Page 1

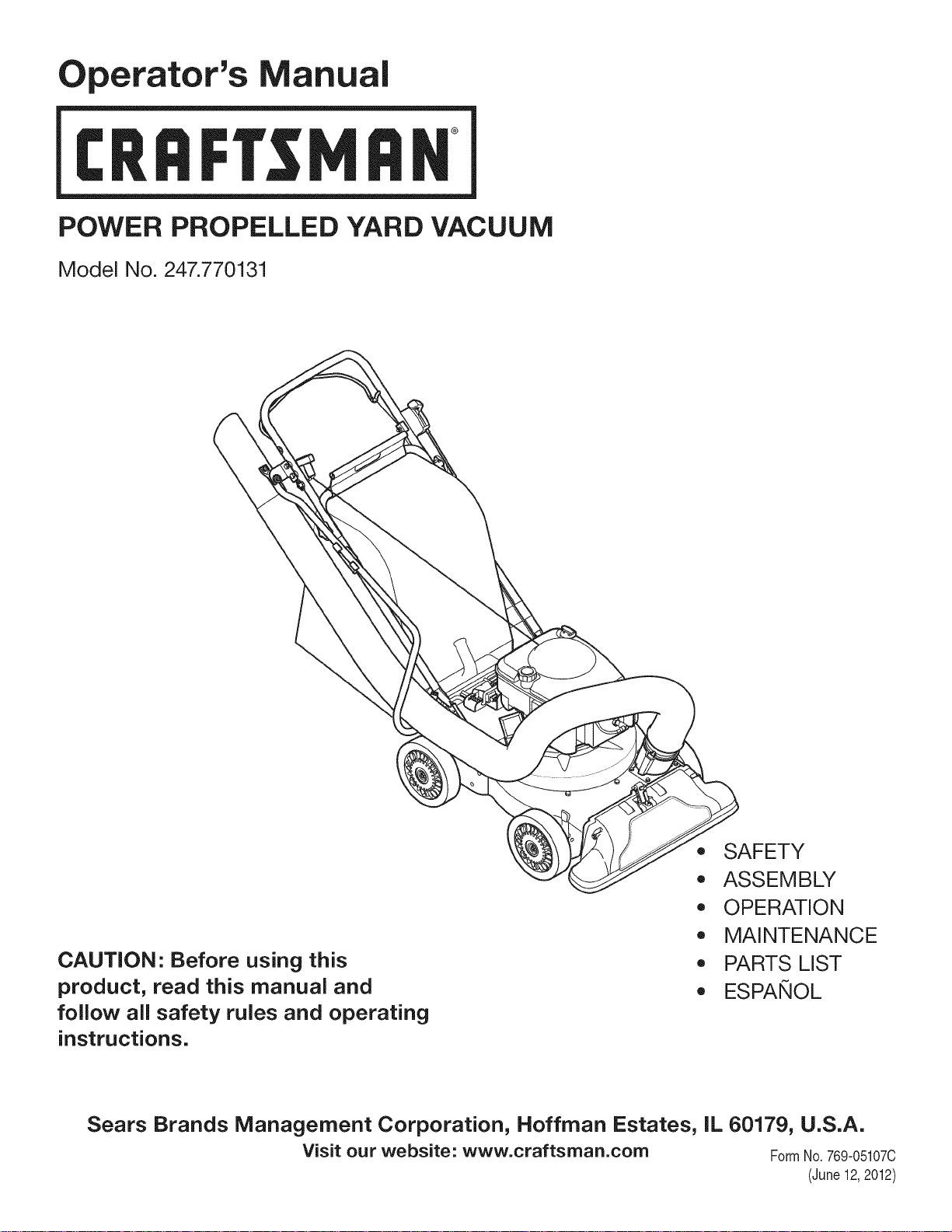

Operator's Manual

CRRFr MRN

POWER PROPELLED YARD VACUUM

Model No. 247.770131

,, SAFETY

o ASSEMBLY

OPERATION

MAINTENANCE

CAUTION" Before using this

product, read this manual and

follow all safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FormNo. 769-05107C

PARTS LIST

o ESPANOL

(June 12,2012)

Page 2

Warranty Statement .................................. Page 2

Safe Operation Practices .......................... Page 3

Safety Labels ............................................ Page 7

Assembly .................................................. Page 8

Operation .................................................. Page 12

Service and Maintenance ......................... Page 16

Off-Season Storage .................................. Page 22

Trouble Shooting ....................................... Page 23

Parts List ................................................... Page 24

Repair Protection Agreement ................... Page 38

Espa_ol ..................................................... Page 39

Service Numbers ...................................... Back Cover

CRAFTSMAN TWO YEAR FULL WARRANTY

FORTWOYEAR(S)fromthe dateof purchase,thisproductiswarrantedagainstanydefectsinmaterialorworkmanship.A defectiveproductwill

receivefreerepairorreplacementif repairisunavailable.

Forwarrantycoveragedetailsto obtainfreerepairor replacement,visittheweb site:www.craftsman.com

ThiswarrantycoversONLYdefectsin materialandworkmanship.WarrantycoveragedoesNOTinclude:

• Expendableitemsthatcanwearout fromnormalusewithinthe warrantyperiod,suchas theblades, sparkplug,aircleaner,flail

screenand catcherbag.

• Productdamageresultingfromuserattemptsatproductmodificationor repairorcausedby productaccessories.

• Repairsnecessarybecauseof accidentor failuretooperateormaintaintheproductaccordingto all suppliedinstructions.

• Preventivemaintenance,or repairsnecessarydueto improperfuel mixture,contaminatedorstalefuel.

Thiswarrantyis voidifthis productis everusedwhileprovidingcommercialservicesorif rentedtoanotherperson.

Thiswarrantygivesyouspecificlegal rights,andyoumayalsohaveotherrightswhichvaryfromstateto state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

EngineSeries: 675

EngineOilType: SAE30

EngineOilCapacity: 18ounces

FuelCapacity: 1.5Quarts

SparkPlugGap: .020"

ModelNumber.................................................................

Serial Number.................................................................

Dateof Purchase .............................................................

Recordthe modelnumber,serialnumber

anddateof purchaseabove

©SearsBrands,LLC 2

Page 3

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthe personalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingto the safeopera-

tionpracticesinthismanual.As withany typeof powerequipment,

carelessnessorerroronthepartoftheoperatorcan resultin

seriousinjury.Thismachineis capableofamputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethefollowing

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateof California

tocausecancerandbirthdefectsorotherreproductiveharm.

TRAINING

• Read,understand,andfollowall instructionson themachineand

in themanualbeforeattemptingto assembleandoperate.Keep

thismanualina safeplaceforfutureandregularreferenceandfor

orderingreplacementparts.

• ReadtheOperator'sManualand followallwarningsandsafety

instructions.Failuretodosocan resultin seriousinjuryto the

operatorand/orbystanders.Forquestionscall, 1-800-4MY-

HOME.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthemachineanddisengagethemquickly.

• Neverallowchildrenunder16yearsofagetooperatethis

machine.Children16andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultstooperatethismachinewithoutproper

instruction.

• Keepbystanders,pets,andchildrenatleast75feetfromthe

machinewhile it isin operation.Stopmachineifanyoneenters

thearea.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Do not puthandsandfeetnearrotatingpartsor inthe feeding

chambersanddischargeopening.Contactwiththe rotating

impellercanamputatefingers,hands,andfeet.

• Neverattemptto unclogeitherthe feedintakeordischarge

opening,removeor emptybag,or inspectandrepairthe machine

whilethe engineisrunning.Shuttheengineoff andwaituntilall

movingpartshavecometo a completestop.Disconnectthe spark

plugwireandgroundit againstthe engine.

Your Responsibility--Restrictthe useofthispowermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandon the machine.

SAVETHESEINSTRUCTIONS!

PREPARATION

• Thoroughlyinspecttheareawherethe equipmentistobeused.

Removeall rocks,bottles,cans,or otherforeignobjectswhich

couldbepickedupor thrownandcausepersonalinjuryor

damageto themachine.

• Alwayswearsafetyglassesorsafetygogglesduringoperation

andwhileperformingan adjustmentorrepair,to protectyour

eyes.Thrownobjectswhichricochetcancauseseriousinjuryto

theeyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesorjewelrycanbecaughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.Wear

leatherworkgloveswhenfeedingmaterialinthe chipperchute.

• Beforestarting,checkallboltsandscrewsforpropertightnessto

besurethe machineis insafeworkingcondition.Also,visually

inspectmachineforany damageatfrequentintervals.

• Maintainorreplacesafetyandinstructionslabels,asnecessary.

3

Page 4

SafeHandling of Gasoline:

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

onyourselforyourclotheswhichcanignite.Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Neverfill containersinsidea vehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthegroundaway

fromyourvehiclebeforefilling.

• Whenpractical,removegas-poweredequipmentfromthetruck

ortrailerand refuelitontheground.Ifthisisnotpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

• Keepthe nozzleincontactwiththerimofthefueltankor

containeropeningat alltimes untilfuelingis complete.Donotuse

a nozzlelock-opendevice.

• Extinguishallcigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuel machineindoors.

• Neverremovegascaporaddfuelwhiletheengineishotor run-

ning.Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillfueltank. Fill tankto nomorethan1/2inchbelow

bottomoffillernecktoallowspacefor fuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitoff theengineandequipment.Move

unitto anotherarea.Wait5 minutesbeforestartingtheengine.

• To reducefirehazards,keepmachinefreeofgrass,leaves,or

otherdebrisbuild-up.Cleanupoil orfuelspillageand removeany

fuelsoakeddebris.

• Neverstorethe machineorfuel containerinsidewherethereis an

openflame,sparkor pilotlightason awaterheater,spaceheater,

furnace,clothesdryer orothergasappliances.

OPERATION

• Do not puthandsandfeetnearrotatingpartsor in thefeeding

chambersanddischargeopening.Contactwiththe rotating

impellercanamputatefingers,hands,andfeet.

• Beforestartingthe machine,makesurethe chipperchute,feed

intake,andcuttingchamberare emptyandfreeofall debris.

• Thoroughlyinspectall materialtobe shreddedandremoveany

metal,rocks,bottles,cans,or otherforeignobjectswhichcould

causepersonalinjuryor damagetothe machine.

• Ifthe impellerstrikesa foreignobjector ifyourmachineshould

startmakinganunusualnoiseorvibration,immediatelyshut

theengineoff. Allowtheimpellertocometoa completestop.

Disconnectthesparkplugwire,grounditagainstthe engineand

performthefollowingsteps:

a. Inspectfor damage.

b. Repairorreplaceanydamagedparts.

c. Checkforanyloose partsandtightento assurecontinued

safeoperation.

• Donotallowanaccumulationof processedmaterialto buildupin

thedischargearea.Thiscanpreventproperdischargeandresult

inkickbackof materialthroughthe feedopening.

• Donotattempttoshredorchipmateriallargerthanspecified

on themachineor inthis manual.Personalinjuryor machine

damagecouldresult.

• Neverattempttounclogeitherthefeedintakeor discharge

openingwhilethe engineis running.Shuttheengineoff,waituntil

all movingpartshavestopped,disconnectthe sparkplugwireand

grounditagainsttheenginebeforeclearingdebris.

• Neveroperatewithoutvacuumbaganddischargechuteproperly

attachedtothe machine.Neveremptyor changevacuumbag

whilethe engineisrunning.Vacuumbagmustbekeptclosedat

all timesduringoperation.

• Neveroperatewithouteitherthe inletnozzleor optionalhose

attachment(ifapplicable)properlyattachedtothemachine.

Neverattemptto attachor changeeitherattachmentwhilethe

engineisrunning.

• Keepallguards,deflectorsandsafetydevicesin placeand

operatingproperly.

• Keepyourfaceandbodybackandtothesideofthechipper

chutewhilefeedingmaterialintothemachineto avoidaccidental

kickbackinjuries.

• Neveroperatethis machinewithoutgoodvisibilityorlight.Always

be sureofyourfootingand keepa firmholdon thehandles.

• Donotoperatethismachineona paved,gravelornon-level

surface.

• Donotoperatethismachinewhileundertheinfluenceof alcohol

or drugs.

• Mufflerandenginebecomehotandcancausea burn.Do not

touch.

• Neverpickuporcarrymachinewhiletheengineis running.

• Ifsituationsoccurwhichare notcoveredinthis manual,use care

andgoodjudgement.ContactCustomerSupportforassistance

andthenameof thenearestservicedealer.

4

Page 5

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.

• Checkboltsand screwsforpropertightnessatfrequentintervals

tokeepthemachinein safeworkingcondition.Also,visually

inspectmachineforanydamageand repair,ifneeded.

Beforecleaning,repairing,or inspecting,stopthe engineand

makecertaintheimpellerand allmovingpartshavestopped.

