MTD 24A464G729 Owner’s Manual

Safety • Assembly • Operation • Tips & Techniques • Maintenance • Troubleshooting • Parts Lists • Warranty

OF A O AL

/

/

/

/

/

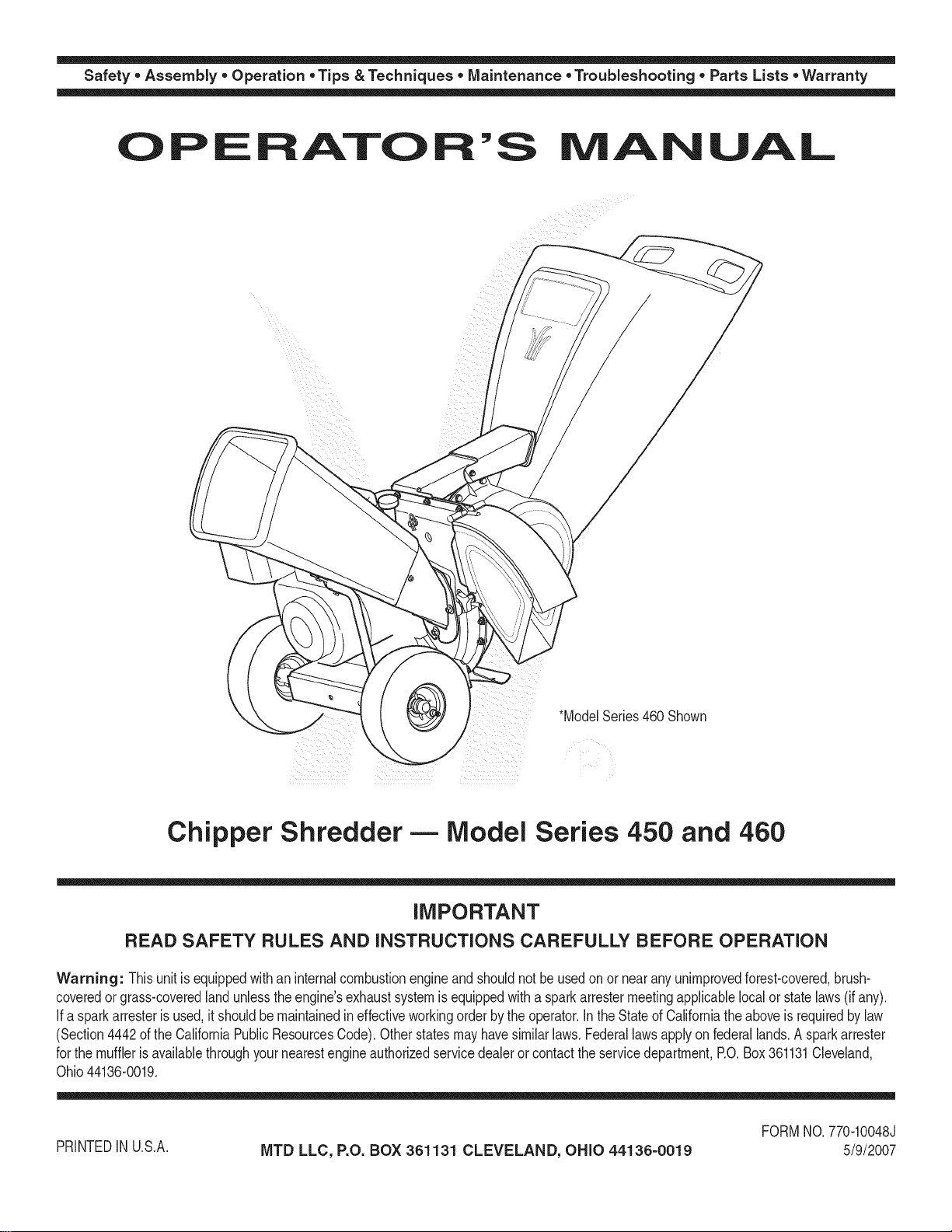

*ModelSeries460Shown

Chipper Shredder- Model Series 450 and 460

IMPORTANT

READ SAFETY RULES AND iNSTRUCTiONS CAREFULLY BEFORE OPERATION

Warning: Thisunitisequippedwithan internalcombustionengineandshouldnot beusedon or nearanyunimprovedforest-covered,brush-

coveredor grass-coveredlandunlesstheengine'sexhaustsystemisequippedwithasparkarrestermeetingapplicablelocalorstatelaws(if any).

If a sparkarresterisused,it shouldbemaintainedineffectiveworkingorderbytheoperator.IntheStateofCaliforniatheaboveisrequiredbylaw

(Section4442ofthe CaliforniaPublicResourcesCode).Otherstatesmayhavesimilarlaws.Federallawsapplyonfederallands.A sparkarrester

forthe mufflerisavailablethroughyournearestengineauthorizedservicedealeror contacttheservicedepartment,RO.Box361131Cleveland,

Ohio44136-0019.

FORMNO.770-10048J

PRINTEDIN U.S.A.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

5/9/2007

This Operator's IVlanual is an important part of your new chipper shredder, it will help you assemble, pre-

pare and maintain the unit for best performance. Please read and understand what it says.

Table of Contents

Customer Support .............................................. 2

Safety Labels ...................................................... 3

Safe Operation Practices ................................... 4

Setting UpYour Chipper Shredder .................... 6

Operating Your Chipper Shredder ................... 10

Finding and Recording Model Number

BEFOREYOU STARTASSEMBLING

YOURNEW EQUIPMENT,

pleaselocate themodel plateon the equipment and copy

the informationtothe samplemodel plate providedto the

right.Youcan locatethe model plate by standing behind the

unitand looking down at the frame belowtheengine. This

informationwill benecessaryto usethe manufacturer'sweb

site and/or obtainassistancefromthe CustomerSupport

Departmentoran authorizedservice dealer.

Maintaining Your Chipper Shredder ................ 12

Troubleshooting ................................................ 14

Parts List ........................................................... 16

Warranty ............................................................ 20

EspaSol .............................................................. 21

r

Model Number

®

www.mtdproducts.com

Serial Number

MTD LLC

P.O. BOX 361131

CLEVELAND, OH 44136

330 -220-4683

800-800-731 0

Customer Support

Please do NOTreturn the unit to the retailer from which it was

purchased, without first contacting Customer Support.

Ifyou havedifficultyassemblingthis product or haveany questionsregardingthecontrols, operation,or maintenanceof this

unit,youcan seek helpfrom the experts. Choosefrom the optionsbelow:

1. Visit mtdproducts.com. Click on the CustomerService menuoption.

2. Phonea CustomerSupport Representativeat 1.800.800.7310. Spanish speaking agents are available.

3. Theengine manufacturer isresponsiblefor all engine-related issueswith regards to performance,power-rating,specifica-

tions,warrantyandservice. Pleaserefer tothe engine manufacturer'sOwner's/Operator'sManual, packedseparatelywith

your unit,for more information.

