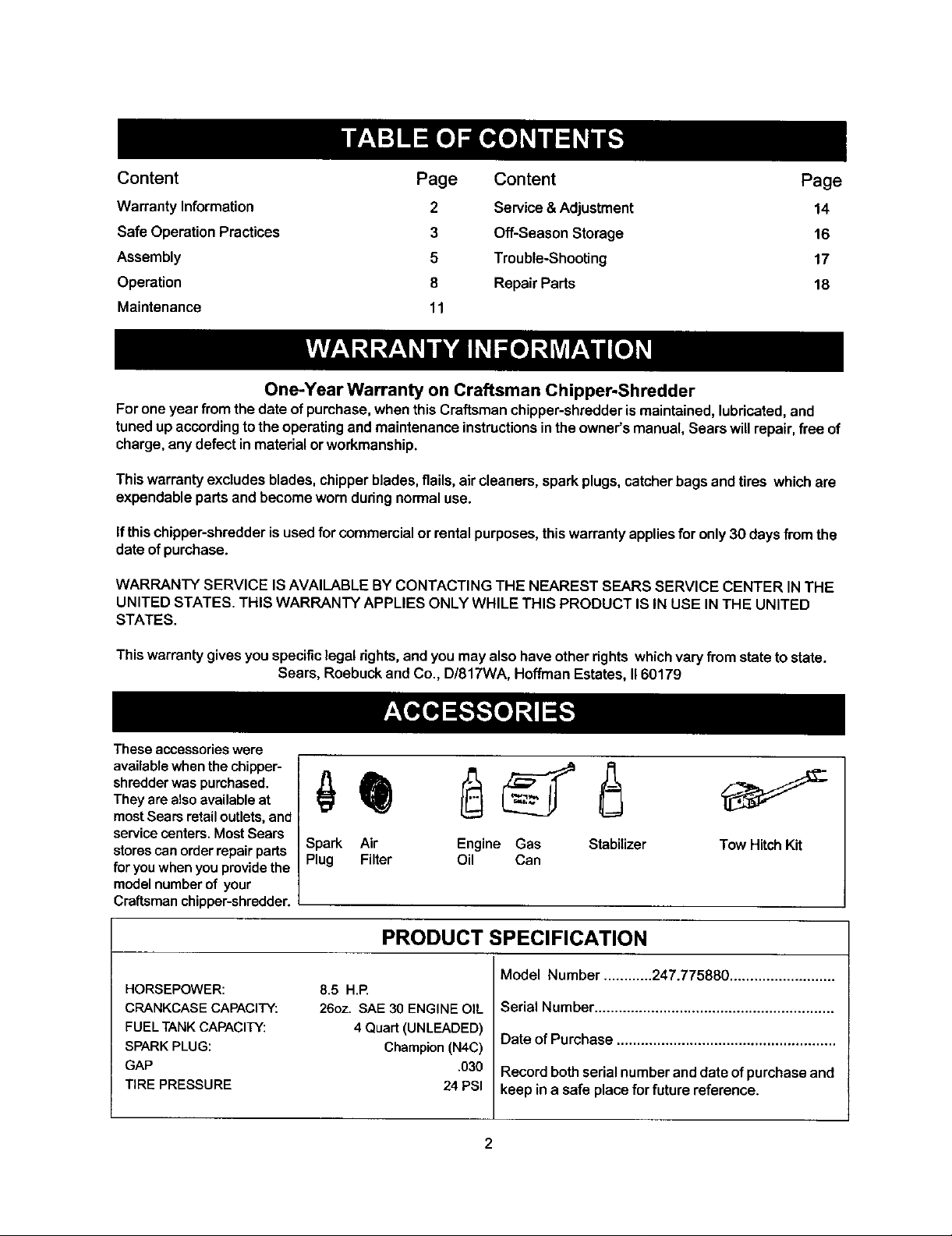

These accessories were

available when the chipper-

shredder was purchased.

They are also available at

most Sears retail outlets, and

service centers. Most Sears

stores can order repair parts

for you when you provide the

model number of your

Craftsman chipper-shredder.

Spark Air Engine Gas Stabilizer Tow HitchKit

Plug Filter Oil Can

PRODUCT SPECIFICATION

HORSEPOWER:

CRANKCASE CAPACITY:

FUEL TANK CAPACITY:

SPARK PLUG:

GAP

TIRE PRESSURE

8,5 H.R

26oz. SAE 30 ENGINE OIL

4 Quart (UNLEADED)

Champion (N4C)

24 PSI

Model Number ............247.775880 ..........................

Serial Number ...........................................................

Date of Purchase ......................................................

.030

Record both serial number anddate of purchase and

keep in asafe place for future reference.

