MTD 24A464N299 Owner’s Manual

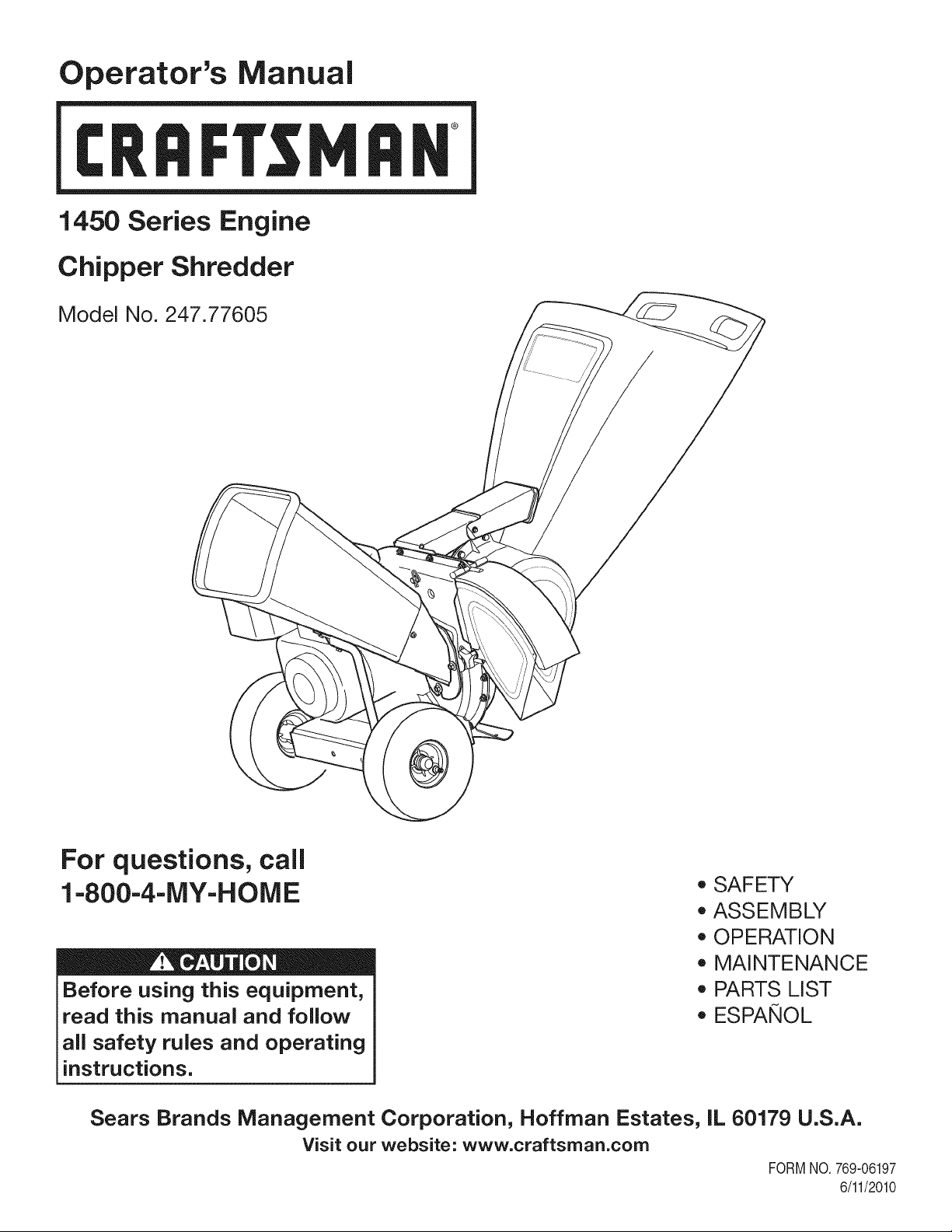

Operator's Manual

I:Rl FI'SlVl N

1450 Series Engine

Chipper Shredder

Model No. 247.77605

For questions, call

1-800-4-MY-HOME

Before using this equipment,

read this manual and follow

all safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, iL 60179 U.S.A.

Visit our website: www.craftsman.com

* SAFETY

* ASSEMBLY

* OPERATION

* MAINTENANCE

* PARTS LIST

* ESPANOL

FORMNO.769-06197

6/11/2010

WarrantyStatement..................................Pac

SafeOperationPractices..........................Pac

SafetyLabels............................................Pac

Assembly..................................................Pac

Operation..................................................Pac

ServiceandMaintenance.........................Pac

Off-SeasonStorage..................................Pac

Whenoperatedand maintainedaccordingtoallsuppliedinstructions,ifthischippershredderfailsdueto a defectin materialorworkmanship

withintwoyearsfromthedate ofpurchase,returnitto anySearsstore,SearsParts& RepairServiceCenter,or otherCraftsmanoutletinthe

UnitedStatesforfreerepair(or replacementif repairprovesimpossible).

Thiswarrantyappliesfor only90 daysfromthedateof purchaseifthischippershredderiseverusedforcommercialorrentalpurposes.

ThiswarrantycoversONLYdefectsinmaterialandworkmanship.SearswillNOTpayfor:

• Expendableitemsthatbecomewornduringnormaluse,includingbutnotlimitedto blades, sparkplug,aircleaner,flailscreenandcatcher

bag.

• Standardmaintenanceservicing,oilchanges,or tune-ups.

• Tirereplacementorrepaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireorwheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationor maintenance.

• Repairsnecessarybecauseofoperatorabuse,includingbutnotlimitedtodamagecausedbyimpactingobjectsthat bendtheframeor

crankshaft,orover-speedingtheengine.

• Repairsnecessarybecauseofoperatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethepropergradeand amountofengineoil,or failureto maintainthe equipmentaccordingtothe instructions

containedin theoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfuel determinedto becontaminatedor oxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

• Normaldeteriorationandwearofthe exteriorfinishes,or productlabelreplacement.

e2

es3-6

e7

es8-11

es12-13

es14-17

TroubleShooting.......................................Page19

PartsList...................................................Page20-32

LabelMap.................................................Page33

RepairProtectionAgreement...................Page36

Espa_ol.....................................................Page37

ServiceNumbers......................................BackCover

e18

CRAFTSMAN FULLWARRANTY

Thiswarrantyappliesonlywhilethisproductiswithinthe UnitedStates.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstateto state.

Sears BrandsManagementCorporation, HoffmanEstates,IL60179

EngineSeries: 1450

EngineOilType: SAE30

EngineOilCapacity: 28ounces

Fuel: UnleadedGasoline

SparkPlug: Champion®RC-12YC

SparkPlugGap: .030"

©SearsBrands,LLC 2

Model Number.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthe personalsafetyand/orpropertyof

yourselfandothers. Readandfollowallinstructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothesafeopera-

tionpracticesinthismanual.Aswithanytypeof powerequipment,

carelessnessorerroronthepart of theoperatorcan resultin

seriousinjury.Thismachineis capableofamputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethefollowing

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknownto Stateof California

tocausecancerandbirthdefectsorotherreproductiveharm.

TRAINING

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualinasafeplacefor futureand regularreference

andfororderingreplacementparts.

• Readthe Operator'sManualandfollowallwarningsand safety

instructions.Failuretodosocanresultin seriousinjurytothe

operatorand/orbystanders.Forquestions,call 1-800-659-5917.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder16yearsofageto operatethis

machine.Children16andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultsto operatethismachinewithoutproper

instruction.

• Keepbystanders,pets,andchildrenatleast75feetfromthe

machinewhileitisin operation.Stopmachineifanyoneenters

thearea.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Donot puthandsandfeetnearrotatingpartsor inthe feeding

chambersanddischargeopening.Contactwiththe rotating

impellercanamputatefingers,hands,andfeet.

• Neverattempttounclogeitherthe feedintakeordischarge

opening,removeor emptybag,or inspectand repairthemachine

whilethe engineisrunning.Shuttheengineoff andwaituntilall

movingpartshavecometo a completestop.Disconnectthespark

plugwireandgroundit againsttheengine.

Your Responsibility--Restricttheuse ofthispowermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandonthemachine.

SAVETHESEINSTRUCTIONS!

PREPARATION

• Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall rocks,bottles,cans,or otherforeignobjectswhich

couldbepickedupor thrownandcausepersonalinjuryor

damageto themachine.

• Alwayswearsafetyglassesorsafetygogglesduringoperation

andwhileperformingan adjustmentorrepair,to protectyour

eyes.Thrownobjectswhichricochetcancauseseriousinjuryto

theeyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesorjewelrycan becaughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.Wear

leatherworkgloveswhenfeedingmaterialinthe chipperchute.

• Beforestarting,checkallboltsandscrewsforpropertightnessto

besurethe machineisinsafeworkingcondition.Also,visually

inspectmachineforany damageatfrequentintervals.

• Maintainor replacesafetyandinstructionslabels,asnecessary.

3

SafeHandling of Gasoline:

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Neverfillcontainersinsidea vehicleor onatruckor trailerbed

witha plasticliner.Alwaysplacecontainersonthegroundaway

fromyourvehiclebeforefilling.

• Whenpractical,removegas-poweredequipmentfromthe truck

ortrailerand refuelitontheground.Ifthisis notpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

• Keepthenozzleincontactwiththe rimofthefueltankor

containeropeningatalltimesuntilfuelingiscomplete.Donotuse

a nozzlelock-opendevice.

• Extinguishallcigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuelmachineindoors.

• Neverremovegascaporaddfuelwhilethe engineishotor run-

ning.Allowenginetocool atleasttwo minutesbeforerefueling.

• Neveroverfill fueltank.Filltankto nomorethan1/2inchbelow

bottomoffillerneckto allowspaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitoff theengineandequipment.Move

unitto anotherarea.Wait5 minutesbeforestartingtheengine.

• Toreducefirehazards,keepmachinefreeofgrass, leaves,or

otherdebrisbuild-up.Cleanupoil orfuelspillageandremoveany

fuelsoakeddebris.

• Neverstorethemachineorfuel containerinsidewherethereis an

openflame,sparkor pilotlightason awaterheater,spaceheater,

furnace,clothesdryer orothergasappliances.

OPERATION

• Donot puthandsandfeetnearrotatingpartsor in thefeeding

chambersanddischargeopening.Contactwiththe rotating

impellercanamputatefingers,hands,andfeet.

• Beforestartingthemachine,makesurethe chipperchute,feed

intake,andcuttingchamberare emptyandfreeofall debris.