2

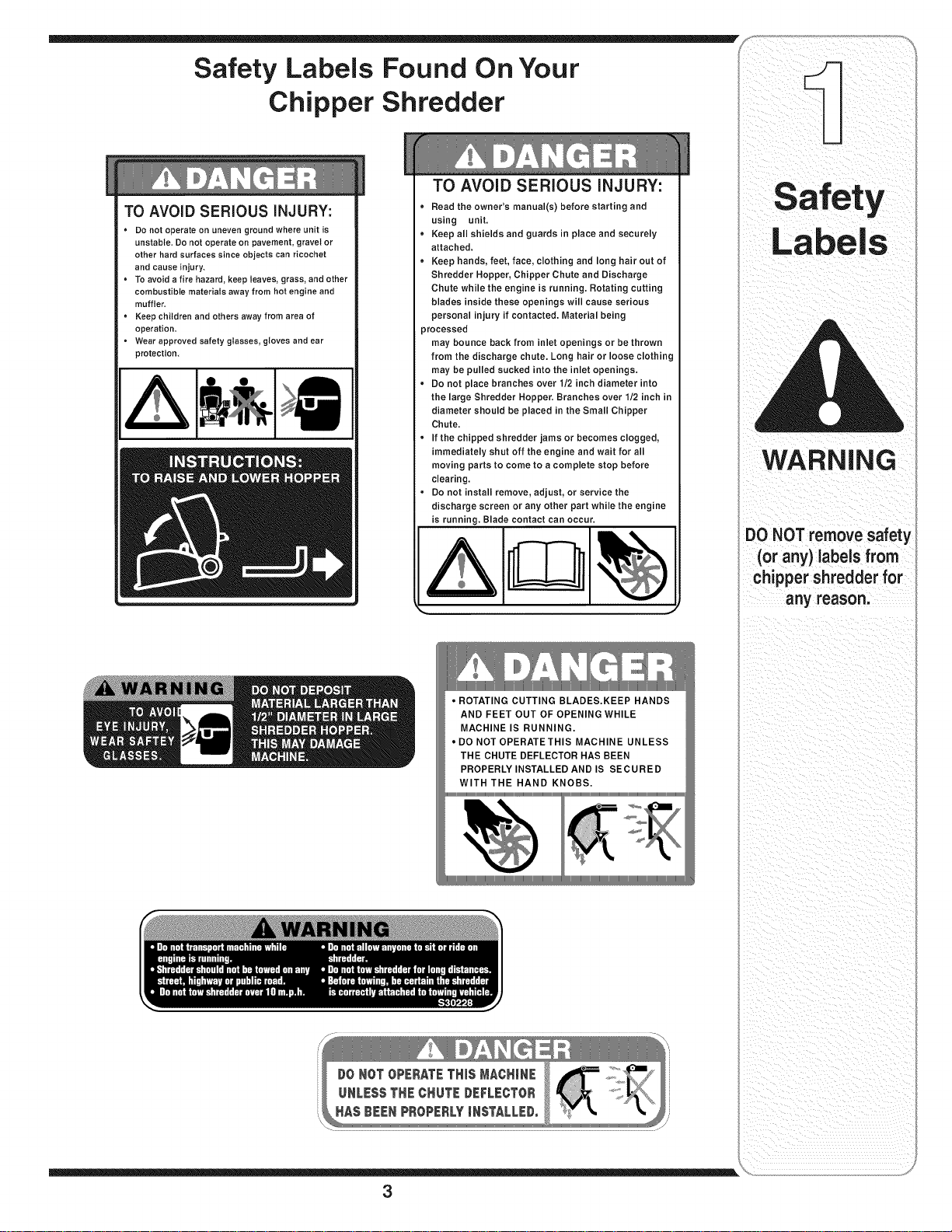

Safety Labels Found On Your

Chipper Shredder

TO AVOID SERIOUS iNJURY:

° Do not operate on uneven ground where unit is

unstable. Do not operate on pavement, gravel or

other hard surfaces since objects can ricochet

and cause injury.

• To avoid a fire hazard, keep leaves, grass, and other

combustible materials away from hot engine and

muffler,

° Keep children and others away from area of

operation.

° Wear approved safety glasses, gloves and ear

protection.

TO AVOID SERIOUS iNJURY:

• Read the owner's manual(s) before starting and

using unit.

• Keep all shields and guards in place and securely

attached.

• Keep hands, feet, face, clothing and long hair out of

Shredder Hopper, Chipper Chute and Discharge

Chute while the engine is running. Rotating cutting

blades inside these openings will cause serious

personal injury if contacted. Material being

_rocessed

may bounce back from inlet openings or be thrown

from the discharge chute. Long hair or loose clothing

may be pulled sucked into the inlet openings.

• Do not place branches over 1/2 inch diameter into

the large Shredder Hopper. Branches over 1/2 inch in

diameter should be placed in the Small Chipper

Chute.

• If the chipped shredder jams or becomes clogged,

immediately shut off the engine and wait for all

moving parts to come to a complete stop before

clearing.

• Do not install remove, adjust, or service the

discharge screen or any other part while the engine

is running. Blade contact can occur.

Labels

WARNING

DO NOTremove safety

(or any) labels from

chipper shredder for

any reason.

3

WARNING: EngineExhaust,some of its constituents, andcertain vehicle compo-

nentscontain or emit chemicals knownto Stateof Californiato cause cancer and

birth defects or other reproductiveharm.

DANGER: This machinewas builtto beoperatedaccordingto the rulesfor safe operation in this

manual.As with any type of powerequipment,carelessnessor erroronthe part ofthe operatorcan

result in seriousinjury.This machine is capable of amputatinghands andfeet andthrowing objects.

Failureto observethe followingsafety instructionscould resultinserious injuryordeath.

WARNING

Thissymbolpoints

out importantsafety

instructionswhich,if

notfollowed,could

endangerthe personal

i safetyand/or property

I ofyourselfand others.

Readandfollowall

instructionsinthis

manualbeforeat-

temptingto operate

i this machine.Failure

I to complywith these

instructionsmayresult

i inpersonalinjury.When

youseethis symbol.

i HEED ITS WARNING!

i Your Responsibility

Restrictthe use

ofthis powermachine

to personswho read.

i understand

andfollow thewarnings

and instructions

i inthis manual

and on the machine.

Training

1. Read,understand,andfollowall instructionsonthe ma- 1.

chineandin the manual(s)beforeattemptingtoassemble

andoperate.Keepthis manualinasafe placeforfuture

andregularreferenceandfor orderingreplacementparts.

2. Befamiliarwithallcontrolsandtheirproperoperation. 2.

Knowhowtostopthe machineanddisengagethem

quickly.

3. Neverallow childrenunder16years oldto operatethis

machine.Children16yearsoldandovershouldreadand 3.

understandthe operationinstructionsandsafetyrulesin

thismanualand shouldbetrainedand supervisedbya

parent.

4. Neverallow adultsto operatethismachinewithoutproper

instruction. 4.

5. Keepbystanders,helpers,pets,and childrenat least

75feetfromthemachinewhile it isin operation.Stop

machineif anyoneentersthe area.

6. Neverrunan engineindoorsor in apoorlyventilatedarea. 5.

Engineexhaustcontainscarbon monoxide,anodorless

anddeadly gas. 6.

7. Do notputhandsandfeetnearrotatingpartsorinthe

feedingchambersanddischargeopening.Contactwith

the rotatingimpellercanamputatefingers,hands,and

feet.

8. Neverattemptto unclogeitherthefeedintakeor

dischargeopening,removeor emptybag,or inspectand

repairthe machinewhilethe engineis running.Shutthe

engineoff andwaituntil allmovingpartshavecometo a

completestop.Disconnectthespark plugwireandground

it againsttheengine.

Preparation

Thoroughlyinspecttheareawheretheequipmentisto

beused.Removeall rocks,bottles,cans,or otherforeign

objectswhichcouldbe pickedupor thrownandcause

personalinjuryor damageto the machine.

Alwayswearsafetyglassesor safetygogglesduringopera-

tionor whileperforminganadjustmentor repair,to protect

eyes.Thrownobjectswhichricochetcancause serious

injurytothe eyes.

Wearsturdy,rough-soledworkshoesand close-fitting

slacksandshirts. Loosefittingclothesor jewelrycan be

caughtin movableparts.Neveroperatethis machine

in barefeetor sandals.Wearleatherworkgloveswhen

feedingmaterialin thechipperchute.

Beforestarting,checkallboltsand screwsforpropertight-

nessto besurethe machineis insafeworkingcondition.

Also,visuallyinspectmachinefor anydamageatfrequent

intervals.