Disconnectthesparkplugwireandgrounditagainstthe engine

topreventunintendedstarting.

Donotchangetheenginegovernorsettingsor overspeedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

Maintainor replacesafetyandinstructionlabels,asnecessary.

Followthismanualforsafeloading,unloading,transporting,and

storageof thismachine.

Neverstorethemachineorfuelcontainerinsidewherethereisan

openflame,sparkorpilotlightsuchasa waterheater,furnace,

clothesdryer,etc.

Allowmachinetocoolatleast5 minutesbeforestoring.

• Alwaysreferto the operator'smanualforproperinstructionson

off-seasonstorage.

• If thefuel tankhasto bedrained,dothisoutdoors.

• Observeproperdisposallawsand regulationsforgas,oil,etc.to

protecttheenvironment.

• AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan Average UsefulLifeofseven(7)years,or 60hoursof

operation.At theendoftheAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealerto ensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failureto do socan resultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donotmodifyenginein anyway.

Tamperingwiththegovernorsettingcanleadto a runawayengineand

causeitto operateatunsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brushcoveredor grass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocal or

statelaws(if any).

Ifa sparkarrestoris used,it shouldbe maintainedin effectiveworking

orderbytheoperator.IntheStateofCaliforniathe aboveis required

bylaw (Section4442of theCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorforthemuffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

Page 6

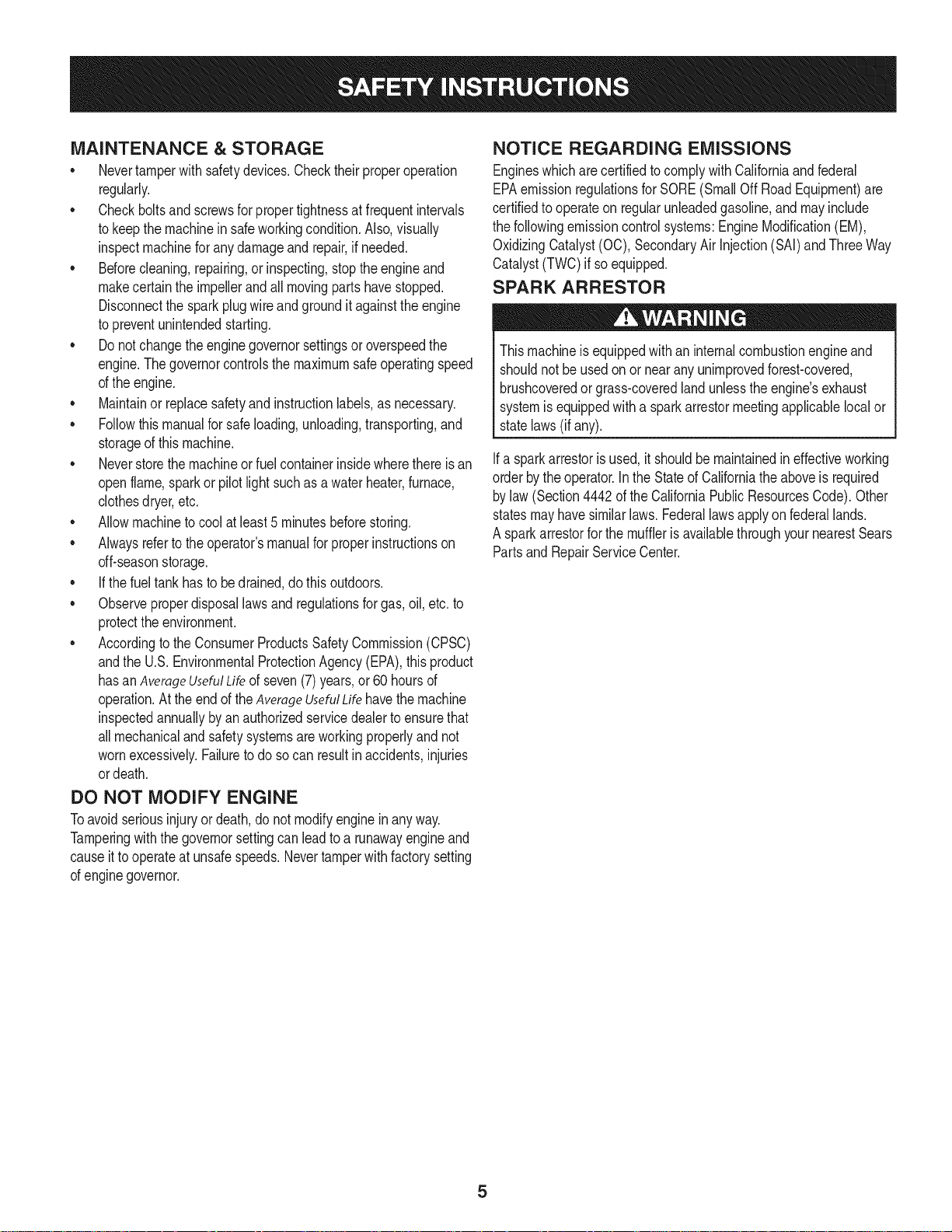

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

• ®

® •

llm

il

BYSTANDARDS

Keep bystanders, pets, and children at least 75 feet from the machine while it is in operation. Stop

machine if anyone enters the area.

BYSTANDARDS

Keep bystanders, pets, and children at least 75 feet from the machine while it is in operation. Stop

machine if anyone enters the area.

WARNING-- THROWN OBJECTS

This machine may pick up and throw and objects which can ricochet.

EYEPROTECTION

Always wear safety glasses or safety goggles when operating this machine.

WARNING-- GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

6

Page 7

Thispageleftintentionallyblank.

7

Page 8

IMPORTANT:Thisunit isshippedwithoutgasolineoroil intheengine.

Becertaintoserviceenginewithgasolineandoilas instructedinthe

Operationsectionof this manualbeforeoperatingyourmachine.

NOTE:Referenceto rightand lefthandsideoftheYardVacuumis

observedfromthe operatingpositionlookingforwardtothefrontof the

machine.

OPENING CARTON

1. Cuteachcornerofthecartonverticallyfromtopto bottom.

2. Removeall looseparts.

3. Removeloosepackingmaterial.

REMOVING UNIT FROM CARTON

1. Liftunitfromthereartodetachitfromunderlyingcartonmaterial

androllunitoutofcarton.

2. Checkcartonthoroughlyforanyotherlooseparts.

NOTE:Makesurenottocrimpcableswhileremovingloosepartsor

theentire unitfromthecarton.

LOOSE PARTS IN CARTON

f

(See Figure 1)

* UpperandLowerHandle

. HoseAssembly

* SafetyGlasses

. EngineOil(Maybelocatedinbag)

* Bag

. BlowerChute

* Operator'sManual

Safety Glasses

Operator'sManual

\

Hose

Assembly

BlowerChute

Bottle of EngineOil

J

Figure1

8

Page 9

ATTACHING THE HANDLE

1. Removethehairpinclipsfromthehandlebracketsand removethe

carriagescrewsandwingnutsfromthelowerhandle.

a. Placethebottomholesinlowerhandleoverthepinson the

handlebracketsand securewith hairpinclips. SeeFigure2.

b. insertcarriagescrewsthroughupperholeinlowerhandlefrom

theinsideandsecurewithwingnuts.SeeFigure2.

2. a. Unfoldthe upperhandleuntilitalignswithlowerhandle.Make

surethe ropeguideis onthe rightsideof upperhandle.See

Figure3.

IMPORTANT:Makesurethecablesareroutedoutsidethelower

handle.Also,donot crimpthe cableswhileliftingupthe handles.

b. Securethetwo handlesbytighteningthehandleknobs(carriage

boltsmustbeseatedproperlyintothehandle).SeeFigure3.

.

Pullthetwo cabletiesattachedtothecablestightapproximately

8 inchesfromeachcableendandplacethe cablesintothecable

guide.

.

Loosenthewingnut thatsecurestheropeguidetothe rightsideof

upperhandle.

a. Pullthe starterropeoutof the engineslowly.SeeFigure4.

b. Slipthe starterropeintothe ropeguide.Tightenthewingnut.

SeeFigure4.

Figure2

J

Figure3

J

Figure4

9

Page 10

f

_, ATTACHING THE HOSE ASSEMBLY

1. a. Slidehoseadapterof hoseassemblyintothebaseadapter

locatedon theleftfrontoftheYardVacuum.SeeFigure5.

b. Pullspringloadedpinouton thebaseandalignpinwiththefirst

hole(closestto the endof the tube)inthehoseadapter.

c. Releasethe pinto lockthe hosein place.

2. a. Snapthehosehandlefirstintothe upperhose handlebracket

andthenintothe lowerhosehandlebracket.

b. Layhosetubingincurvedendofhandlenexttochipperchute.

SeeFigure6.

ATTACHING THE BAG

Graspbaghandlewithonehandandslidelockingrodonmounting

bracketwithotherhandtowardengine.Usetheendof mounting

bracketas leveragewhenslidingthe lockingrod.

a. Slipbagovertherimofthe dischargeopeningandrelease

lockingrodtosecurebagin place.SeeFigure7.

Figure5

b. Snapbagclipto thetopof the lowerhandle.

c. Placethelowerstrapson thebagoverthetopof lowerhandle,

hookingthemon thestuds.SeeFigure7.

NOTE:The bag/chuteswitchbuttonattachedtothemountingbracket

mustbefullydepressedby thetipof fronttabon baghandlewhen

securingthebagorenginewillnotstart.

Figure6

Figure7

10

Page 11

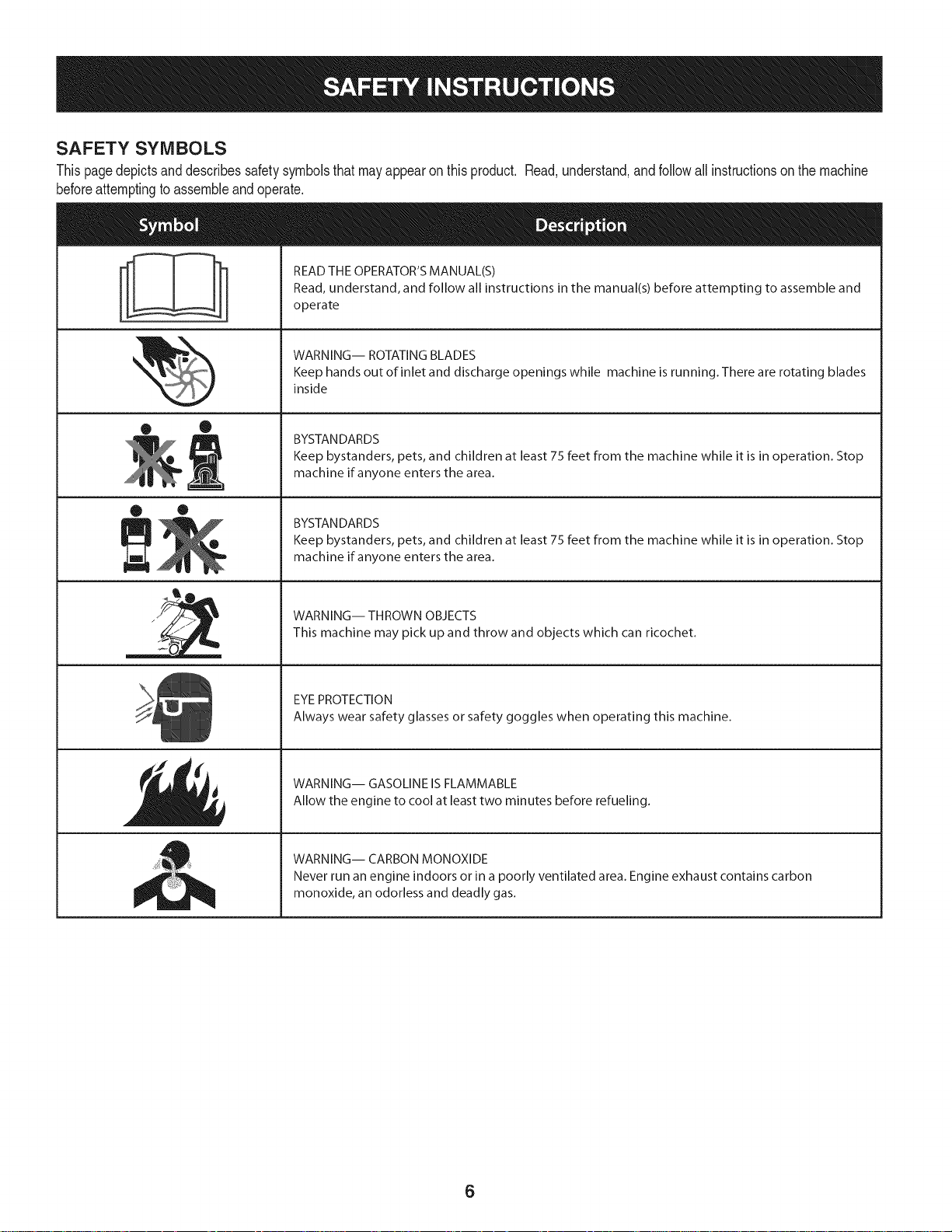

ATTACHING THE BLOWER CHUTE f

NOTE:Thebagmustberemovedbeforeinstallingtheblowerchute.