• Thoroughlyinspectall materialtobe shreddedandremoveany

metal,rocks,bottles,cans,or otherforeignobjectswhichcould

causepersonalinjuryor damagetothemachine.

• If itbecomesnecessaryto pushmaterialthroughtheshredder

hopper,usea smalldiameterstick.Donot useyourhandsorfeet.

• Iftheimpellerstrikesaforeignobjector ifyourmachineshould

startmakinganunusualnoiseorvibration,immediatelyshut

theengineoff. Allowtheimpellertocometoa completestop.

Disconnectthesparkplugwire,grounditagainsttheengineand

performthefollowingsteps:

a. Inspectfor damage.

b. Repairor replaceanydamagedparts.

c. Checkforanyloosepartsandtightento assurecontinued

safeoperation.

• Donotallowanaccumulationof processedmaterialto buildupin

thedischargearea.Thiscanpreventproperdischargeandresult

inkickbackof materialthroughthefeedopening.

• Donotattempttoshredorchip materiallargerthanspecified

on themachineor inthis manual.Personalinjuryormachine

damagecouldresult.

• Neverattempttounclogeitherthe feedintakeordischarge

openingwhilethe engineisrunning.Shuttheengineoff,waituntil

all movingpartshavestopped,disconnectthesparkplugwireand

grounditagainsttheenginebeforeclearingdebris.

• Neveroperatewithouttheshredderhopper,chipperchute,or

chutedeflectorproperlyattachedtothe machine.Neveremptyor

changedischargebagwhiletheengineis running.

• Keepallguards,deflectorsand safetydevicesinplaceand

operatingproperly.

• Keepyourfaceandbodybackandtothe sideofthe chipper

chutewhilefeedingmaterialintothemachineto avoidaccidental

kickbackinjuries.

• Neveroperatethismachinewithoutgoodvisibilityorlight.

• Donotoperatethismachineona paved,gravelornon-level

surface.

• Donotoperatethismachinewhileundertheinfluenceof alcohol

or drugs.

• Mufflerandenginebecomehotandcancausea burn.Donot

touch.

• Neverpick uporcarrymachinewhiletheengineis running.

• Ifsituationsoccurwhichare notcoveredinthismanual,usecare

andgoodjudgement.ContactCustomerSupportforassistance

andthenameofthe nearestservicedealer.

MAINTENANCE & STORAGE

• Nevertamperwith safetydevices.Checktheirproperoperation

regularly.

• Checkboltsandscrewsfor propertightnessatfrequentintervals

to keepthemachineinsafeworkingcondition.Also,visually

inspectmachinefor anydamageandrepair,ifneeded.

• Beforecleaning,repairing,or inspecting,stoptheengineand

makecertaintheimpellerandall movingpartshavestopped.

Disconnectthesparkplugwireandgrounditagainsttheengine

to preventunintendedstarting.

• Donotchangetheenginegovernorsettingsoroverspeedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

4

• Maintainorreplacesafetyandinstructionlabels,asnecessary.

Followthismanualforsafeloading,unloading,transporting,and

storageof thismachine.

Neverstorethemachineorfuel containerinsidewherethereis an

openflame,sparkorpilot lightsuchasa waterheater,furnace,

clothesdryer,etc.

Allowmachinetocoolat least5 minutesbeforestoring.

• Alwaysrefertothe operator'smanualforproperinstructionson

off-seasonstorage.

• If thefueltankhasto bedrained,do thisoutdoors.

• Observeproperdisposallawsand regulationsfor gas,oil,etc.to

protecttheenvironment.

• AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan Average UsefulLifeofseven(7)years,or 60hoursof

operation.At the endoftheAverageUsefulLife havethemachine

inspectedannuallybyan authorizedservicedealerto ensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failuretodo socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyengineinanyway.

Tamperingwiththegovernorsettingcanleadto a runawayengineand

causeitto operateatunsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(CO),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonornearanyunimprovedforest-covered,

brushcoveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any)

Ifa sparkarrestorisused,itshouldbe maintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorforthemufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

• ®

il

BYSTANDERS

Keep bystanders, pets, and children at least 75 feet from the machine while it is in operation. Stop

machine if anyone enters the area.

WARNING-- THROWN DEBRIS

Never operate without the chute deflector properly attached to the machine.

EYEPROTECTION

Always wear safety glasses or safety goggles when operating this machine.

warningsandinstructionsinthis manualandonthemachine.

I_l_ ARNING: YourResponsibility--Restrictthe useofthispowermachinetopersonswho read,understandandfollowthe

SAVETHESEINSTRUCTIONS!

6

J

r

100/.LIIO-NV:IIO

"lVflNV_ S,UOIVU3dOQV3H"G

"S3OV_IJflS]3AVUONO9NIIV_J3dO

N3HMNOIIflVOVSIX]qsfl"S9]ONVIS181V]98VHOSIO

10381083A3N'S]IUflrNI SI03PgoNMOUHIQIOAV01 "_

"3NIHOV_ONIOIA83SUOONIOOO]ONfl

]UO_38O3ddOIS]AVHSlHPd9NIAOW11VlllNfl S]IQNVH

ONIH]8NIVW3UONV']NION]dOlS'88]A]1HOlnlo]9VON]SIO"8

"]lnHg ]gHVHOSIO9010Nfl01 1001 lflO-NP]lO ]Sfl "Z

"l]]d ONVSONVH]lPlnd_P NVOH3onvuoHq]l]d_JIHIIM

IOVINO0"u39npONV_J3113dWI9NllVIOU_JOH_IVMVd]3H "L

7

IMPORTANT:Thisunitisshippedwithoutgasolineoroil inthe engine.

Becertaintoserviceenginewithgasolineandoilas instructedinthe

Operationsectionof this manualbeforeoperatingyourmachine.

NOTE:Referenceto rightandlefthandsideof the ChipperShredder

isobservedfromthe operatingposition.

OPENING CARTON

1. Cuteachcornerofthecartonverticallyfromtopto bottom.

2. Removeall looseparts.

3. Removeloosepackingmaterial.

REMOVING UNiT FROM CARTON

1. Liftunitfromthereartodetachit fromunderlyingcartonmaterial

androllunitout ofcarton.

2. Checkcartonthoroughlyforanyotherlooseparts.

LOOSE PARTS IN CARTON

• HopperAssembly

• Bag

• ChuteDeflector

• ChipperChute

• Tamper

• SafetyGlasses

• EngineOil

• Owner'sManual

f

J

Figure1

f

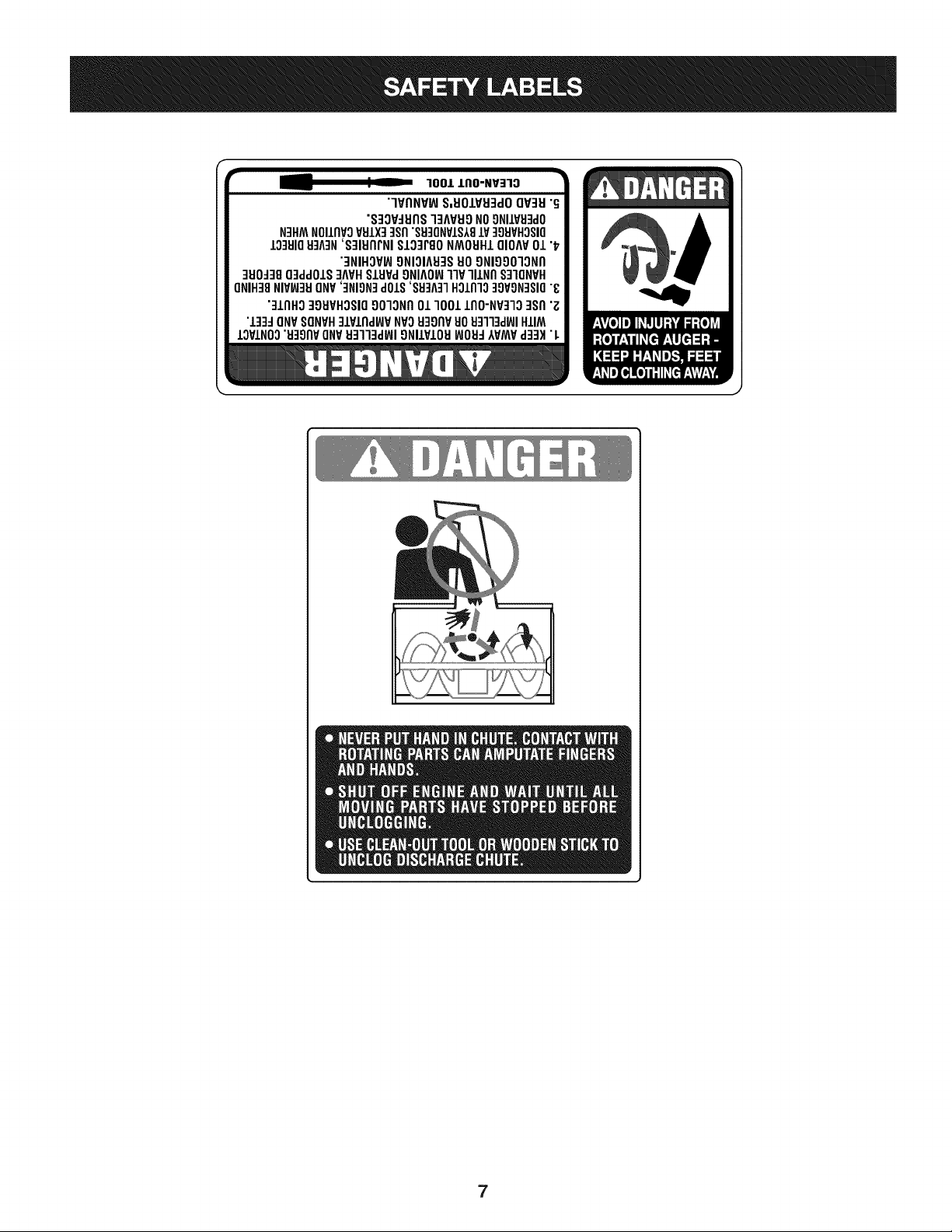

ATTACHING THE HOPPER ASSEMBLY

1. A. Removesixhex nutsandwashersfromtheweldstudson the

impellerhousing.Donotremovesupportplate.SeeFigure1.

B. Placehopperassemblyintopositioninfrontof impeller

housing,aligningholesinhopperassemblycollarwithweld

studs.

C. Slidehopperassemblyontoweldstudsand replacewashers

andhexnuts.Donottightencompletely.

2. A. Lifthopperassemblyupto impellerbracketassembly.See

Figure2.