Maintainorreplacesafetyandinstructionslabels,as

necessary.

Toavoidpersonalinjuryorpropertydamageuseextreme

careinhandlinggasoline.Gasolineisextremelyflammable

andthe vaporsare explosive.Seriouspersonalinjurycan

occurwhengasolineis spilledonyourselforyourclothes

whichcanignite.Washyourskinand changeclothes

immediately.

a. Useonlyanapprovedgasolinecontainer.

b. Extinguishallcigarettes,cigars, pipes,andother

sourcesofignition.

c. Neverfuelmachineindoors.

d. Neverremovegascap oradd fuelwhilethe engineis hot

or running.

e. Allowengineto coolat leasttwo minutesbeforerefuel-

ing.

f. Neveroverfill fueltank. Filltankto nomorethan1/2

inchbelowbottomoffiller neckto providespacefor fuel

expansion.

g. Replacegasolinecap andtightensecurely.

h. If gasolineis spilled,wipe itoff theengineand equip-

ment.Movemachinetoanotherarea.Wait5 minutes

beforestartingtheengine.

i. Neverstorethe machineorfuel containerinsidewhere

there isan openflame,spark,orpilot light(e.g.furnace,

waterheater,spaceheater,clothesdryer,etc.)

j. Toreducea fire hazard,keepmachinefreeofgrass,

leaves,orotherdebrisbuild-up.Cleanupoilor fuel

spillageandremoveanyfuel soakeddebris.

k. Allowmachinetocoolat least5 minutesbeforestoring.

4

Operation

1. Donot puthandsandfeetnearrotatingpartsor inthe

feedingchambersanddischargeopening.Contactwith the

rotatingimpellercanamputatefingers, hands,andfeet.

2. Beforestartingthemachine,makesurethe chipperchute,

feedintake,andcuttingchamberareemptyandfreeofall

debris.

3. Thoroughlyinspectall materialto beshreddedandremove

any metal,rocks,bottles,cans,orotherforeignobjects

whichcouldcausepersonalinjuryor damagetothe

machine.

4. f it becomesnecessarytopushmaterialthroughthe

shredderhopper,usea smalldiameterstick. Do notuse

yourhandsorfeet.

5. f the impellerstrikesaforeignobjector ifyour machine

shouldstart makinganunusualnoiseor vibration,

immediatelyshuttheengineoff.Allowthe impellertocome

to a completestop.Disconnectthesparkplugwire,ground

itagainstthe engineandperformthe followingsteps:

a. Inspectfordamage.

b. Repairorreplaceanydamagedparts.

c. Checkfor anyloosepartsandtightento assure

continuedsafeoperation.

6. Donotallow anaccumulationof processedmaterialtobuild

upinthe dischargearea.Thiscan preventproperdischarge

andresult in kickbackof materialthroughthefeedopening.

7. Donotattemptto shredorchipmateriallargerthan

specifiedonthe machineor inthismanual.Personalinjury

or machinedamagecouldresult.

8. Neverattemptto unclogeitherthe feed intakeordischarge

openingwhilethe engineisrunning.Shutthe engineoff,

wait untilall movingpartshavestopped,disconnectthe

sparkplugwireandgroundit againsttheenginebefore

clearingdebris.

9. Neveroperatewithouttheshredderhopper,chipperchute,

or chutedeflectorproperlyattachedto the machine.Never

emptyor changedischargebagwhiletheengineis running.

10.Keepall guards,deflectorsandsafetydevicesin placeand

operatingproperly.

11.Keepyourface andbody backandto theside ofthe chipper

chutewhilefeedingmaterialintothe machineto avoid

accidentalkickbackinjuries.

12.Neveroperatethis machinewithoutgoodvisibility or light.

13.Donotoperatethis machineon apaved,gravelor non-level

surface.

14.Donotoperatethis machinewhileunderthe influenceof

alcoholordrugs.

15.Mufflerandenginebecomehotandcan causeaburn.Do

nottouch.

16.Neverpickupor carrymachinewhilethe engineisrunning.

Maintenance & Storage

1. Nevertamperwithsafetydevices.Checktheir proper

operationregularly.

2. Checkbolts andscrewsfor propertightnessatfrequent

intervalstokeepthe machineinsafeworkingcondition.

Also,visuallyinspectmachinefor anydamageand repair,if

needed.

3. Beforecleaning,repairing,orinspecting,stopthe engine

andmakecertainthe impellerandall movingpartshave

stopped.Disconnectthesparkplugwireand groundit

againsttheengineto preventunintendedstarting.

4. Do notchangetheenginegovernorsettingsor overspeed

theengine.The governorcontrolsthemaximumsafe

operatingspeedoftheengine.

5. Maintainor replacesafetyandinstructionlabels,as neces-

sary.

6. Followthis manualforsafe loading,unloading,transporting,

andstorageofthis machine.

7. Neverstorethe machineorfuel containerinsidewhere

thereisan openflame,sparkor pilotlightsuchas a water

heater,furnace,clothesdryer,etc.

8. Alwaysreferto theoperator'smanualfor properinstructions

onoff-seasonstorage.

9. If thefueltank hasto bedrained,dothis outdoors.

10.Observeproperdisposallawsandregulationsforgas,oil,

etc.toprotectthe environment.

Do not modify engine

Toavoidseriousinjuryordeath,donot modifyengineinany

way.Tamperingwiththegovernorsettingcan leadto a runaway

engineandcauseit tooperateat unsafespeeds.Nevertamper

withfactorysettingofenginegovernor.

Notice regarding Emissions

Engineswhicharecertifiedto complywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOff RoadEquipment)

arecertifiedto operateonregularunleadedgasoline,andmay

includethefollowingemissioncontrolsystems:EngineModifica-

tion(EM)andThreeWayCatalyst(TWO)ifso equipped.

Your Responsibility

Restrictthe useofthis powermachineto personswhoread,un-

derstandandfollowthe warningsandinstructionsin thismanual

andon themachine.

Practices

WARNING

Thissymbol points

out importantsafety

instructions,which if

notfollowed,could

endangerthe personal

safety and/or property

of yourself and others.

Readand followall

instructions inthis man-

ual before attemptingto

operatethis machine.

Failureto comply with

these instructionsmay

result in personalinjury.

Whenyou seethis

symbol.

HEED iT S WARNING!

Your Responsibility

Restrictthe use

of this powermachine

to personswho read.

understand

and followthe warnings

and instructions

in this manua

and on the machine.

5

IMPORTANT:Thisunit isshippedwithoutgasolineoroil

in theengine.Becertainto serviceenginewithgasoline

andoilas instructedinthe separateenginemanual

beforeoperatingyourmachine.

Loose Parts In Carton

a. HopperAssembly d. Bag

b. ChuteDeflector e.SafetyGlasses

c. ChipperChute f. EngineOil

Shredder

IMPORTANT

This unit is shipped

without gasolineor

oil in the engine.Be

certainto service

enginewith gasoline

andoil as instructed

in the separateengine

manual beforeoperat-

ingyour machine.

NOTE: All references

in this manualto the

left or rightside of

thechipper shredder

isfrom theoperating

i positiononly. Excep-

tions ifany willbe

specified.