1. a. Graspblowerchutewithone handandslidelockingrodon

mountingbracketwithotherhandtowardengine.Usethe endof

mountingbracketas leveragewhenslidingthelockingrod.See

Figure8.

b. Slipblowerchuteoverrimof dischargeopeningandrelease

lockingrodto securechutein place,asin Figure8.

c. Raisethe nozzleheighttothe highestsettingwhenusingthe

blowerchute.Refertonozzleheightadjustmentbelow.

NOTE:Thebag/chuteswitchbuttonattachedtothe mountingbracket

mustbefullydepressedbythe tipoffronttabontheblowerchuteor

enginewillnot start.

Alwaysstopengineanddisconnectsparkplugwire beforeperforming

anymaintenanceoradjustments.Alwayswearsafetyglassesduring

operationorwhileperforminganyadjustmentsor repairs.

NOZZLE HEIGHT ADJUSTMENT

Thenozzlecan beadjustedto anyfive positions,rangingfrom5/8"

to4-1/8"groundclearance.Thenozzleheighthastobe adjusted

accordingto yardconditions.

1. Depressnozzleheightadjustmentlevertowardswheel.See

Figure9.

2. Movetheheightadjustmentleverforwardor backwardto adjust

thenozzleupwardsordownwards.Makesurebothleversarein

thesameposition.

3. Releaselevertowardsdeck.

\\

J

Figure8

f

NOTE:In general,raisethenozzleheighttovacuuma thicklayerof

leavesortooperatewiththeblowerchute.Lowerthenozzleheightfor

smoothersurfaces.

J

Figure9

11

Page 12

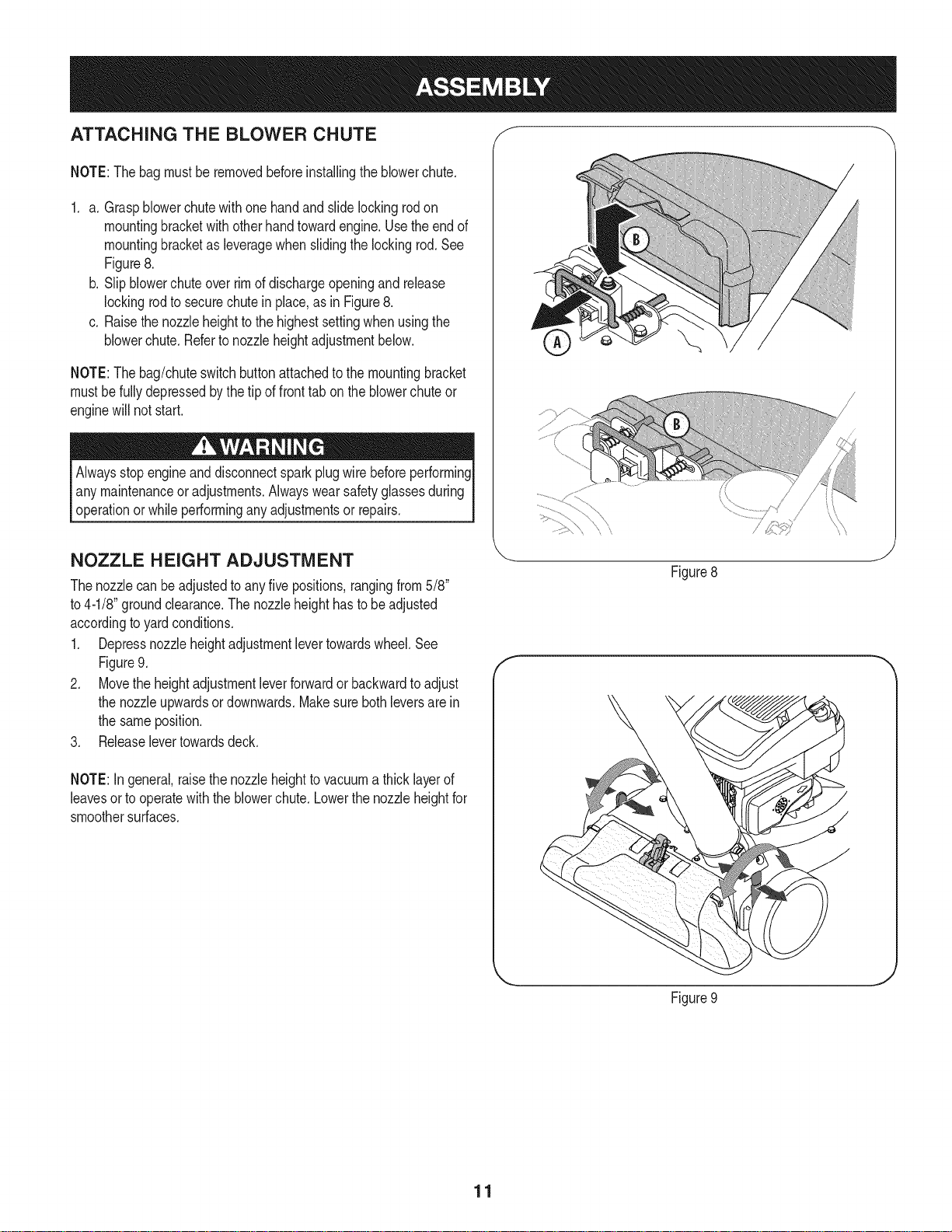

f

Drive Control

Speed Thr( Control Choke Control

Starter

Bag

Lower

Hose

Bracket

Bag Handle

HoseAssembl'

Hose

Blower Chipper

Chute Chute

NozzleHeig

Adjustment Lever

Figure10

Nowthat youhavesetup youryardvacuumforoperation,get

acquaintedwith itscontrolsandfeatures.Thesearedescribedbelow

andillustratedon thispage.Thisknowledgewill allowyoutouseyour

newequipmenttoits fullestpotential.

Theoperationofanyyardvacuumcanresultinforeignobjectsbeing

thrownintothe eyes,whichcandamageyoureyesseverely.Always

Iwearthesafetyglassesprovidedwiththisunitoreyeshieldswhile

[operatingor performinganyadjustmentsor repairsonit.

CHIPPER CHUTE

Allowstwigsandsmallbranchesupto 1-1/2"indiametertobe fedinto

theimpellerforchipping.SeeFigure10.

DRIVE CONTROL

Locatedon theundersideof the upperhandle,thedrivecontrolisused

toengage/disengagewheels.Fullysqueezethedrivecontrolagainst

theupperhandleto engagethe wheels;releasetodisengage.(DO

NOTslipclutch).

SPEED CONTROL

Locatedon theleftsideof the upperhandle,thespeedcontrolis used

toselecttheforwardspeedoftheyardvacuum.

Oil Fill

GasolineFill

)ark PlugWire

Nozzle/Hose

Lever

Nozzle

iMPORTANT:Movethe speedcontrolonlywhentheengineisrunning.

Changingthespeedcontrolsettingwiththeengineoffcandamagethe

yardvacuum.

NOZZLE HEIGHT ADJUSTMENT LEVER

Usedtoadjustthe nozzlegroundclearancerangingapproximately

from5/8"to 4-1/8".See Figure10.

NOZZLE

Yardwastesuchas leavesorpineneedlescanbevacuumedup

throughthe nozzleforshredding.

HOSE ASSEMBLY

Usedasanalternativeto thenozzleto vacuumyardwastesuchas

leavesor pineneedlesin hardto reachplaces.SeeFigure10.

NOZZLE/HOSE VAC LEVER

Thenozzle/hosevachandleis locatedon topofthenozzle.Useit to

switchvacuumsuctionbetweenthenozzleandthe hoseassembly.

HOSE HANDLE

Usedtoguidehoseassemblywhenvacuuming.

Meets ANSI Safety Standards

CraftsmanYardVacuumsconformto thesafetystandardof the AmericanNationalStandardsinstitute(ANSi).

12

Page 13

BAG HANDLE

Usedtograsp baginorderto assistinattaching,removing,and

emptyingbag.SeeFigure10.

BLOWER CHUTE

Whenattachedtounit,theblowerchuteisusedtodischargeyard

wastesuchas leaves,pineneedle,orsmalltwigsacrossyard.

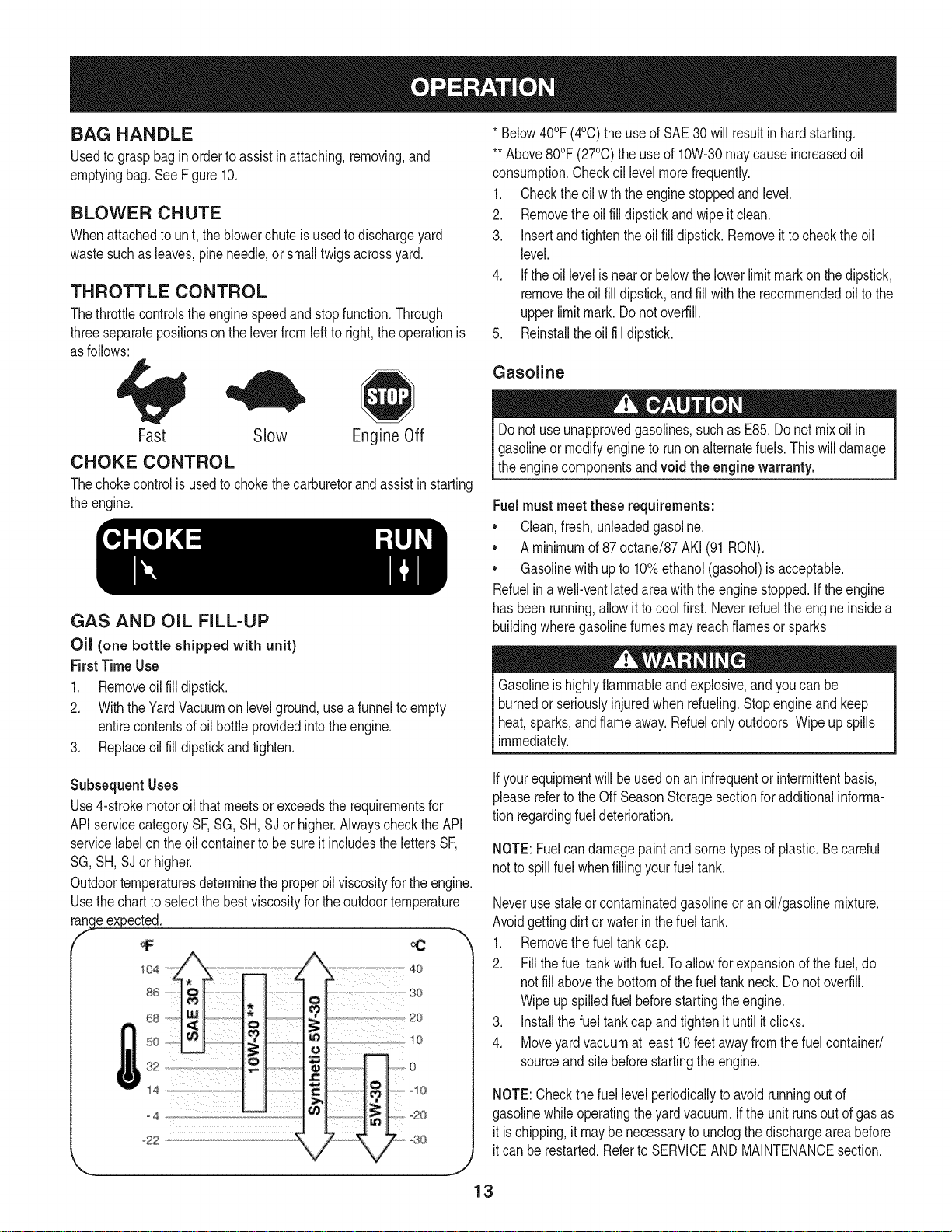

THROTTLE CONTROL

Thethrottlecontrolstheenginespeedandstopfunction.Through

threeseparatepositionson theleverfromleftto right,theoperationis

asfollows:

*Below40°F(4°C)theuseof SAE30will resultinhardstarting.

**Above80°F(27°C)the useof 10%30 maycauseincreasedoil

consumption.Checkoillevelmorefrequently.

1. Checktheoilwiththeenginestoppedandlevel.

2. Removetheoilfilldipstickandwipeitclean.

3. Insertandtightentheoil fill dipstick.Removeitto checktheoil

level.