B.Slidethe releaserodoutslightlytohookthehopperbracket

ontothe rod.SeeFigure2.

C.Tightenthesixhex nutsthatsecurehopperassemblyto

impellerhousingandalsotightenthe hexnutsthat secure

hopperbracketto hopperassembly.

Figure2

8

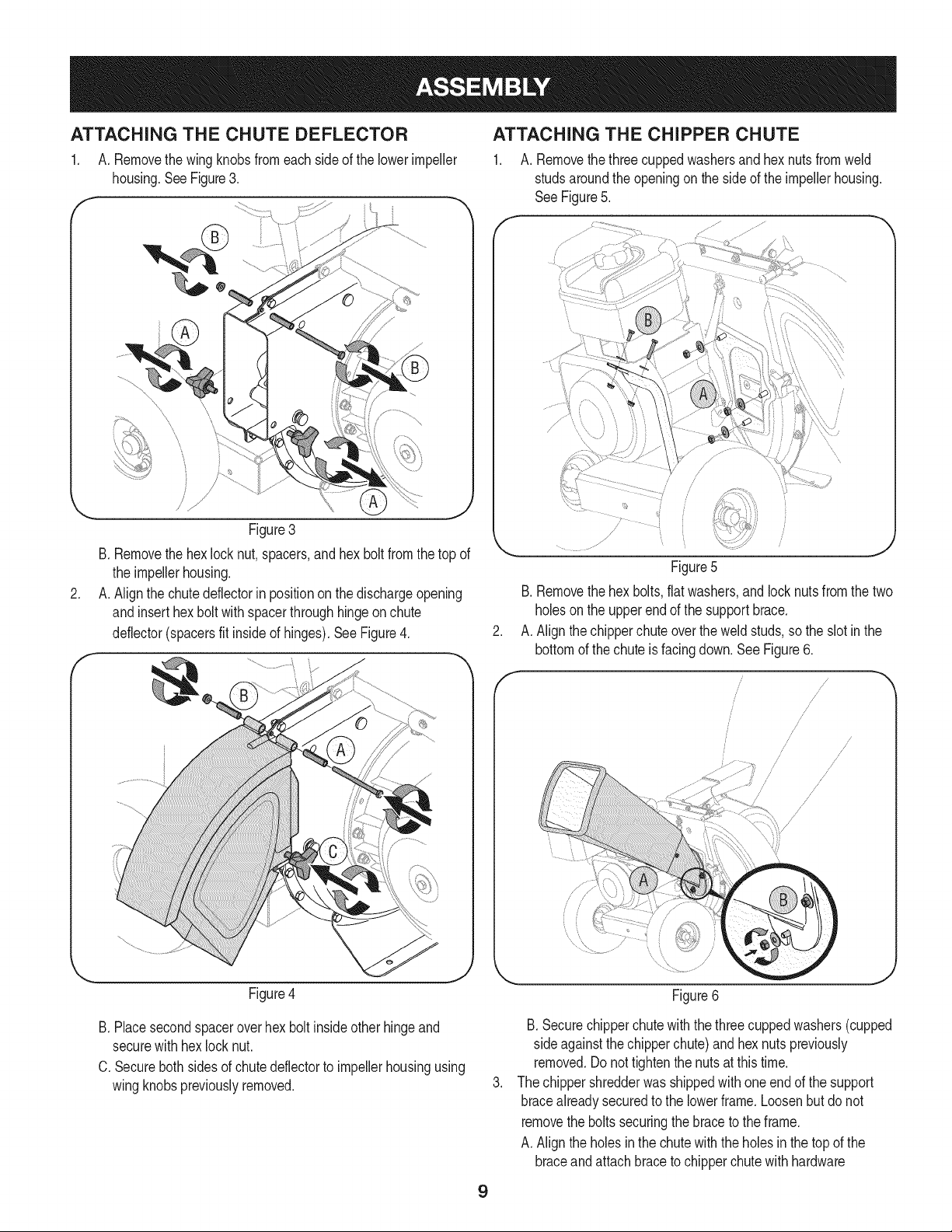

ATTACHING THE CHUTE DEFLECTOR

1. A. Removethewingknobsfromeachsideofthe lowerimpeller

housing.SeeFigure3.

Figure3

B.Removethehexlocknut,spacers,andhexboltfromthetopof

theimpellerhousing.

.

A.Alignthe chutedeflectorinpositiononthedischargeopening

andinserthexbolt withspacerthroughhingeonchute

deflector(spacersfit insideofhinges).SeeFigure4.

f

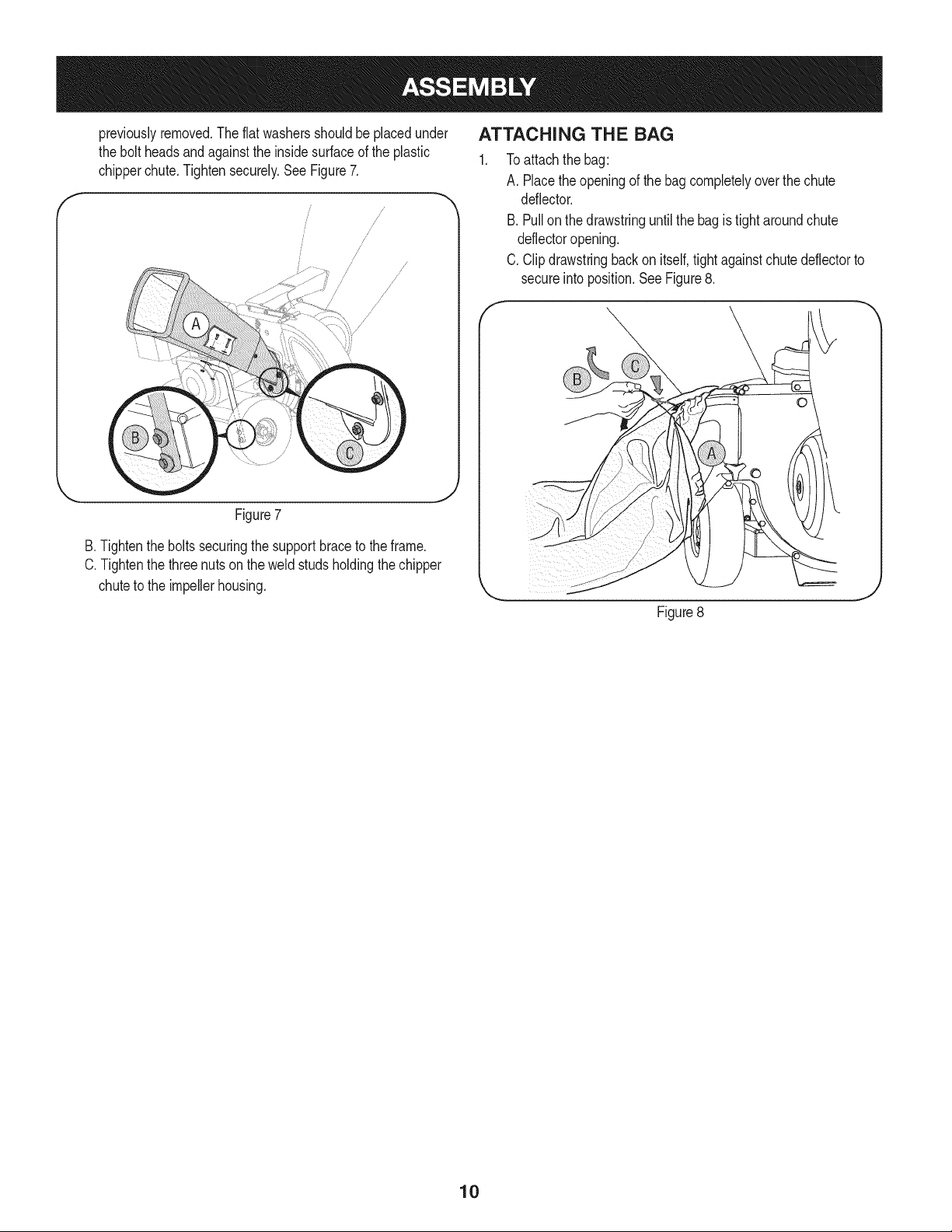

ATTACHING THE CHIPPER CHUTE

1. A. Removethe threecuppedwashersand hexnutsfromweld

studsaroundtheopeningontheside oftheimpellerhousing.

SeeFigure5.

Figure5

B.Removethehexbolts,flatwashersandlocknutsfromthetwo

holesonthe upperendofthe supportbrace.

A.Alignthechipperchuteovertheweldstuds,sothe slotinthe

bottomofthechuteis facingdown.SeeFigure6.

f

i

i

/

i

/

/

/ i"

/ ,/

/ /s

/

/

/

/

/

/

/

/

/

/ /

i

/

/

/

J

Figure4

B.Placesecondspaceroverhex boltinsideotherhingeand

securewithhexlocknut.

C. Securebothsidesofchutedeflectorto impellerhousingusing

wingknobspreviouslyremoved.

/

/ ,

/ /

Figure6

B.Securechipperchutewiththethreecuppedwashers(cupped

sideagainstthe chipperchute)andhexnutspreviously

removed.Donottightenthe nutsatthistime.

Thechippershredderwasshippedwithoneendof thesupport

bracealreadysecuredto the lowerframe.Loosenbutdonot

removetheboltssecuringthebracetotheframe.

A.Aligntheholesinthe chutewiththeholesin thetopofthe

braceandattachbraceto chipperchutewithhardware

9

J

previouslyremoved.Theflatwashersshouldbe placedunder

thebolt headsandagainsttheinsidesurfaceoftheplastic

chipperchute.Tightensecurely.SeeFigure7.

Figure7

B.Tightenthe boltssecuringthesupportbraceto theframe.

C.Tightenthethreenutsontheweld studsholdingthechipper

chuteto theimpellerhousing.