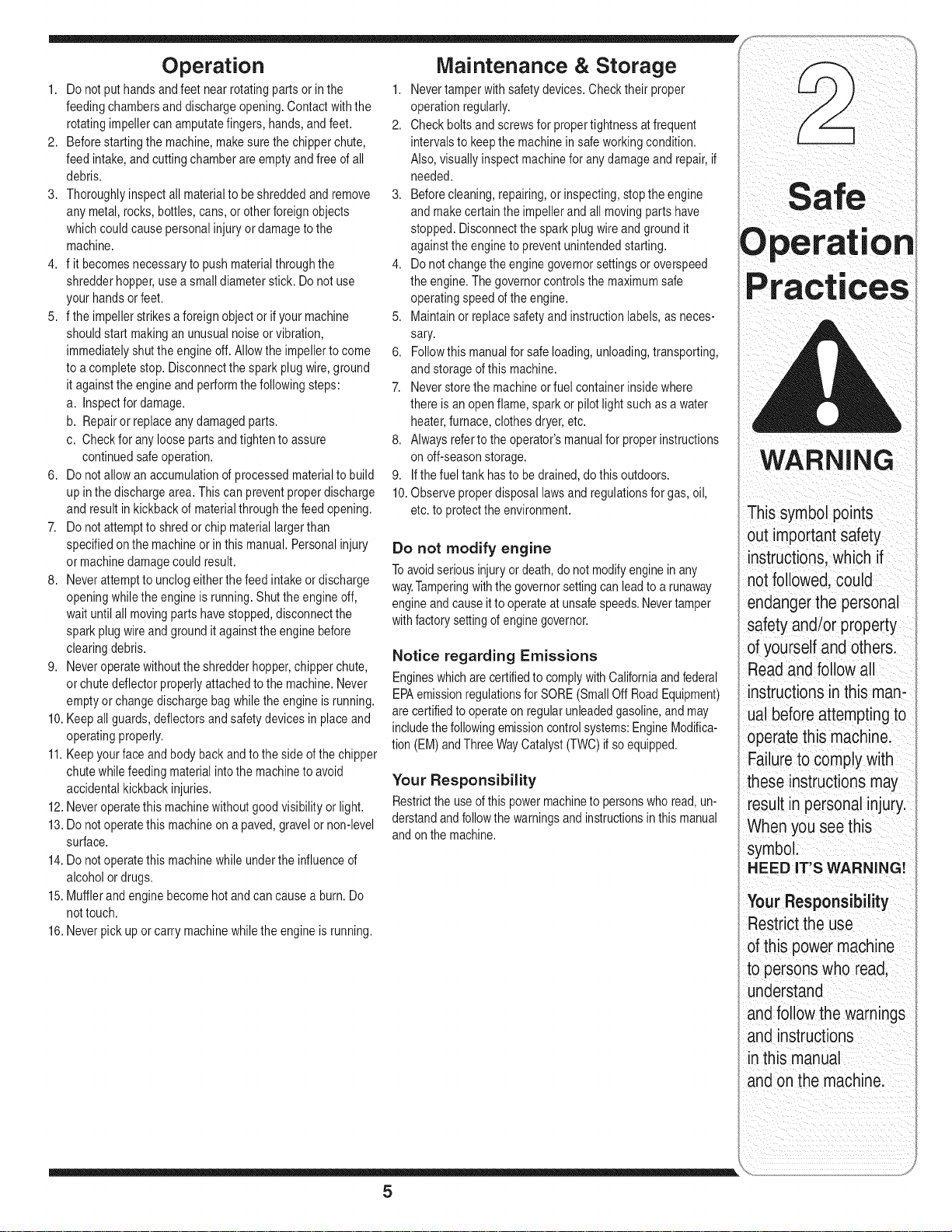

Figure 3=1

Figure 3-2

Attaching The Hopper

Assembly

1. a. Removesixhexnutsandwashersfromtheweld

studsonthe impellerhousing.Donotremovethe

supportplate.SeeFigure3-1.

b. Placehopperassemblyintopositioninfrontof

impellerhousing,aligningholesinhopperassembly

collarwithweldstuds.

c. Slidehopperassemblyontoweld studsandreplace

washersandhex nuts.Donottightencompletely.

2. a. Lift hopperassemblyupto impellerbracket

assembly.

b. Slidethe releaserodout slightlyto hookthehopper

bracketontothe rod.SeeFigure3-2.

c. Tightenthe sixhexnutsthatsecurehopper

assemblyto impellerhousingandalsotightenthe

hexnutsthatsecurehopperbrackettohopper

assembly.

NOTE:This Operators

i Manual coversarange

of product specifica-

tions for various

models.Characteristics

and featuresdiscussed

and/or illustratedinthis

manualmay not be ap-

plicableto allmodels.

MTD LLCreservesthe

rightto change product

specifications,designs

and equipmentwithout

notice andwithout

=ncurringobligation.

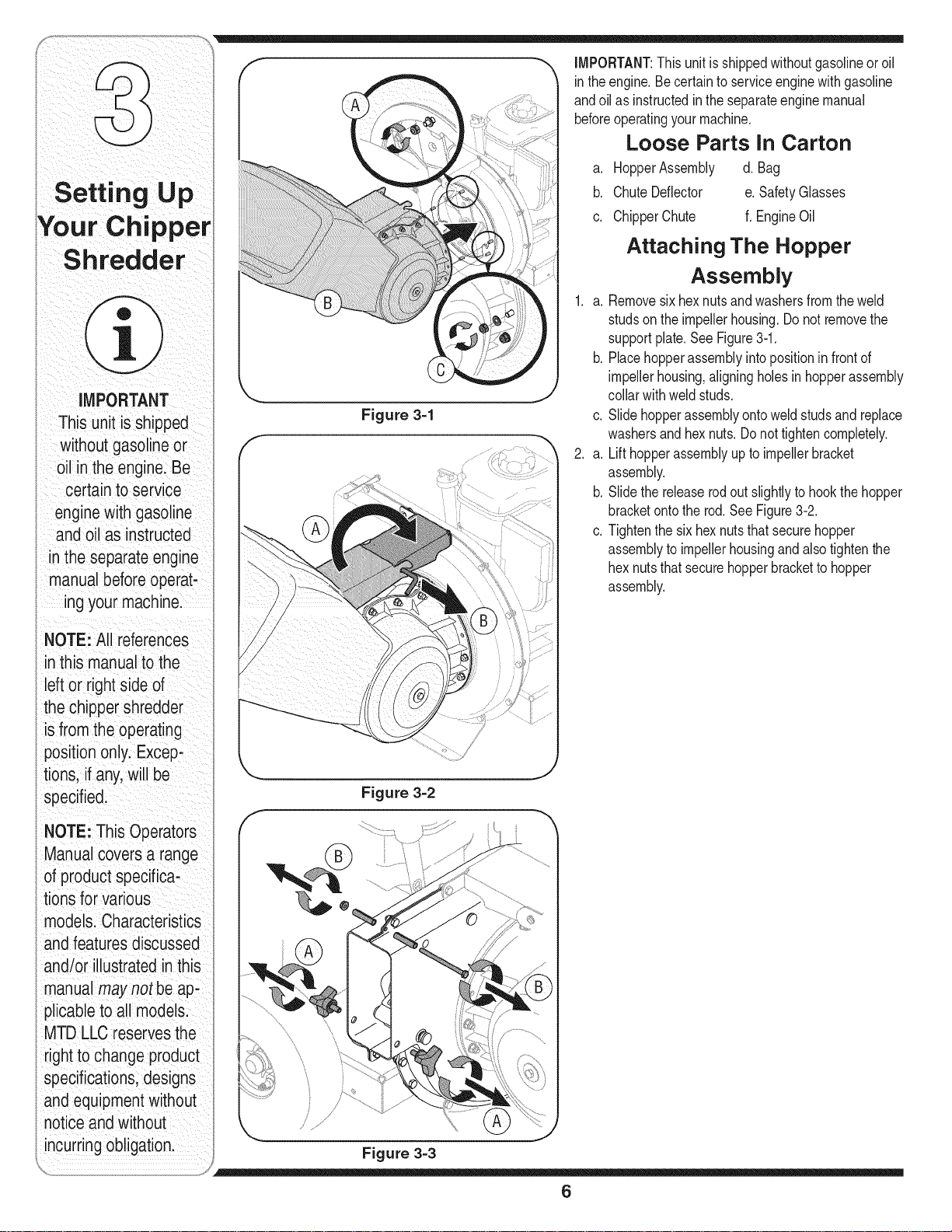

Figure 3-3

6

Attaching The Chute Deflector

3. a. Removethewingknobsfromeachsideofthelower

impellerhousing.

b. Removethehexlocknut,spacers,andhexboltfrom

thetopoftheimpellerhousing.SeeFigure3-3.

