Page 1

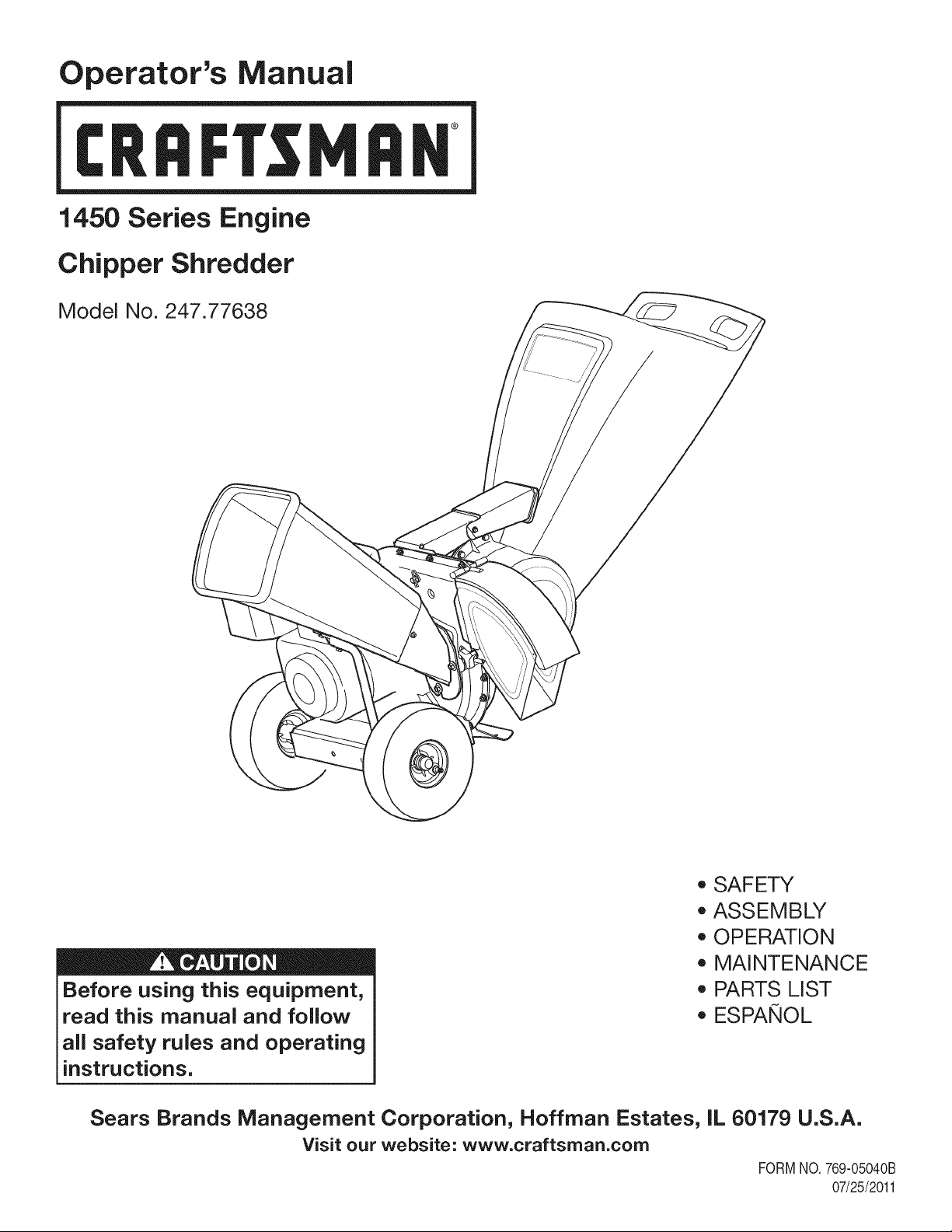

Operator's Manual

I:Rl FI'SlVl N

1450 Series Engine

Chipper Shredder

Model No. 247.77638

* SAFETY

* ASSEMBLY

* OPERATION

* MAINTENANCE

Before using this equipment,

read this manual and follow

all safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, iL 60179 U.S.A.

Visit our website: www.craftsman.com

* PARTS LIST

* ESPANOL

FORMNO.769-05040B

07/25/2011

Page 2

WarrantyStatement..................................Pac

SafeOperationPractices..........................Pac

SafetyLabels............................................Pac

Assembly..................................................Pac

Operation..................................................Pac

ServiceandMaintenance.........................Pac

Off-SeasonStorage..................................Pac

CRAFTSMAN TWO YEAR FULL WARRANTY

FORTWOYEARSfromthe dateof purchase,thisproductis warrantedagainstany

defectsin materialor workmanship.Adefectiveproductwill receivefreerepairor

replacementif repairisunavailable.

Forwarrantycoveragedetailstoobtainfreerepairor replacement,visitthewebsite:

www.craftsman.com

ThiswarrantycoversONLYdefectsin materialandworkmanship.Warrantycoverage

doesNOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarranty

period,suchas theblades, sparkplug,aircleaner,flail screenandcatcher

bag.

e2

e3

e7

e8

e12

e14

e18

TroubleShooting.......................................Page19

PartsList...................................................Page20

LabelMap.................................................Page31

RepairProtectionAgreement...................Page34

Espa_ol.....................................................Page35

ServiceNumbers......................................BackCover

Productdamageresultingfromuserattemptsatproductmodificationor

repairorcausedbyproductaccessories.

Repairsnecessarybecauseof accidentorfailuretooperateor maintainthe

productaccordingtoall suppliedinstructions.

• Preventivemaintenance,orrepairsnecessarydueto improperfuelmixture,

contaminatedor stalefuel.

Thiswarrantyisvoidif this productisever usedwhileprovidingcommercialservicesor if

Thiswarrantygivesyou specificlegalrights,andyou mayalsohaveotherrightswhich

Sears Brands ManagementCorporation, Hoffman Estates,IL60179

EngineSeries: 1450

EngineOilType: SAE30

EngineOilCapacity: 28ounces

Fuel: UnleadedGasoline

SparkPlug: Champion®RC-12YC

SparkPlugGap: .030"

rentedtoanotherperson.

varyfromstateto state.

Model Number.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

KCDIRLLC 2

Page 3

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthe personalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothe safeopera-

tionpracticesinthismanual.Aswithanytypeof powerequipment,

carelessnessorerroronthepart ofthe operatorcan resultin

seriousinjury.Thismachineis capableof amputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethefollowing

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknownto StateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm.

TRAINING

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingto assembleandoperate.

Keepthis manualina safeplaceforfutureand regularreference

andfororderingreplacementparts.

• Readthe Operator'sManualand followallwarningsand safety

instructions.Failuretodosocan resultin seriousinjuryto the

operatorand/orbystanders.

• Befamiliarwithall controlsandtheir properoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder16yearsofageto operatethis

machine.Children16andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultsto operatethismachinewithoutproper

instruction.

• Keepbystanders,pets,andchildrenatleast75feetfromthe

machinewhileit isin operation.Stopmachineifanyoneenters

thearea.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Donot puthandsandfeetnearrotatingpartsor inthefeeding

chambersanddischargeopening.Contactwiththe rotating

impellercanamputatefingers,hands,andfeet.

• Neverattempttounclogeitherthe feedintakeordischarge

opening,removeor emptybag,or inspectandrepairthe machine

whilethe engineisrunning.Shutthe engineoff andwaituntilall

movingpartshavecometo a completestop.Disconnectthespark

plugwireandgroundit againsttheengine.

Your Responsibility--Restrict theuseofthispowermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsinthismanualandon the machine.

SAVETHESEINSTRUCTIONS!

PREPARATION

• Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall rocks,bottles,cans,or otherforeignobjectswhich

couldbepickedupor thrownandcausepersonalinjuryor

damageto themachine.

• Alwayswearsafetyglassesorsafetygogglesduringoperation

andwhileperformingan adjustmentor repair,to protectyour

eyes.Thrownobjectswhichricochetcancauseseriousinjuryto

theeyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesorjewelrycan becaughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.Wear

leatherworkgloveswhenfeedingmaterialinthe chipperchute.

• Beforestarting,checkallboltsandscrewsforpropertightnessto

besurethe machineisinsafeworkingcondition.Also,visually

inspectmachineforany damageatfrequentintervals.

• Maintainor replacesafetyandinstructionslabels,asnecessary.

3

Page 4

SafeHandling of Gasoline:

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Neverfillcontainersinsidea vehicleor ona truckortrailerbed

witha plasticliner.Alwaysplacecontainersonthe groundaway

fromyourvehiclebeforefilling.

• Whenpractical,removegas-poweredequipmentfromthe truck

ortrailerand refuelitonthe ground.Ifthisis notpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

• Keepthenozzleincontactwiththe rimof thefuel tankor

containeropeningatalltimes untilfuelingiscomplete.Donotuse

a nozzlelock-opendevice.

• Extinguishallcigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuelmachineindoors.

• Neverremovegascapor addfuelwhiletheengineishotor run-

ning.Allowenginetocool atleasttwo minutesbeforerefueling.

• Neveroverfill fueltank. Filltankto nomorethan1/2inchbelow

bottomoffillerneckto allowspacefor fuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitoff theengineandequipment.Move

unitto anotherarea.Wait5 minutesbeforestartingtheengine.

• Toreducefirehazards,keepmachinefreeofgrass, leaves,or

otherdebrisbuild-up.Cleanupoil orfuelspillageand removeany

fuelsoakeddebris.

• Neverstorethemachineorfuel containerinsidewherethereisan

openflame,sparkor pilotlightas on awaterheater,spaceheater,

furnace,clothesdryer orothergas appliances.

OPERATION

• Donot puthandsandfeetnearrotatingpartsor in thefeeding

chambersanddischargeopening.Contactwiththe rotating

impellercanamputatefingers,hands,andfeet.

• Beforestartingthemachine,makesurethe chipperchute,feed

intake,andcuttingchamberare emptyandfreeof all debris.

• Thoroughlyinspectall materialtobe shreddedandremoveany

metal,rocks,bottles,cans,or otherforeignobjectswhichcould

causepersonalinjuryor damagetothemachine.

• If itbecomesnecessaryto pushmaterialthroughtheshredder

hopper,usea smalldiameterstick. Donotuseyour handsorfeet.

• Iftheimpellerstrikesa foreignobjectorifyourmachineshould

startmakinganunusualnoiseorvibration,immediatelyshut

theengineoff. Allowthe impellerto cometoa completestop.

Disconnectthesparkplugwire,grounditagainsttheengineand

performthefollowingsteps:

a. Inspectfor damage.

b. Repairor replaceanydamagedparts.

c. Checkforanyloosepartsandtightento assurecontinued

safeoperation.

• Donotallowanaccumulationof processedmaterialto buildupin

thedischargearea.Thiscanpreventproperdischargeandresult

inkickbackof materialthroughthefeedopening.

• Donotattempttoshredorchipmateriallargerthanspecified

on themachineorinthis manual.Personalinjuryor machine

damagecouldresult.

• Neverattempttounclogeitherthefeedintakeor discharge

openingwhilethe engineisrunning.Shuttheengineoff,waituntil

all movingpartshavestopped,disconnectthesparkplugwireand

grounditagainsttheenginebeforeclearingdebris.

• Neveroperatewithouttheshredderhopper,chipperchute,or

chutedeflectorproperlyattachedtothe machine.Neveremptyor

changedischargebagwhiletheengineis running.

• Keepallguards,deflectorsand safetydevicesinplaceand

operatingproperly.

• Keepyourfaceandbodybackandtothe sideof thechipper

chutewhilefeedingmaterialintothemachineto avoidaccidental

kickbackinjuries.

• Neveroperatethismachinewithoutgoodvisibilityorlight.

• Donotoperatethismachineona paved,gravelor non-level

surface.

• Donotoperatethismachinewhileundertheinfluenceof alcohol

or drugs.

• Mufflerandenginebecomehotandcancausea burn.Donot

touch.

• Neverpick uporcarrymachinewhiletheengineisrunning.

• Ifsituationsoccurwhichare notcoveredinthismanual,usecare

andgoodjudgement.Contact1-800-4-MY-HOMEfor thelocation

ofthe nearestSearsParts& RepairServiceCenter.

MAINTENANCE & STORAGE

• Nevertamperwith safetydevices.Checktheirproperoperation

regularly.

• Checkboltsandscrewsfor propertightnessat frequentintervals

to keepthemachineinsafeworkingcondition.Also,visually

inspectmachinefor anydamageandrepair,ifneeded.

• Beforecleaning,repairing,or inspecting,stoptheengineand

makecertaintheimpellerandall movingpartshavestopped.

Disconnectthesparkplugwireandgrounditagainsttheengine

to preventunintendedstarting.

• Donotchangetheenginegovernorsettingsoroverspeedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

4

Page 5

• Maintainor replacesafetyandinstructionlabels,asnecessary.

Followthismanualforsafeloading,unloading,transporting,and

storageof thismachine.

Neverstorethemachineorfuel containerinsidewherethereisan

openflame,sparkorpilot lightsuchas a waterheater,furnace,

clothesdryer,etc.

Allowmachinetocoolat least5 minutesbeforestoring.

• Alwaysrefertothe operator'smanualforproperinstructionson

off-seasonstorage.

• If thefuel tankhasto bedrained,dothisoutdoors.

• Observeproperdisposallawsand regulationsforgas,oil,etc.to

protecttheenvironment.

• Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeofseven(7)years,or 60hoursof

operation.At theendof theAverageUsefulLife havethe machine

inspectedannuallybyan authorizedservicedealerto ensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failuretodosocanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyenginein anyway.

Tamperingwiththegovernorsettingcan leadto a runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(CO),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brushcoveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any)

Ifa sparkarrestorisused,it shouldbe maintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorforthe muffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

Page 6

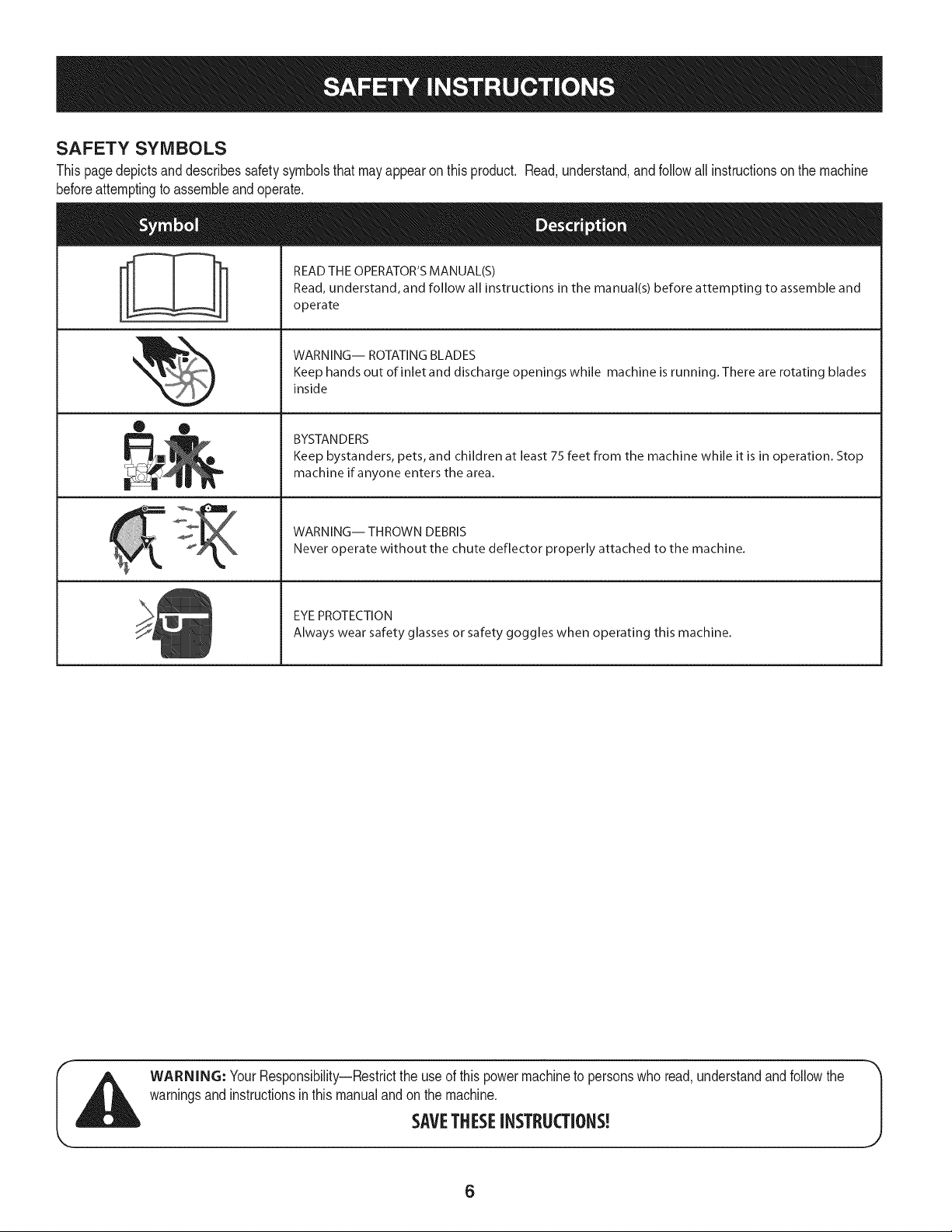

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

• ®

il

BYSTANDERS

Keep bystanders, pets, and children at least 75 feet from the machine while it is in operation. Stop

machine if anyone enters the area.

