Page 1

Safety • Assembly • Operation • Tips & Techniques • Maintenance • Troubleshooting • Parts Lists • Warranty

OF A O AL

/

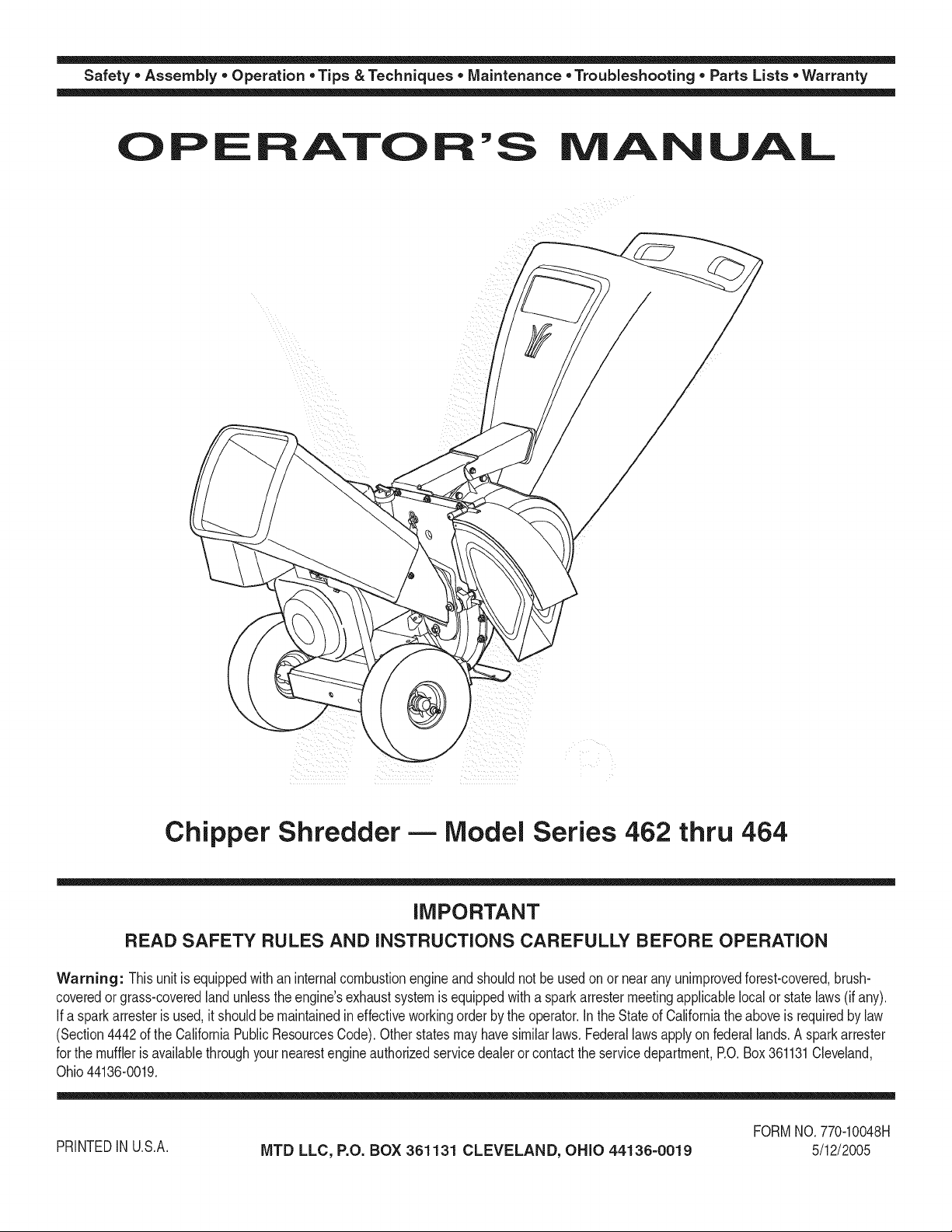

Chipper Shredder- Model Series 462 thru 464

iMPORTANT

READ SAFETY RULES AND iNSTRUCTiONS CAREFULLY BEFORE OPERATION

Warning: Thisunitisequippedwithaninternalcombustionengineandshouldnotbeusedon or nearanyunimprovedforest-covered,brush-

coveredor grass-coveredlandunlesstheengine'sexhaustsystemisequippedwitha sparkarrestermeetingapplicablelocalor statelaws(if any).

If a sparkarresterisused,it shouldbemaintainedineffectiveworkingorderby theoperator.IntheStateofCaliforniatheaboveisrequiredbylaw

(Section4442oftheCaliforniaPublicResourcesCode).Otherstatesmayhavesimilarlaws.Federallawsapplyonfederallands.A sparkarrester

forthemufflerisavailablethroughyournearestengineauthorizedservicedealeror contactthe servicedepartment,RO.Box361131Cleveland,

Ohio44136-0019.

FORMNO.770-10048H

PRINTEDIN U.S.A.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

5/12/2005

Page 2

This Operator's Manual is an important part of your new chipper shredder, it will help you assemble, pre-

pare and maintain the unit for best performance. Please read and understand what it says.

Table of Contents

Customer Support .............................................. 2

Safety Labels ...................................................... 3

Safe Operation Practices ................................... 4

Setting UpYour Chipper Shredder .................... 6

Operating Your Chipper Shredder ..................... 8

Finding and Recording Model Number

BEFOREYOUSTARTASSEMBLING

YOURNEW EQUIPMENT,

pleaselocate themodel plateon the equipment and copy

the informationto the sample model plate providedto the

right.Youcan locatethe modelplate by standing behindthe

unitand looking down at the frame belowtheengine. This

informationwill benecessary to usethe manufacturer'sweb

site and/or obtainassistancefrom the CustomerSupport

Departmentor an authorizedservice dealer.

Maintaining Your Chipper Shredder ................ 10

Troubleshooting ................................................ 12

Parts List ........................................................... 14

Warranty ............................................ Back Cover

f *x,

Model Number

Serial Number

MTD LLC

P.O. BOX 361131

CLEVELAND, OH 44136

®

www.mtdproducts,com

330 -220 -4683

800-800-7310

J

Customer Support

Please do NOTretum the unit to the retailer from which it was

purchased, without first contacting Customer Support.

Ifyou havedifficulty assembling this productor haveany questionsregarding the controls, operation, or maintenanceof this

unit,youcan seek helpfrom the experts. Choose from the options below:

1. Visit mtdproducts.com. Click on the Service& Support menu option.

2. Phonea Customer Support Representative at 1 (800) 800-7310.

3. Theengine manufacturer isresponsiblefor all engine-related issueswithregards to performance,power-rating,specifica-

tions,warrantyand service. Pleaserefer to the engine manufacturer'sOwner's/Operator'sManual, packedseparatelywith

your unit,for more information.