2

This symbol points out important safety instructions which, if not followed, could endanger the per-

sonal safety and/or property of yourself and others. Read and follow all instructions in this manual before

attempting to operate yourchipper shredder. Failure to comply with these instructions may result in per-

sonal injury.When you see this symbol-heed its warning.

Your chipper-shredder was builtto be operated according to the rules for safe operation in /

RAN P_I=R- this manual. As withany type of power equipment, carelessness or error on the pert of the oper- /

.......... ator can result in serious injury. If you violate any of these rules, you may cause serious /

injury to yourself or others. /

]

J

,_ WARNING: The Engine Exhaustfrom this product containschemicalsknownto the State ofCalifornia

GENERAL OPERATION

tocause cancer, birthdefects orotherreproductiveharm.

Read thisowner's guidecarefully in itsentiretybefore

attemptingtoassemble thismachine. Read,

understand,and follow all instructionsonthe machine

and inthe manual(s) beforeoperation. Be completely

familiar withthe controlsand the proper useofthe

machinebefore operatingit. Keep thismanual ina

safe place for future andregular referenceand for

orderingreplacement parts.

Your chipper-shredderisa powerful tool, not a

plaything. Therefore, exerciseextreme cautionat all

times. Your unit hasbeen designedto performtwo

jobs;to chipand shred vegetationfound ina normal

yard. Do not use itfor anyother purpose.

Never allowchildrenunder age 16 tooperate the unit.

Children16 years and oldershouldonlyoperate the

unitunderclose parentalsupervision. Only

responsibleindividualswhoare familiar withthese

rulesofsafe operationshouldbe allowedtouse your

unit,

Keep the area ofoperation clearofall persons,

particularlysmallchildrenand pets. Stopthe engine

whenthey are inthe vicinityof the unit. Keep work

area clean and clearofbranches or obstacleswhich

could cause you tostumbleor fall.

When feeding material intothisequipment, be

extremely carefulthat piecesof metal, rocks,bottles,

cans or otherforeign objectsare notincluded.

Personal injuryordamage to the machine could result.

Alwayswear safetyglasses or safetygoggles, during

operationand while performingan adjustmentor

repair,toprotecteyesfrom foreign objects thatmay be

thrownfrom the machine.

Wear sturdy,reugh-soled work shoes and closefitting

slacksand shirt. Shirt and slacksthat coverthe arms

and legs and steel-tood shoesare recommended. Do

notwear loosefitting clothesorjewelryand secure hair

so it is above shoulder length. They can be caughtin

movingparts. Never operate a unitin barefeet,

sandalsor sneakers. Wear glovss whenfeeding

matedal in the chipperchute orshredder hopper.

Never placeyour hands,feet, orany partof your body

intothe shredder hopper,chipperchute, discharge

opening, or near any moving partwhilethe engine is

running. Keep clear of the dischargeopeningat all

times. Ifit becomes necassaryto push matedal into

the chipper chute orshredder hopper,usea small

diameter stick, NOT YOUR HANDS.

If it isnecessaryfor any reasonto unclogthefeed

intakeordischargeopeningsorto inspectorrepair any

partofthe machine where a movingpart can come in

contact withyour bodyorclothing,stopthe machine,

allowitto cool,disconnectthe spark plug wirefrom the

spark plugand move it away from the spark plug

before attemptingtounclog, inspector repair.

Donot operate unitwhileunderthe influence ofalcohol

or drugs.

The machine shouldonlybe operated ona level

surface. Never operate yourunitona slippery,wet,

muddyor icysurface. Keep yourworkarea clean and

clear ofbranches orobstacleswhich could causeyou

to stumbleand fall. Do notoverreach. Maintaining

properfooting and balanceis essentialtopreventing

accidents.

Do notallow an accumulationofprocessedmaterialto

buildupinthe dischargearea as thiswillprevent

properdischarge and can resultin kick-backfrom the

chipperchute.

Keepyour face and bodybackfrom chipperchute to

avoidaccidentalbounce back ofany material.

Do nottransportmachine whileengine isrunning.

Ifthe cuttingmechanismstdkesaforeign objector if

your machineshouldstart makingan unusual noiseor

vibration,immediately stopthe engineand allowthe

machine tocome to a complete stop. Disconnectthe

spark plugwire and move itaway from thespark plug.

Take thefollowing steps.

a. Inspectfor damage.

b. Repair or replace any damaged parts.

o. Check for any loosepartsand tighten to assure

continuedsafe operation.

Never attempttoattachor remove catcher bagwhen

engine isrunning. Shutthe engine off and waitfor the

impellertocometoacompletestop.Theimpeller

continuestorotatefor a few seconds after the engine

isshut off. Never place any partof the body inthe

impellerarea untilyouare sure the impeller has

stoppedrotating.

Mufflerand engine become hotand cancause a bum.