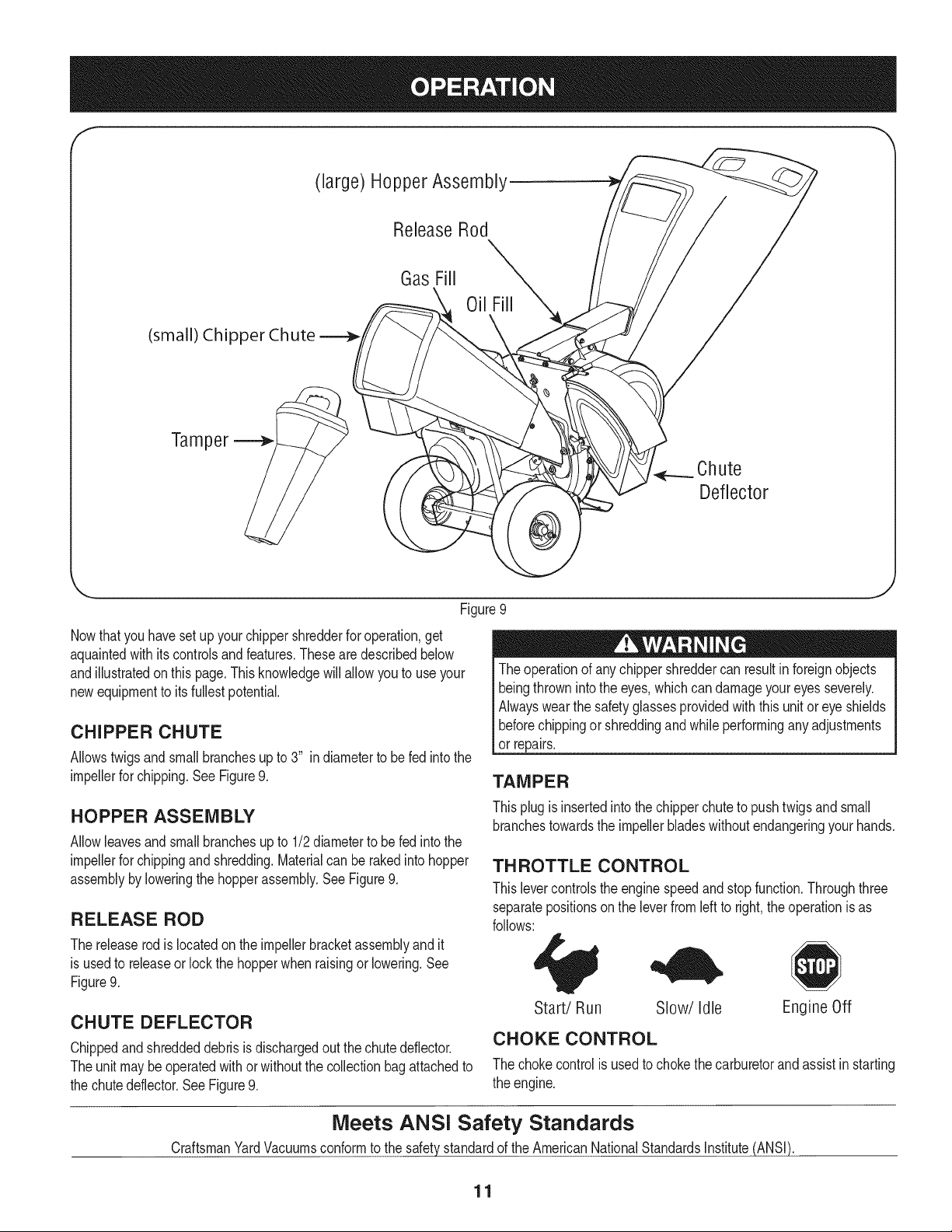

ATTACHING THE BAG

Toattachthebag:

A. Placetheopeningofthebagcompletelyoverthechute

deflector.

B.Pullon thedrawstringuntilthebagistightaroundchute

deflectoropening.

C.Clipdrawstringbackon itself,tightagainstchutedeflectorto

secureintoposition.SeeFigure8.

f

Figure8

10

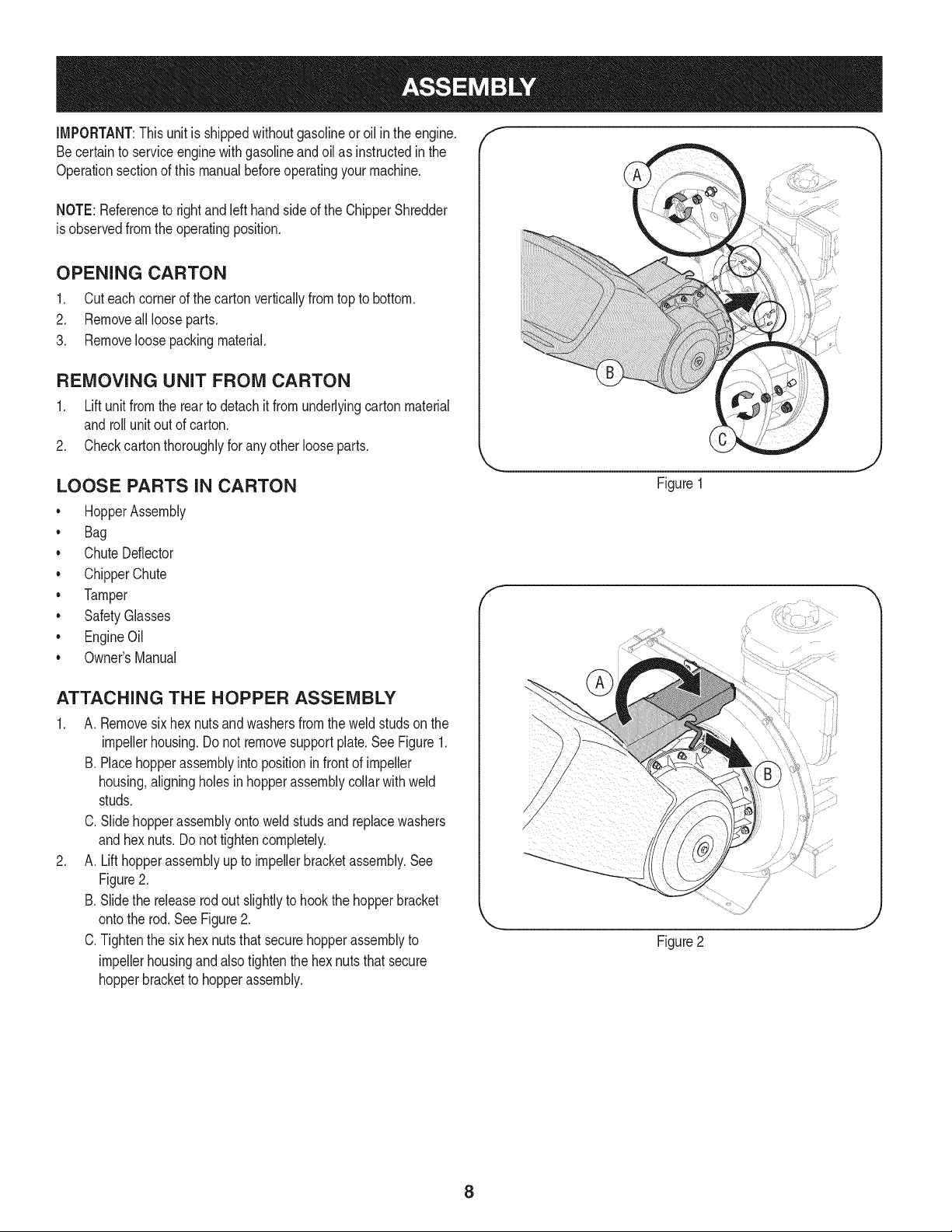

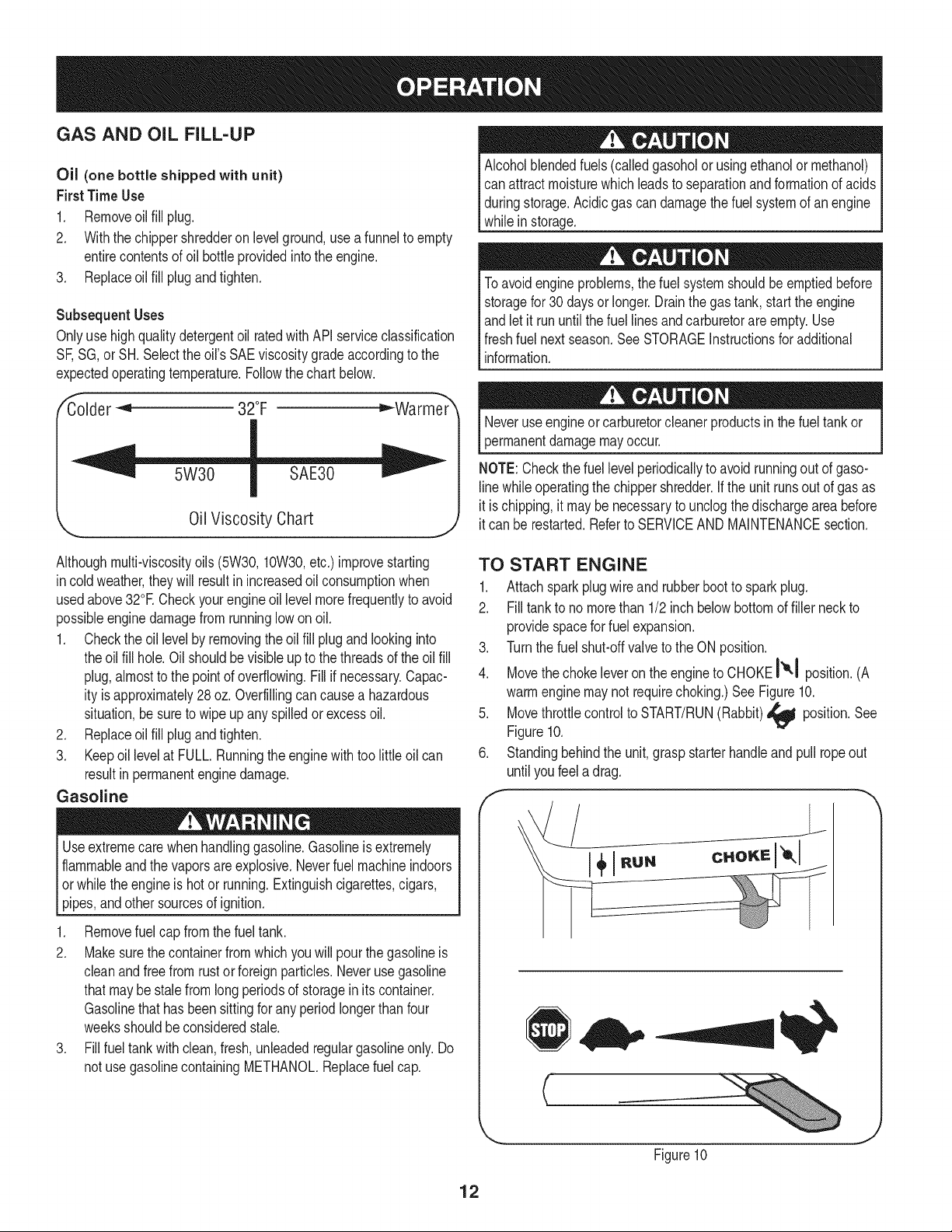

(large) HopperAssembly

ReleaseRod

GasFill

(small) Chipper Chute

Tamper===--_

Figure9

Nowthatyouhavesetupyourchippershredderforoperation,get

aquaintedwith itscontrolsandfeatures.Theseare describedbelow

andillustratedon thispage.Thisknowledgewillallowyou to useyour

newequipmenttoits fullestpotential.