MTD Hin_r_oti®d A_wJ_d Wi_n i_g ?rod_t_ O'_r Comp_y

Ser,oqce & Suppo ±

Product. Registration

Con_@_z_Us

?rba_y Policy

2

Page 3

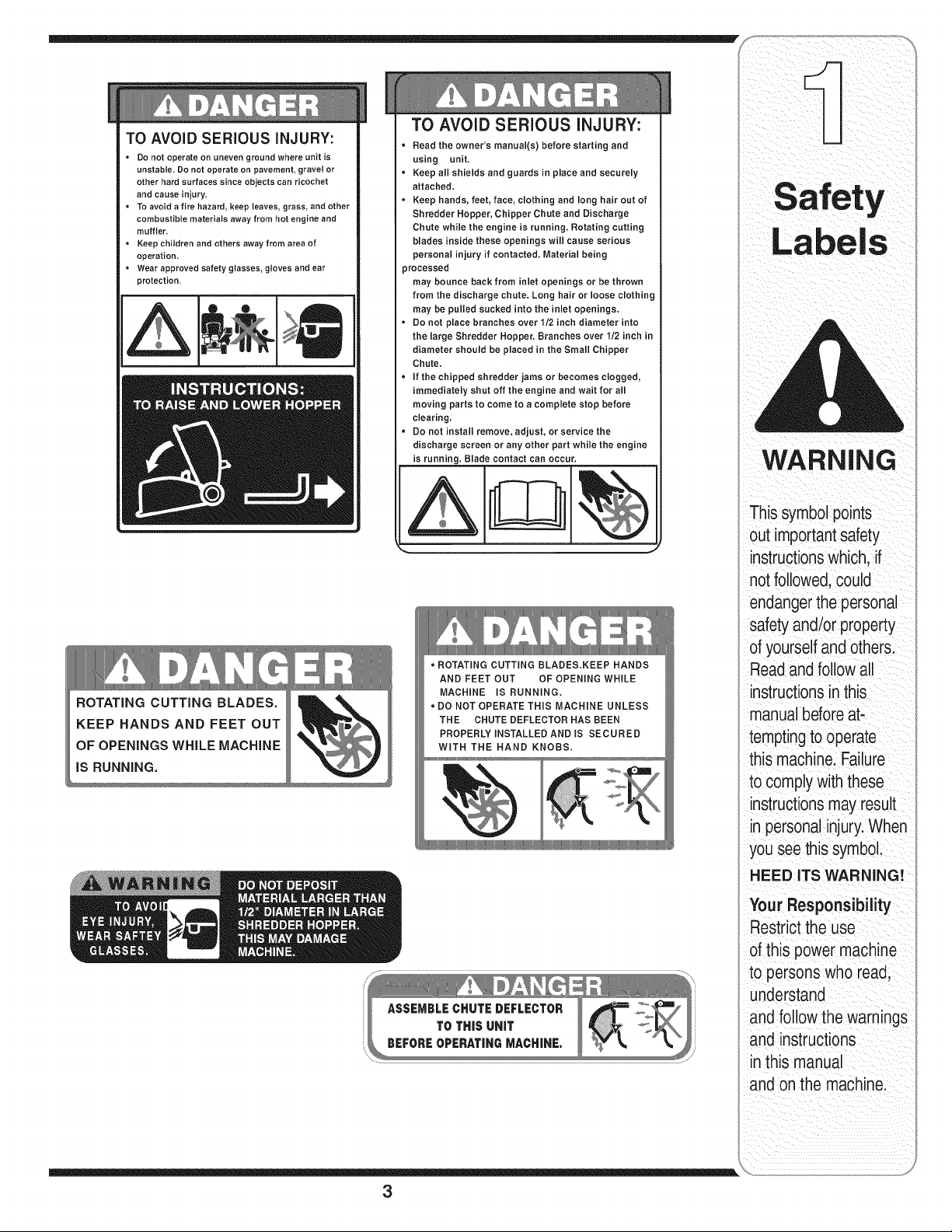

TO AVOID SERIOUS iNJURY:

• Do not operate on uneven ground where unit is

unstable, Do not operate on pavement, gravel or

other hard surfaces since objects can ricochet

and cause injury,

• To avoid a fire hazard, keep leaves, grass, and other

combustible materials away from hot engine and

muffler,

• Keep children and others away from area of

operation,

• Wear approved safety glasses, gloves and ear

protection.

ROTATING CUTTING BLADES.

KEEP HANDS AND FEET OUT

OF OPENINGS WHILE MACHINE

iS RUNNING.

TO AVOID SERIOUS iNJURY:

• Read the owner's manual(s) before starting and

using unit,

• Keep all shields and guards in place and securely

attached.

• Keep hands, feet, face, clothing and long hair out of

Shredder Hopper, Chipper Chute and Discharge

Chute while the engine is running, Rotating cutting

blades inside these openings will cause serious

personal injury if contacted. Material being

processed

may bounce back from inlet openings or be thrown

from the discharge chute. Long hair or loose clothing

may be pulled sucked into the inlet openings.

• Do not place branches over 1/2 inch diameter into

the large Shredder Hopper. Branches over 1/2 inch in

diameter should be placed in the Small Chipper

Chute.

• If the chipped shredder jams or becomes clogged,

immediately shut off the engine and wait for all

moving parts to come to a complete stop before

clearing.

• Do not install remove, adjust, or service the

discharge screen or any other part while the engine

is running. Blade contact can occur.

• ROTATING CUTTING BLADES.KEEP HANDS

AND FEET OUT OF OPENING WHILE

MACHINE iS RUNNING.

DO NOT OPERATE THiS MACHINE UNLESS

THE CHUTE DEFLECTOR HAS BEEN

PROPERLY iNSTALLED AND IS SECURED

WITH THE HAND KNOBS.

iil _I ii_ _ i _iii_!i _ _ii_ ii

WARNING

Thissymbolpoints

J

out importantsafety

instructionswhich,if

notfollowed,could

endangerthepersonal

safetyand/or property

of yourselfandothers.

Readandfollowall

instructionsinthis

manualbeforeat-

temptingto operate

this machine.Failure

to complywiththese

instructionsmayresult

in personalinjury.When

youseethis symbol.

HEED ITS WARNING!

Your Responsibility

Restrictthe use

ofthis power machine

to persons who read,

understand

and follow thewarnings

and instructions

in this manual

and onthe machine.

3

Page 4

WARNING: EngineExhaust,some of its constituents,andcertain vehicle compo-

nentscontain or emit chemicals knownto Stateof Californiato cause cancerand

birth defects or other reproductiveharm.

DANGER: This machinewas builtto beoperatedaccordingto the rulesfor safe operationin this

manual.As with anytypeof power equipment,carelessnessor error on the part of the operator can

result in seriousinjury.This machine iscapableof amputatinghands andfeet andthrowing objects.

Failureto observethe followingsafetyinstructionscould result in serious injury or death.

WARNING

Thissymbolpoints

out importantsafety

instructionswhich,if

notfollowed,could

endangerthe personal

i safetyand/or property

I ofyourselfandothers.

Readandfollowall

instructionsinthis

manualbeforeat-

temptingto operate

i this machine.Failure

I to complywiththese

instructionsmayresult

i inpersonalinjury.When

youseethis symbol.

i HEED ITS WARNING!