Do nottouch.

Do notallow leaves or otherdebristobuild-upon

engine's muffler. The debriscouldignite and causea

fire.

Do notattemptto shred orchip material larger than

specifiedinthis manual. Personal injuryordamage to

the machine could result.

Donot operate engine ifair cleaner or cover over

carburetor air-intakeis removed, exceptfor

adjustment. Removal of such parts could createa fire

hazard.

Only useaccessoriesapprovedfor thismachine by the

manufacturer. Read, understand,andfollow all

instructionsprovidedwiththe approvedaccessory.

Ifsituationsoccur whichare not covered by this

manual, use care and goodjudgment. Contact your

dealer for assistance.

Keepdischarge chute deflector,chipperchute door,

and all otherguards and safetydevices in place and

operatingpropady.

Only operate unit ingooddaylight. Do notoperate unit

at nightor indark areas where yourvisionmay be

impaired,

CHILDREN

Tragic accidentscan occurifthe operator is not alertto the

presence of small children. Childrenare often attracted to

the chippar-shredderand the chippingand shredding

activity. Neverassume that childrenwillremainwhere you

lastsaw them.

Keep childrenoutofthe work area and underthe

watchfuleye of a responsibleadultotherthan the

operator.

Be alert and turnthe unitoff ifa childentersthe area.

Never allowchildrenunderthe age of16 to operate the

chipper-shredder,

SERVICE

least twominutesbefore refueling.

b. Replacogasoline capsecurely and wipe offany

spilledgasolinebefore startingthe engine as it

may cause a fire orexplosion.

c. Extinguishall cigarettes,cigars, pipesand other

sourcesof ignition.

d. Never refuelunit indoorsbecauseflammable

vaporswillaccumulate inthe area.

e. Neverstorethe machineor fuel container inside

where there isan openflame or sparksuchas a

gas hotwater heater, space heater, clothesdryer

orfurnace.

Never runyour machineinan enclosed area asthe

exhaustfrom the enginecontains carbon monoxide,

whichis an odorless, tastelessand deadly poisonous

gas.

To reducefire hazard, keep engineand mufflerfree of

leaves,grass, and otherdebrisbuild-up. Clean up fuel

andoil spillage. Allowunittocool at least 5 minutes

beforestoring.

Before cleaning,repairing,orinspecting,make certain

the impellerand all movingpartshave stopped.

Disconnectthe spark plug wire and keepwire away

from spark plugto prevent accidentalstarting. Do not

useflammable solutionsto cleanairfilter.

Checkthe bladeand engine mountingscrewsat

frequent intervalsfor propertightness. Also visually

inspect bladesfor wearand/or damage (e.g., bent,

cracked). Replacewithblades which meet original

equipmentspecifications.

Keep allnuts,bolts,and screws fight tobe sure the

equipmentis in safe workingcondition.

Never tampar withsafety devices. Check their proper

operationregularly.

After strikinga foreign object,immediatelystop the

engine,disconnectthespark plug wire from the spark

plug,and thoroughlyinspectthe unitfor anydamage.

Repair damage beforestartingand operatingunit.

Do notalter ortamper withthe engine's governor

setting. The governor controlsthe maximum safe

operatingspeed ofthe engine. Over-speedingthe

engineis dangerousand will cause damage tothe

engineand toother movingpartsof the machine.

YOUR RESPONSIBILITY

Use extremecare in handlinggasolineand otherfuels.

They are extremely flammable andthe vapors are

explosive.

a. Storefuel and oil inapprovedcontainers, away

from heat andopen flame, and outof the reachof

children. Check and add fuel beforestartingthe

engine. Never remove gas cap or add fuel while

the engine is running. Allow engineto coolat

This unitis equipped with an internalcombustion egine and should not be used on or near any unimprovedforest-

covered, brush-coveredor grass-covered landunlessthe engine's exhaust system is equipped with a spark arrester

meeting applicablelocal orstate laws (ifany). Ifa spark arrester is used, it shouldbe maintained ineffective working

orderby the operator.

In the State ofCalifornia the above isrequired by law (Section4442 ofthe California Public Resources Code). Other

states may havesimilar laws. Federal laws apply onfederal lands.A sparkarresterfor the mufflerisavailable through

your nearest Sears AuthorizedService Center (See the REPAIR PARTS sectionof thismanual.)

Restrictthe use of thispower machine to

persons who read, understandand follow the

warningsand instructionsinthis manualand on

the machine.