WARNING-- THROWN DEBRIS

Never operate without the chute deflector properly attached to the machine.

EYEPROTECTION

Always wear safety glasses orsafety goggles when operating this machine.

warningsand instructionsinthis manualandonthe machine.

I_ ARNING: YourResponsibility--Restrictthe useof this powermachineto personswho read,understandandfollowthe

SAVETHESEINSTRUCTIONS!

6

J

Page 7

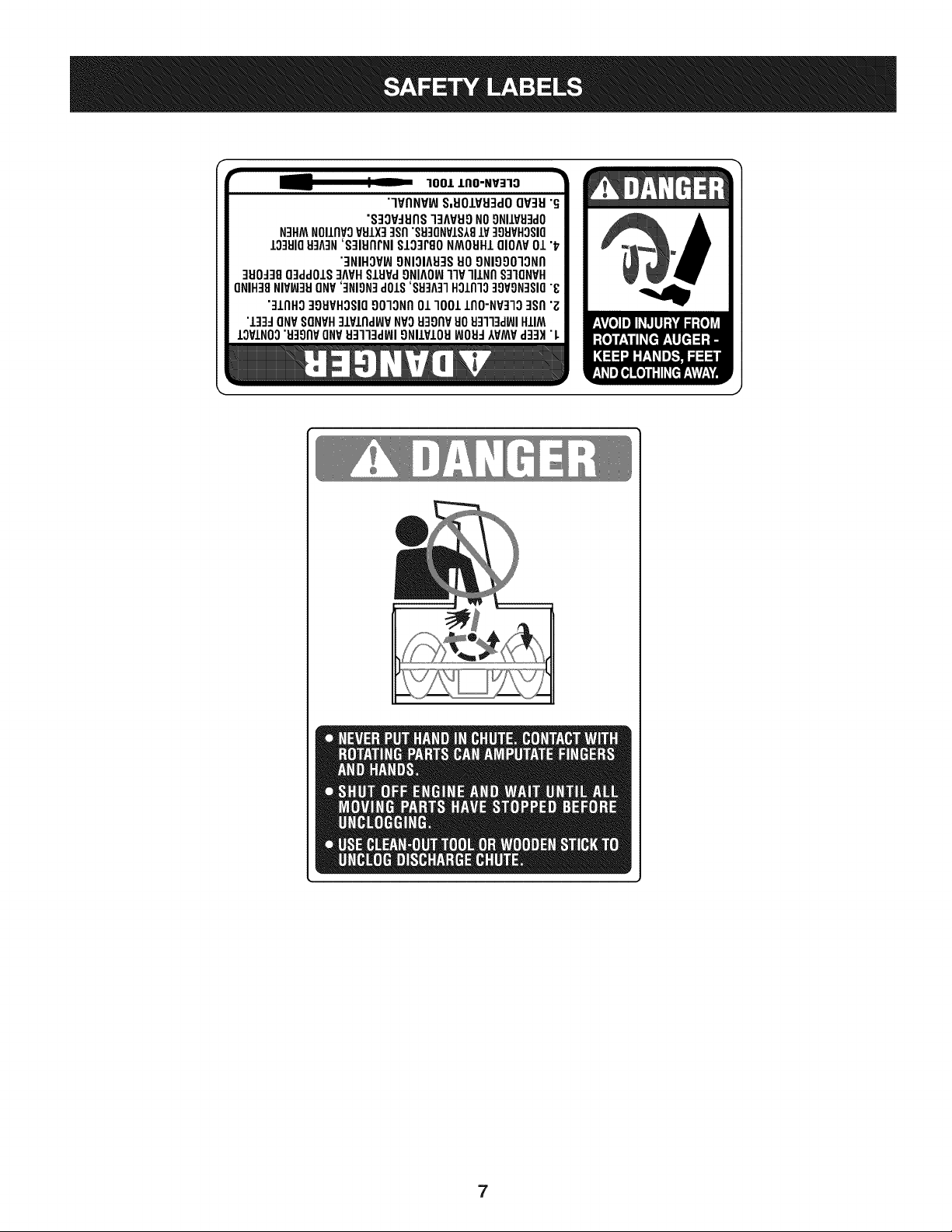

r

100/.LIIO-NV:IIO

"lVflNV_ S,UOIVU3dOQV3H"G

"S3OV_IJflS]3AVUONO9NIIV_J3dO

N3HMNOIIflVOVSIX]qsfl"S9]ONVIS181V]98VHOSIO

10381083A3N'S]IUflrNI SI03PgoNMOUHIQIOAV01 "_

"3NIHOV_ONIOIA83SUOONIOOO]ONfl

]UO_38O3ddOIS]AVHSlHPd9NIAOW11VlllNfl S]IQNVH

ONIH]8NIVW3UONV']NION]dOlS'88]A]1HOlnlo]9VON]SIO"8

"]lnHg ]gHVHOSIO9010Nfl01 1001lflO-NP]lO ]Sfl "Z

"l]]d ONVSONVH]lPlnd_P NVOH3onvuoHq]l]d_JIHIIM

IOVINO0"u39npONV_J3113dWI9NllVIOU_JOH_IVMVd]3H "L

7

Page 8

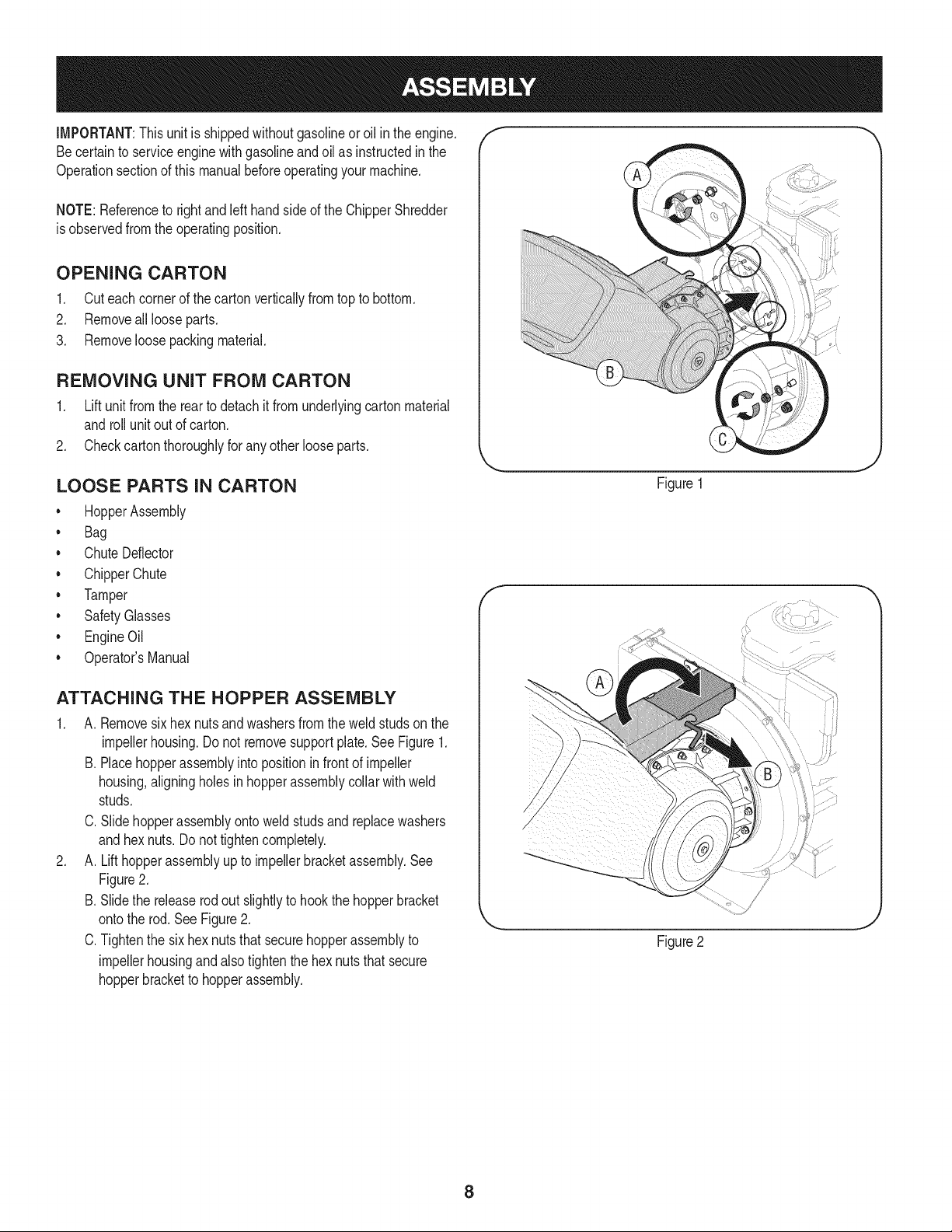

IMPORTANT:Thisunitisshippedwithoutgasolineoroil intheengine.

Becertaintoserviceenginewithgasolineandoilas instructedinthe

Operationsectionof this manualbeforeoperatingyourmachine.

NOTE:Referenceto rightandlefthandsideoftheChipperShredder

isobservedfromthe operatingposition.

OPENING CARTON

1. Cuteachcornerofthecartonverticallyfromtopto bottom.

2. Removeall looseparts.

3. Removeloosepackingmaterial.

REMOVING UNiT FROM CARTON

1. Liftunitfromthereartodetachitfromunderlyingcartonmaterial

androllunitout ofcarton.

2. Checkcartonthoroughlyforanyotherlooseparts.

LOOSE PARTS IN CARTON

• HopperAssembly

• Bag

• ChuteDeflector

• ChipperChute

• Tamper

• SafetyGlasses

• EngineOil

• Operator'sManual

f

J

Figure1

f

ATTACHING THE HOPPER ASSEMBLY

1. A. Removesixhex nutsandwashersfromthe weldstudson the

impellerhousing.Donotremovesupportplate.SeeFigure1.

B. Placehopperassemblyinto positioninfrontofimpeller

housing,aligningholesinhopperassemblycollarwithweld

studs.

C. Slidehopperassemblyontoweldstudsand replacewashers

andhexnuts.Donottightencompletely.

2. A. Lifthopperassemblyuptoimpellerbracketassembly.See

Figure2.

B.Slidethe releaserodout slightlyto hookthe hopperbracket

ontothe rod.SeeFigure2.

C.Tightenthesixhex nutsthatsecurehopperassemblyto

impellerhousingandalsotightenthe hexnutsthat secure

hopperbracketto hopperassembly.

Figure2

8

Page 9

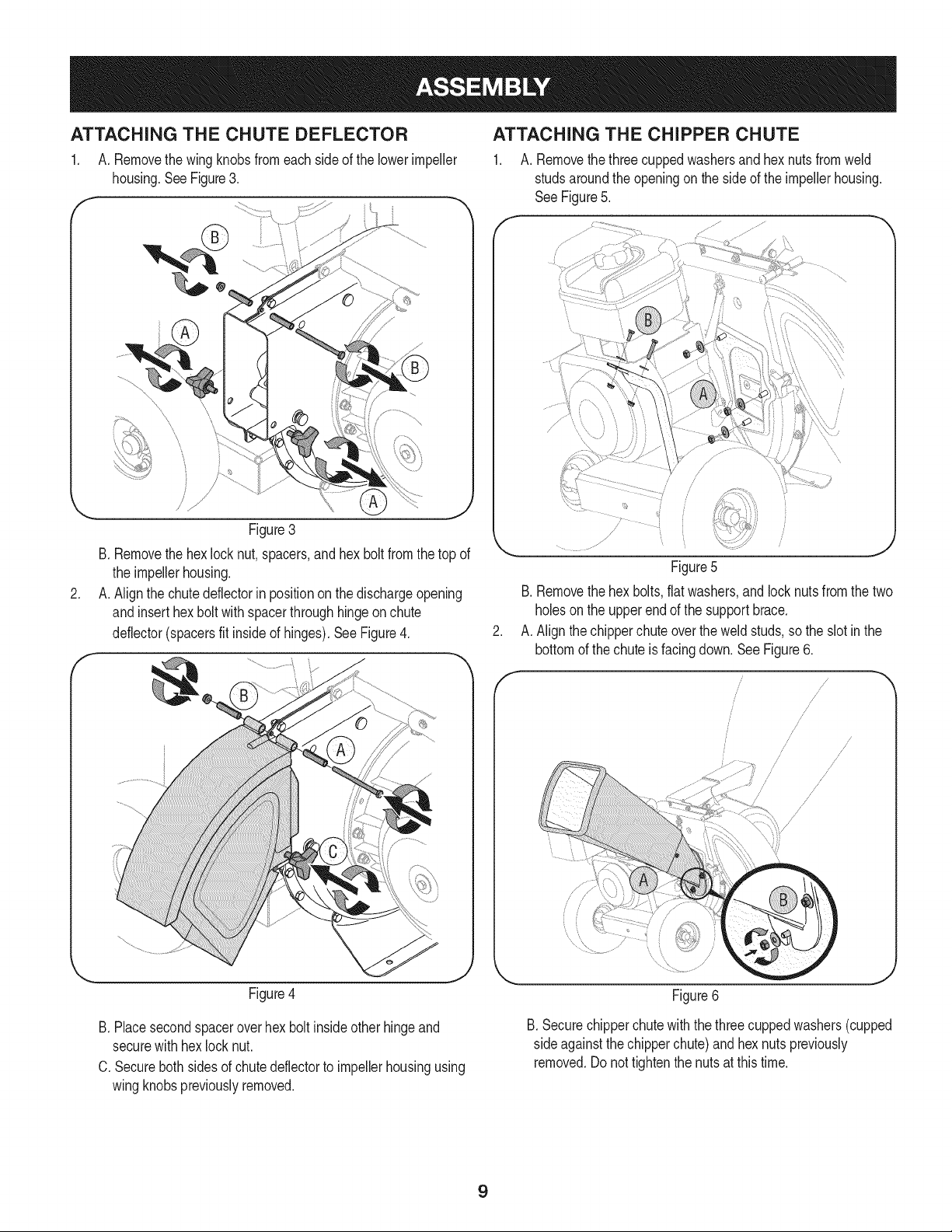

ATTACHING THE CHUTE DEFLECTOR

1. A. Removethewingknobsfromeachsideof thelowerimpeller

housing.SeeFigure3.