4. Iftheoil levelisnearor belowthelowerlimitmarkonthedipstick,

removethe oilfill dipstick,andfillwiththerecommendedoilto the

upperlimitmark.Do notoverfill.

5. Reinstalltheoil filldipstick.

Gasoline

Fast Slow EngineOff

CHOKE CONTROL

Thechokecontrolis usedtochokethecarburetorandassistinstarting

theengine.

GAS AND OiL FILL-UP

Oil (one bottle shipped with unit)

First TimeUse

1. Removeoilfilldipstick.

2. WiththeYardVacuumon levelground,usea funnelto empty

entirecontentsofoil bottleprovidedintotheengine.

3. Replaceoilfilldipstickandtighten.

Subsequent Uses

Use4-strokemotoroilthatmeetsorexceedstherequirementsfor

APIservicecategorySF,SG,SH,SJor higher.Alwayscheckthe API

servicelabelon theoilcontainerto besureit includesthelettersSF,

SG,SH, SJor higher.

Outdoortemperaturesdeterminetheproperoilviscosityfortheengine.

Usethechartto selectthe bestviscosityfortheoutdoortemperature

r_..ge #xpected.

68 20

so _o

s2,,

14 C _ '"t'x '_10

=_[_ 1._ [ o

, °°I,

Donot useunapprovedgasolines,suchas E85.Donotmixoil in

Igasolineor modifyenginetorunonalternatefuels.Thiswilldamage

[the enginecomponentsandvoid the enginewarranty.

Fuelmust meetthese requirements:

• Clean,fresh,unleadedgasoline.

• A minimumof87octane/87AKI(91RON).

• Gasolinewithup to 10%ethanol(gasohol)isacceptable.

Refuelina well-ventilatedareawiththeenginestopped.Iftheengine

hasbeenrunning,allowittocoolfirst.Neverrefueltheengineinsidea

buildingwheregasolinefumesmayreachflamesor sparks.

Gasolineishighlyflammableand explosive,andyoucanbe

burnedor seriouslyinjuredwhenrdueling.Stopengineandkeep

heat,sparks,andflameaway.Refuelonlyoutdoors.Wipeup spills

immediately.

Ifyourequipmentwillbe usedon an infrequentor intermittentbasis,

pleaserefertothe Off SeasonStoragesectionforadditionalinforma-

tionregardingfueldeterioration.

NOTE:Fuelcandamagepaintandsometypesof plastic.Becareful

notto spillfuelwhenfillingyourfuel tank.

Neverusestaleorcontaminatedgasolineoranoil/gasolinemixture.

Avoidgettingdirt or waterinthefueltank.

1. Removethefueltankcap.

2. Fillthe fueltankwithfuel.Toallowforexpansionofthe fuel,do

notfill abovethebottomofthefueltank neck.Donotoverfill.

Wipeupspilledfuelbeforestartingtheengine.

3. Installthefueltankcap andtightenit untilitclicks.

4. Moveyard vacuumatleast10feetawayfromthefuelcontainer/

sourceand sitebeforestartingtheengine.

NOTE:Checkthefuellevelperiodicallytoavoidrunningoutof

gasolinewhileoperatingtheyardvacuum.Ifthe unit runsoutof gas as

itis chipping,it maybenecessaryto unclogthedischargeareabefore

itcan berestarted.Referto SERVICEAND MAINTENANCEsection.

13

Page 14

TopView

TO START ENGINE

BagYC_hutei/

Switch:Wire /

/

iiii FrontTab i i

/

Figure11

ChokeControl

Besurenooneotherthan theoperatoris standingnearthe yard

vaccumwhilestartingengineoroperatingvacuum.Neverrunengine

indoorsorin enclosed,poorlyventilatedareas.Engineexhaust

containscarbonmonoxide,an odorlessanddeadlygas.Keephands,

feet,hairand looseclothingawayfromany movingpartson engine

andyardvacuum.

1. Thebag/chuteswitchbuttonmustbefullydepressedbythe tip

offronttabon baghandleorblowerchuteforengineto start.See

Figure11.

2. Makesurebag/chuteswitchwireis connectedtoengineand

groundedtomountingbracket.SeeFigure11.

3. Movethrottlecontroltothe FAST(Rabbit)4_ position.See

Figure12.

4. Movethechokecontrolto the CHOKE_,1 position(Awarm

enginemaynotrequirechoking.)SeeFigure12.

5. Standingbehindtheunit,graspstarterhandleandpull ropeout

untilyoufeeladrag.

6. Pulltheropewitha rapid,continuous,fullarmstroke.Keepa firm

gripon the starterhandle.Letthe roperewindslowly.

7. Repeat,ifnecessary,untilenginestarts.Astheenginewarmsup,

movethechokecontroltothe RUNI _'I position.

8. ALWAYSkeepthethrottlecontrolinthe FAST(rabbit)

positionwhenoperatingtheYardVacuum.

TO STOP ENGINE

1. Movethrottlecontrolleverto STOP or OFFposition.

TO EMPTY BAG

1. Unhookbagstrapsfromthe lowerhandle.

Figure12

f

;/

2. Unsnapbagclip fromthetopoflowerhandle.See Figure13.

3. Graspbaghandlewithonehandandpulllock rodonmounting

bracketwithotherhandtowardengineto release.

4. Liftbagoffbackof unit.

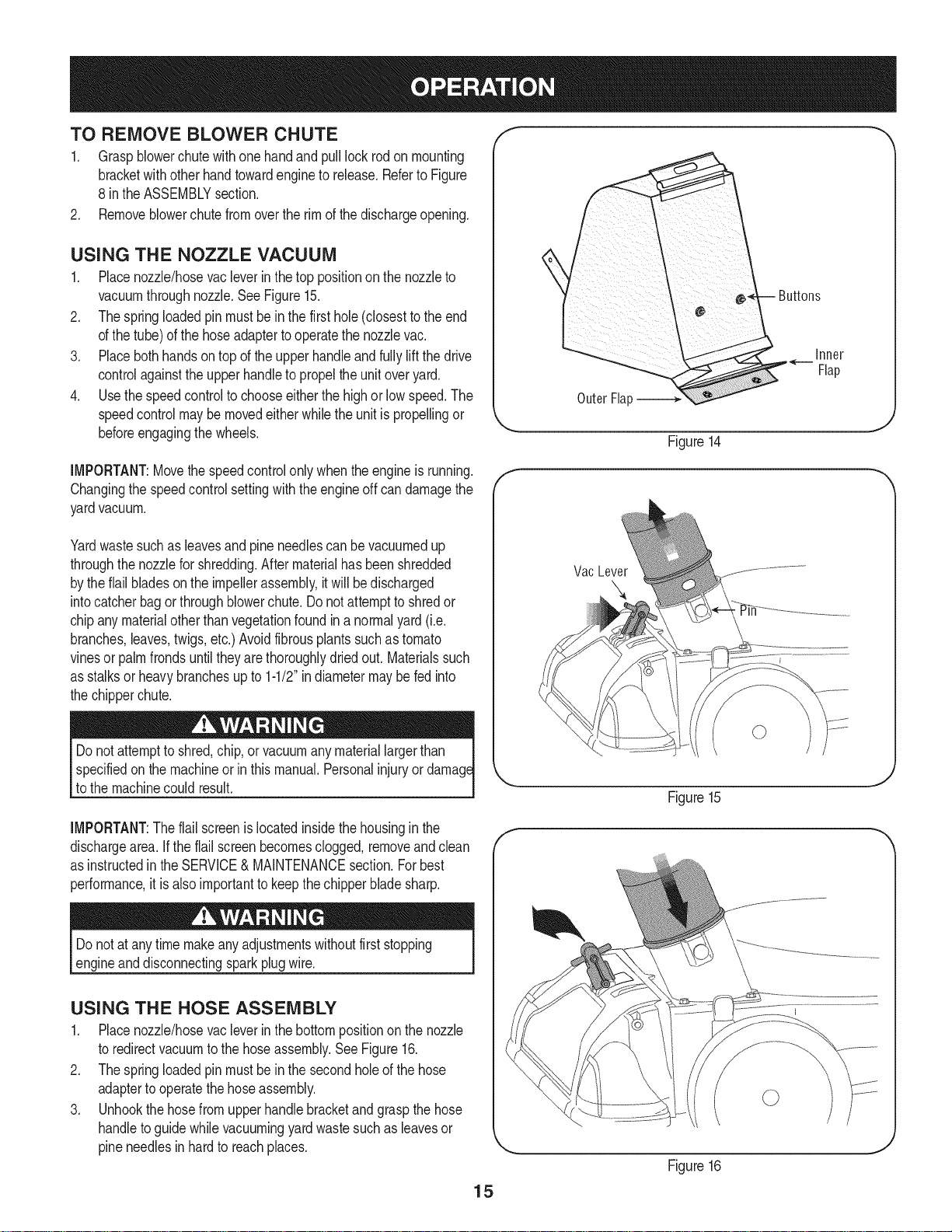

5. Twistthetwobuttonsonthe backofthe bagto unlockandempty

contents.SeeFigure14.Holdbaghandleandbagclip while

emptyingthecontents.

6. Compressbagopeningandfoldinnerflapoveropening.

7. Foldouterflapoverinnerflapandinsertbuttonsonthebag

throughmetaloutlets.SeeFigure14.

8. Twistthebuttonsto lockbag.Placebagbackonto unitas

instructedintheASSEMBLYsection.

Figure13

Page 15

TO REMOVE BLOWER CHUTE

1. Graspblowerchutewithonehandandpull lockrodonmounting

bracketwithotherhandtowardengineto release.Referto Figure

8 inthe ASSEMBLYsection.

2. Removeblowerchutefromoverthe rimofthedischargeopening.

USING THE NOZZLE VACUUM

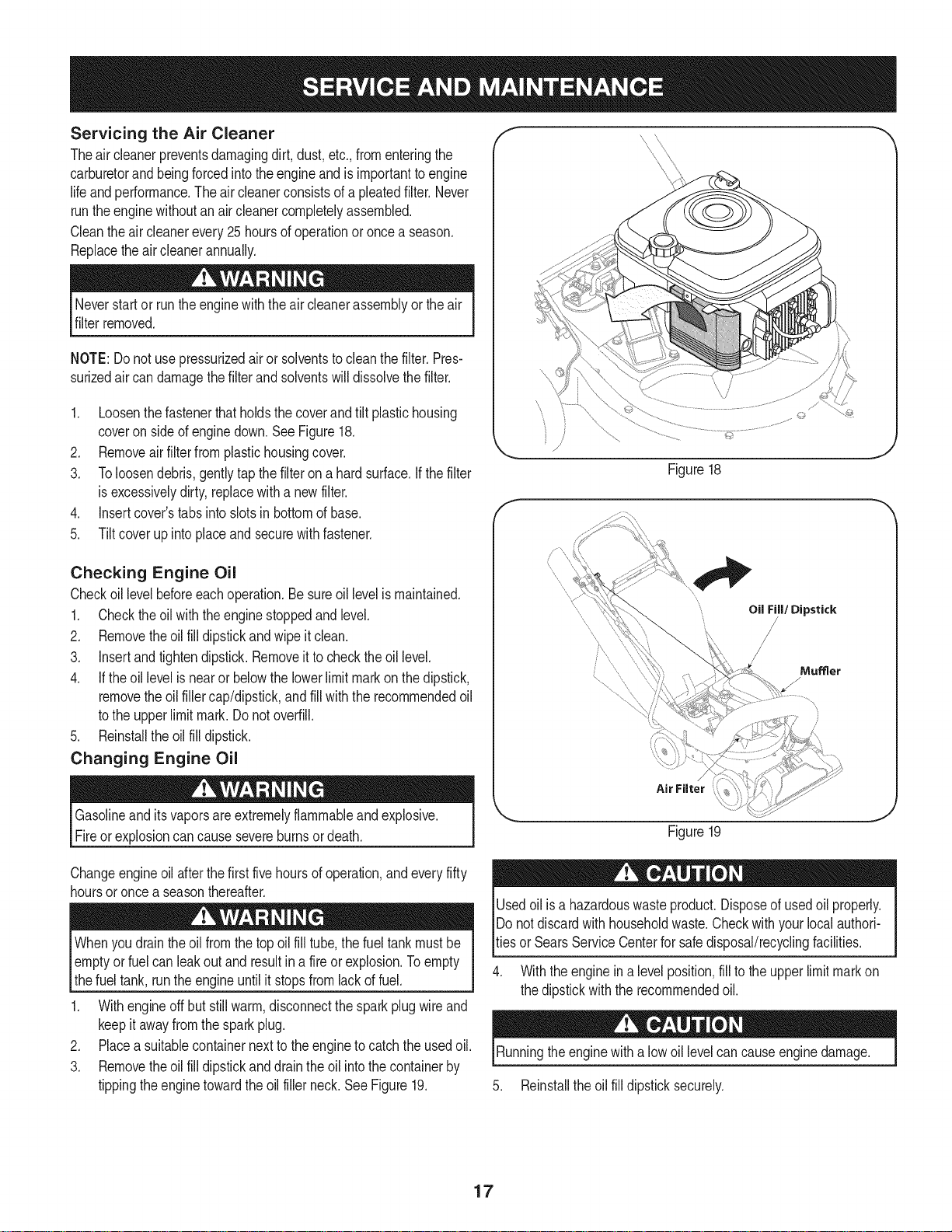

1. Placenozzle/hosevacleverinthetop positiononthe nozzleto

vacuumthroughnozzle.SeeFigure15.