4. a. Alignthechutedeflectorinpositionon the

dischargeopeningand inserthexboltwithspacer

throughhingeon chutedeflector(spacersfitinside

of hinges).SeeFigure314.

b. Placesecondspaceroverhex boltinsideother

hingeandsecurewithhexlocknut.

c. Securebothsidesofchutedeflectorto impeller

housingusingwingknobspreviouslyremoved.

Attaching The Chipper Chute

(Model Series 460)

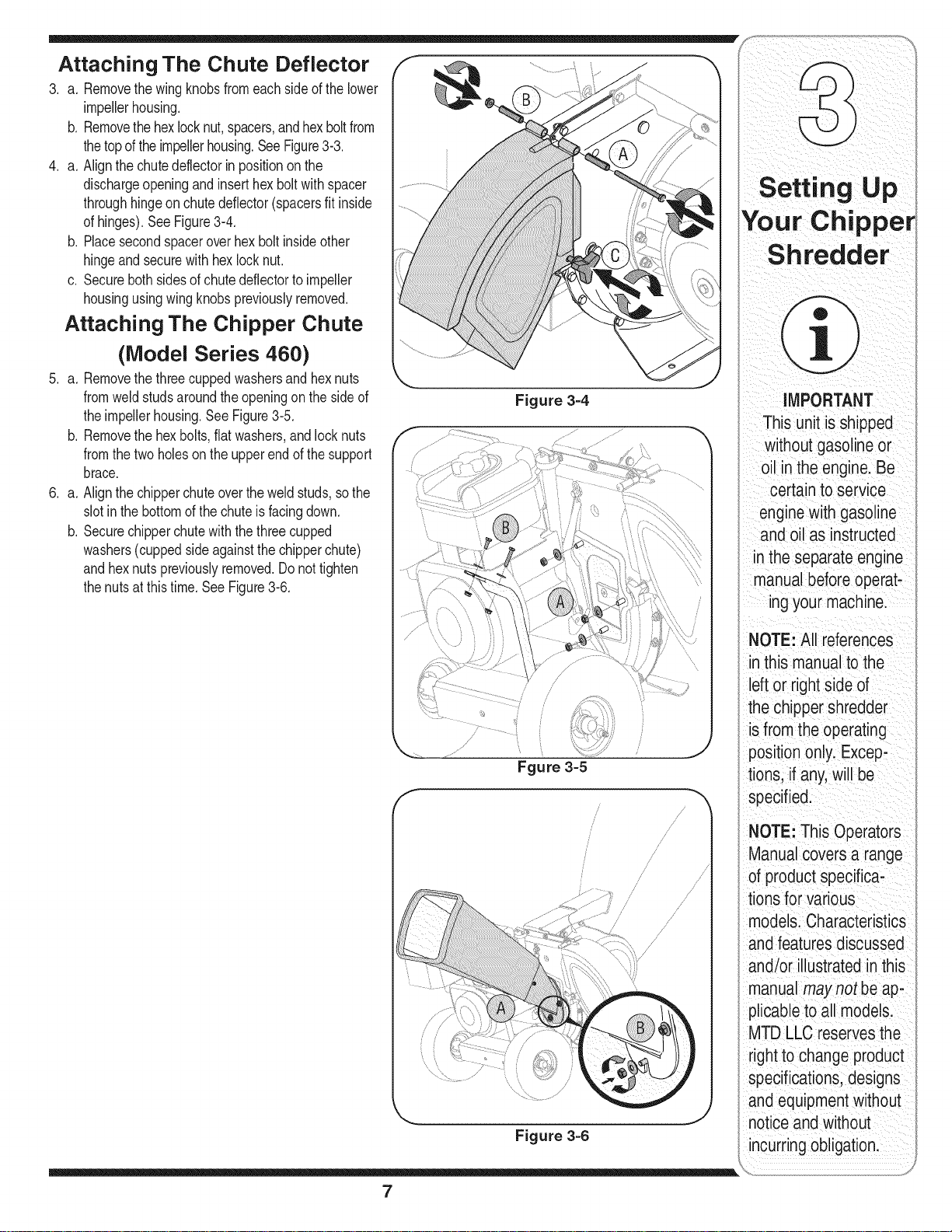

5. a. Removethethreecuppedwashersandhexnuts

fromweldstudsaroundtheopeningonthesideof

theimpellerhousing.SeeFigure3-5.

b. Removethehexbolts,flat washers,andlocknuts

fromthetwoholeson theupperendofthesupport

brace.

6. a. Alignthechipperchuteovertheweldstuds,sothe

slotinthebottomofthe chuteisfacingdown.

b. Securechipperchutewiththe threecupped

washers(cuppedsideagainstthe chipperchute)

and hexnutspreviouslyremoved.Do nottighten

thenutsat thistime.SeeFigure316.

Figure 3-4

Your Chipper

Sh redder

IMPORTANT

This unit is shipped

without gasolineor

oil in the engine. Be

certainto service

enginewith gasoline

and oil as instructed

in the separate engine

manual beforeoperat-

ingyour machine.

NOTE: All references

in this manualto the

leftor rightsideof

the chipper shredder

isfromthe operating

positiononly. Excep-

Fgure 3=5

f

/J

/

/

/ /

..........1,/

/

/

/

/

//

/

/

/

/

//

/

tions, if any, will be

specified.

NOTE: This Operators

Manual coversa range

of product specifica-

tionsfor various

models.Characteristics

andfeatures discussed

and/or illustrated inthis

manual may not be ap-

plicableto allmodels.

MTD LLC reservesthe

rightto change product

/

specifications,designs

and equipmentwithout

notice andwithout

Figure 3=6

_ncurringobligation.