Figure3

B.Removethehexlocknut,spacers,andhexboltfromthetopof

theimpellerhousing.

.

A.Alignthe chutedeflectorinpositiononthe dischargeopening

andinserthexbolt withspacerthroughhingeonchute

deflector(spacersfit insideofhinges).SeeFigure4.

f

ATTACHING THE CHIPPER CHUTE

1. A. Removethe threecuppedwashersand hexnutsfromweld

studsaroundtheopeningontheside ofthe impellerhousing.

SeeFigure5.

Figure5

B.Removethehex bolts,flatwashers andlocknutsfromthetwo

holesonthe upperendofthe supportbrace.

A.Alignthechipperchuteovertheweldstuds,sothe slotinthe

bottomofthechuteis facingdown.SeeFigure6.

f

i

i

/

i

/

/

/ i"

/ ,/

/ /s

/

/

/

/

/

/

/

/

/

/ /

i

/

/

/

J

Figure4

B.Placesecondspaceroverhex boltinsideotherhingeand

securewithhexlocknut.

C. Securebothsidesofchutedeflectorto impellerhousingusing

wingknobspreviouslyremoved.

/

/ ,

/ /

J

Figure6

B.Securechipperchutewiththethreecuppedwashers(cupped

sideagainstthe chipperchute)andhex nutspreviously

removed.Donottightenthe nutsatthistime.

9

Page 10

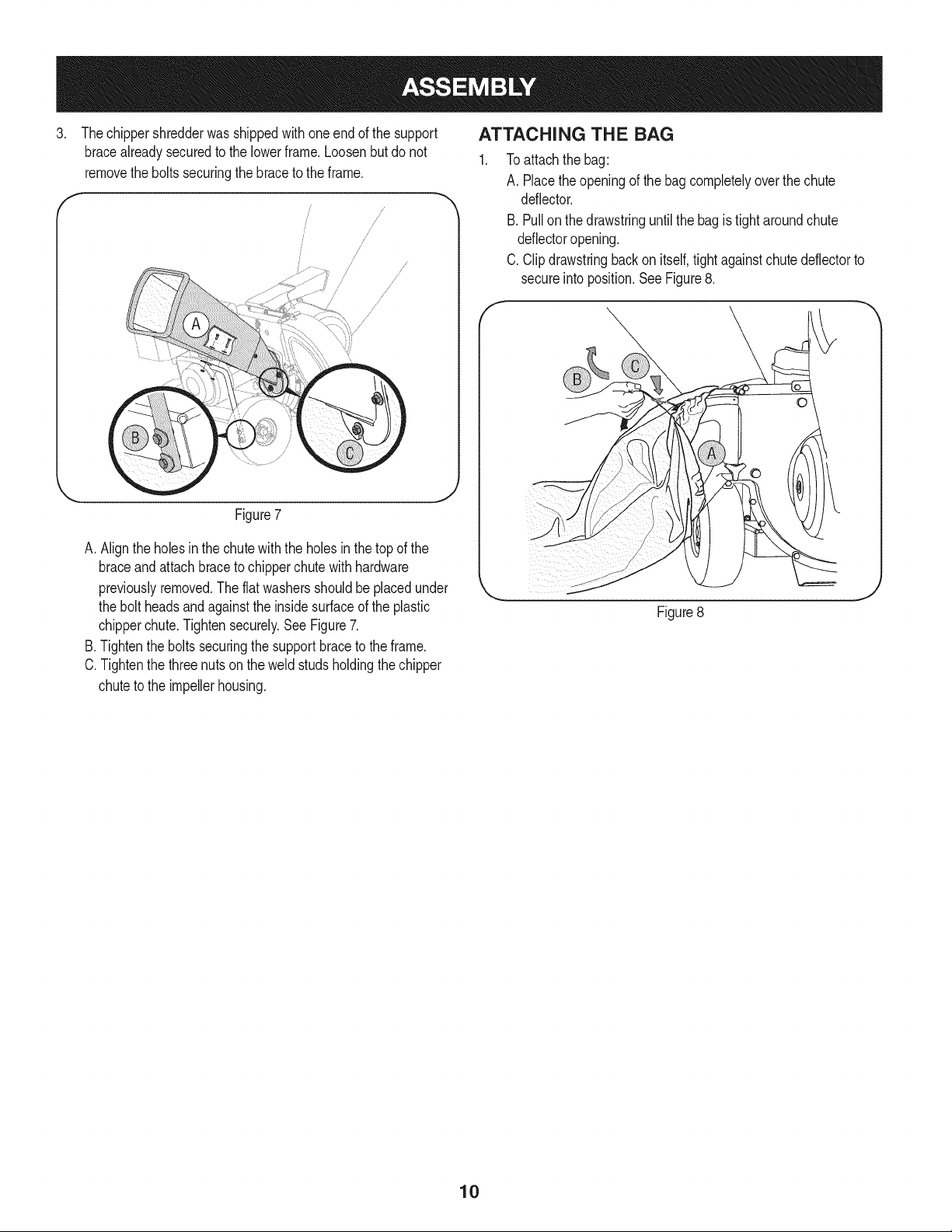

.

Thechippershredderwasshippedwithoneendofthesupport

bracealreadysecuredto thelowerframe.Loosenbutdo not

removetheboltssecuringthe braceto theframe.

Figure7

A.Alignthe holesinthe chutewiththeholesinthetop ofthe

braceandattachbraceto chipperchutewithhardware

previouslyremoved.Theflatwashersshouldbeplacedunder

thebolt headsandagainstthe insidesurfaceofthe plastic

chipperchute.Tightensecurely.SeeFigure7.

B.Tightenthe boltssecuringthe supportbraceto theframe.

C.Tightenthethreenutsontheweld studsholdingthechipper

chutetothe impellerhousing.

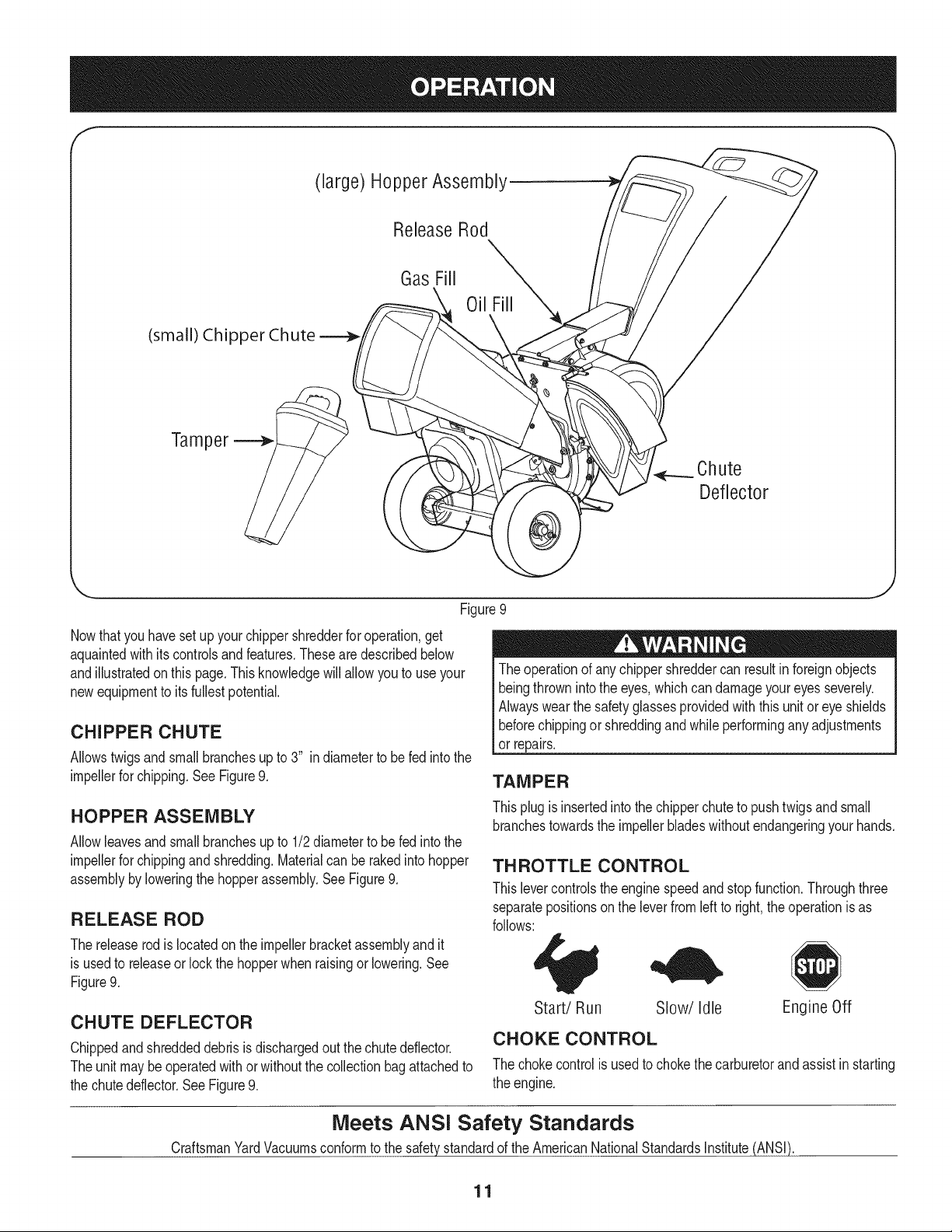

ATTACHING THE BAG

Toattachthebag:

A. Placetheopeningof thebagcompletelyoverthechute

deflector.

B.Pullon the drawstringuntilthebagistightaroundchute

deflectoropening.

C.Clipdrawstringbackon itself,tightagainstchutedeflectorto

secureintoposition.SeeFigure8.

f

J

Figure8

10

Page 11

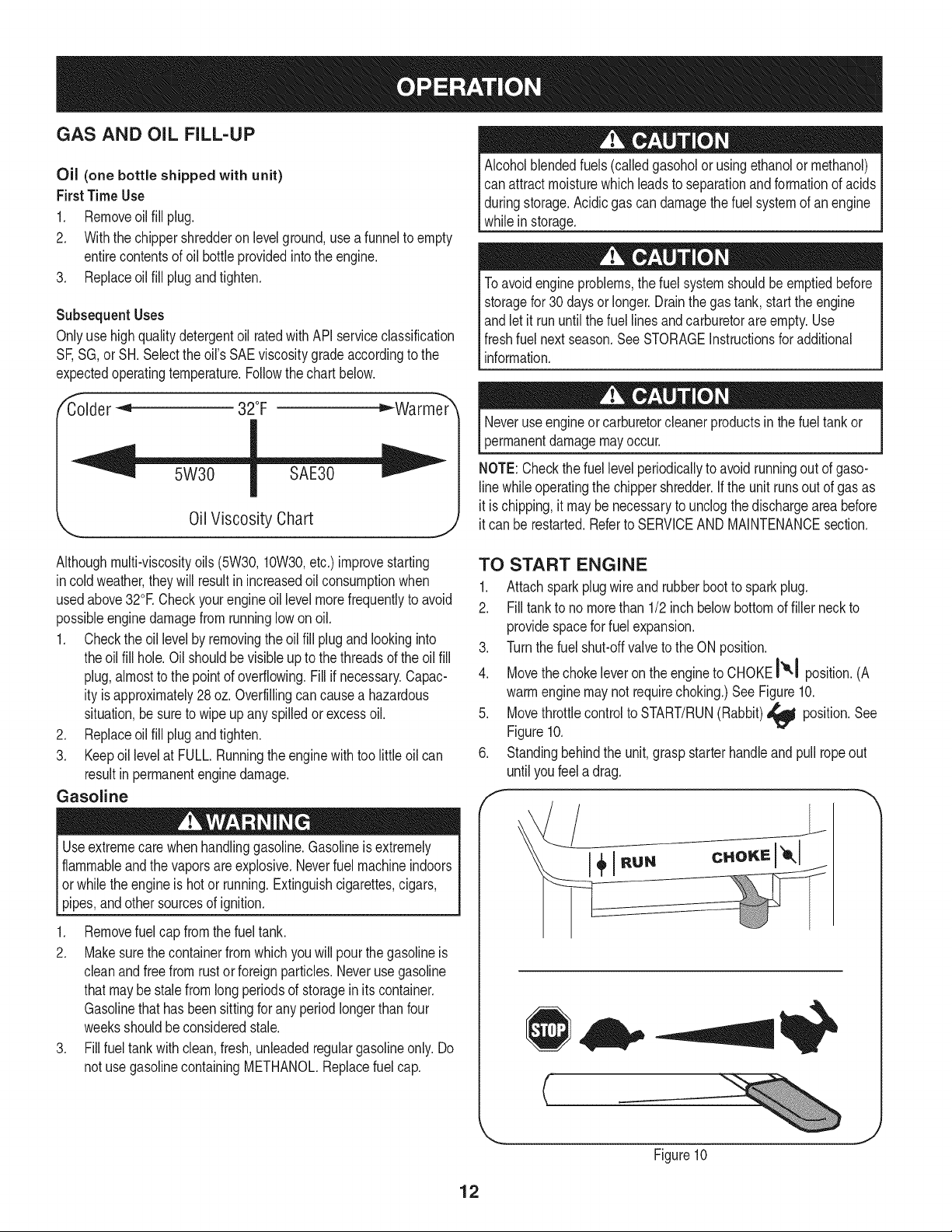

(large) Hopper Assembly

ReleaseRod

GasFill

(small) Chipper Chute

Tamper--=_

Figure9

Nowthatyouhavesetupyourchippershredderforoperation,get

aquaintedwithits controlsandfeatures.Thesearedescribedbelow

andillustratedon thispage.Thisknowledgewillallowyou touseyour

newequipmenttoits fullestpotential.

CHIPPER CHUTE

Allowstwigsandsmallbranchesupto 3" indiametertobefed intothe

impellerforchipping.SeeFigure9.

HOPPER ASSEMBLY

Allowleavesandsmallbranchesupto 1/2diameterto befedintothe

impellerforchippingandshredding.Materialcanberakedintohopper

assemblybyloweringthehopperassembly.SeeFigure9.

RELEASE ROD

Thereleaserodislocatedon the impellerbracketassemblyandit

isusedto releaseorlockthehopperwhen raisingorlowering.See

Figure9.

CHUTE DEFLECTOR

Chippedandshreddeddebrisis dischargedout thechutedeflector.

Theunit maybeoperatedwithorwithoutthecollectionbagattachedto

thechutedeflector.SeeFigure9.

Chute

Deflector

@

Theoperationof anychippershreddercan resultinforeignobjects

beingthrownintothe eyes,whichcan damageyoureyesseverely.

Alwayswearthesafetyglassesprovidedwiththisunitor eyeshields

beforechippingor shreddingandwhileperforminganyadjustments

or repairs.

TAMPER

Thisplugisinsertedinto thechipperchuteto pushtwigsandsmall

branchestowardstheimpellerbladeswithoutendangeringyour hands.