2. Thespringloadedpinmustbein the firsthole(closesttotheend

ofthe tube)ofthehoseadaptertooperatethe nozzlevac.

3. Placebothhandsontopof the upperhandleandfullyliftthedrive

controlagainsttheupperhandleto propelthe unitoveryard.

4. Usethespeedcontrolto chooseeitherthe highorlowspeed.The

speedcontrolmaybemovedeitherwhiletheunitis propellingor

beforeengagingthewheels.

IMPORTANT:Movethe speedcontrolonlywhentheengineis running.

Changingthespeedcontrolsettingwiththeengineoff candamagethe

yardvacuum.

Yardwastesuchas leavesandpineneedlescanbevacuumedup

throughthenozzleforshredding.Aftermaterialhasbeenshredded

bytheflailbladesontheimpellerassembly,itwillbedischarged

intocatcherbagorthroughblowerchute.Donotattempttoshredor

chipany materialotherthanvegetationfoundin a normalyard(i.e.

branches,leaves,twigs,etc.)Avoidfibrousplantssuchastomato

vinesor palmfrondsuntiltheyare thoroughlydriedout. Materialssuch

asstalksor heavybranchesupto 1-1/2"indiametermaybe fedinto

thechipperchute.

Inner

Flap

Outer Flap

Figure14

Vac Lever

specifiedonthe machineorin thismanual.Personalinjuryor

to themachinecouldresult.

IMPORTANT:Theflailscreenis locatedinsidethehousinginthe

dischargearea. Ifthe flail screenbecomesclogged,removeandclean

asinstructedintheSERVICE&MAINTENANCEsection.Forbest

performance,itis alsoimportanttokeepthechipperbladesharp.

Donotatanytimemakeanyadjustmentswithoutfirststopping

engineanddisconnectingsparkplugwire.

USING THE HOSE ASSEMBLY

1. Placenozzle/hosevacleverinthebottompositionon thenozzle

toredirectvacuumtothehoseassembly.SeeFigure16.

2. Thespringloadedpinmustbein the secondholeof thehose

adaptertooperatethehoseassembly.

3. Unhookthehosefromupperhandlebracketandgraspthe hose

handletoguidewhilevacuumingyardwastesuchas leavesor

pineneedlesinhardto reachplaces.

Figure15

F

Figure16

15

Page 16

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgroundit toprevent

unintendedstarting.Alwayswearsafetyglassesduringoperationorwhile

performinganyadjustmentsorrepairs.

EachUse

1st5 hours

Annuallyor25hours

Annuallyor50hours

Annually

BeforeStorage

Cleanmoreoftenunderdustyconditionsor whenairbornedebrisis

.

Engineoillevel

2.

Looseormissinghardware

3.

Unitandengine.

1.

Engineoil

1.

Aircleaned-

2.

Controllinkages/pivotsandwheels

3.

Undersideof mowerdeck

1.

Engineoil

1.

Sparkplug

2.

AirCleaner

1.

Fuelsystem

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.Usethe ServiceLogcolumnto keeptrackof

completedmaintenancetasks.To locate the nearest SearsService

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Clean

2. Lubewithlightoil

3. Clean

1. Change

1. Replace

2. Replace

1. Runengineuntilitstopsfromlackof

fuel,oraddstabilizertoa fulltankof

freshfuelpriortostorage.

_resent.Replaceaircleanerif verydirty.

Alwaysstopengineanddisconnectsparkplugwire beforeperforming

Ianymaintenanceoradjustments.Alwayswearsafetyglassesduring

_operationor whileperforminganyadjustmentsor repairs.

GENERAL RECOMMENDATIONS

• Alwaysobservesafetyruleswhenperforming

anymaintenance.

• Thewarrantyonthisyardvacuumdoesnotcoveritemsthat have

beensubjectedtooperatorabuseor negligence.To receivefull

valuefromwarranty,operatormustmaintaintheequipmentas

instructedhere.

• Someadjustmentswillhavetobe madeperiodicallytomaintain

yourunit properly.

• Periodicallycheckall fastenersand makesurethesearetight.

ENGINE MAINTENANCE

Checking the Spark Plug

Cleansparkplugandresettheelectrodegapto0.020"atleastonce a

season;replaceevery100hoursof operation.

Cleanareaaroundthe sparkplugbase.Do not sandblastspark

plug.Sparkplugshouldbecleanedbyscrapingorwirebrushing

andwashingwitha commercialsolvent.

f

Electrode

.020inch (.51 ram)gap

Removeandinspectthe sparkplug.Checkgaptomakesureit is

setat .020".SeeFigure17.

• Replacethesparkplugif electrodesare pitted,burned,orthe

porcelainiscracked.

Porcelain

Figure17

J

16

Page 17

Servicing the Air Cleaner

Theair cleanerpreventsdamagingdirt, dust,etc.,fromenteringthe

carburetorand beingforcedintothe engineandis importanttoengine

lifeandperformance.Theaircleanerconsistsofa pleatedfilter.Never

runtheenginewithoutanaircleanercompletelyassembled.

Cleantheair cleanerevery25hoursofoperationoroncea season.

Replacetheaircleanerannually.

Neverstartor runtheenginewiththeaircleanerassemblyortheair

filterremoved.

NOTE:Do notusepressurizedairor solventstocleanthe filter.Pres-

surizedair candamagethefilterandsolventswilldissolvethefilter.

1. Loosenthefastenerthatholdsthecoverandtilt plastichousing

coveron sideofenginedown.SeeFigure18.

2. Removeairfilterfromplastichousingcover.

3. Toloosendebris,gentlytapthefilterona hardsurface.Ifthefilter

isexcessivelydirty,replacewitha newfilter.

4. Insertcover'stabsinto slotsin bottomofbase.

5. Tiltcoverupinto placeandsecurewithfastener.

Checking Engine Oil

Checkoillevelbeforeeachoperation.Be sureoillevelismaintained.

1. Checktheoil withthe enginestoppedandlevel.

2. Removetheoil fill dipstickandwipe itclean.

3. Insertandtightendipstick.Removeit tochecktheoil level.

4. If theoil levelisnearor belowthelowerlimitmarkon thedipstick,

removethe oil fillercap/dipstick,andfillwiththerecommendedoil

tothe upperlimitmark. Donotoverfill.

5. Reinstalltheoilfilldipstick.

Changing Engine Oil

Oil Fill/Dipstick

/

Mumer

/

Gasolineanditsvaporsareextremelyflammableandexplosive.

Fireor explosioncancausesevereburnsordeath.

Changeengineoilafterthe first fivehoursofoperation,andeveryfifty

hoursoronce a seasonthereafter.

Whenyoudraintheoilfromthetopoil filltube,thefueltankmustbe

Iemptyor fuel canleakoutand resultinafireor explosion.Toempty

Ithe fueltank,runtheengineuntilit stopsfromlackoffuel.

1. Withengineoffbutstillwarm,disconnectthesparkplugwireand

keepit awayfromthe sparkplug.

2. Placea suitablecontainernextto theenginetocatchthe usedoil.

3. Removetheoil fill dipstickanddraintheoil intothecontainerby

tippingtheenginetowardtheoil fillerneck.See Figure19.

Figure19

Usedoil isa hazardouswasteproduct.Disposeofusedoilproperly.

IDo notdiscardwithhouseholdwaste.Checkwithyourlocalauthori-

_tiesorSearsServiceCenterforsafedisposal/recyclingfacilities.

4. Withtheenginein a levelposition,fillto theupperlimitmarkon

thedipstickwiththerecommendedoil.

Runningtheenginewitha low oil levelcancauseenginedamage.

5. Reinstalltheoil filldipsticksecurely.

17

Page 18

Cleaning Engine

• Dailyor beforeeveryuse,cleangrass,chaffor accumulated

debrisfromengine.Keeplinkage,spring,andcontrolsclean.

Keepareaaroundandbehindmufflerfreeofanycombustible

debris.

• Keepingenginecleanallowsairmovementaroundengine.

• Enginepartsshouldbekeptcleanto reducetheriskofoverheat-

ingandignitionofaccumulateddebris.

Donot usewatertocleanengineparts.Watercouldcontaminatefuel

system.Usea brushor drycloth.

LUBRICATION

* Wheels- Placea fewdropsofSAE30 oilon eachshoulderscrew

oncea season.

, Nozzleheightadjustment levers-Lubricatenozzleheight

adjustmentleverswithlightoil.

, Locking Rod- Lubricatethelock rodandcompressionsprings

whichattachto themountingbracket.

, Nozzle/HoseVacLever: Lubricatethenozzle/hosevacleveron

topof the nozzleoncea seasonwithlightoil.

CLEANING EQUIPMENT

Cleanundersideof theyardvacuumoncea seasontopreventbuild-up

ofdebris.Followstepsbelowforthisjob.

1. Disconnectandgroundsparkplugwire.Emptythefueltankby

runningengineuntiltankis dry.

2. Tipthe yard vacuumsothatit restson itsside,keepingthe

mufflersidedown.Holdyardvacuumfirmly.

3. Scrapeandcleantheundersideofthedeckandnozzlewitha

suitabletool.Donot spraywithwater.

Figure20

f

IMPORTANT:Donot usea pressurewasherorgardenhosetoclean

yourunit.Thesemaycausedamagetobearings,ortheengine.The

useof waterwill resultin shortenedlifeandreduceserviceability.

4. Putthe yardvacuumbackon itswheelson theground.

CLEANING THE FLAIL SCREEN

Ifthedischargeareabecomesclogged,removetheflail screenand

cleanareaas follows:

1. Stopthe engine.Makecertainthechipper/shreddervacuumhas

cometoa completestop.

2. Beforeuncloggingthe dischargechute,disconnect and ground

the spark plugwire.

3. Removethevacuumbagor blowerchutefromthe unitas

instructedin theOPERATIONsectiontoobtainaccesstoflail

screen.

4. Removethethreeselftappingscrewssecuringthebeltcover,and

removebeltcover.SeeFigure20.

5. Removeselftappingscrewonrightsideof unitthatattachesto

theflail screen.SeeFigure21.

/

J

Figure21

18

Page 19

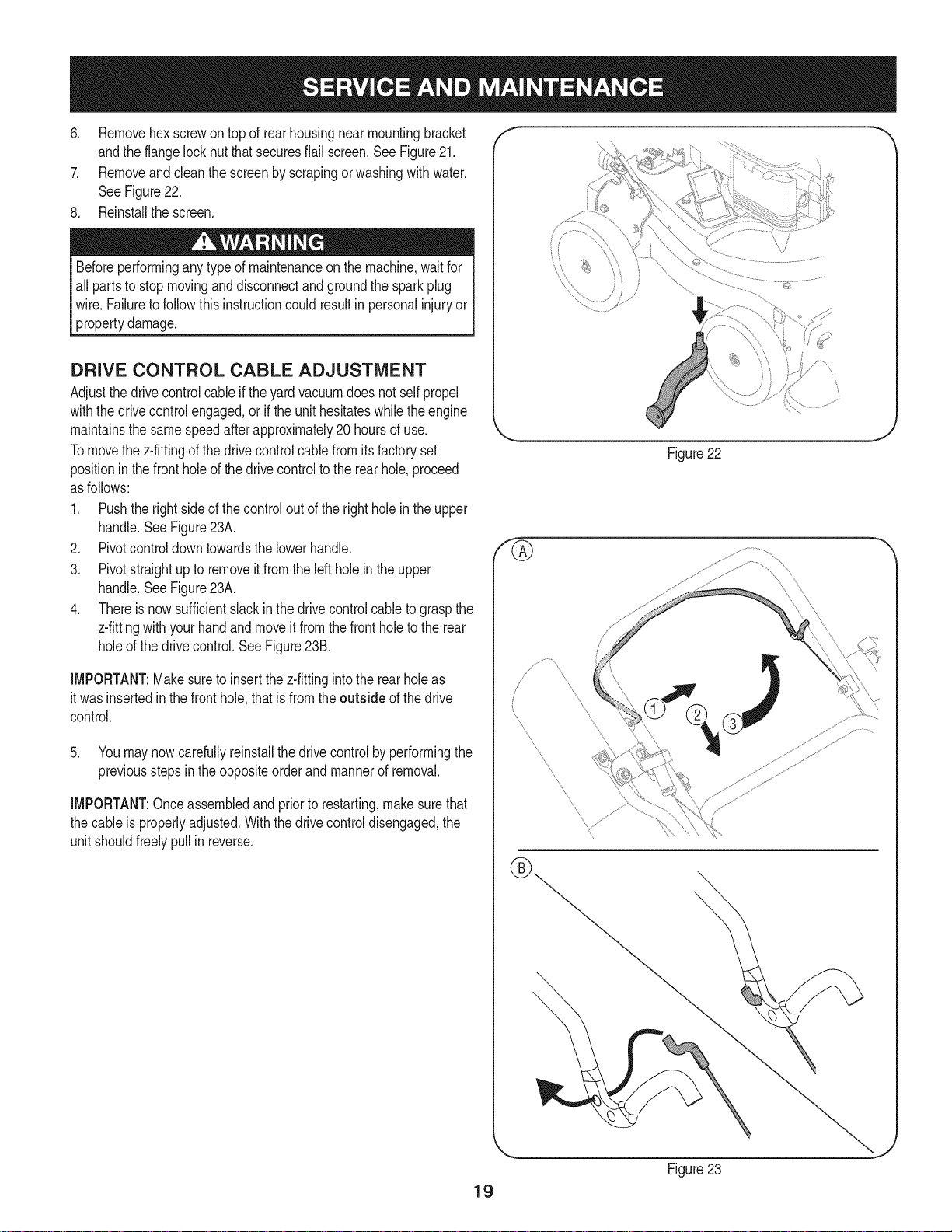

6. Removehexscrewontop of rearhousingnearmountingbracket

andtheflangelocknutthatsecuresflailscreen.SeeFigure21.