CHIPPER CHUTE

Allowstwigsandsmallbranchesupto 3" indiameterto befedintothe

impellerforchipping.SeeFigure9.

HOPPER ASSEMBLY

Allowleavesandsmallbranchesupto 1/2diameterto befed intothe

impellerforchippingandshredding.Materialcanberakedintohopper

assemblybyloweringthehopperassembly.SeeFigure9.

RELEASE ROD

Thereleaserodislocatedon theimpellerbracketassemblyandit

isusedto releaseorlockthehopperwhen raisingorlowering.See

Figure9.

CHUTE DEFLECTOR

Chippedandshreddeddebrisis dischargedoutthechutedeflector.

Theunit maybeoperatedwithorwithoutthecollectionbagattachedto

thechutedeflector.SeeFigure9.

Chute

Deflector

@

Theoperationof anychippershreddercan resultinforeignobjects

beingthrownintothe eyes,whichcandamageyoureyesseverely.

Alwayswearthesafetyglassesprovidedwiththisunitor eyeshields

beforechippingor shreddingandwhileperformingany adjustments

or repairs.

TAMPER

Thisplugisinsertedinto thechipperchuteto pushtwigsandsmall

branchestowardstheimpellerbladeswithoutendangeringyourhands.

TH ROTTLE CONTROL

Thislevercontrolstheenginespeedandstopfunction.Throughthree

separatepositionsontheleverfromleftto right,theoperationisas

follows:

Start/Run Slow/Idle Engine Off

CHOKE CONTROL

Thechokecontrolis usedtochokethecarburetorand assistinstarting

theengine.

Meets ANSI Safety Standards

CraftsmanYardVacuumsconformtothesafetystandardofthe AmericanNationalStandardsInstitute(ANSI).

11

GAS AND OIL FILL-UP

Oil (one bottle shipped with unit)

FirstTimeUse

1. Removeoil fillplug.

2. Withthechippershredderonlevelground,useafunnelto empty

entirecontentsofoil bottleprovidedintotheengine.

3. Replaceoil fillplugandtighten.

Subsequent Uses

Onlyuse highqualitydetergentoil ratedwithAPIserviceclassification

SF,SG,or SH.Selecttheoil'sSAEviscositygradeaccordingto the

expectedoperatingtemperature.Followthechartbelow.

_older _ 32°F _Warmer'_

OilViscosity Chart

Althoughmulti-viscosityoils(5W30,10W30,etc.)improvestarting

incoldweather,theywill resultinincreasedoilconsumptionwhen

usedabove32°E Checkyourengineoillevel morefrequentlytoavoid

possibleenginedamagefromrunninglowon oil.

1. Checktheoillevelby removingtheoilfillplugand lookinginto

theoil fillhole.Oilshouldbevisibleup tothethreadsof theoil fill

plug,almosttothe pointofoverflowing.Fill if necessary.Capac-

ity isapproximately28 oz.Overfillingcancauseahazardous

situation,be suretowipeupanyspilledor excessoil.

2. Replaceoil fillplugandtighten.

3. Keepoillevelat FULL.Runningtheenginewithtoolittleoil can

resultinpermanentenginedamage.

Gasoline

J

Alcoholblendedfuels(calledgasoholorusingethanolormethanol)

canattractmoisturewhichleadsto separationand formationof acids

duringstorage.Acidicgascandamagethefuel systemofanengine

whileinstorage.

Toavoidengineproblems,thefuelsystemshouldbeemptiedbefore

storagefor30daysorlonger.Drainthegastank,starttheengine

andletit rununtilthefuellinesandcarburetorare empty.Use

freshfuelnextseason.See STORAGEInstructionsforadditional

information.

Neveruseengineorcarburetorcleanerproductsinthefueltankor

permanentdamagemayoccur.

NOTE:Checkthefuel levelperiodicallytoavoid runningoutofgaso-

linewhileoperatingthe chippershredder.Ifthe unit runsoutofgasas

itischipping,itmaybe necessarytounclogthedischargeareabefore

itcan be restarted.RefertoSERVICEANDMAINTENANCEsection.

TO START ENGINE

1. Attach sparkplugwireandrubberbootto sparkplug.

2. Filltankto nomorethan 1/2inchbelowbottomoffillerneckto

providespaceforfuelexpansion.

3. Turnthefuelshut-offvalveto the ONposition.

4. MovethechokeleverontheenginetoCHOKEI'_1 position.(A

warmenginemaynotrequirechoking.)See Figure10.

5. MovethrottlecontroltoSTART/RUN(Rabbit)_ position.See

Figure10.

6. Standingbehindtheunit,graspstarterhandleand pullropeout

untilyoufeela drag.

f

Useextremecarewhenhandlinggasoline.Gasolineis extremely

flammableandthevaporsareexplosive.Neverfuelmachineindoors

orwhilethe engineis hotor running.Extinguishcigarettes,cigars,

pipes,andothersourcesof ignition.

1. Removefuelcap fromthefueltank.

2. Makesurethecontainerfromwhichyouwill pourthegasolineis

cleanandfreefromrustor foreignparticles.Neverusegasoline

thatmaybestalefromlongperiodsofstorageinitscontainer.

Gasolinethathasbeensittingfor anyperiodlongerthanfour

weeksshouldbeconsideredstale.

3. Fillfueltankwithclean,fresh,unleadedregulargasolineonly.Do

notusegasolinecontainingMETHANOL.Replacefuelcap.

J

Figure10

12

NOTE:A noisewillbe heardwhenfindingthestartofthecompression

cycle.Thisnoiseis causedbytheflailsandfingers,whicharepartof

theshreddingmechanism,andit shouldbe expecteduntilthe impeller

reachesfull speed.

7. Pulltheropewitha rapid,continuous,fullarmstroke.Keepafirm

griponthestarterhandle.Lettheroperewindslowly.

8. Repeat,ifnecessary,untilenginestarts.Whenenginestarts,

movechokecontrolgraduallytowardtheRUNI JtIposition..

9. Ifenginefalters,movechokecontrolbacktowardtheCHOKE

I'o,I positionandrepeatsteps5 though8.

10. ALWAYSkeepthe throttlecontrolintheSTART/RUNposition

whenoperatingthe chippershredder.

TO STOP ENGINE

1. Movethrottlecontrolleverto slow(turtle)'_ position.

Wheneverpossible,graduallyreduceenginespeedbefore

stoppingengine.

2. MovethrottlecontrollevertoSTOPI or OFFposition.

3. Turnthefuelshut-offvalvetotheOFFposition.

4. Disconnectsparkplugwireandgrounditagainsttheengineto

preventaccidentalstartingwhiletheequipmentisunattended.

SHREDDING

Yardwastesuchas leavesandpineneedlescanbe placedinthe

hopperforshredding.Aftermaterialhasbeenprocessedbythe shred-

derbladeandflails,it willbeforcedoutof the chutedeflector,and,if

attached,into adebriscollectionbag.

Observethefollowingguidelineswhenshreddingyarddebris:

• Neverattempttoshredmaterialotherthannormalyarddebris

(leaves,twigs,pinecones,etc.).

• Avoidshreddingfibrousplantssuchas tomatovines,palmfronds,

etc.,untiltheyare thoroughlydriedout. Freshvinesdo notshred

wellandtend towrapthemselvesaroundtheimpellerandflails.

• Placereasonableamountsofdebrisintothe hopperat a time. Do

notoverloadthe hopper.

• Allowthe materialin the hoppertobedrawnintothebladesand

shreddedbeforeaddingadditionaldebristo the hopper.Failureto

duesomayresultin acloggedhopper,cloggedchutedeflectoror

a stalledengine.

CHIPPING

Branchesupto3" in diametercanbefedintothe chipperchute.

Observethefollowingguidelineswhenchippingbranches:

• Keepbothhandsfirmlyonthe branchasyoufeedit intothe

chipperchute.

• Neverfeedmorethanonebranchintothe chipperchuteata time.

• Neverfeedanythingotherthanbranches(orwood) intothe

chipperchute.

• Applyintermittentpressure(force,inshortpulses)whilefeeding

larger(3-inchdiameter)branchesintothechipperchute,toavoid

boggingor stallingtheengine.

IMPORTANT:Neverfeed brancheswitha diametergreaterthan

three(3)inchesintothechipperchute.Doingsocan resultin serious

damageto yourunit'schipperblades,flailsor impeller.

NOTE:Forbestperformance,alwaysoperatetheunitwith sharp

chipperblades.If anoticeablelossinperformanceisencountered

whilechippingbranches,thechipperbladesshouldbe replaced.

LOWERING THE HOPPER ASSEMBLY

1. Withonehandgraspthehandleat thetopof the hopperassem-

blyandlift slightly.

2. Withtheotherhandpulloutonthereleaserodandlowerthe

hopperassemblytotheground.

TO EMPTY BAG

1. Un-clipdrawstringandloosenbagfromchutedeflectoropening.

2. Emptybagandreattachtothedischargechuteopening.Pullon

thedrawstringuntilthe bagistightaroundthechuteopeningand

clipthe drawstringtightagainstthe chutedeflector.

IMPORTANT:The flailscreenislocatedinsidethehousingin the

dischargearea.Iftheflailscreenbecomesclogged,removeand

cleanas instructedintheServiceand Maintenancesection.For best

performance,itisalso importanttokeepthechipperbladessharp.

13

MAINTENANCE SCHEDULE

Beforeperforminganytypeof maintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationor whileperforminganyadjustmentsor repairs.

EachUse

1st5 - 8 hours

25 hours

Annuallyor50hours

Annuallyor100hours

BeforeStorage 1. Fuelsystem

Underheavyloador inhightemperatures

.

Engineoillevel

2.

Looseormissinghardware

3.

Unitandengine.

1.

Engineoil

1.

Engineoill-

2.

Aircleaner

3.

Controllinkagesand pivots

1.

Engineoil

2.

Muffler

1.