Your Responsibility

Restrictthe use

ofthis powermachine

to personswho read,

_understand

ane followthe warnings

and instructions

inthis manual

and on the machine.

Training

1. Read,understand,andfollowall instructionsonthe 1.

machineandin themanual(s)beforeattemptingto

assembleandoperate.Keepthis manualina safe placefor

futureandregularreferenceandfor orderingreplacement

parts. 2.

2. Befamiliarwithall controlsandtheirproperoperation.

Knowhowto stopthe machineanddisengagethemquickly.

3. Neverallowchildrenunder16yearsoldto operatethis

machine.Children16yearsoldandovershouldreadand

understandtheoperationinstructionsandsafetyrulesin 3.

thismanualand shouldbetrainedandsupervisedbya

parent.

4. Neverallowadultsto operatethis machinewithoutproper

instruction.

5. Keepbystanders,helpers,pets,andchildrenatleast75 4.

feetfromthe machinewhileit isin operation.Stop machine

ifanyoneentersthearea.

6. Neverrunanengineindoorsorina poorlyventilatedarea.

Engineexhaustcontainscarbonmonoxide,an odorless

anddeadlygas. 5.

7. Donot puthandsandfeet nearrotatingpartsor inthe

feedingchambersand dischargeopening.Contactwiththe 6.

rotatingimpellercanamputatefingers,hands,andfeet.

8. Neverattemptto unclogeitherthefeedintakeordischarge

opening,removeoremptybag, orinspectandrepairthe

machinewhiletheengineis running.Shuttheengineoff

andwaituntilallmovingparts havecometo acomplete

stop.Disconnectthe sparkplugwireandgroundit against

theengine.

Preparation

Thoroughlyinspecttheareawherethe equipmentisto

beused.Removeallrocks,bottles,cans,or otherforeign

objectswhichcouldbe pickeduporthrownandcause

personalinjuryor damageto the machine.

Alwayswearsafetyglassesorsafetygogglesduringopera-

tionor whileperforminganadjustmentor repair,to protect

eyes.Thrownobjectswhichricochetcancauseserious

injurytothe eyes.

Wearsturdy,rough-soledworkshoesand close-fitting

slacksandshirts. Loosefittingclothesor jewelrycan be

caughtinmovableparts.Neveroperatethis machine

in barefeet or sandals.Wearleatherworkgloveswhen

feedingmaterialin thechipperchute.

Beforestarting,checkallboltsandscrewsfor propertight-

nessto besurethemachineisin safeworkingcondition.

Also,visuallyinspectmachinefor anydamageatfrequent

intervals.

Maintainorreplacesafetyandinstructionslabels,as

necessary.

Toavoidpersonalinjuryor propertydamageuseextreme

careinhandlinggasoline.Gasolineisextremelyflammable

andthe vaporsare explosive.Seriouspersonalinjurycan

occurwhengasolineis spilledonyourselforyour clothes

whichcanignite.Washyour skinandchangeclothes

immediately.

a. Useonlyanapprovedgasolinecontainer.

b. Extinguishallcigarettes,cigars, pipes,andother

sourcesofignition.

c. Neverfuelmachineindoors.

d. Neverremovegascap oradd fuelwhilethe engineis hot

or running.

e. Allowengineto coolat leasttwo minutesbeforerefuel-

ing.

f. Neveroverfillfueltank. Filltankto nomorethan1/2

inchbelowbottomoffiller neckto providespaceforfuel

expansion.

g. Replacegasolinecap andtightensecurely.

h. If gasolineis spilled,wipe itoff theengineandequip-

ment.Movemachinetoanotherarea.Wait5 minutes

beforestartingtheengine.

i. Neverstorethe machineorfuel containerinsidewhere

there is an openflame,spark,or pilotlight (e.g.furnace,

waterheater,spaceheater,clothesdryer,etc.)

j. Toreducea fire hazard,keepmachinefreeofgrass,

leaves,orotherdebrisbuild-up.Cleanupoilor fuel

spillageandremoveanyfuel soakeddebris.

k. Allowmachinetocoolat least5 minutesbeforestoring.

4

Page 5

Operation

1. Donot puthandsandfeet nearrotatingpartsor in the

feedingchambersanddischargeopening.Contactwith the

rotatingimpellercanamputatefingers, hands,andfeet.

2. Beforestartingthemachine,makesurethechipperchute,

feedintake,andcuttingchamberare emptyandfree ofall

debris.

3. Thoroughlyinspectall materialto beshreddedand remove

any metal,rocks,bottles,cans,orotherforeignobjects

whichcouldcausepersonalinjuryordamageto the

machine.

14.f it becomesnecessaryto pushmaterialthroughthe

shredderhopper,usea smalldiameterstick. Do notuse

yourhandsorfeet.

15.fthe impellerstrikesa foreignobject or ifyourmachine

shouldstart makinganunusualnoiseor vibration,

immediatelyshuttheengineoff.Allowthe impellertocome

to a completestop.Disconnectthesparkplugwire,ground

itagainstthe engineandperformthefollowingsteps:

a. Inspectfordamage.

b. Repairorreplaceanydamagedparts.

c. Checkfor any loosepartsand tightento assure

continuedsafeoperation.

6. Donotallow an accumulationof processedmaterialtobuild

upinthedischargearea.Thiscan preventproperdischarge

andresult in kickbackof materialthroughthefeed opening.

7. Donotattemptto shredorchipmateriallargerthan

specifiedonthe machineor inthis manual.Personalinjury

or machinedamagecouldresult.

8. Neverattemptto unclogeitherthe feed intakeordischarge

openingwhilethe engineisrunning.Shutthe engineoff,

wait until all movingpartshavestopped,disconnectthe

sparkplugwireandgroundit againsttheenginebefore

clearingdebris.

9. Neveroperatewithouttheshredderhopper,chipperchute,

or chutedeflectorproperlyattachedto the machine.Never

emptyor changedischargebagwhiletheengineis running.

10.Keepall guards,deflectorsandsafetydevicesin placeand

operatingproperly.

11.Keepyourface andbodybackand totheside ofthechipper

chutewhilefeedingmaterialintothe machineto avoid

accidentalkickbackinjuries.

12.Neveroperatethis machinewithoutgoodvisibility or light.

13.Donotoperatethismachineon a paved,gravelor non-level

surface.

14.Donotoperatethismachinewhile undertheinfluenceof

alcoholordrugs.

15.Mufflerandenginebecomehotandcan causea burn.Do

nottouch.

16.Neverpickupor carrymachinewhilethe engineisrunning.

Maintenance & Storage

1. Nevertamperwithsafetydevices.Checktheirproper

operationregularly.

2. Checkbolts and screwsfor propertightnessatfrequent

intervalstokeepthe machineinsafeworkingcondition.

Also,visuallyinspectmachinefor anydamageandrepair,if

needed.

3. Beforecleaning,repairing,or inspecting,stoptheengine

andmakecertainthe impellerand all movingpartshave

stopped.Disconnectthesparkplugwireandgroundit

againsttheengineto preventunintendedstarting.