7. Removeandcleanthescreenbyscrapingorwashingwithwater.

SeeFigure22.

8. Reinstallthescreen.

Beforeperforminganytypeof maintenanceon the machine,waitfor

all partsto stopmovinganddisconnectandgroundthe sparkplug

wire. Failureto followthisinstructioncouldresultin personalinjuryor

propertydamage.

DRIVE CONTROL CABLE ADJUSTMENT

Adjustthedrivecontrolcableif theyardvacuumdoesnotselfpropel

withthedrivecontrolengaged,orif theunithesitateswhilethe engine

maintainsthesamespeedafterapproximately20 hoursofuse.

Tomovethe z-fittingofthedrivecontrolcablefromitsfactoryset

positioninthefrontholeofthedrivecontrolto therearhole,proceed

asfollows:

1. Pushtherightsideof thecontroloutof the rightholeintheupper

handle.SeeFigure23A.

2. Pivotcontroldowntowardsthelowerhandle.

3. Pivotstraightupto removeitfromtheleftholein theupper

handle.SeeFigure23A.

4. Thereis nowsufficientslackinthedrivecontrolcableto graspthe

z-fittingwithyourhandandmoveitfromthefrontholetothe rear

holeofthedrivecontrol.SeeFigure23B.

f

\

Figure22

IMPORTANT:Makesureto insertthez-fittingintothe rearholeas

itwasinsertedinthefronthole,thatis fromtheoutside ofthedrive

control.

5. Youmaynowcarefullyreinstallthedrivecontrolbyperformingthe

previoussteps inthe oppositeorderandmannerof removal.

IMPORTANT:Onceassembledand priorto restarting,makesurethat

thecableisproperlyadjusted.Withthedrivecontroldisengaged,the

unitshouldfreelypullin reverse.

\

19

Figure23

Page 20

SHARPENING OR REPLACING CHIPPER

BLADE

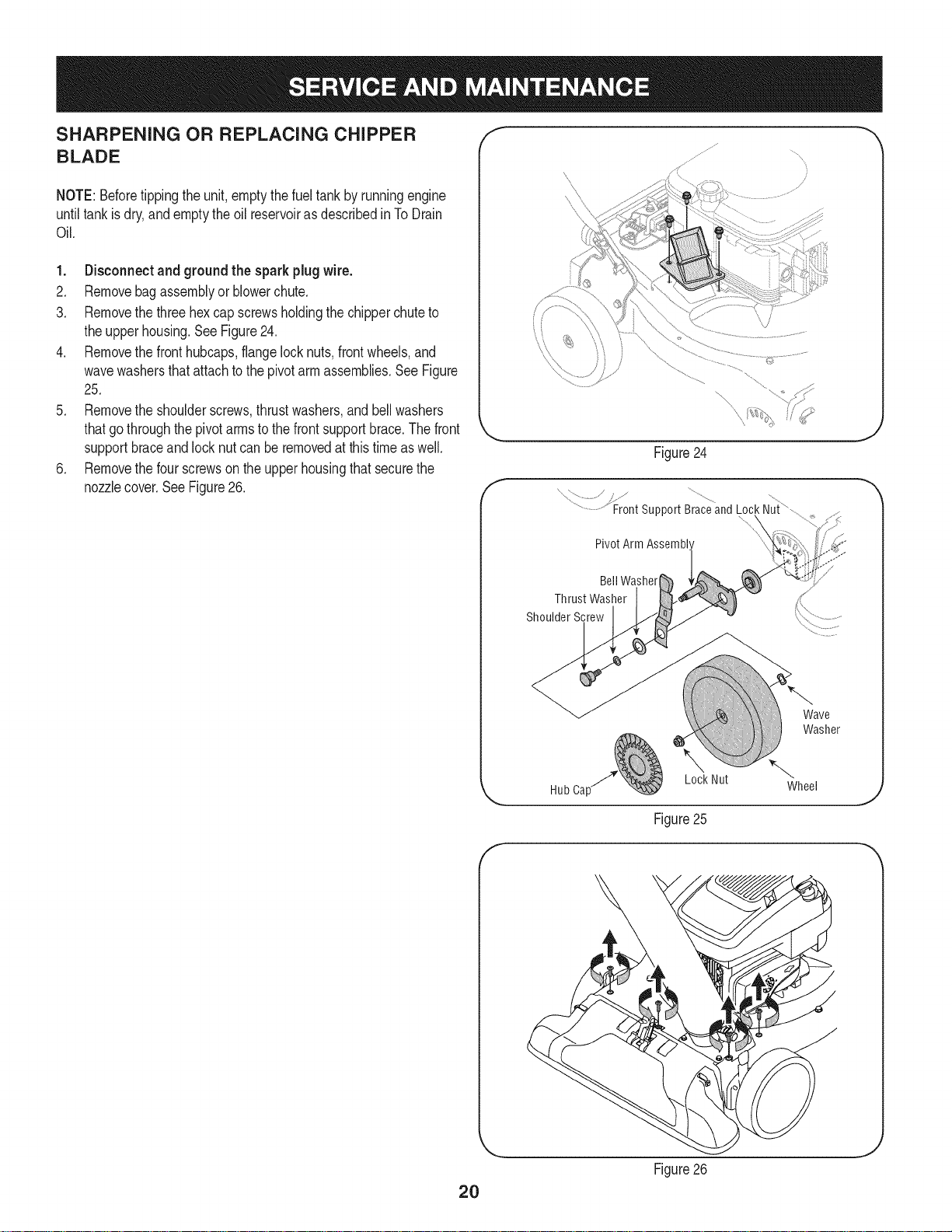

NOTE:Beforetippingthe unit,emptythefuel tankby runningengine

untiltankisdry,andemptytheoil reservoiras describedinTo Drain

Oil.

1. Disconnectand groundthe sparkplugwire.

2. Removebagassemblyorblowerchute.

3. Removethethreehexcapscrewsholdingthe chipperchuteto

theupperhousing.SeeFigure24.

4. Removethefronthubcaps,flangelocknuts,frontwheels,and

wavewashersthatattachtothepivotarm assemblies.SeeFigure

25.

5. Removethe shoulderscrews,thrustwashers,andbellwashers

thatgothroughthepivotarmsto thefrontsupportbrace.Thefront

supportbraceandlocknutcan beremovedatthistimeas well.

6. Removethefourscrewsontheupperhousingthat securethe

nozzlecover.SeeFigure26.

f

J

Figure24

x /

..........................Front support Braceand Lock Nui

PivotArm Assembl'

BellWasher

Thrust Washer

Shoulder Screw

2O

Wave

Washer

Lock Nut

HubCa[ Wheel

J

Figure25

f

J

Figure26

Page 21

7. Carefullytilt andsupportthe unit upto provideaccessunderneath

tothe nozzlemountinghardwareandimpeller.Removethethree

shoulderboltssecuringtheblackplasticlowerflailhousingtothe

lowerhousing.Referto Figure27.

8. Tilttopofblackplasticlowerflailhousingtowardtheengineto

remove.

9. Usinga 3/16"allenwrench,removetheflat headcapscrewsthat

holdthechipperbladeto theimpeller.Thesescrewsareacces-

siblethroughtheopeningcreatedwhenthechipperchutewas

removedearlier.SeeFigure28.

10. Thenutsontheflat headcap screwscan bereachedfrom

underneathusinga 1/2-inchsocket,universal,andextension.

SeeFigure29.

11. Replaceorsharpenchipperblade.Thebladecanbe sharpened

witha fileor ona grindingwheel.

\

Black

Nozzle

ShoulderScrews

Thechipperbladeis sharp.Whensharpeningblade,wearleather

workglovestoprotectyourhandsandfollowtheoriginalangleof

grind.

12. Reassemblebyperformingthepreviousstepsin theopposite

orderand mannerofremoval.

NOTE:Tightenbladescrewsto 210- 250in-lbs.Makecertainchipper

bladeis reassembledwiththe sharpedgefacingupward.

Figure27

f

C

Flat HeadCa Screws

Chipper Blade

J

Figure28

Impeller

21

J

Figure29

Page 22

Neverstoreyardvacuumwithfuelintankindoorsorinpoorly

ventilatedareaswherefuelfumesmayreachanopenflame,spark,

or pilotlightas ona furnace,waterheater,clothesdryer,or gas

appliance.

PREPARING THE ENGINE

Forenginesstoredover30 days:

1. Topreventgumfromforminginfuelsystemoroncarburetor

parts,runengineuntilit stopsfromlackof fuelor adda gasoline

additivetothe gas inthe tank.Ifyouuseagasadditive,runthe

engineforseveralminutestocirculatetheadditivethroughthe

carburetor--afterwhichtheengineandfuelcan bestoredup to

six months.

2. Whileengineis stillwarm,changethe oil.

3. Cleanengineof surfacedebris.

PREPARING THE YARD VACUUM

• Whenstoringtheyardvacuumin an unventilatedor metalstorage

shed,careshouldbetakento rustproofthenon-paintedsurfaces.

Usinga lightoil orsilicone,coattheequipment,especiallyany

springs,bearings,andcables.

• Cleanandlubricatemowerthoroughlyas describedinthe lubrica-

tioninstructions.

• Donotusea pressurewasheror gardenhosetocleanyourunit.

• Store mowerina dry,cleanarea. Do notstorenexttocorrosive

materials,suchas fertilizer.

22

Page 23

Enginefailstostart

1. Throttlelevernotincorrectstartingposition

2. ChokecontrolnotinCHOKEposition

3. Sparkplugwire disconnected

4. Faultysparkplug

5. Fueltankemptyorstalefuel

6. Cannotpullrecoilcord

7. Safetyswitchnotdepressed

8. Safetyswitchwireisnotconnectedto

engineor notproperlygrounded

Enginerunserratically

1. Unitrunningon CHOKE

2. Sparkplugwire loose

3. Stalefuel

4. Wateror dirtin fuelsystem

5. Dirtyair cleaner

6. LowengineRPM

7. Carburetoroutofadjustment

Engineoverheats

1. Engineoil levellow

2. Airflowrestricted

Enginehesitatesat high RPMs 1. Sparkpluggap settooclose

Engineidlespoorly 1. Fouledsparkplug

2. Dirtyair cleaner

Excessivevibration 1. Loosepartsor damagedimpeller

Unitdoesnot discharge 1. Dischargeareaclogged

2. Foreignobjectlodgedin impeller

3. LowengineRPM

4. Vacuumbagis full

Rated dischargeslows

considerablyor compositionof

1. LowengineRPM

2. Chipperbladedull

dischargedmaterialchanges

Unitfailstopropelitselforslips

1. Drivecontrolcableout of adjustment

whendrivecontrolisengaged

2. Drivebeltworn ordamaged

1. Movethrottleleverto FASTposition.

2. MovechokecontroltoCHOKEposition.

3. Connectwiretosparkplug.

4. Clean,adjustgap,or replace.

5. Filltankwithclean,freshgasoline.

6. Obstructionlodgedin impeller.Disconnectspark

plugwireandremovelodgedobject.