TH ROTTLE CONTROL

Thislevercontrolstheenginespeedandstopfunction.Throughthree

separatepositionsontheleverfromleftto right,theoperationis as

follows:

Start/Run Slow/Idle Engine Off

CHOKE CONTROL

Thechokecontrolis usedto chokethecarburetorand assistinstarting

theengine.

Meets ANSI Safety Standards

CraftsmanYardVacuumsconformtothesafetystandardof theAmericanNationalStandardsInstitute(ANSI).

11

Page 12

GAS AND OIL FILL-UP

Oil (one bottle shipped with unit)

FirstTimeUse

1. Removeoil fillplug.

2. Withthechippershredderonlevelground,useafunneltoempty

entirecontentsofoil bottleprovidedintotheengine.

3. Replaceoil fill plugandtighten.

Subsequent Uses

Onlyuse highqualitydetergentoil ratedwithAPIserviceclassification

SF,SG,or SH.Selectthe oil'sSAEviscositygradeaccordingto the

expectedoperatingtemperature.Followthechartbelow.

_older _ 32°F _Warmer'_

OilViscosity Chart

Althoughmulti-viscosityoils(5W30,10W30,etc.)improvestarting

incoldweather,theywill resultinincreasedoil consumptionwhen

usedabove32°E Checkyourengineoillevelmorefrequentlyto avoid

possibleenginedamagefromrunninglowon oil.

1. Checktheoillevelbyremovingthe oilfillplugand lookinginto

theoil fill hole.Oil shouldbevisibleup tothethreadsof theoil fill

plug,almosttothe pointof overflowing.Fillifnecessary.Capac-

ity isapproximately28oz.Overfillingcancausea hazardous

situation,be suretowipeup anyspilledor excessoil.

2. Replaceoil fill plugandtighten.

3. KeepoillevelatFULL.Runningtheenginewithtoolittleoilcan

resultinpermanentenginedamage.

Gasoline

J

Alcoholblendedfuels(calledgasoholorusingethanolormethanol)

canattractmoisturewhichleadsto separationand formationof acids

duringstorage.Acidicgascandamagethefuel systemofanengine

whileinstorage.

Toavoidengineproblems,thefuelsystemshouldbeemptiedbefore

storagefor30daysorlonger.Drainthegastank,starttheengine

andletit rununtilthe fuellinesandcarburetorare empty.Use

freshfuelnextseason.See STORAGEInstructionsfor additional

information.

Neveruseengineorcarburetorcleanerproductsinthe fueltankor

permanentdamagemayoccur.

NOTE:Checkthefuel levelperiodicallytoavoid runningoutof gaso-

linewhileoperatingthe chippershredder.Ifthe unitrunsoutof gasas

itischipping,itmaybe necessarytounclogthedischargeareabefore

itcan be restarted.RefertoSERVICEANDMAINTENANCEsection.

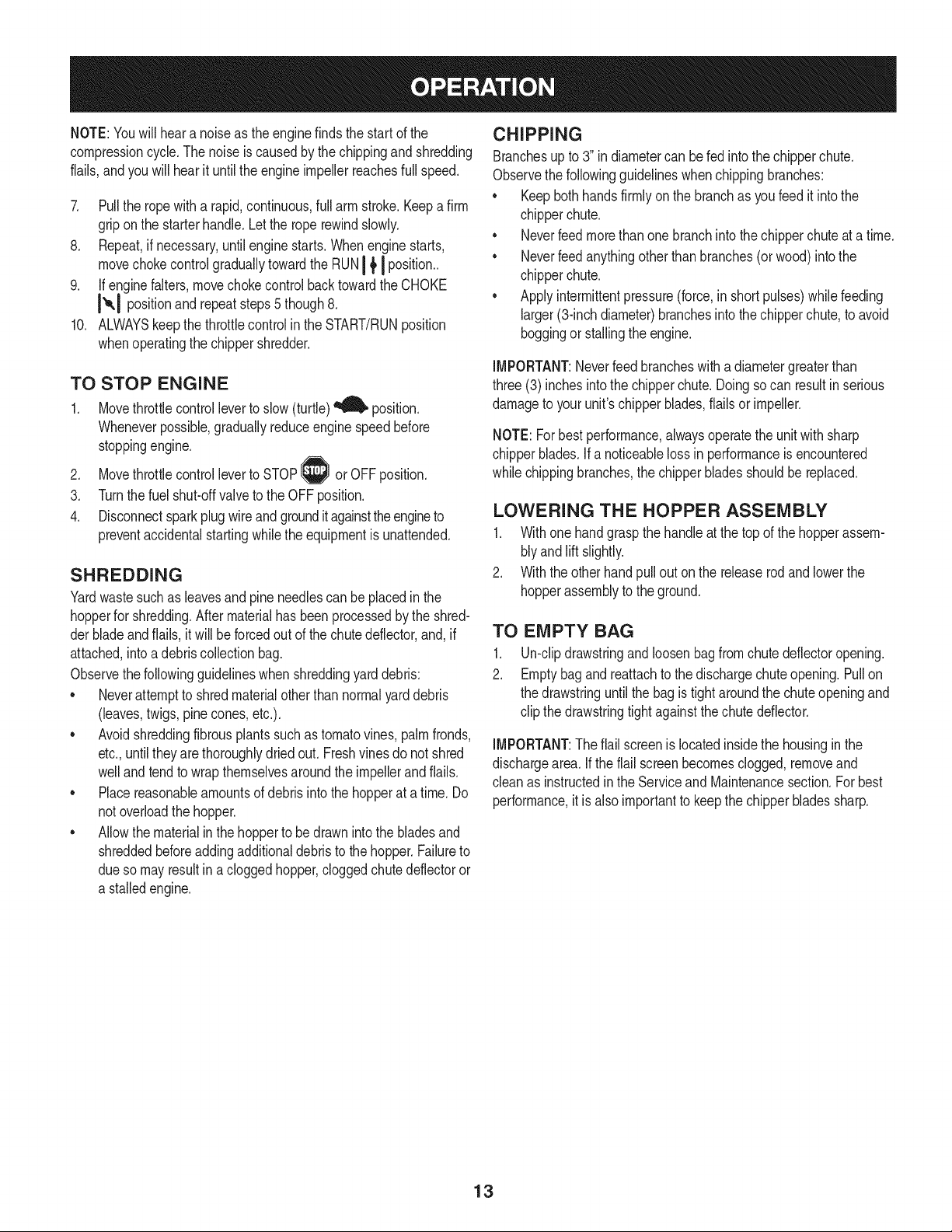

TO START ENGINE

1. Attach sparkplugwireand rubberboottosparkplug.

2. Filltankto nomorethan 1/2inchbelowbottomoffiller neckto

providespaceforfuelexpansion.

3. Turnthefuelshut-offvalvetotheONposition.

4. MovethechokeleverontheenginetoCHOKEI'_1 position.(A

warmenginemaynotrequirechoking.)See Figure10.

5. MovethrottlecontroltoSTART/RUN(Rabbit)_ position.See

Figure10.

6. Standingbehindtheunit,graspstarterhandleandpullropeout

untilyoufeela drag.

f

Useextremecarewhenhandlinggasoline.Gasolineis extremely

flammableandthevaporsareexplosive.Neverfuelmachineindoors

orwhilethe engineishotor running.Extinguishcigarettes,cigars,

pipes,andothersourcesof ignition.

1. Removefuelcap fromthefuel tank.

2. Makesurethecontainerfromwhichyouwillpourthegasolineis

cleanandfreefromrustor foreignparticles.Neverusegasoline

thatmaybestalefromlongperiodsofstorageinitscontainer.

Gasolinethathasbeensittingfor anyperiodlongerthanfour

weeksshouldbeconsideredstale.

3. Fillfueltankwithclean,fresh,unleadedregulargasolineonly.Do

notusegasolinecontainingMETHANOL.Replacefuelcap.

J

Figure10

12

Page 13

NOTE:Youwill heara noiseas theenginefindsthe startof the

compressioncycle.Thenoiseiscausedbythechippingandshredding

flails,andyouwillhearit untiltheengineimpellerreachesfullspeed.

7. Pulltheropewitha rapid,continuous,fullarmstroke.Keepa firm

griponthestarterhandle.Lettheroperewindslowly.

8. Repeat,ifnecessary,untilenginestarts.Whenenginestarts,

movechokecontrolgraduallytowardtheRUNI JtIposition..

9. Ifenginefalters,movechokecontrolbacktowardtheCHOKE

I'o,I positionandrepeatsteps5 though8.

10. ALWAYSkeepthe throttlecontrolinthe START/RUNposition

whenoperatingthe chippershredder.

TO STOP ENGINE

1. Movethrottlecontrolleverto slow(turtle)'_ position.

Wheneverpossible,graduallyreduceenginespeedbefore

stoppingengine.

2. MovethrottlecontrollevertoSTOPI or OFFposition.

3. Turnthefuelshut-offvalvetotheOFFposition.

4. Disconnectsparkplugwireandgrounditagainsttheengineto

preventaccidentalstartingwhilethe equipmentis unattended.

SHREDDING

Yardwastesuchas leavesandpineneedlescanbe placedinthe

hopperforshredding.Aftermaterialhasbeenprocessedbythe shred-

derbladeandflails,it willbeforcedout ofthe chutedeflector,and, if

attached,into adebriscollectionbag.

Observethefollowingguidelineswhenshreddingyarddebris:

• Neverattempttoshredmaterialotherthannormalyarddebris

(leaves,twigs,pinecones,etc.).

• Avoidshreddingfibrousplantssuchas tomatovines,palmfronds,

etc.,untiltheyare thoroughlydriedout.Freshvinesdo notshred

wellandtend towrapthemselvesaroundtheimpellerandflails.

• Placereasonableamountsofdebrisintothe hopperata time. Do

notoverloadthe hopper.

• Allowthe materialin thehopperto bedrawnintothebladesand

shreddedbeforeaddingadditionaldebristo thehopper.Failureto

duesomayresultin acloggedhopper,cloggedchutedeflectoror

a stalledengine.

CHIPPING

Branchesupto3" in diametercanbefedintothechipperchute.

Observethefollowingguidelineswhenchippingbranches:

• Keepbothhandsfirmlyonthe branchas youfeed itintothe

chipperchute.

• Neverfeedmorethanonebranchintothechipperchuteat a time.

• Neverfeedanythingotherthanbranches(orwood)intothe

chipperchute.

• Applyintermittentpressure(force,inshortpulses)whilefeeding

larger(3-inchdiameter)branchesintothechipperchute,toavoid

boggingor stallingtheengine.

IMPORTANT:Neverfeed brancheswitha diametergreaterthan

three(3)inchesintothechipperchute.Doingsocan resultin serious

damageto yourunit'schipperblades,flailsor impeller.

NOTE:Forbestperformance,alwaysoperatetheunitwith sharp

chipperblades.If a noticeablelossin performanceisencountered

whilechippingbranches,thechipperbladesshouldbe replaced.

LOWERING THE HOPPER ASSEMBLY

1. Withonehandgraspthehandleat thetopofthe hopperassem-

blyandlift slightly.

2. Withtheotherhandpulloutonthereleaserodandlowerthe

hopperassemblytotheground.

TO EMPTY BAG

1. Un-clipdrawstringandloosenbagfromchutedeflectoropening.

2. Emptybagandreattachtothedischargechuteopening.Pullon

thedrawstringuntilthe bagistightaroundthe chuteopeningand

clipthe drawstringtightagainstthechutedeflector.

IMPORTANT:The flailscreenis locatedinsidethe housinginthe

dischargearea.Ifthe flailscreenbecomesclogged,removeand

cleanas instructedintheServiceandMaintenancesection.For best

performance,itisalsoimportanttokeepthechipperbladessharp.

13

Page 14

MAINTENANCE SCHEDULE

Beforeperforminganytypeof maintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationor whileperforminganyadjustmentsor repairs.

EachUse

1st5 - 8 hours

25 hours

Annuallyor50hours

Annuallyor100hours

BeforeStorage 1. Fuelsystem

Underheavyloador inhightemperatures

.

Engineoillevel

2.

Looseormissinghardware

3.

Unitandengine.

1.

Engineoil

1.

Engineoill-

2.

Aircleaner

3.

Controllinkagesand pivots

1.

Engineoil

2.

Muffler

1.

Sparkplug

1. Check

2. Tightenorreplace

3. Clean

1. Change

1. Change

2. Replace

3. Lubewithlightoil

1. Change

2. Inspect

1. Clean,checkand resetgap,or

1. Runengineuntilit stopsfromlackof

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.Tolocatethe nearest SearsService

Centeror toscheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

replacesparkplug.

fueloradda gasolineadditivetothe

gasin thetank.

Alwaysstopengineanddisconnectsparkplugwire beforeperforming

Ianymaintenanceoradjustments.Alwayswearsafetyglassesduring

_operationorwhileperforminganyadjustmentsor repairs.

GENERAL RECOMMENDATIONS

• Alwaysobserveallsafetyrulesfoundonproductlabelsandin

thisoperator'smanualwhenperforminganymaintenance.Safety

rulescan befoundonthe productlabelsandin thisOperator's

Manualbeginningon page3.

• Thewarrantyon thischippershredderdoes notcoveritemsthat

havebeensubjectedto operatorabuseor negligence.To receive

fullvalue fromwarranty,operatormustmaintainthe equipmentas

instructedhere.

• Someadjustmentswillhaveto be madeperiodicallytomaintain

yourunit properly.

• Periodicallycheckallfastenersand makesurethesearetight.

ENGINE MAINTENANCE

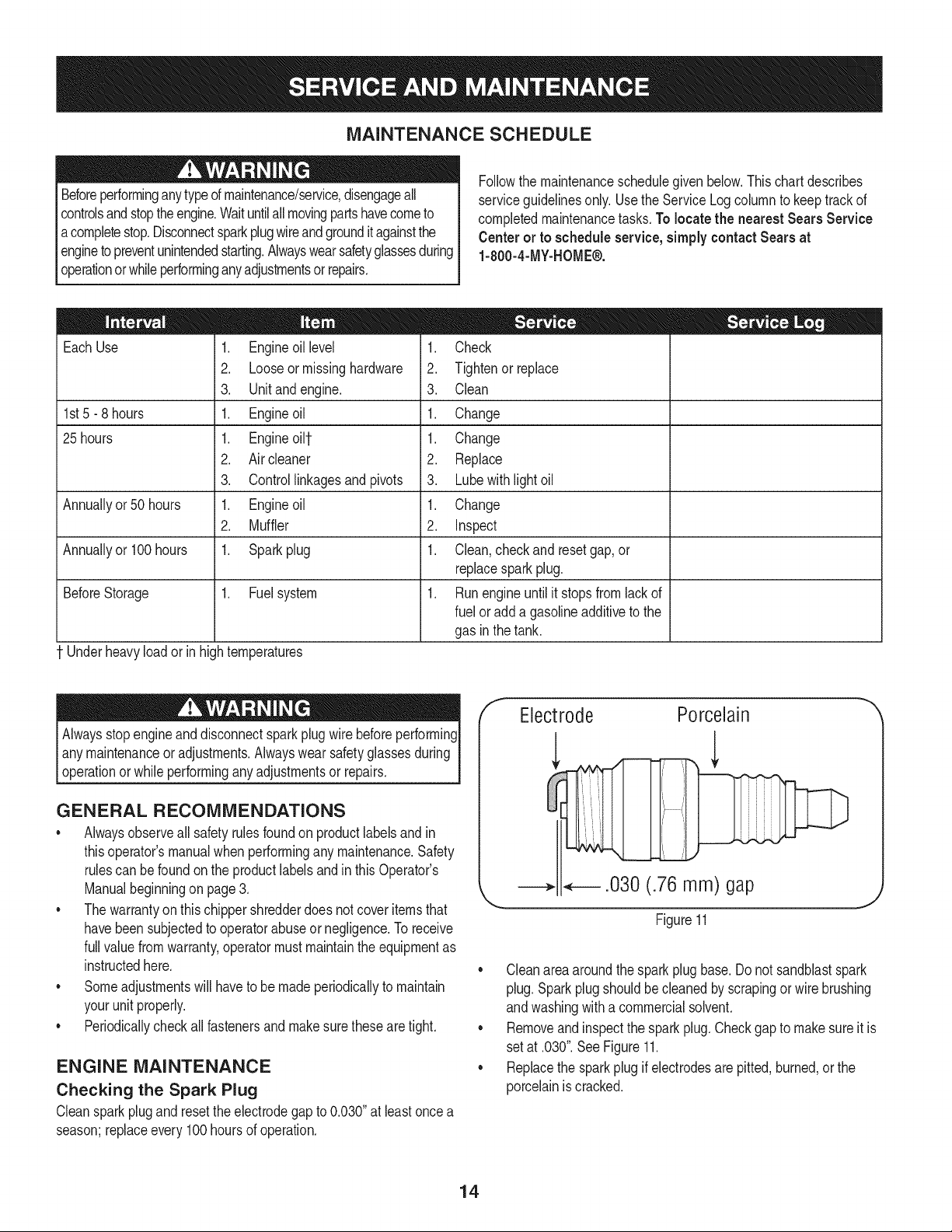

Checking the Spark Plug

Cleansparkplugandresettheelectrodegapto0.030"atleastoncea

season;replaceevery100hoursof operation.

f

Electrode

Porcelain

,L

.030 (.76 mm) gap

Figure 11

• Cleanareaaroundthe sparkplugbase.Donot sandblastspark

plug.Sparkplugshouldbecleanedbyscrapingorwirebrushing

andwashingwitha commercialsolvent.