SAVE THESE INSTRUCTIONS FOR

FUTURE REFERENCE

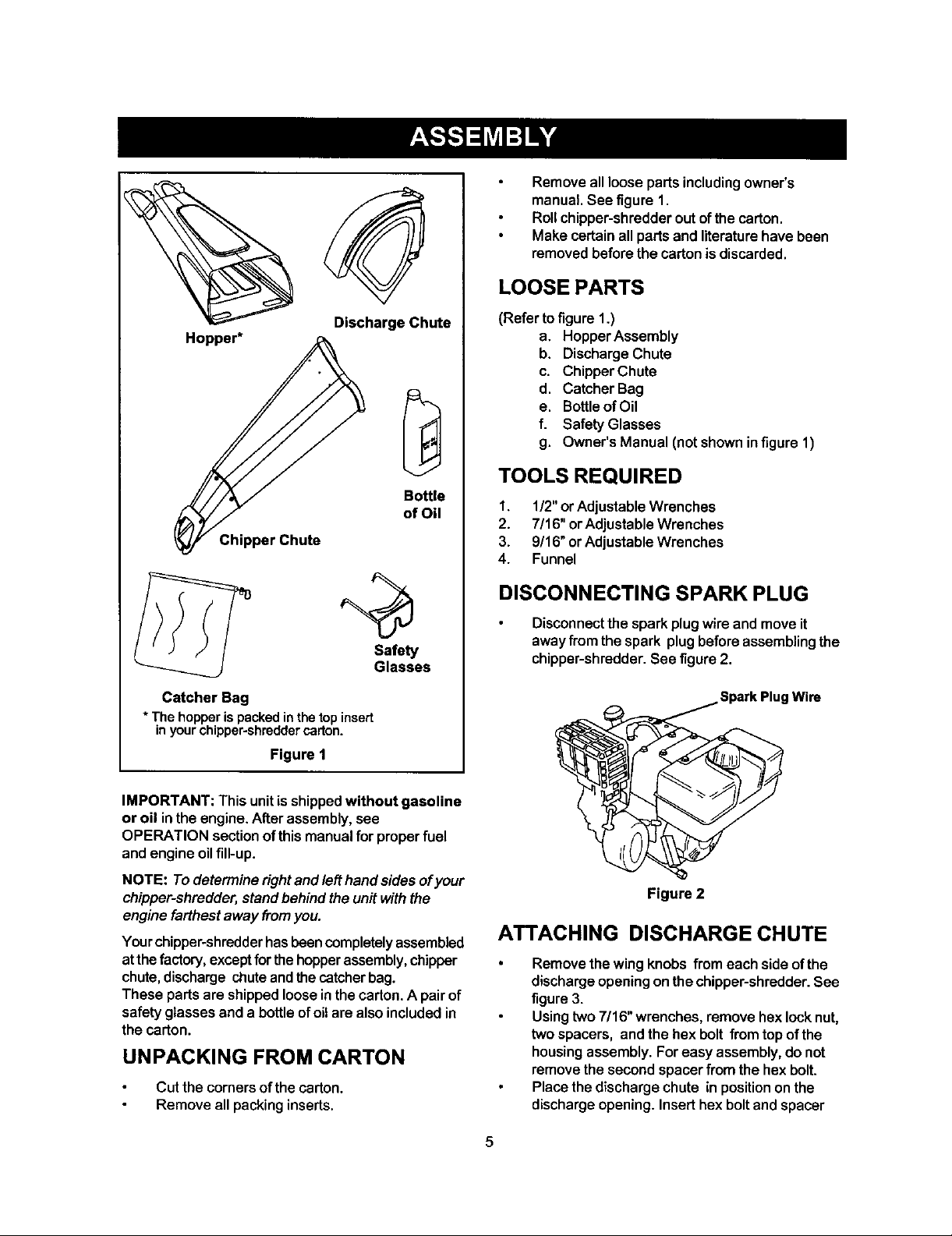

Remove all loose parts includingowner's

manual.See figure 1.

Rollchipper-shredderoutof the canon.

Make certainall partsand literaturehave been

removedbefore the cartonis discarded.

LOOSE PARTS

Discharge Chute

Hopper*

ChipperChute

Catcher Bag

* The hopperis packedin the top insert

inyour chipper-shreddercarton.

Figure 1

Bottle

of Oil

Safety

Glasses

(Refer to figure 1.)

a, Hopper Assembly

b. DischargeChute

c. Chipper Chute

d. Catcher Bag

e. Bottle of Oil

f. Safety Glasses

g. Owner's Manual (not shown infigure 1)