7. Safetyswitchmustbedepressedbythefronttabon

thebag handlewhen securingthebag.

8. Connectsafetyswitchwireto engineconnectorand

groundto mountingbracket.

1. Movechokecontrolto RUNposition.

2. Connectandtightensparkplugwire.

3. Filltankwithfreshgasoline.

4. Drainfuel.Refillwithfreshfuel.

5. Cleanorreplaceaircleanerfilter.

6. Alwaysrunengineat fullthrottle.

7. ContactyourSearsParts& RepairCenter.

1. Fillenginewith properamountandtype ofoil.

2. Cleangrassclippingsanddebrisfromaroundthe

engine'scoolingfinsandblowerhousing.

1. Removesparkplugandadjustgap.

1. Replacesparkplugandadjustgap.

2. Replaceair cleanercartridge.

1. Stopengineimmediatelyanddisconnectsparkplug

wire.ContactyourSearsParts& RepairCenter.

1. Stopengineimmediatelyanddisconnectsparkplug

wire.Cleanflail screenandinsideofdischargeopen-

ing.

2. Stopengineanddisconnectsparkplugwire.Remove

lodgedobject.

3. Alwaysrunengineatfullthrottle.

4. Emptybag.

1. Alwaysrunengineatfullthrottle.

2. Replacechipperbladeor contactyourSearsParts&

RepairCenter.

1. Followadjustmentprocedurein Service& Mainte-

nancesection.

2. ContactyourSearsParts& RepairCenter.

Find this and all your other product manuals online.

Get answers from our team of home experts.

Get a personalized maintenance plan for your home.

Find information and tools to heLp with home projects.

23

Page 24

Craftsman Power Propelled Yard Vacuum Model No. 247.770131

14

44

41

54

63

24

38

Page 25

Ref.No. Part No. Description

1. 731-07001 HubCap

2. 749-04163-0637 UpperHandle

3. 720-0279 Knob

4. 710-1205 EyeBolt

5. 781-1056-0637 UpperHandleBracket

6. 710-0726 HexCapScrew5/16-12x.750

7. 720-04072A HandleKnob5/16-18

8. 710-1174 CarriageBolt

9. 731-04911 NozzleHandleClip

10. 749-04165-0637 LowerHandle

11. 711-1293 Studs

12. 710-0703 CarriageScrew1/4-20x.75

13. 712-0397A WingNut1/4-20

14. 710-1611B TT Screw,5/16-18x .750

15. 710-05073 Screw,1/4-20x .500

16. 912-0442 CapLockNut, 1/4-20

17. 710-0751 HexCapScrew1/4-20x.620

18. 681-0195 HoseBaseAdapterAssembly

(Incl.Ref.#19-21)

19. 916-0104 E Ring.500Dia

20. 932-3035 CompressionSpring

21. 711-1571 ClevisPin

22. 936-3020 FiatWasher.271IDx.630OD

23. 781-04266-4044 UpperFlailHousing

24. 746-04156 DriveControlCable

25. 731-1820 CableGuide

26. 681-04088-4044 ChipperChuteAssembly

27. 746-04155 SpeedControlCable

28. 710-1122 HexScrew,1/4-20x 2.50

29. 981-0156A-4044 HandleBracketAss'yRH

981-0155A-4044 HandleBrktAss'y LH(NotShown)

30. 717-1762 SpurGear- RH

717-1761 SpurGear- LH (NotShown)

31. 748-0457 Spacer

32. 731-2478 HoseNozzle

33. 710-3288 HexCapScrew1/4-20x 2.625

34. 723-0295 AdjustmentClamp

35. 749-1270A NozzleHandle

36. 764-0648A VacuumHose

37. 720-0369 HandlePlug

38. 731-2292 HoseAdapter

39. 747-04305A DriveControl

Ref.No. Part No. Description

40. 725-0157 CableTie

41. 918-04460 TransmissionAssembly

42. 732-04217 ExtensionSpring,.375x 2.95

43. 710-1650 ShoulderScrew,#12-24x .30x .46

44. 710-1220 Screw,#12-16x .750

45. 911-04245 ImpellerHub

46. 915-0221 DowelPin

47. 781-04082-0637 FrontWheelSupportBrace

48. 781-04081-0637 RearWheelSupportBrace

49. 914-0104 CotterPin

50. 916-0104 E-Ring

51. 936-3004 FiatWasher,.406x .875x .105

52. 712-04217 Nut,Flglk.,3/8-16

53. 738-04523 ShoulderScrew,.496x 1.605

54. 734-04596 RearWheel

55. 716-0865 SnapRing

56. 741-04242 HeightAdjustmentBearing

57. 681-04195 PivotArmAssembly

58. 720-0426 HeightAdjustmentKnob

59. 732-1026 SpringLever

60. 736-0741 BellWasher.760IDx.25OD

61. 738-1172 ShoulderScrew,.750x.500

62. 987-02051 HeightLeverAssy(Incl.Ref.#58-59)

63. 734-04568 FrontWheel

64. 710-1652 Screw,1/4-20x .625

65. 712-04065 FlangeLockNut,3/8-16

66. 731-04879 BeltCover

67. 936-0314 ThrustWasher.375IDx.70OD

68. 731-04643 WheelCover

69. 936-0369 FiatWasher,.5081Dxl .O00Dx.020

70. 738-0930 ShoulderScrew,.560x.165

71. 741-04108 DriveAxle Bushing

72. 781-04078-0637 TransmissionMountingBracket

73. 710-0597 Screw,1/4-20x 1.00

74. 712-04064 FlangeLockNut,1/4-20

75. 941-0600 Ball Bearing

76. 750-1050 FlangeSpacer,.260x.659x.517

77. 954-0369 Belt,3/8x 32.5

78. 781-04077-0637 Idler Bracket

79. 782-7598 Belt Keeper

80. 126MO2-O434-F1Engine

25

Page 26

Craftsman Power Propelled Yard Vacuum Model 247.770131

[]

45

[]

30/i_31

7

6

25

26

Page 27

Craftsman Power Propelled Yard Vacuum IViodel 247.770131

Ref.No. Part No. Description

1. 664-0094 BagAssembly

2. 681-0154-0637 ScreenAssembly

3. 710-1054 HexScrew5/16-24x 1.0

4. 981-0490 ChipperBlade

5. 781-0735 PinClip

6. 719-0329 Flail

7. 715-0166 SpiralPin

8. 711-1401 ClevisPin

9. 912-0411 LockNut,5/16-24

10. 936-0119 LockWasher,5/16

11. 981-0152 ImpellerAssembly

(Incl.Ref.#3 - 10)

12. 781-0721B-4044 LowerFlailHousing

13. 712-04063 FlangeLockNut5/16-18

14. 710-0607 Screw,5/16-18x.500

15. 981-04031 Nozzle(Incl.Ref.#16-26)

16. 747-04297 HingePin

17. 781-1064 BaseAdapterDoor

18. 732-1156 TorsionSpring

19. 926-0106 CapSpeedNut1/4

20. 711-1551 PivotRod

21. 731-04967 NozzleDoorLever

22. 710-1256 HexScrew,#8-18x 1.25

23. 750-1294 ShoulderSpacer

24. 732-3118 ExtensionSpring

25. 732-1151A NozzleDoorTorsionSpring

26. 731-2294A NozzleDoor

Ref.No. Part No. Description

27. 664-04039 Bag

28. 631-0083 ChuteAssembly

29. 736-0247 FiatWasher.375IDx 1.25OD

30. 936-0217 LockWasher3/8

31. 710-1273 HexCapScrew,3/8-24x2.75

32. 631-04118 EngineSpacerAssembly

33. 710-1008 Screw,3/8-16x 1.875

34. 925-1700 SwitchCover

35. 925-3166 SafetySwitch

36. 931-1613 SafetySwitchCover

37. 910-0224 HexWasherScrew#10-16x.50

38. 629-0920A WireHarness

39. 914-0104 CotterPin

40. 732-0962 CompressionSpring

41. 781-0778A-0637 MountingBracket

42. 747-1153 LockRod

43. 710-3195 HexCapScrew5/16-18x4.5

44. 710-3025 HexCapScrew5/16-18x.625

45. 710-1220 Screw,#12-16x.750

46. 710-0351 Screw#10- 16x.500

47. 736-0607 ExternalbWasher5/16

48. 726-0139 SpeedNut

49. 710-0726 HexindexScrew,5/16-12x.750

50. 710-1650 ShoulderScrew,#12-24x .30x .46

51. 0EM-290-012 BlowerChute

52. 629-0923 WireHarnessAdapter

-- 723-0400 SafetyGlasses(NotShown)

27

Page 28

Craftsman Engine Model No. 126M02=0434=F1 For Craftsman Yard Vacuum Model No. 247.770131

I%

15o5

615

404 @

616

635

306

7_

307

36_0_ 5_

33/.._ 40 45_:9d_

(_ 35_

868 _) _._

3@

©

718 [_

241_

287

54

I}

28

524

4--]

20

158

Page 29

Craftsman Engine IVlodel No. 1261V102-0434-F1 For Craftsman Yard Vacuum IViodel No. 247.770131

108

@

3_s

163

@ _3 ®

692 I

190

130

I 276 @

276 @

4_

883

2221 621_

188

843 843A _

968

443 '_

445

29

Page 30

Craftsman Engine Model No. 126M02=0434=F1 For Craftsman Yard Vacuum Model No. 247.770131

6s

55

1211 (__

1036E MISSIONS LABEL ]

1210

689 0

456 _

597

305

304

305A (_

332

78

455

23

30

Page 31

Craftsman Engine Model No. 126M02=0434=F1 For Craftsman Yard Vacuum Model No. 247.770131

121 CARBURETOR OVERHAUL KiT

137 O 617 (_

633 @

127 (_

163 276Q

633A

358 ENGINE GASKET SET

3

617

842 O

1095V ALVE GASKET SET

2o1_

163 _!_

524

883

31

Page 32

Craftsman Engine Model No. 126MO2=O434-F1 For Craftsman Yard Vacuum Model No. 247.770131

D = = O e

590401 CylinderAssembly

2. 399269 Kit-Bushing/Seal

3. 299819s Seal-Oil(MagnetoSide)

4. 493279 Sump-Engine

5. 590411 Head-Cylinder

7. 799875 Gasket-CylinderHead

8. 590395 BreatherAssembly

9. 699472 Gasket-Breather

10. 691125 Screw(BreatherAssembly)

11. 691781 Tube-Breather

11A. 691923 Tube-Breather

12. 692232 Gasket-Crankcase

13. 590422 Screw(CylinderHead)

15. 691680 Plug-OilDrain

16. 694478 Crankshaft

20. 399781s Seal-Oil(PTOSide)

22. 691092 Screw(CrankcaseCover/Sump)

23. 691987 Flywheel

24. 222698s Key-Flywheel

25. 590404 PistonAssembly(Standard)

590405 PistonAssembly(.020"Oversize)

26. 590402 RingSet(Standard)

590403 RingSet(.020"Oversize)

27. 691588 Lock-PistonPin

28. 298909 Pin-Piston

29. 797306 Rod-Connecting

32. 691664 Screw(ConnectingRod) (1/4-28x 1.09)

32A. 695759 Screw(ConnectingRod) (1/4-28x 1.52)

33. 590394 Valve-Exhaust

34. 590393 Valve-Intake

D = O

691270 Spring-Valve(Intake)

36. 691270 Spring-Valve(Exhaust)

37. 793756 Guard-Flywheel

40. 692194 Retainer-Valve

43. 691997 Slinger-Governor/Oil

45. 690548 Tappet-Valve

46. 691449 Camshaft

48. N/A ShortBlock- Notavailableatthisprinting

50. 794305 Manifold-Intake

51. 794306 Gasket-Intake

54. 691650 Screw(IntakeManifold)

55. 691421 Housing-RewindStarter

58. 697316 Rope-Starter

60. 281434s Grip-StarterRope

65. 690837 Screw(RewindStarter)

78. 691108 Screw(FlywheelGuard)

81. 691740 Lock-MufflerScrew

89. 692348 Plug-Oil(Cylinder)

97. 696565 Shaft-Throttle

104. 797622 Pin-FloatHinge

108. 695807 Valve-Choke

109. 498593 Shaft-Choke

117. 797574 Jet-Main(Standard)

118. 797575 Jet-Main(HighAltitude)

121. 498260 Kit-CarburetorOverhaul

125. 799869 Carburetor

127. 694468 Plug-Welch

130. 696564 Valve-Throttle

133. 398187 Float-Carburetor

134. 398188 Valve-Needle/Seat

32

Page 33

Craftsman Engine

IViodel No. 126MO2=O434=F1 For Craftsman Yard Vacuum IViodel No. 247.770131

D = O

796610 Gasket-FloatBowl

163. 795629 Gasket-AirCleaner

187. 791766 Line-Fuel(Cutto RequiredLength)