Removeandinspectthe sparkplug.Checkgaptomakesureitis

setat .030".SeeFigure11.

Replacethesparkplugif electrodesare pitted,burned,or the

porcelainiscracked.

14

Page 15

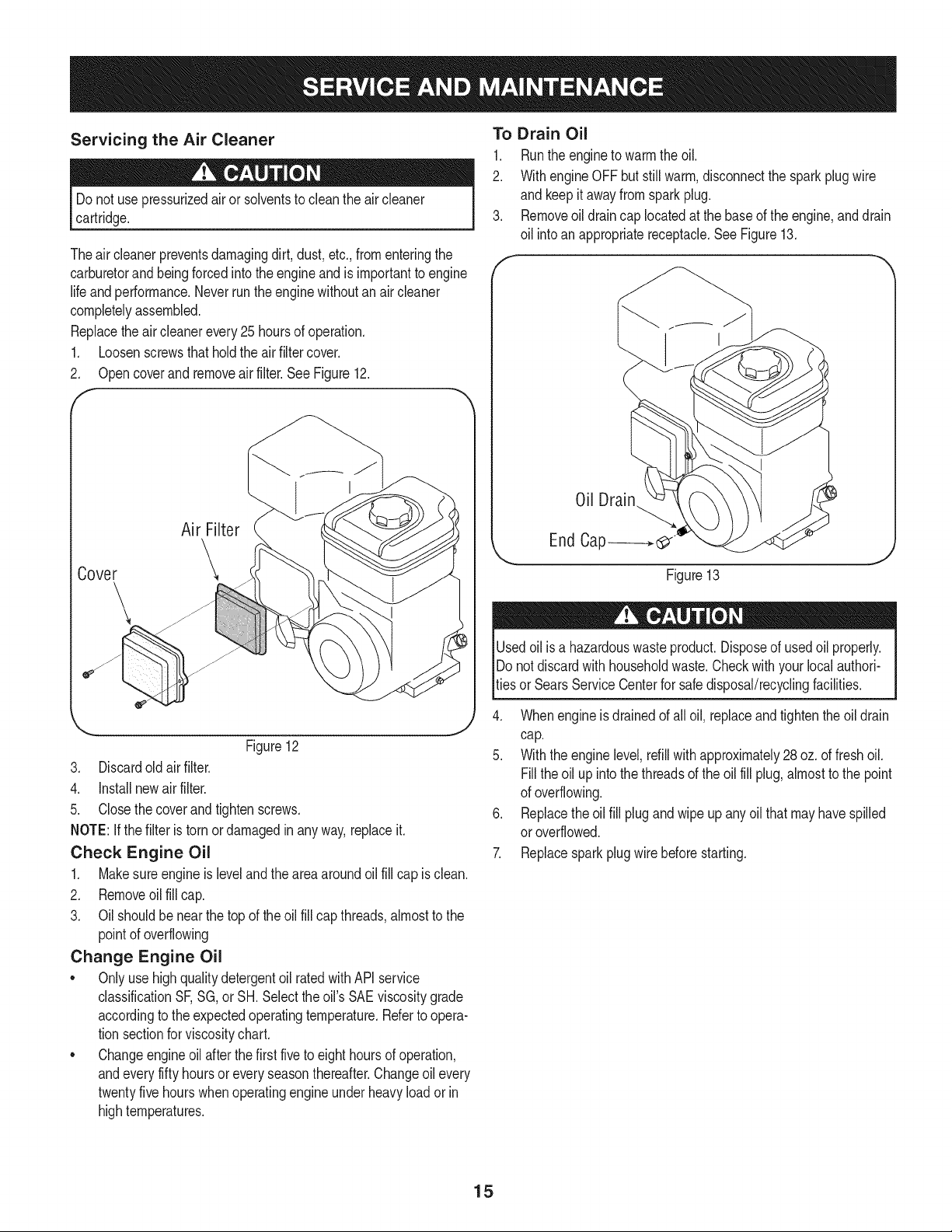

Servicing the Air Cleaner

Donotusepressurizedairor solventsto cleanthe aircleaner

cartridge.

Theair cleanerpreventsdamagingdirt, dust,etc.,fromenteringthe

carburetorand beingforcedintotheengineandisimportanttoengine

lifeandperformance.Neverruntheenginewithoutan aircleaner

completelyassembled.

Replacetheaircleanerevery25 hoursof operation.

1. Loosenscrewsthatholdtheairfiltercover.

2. Opencoverandremoveair filter.See Figure12.

f

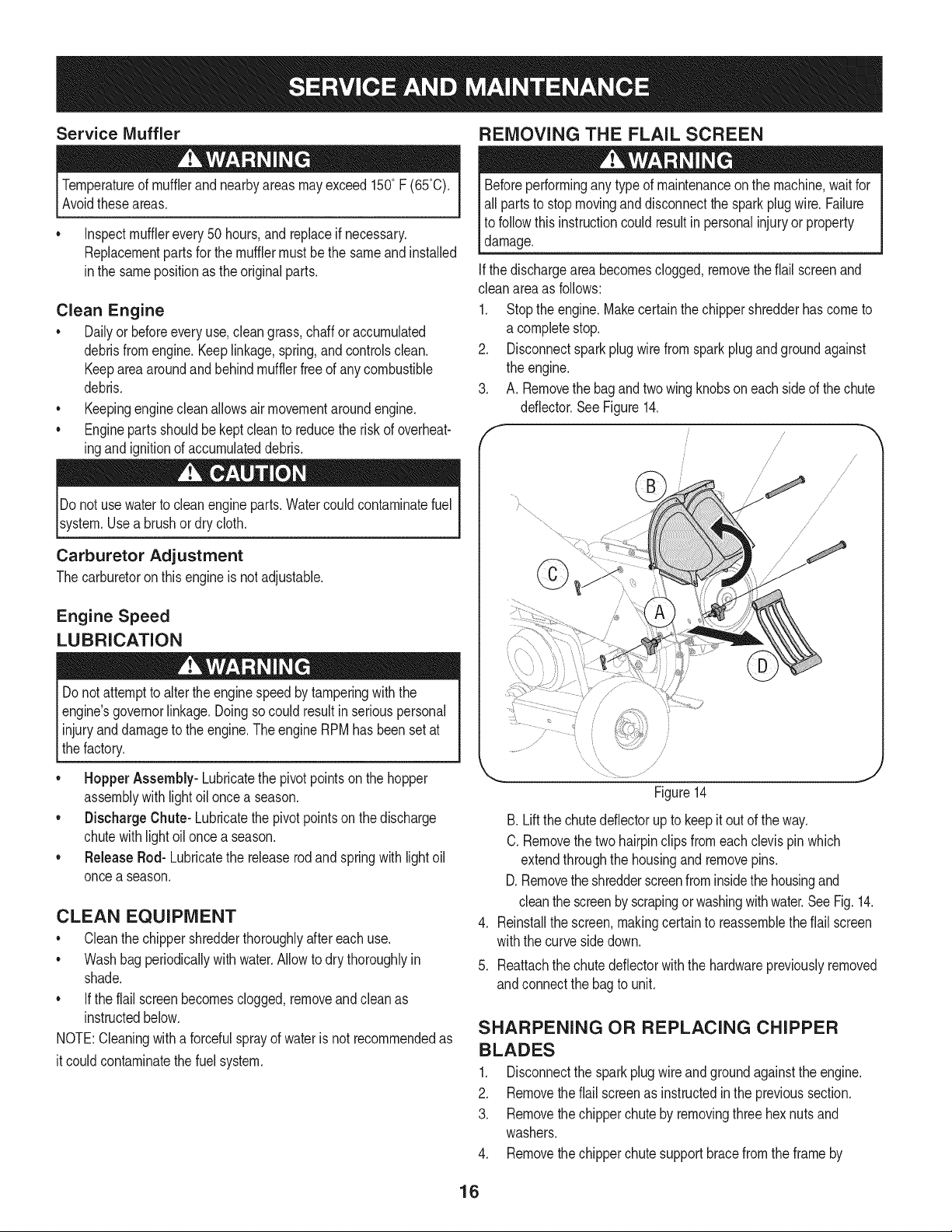

To Drain Oil

1. Runtheengineto warmtheoil.

2. WithengineOFFbutstillwarm,disconnectthe sparkplugwire

and keepitawayfromsparkplug.

3. Removeoil draincaplocatedat thebaseofthe engine,anddrain

oil intoan appropriatereceptacle.SeeFigure13.

Oil Drain

Air Filter

Cover

3. Discardoldairfilter.

4. installnewairfilter.

5. Closethecoverandtightenscrews.

NOTE:Ifthe filteristorn ordamagedinanyway,replaceit.

Check Engine Oil

1. Makesureengineislevelandtheareaaroundoil fill capis clean.

2. Removeoilfillcap.

3. Oilshouldbe nearthetopoftheoil fillcapthreads,almosttothe

pointof overflowing

Change Engine Oil

* OnlyusehighqualitydetergentoilratedwithAPIservice

classificationSF,SG,orSH.Selecttheoil'sSAEviscositygrade

accordingtothe expectedoperatingtemperature.Refertoopera-

tionsectionforviscositychart.

. Changeengineoil afterthefirst fivetoeighthoursof operation,

andeveryfifty hoursoreveryseasonthereafter.Changeoilevery

twentyfivehourswhenoperatingengineunderheavyloadorin

hightemperatures.

\

y

Figure12

End Cap _"

J

Figure13

e

Usedoil isa hazardouswasteproduct.Disposeof usedoil properly.

IDo notdiscardwithhouseholdwaste.Checkwithyour localauthori-

_tiesorSearsServiceCenterforsafedisposal/recyclingfacilities.

4. Whenengineisdrainedofall oil,replaceandtightentheoildrain

cap.

5. Withtheenginelevel,refillwithapproximately28oz. offreshoil.

Fillthe oil upintothe threadsofthe oilfill plug,almosttothepoint

ofoverflowing.

6. Replacethe oilfill plugandwipe upanyoil thatmayhavespilled

or overflowed.

7. Replacesparkplugwire beforestarting.

15

Page 16

Service IVluffler

REMOVING THE FLAIL SCREEN

Temperatureof mufflerandnearbyareasmayexceed150°F (65°C).

Avoidtheseareas.

• Inspectmufflerevery50 hours,andreplaceif necessary.

Replacementpartsforthemufflermustbethe sameandinstalled

inthe samepositionas theoriginalparts.

Clean Engine

Dailyor beforeeveryuse,cleangrass,chaffor accumulated

debrisfromengine.Keeplinkage,spring,andcontrolsclean.

Keepareaaroundandbehindmufflerfreeofanycombustible

debris.

• Keepingenginecleanallowsairmovementaroundengine.

• Enginepartsshouldbekeptcleanto reducetheriskof overheat-

ingandignitionofaccumulateddebris.

Donot usewaterto cleanengineparts.Watercouldcontaminatefuel

system.Usea brushor dry cloth.

Carburetor Adjustment

Thecarburetoronthis engineisnotadjustable.

Engine Speed

LUBRICATION

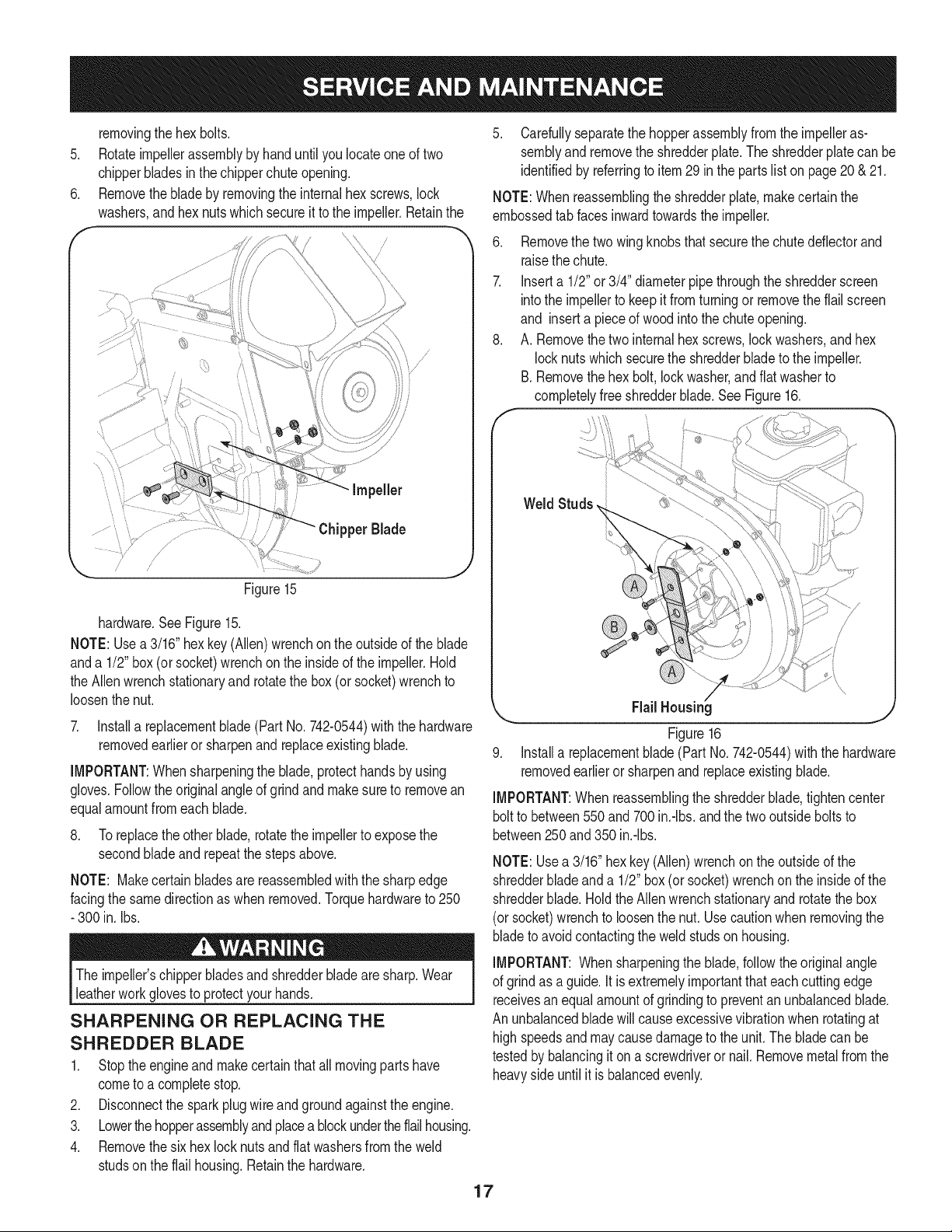

Beforeperforminganytypeofmaintenanceonthe machine waitfor

all partsto stopmovinganddisconnectthesparkplugwire. Failure

tofollowthis instructioncouldresultinpersonalinjuryor property

damage.