4. Do notchangetheenginegovernorsettingsor overspeed

theengine.The governorcontrolsthemaximumsafe

operatingspeedoftheengine.

5. Maintainor replacesafetyandinstructionlabels,as neces-

sary.

6. Followthis manualforsafeloading,unloading,transporting,

andstorageofthis machine.

7. Neverstorethe machineorfuel containerinsidewhere

thereisan openflame,sparkor pilot lightsuchasa water

heater,furnace,clothesdryer,etc.

8. Alwaysreferto theoperator'smanualfor properinstructions

onoff-seasonstorage.

9. If thefueltankhasto be drained,dothisoutdoors.

10.Observeproperdisposallawsandregulationsfor gas,oil,

etc.toprotecttheenvironment.

Do not modify engine

Toavoidseriousinjuryordeath,donot modifyengineinany

way.Tamperingwiththegovernorsettingcan leadto arunaway

engineandcauseit tooperateatunsafespeeds.Nevertamper

withfactorysettingofenginegovernor.

Notice regarding Emissions

Engineswhicharecertifiedto complywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOff RoadEquipment)

arecertifiedtooperateonregularunleadedgasoline,andmay

includethefollowingemissioncontrolsystems:EngineModifica-

tion(EM)andThreeWayCatalyst(TWO)ifso equipped.

Your Responsibility

Restrictthe useofthispowermachineto personswhoread,un-

derstandandfollowthe warningsandinstructionsin this manual

andon the machine.

Operation

WARNING

Thissymbol points

out importantsafety

instructions,which if

notfollowed,could

endangerthe personal

safety and/or property

of yourself and others.

Readand followall

instructions inthis man-

ual before attemptingto

operatethis machine.

Failureto comply with

these instructionsmay

result in personalinjury.

Whenyou seethis

symbol.

HEED iT S WARNING!

YourResponsibility

Restrictthe use

of this powermachine

to personswho read.

understand

and followthe warnings

and instructions

in this manua

and on the machine.

5

Page 6

iMPORTANT

Thisunitisshipped

without gasolineor

oil inthe engine.Be

certainto service

enginewith gasoline

and oil as instructed

inthe separateengine

manual beforeoperat-

ingyour machine.

Figure 1

Figure 2

iMPORTANT:Thisunitisshippedwithoutgasolineoroil

in theengine.Becertainto serviceenginewithgasoline

andoilas instructedintheseparateenginemanual

beforeoperatingyourmachine.

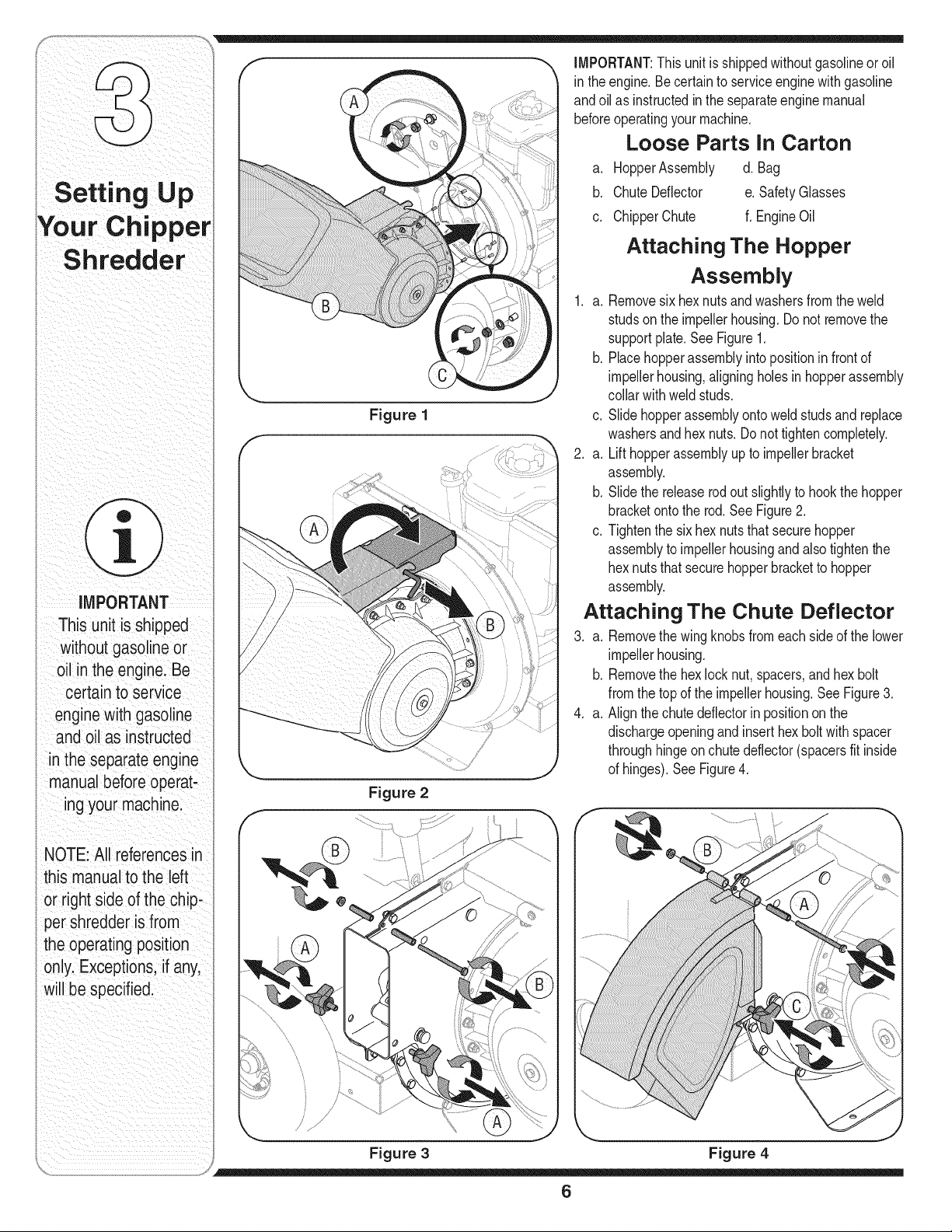

Loose Parts In Carton

a. HopperAssembly d. Bag

b. ChuteDeflector e.SafetyGlasses

c. ChipperChute f. EngineOil

Attaching The Hopper

Assembly

1. a. Removesixhexnutsandwashersfromtheweld

studsontheimpellerhousing.Donotremovethe

supportplate.SeeFigure1.

b. Placehopperassemblyintopositioninfrontof

impellerhousing,aligningholesinhopperassembly

collarwithweldstuds.

c. Slidehopperassemblyontoweld studsandreplace

washersandhex nuts.Donottightencompletely.

2. a. Lift hopperassemblyupto impellerbracket

assembly.

b. Slidethereleaserodoutslightlyto hookthehopper

bracketontothe rod.SeeFigure2.

c. Tightenthe sixhexnutsthatsecurehopper

assemblytoimpellerhousingandalsotightenthe

hexnutsthatsecurehopperbrackettohopper

assembly.