7

Settingup

MPORTANT

This unitis shipped

without gasolineor

oil in the enginelae

certainto serv ce

enginewith gasoline

an_Joil as instructed

in the separateengine

manUaIbeforeope!at-

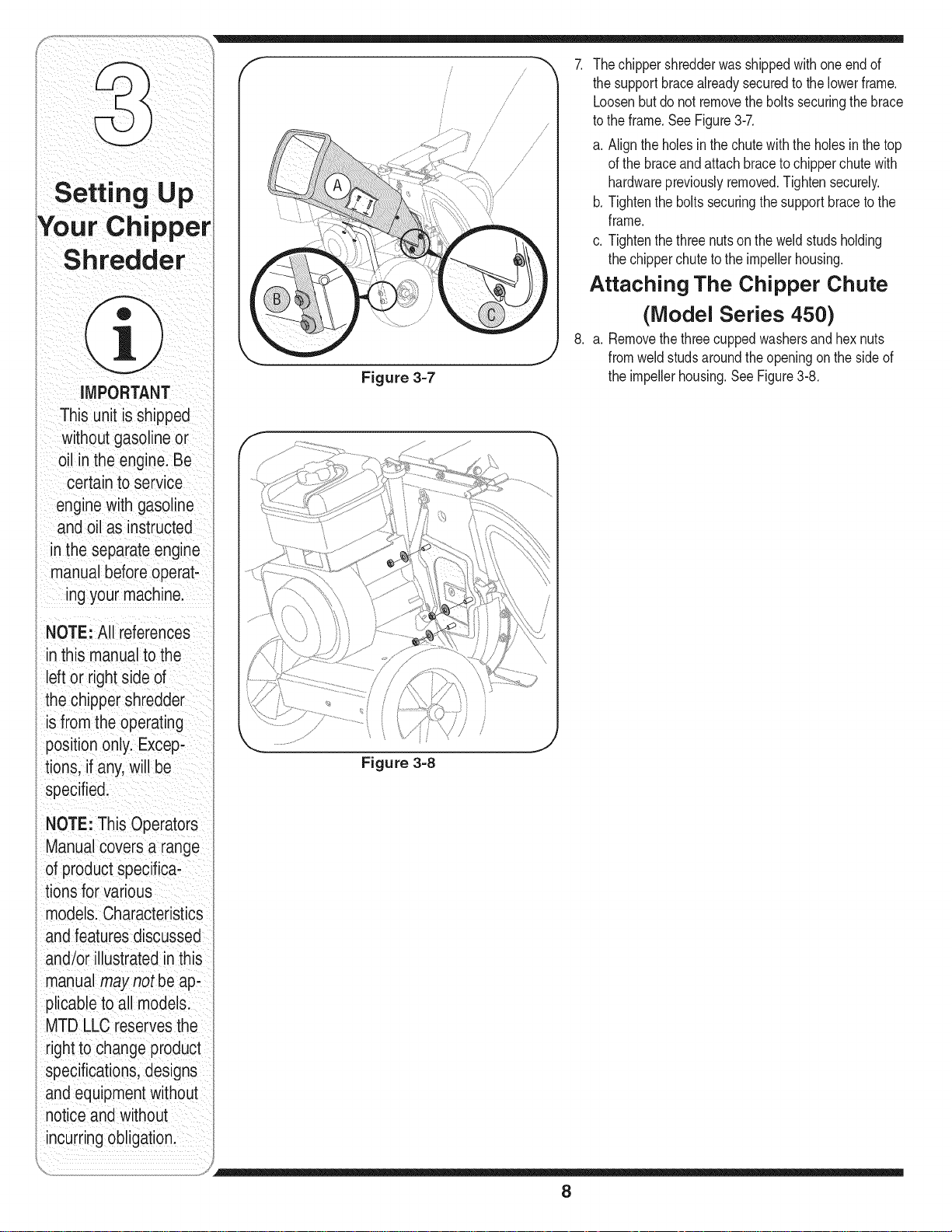

Figure 3-7

/

/

/

/

ji

//

// ///

//

/

7. Thechippershredderwasshippedwithoneendof

thesupportbracealreadysecuredtothelowerframe.

Loosenbutdo notremovetheboltssecuringthebrace

tothe frame.SeeFigure3-7.

a. Alignthe holesinthe chutewiththeholesinthetop

ofthe braceandattachbraceto chipperchutewith

hardwarepreviouslyremoved.Tightensecurely.

b. Tightenthe boltssecuringthesupportbracetothe

frame.

c. Tightenthethree nutson theweldstudsholding

thechipperchuteto the impellerhousing.

Attaching The Chipper Chute

(Model Series 450)

8. a. Removethethreecuppedwashersandhexnuts

fromweldstudsaroundtheopeningon thesideof

theimpellerhousing.SeeFigure3-8.

ingyour machine

NOTE: All references

in this manualtOthe

left orright side of

the chipper shredder

iSfromthe operating

positiononlylExcep;

tions,ifany, wIibe

specified:

i

NOTE: This Operators

ManUalcoversa range

Of productspecifiCa:

tionsfor Various

mode!s:Characteristics

and featuresdiscussed

andior ilUstratedinthiS

manual may not be ap,

plicabletoali models!

MTD LLC reservesthe

right tochange product

specificationsidesigns

Figure 3=8

andequipment wthout

notice and without

incurringobligationl

8

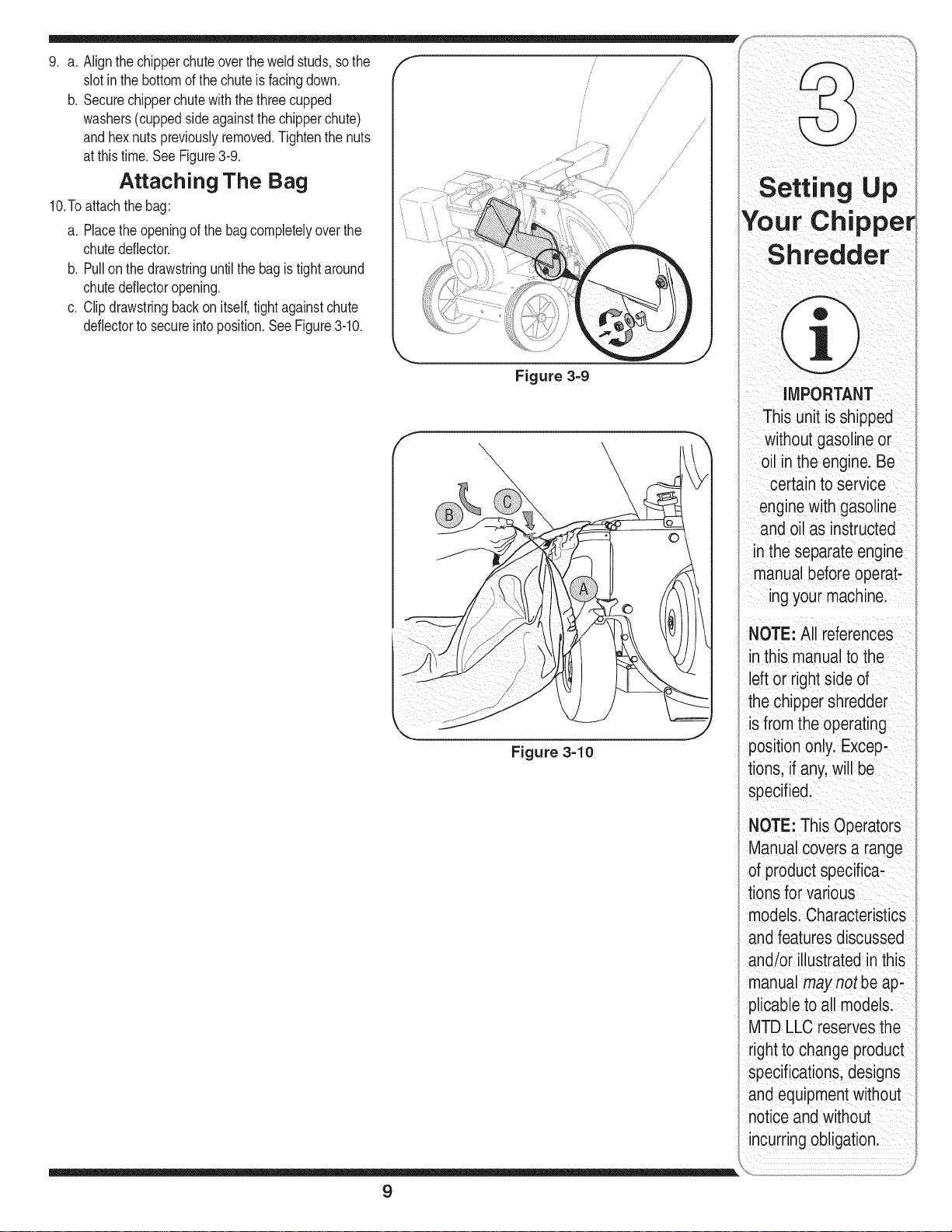

9. a. Alignthechipperchuteovertheweldstuds,sothe

slotinthebottomofthe chuteisfacingdown.

b. Securechipperchutewiththe threecupped

washers(cuppedsideagainstthe chipperchute)

and hexnutspreviouslyremoved.Tightenthenuts

atthis time.SeeFigure3-9.