Ifthedischargeareabecomesclogged,removethe flailscreenand

cleanareaas follows:

Stopthe engine.Makecertainthe chippershredderhascometo

a completestop.

.

Disconnectsparkplugwirefromsparkplugandgroundagainst

theengine.

3.

A. Removethebagandtwowingknobsoneachsideofthechute

deflector.SeeFigure14.

f

/

s /

/ /

//

/

s'

/

Donot,attempttoaltertheenginespeedbytamperingwiththe

engines governorlinkage.Doingsocould resultin seriouspersonal

Iinjuryanddamagetotheengine.TheengineRPMhasbeensetat

thefactory.

• HopperAssembly- Lubricatethe pivotpointson thehopper

assemblywithlightoiloncea season.

• DischargeChute- Lubricatethepivotpointsonthedischarge

chutewithlightoilonce a season.

• ReleaseRod-Lubricatethereleaserodand springwith lightoil

oncea season.

CLEAN EQUIPMENT

• Cleanthechippershredderthoroughlyaftereachuse.

• Washbagperiodicallywithwater.Allowto drythoroughlyin

shade.

• Iftheflail screenbecomesclogged,removeandcleanas

instructedbelow.

NOTE:Cleaningwitha forcefulsprayofwaterisnotrecommendedas

itcouldcontaminatethefuelsystem.

j

Figure14

B.Liftthe chutedeflectorupto keepit outof theway.

C.Removethetwo hairpinclipsfromeachclevispinwhich

extendthroughthehousingandremovepins.

D.Removetheshredderscreenfrominsidethehousingand

cleanthe screenbyscrapingorwashingwithwater.SeeFig.14.

4. Reinstallthescreen,makingcertaintoreassembletheflail screen

withthecurvesidedown.

5. Reattachthechutedeflectorwiththehardwarepreviouslyremoved

andconnectthe bagto unit.

SHARPENING OR REPLACING CHIPPER

BLADES

1. Disconnectthesparkplugwireandgroundagainsttheengine.

2. Removetheflail screenasinstructedinthe previoussection.

3. Removethechipperchutebyremovingthreehexnutsand

washers.

4. Removethechipperchutesupportbracefromthe frameby

16

Page 17

removingthehexbolts.

5. Rotateimpellerassemblyby handuntilyoulocateone oftwo

chipperbladesin thechipperchuteopening.

6. Removethebladebyremovingtheinternalhexscrews,lock

washers,andhexnutswhichsecureit tothe impeller.Retainthe

/

/

5. Carefullyseparatethehopperassemblyfromthe impelleras-

semblyandremovetheshredderplate.Theshredderplatecanbe

identifiedby referringtoitem29 in thepartslistonpage20& 21.

NOTE:Whenreassemblingtheshredderplate,makecertainthe

embossedtabfacesinwardtowardstheimpeller.

6. Removethetwowingknobsthatsecurethechuteddlector and

raisethechute.

7. Inserta 1/2"or 3/4"diameterpipethroughtheshredderscreen

intothe impellertokeepit fromturningor removetheflailscreen

and inserta pieceofwoodintothechuteopening.

8. A. Removethe twointernalhexscrews,lockwashers,andhex

locknutswhichsecuretheshredderbladetothe impeller.

B.Removethehex bolt,lockwasher,andflatwasherto

completelyfreeshredderblade.SeeFigure16.

f

Weld

Figure15

hardware.SeeFigure15.

NOTE:Usea3/16"hexkey(Allen)wrenchon theoutsideoftheblade

anda 1/2"box(orsocket)wrenchontheinsideoftheimpeller.Hold

theAllenwrenchstationaryandrotatethe box(or socket)wrenchto

loosenthenut.

7. Installareplacementblade(Part No.742-0544)withthehardware

removedearlieror sharpenandreplaceexistingblade.

IMPORTANT:Whensharpeningthe blade,protecthandsby using

gloves.Followtheoriginalangleofgrindandmakesuretoremovean

equalamountfromeachblade.

8. Toreplacetheotherblade,rotatetheimpellertoexposethe

secondbladeand repeatthestepsabove.

NOTE: Makecertainbladesare reassembledwiththesharpedge

facingthesamedirectionas whenremoved.Torquehardwareto250

- 300in.Ibs.

Theimpeller'schipperbladesandshredderbladearesharp.Wear

leatherworkglovesto protectyourhands.

SHARPENING OR REPLACING THE

SHREDDER BLADE

1. Stoptheengineandmakecertainthatallmovingpartshave

cometoa completestop.

2. Disconnectthesparkplugwire andgroundagainsttheengine.

3. Lowerthehopperassemblyandplacea blockundertheflailhousing.

4. Removethesixhexlocknutsandflatwashersfromtheweld

studsonthe flailhousing.Retainthehardware.

FlailHousing

Figure16

9. Installa replacementblade(PartNo.742-0544)with thehardware

removedearlierorsharpenandreplaceexistingblade.

IMPORTANT:When reassemblingtheshredderblade,tightencenter

boltto between550and700in.-Ibs,andthe twooutsideboltsto

between250and350in.-Ibs.

NOTE:Usea 3/16"hexkey(Allen)wrenchontheoutsideofthe

shredderbladeanda 1/2"box(or socket)wrenchon the insideof the

shredderblade.HoldtheAllenwrenchstationaryandrotatethebox

(orsocket)wrenchtoloosenthenut. Usecautionwhen removingthe

bladetoavoidcontactingthe weldstudson housing.

IMPORTANT:Whensharpeningtheblade,followtheoriginalangle

ofgrindas a guide.It is extremelyimportantthateachcuttingedge

receivesan equalamountofgrindingto preventan unbalancedblade.

An unbalancedbladewillcauseexcessivevibrationwhenrotatingat

highspeedsandmaycausedamagetothe unit.Thebladecan be

testedby balancingiton ascrewdriverornail. Removemetalfromthe

heavysideuntil itis balancedevenly.

17

Page 18

Neverstorechippershredderwithfuelintankindoorsorinpoorly

ventilatedareaswherefuelfumesmayreachanopenflame,spark,

orpilotlightasonafurnace,waterheater,clothesdryer,orgas

appliance.

PREPARING THE ENGINE

Forenginesstoredover30 days:

1. To preventgumfromforminginfuel systemoroncarburetor

parts,runengineuntilit stopsfromlackof fuelor adda gasoline

additivetothe gasinthe tank.Ifyou usea gas additive,runthe

engineforseveralminutestocirculatetheadditivethroughthe

carburetor--afterwhichtheengineandfuel canbestoredup to

six months.

2. Whileengineis stillwarm,changetheoil. SeeChangeEngineOil

in SERVICEANDMAINTENANCEsection.

3. Removesparkplugand pourapproximately1oz. (30ml)ofclean

engineoil intothe cylinder.Pullthe recoilstarterseveraltimesto

distributetheoil,andreinstallthe sparkplug.

4. Cleanengineofsurfacedebris.

PREPARING THE CHIPPER SHREDDER

* Whenstoringthechippershredderinan unventilatedor metal

storageshed,careshouldbetakento rustproofthe non-painted

surfaces.Usinga lightoil orsilicone,coatthe equipment,

especiallyanysprings,bearings,andcables.

, Removealldirt fromexteriorof engineandequipment.

, Followlubricationrecommendations.

o Storeequipmentina clean,dry area.Do notstorenextto

corrosivematerials,suchasfertilizer.Donotstoreinan area

whereequipmentispresentthatmayusea pilot lightor hasa

componentthatcancreatea spark.

18

Page 19

Beforeperforminganytyped maintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationorwhileperforminganyadjustmentsor repairs.

Enginefailstostart

1. Throttlelevernot incorrectstartingposition

2. ChokenotintheCHOKEposition

3. Sparkplugwiredisconnected

4. Faultysparkplug

5. Fueltankemptyorstalefuel

6. Cannotpullrecoilcord

7. Engineflooded

Enginerunserratically

1. UnitrunningonCHOKE

2. Sparkplugwireloose

3. Stalefuel

4. Waterordirtinfuel system

5. Dirtyair cleaner

6. LowengineRPM

7. Carburetoroutofadjustment

Engineoverheats

1. Engineoillevellow

2. Airflowrestricted

Enginehesitatesat highRPMs 1. Sparkpluggap settooclose

Engineidlespoorly 1. Fouledsparkplug

2. Dirtyair cleaner

Excessivevibration 1. Loosepartsor damagedimpeller

Unitdoesnotdischarge 1. Chuteddlector clogged

2. Foreignobjectlodgedin impeller

3. LowengineRPM

Rateofdischargeslows

considerablyorcompositionof

1. LowengineRPM

2. Chipperbladedull

dischargedmaterialchanges

1. Movethrottleleverto START/RUNposition.

2. MoveCHOKEto theCHOKEposition.

3. Connectwiretosparkplug.

4. Clean,adjustgap,or replace.

5. Filltankwithclean,freshgasoline.

6. Obstructionlodgedinimpeller.Disconnectspark

plugwireandremovelodgedobject.

7. Waitafewminutestorestart.

1. MovechokelevertotheRUNposition.

2. Connectandtightensparkplugwire.

3. Filltankwithfreshgasoline.

4. Refillwithfreshfuel.

5. Cleanor replaceair cleanerfilter.

6. Alwaysrunengineatfullthrottle.

7. ContactyourSearsParts&RepairCenter.

1. Fillenginewith properamountandtype ofoil.

2. Cleandebrisfromaroundtheengine'scoolingfins

and blowerhousing.

1. Removesparkplugandadjustgap.

1. Replacesparkplugandadjustgap.

2. Replaceair cleanercartridge.

1. Stopengineimmediatelyanddisconnectsparkplug

wire.ContactyourSearsParts& RepairCenter.

1. Stopengineimmediatelyanddisconnectspark

plugwire.Cleanflail screenandinsided discharge

opening.

2. Stopengineanddisconnectsparkplugwire.

Removelodgedobject.

3. Alwaysrunengineatfullthrottle.

1. Alwaysrunengineatfull throttle.

2. Replaceor sharpenchipperbladeor contactyour

SearsParts& RepairCenter.

NEED MORE HELP?

Find tMs and a[[ your other product rnanuats online.

Get answers from our team of home experts.

Get a personal}zeal rnaintenance p[an for your home,

Find information and tools to help with home projects.

b_te_ght te ye_ by $¢alts

19

Page 20

Craftsman Chipper Shredder -- Model No. 247.77638

/ ;/

/ /

; /

/

_ ....

/

2O

Page 21

Craftsman Chipper Shredder B IViodel No. 247.77638

936-0217 LockWasher,3/8 710-3008

2. 914-0149B CotterPin 23. 736-0247

3. 720-0170 WingKnob5/16-18 24. 942-0571

4. 681-0094A-4044 ChuteDeflectorAssembly 25. 710-1254

5. 911-0835 ClevisPin 26. 681-0004A-4044

6. 781-0457-0637 ShredderScreen 27. 710-0825

7. 926-0211 U-Nut5/16-18 28. 781-0515-0637

8. 950-0793 Spacer 29. 781-0574-0637

9. 912-3027 HexLockNut,1/4-20 30. 681-0104-4044

10. 712-3004A HexLockNut5/16-18 31. 932-0306A

11. 936-0119 LockWasher5/16 32. 936-0117

12. 681-04116 innerImpellerHousingAssembly 33. 914-0104

13. 710-3025 HexCapScrew5/16-18x.625 34. 936-0264

14. 710-0157 HexCapScrew5/16-24x .75 35. 710-0376

15. 942-0544B ChipperBlade 36. 748-0453

16. 710-1054 HexCapScrew5/16-24x 1.0 37. 731-1707A

17. 681-04095 ImpellerAssembly 38. 912-0429

18. 912-0411 HexLockNut5/16-24 39. 731-1710A

19. 712-0266A Nut,JamLock,3/8-16 40. 681-0123-4044

20. 719-04308 FlailBlade 41. 711-1128

21. 738-04286A ShoulderPin, .5x 2.625

HexCapScrew5/16-18x .75

FiatWasher3/8 x 1.25

ShredderBlade

HexCapScrew3/8-24 x2.25

OuterimpellerHousingAssembly

HexCapScrew1/4-20x3.75

FrontSupportBracket

ShredderPlate

RearHopperBracketAssembly

CompressionSpring1.75

FlatWasher

CotterPin

FlatWasher.330IDx.630 OD

HexCapScrew5/16-18x 1.0

Spacer,.375IDx 2.50LG

HopperAssembly

HexLockNut5/16-18

HopperCollar

FrontHopperBracketAssembly

LockRod

21

Page 22

Craftsman Chipper Shredder B IViodel No. 247.77638

22

Page 23

Craftsman Chipper Shredder B IViodel No. 247.77638

728-0175 PopRivet

2 753-05094 ChipperShredderChute 17

3 735-0249A ChuteFlap 18

4 781-0633 ChuteFlapStrip 19

5 681-04119-4044 ChipperChuteAssembly 20

6 710-0751 HexCapScrew1/4-20x.620 21

7 712-04064 HexLockNut1/4-20 22

8 710-0809 HexCapScrew1/4-20x 1.25 23

9 736-0173 FlatWasher.28 IDx .74OD 24

10 736-0242 BellWasher.340IDx .872OD 25

11 912-3010 HexNut5/16-18 26

12 749-1004-4044 SupportBrace

13 712-3004A HexLockNut5/16-18

14 710-3180 HexCapScrew5/16-18x 1.75

15 936-0170 BellWasher5/16x 1.0

27 731-1617 Tamper

28 20T212-O835-F1 ReplacementEngine

29 710-0106 HexScrew,1/4-20x 1.25

950-0786 Spacer

738-0813 AxleAssembly

737-0298 Pipe,OilDrain

934-04009 WheelComplete,10.0x 4.0 Gray

726-0214 PushCap

681-0183B-4044 Frame

936-0451 Washer,.320IDx.93OD

710-0502A Screw,3/8-16x 1.250

723-0400 SafetyGlasses(NotShown)

964-04024 ChipperBagAss'y(NotShown)

737-0132 Oil DrainEndCap

23

Page 24

Craftsman Engine Model 204312=0529 For Chipper Shredder Model No. 247.77638

110_8OPERATORSMA,0A']I 48S,OmB.OOKI I1329_EP.AOEMENTENG,NEII 13_9_E_A'_A"0A']

529 _,

396

615 _)

616

5o5 _

397

24_j

746

742 _

12

'Y 718 __b

J

...."_ 718A

1427 _

1194

22

32

30

358 ENGINE GASKET SET

2O

12

163

12

868

24

51A

1022

Page 25

Craftsman Engine IViodel 204312-0529 For Chipper Shredder IViodel No. 247.77638

632

_o9_

1095 VALVE GASKET SET

51A

_22

1O22

188 (_

25

Page 26

Craftsman Engine IViodel 204312-0529 For Chipper Shredder IViodel No. 247.77638

121 CARBURETOR OVERHAUL KiT

633 3 C:-._

130

95@

127°

117@

118 _@

51A(

127 0

163

633 (o_

51A(

369 i_

137

1127 _

105 0

\

53

_%_.. 967

I _ 445

161I'i_'_s

957 _,."'t_,_- _"s

613

i_72A]

24O

190 _?'