Sparkplug

1. Check

2. Tightenorreplace

3. Clean

1. Change

1. Change

2. Replace

3. Lubewithlightoil

1. Change

2. Inspect

1. Clean,checkand resetgap,or

1. Runengineuntilit stopsfromlackof

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.Tolocatethe nearest SearsService

Centeror toscheduleservice,simplycontactSears at

1-800-4-MY-HOME®.

replacesparkplug.

fueloradda gasolineadditivetothe

gasin thetank.

Alwaysstopengineanddisconnectsparkplugwire beforeperforming

Ianymaintenanceoradjustments.Alwayswearsafetyglassesduring

[operationor whileperforminganyadjustmentsor repairs.

GENERAL RECOMMENDATIONS

• Alwaysobserveallsafetyrulesfoundonproductlabelsandin

thisoperator'smanualwhenperforminganymaintenance.Safety

rulescan befoundonthe productlabelsandin thisOperator's

Manualbeginningon page3.

• Thewarrantyon thischippershredderdoes notcoveritemsthat

havebeensubjectedto operatorabuseor negligence.Toreceive

fullvalue fromwarranty,operatormustmaintaintheequipmentas

instructedhere.

• Someadjustmentswillhaveto be madeperiodicallytomaintain

yourunit properly.

• Periodicallycheckallfastenersand makesurethesearetight.

ENGINE MAINTENANCE

Checking the Spark Plug

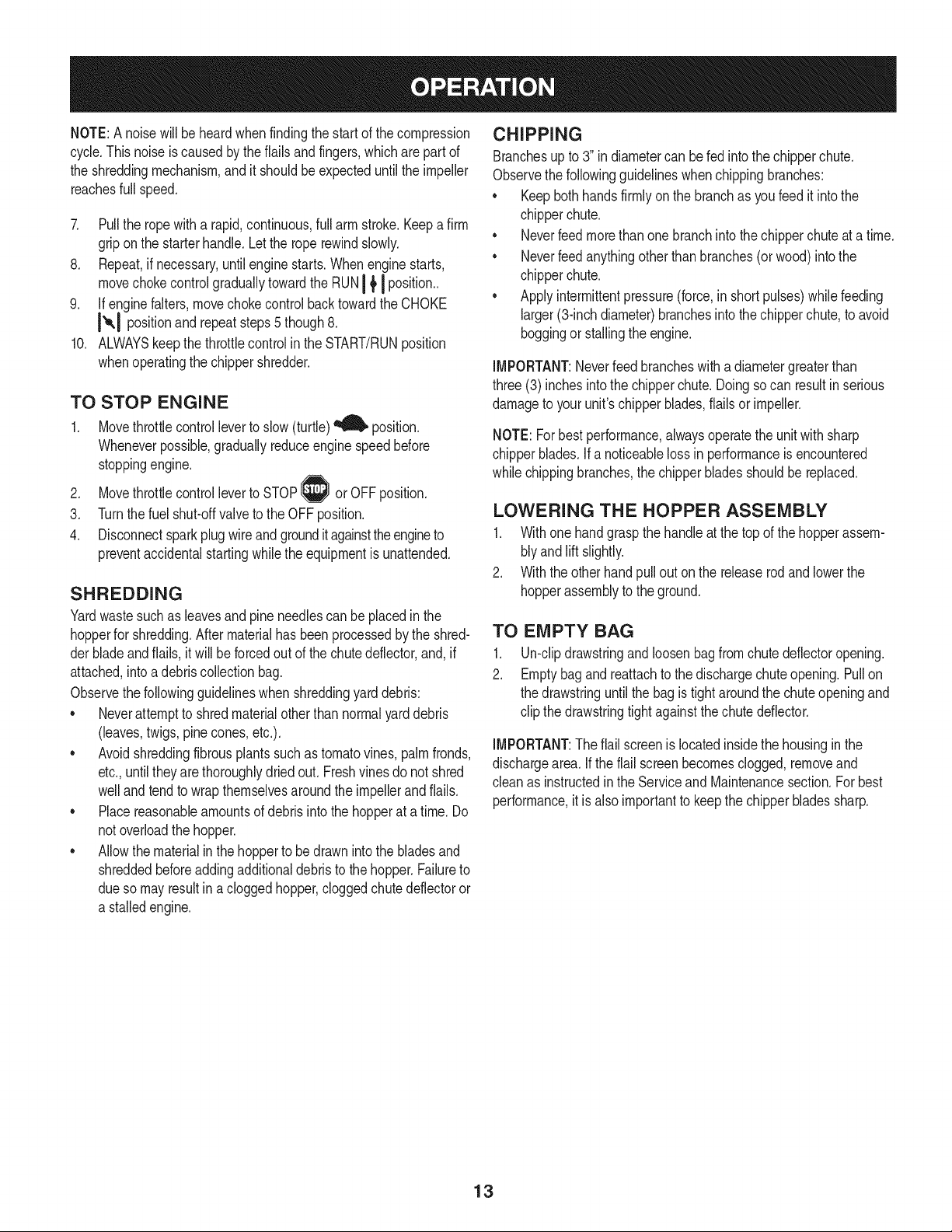

Cleansparkplugandresettheelectrodegapto0.030"atleastoncea

season;replaceevery100hoursof operation.

f

Electrode

Porcelain

,L

.030 (.76 mm) gap

Figure 11

• Cleanareaaroundthe sparkplugbase.Donotsandblastspark

plug.Sparkplugshouldbecleanedbyscrapingorwirebrushing

andwashingwitha commercialsolvent.

• Removeandinspectthesparkplug.Checkgaptomakesureit is

setat .030".SeeFigure11.

• Replacethesparkplugif electrodesare pitted,burned,orthe

porcelainiscracked.

14

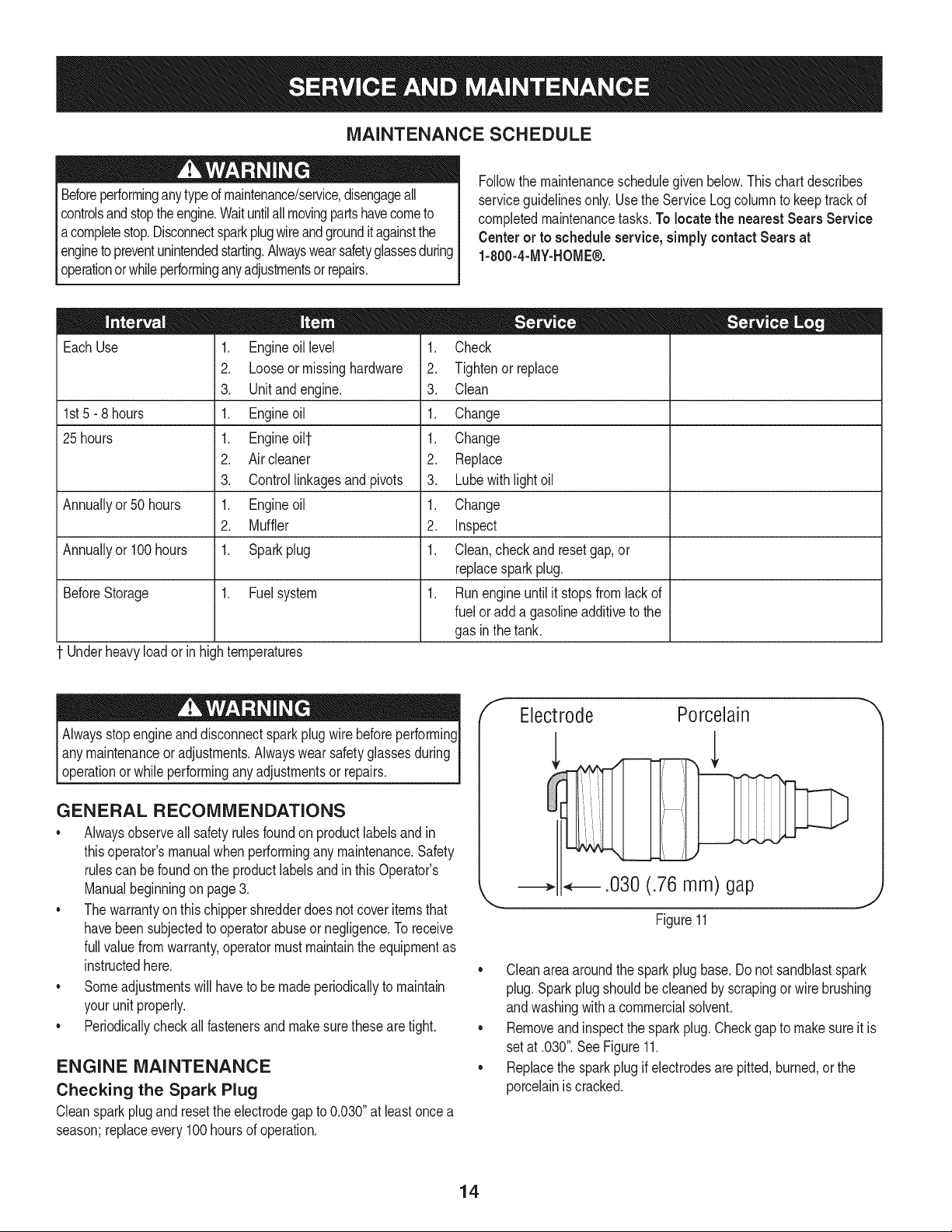

Servicing the Air Cleaner

Donotusepressurizedairor solventsto cleantheaircleaner

cartridge.

Theair cleanerpreventsdamagingdirt, dust,etc.,fromenteringthe

carburetorand beingforcedintotheengineandis importanttoengine

lifeandperformance.Neverruntheenginewithoutan aircleaner

completelyassembled.

Replacetheaircleanerevery25 hoursofoperation.