TOOLS REQUIRED

1. 1/2"or AdjustableWrenches

2. 7/16" orAdjustableWrenches

3. 9/16"or AdjustableWrenches

4. Funnel

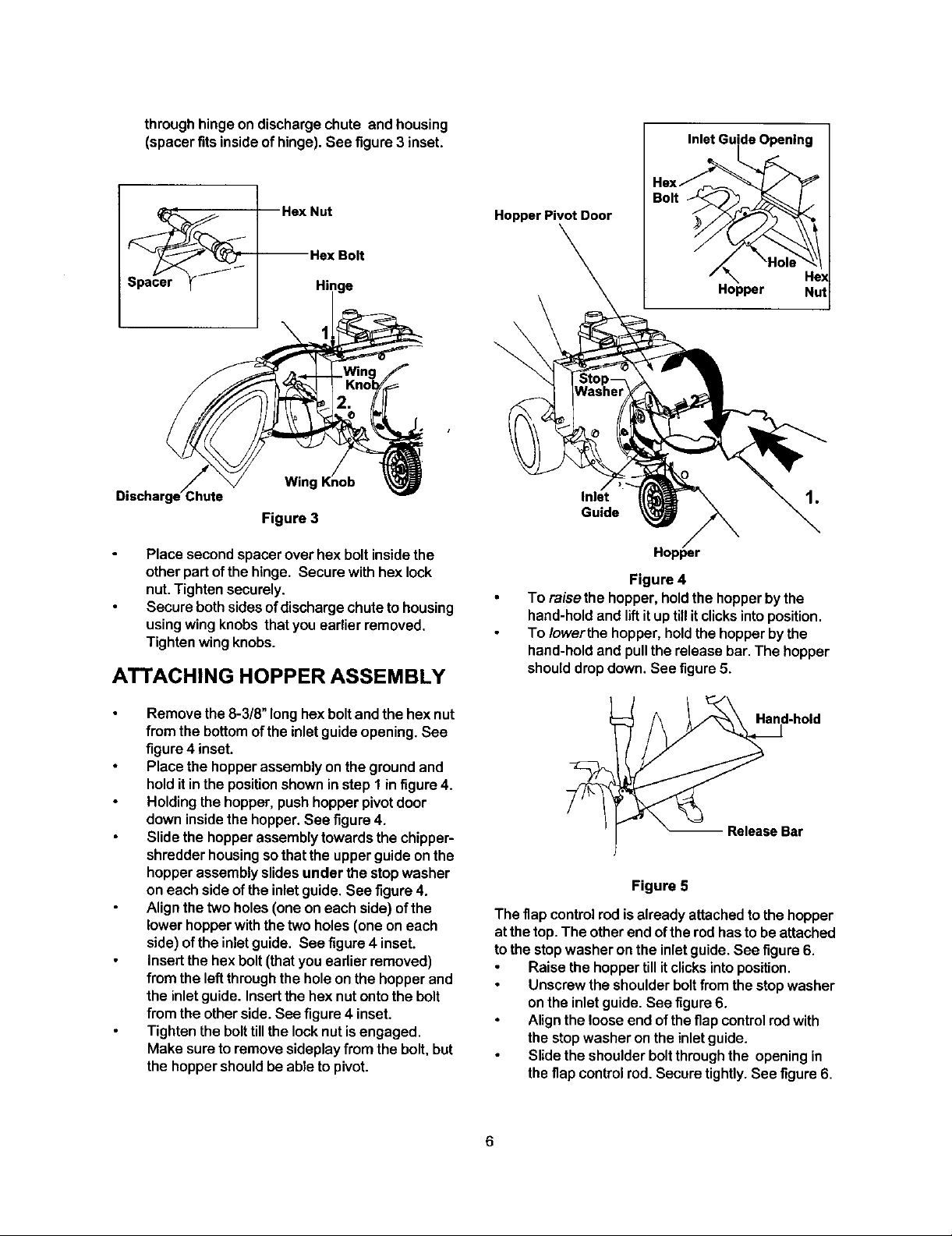

DISCONNECTING SPARK PLUG

Disconnect the sparkplug wireand move it

awayfrom the spark plugbefore assemblingthe

chipper-shredder. Seefigure 2.

SparkPlugWire

IMPORTANT: Thisunitisshippedwithout gasoline

or oil inthe engine,Al_erassembly,see

OPERATION sectionofthismanual forproper fuel

and engine oilfill-up.

NOTE: Todetermine rightand left hand sidesof your

chipper-shredder, standbehind the unit with the

engine farthest away from you.

Yourchipper-shredderhasbeencompletelyassembled

atthefactory, exceptforthehopperassembly,chipper

chute,discharge chuteandthecatcherbag.

These parts are shippedlooseinthe carton.A pairof

safetyglasses and a bottleofoil are also includedin

thecanon.

UNPACKING FROM CARTON

Cut the cornersof the canon.

Remove all packing inserts.

Figure 2

ATTACHING DISCHARGE CHUTE

Remove the wing knobs from each sideof the

discharge openingon the chipper-shredder.See

figure3.

Usingtwo7/16"wrenches, removehex locknut,

twospacers, and the bex bolt fromtop ofthe

housingassembly.Foreasy assembly,do not

remove the second spacerfromthe hex bolt.