26

Page 27

Craftsman Engine IViodel 204312=0529 For Chipper Shredder IViodel No. 247.77638

356

37

78 _ 306

363

1005

1070

334

332

774

635

356A ........... C_

12

1211

592 @) 55

65

27

Page 28

Craftsman Engine IViodel 204312=0529 For Chipper Shredder IViodel No. 247.77638

D = O

1

2

3

5

7

11

12

794849

698340

391086s.

794870

694872.+

696796

694953.

CylinderAssembly

Kit-Bushing/Seal(MagnetoSide)

Seal-Oil(MagnetoSide)

Head-Cylinder

Gasket-CylinderHead

Tube-Breather

Gasket-Crankcase

13 794829 Screw(CylinderHead)

15 697757 Plug-OilDrain

16 794874 Crankshaft

18 791965 Cover-Crankcase

19 698340 Kit-Bushing/Seal(PTOSide)

20 391086s• Seal-Oil(PTOSide)

21 281658s Cap-OilFill

22 794825 Screw(CrankcaseCover/Sump)

23 794814 Flywheel

24 222698s Key-Flywheel

25 792117 PistonAssembly(Standard)

792144 PistonAssembly(.020"Oversize)

26 793561 RingSet (Standard)

792073 RingSet(.020"Oversize)

27 690975 Lock-PistonPin

28 696581 Pin-Piston

29 691691 Rod-Connecting

30 694692 Dipper-ConnectingRod

32 690976 Screw(ConnectingRod)

33 499596 Valve-Exhaust

34 792200 Valve-Intake

35 694865 Spring-Valve(Intake)

36 694865 Spring-Valve(Exhaust)

37 790730 Guard-Flywheel

42 499586 Keeper-Valve

45 690977 Tappet-Valve

46 790958 Camshaft

48 N/A Short Block

D = O I

51

51A

53

55

58

59

6948740.+

6948750.+

794830

695288

693389

805957

Gasket-Intake

Gasket-Intake

Stud(Carburetor)

Housing-RewindStarter

Rope-Starter

Insert-Grip

60 490652 Grip-StarterRope

65 699228 Screw(RewindStarter)

78 795026 Screw(FlywheelGuard)

81 794817 Lock-MufflerScrew

95 690718 Screw(ThrottleValve)

97 696387 Shaft-Throttle

98 6954080 KiNdle Speed

104 6949180 Pin-FloatHinge

105 6961360 Valve-FloatNeedle

108 696143 Valve-Choke

109 790149 Shaft-Choke

117 696134 Jet-Main(Std.)(InclO-RingSeal)

118 696135 Jet-Main(HighAIt.)(InclO-RingSeal)

121 696146 Kit-CarburetorOverhaul

122 694876 Spacer-Carburetor

125 699966 Carburetor

127 6907270 Plug-Welch

130 696139 Valve-Throttle

133 694914 Float-Carburetor

135 696142 Tube-FuelTransfer

137 6954260 Gasket-FloatBowl

141 696145 Kit-ChokeShaft

146 690979 Key-Timing

161 794768 Base-AirCleaner

163 6922770. Gasket-AirCleaner

187 791766 Line-Fuel(CutToRequiredLength)

188 699479 Screw(ControlBracket)

190 699220 Screw(FuelTank)

192 690083 Adjuster-RockerArm

28

Page 29

Craftsman Engine IViodel 204312=0529 For Chipper Shredder IViodel No. 247.77638

m = I! II

209

211

219

220

694867

695307

693578

691724

Spring-Governor(Red)

Spring-GovernedIdle

Gear-Governor

Washer(GovernorGear)

222 794799 Bracket-Control

227 694864 Lever-GovernorControl

240 298090s Filter-Fuel

265 691024 Clamp-Casing

267 699492 Screw(CasingClamp)

271 695381 Lever-Control

278 792008 Washer(GovernorControlLever)

281 697268 Panel-Control

300 794806 Muffler

304 791478 Housing-Blower

305 699480 Screw(BlowerHousing)

306 697240 Shield-Cylinder

307 794822 Screw(CylinderShield)

332 794824 Nut(Flywheel)

333 492341 Armature-Magneto

334 699477 Screw(MagnetoArmature)

337 491055s Plug-Spark

356 692603 Wire-Stop

356A 692390 Wire-Stop

356B 695815 Wire-Stop

356C 695295 Wire-Stop

358 695438 GasketSet-Engine

363 19203 Puller-Flywheel

369 695422 Spring-FloatBowl

383 19374s Wrench-SparkPlug

410 695382 Link-Control

415 691363 Plug(Cylinder)

425 794835 Screw(AirCleanerCover)

445 491588s Filter-AirCleanerCartridge

446 794941 Spring-Retainer

455 794867 Cup-Flywheel

D = I! It

456

459

493

5O4

5O5

529

692299

281505s

691177

695383

691251

791822

Plate-PawlFriction

PawI-Ratchet

Bracket-Mounting

WasherSet-Friction

Nut(GovernorControlLever)

Grommet(Cylinder)

552 694674 Bushing-GovernorCrank

562 793216 Bolt(GovernorControlLever)

592 690800 Nut(RewindStarter)

597 691696 Screw(PawlFrictionPlate)

601 791850 Hose-Clamp

608 695287 Starter-Rewind

613 794846 Screw(Muffler)

613A 794848 Screw(Muffler)

615 694676 Retainer-GovernorShaft

616 694675 Crank-Governor

621 692310 Switch-Stop

632 695917 Spring/Link-MechanicalGovernor

633O 690998 Seal-Choke/ThrottleShaft

635 691909 Boot-SparkPlug

663 699492 Screw(ControlPanel)

663A 795026 Screw(ControlPanel)

668 694257 Spacer(ControlBracket)

689 691855 Spring-Friction

718 690959 Pin-Locating(Cylinder)

718A 695178 Pin-Locating(CylinderHead)

741 691288 Gear-Timing

742 692564 Retainer-ERing

746 694679 Gear-Idler

773 694258 Retainer

774 695447 Screw(StopWire)

798 697890 Screw(RockerArm)

832 795035 Guard-Muffler

836 794845 Screw(MufflerGuard)

836A 710023 Screw(MufflerGuard)

29

Page 30

Craftsman Engine IViodel 204312=0529 For Chipper Shredder IViodel No. 247.77638

I = O O

851

868

883

914

951

957

967

968

692424

690968.+

794818.

794827

699961

792647

491435s

794785

Terminal-SparkPlug

Seal-Valve

Gasket-Exhaust

Screw(RockerCover)

Lever-Choke

Cap-FuelTank

Filter-PreCleaner

Cover-AirCleaner

972 694260 Tank-Fuel

975 696138 Bowl-Float

998 696683 Pipe-Oil

1005 794815 Fan-Flywheel

1022 690971.+ Gasket-RockerCover

1023 697691 Cover-Rocker

1026 695177 Rod-Push

1029 690972 Arm-Rocker

1036 Label-Emissions

1058 MS3797 Operator'sManual

1070 794821 Screw(FlywheelFan)

1095 695440 GasketSet-Valve

1100 791959 Pivot-RockerArm

1127 695407 Screw(FloatBowl)

1138 694255 Nut(ControlBracket)

• 1194 691876 Seal-ORing(Plug)

1210 498144 Pulley/SpringAssembly(Pulley)

1211 498144 Pulley/SpringAssembly(Spring)

1329 2043120536e9 ReplacementEngine

1330 272147 RepairManual

1427 695757 Cap-Pipe

• IncludedinEngineGasketSet,KeyNumber358

0 IncludedinCarburetorOverhaulKit,KeyNumber121

+ IncludedinValveGasketSet,KeyNumber1095

3O

Page 31

Craftsman Chipper Shredder Model No. 247.77638

777333113 777333200 777332036

®ROTATING CUTTING BLADES. KEEP HANDS AND

FEET OUT OF OPENING WHILE MACHINE mS

RUNNING.

=DO NOT OPERATE THiS MACHINE UNLESS THE

CHUTE DEFLECTOR HAS BEEN PROPERLY

iNSTALLED ANDJS SECURED WiTH THE HAND

KNOBS.

777S30185

777S30181

ROTATING CUTTING BLADES.

KEEP HANDS AND FEET OUT

OF OPENINGS WHILE MACHINE

iS RUNNING.

777S32282

DONOTOPERATETHISMACHINE

UNLESSTHECHUTEDEFLECTOR

Operatien Of This Equipment May Create

Sparks That Can Start Fires Around Dry

Vegetation. A Spark Arrestor May Be

Required. The Operator Should Contact

Local Fire Agencies For Laws Or ReguJa=

ionsTo Fire Prevention Requirements.

777X43688

.................DOHOT...................

USEE85 ORFUEL ......

CONTAiNiNGMORE

THAN10% ETHANOL

TO AVOID SERIOUS iNJURY:

• Read the operator's manuaJ(s) before starting and

using unit.

• Keep ag shieJds and guards in place and secureJy

attached.

• Keep hands, feet, face, cJothing and Jong hair out of

Shredder Hopper, Chipper Chute and Discharge

Chute whge the engine is running. Rotating cutting

bJades inside these openings wiJJcause serious

personal injury if contacted. Material being processed

may bounce back from inJetopenings or be thrown

from the discharge chute. Long hair or Jeose clothing

may be puJJedor sucked into the inlet openings.

• Do not pJace branches over 1/2 inch diameter into

the Jarge Shredder Hopper. Branches over 1/2 inch in

diameter sheuJd be pJaeed in the SmaJJChipper

Chute.

• if the chipped shredder jams or becomes clogged,

immediateJy shut off the engine and wait for ail

moving parts to come to a complete stop before

cJearing.

• Do not instaJJ,remove, adjust, or service the

discharge screen or any other part whiJe the engine

is running. Blade contact can occur.

$32O36 AC

777332037

TO AVOID SERIOUS iNJURY:

DO not operate on uneven ground where unit is

unstabJe. Do net operate on pavement, gravel or

other hard surfaces since objects can ricochet

and cause injury.

To avoid a fire hazard, keep Jeaves, grass, and other

combustible materiaJs away from hot engine and

muffler.

• Keep children and ethers away from area of

operation,

, Wear approved safety glasses, gloves and ear

protection.

777D12676

31

Page 32

(Thispageapplicableinthe U.S.A.and Canadaonly.)

Sears Brands Management Corporation (Sears), the California Air Resources Board (CARD)

and the United States Environmental Protection Agency (U.S. EPA)

Emission Control System Warranty Statement (Owner's Defect Warranty Rights and Obligations)

EMISSIONCONTROLWARRANTYCOVERAGEISAPPLICABLETOCERTI-

FIEDENGINESPURCHASEDINCALIFORNIAIN1995ANDTHEREAF-

TER,WHICHAREUSEDINCALIFORNIA,ANDTOCERTIFIEDMODEL

California and United States Emission

TheCaliforniaAirResourcesBoard(CARD),U.S.EPAand Searsare pleased

toexplainthe EmissionControlSystemWarrantyonyour modelyear2000and

latersmalloff-roadengine(SORE).InCalifornia,newsmalloff-roadengines

mustbe designed,builtand equippedto meettheState'sstringentanti-smog

standards.Elsewherein theUnitedStates,newnon-road,spark-ignition

enginescertifiedformodelyear1997and latermustmeetsimilarstandardsset

forthbythe U.S.EPA.Searsmustwarranttheemissioncontrolsystemonyour

YEAR1997ANDLATERENGINESWHICHAREPURCHASEDANDUSED

ELSEWHEREINTHEUNITEDSTATES(ANDAFTERJANUARY1,2001 IN

CANADA).

Control Defects Warranty Statement

enginefortheperiodsoftime listedbelow,providedtherehasbeennoabuse,

neglector impropermaintenanceofyour smalloff-roadengine.Youremis-

sioncontrolsystemincludespartssuchasthecarburetor,aircleaner,ignition

system,mufflerandcatalyticconverter.Also includedmaybeconnectorsand

otheremissionrelatedassemblies.Wherea warrantableconditionexists,Sears

will repairyoursmalloff-roadengineatnocostto youincludingdiagnosis,parts

andlabor.

Sears Emission Control Defects Warranty Coverage

Smalloff-roadenginesarewarrantedrelativeto emissioncontrolpartsdefects

fora periodofone year,subjecttoprovisionssetforthbelow.Ifanycovered

Owner's Warranty

Asthe smalloff-roadengineowner,youare responsiblefor theperformanceof

therequiredmaintenancelistedinyourOperatingand MaintenanceInstruc-

tions.Searsrecommendsthatyouretainallyourreceiptscoveringmaintenance

onyoursmalloff-roadengine,butSearscannotdenywarrantysolelyforthe

lackofreceiptsorforyourfailuretoensuretheperformanceof allscheduled

maintenance.As the smalloff-roadengineowner,youshouldhoweverbe

awarethat Searsmaydenyyouwarrantycoverageifyoursmalloff-roadengine

ora parthasfaileddueto abuse,neglect,impropermaintenanceor unap-

parton yourengineis defective,the partwillbe repairedorreplacedbySears.

Responsibilities

provedmodifications.Youareresponsiblefor presentingyour smalloff-road

engineto anAuthorizedSearsServiceDealerassoonas aproblemexists.The

undisputedwarrantyrepairsshouldbecompletedina reasonableamountof

time,notto exceed30days.Ifyouhaveanyquestionsregardingyourwarranty

rightsandresponsibilities,youshouldcontacta SearsServiceRepresentative

at 1-800-469-4663.Theemissionwarrantyisa defectswarranty.Defectsare

judgedonnormalengineperformance.Thewarrantyisnotrelatedtoan in-use

emissiontest.

Sears Emission Control Defects Warranty Provisions

ThefollowingarespecificprovisionsrelativetoyourEmissionControlDefectsWarrantyCoverage.ItisinadditiontotheSearsenginewarrantyfornon-regulated

enginesfoundin theOperatingandMaintenanceInstructions.

1. WarrantedParts

Coverageunderthiswarrantyextendsonlytothe partslistedbelow(the

emissioncontrolsystemsparts)to the extentthesepartswerepresenton

theenginepurchased.

a. FuelMeteringSystem

• Cold startenrichmentsystem

• Carburetorandinternalparts

• FuelPump

b. AirlnductionSystem

• Aircleaner

• Intakemanifold

c. IgnitionSystem

• Sparkplug(s)

• Magnetoignitionsystem

d. CatalystSystem

• Catalyticconverter

• Exhaustmanifold

• Air injectionsystemorpulsevalve

e. MiscellaneousItemsUsedin AboveSystems

• Vacuum,temperature,position,timesensitivevalves

andswitches

• Connectorsandassemblies

2. Lengthof Coverage

Searswarrantsto theinitialownerand eachsubsequentpurchaserthat

theWarrantedPartsshallbefree fromdefectsin materialsandworkman-

shipwhich causedthefailureofthe WarrantedPartsfor aperiodof one

yearfromthe datetheengineis deliveredtoa retailpurchaser.