1. Loosenscrewsthatholdtheairfiltercover.

2. Opencoverandremoveair filter.See Figure12.

f

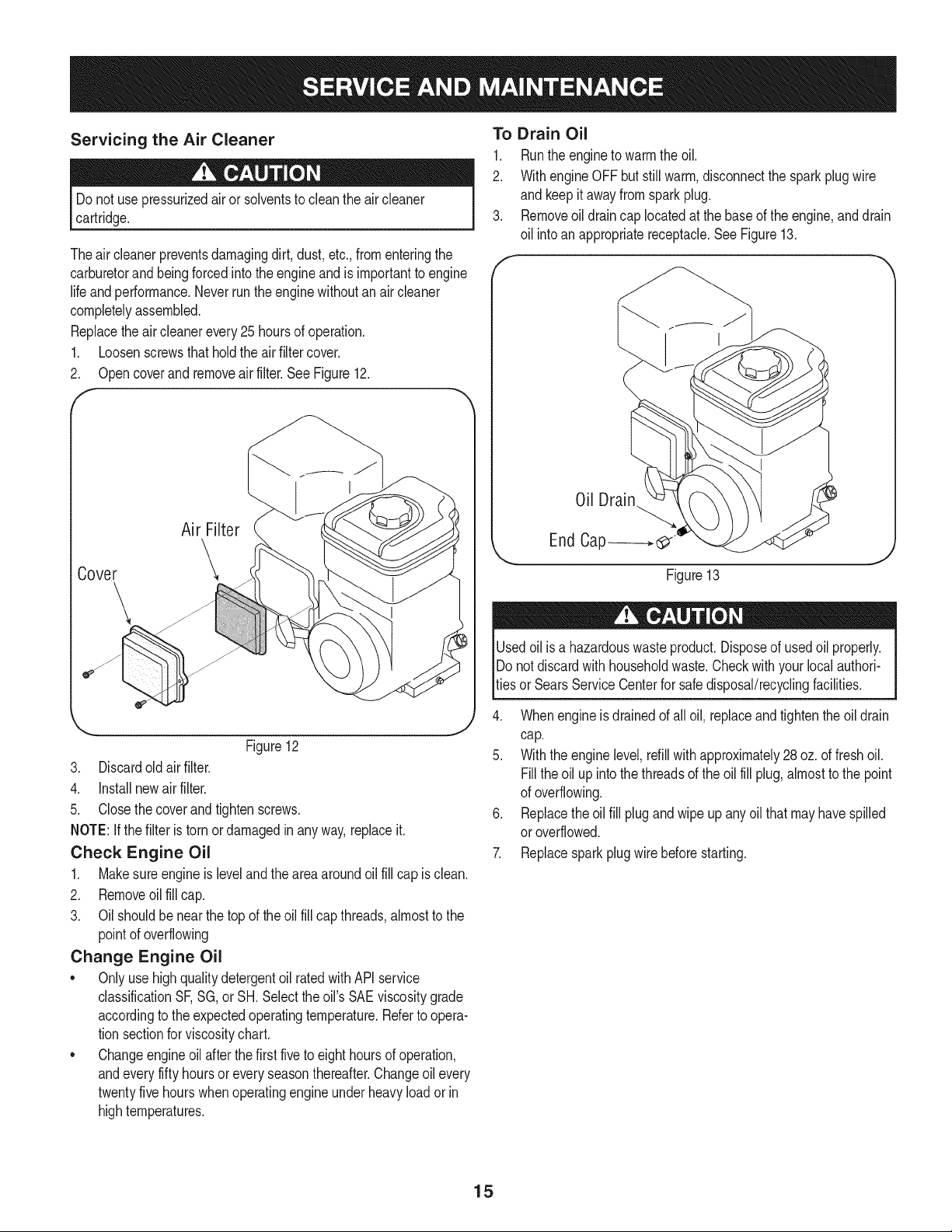

To Drain Oil

1. Runtheengineto warmtheoil.

2. WithengineOFFbutstillwarm,disconnectthe sparkplugwire

and keepitawayfromsparkplug.

3. Removeoil draincaplocatedatthe baseofthe engine,anddrain

oil intoanappropriatereceptacle.SeeFigure13.

Oil Drain

Air Filter

Cover

3. Discardoldairfilter.

4. installnewairfilter.

5. Closethecoverandtightenscrews.

NOTE:Ifthe filteristornordamagedin anyway,replaceit.

Check Engine Oil

1. Makesureengineislevelandtheareaaroundoil fillcapisclean.

2. Removeoilfillcap.

3. Oilshouldbe nearthe top oftheoil fillcapthreads,almostto the

pointof overflowing

Change Engine Oil

* OnlyusehighqualitydetergentoilratedwithAPIservice

classificationSF,SG, orSH.Selecttheoil'sSAEviscositygrade

accordingtotheexpectedoperatingtemperature.Refertoopera-

tionsectionforviscositychart.

. Changeengineoil afterthe firstfivetoeighthoursof operation,

andeveryfifty hoursoreveryseasonthereafter.Changeoilevery

twentyfivehourswhenoperatingengineunderheavyloadorin

hightemperatures.

\

y

Figure12

End Cap _"

J

Figure13

e

Usedoil isa hazardouswasteproduct.Disposeof usedoil properly.

IDo notdiscardwithhouseholdwaste.Checkwithyourlocalauthori-

_tiesorSearsServiceCenterforsafedisposal/recyclingfacilities.

4. Whenengineisdrainedofall oil,replaceandtightentheoil drain

cap.

5. Withtheenginelevel,refillwithapproximately28oz. offreshoil.

Fillthe oil upintothethreadsof the oilfill plug,almosttothe point

ofoverflowing.

6. Replacethe oilfill plugandwipeupanyoil thatmayhavespilled

or overflowed.

7. Replacesparkplugwire beforestarting.

15

Service IVluffler

REMOVING THE FLAIL SCREEN

Temperatureof mufflerandnearbyareasmayexceed150°F (65°C).

Avoidtheseareas.

• Inspectmufflerevery50 hours,andreplaceif necessary.

Replacementpartsforthemufflermustbethe sameandinstalled

inthe samepositionastheoriginalparts.

Clean Engine

Dailyor beforeeveryuse,cleangrass,chaffor accumulated

debrisfromengine.Keeplinkage,spring,andcontrolsclean.

Keepareaaroundandbehindmufflerfreeofanycombustible

debris.

• Keepingenginecleanallowsairmovementaroundengine.

• Enginepartsshouldbekeptcleanto reducetheriskof overheat-

ingandignitionofaccumulateddebris.

Donot usewatertocleanengineparts.Watercouldcontaminatefuel

system.Usea brushordrycloth.

Carburetor Adjustment

Thecarburetoronthis engineisnotadjustable.

Engine Speed

LUBRICATION

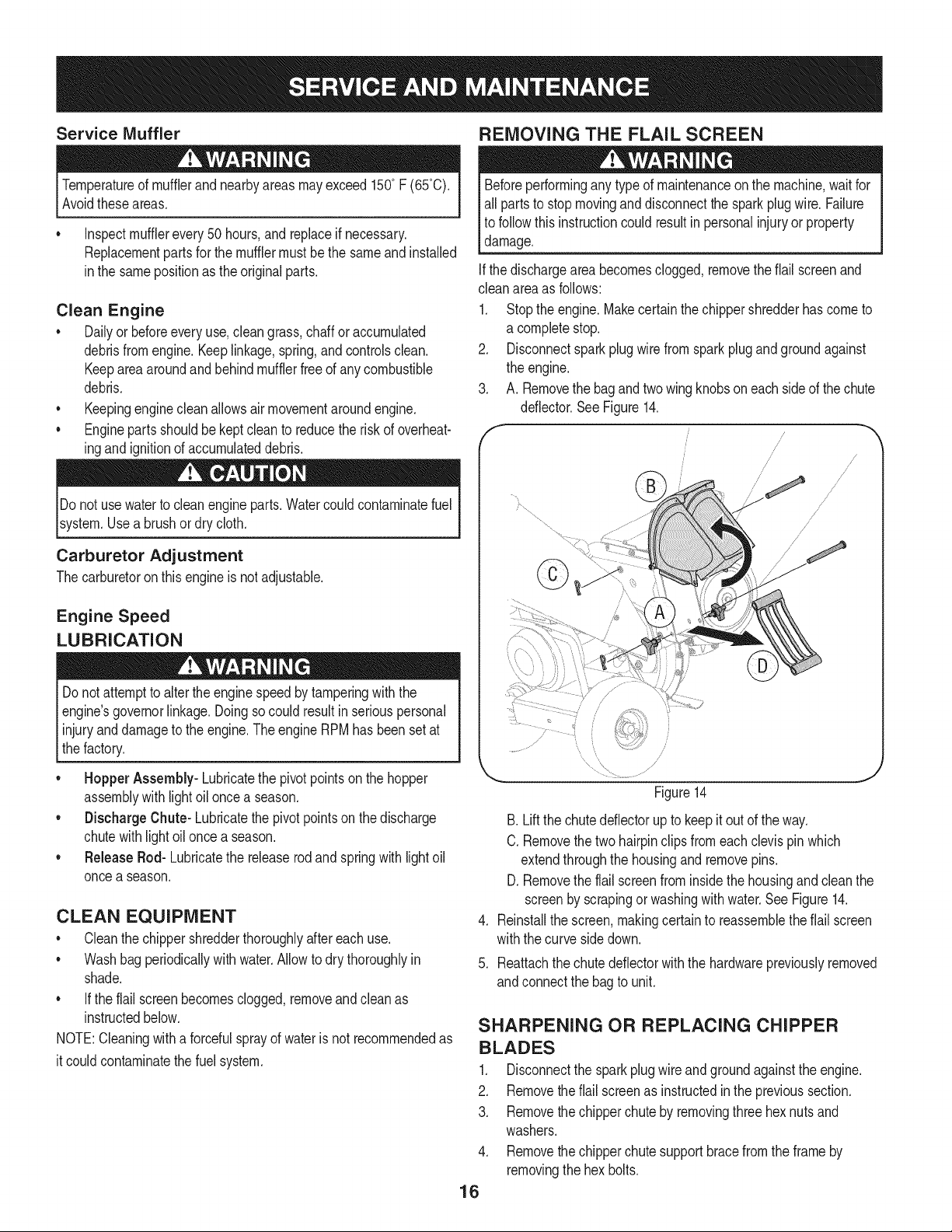

Beforeperforminganytypeofmaintenanceonthemachine waitfor

all partsto stopmovinganddisconnectthe sparkplugwire. Failure

tofollowthis instructioncouldresultinpersonalinjuryorproperty

damage.

Ifthedischargeareabecomesclogged,removethe flail screenand

cleanareaas follows:

Stopthe engine.Makecertainthechippershredderhascometo

a completestop.

.

Disconnectsparkplugwirefromsparkplugandgroundagainst

theengine.

3.

A. Removethe bagandtwowingknobsoneachsideofthechute

deflector.SeeFigure14.

f

/

s /

/ /

//

/

s'

/

Donot,attempttoaltertheenginespeedbytamperingwiththe

engines governorlinkage.Doingsocouldresultin seriouspersonal

Iinjuryanddamagetotheengine.TheengineRPMhasbeensetat

thefactory.