Placethedischargechute in positionon the

dischargeopening. Inserthexboltand spacer

through hingeon dischargechute and housing

(spacer fits inside of hinge). See figure 3 inset.

Inlet Guide Opening

Hex Nut

--Hex Bolt

Spac_er_-J-_

Hinge

\

Dischargl

Wing

Figure 3

Place secondspacerover hex boltinsidethe

otherpart ofthe hinge. Secure with hex lock

nut.Tightensecurely.

Secure both sidesof dischargechute to housing

usingwingknobs that you earlier removed.

Tightenwingknobs.

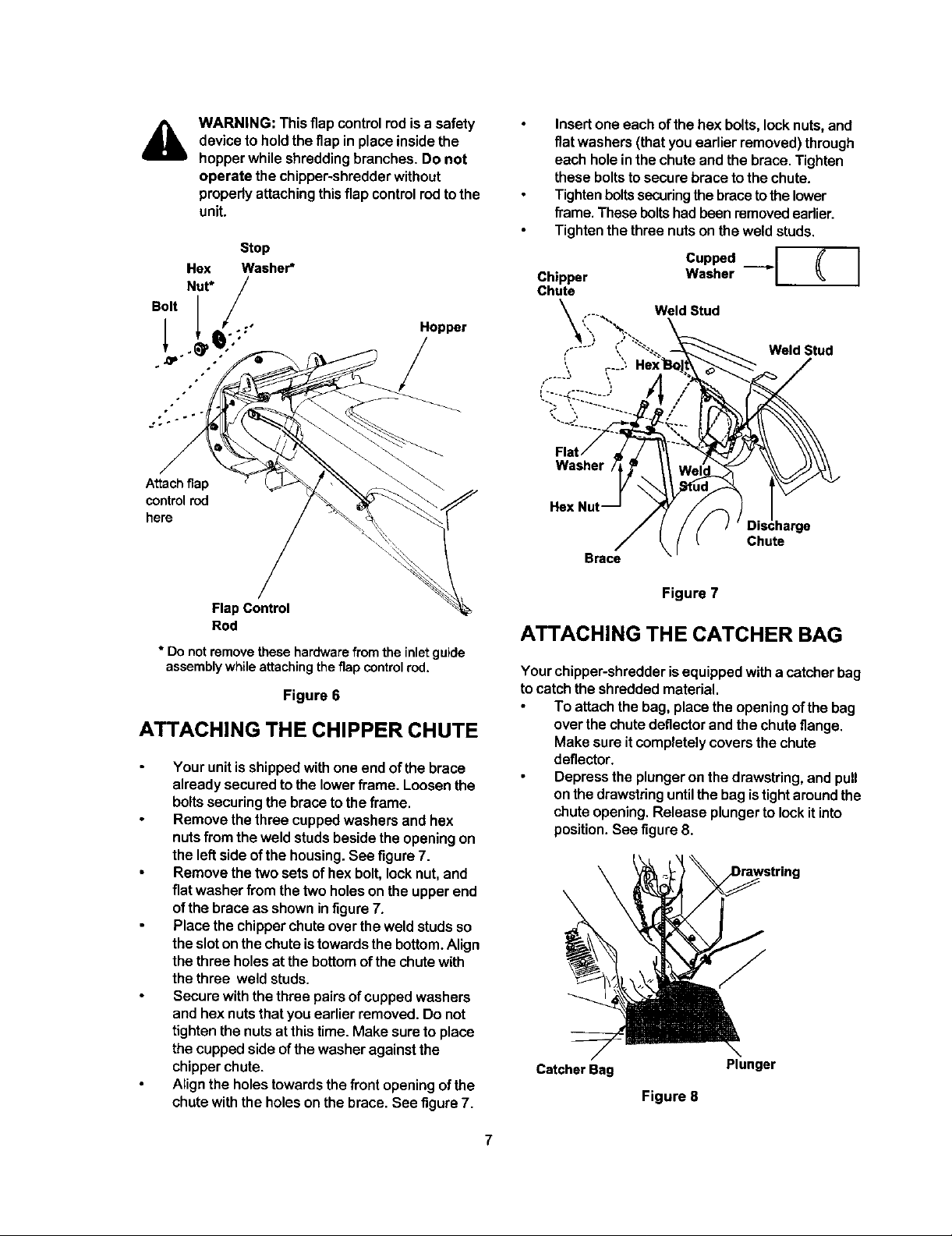

ATTACHING HOPPER ASSEMBLY

Hopper Pivot Door

He_

Hopper Nut

Inlet 1.

Guide

Hopper

Figure 4

To raisethe hopper,holdthe hopperby the

hand-holdand liftituptillitclicksintoposition.