Attaching The Chute Deflector

3. a. Removethewingknobsfromeachsideofthe lower

impellerhousing.

b. Removethe hexlocknut,spacers,andhexbolt

fromthetopoftheimpellerhousing.SeeFigure3.

4. a. Alignthechutedeflectorin positiononthe

dischargeopeningandinserthexboltwithspacer

throughhingeonchutedeflector(spacersfit inside

ofhinges).See Figure4.

NOTE:All referencesin

this manualto the left

or rightside ofthe chip-

per shredderis from

theoperating position

only.Exceptions.ifany,

will be specified.

j {

/j /'

Figure 3

Figure 4

6

Page 7

b. Placesecondspaceroverhex boltinsideother

hingeandsecurewithhexlocknut.

c. Securebothsidesofchutedeflectorto impeller

housingusingwingknobspreviouslyremoved.

Attaching The Chipper Chute

5. a. Removethethreecuppedwashersandhexnuts

fromweldstudsaroundtheopeningonthesideof

theimpellerhousing.SeeFigure5.

b. Removethehexbolts,flat washers,andlocknuts

fromthetwoholeson the upperendofthesupport

brace.

6. a. Alignthechipperchuteovertheweldstuds,sothe

slotinthebottomof thechuteisfacingdown.

b. Securechipperchutewiththe threecupped

washers(cuppedsideagainstthe chipperchute)

and hexnutspreviouslyremoved.Donottighten

thenutsatthistime. SeeFigure6.

7. The chippershredderwasshippedwithoneendof

thesupportbracealreadysecuredtothe lowerframe.

Loosenbutdo notremovetheboltssecuringthebrace

totheframe.SeeFigure7.

a. Aligntheholesin thechutewiththe holesinthetop

ofthebraceandattachbracetochipperchutewith

hardwarepreviouslyremoved.Tightensecurely.

b. Tightenthe boltssecuringthesupportbracetothe

frame.

c. Tightenthethreenutsontheweldstudsholding

thechipperchutetotheimpellerhousing.

Attaching The Bag

8. Toattachthe bag:

a. Placetheopeningof thebagcompletelyoverthe

chutedeflector.

b. Pullon the drawstringuntilthebagistightaround

chutedeflectoropening.

c. Clipdrawstringbackon itself,tightagainstchute

deflectorto secureintoposition.SeeFigure8.

Your Chipper

Shredder

.//

Figure 5

f

Figure 6

i

/

i

i

/

/

/

/

/

/

/

/

i /

/ /

/

/

/

/

/

/

/

ii i _iI_ ii

J

Figure 8 Figure 7

7

i

i

i s

/

/

/

Page 8

WARNING

The operation of any

chippershredder

can result inforeign

objects being thrown

intothe eyes,which

can damageyour

I eyes severely.Always

i wear the safety

glasses provided

with this unit or eye

i shields before chip-

pingor shredding

and while performing

i any adjustmentsor

repairs.

I Use extreme care

when handling

gasoline.Gasolineis

i extremelyflammable

and the vaporsare

explosive. Never fuel

i the machine indoors

or while the engine

is hot or running.

; Extinguishcigarettes,

cigars, pipes and

other sources of

i ignition.

Know Your Chipper Shredder

HopperAssembly

ReleaseRod

Oil Fill1-

Chipper

TowBart'_

Now that you have set up your chipper shredder

for operation, get aquainted with its controls and

features. These are described below and illustrated

on this page. This knowledge will allow you to use

your new equipment to its fullest potential.

Chipper Chute

Allows twigs and small branches up to 3" in diam-

eter to be fed into the impeller for chipping. See

Figure 9.

Hopper Assembly

Allow leaves and small branches up to 1/2 diameter

to be fed into the impeller for chipping and shred-

ding. Material can be raked into hopper assembly

by lowering the hopper assembly. See Figure 9.

Release Rod

The release rod is located on the impeller bracket

assembly and it is used to release or lock the hop-

per when raising or lowering. See Figure 9.

Tow Bar (if Equipped)

Use the tow bar to tow the chipper shredder behind

a tractor to a job site. See Figure 9.

NOTE:Ifyourunitisnotequippedwithatowbar,you

maycontactCustomerSupportasinstructedonpage2

forinformationregardingpriceandavailability.

Oil Fill

@

1-If Equipped

Figure 9

Gas and Oil Fill-Up

1. Check oil level and add oil if necessary. Follow engine

manual for this. See Figure 9 above for location of the

oil fill.

2. Servicethe enginewithgasolineasinstructedinthe

enginemanual. SeeFigure9 aboveforlocationof

gas fill.

WARNING:Useextremecarewhen han-

dling gasoline.Gasolineisextremely

flammableand the vapors areexplosive.

Neverfuel the machine indoorsor while

the engineis hotor running. Extinguish

cigarettes,cigars,pipesandother

sourcesof ignition.

WARNING:Theoperation of any

chippershreddercanresultinforeign

objectsbeingthrown intothe eyes,

which candamage youreyesse-

verely.Alwayswearthe safetyglasses

providedwith this unit or eyeshields

before chippingor shreddingandwhile

performingany adjustments or repairs.

8

Page 9

Starting Engine

_hlk ARNING:Neverrun the engine

1. Attachsparkplugwiretosparkplug.Makecertain

themetalcapontheend ofthe sparkplugisfastened

securelyoverthemetaltiponthe sparkplug.

2. Engines with choke lever:

Movechokeleveronengineto CHOKEposition.(A

warmenginemaynotrequirechoking).

Engineswith primer:

Primeengineasinstructedinseparateenginemanual.

3. The throttlecontrolleverislocatedontheengine.

MoveenginethrottlecontrollevertoFASTor START

position.SeeFigure10.

4. Graspstarterhandleand pullropeoutslowlyuntil

enginereachesstartofcompressioncycle(ropewill

pull slightlyharderatthispoint).

NOTE:A noisewillbeheardwhenfindingthestartof

thecompressioncycle.Thisnoiseis causedbytheflails

andfingers,whichare partoftheshreddingmechanism,

and itshouldbeexpecteduntilthe impellerreachesfull

speed.

indoorsor in a poorly ventilatedarea.

Engineexhaustcontainscarbonmonox-

ide,an odorlessand deadly gas.

Figure 10

Using The Chipper Shredder

Yardwastesuchas leavesandpineneedlescanbe

rakedupthroughthehopperassemblyforshredding.

Aftermaterialhasbeenshreddedbytheflail bladeson

theimpellerassembly,itwillbe dischargedoutofopen-

ingorintocatcherbag.Donotattemptto shredorchip

anymaterialotherthanvegetationfoundina normal

yard(i.e.branches,leaves,twigs,etc.)Avoidfibrous

plantssuchastomatovinesuntiltheyarethoroughly

driedout. Twigsandsmallbranchesupto3" in diameter

canbefedintothechipperchute.

Lowering The Hopper Assembly

1. Withonehandgraspthehandleatthetopofthe

hopperassemblyandliftslightly.

2. Withtheotherhandpulloutonthe releaserod

andlowerthehopperassemblytotheground.See

Figure9.