Inthe USAandCanada,a 24hourhotline,1-800-469-4663,hasamenuof pre-recordedmessagesofferingyouenginemaintenanceinformation.

3. NoCharge

Repairorreplacementof anyWarrantedPartwillbe performedat no

chargeto the owner,includingdiagnosticlaborwhichleadstothe

determinationthata WarrantedPartisdefective,ifthediagnosticwork is

performedatanAuthorizedSearsServiceDealer.Foremissionswarranty

servicecontact yournearestAuthorizedSearsServiceDealeras listedin

the "YellowPages"under"Engines,Gasoline,""GasolineEngines,""Lawn

Mowers,"orsimilarcategory.

4. Claimsand CoverageExclusions

Warrantyclaimsshallbefiled inaccordancewiththe provisionsof the

SearsEngineWarrantyPolicy.Warrantycoverageshallbeexcludedfor

failuresof WarrantedPartswhicharenotoriginalSears partsor because

ofabuse,neglector impropermaintenanceassetforth intheSears

EngineWarrantyPolicy.Searsisnotliableto coverfailuresof Warranted

Partscausedby theuseof add-on,non-original,or modifiedparts.

5. Maintenance

AnyWarrantedPartwhichis notscheduledforreplacementasrequired

maintenanceor whichis scheduledonlyfor regularinspectiontothe effect

of"repairor replaceasnecessary"shallbe warrantedasto defectsfor the

warrantyperiod.AnyWarrantedPartwhichis scheduledfor replacement

asrequiredmaintenanceshallbewarrantedas todefectsonly forthe

periodoftime uptothe firstscheduledreplacementfor that part.Any

replacementpartthat isequivalentinperformanceanddurabilitymay

beusedinthe performanceofanymaintenanceor repairs.Theowneris

responsiblefortheperformanceof all requiredmaintenance,as definedin

the SearsOperatingandMaintenanceInstructions.

6. ConsequentialCoverage

Coveragehereundershallextendto thefailure ofanyenginecomponents

causedbythefailureofanyWarrantedPartstill underwarranty.

GDOC-100188Rev.B

32

Page 33

Look For Relevant Emissions Durability Period and

Air index information On Your Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) Tier 2 Emission Standards must

display information regarding the Emissions Durability Period and the Air Index. Sears Brands Management

Corporation makes this information available to the consumer on our emission labels.

The Emissions Durability Period describes the number of hours of actual running time for which the engine is

certified to be emissions compliant, assuming proper maintenance in accordance with the Operating & Mainte-

nance Instructions. The following categories are used:

Moderate: Engine is certified to be emission compliant for 125 hours of actual engine running time.

Intermediate: Engine is certified to be emission compliant for 250 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore, the Emissions

Durability Period of an engine with an intermediate rating would equate to 10 to 12 years.

The Air index is a calculated number describing the relative level of emissions for a specific engine family. The

lower the Air Index, the cleaner the engine. This information is displayed in graphical form on the emissions label.

After July 1,2000, Look For Emissions Compliance Period

On Engine Emissions Compliance Label

After July 1, 2000 certain Sears Brands Management Corporation engines will be certified to meet the United

States Environmental Protection Agency (USEPA) Phase 2 emission standards. For Phase 2 certified engines, the

Emissions Compliance Period referred to on the Emissions Compliance label indicates the number of operating

hours for which the engine has been shown to meet Federal emission requirements.

For engines less than 225 cc displacement, Category C = 125 hours, B = 250 hours and A = 500 hours.

For engines of 225 cc or more, Category C = 250 hours, B = 500 hours and A = 1000 hours.

This is a generic representation of the emission label typically found on a certified engine.

FAMILYYBSXS.3192VA 274812

33

GDOC-100182Rev.B

Page 34

Congratulations on making a smart purchase. Your new Craftsman® product is designed and

manufactured for years of dependable operation. But like all products, it may require repair

from time to time. That's when having a Repair Protection Agreement can save you money and

aggravation.

Here's what the Repair Protection Agreement* includes:

[] Expert service by our 10,000 professional repair specialists

[] Unlimited service and no charge for parts and labor on all covered repairs

[] Product replacement up to $1500 if your covered product can't be fixed

[] Discount of 25% from regular price of service and related installed parts not covered by the

agreement; also, 25% off regular price of preventive maintenance check

[] Fast help by phone - we call it Rapid Resolution - phone support from a Sears representative.

Think of us as a "talking owner's manual."

Once you purchase the Repair Protection Agreement, a simple phone call is all that it takes for you

to schedule service. You can call anytime day or night, or schedule a service appointment online.

The Repair Protection Agreement is a risk-free purchase. If you cancel for any reason during the

product warranty period, we will provide a full refund. Or, a prorated refund anytime after the

product warranty period expires. Purchase your Repair Protection Agreement today!

Some limitations and exclusions apply. For prices and additional information in the U.S.A.

call 1=800=827=6655.

*Coverage in Canada varies on some items. For full details call Sears Canada at 1=800=361=

6665.

Sears Installation Service

For Sears professional installation of home appliances, garage door openers, water heaters, and

other major home items, in the U.S.A. or Canada call 1=800=4=MY=HOME®.

34

Page 35

Declaraci6n de garantia ....................... Pagina 35

Practicas operacion seguras ............... Pagina 36

Montaje ................................................ Pagina 40

Operacion ............................................ Pagina 44

Servicio y Mantenimiento .................... Pagina 46

Almacenamiento fuera de temporada .... Pagina 50

Solucion de problemas ...................... Pagina 51

ARTESANODEDOSAI/OS DEGARANT{A

PORDOSAI_OSSapartirdelafechadecompra,esteproductoestAgarantizadocontracualquier

defectodematerialo manodeobra.Unproductodefectuosorecibir&lareparacbnola sustitucbnsila

reparaci6nnoest&disponible.

Paraobtenerinformacbndetalladacoberturadela garanfiaparaobtenerlareparaci6no sustitucbn

gratuita,visiteelsitioweb:www.craftsman.com

EstagarantiacubrelosdefectosSOLOdernaterialesy fabricaci6n.Lagarantianoinduye:

• BementosreutilizaNesque puedengastarseporeluso normaldentrodel periodode

garanfia,talescomolascuchillas,bujias,filtrodeaire, pantalladedesgranadoy una

bolsa.

Etiquetas de seguridad ....................... Pagina 7

Lista de piezas ..................................... Pagina 20

Acuerdo de Proteccion Para

Reparaciones ....................................... Pagina 55

Labels .................................................. Pagina 31

NOmero de servicio ..................... Cubierta posterior

• ProductodaSosresultantesde losintentosdel usuariodernodificaci6ndel producto,

reparaci6nocausadosporaccesoriosdeproductos.

• Reparacionesnecesariasdebidoal accidenteopornooperaromantenerel producto

segQnlasinstruccionesprovistas.

• Elmantenimientopreventivoo reparacionesnecesariasdebidoa unamezclaincorrectade

combustible,combustiblecontaminadoo pasado.

Estagarantiaes inv_Jidasiesteproductose utilizaal mismotiempola prestaci6nde servicios

comercialeso sise alquilaa otrapersona.

Estagarantialeotorgaderechoslegalesespecificos,y ustedtambi_npuedetenerotrosderechos

quevariandeestadoa estado.

SearsBrands ManagementCorporation, Hoffman Estates,IL 60179

Serie: 1450

Tipodeaceitedelmotor: SAE30

Capacidadde aceitedel motor: 28onzas

Elcombustible: GasolinasinPIomo

Bujias: Champion®RC-12YC

Separaci6ndelasbujias: .030"

NSrnerode modelo ..........................................................

N_mero de serie..............................................................

Fechade compra .............................................................

RegistrearribaelnOmerodel modelo,el nOmerode serieyla fecha

de compra

KCDIRLLC 35

Page 36

Lapresenciade estesirnboloindicaquesetratadeinstrucciones

irnportantesdeseguridadque sedebenrespetarparaevitar

poneren peligrosuseguridadpersonaly/o materialyla deotras

personas.Leay sigatodaslas instruccionesdeestemanualantes

deponeren funcionarnientoestarn_.quina.Sinorespetaestas

instruccionespodriaprovocarlesionespersonales.Cuandoveaeste

sirnbolo,ipresteatenci6na laadvertencia!

Estarn_.quinarueconstruidaparaseroperadade acuerdocon

lasreglasdeseguridadcontenidaseneste manual.AIigualque

concualquiertipo de equipornotorizado,undescuidoo errorpor

partedel operadorpuedeproducirlesionesgraves.Estarn_.quina

escapazde arnputarrnanosypiesy dearrojarobjetoscongran

fuerza.De norespetarlas instruccionesde seguridadsiguientesse

puedenproducirlesionesgravesolarnuerte.

PROPOSICION 65 DE CALIFORNIA

Elescapedel motorde esteproducto,algunosdesuscornponentes

y algunoscornponentesdelvehiculocontieneno liberansustancias

quirnicasqueelestadode Californiaconsideraquepuedenproducir

c_.ncer,defectosde nacirnientouotrosproblernasreproductivos.

CAPACITACiON

• Lea,entienday curnplatodaslasinstruccionesincluidasen

la rnAquinay enlosrnanualesantesde rnontarlayutilizarla.

Guardeestemanualenun lugarseguroparaconsultasfuturasy

regulares,asicornoparasolicitarrepuestos.

• Leael ManualdelOperadory sigatodaslas advertenciase

instruccionesdeseguridad.El fracasodehacerasi puedecausar

la heridaseriaal operadory/opersonaspresentes.

• Farniliaricesecontodosloscontrolesysuoperaci6nadecuada.

Sepac6rnodetenerla rn_.quinay c6rnodesengranarloscontroles

r_.pidarnente.

• Noperrnitanuncaquelosnifos rnenoresde 16afrosutilicen

estarn_.quina.Los nifos de 16afrosy rn_.srnayoresdeben

leerycornprenderlas instruccionesde operaci6nylasreglas

de seguridadcontenidasen estemanual,ytarnbi_ndebenser

capacitadosy estarsupervisadosporunode lospadres.

• Nuncaperrnitaquelos aduitosoperenestarn_.quinasin recibir

antesla instrucci6napropiada.

• Mantengaa lostranseQntes,ayudantes,rnascotasy nifos al

rnenosa75piesde la rn_.quinarnientrasest,.operando.Detenga

la rn_.quinasi alguienentraenla zona.

• Nuncaenciendaunmotorenespacioscerradoso enunazona

conpocaventilaci6n.Elescapedel motorcontienernon6xidode

carbono,un gasinodoroy letal.

• Nopongalas rnanosolos piescercadelas piezasrotatoriaso

en lasc_.rnarasde alirnentaci6nnien laaberturadedescarga.El

contactocon el motorrotatoriopuedeproducirlaarnputaci6nde

dedos,rnanosopies.

• Nuncatratededestapar[atornade alirnentaci6no la aberturade

descarga,nitratede sacaro vaciarla bolsade laaspiradora,ni

de revisary repararlarn_.quinarnientrasel motorest,.enrnarcha.

Apagueel motory esperehastaquetodaslaspiezasrn6vilesse

hayandetenidoporcornpleto.Desconecteel cablede la bujiay

p6ngalodernaneraque hagarnasacontrael motor.

Su responsabilidad--Restrinja el uso deestarn_.quina

rnotorizadaalas personasque lean,cornprendany respetenlas

advertenciase instruccionesqueaparecenenestemanualyen la

rn_.quina.

iGUARDEESTASINSTRUCCIONES!

PREPARATIVOS

* Inspeccionerninuciosarnenteel _.readondeutilizar_,el equipo.

Retiretodaslaspiedras,botellas,latasu otrosobjetosextrafos

que puedanserlevantadoso arrojadoscausandolesiones

personaleso dafos a larn_.quina.

, Paraprotegerselosojosutilicesiernpreanteojosoantiparras

de seguridadrnientrasoperalarn_.quinao rnientrasla ajusta

o repara.Losobjetosarrojadosquerebotanpuedenlesionar

gravernentelavista.

, Utilicezapatosde trabajoresistentes,desuelafuerte,asicorno

pantalonesy carnisasajustados.Lasprendassueltasolas

alhajaspuedenquedaratrapadasen laspiezasrn6viles.Nunca

utilicela rn_.quinadescaizoocon sandalias.Utiiiceguantesde

trabajodecuerocuandoalirnentematerialporelcanal dela

cortadora.

, Antesde encenderla rn_.quinacontrolequetodoslospernosy

tornillosest_nbienajustadosparacornprobarquela rn_.quinase

encuentraen condicionessegurasdeoperaci6n.Adern_.s,realice

una inspecci6nvisualde la rn_.quinaa intervalosfrecuentespara

controlarsila rnisrnaest,.dafada.

, Mantengao reernplacelasetiquetasdeseguridadeinstrucciones

segQnseanecesario.

36

Page 37

Manejoseguro de la gasolina

Paraevitarlesionespersonaleso daSosrnaterialesseasurnarnente

cuidadosoal rnanipularla gasolina.Lagasolinaesaltarnenteinflarno

ableysusvaporespuedencausarexplosiones.Se puedelesionar

gravernentesiderrarnagasolinasobreustedosobrela ropayaquese

puedeencender.L_veselapiely c&rnbiesede ropadeinrnediato.

• Utilices61orecipientesparagasolinaautorizados.

• NuncaIlenelos contenedoresenelinteriordeun vehiculo

o carni6nocaja decarnionetacon recubrirnientospl&sticos.

Coloquesiernprelos recipientesenel pisoy lejosdelvehiculo

antesde Ilenarlos.

• Retireel equipoa gasolinadelcarni6no rernolquey II_neloen

el piso.Si estonoesposible,entoncesIlenedichoequipoenun

rernolqueconun recipienteport&til,en vezdedesdeundispen-

sadordegasolina.

• Mantengala boquillade Ilenadoencontactoconel bordedela

entradadeltanquedegasolinao contenedorentodornornento

hastaqueest_Ileno.Noutiliceundispositivoparaabrir/cerrarla

boquilla.

• Apaguetodosloscigarrillos,cigarros,pipasy otrasfuentesde

cornbusti6n.

• Nuncacarguecornbustibben la rn&quinaen unespaciocerrado.

• Nuncasaquelatapa delgasni agreguecombustiblernientrasel

motorest&calienteo enrnarcha.Dejequeel motorseenfriepor

Iornenosdosrninutosantesdevolvera cargarcombustible.

• Nuncarecargueel tanquedecombustible.Lleneel tanqueno

rn&sde1/2 pulgadapordebajode la basedelcuellodelfiltro

paradejarespacioparala dilatacbndelcornbustibb.

• Vuebaa colocarla tapade lagasolinay aj_steb bien.

• Lirnpielagasolinaderrarnadasobreelmotory elequipo.Trasbde

la rn&quinaa otrazona.Espere5rninutosantesdeencenderel

motor.

• Nuncaalrnacenela rn&quinao el recipientede combustibleen

unespaciocerradodondehayafuego,chispasoluzpiloto(por

ejernplo,hornos,calentadoresdeagua,calefactores,secadores

de ropa,etc.)

• Parareducirelriesgodeincendiornantengalarn_.quinalirnpia

depasto,hojasyde acurnulaci6ndeotrosdesechos.Lirnpielos

derrarnesdeaceiteo combustibley saquetodoslosdesechos

ernbebidosconcombustible.

OPERACION

• Nopongalas rnanosolos piescercadelas piezasrotatoriaso

enlasc_.rnarasdealirnentaci6nni en laaberturade descarga.El