To Iowerthe hopper,holdthe hopperbythe

hand-holdand pullthe releasebar.The hopper

shoulddropdown. See figure 5.

Remove the 8-3/8" longhex boltand the hexnut

fromthe bottomoftheinletguideopening. See

figure4 inset.

Placethe hopperassemblyon the groundand

holditinthe positionshowninstep 1infigure4.

Holdingthe hopper,pushhopperpivotdoor

down insidethe hopper.See figure 4.

Slidethe hopperassemblytowards the chipper-

shredderhousingsothatthe upperguideonthe

hopperassemblyslidesunder the stopwasher

on each side of the inletguide,See figure 4.

Alignthetwo holes(one on each side)of the

lower hopperwiththe two holes (one on each

side) ofthe inletguide. See figure4 inset.

insertthehex bolt(that youearlier removed)

from the leftthroughthe holeon the hopperand

the inletguide. Insertthe hexnutonto the bolt

from the otherside.See figure4 inset.

Tightenthe bolttillthe locknutisengaged.

Make sure to removesideplayfromthe bolt,but

the hoppershouldbe able to pivot.

Release Bar

Figure 5

The flap controlrodis already attachedtothe hopper

atthe top. The otherendoftherodhastobe attached

tothestopwasher onthe inletguide.See figure6.

Raise the hopper tillitclicksintoposition.

Unscrewthe shoulderboltfrom the stopwasher

on the inlet guide. See figure6.

Align the loose end of the flapcontrolrodwith

the stopwasheron theinletguide.

Slidethe shoulderboltthroughthe openingin

theflap controlrod.Secure tightly.See figure 6.

&

Hex Washer*

Nut* //

=ettI /

Attachflap

controlrod

here

WARNING; Thisflapcontrolrod isa safety

device to hold theflap in place insidethe

hopperwhileshreddingbranches.Do not

operate the chipper-shredderwithout

properlyattachingthisflapcontrolrodtothe

unit.

Stop

io_

Insertone each of the hex bolts,lock nuts,and

flat washers(thatyou earlierremoved)through

each holeinthe chuteand the brace.Tighten

these boltstosecure brace to the chute.

Tightenboltssecuringthe bracetothelower

frame.Theseboltshadbeen removedeadier.

Tightenthethree nutsonthe weldstuds.

Washer

Chipper

Chute

\

\

Washer

Bmce

Cupped

Weld Stud

Weld Stud

Chu_

Flap Control

Rod

* Do not removethese hardware from the inlet guide

assemblywhile attaching the flap controlrod.

Figure 6

ATTACHING THE CHIPPER CHUTE

Your unitis shippedwith oneend ofthe brace

already securedto the lower frame.Loosenthe

boltssecuringthe braceto the frame.

Remove the three cuppedwashersand hex

nutsfrom the weld studsbesidetheopeningon

the leftsideof the housing.See figure7.

Remove the two sets ofhexbolt,locknut, and

fiatwasher fromthetwo holes onthe upperend

ofthe brace as shown infigure7.

Placethe chipperchuteoverthe weldstudsso

the slotonthe chute istowardsthebottom.Align

the three holesat the bottomofthe chutewith

the three weldstuds.

Securewith thethree pairsofcuppedwashers

and hex nutsthat you earlier removed.Do not

tightenthenutsat thistime. Make sureto place

the cuppedsideof the washer againstthe

chipperchute.

Align the holestowardsthefront openingofthe

chutewiththe holes onthe brace.See figure7.

Figure 7

ATTACHING THE CATCHER BAG

Your chipper-shredderisequippedwitha catcherbag

tocatchthe shreddedmaterial.

To attach the bag, placethe openingof the bag

overthechute deflectorand the chute flange.

Make sure itcompletelycoversthe chute

deflector.

Depress the plunger on the drawstring, and pull

on the drawstring until the bag istight around the

chute opening. Release plunger to lock it into

position. See figure 8.