WARNING

Never run the engine

indoorsorin a poorly

ventilated area: Engine

exhaust contains

carbon monoxide, an

_dorless and deadly

5. Pullropewitha rapid,continuous,fullarmstroke.

Keepa firmgriponstarterhandle.Let roperewind

slowly.

6. Repeatthepreviousstepsuntilenginefires.When

enginestarts,movechokecontrol(ifequipped)

graduallyto RUNposition.

Stopping Engine

1. Movethrottlecontrolleverto STOPorOFFposition.

2. Disconnectsparkplugwirefromsparkplugand

groundagainsttheengine.

NOTE:Seeyourenginemanualpackedwithyourunitfor

moredetailedinstructions.

To Empty Bag

1. Un-clipdrawstringand loosenbagfromchute

deflectoropening.

2. Emptybagandreattachtothe dischargechute

opening.Pullonthedrawstringuntilthebagistight

aroundthechuteopeningandclipthedrawstring

tightagainstthechutedeflector.

IMPORTANT:Theflailscreenislocatedinsidethe

housinginthedischargearea.If theflail screen

becomesclogged,removeandcleanasinstructedin

SECTION5: MAINTAININGYOURCHIPPERSHRED-

DER.Forbestperformance,it isalsoimportantto keep

thechipperbladesharp.

NOTE: A noisewillbe

heardwhenfindingthestart

ofthe compressioncycle.

Thisnoiseiscausedby

theflailsand fingers,which

arepartoftheshredding

mechanismanditshould

oeexpecteduntilthe impel-

er reachesfullspeed.

9

Page 10

WARNING

Alwaysstop engine,

isconnect spark plug,

groundagainst

pnginebeforecleaning,

lubricating or doing any

Kind of maintenance on

yourmachine.

points before

reassembly.

Figure 11

i

/

Figure 12

General Recommendations

1. Alwaysobservesafetyruleswhen performing

anymaintenance.

2. Thewarrantyonthischippershredderdoesnot

coveritemsthathavebeensubjectedtooperator

abuseornegligence.Toreceivefullvaluefromwar-

ranty,operatormustmaintainthechippershredder

asinstructedhere.

3. Changingofengine-governedspeedwillvoid

enginewarranty.

4. Alladjustmentsshouldbecheckedat leastonce

eachseason.

5. Periodicallycheckallfastenersand makesurethese

aretight.

_ ARNING:Alwaysstopengine,

disconnect sparkplug, and ground

against enginebeforecleaning,

lubricating or doing any kind of

maintenanceon yourmachine.

/

/

/

/ "

/"

Lubrication

1. Lubricatethereleaserodand springwithlightoil once

a season.SeeFigure11.

2. Lubricatethepivotpointsonthehopperassemblywith

lightoil onceaseason.See Figure11.

3. Lubricatethepivotpointsonthedischargechutewith

lightoil onceaseason.See Figure11.

4. Followtheaccompanyingenginemanualforlubrica-

tionscheduleandinstructionforenginelubrication.

Engine Care

1. Maintainoillevelasinstructedin enginemanual.

2. Serviceaircleanerevery25hoursundernormal

conditions.Cleaneveryfewhoursunderextremely

dustyconditions.Refertoenginemanual.

3. Cleansparkplugandresetthegaponcea season.

Checkenginemanualforcorrectplugtypeandgap

specifications.

4. Cleanengineregularlywitha clothorbrush.Keepthe

coolingsystem(blowerhousingarea)cleantopermit

properaircirculation.Removeall grass,dirtand

combustibledebrisfrommufflerarea.

Removing The Flail Screen

If thedischargeareabecomesclogged,removetheflail

screenandcleanareaasfollows:

1. Stoptheengineandmakecertainthechippershred-

derhascometoa completestop.

2. Disconnectsparkplugwirefromsparkplugand

groundagainsttheengine.

3. a. Removethebagandtwo wingknobson eachside

ofthechutedeflector.SeeFigure12.

b. Liftthechutedeflectorupto keepitoutof theway.

c. Removethetwo hairpinclipsfromeachclevispin

whichextendthroughthe housingandremovepins.

d. Removetheflail screenfrominsidethehousing

andcleanthescreenbyscrapingor washingwith

water.SeeFigure12.

4. Reinstallthescreen,makingcertainto reassemblethe

flailscreenwiththecurvesidedown.

5. Reattachthechutedeflectorwiththehardware

previouslyremovedandconnectthe bagtounit.

Sharpening Or Replacing Chipper

Blades

1. Disconnectthesparkplugwireandgroundagainstthe

engine.

2. Removetheflail screenasinstructedintheprevious

section.

3. Removethechipperchutebyremovingthreehexnuts

andwashers.

4. Removethechipperchutesupportbracefromthe

framebyremovingthehexbolts.

5. Rotatetheimpellerassemblybyhanduntilyoulocate

oneofthetwochipperbladesin thechipperchute

opening.

10

Page 11

6. Removethebladebyremovingthe internalhex

screws,lockwashers,andhexnutswhichsecureitto

theimpeller.Retainthehardware.SeeFigure13.

NOTE:Usea 3/16"hex key(Allen)wrenchontheoutside

ofthebladeanda1/2"box(or socket)wrenchonthe

insideof theimpeller.HoldtheAllenwrenchstationary

and rotatethebox(orsocket)wrenchto loosenthenut.

7. Installa replacementblade(PartNo.781-0490)with

thehardwareremovedearlierorsharpen.

IMPORTANT:Whensharpeningtheblade,protecthands

byusinggloves.Followtheoriginalangleof grindand

makesuretoremoveanequalamountfromeachblade.

8. To replacetheotherblade,rotatetheimpellerto

exposethesecondbladeandrepeatthestepsabove.

NOTE: Makecertainbladesarereassembledwiththe

sharpedgefacingupward.Torquehardwareto250- 300

in.Ibs.

Sharpening Or Replacing The

Shredder Blade

Figure 13

WARi ,,ING

The impeller S

chipper blades and

shredder blade are

_ ARNING:Theimpeller'schipperblades

__ protectyour hands.

1. Stop theengineand makecertainthatall moving

partshavecometoacompletestop.

2. Disconnectthesparkplugwireandgroundagainstthe

engine.

3. Lowerthehopperassemblyandblockupthehousing.

4. Removethesixhexlocknutsandflatwashers

fromtheweldstudson theflail housing.Retainthe

hardware.

5. Carefullyseparatethehopperassemblyfromthe

impellerassemblyandremovethesupportplate.

NOTE:When reassemblingthe supportplate,make

certaintheembossedtabfacesinwardtowardsthe

impeller.

6. Removethetwowingknobsandcuppedwashersthat

securethechutedeflectorandraisethechute.

7. Inserta 1/2"or 3/4"diameterpipethroughtheflail

screenintotheimpellertokeepit fromturningor

removetheflailscreenandinsertapieceofwoodinto

thechuteopening.

8. a. Removethetwointernalhexscrews,lockwashers,

b. Removethehexbolt,lockwasher,andflatwasher

are sharp. Wearleather work gloves to

and hexlocknutswhichsecuretheshredderblade

totheimpeller.

tocompletelyfreeshredderblade.SeeFigure14.