Attaching The Bag

10.Toattachthe bag:

a. Placetheopeningof thebagcompletelyoverthe

chutedeflector.

b. Pullon the drawstringuntilthebagis tightaround

chutedeflectoropening.

c. Clipdrawstringbackon itself,tightagainstchute

deflectorto secureintoposition.SeeFigure3-10.

f

/

/

Setting Up

YourChippe

Shredder

Figure 3=9

Figure 3=10

MPORTANT

This unit iSshipped

without gaso ine or

oilin the enginelBe

Certain to service

engine with gasoline

and Oilas instrUCted

theseparate engine

manualbefore operati

ingyour machine:

NOTE: All references

this manual tothe

left or rightside of

thechipper shredder

isfromthe operating

position only. Excepi

tions, if any.will be

specified:

NOTE: This OPerators

ManUal covers a range

of product specifiCa,

tions for Various

models: CharacteriStics

andfeatures discussed

and/or iilustrated inthis

manual may notbe ap.

plicable to allmodels:

MTD LLC reservesthe

rightto Changeproduct

specifications; designs

and equipmentwithout

notice and w thout

incurr ng Obligationl

9

Operating

WARNING

The operation of any

chipper shredder

can resuffin foreign

objects being thrown

intothe eyes,which

candamageyour

eyesseverely. Always

wear the safety

glassesprovided

with this unit or eye

shields before chip-

i ping or shredding

and while performing

any adjustments or

repairs.

Use extreme care

when handling

i gasoline.Gasoline is

i extremely flammable

and the vapors are

explosive. Never fuel

i the machine indoors

or while the engine

is hot or running.

i Extinguish cigarettes,

cigars, pipes and

other sources of

ignition.

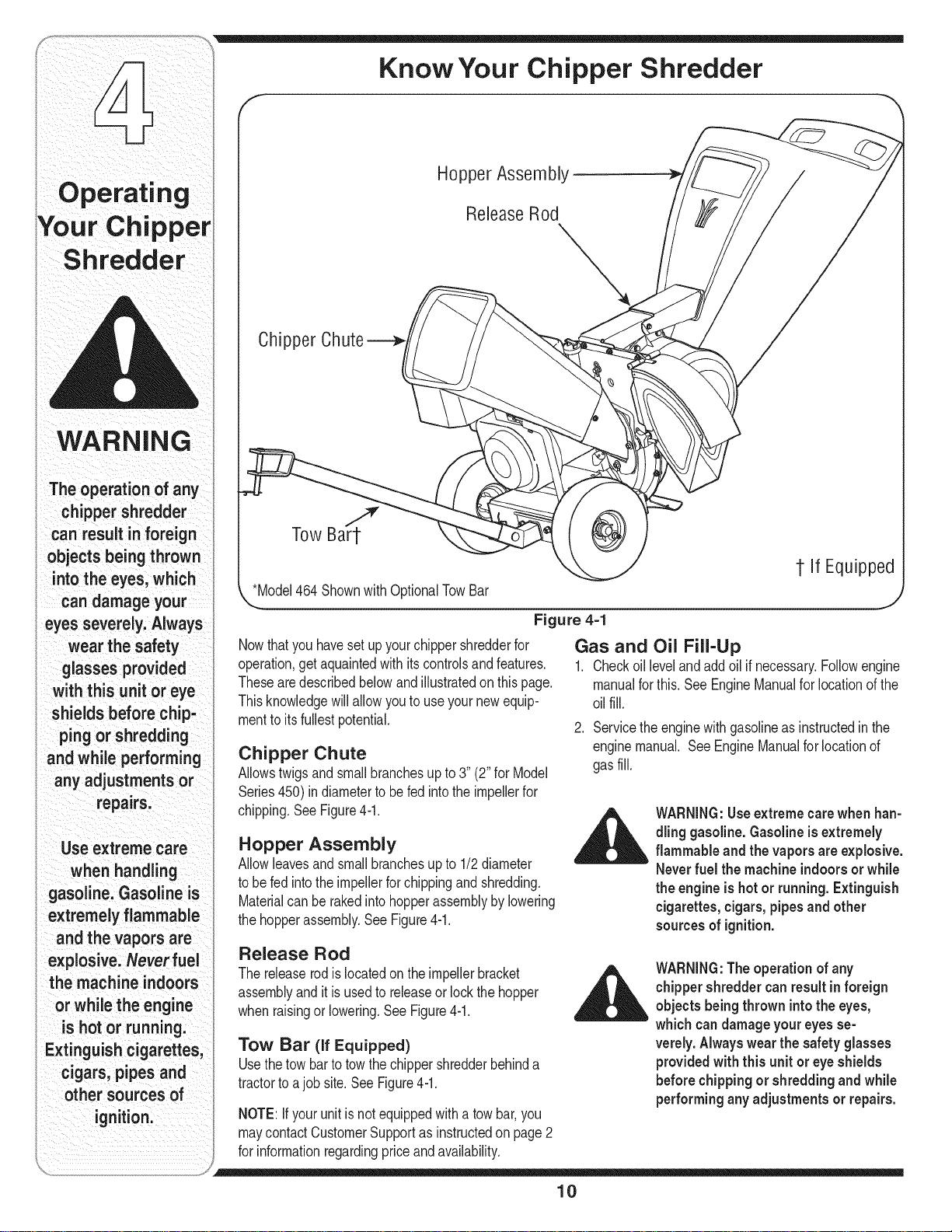

Know Your Chipper Shredder

HopperAssembly-

ReleaseRod

Chipper

*Model464Shownwith0 TowBar

Figure 4=1

Nowthatyouhavesetupyourchippershredderfor

operation,getaquaintedwithits controlsandfeatures.

Thesearedescribedbelowandillustratedonthis page.

Thisknowledgewillallowyouto useyournewequip-

mentto itsfullestpotential.

Chipper Chute

Allowstwigsandsmallbranchesupto 3"(2"for Model

Series450)indiameterto befedintothe impellerfor

chipping.SeeFigure4-1.

Hopper Assembly

Allowleavesandsmallbranchesupto 1/2diameter

tobefed intotheimpellerforchippingandshredding.

Materialcanbe rakedintohopperassemblybylowering

thehopperassembly.SeeFigure4-1.

Release Rod

Thereleaserodislocatedon the impellerbracket

assemblyandit is usedto releaseorlockthe hopper

whenraisingor lowering.See Figure4-1.

Tow Bar (if Equipped)

Usethetow barto towthechippershredderbehinda

tractorto ajobsite.See Figure4-1.

NOTE:Ifyour unitisnotequippedwitha towbar,you

maycontactCustomerSupportasinstructedon page2

forinformationregardingpriceandavailability.

@

1-If Equipped

Gas and Oil Fill-Up

1. Checkoillevelandaddoil if necessary.Followengine

manualforthis.SeeEngineManualforlocationofthe

oilfill.

2. Servicethe enginewithgasolineasinstructedinthe

enginemanual. SeeEngineManualforlocationof

gasfill.

WARNING:Useextremecarewhenhan-

dling gasoline.Gasolineis extremely

flammableand the vapors areexplosive.

NeverfueJthe machine indoorsor while

the engine is hot or running. Extinguish

cigarettes, cigars, pipesandother

sources of ignition.

WARNING:Theoperation of any

chippershredder canresultinforeign

objects being thrown intothe eyes,

which candamage your eyesse-

verely.Always wearthe safety glasses

providedwith this unit or eyeshields

before chippingor shredding andwhile

performingany adjustments or repairs.

10

ThisOperatorsManualcoversa rangeof product /" _

specificationsforvariousmodels.Characteristicsandfea- _ //1

turesdiscussedand/orillustratedinthismanualmaynot _,,= _ //[

be applicabletoallmodels.MTDLLCreservestheright ._ _IiI_

tochangeproductspecifications,designsandequipment _

withoutnoticeandwithoutincurringobligation.