Catcher Bag

Figure8

Plunger

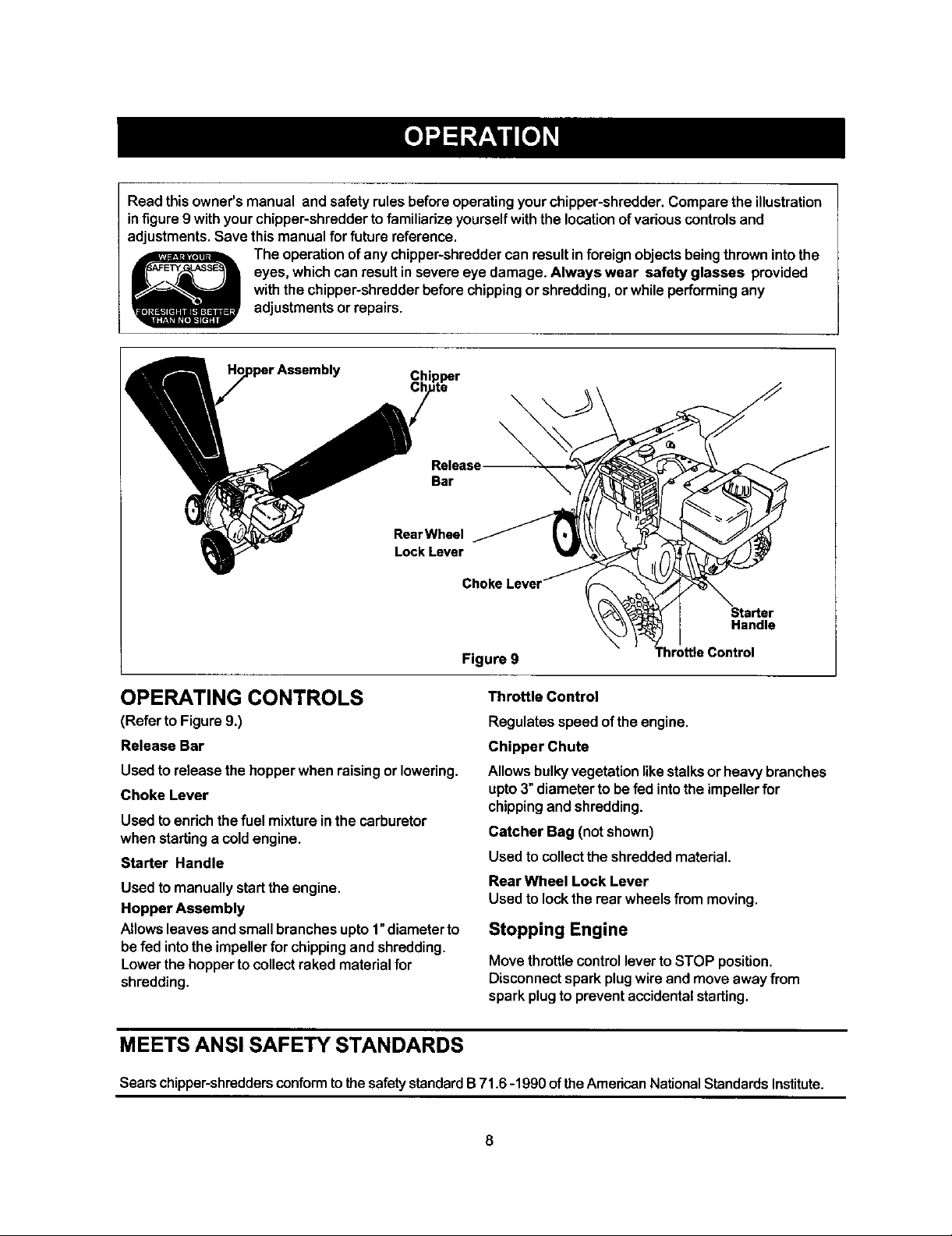

Read thisowner'smanual and safety rules before operatingyour chipper-shredder.Compare the illustration

infigure9 withyour chipper-shredderto familiarize yourselfwiththe locationofvariouscontrolsand

adjustments.Save this manual for future reference.

eyes,whichcan resultinsevere eye damage. Always wear safety glasses provided

_ he operation of any chipper-shredder can result in foraign objects being thrown intothe

withthe chipper-shredderbefore chippingor shredding,orwhileperformingany

adjustmentsor repairs.

Release

Bar

Rear Wheel

Lock Lever

Figure 9

OPERATING CONTROLS

(Refer to Figure 9,)

Release Bar

Used to release thehopperwhen raisingor lowering.

Choke Lever

Used to enrichthefuel mixtureinthe carburetor

when startinga coldengine.

Starter Handle

Used to manuallystarttheengine.

Hopper Assembly

Allowsleavesand smallbranchesupto1"diameterto

be fedintothe impellerforchippingand shredding,

Lowerthe hopper to collectraked materialfor

shredding.

Throttle Control

Regulatesspeed ofthe engine.

Chipper Chute

Allows bulkyvegetationlikestalksor heavy branches

upto 3" diameter to be fed intotheimpellerfor

chippingandshredding.

Catcher Bag(not shown)

Used to collectthe shredded material.

Rear Wheel Lock Lever

Used to lockthe rearwheels frommoving.

Stopping Engine

Move throttlecontrolleverto STOP position.

Disconnectspark plugwireand move awayfrom

spark plugto preventaccidentalstarting.

MEETS ANSI SAFETY STANDARDS

Sears chipper-shredders conform tothe safetystandardB71.6-1990 ofthe American National Standards Institute.

8

Loading...

Loading...