Figure 14

NOTE:Usea3/16"hexkey(Allen)wrenchonthe

outsideoftheshredderbladeanda 1/2"box(orsocket)

wrenchontheinsideoftheshredderblade.Holdthe

Allenwrenchstationaryandrotatethebox(orsocket)

wrenchtoloosenthenut. Usecautionwhenremoving

thebladetoavoidcontactingtheweldstudsonhousing.

IMPORTANT:Whensharpeningthe blade,follow

theoriginalangleofgrindasa guide.It is extremely

importantthateachcuttingedgereceivesanequal

amountofgrindingtopreventanunbalancedblade.

Anunbalancedbladewillcauseexcessivevibration

whenrotatingat highspeedsandmaycausedamage

totheunit.Thebladecanbetestedbybalancingit on a

screwdriveror nail.Removemetalfromtheheavyside

untilitisbalancedevenly.

Storing Your Chipper Shredder

Thefollowingstepsshouldbetakento prepareyour

chippershredderforstorage.

1. Cleantheequipmentthoroughly.

2. Wipeequipmentwithanoiledragto preventrust.

3. Referto enginemanualforcorrectenginestorage

instructions.

4. Storeunitina clean,dryarea. Donot storenextto

corrosivematerialssuchasfertilizer.

work gloves to

protect your hands:

IMPORTANT

Makecertain chipper

bladesare reassem-

bledwith the sharp

edgefacing upward.

Torquehardwareto

250- 300 in. Ibs.

iMPORTANT

When reassemblingthe

shredderblade, tighten

center boltto between

550 and 700 in.-Ibs.

andthe two out bolts to

between250 and 350

in.-Ibs.

11

Page 12

Forrepairs beyond

the minor adjustments

listed here, contact

an authorized service

Problem Cause Remedy

En_in f_il rf I 1 Throtte evernot n correctstartng 1 Movethrotte everto FASTor

= e _ stosta,

position(ifequipped). STARTposition,

2. Sparkplugwiredisconnected, 2. Connectwireto sparkplug.

3. Chokenot inCHOKEposition(if 3. Movechokeleverto CHOKE

equipped), position.

4. Fueltankemptyorstalefuel. 4. Filltankwithclean,freshgasoline.

5. Enginenot primed(ifequipped). 5. Primeengineas nstructedin

EngineManual.

6. Fauty sparkpug. 6. C can adjustgap or repace.

7, Blockedfuelline. I 7. Cleanfuelline.

8. Engineflooded. 8. Waitafew mnutestorestart,but

Engineruns erratic 1, Sparkplugwireloose, 1, Connectandtightenspark

2, UnitrunningonCHOKE(ifequipped), 2, Movechokeleverto OFFposition,

3. Blockedfuellineorstalefuel. 3. Cleanfuelline;filltankwithclean,

4. Ventingascapplugged. 4. Clearvent.

5. Waterordirt infuelsystem. 5. Drainfueltank.Refillwith

6. Dirty aircleaner. 6. Referto enginemanual.

7. Carburetorout ofadjustment. 7. Seeauthorizedservicedealer.

do notprime.

plugwire,

freshgasoline.

freshfuel.

Engineoverheats 1. Engineoil levellow. 1. Fillcrankcasewithproperoil.

2 Drtyarceaner I 2 Refertoengnemanua

I

• 3. Carburetornotadjustedproperly. " 3. Seeauthorizedservicedealer.

Occasionalskips 1. Sparkpluggaptooclose. 1. Adjustgap to .030".

(hesitates)at 2. Carburetoridlemixtureadjustment 2. Seeauthorizedservicedealer.

highspeed improperlyset.

N m

Excessive I 1. Loosepartsordamagedimpeler I 1 Seeauthorzedservcedeeer

Vibration I I

Unit does not 1. Chutedeflectorclogged. 1. Stop engineimmediatelyand

discharge disconnectsparkplugwire.Clean

flailscreenandinsideofdischarge

opening.

2. Foreignobjectlodgedin impeller. 2. Stop engineanddisconnectspark

plugwire.Removelodgedobject.

3. LowengineRPM. 3. Alwaysrunengineatfullthrottle.

Rateof discharge 1 LowengineRPM. 1. Alwaysrunengineatfullthrottle.

slowsconsiderably I 2. Chipperbladedul. I 2. Replacechipperbladeor seeyour

or composition of authorzedservcedeeer.

changes ,

12

Page 13

_ii ii i_ __ _ i iiiiii ii ii ii_i _ i

usethispagetomake

notes and write down

important information,

13

Page 14

odel Series 462 Thru 464

- ' .._ .,q8;

14

Page 15

1. 736-0217 LockWasher,3/8

2. 714-0149B CotterPin

3. 681-0048 WingKnob5/16-18

4. 681-0094 ChuteDeflectorAssembly

5. 711-0835 ClevisPin

6. 781-0457 ShredderScreen

7. 726-0211 U-Nut5/16-18

8. _ 750-0793 _ Spacer

9. 712-3027 HexLockNut1/4-20

10. 712-3004A HexLockNut5/16-18

11. 736-0119 LockWasher5/16

12. 681-0117 InnerImpellerHousingAssembly

13. 710-3025 HexCapScrew5/16-18x.625

14. 710-0157 HexCapScrew5/16-24x.75

15. 781-0490 ChipperBlade

16. 710-1054 HexCapScrew5/16-24x 1.0

17. 681-0030 impellerAssembly

18. 712-0411 HexLockNut5/16-24

19. 781-0735 RetainerPinClip

20. 719-0329 FlailBlade

21. 711-0833B ClevisPin

22. 715-0166 Pin

23. 736-0247 FlatWasher3/8 x 1.25

24. 742-0571 ShredderBlade

25. 710-1254 HexCapScrew3/8-24x 2.25

26. 681-0004A OuterImpellerHousingAssembly

27. 710-0825 HexCapScrew1/4-20x 3.75

28. 781-0515 FrontSupportBracket

29. 781-0574 ShredderPlate

Toorder replacement

parts, contact

1=800-800-7310or visit

www.mtdproducts.com.