• HopperAssembly- Lubricatethe pivotpointson thehopper

assemblywithlightoilonceaseason.

• DischargeChute- Lubricatethepivotpointsonthedischarge

chutewithlightoilonce a season.

• ReleaseRod-Lubricatethereleaserodand springwith lightoil

oncea season.

CLEAN EQUIPMENT

• Cleanthechippershredderthoroughlyaftereachuse.

• Washbagperiodicallywithwater.Allowto dry thoroughlyin

shade.

• Iftheflail screenbecomesclogged,removeandcleanas

instructedbelow.

NOTE:Cleaningwitha forcefulsprayofwaterisnotrecommendedas

itcouldcontaminatethefuelsystem.

j

Figure14

B.Liftthe chutedeflectoruptokeepitoutofthe way.

C.Removethetwo hairpinclipsfromeachclevispinwhich

extendthroughthehousingandremovepins.

D.Removetheflailscreenfrominsidethehousingandcleanthe

screenbyscrapingorwashingwithwater.SeeFigure14.

4. Reinstallthescreen,makingcertainto reassemblethe flail screen

withthecurvesidedown.

5. Reattachthechutedeflectorwiththehardwarepreviouslyremoved

andconnectthe bagto unit.

SHARPENING OR REPLACING CHIPPER

BLADES

1. Disconnectthesparkplugwireandgroundagainsttheengine.

2. Removetheflail screenasinstructedinthe previoussection.

3. Removethechipperchutebyremovingthreehexnutsand

washers.

4. Removethechipperchutesupportbracefromthe frameby

removingthehexbolts.

16

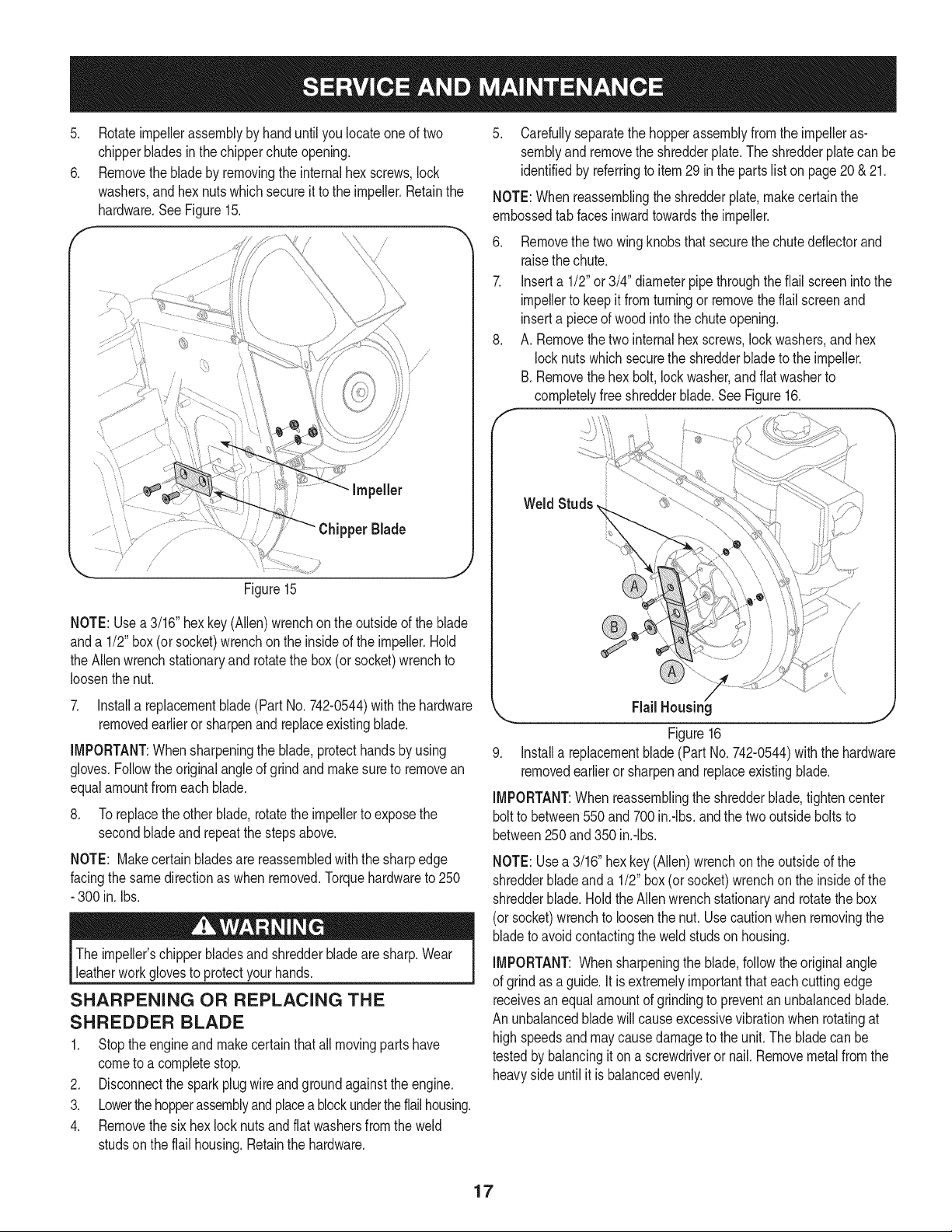

5. Rotateimpellerassemblybyhanduntilyoulocateoneoftwo

chipperbladesinthechipperchuteopening.

6. Removethebladebyremovingtheinternalhexscrews,lock

washers,andhexnutswhichsecureittotheimpeller.Retainthe

hardware.SeeFigure15.

/

/

5. Carefullyseparatethehopperassemblyfromtheimpelleras-

semblyandremovetheshredderplate.Theshredderplatecanbe

identifiedby referringtoitem29 inthepartslist onpage20&21.

NOTE:Whenreassemblingtheshredderplate,makecertainthe

embossedtabfacesinwardtowardstheimpeller.

6. Removethetwowingknobsthatsecurethechuteddlector and

raisethechute.

7. Inserta 1/2"or3/4"diameterpipethroughtheflail screenintothe

impellertokeepit fromturningorremovetheflail screenand

inserta pieceofwoodintothechuteopening.

8. A. Removethetwointernalhexscrews,lockwashers,and hex

locknutswhichsecuretheshredderbladetothe impeller.

B.Removethehexbolt,lockwasher,andflatwasherto

completelyfreeshredderblade.SeeFigure16.

f

Weld

Figure15

NOTE:Usea3/16"hexkey(Allen)wrenchon theoutsideoftheblade

anda 1/2"box(or socket)wrenchontheinsideoftheimpeller.Hold

theAllenwrenchstationaryandrotatethe box(orsocket)wrenchto

loosenthenut.

7. Installareplacementblade(Part No.742-0544)withthe hardware

removedearlierorsharpenandreplaceexistingblade.

IMPORTANT:Whensharpeningthe blade,protecthandsbyusing

gloves.Followtheoriginalangleofgrindandmakesuretoremovean

equalamountfromeachblade.

8. Toreplacetheotherblade,rotatetheimpellertoexposethe

secondbladeand repeatthestepsabove.

NOTE: Makecertainbladesare reassembledwiththesharpedge

facingthesamedirectionas whenremoved.Torquehardwareto250

- 300in.Ibs.

Theimpeller'schipperbladesandshredderbladearesharp.Wear

leatherworkglovesto protectyourhands.

SHARPENING OR REPLACING THE

SHREDDER BLADE

1. Stoptheengineandmakecertainthatallmovingpartshave

cometoa completestop.

2. Disconnectthesparkplugwire andgroundagainsttheengine.

3. Lowerthehopperassemblyandplaceablockundertheflailhousing.

4. Removethesixhexlocknutsandflatwashersfromtheweld

studsonthe flailhousing.Retainthehardware.

FlailHousing

Figure16

9. Installa replacementblade(PartNo.742-0544)with thehardware

removedearlierorsharpenandreplaceexistingblade.

IMPORTANT:When reassemblingtheshredderblade,tightencenter

boltto between550and700in.-Ibs,andthetwooutsideboltsto

between250and350in.-Ibs.

NOTE:Usea 3/16"hexkey(Allen)wrenchonthe outsideofthe

shredderbladeanda 1/2"box(or socket)wrenchon theinsideofthe

shredderblade.HoldtheAllenwrenchstationaryandrotatethebox

(orsocket)wrenchtoloosenthenut. Usecautionwhenremovingthe

bladetoavoidcontactingthe weldstudson housing.

IMPORTANT:Whensharpeningtheblade,followtheoriginalangle

ofgrindas a guide.It is extremelyimportantthateachcuttingedge

receivesan equalamountof grindingtopreventan unbalancedblade.

An unbalancedbladewill causeexcessivevibrationwhen rotatingat

highspeedsandmaycausedamagetothe unit.The bladecanbe

testedby balancingiton ascrewdriverornail. Removemetalfromthe

heavysideuntil itisbalancedevenly.

17

Neverstorechippershredderwithfuel in tankindoorsor in poorly

ventilatedareaswherefuelfumesmayreachan openflame,spark,

or pilotlightas ona furnace,waterheater,clothesdryer,orgas

appliance.

PREPARING THE ENGINE

Forenginesstoredover30 days:

1. To preventgumfromforminginfuelsystemoroncarburetor

parts,runengineuntilit stopsfromlackof fuelor adda gasoline

additivetothe gasinthetank. Ifyouuseagasadditive,runthe

engineforseveralminutestocirculatetheadditivethroughthe

carburetor--afterwhichtheengineandfuel canbestoredup to

six months.

2. Whileengineis stillwarm,changetheoil. SeeChangeEngineOil

in SERVICEANDMAINTENANCEsection.

3. Removesparkplugand pourapproximately1oz. (30ml)ofclean

engineoil intothecylinder.Pulltherecoilstarterseveraltimesto

distributetheoil,andreinstallthe sparkplug.

4. Cleanengineofsurfacedebris.

PREPARING THE CHIPPER SHREDDER

* Whenstoringthechippershredderinan unventilatedor metal

storageshed,careshouldbetakento rustproofthe non-painted

surfaces.Usinga lightoil orsilicone,coattheequipment,

especiallyanysprings,bearings,andcables.

, Removealldirt fromexteriorofengineandequipment.

, Followlubricationrecommendations.

o Storeequipmentina clean,dryarea.Donotstorenextto

corrosivematerials,suchasfertilizer.Donotstoreinan area

whereequipmentispresentthatmayusea pilotlightor hasa

componentthatcancreatea spark.

18

Loading...

Loading...