Starting Engine (

Operat.ing

¥o

flARNING: Neverrun the engine

indoorsor in a poorlyventilatedarea.

Engine exhaustcontainscarbonmonox-

ide,an odorless and deadly gas.

IMPORTANT:Becausethismanualcoversseveral

differentmodelunits,differentstartinginstructionsmay

applyto yourparticularengine.Someenginesmayhave

a fuelpetcock,somemaynot.Someenginesmayhave

On/Offswitches,othermaynot.Someunitswill utilizea

chokesystem,whileotherswill requirepriming. These

factorsdependon whatmakeandmodelenginecomes

withyourparticularunit.For thesereasons,pleaserefer

tothe engineoperator'smanualforthecorrectstarting

procedure.

1. Attachsparkplugwireto sparkplug.Makecertain

themetalcap on theend of thesparkplugisfastened

securelyoverthemetaltip onthesparkplug.

2. Engines with choke lever:

Movechokeleveronengineto CHOKEposition.(A

warmenginemaynotrequirechoking).

Engineswith primer:

Primeengineasinstructedinseparateenginemanual.

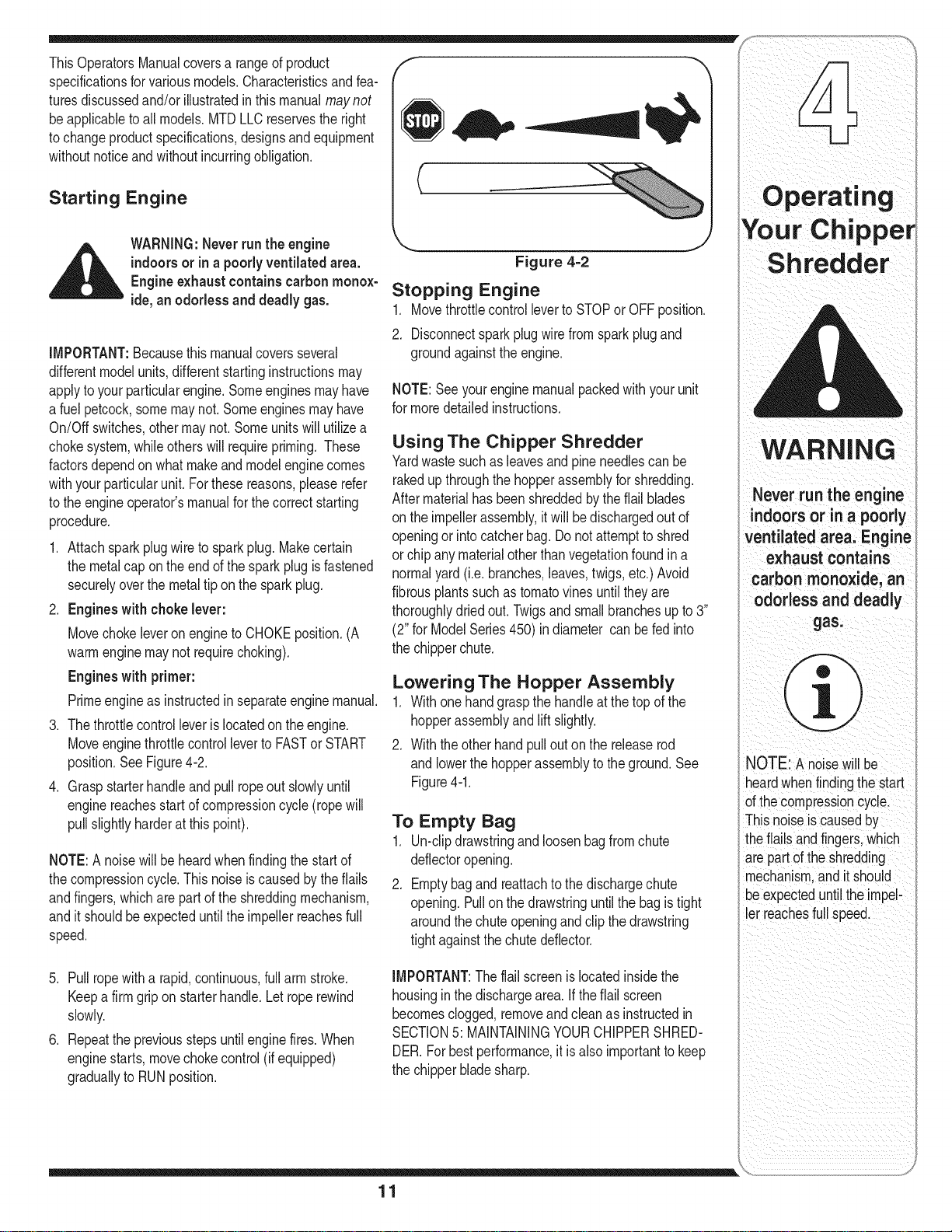

3. The throttlecontrolleverislocatedonthe engine.

MoveenginethrottlecontrollevertoFASTorSTART

position.SeeFigure4-2.

4. Graspstarterhandleand pullropeout slowlyuntil

enginereachesstartof compressioncycle(ropewill

pull slightlyharderatthis point).

NOTE:A noisewillbeheardwhenfindingthestartof

thecompressioncycle.Thisnoiseiscausedby theflails

andfingers,whichare partofthe shreddingmechanism,

and itshouldbeexpecteduntiltheimpellerreachesfull

speed.

Stopping Engine

1. Movethrottlecontrolleverto STOPorOFFposition.

2. Disconnectsparkplugwirefromsparkplugand

groundagainsttheengine.

NOTE:Seeyourenginemanualpackedwithyour unit

formoredetailedinstructions.

Using The Chipper Shredder

Yardwastesuchas leavesandpineneedlescanbe

rakedupthroughthehopperassemblyfor shredding.

Aftermaterialhasbeenshreddedbythe flailblades

ontheimpellerassembly,itwillbedischargedoutof

openingor intocatcherbag.Donotattemptto shred

orchipanymaterialotherthanvegetationfoundina

normalyard(i.e.branches,leaves,twigs,etc.)Avoid

fibrousplantssuchastomatovinesuntiltheyare

thoroughlydriedout. Twigsandsmallbranchesupto 3"

(2"forModelSeries450) indiameter canbefedinto

thechipperchute.

Lowering The Hopper Assembly

1. Withonehandgraspthehandleat thetop ofthe

hopperassemblyandlift slightly.

2. Withtheotherhandpullout onthe releaserod

andlowerthe hopperassemblytothe ground.See

Figure4-1.

To Empty Bag

1. Un-clipdrawstringand loosenbagfromchute

deflectoropening.

2. Emptybagandreattachtothedischargechute

opening.Pullonthe drawstringuntilthebagistight

aroundthechuteopeningandclip thedrawstring

tightagainstthechutedeflector.

Figure 4=2

WARNING

. vorr.°t,oe°g oo

indoorsor in a poorly

Ventilated area: Engine

exhaust contains

carbon monoxide, an

odorless and deadly

NOTE:A noisewillbe

heardwhenfindingthestart

ofthe compressioncycle.

Thisnoiseis causedby

theflailsandfingers,which

arepartoftheshredding

mechanism,andit should

L_eexpecteduntilthe impel-

er reachesfullspeed.

5. Pullropewitha rapid,continuous,fullarm stroke.

Keepa firmgriponstarterhandle.Letroperewind

slowly.

6. Repeatthepreviousstepsuntilenginefires.When

enginestarts,movechokecontrol(if equipped)

graduallyto RUNposition.

IMPORTANT:The flailscreenislocatedinsidethe

housinginthe dischargearea.if theflail screen

becomesclogged,removeandcleanasinstructedin

SECTION5: MAINTAININGYOURCHIPPERSHRED-

DER.Forbestperformance,itisalsoimportantto keep

thechipperbladesharp.

11

Loading...

Loading...