30. 681-0104 RearHopperBracketAssembly

31. 732-0306 CompressionSpring1.75

32. 736-0117 FlatWasher

33. 714-0104 CotterPin

34. 736-0264 FiatWasher.330IDx.630OD

35. 710-0376 HexCapScrew5/16-18x 1.0

36. 748-0453 Spacer,.375IDx 2.50LG

37. 736-0362 FiatWasher.320IDx 1.25OD

38. 712-0429 HexLockNut5/16-18

39. 731-1710 HopperCollar

40. 681-0123 FrontHopperBracketAssembly

41. 711-1128 LockRod

42. 731-1707 HopperAssembly

43. 710-3008 HexCapScrew5/16-18x.75

15

Page 16

odel Series 462 Thru 464

16

1 ModelSeries464

11 Model464GOnly

ModelSeries462

^ Models462&464D

* If Equipped

Page 17

1. 728-0175 PopRivet

2. 731-1899 ChipperShredderChute

3. 735-0249 ChuteFlap

4. 781-0633 ChuteFlapStrip

5. 681-0068A ChipperChuteAssembly

6. 710-0751 HexCapScrew1/4-20x.620

7. 712-3027 HexLockNut1/4-20

8. _ 710-0106 HexCapScrew1/4-20x 1.25

9. 736-0173 FiatWasher.28IDx.74OD

10. 736-0242 BellWasher.340IDx.872OD

11. 712-3010 HexNut5/16-18

12. 749-1004 SupportBrace

13. 712-3004A HexLockNut5/16-18

14. 710-0805 HexCapScrew5/16-18x 1.50

710-3180tt HexCapScrew5/16-18x 1.75

15. 736-0170 BellWasher5/16x 1.0

16. 736-0366t FlatWasher

17. 738-0814_1 AxleAssembly

738-0813t AxleAssembly

18. 750-0786_: Spacer

19. 734-1600:_ WheelComp.,10.0x2.5 Plastic

734-1845t WheelComplete,10.0x4.0 Gray

20. 726-0214 PushCap

21. 681-0184A Frame

681-0183Att Frame

22. 736-0451 Washer,.320IDx.93OD

23. 710-0502A Screw,3/8-16x 1.250

24. 737-0195A ElbowFitting

25. 737-0298tt Oil DrainPipe

26. 737-0132tt Oil DrainEndCap

27. 681-0133" TongueHitchMount

28. 681-0134A* BaseHitchMount

29. 710-3001" HexCapScrew,3/8-16x.88

30. 711-0299" ClevisPin,.625x 2.4

31. 711-0835" ClevisPin,.50x 4.62

32. 712-3017" HexNut,3/8-16

33. 732-0194" SpringPin

34. 736-0133" FiatWasher,.411x 1.25x1.0

35. 736-0169" LockWasher,3/8

-- 723-0400 SafetyGlasses(NotShown)

k

-- 664-04022 ChipperBagAss'y(Not Shown)

-- 664-04023tt ChipperBagAss'y(NotShown)

t ModelSeries464 AModels462& 464D

tt Model464GOnly * IfEquipped

_1ModelSeries462

Toorder replacement

parts, contact

1-800-800-7310 or visit

www.mtdproducts.com.

17

Page 18

Use this page to make

notes and write down

important information:

18

Page 19

notes and write down

important information:

19

Page 20

MANUFACTURER'S LiMiTED WARRANTY FOR

ThelimitedwarrantysetforthbelowisgivenbyMTDLLCwithrespectto

newmerchandisepurchasedandusedin theUnitedStates,itsposses-

sionsandterritories.

"MTD"warrantsthisproductagainstdefectsin materialandworkmanship

fora periodoftwo(2)yearscommencingonthe dateof originalpurchase

andwill,atits option,repairor replace,freeof charge,anypartfoundto

bedefectiveinmaterialsor workmanship.Thislimitedwarrantyshallonly

applyif this producthasbeenoperatedandmaintainedinaccordance

withtheOperator'sManualfurnishedwiththeproduct,andhasnotbeen

subjectto misuse,abuse,commercialuse,neglect,accident,improper

maintenance,alteration,vandalism,theft,fire,water,ordamagebecause

ofotherperilornaturaldisaster.Damageresultingfromtheinstallationor

useof anypart,accessoryorattachmentnotapprovedbyMTDforuse

withtheproduct(s)coveredbythis manualwillvoidyourwarrantyasto

anyresultingdamage.

Normalwearpartsarewarrantedto befreefromdefectsinmaterialand

workmanshipfora periodofthirty(30)daysfromthedateof purchase.

Normalwearpartsinclude,butarenotlimitedto itemssuchas:batteries,

belts,blades,bladeadapters,grassbags,riderdeckwheels,seats,snow

throwerskidshoes,shaveplates,augerspiralrubberandtires.

HOW TO OBTAIN SERVICE: Warrantyservice isavailable,WITH

PROOFOF PURCHASE,throughyour localauthorized service

dealer.Tolocatethe dealer in yourarea, check yourYellowPages, or

contact MTD LLC at RO. Box 361131,Cleveland,Ohio44136-0019,or

call 1-800-800-7310or 1-330-220-4683or log on to our Web site at

www.mtdproducts.com.

Thislimitedwarrantydoesnot providecoverageinthefollowingcases:

a. Theengineor componentpartsthereof.Theseitemsmaycarrya

separatemanufacturer'swarranty.Refertoapplicablemanufacturer's

warrantyfortermsandconditions.

b. Logsplitterpumps,valves,andcylindershavea separateoneyear

warranty.

c. Routinemaintenanceitemssuchas lubricants,filters,blade

sharpening,tune-ups,brakeadjustments,clutchadjustments,deck

adjustments,andnormaldeteriorationoftheexteriorfinishduetouse

orexposure.

d. Servicecompletedbysomeoneotherthananauthorizedservice

dealer.

e. MTDdoesnotextendanywarrantyforproductssoldorexported

outsideofthe UnitedStates,itspossessionsandterritories,except

thosesoldthroughMTD'sauthorizedchannelsofexportdistribution.

f. ReplacementpartsthatarenotgenuineMTDparts.

g. Transportationchargesandservicecalls.

No impliedwarranty,includinganyimpliedwarranty of merchant-

ability of fitness for a particularpurpose,applies afterthe applicable

periodof expresswritten warranty above as to the partsas identi-

fied. Noother expresswarranty, whether written or oral, exceptas

mentionedabove,givenby anypersonor entity,includinga dealer

or retailer,with respect to anyproduct,shallbind MTD.Duringthe

periodof the warranty, the exclusive remedyisrepairor replacement

of the productas set forth above.

Theprovisionsas set forth inthis warranty providethe sole and

exclusive remedyarising from the sale. MTDshall not beliable

for incidentalorconsequential loss or damageincluding,without

limitation, expensesincurredfor substitute orreplacementlawncare

services or for rentalexpensesto temporarily replaceawarranted

product.

Somestatesdo not allowtheexclusionor limitationofincidentalor

consequentialdamages,or limitationson howlonganimpliedwarranty

lasts,sotheaboveexclusionsor limitationsmaynotapplytoyou.

Innoeventshallrecoveryofany kindbegreaterthantheamountof the

purchasepriceof theproductsold.Alterationof safetyfeatures of the

productshall void this warranty. Youassumetheriskandliabilityfor

loss,damage,orinjurytoyouandyourpropertyand/ortoothersandtheir

propertyarisingout ofthemisuseor inabilitytousetheproduct.

Thislimitedwarrantyshallnotextendto anyoneotherthantheoriginal

purchaseror tothepersonforwhomitwaspurchasedasa gift.

HOWSTATELAWRELATESTOTHISWARRANTY: Thislimitedwar-

rantygivesyouspecificlegalrights,andyou mayalsohaveotherrights

whichvaryfromstatetostate.

IMPORTANT:OwnermustpresentOriginalProofofPurchasetoobtain

warrantycoverage.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-800-800-7310, 1-330-220-4683

Loading...

Loading...