188. 693399 Screw(ControlBracket)

190. 690940 Screw(FuelTank)

202. 691829 Link-MechanicalGovernor

209. 691291 Spring-Governor

222. 692150 Bracket-Control

227. 690783 ControlLever-Governor

276. 271716 SealingWasher

287. 690940 Screw(DipstickTube)

300. 692038 Muffler

304. 493294 Housing-Blower

305. 691108 Screw(BlowerHousing)(1/4-20x .62)

305A. 590763 Screw(BlowerHousing)(1/4-20x .78)

306. 690450 Shield-Cylinder

307. 690345 Screw(CylinderShield)

332. 690662 Nut(Flywheel)

333. 590454 Armature-Magneto

334. 691061 Screw(ArmatureMagneto)

337. 799876 Plug-Spark

356. 692390 Wire-Stop

358. 794307 EngineGasketSet

365. 691688 Screw(Carburetor)

404. 690272 Washer(GovernorCrank)

425. 690670 Screw(AirCleanerCover)

443. 692523 Screw(AirCleanerPrimerBase)

D = O

491588s Filter-AirCleanerCartridge

455. 791960 Cup-Flywheel

456. 692299 Plate-PawlFriction

459. 281505s PawI-Ratchet

505. 691251 Nut(GovernorControlLever)

523. 499621 Dipstick

524. 692296 Seal-DipstickTube

525. 495265 Tube-Dipstick

562. 691119 Bolt(GovernorControlLever)

584. 697734 Cover-BreatherPassage

585. 691879 Gasket-BreatherPassage

592. 690800 Nut(RewindStarter)

597. 691696 Screw(PawlFrictionPlate)

601. 791850 HoseClamp(Green)

608. 497680 Starter-Rewind

613. 691340 Screw(Muffler)

615. 798326 Retainer-GovernorShaft

616. 698801 Crank-Governor

617. 270344s SeaI-ORing(IntakeManifold)

621. 692310 Switch-Stop

633. 691321 Seal-Choke/ThrottleShaft(ThrottleShaft)

633A. 693867 Seal-Choke/ThrottleShaft(ChokeShaft)

635. 66538s Boot-SparkPlug

668. 493823 Spacer

684. 690345 Screw(BreatherPassageCover)

689. 691855 Spring-Friction

692. 690572 Spring-Detent

33

Page 34

Craftsman Engine Model No. 126MO2=O434=F1 For Craftsman Yard Vacuum Model No. 247.770131

D = W O

690959 Pin-Locating

725. 590459 Shield-Heat

741. 795755 Gear-Timing

832. 590486 Guard-Muffler

836. 690664 Screw(MufflerGuard)

842. 691031 Seal-ORing(DipstickTube)

843. 691884 Sleeve-Lever

843A. 691895 Sleeve-Lever

847. 692047 Assembly-Dipstick/Tube

851. 493880s Terminal-SparkPlug

868. 590410 Seal-Valve

869. 691155 Seat-Valve(Intake)

870. 690380 Seat-Valve(Exhaust)

871. 590409 Bushing-ValveGuide

883. 793497 Gasket-Exhaust

957. 799585 Cap-FuelTank

D = O O

795259

968. 692298

972. 590490

975. 796611

976. 694395

1036.

Base-AirCleanerPrimer

Cover-AirCleaner

Tank-Fuel

Bowl-Float

Primer-Carburetor

Label-Emission(Availablefromauthorized

Briggs&Strattondealer)

1058. 390567TRI

1059. 692311

1095. 498528

1210. 498144

1211. 498144

1329. N/A

Owner'sManual

Kit-Screw/Washer(FuelTank)

GasketSet-Valve

Assembly-Pulley/Spring(Pulley)

Assembly-Pulley/Spring(Spring)

ReplacementEngine(NotAvailable

atthis Printing)

1330. 270962

RepairManual

CarburetorOverhaulKit ReferenceNumber121

EngineGasketSet ReferenceNumber358

ValveGasketSet ReferenceNumber1095

34

Page 35

Craftsman Power Propelled Yard Vacuum IViodel 247.770131

777S33696 777X43688

777S33695

Operation Of This Equipment May Create Sparks ThatCan Start Fires Around DryVegetation. A Spark Arrestor May Be Required,

FRONT WHEEL / VACUUM NOZZLE

HiGH HEIGHT ADJUSTER LOW

For use in To pick up wet

grass to pick material, pine

Lip Jeaves cones, acorns

and debris or material on

pavement.

The Operator Should Contact Local FireAgencies For Laws Or Regulations Relating To FirePrevention Requirements.

777122415

ITHANIO%ETHANOL

777S33694

777120916

777122416

777122428

777D18140

Do Not

Shift

unless

Engine is

Running

3372

35

Page 36

(Thispageapplicableinthe U.S.A.andCanadaonly.)

Sears Brands Management Corporation (Sears), the California Air Resources Board (CARD)

and the United States Environmental Protection Agency (U.S. EPA)

Emission Control System Warranty Statement (Owner's Defect Warranty Rights and Obligations)

EMISSIONCONTROLWARRANTYCOVERAGEISAPPLICABLETOCERTI-

FIEDENGINESPURCHASEDINCALIFORNIAIN1995ANDTHEREAF-

TER,WHICHAREUSEDINCALIFORNIA,ANDTOCERTIFIEDMODEL

California and United States Emission

TheCaliforniaAirResourcesBoard(CARD),U.S.EPAand Searsare pleased

toexplainthe EmissionControlSystemWarrantyonyour modelyear2000and

latersmalloff-roadengine(SORE).InCalifornia,newsmalloff-roadengines

mustbe designed,builtandequippedto meettheState'sstringentanti-smog

standards.Elsewherein theUnitedStates,newnon-road,spark-ignition

enginescertifiedformodelyear1997andlatermustmeetsimilarstandardsset

forthbythe U.S.EPA.Searsmustwarranttheemissioncontrolsystemonyour

YEAR1997ANDLATERENGINESWHICHARE PURCHASEDANDUSED

ELSEWHEREINTHEUNITEDSTATES(ANDAFTERJANUARY1,2001 IN

CANADA).

Control Defects Warranty Statement

enginefortheperiodsoftime listedbelow,providedtherehasbeennoabuse,

neglector impropermaintenanceofyour smalloff-roadengine.Youremis-

sioncontrolsystemincludespartssuchas thecarburetor,aircleaner,ignition

system,mufflerandcatalyticconverter.Also includedmaybeconnectorsand

otheremissionrelatedassemblies.Wherea warrantableconditionexists,Sears

will repairyoursmalloff-roadengineatnocostto youincludingdiagnosis,parts

andlabor.

Sears Emission Control Defects Warranty Coverage

Smalloff-roadenginesarewarrantedrelativeto emissioncontrolpartsdefects

fora periodof one year,subjecttoprovisionssetforthbelow.Ifanycovered

Owner's Warranty

Asthe smalloff-roadengineowner,youare responsiblefor theperformanceof

therequiredmaintenancelistedinyourOperatingand MaintenanceInstruc-

tions.Searsrecommendsthatyouretainallyourreceiptscoveringmaintenance

onyoursmalloff-roadengine,butSearscannotdenywarrantysolelyforthe

lackofreceiptsorfor yourfailuretoensuretheperformanceof allscheduled

maintenance.Asthe smalloff-roadengineowner,youshouldhoweverbe

awarethatSearsmaydenyyouwarrantycoverageifyoursmalloff-roadengine

ora parthasfaileddueto abuse,neglect,impropermaintenanceor unap-

parton yourengineis defective,the partwillbe repairedorreplacedbySears.

Responsibilities

provedmodifications.Youare responsiblefor presentingyoursmalloff-road

engineto anAuthorizedSearsServiceDealeras soonasaproblemexists.The

undisputedwarrantyrepairsshouldbecompletedina reasonableamountof

time,notto exceed30days.Ifyouhaveanyquestionsregardingyourwarranty

rightsandresponsibilities,youshouldcontacta SearsServiceRepresentative

at 1-800-469-4663.The emissionwarrantyis a defectswarranty.Defectsare

judgedonnormalengineperformance.Thewarrantyis notrelatedtoan in-use

emissiontest.

Sears Emission Control Defects Warranty Provisions

ThefollowingarespecificprovisionsrelativetoyourEmissionControlDefectsWarrantyCoverage.ItisinadditiontotheSearsenginewarrantyfornon-regulated

enginesfoundin theOperatingand MaintenanceInstructions.

1. WarrantedParts

Coverageunderthis warrantyextendsonlyto the partslistedbelow(the

emissioncontrolsystemsparts)tothe extentthesepartswerepresenton

theenginepurchased.

a. FuelMeteringSystem

• Cold start enrichmentsystem

• Carburetorand internalparts

• FuelPump

b. AirlnductionSystem

• Air cleaner

• Intakemanifold

c. IgnitionSystem

• Spark plug(s)

• Magnetoignitionsystem

d. CatalystSystem

• Catalyticconverter

• Exhaustmanifold

• Air injectionsystemor pulsevalve

e. MiscellaneousItemsUsedin AboveSystems

• Vacuum,temperature,position,timesensitivevalves

andswitches

• Connectorsandassemblies

2. LengthofCoverage

Searswarrantsto the initialownerand eachsubsequentpurchaserthat

theWarrantedPartsshallbe freefromdefects in materialsandworkman-

shipwhich causedthefailure ofthe WarrantedPartsfora periodof one

yearfromthe datethe engineis deliveredtoa retailpurchaser.

Inthe USAandCanada,a 24hourhotline, 1-800-469-4663,hasa menuof pre-recordedmessagesofferingyouenginemaintenanceinformation.

3. NoCharge

Repairorreplacementof anyWarrantedPartwill be performedat no

chargeto the owner,includingdiagnosticlaborwhichleadstothe

determinationthata WarrantedPartisdefective,ifthe diagnosticworkis

performedatanAuthorizedSearsServiceDealer.Foremissionswarranty

servicecontact yournearestAuthorizedSearsServiceDealeraslistedin

the "YellowPages"under"Engines,Gasoline,""GasolineEngines,""Lawn

Mowers,"orsimilarcategory.

4. ClaimsandCoverageExclusions

Warrantyclaimsshallbefiledin accordancewiththe provisionsofthe

SearsEngineWarrantyPolicy.Warrantycoverageshall beexcludedfor

failuresof WarrantedPartswhichare notoriginalSearspartsor because

ofabuse,neglector impropermaintenanceassetforth inthe Sears

EngineWarrantyPolicy.Searsisnotliableto coverfailuresof Warranted

Partscausedby theuseof add-on,non-original,ormodifiedparts.

5. Maintenance

AnyWarrantedPartwhichis notscheduledfor replacementasrequired

maintenanceor whichis scheduledonlyforregularinspectiontothe effect

of"repairor replaceas necessary"shallbe warrantedastodefectsfor the

warrantyperiod.AnyWarrantedPartwhich isscheduledfor replacement

asrequiredmaintenanceshallbewarrantedastodefectsonlyforthe

periodoftime uptothe firstscheduledreplacementfor that part.Any

replacementpart that isequivalentin performanceanddurabilitymay

beusedin the performanceofanymaintenanceorrepairs.Theowneris

responsibleforthe performanceof all requiredmaintenance,asdefinedin

the SearsOperatingand MaintenanceInstructions.

6. ConsequentialCoverage

Coveragehereundershallextendto thefailureof anyenginecomponents

causedbythe failureof anyWarrantedPartstill underwarranty.

GDOC-100188Rev.B

36

Page 37

Look For Relevant Emissions Durability Period and

Air index information On Your Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) Tier 2 Emission Standards must

display information regarding the Emissions Durability Period and the Air Index. Sears Brands Management

Corporation makes this information available to the consumer on our emission labels.

The Emissions Durability Period describes the number of hours of actual running time for which the engine is

certified to be emissions compliant, assuming proper maintenance in accordance with the Operating & Mainte-

nance Instructions. The following categories are used:

Moderate: Engine is certified to be emission compliant for 125 hours of actual engine running time.

Intermediate: Engine is certified to be emission compliant for 250 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore, the Emissions

Durability Period of an engine with an intermediate rating would equate to 10 to 12 years.

The Air index is a calculated number describing the relative level of emissions for a specific engine family. The

lower the Air Index, the cleaner the engine. This information is displayed in graphical form on the emissions label.

After July 1,2000, Look For Emissions Compliance Period

On Engine Emissions Compliance Label

After July 1, 2000 certain Sears Brands Management Corporation engines will be certified to meet the United

States Environmental Protection Agency (USEPA) Phase 2 emission standards. For Phase 2 certified engines, the

Emissions Compliance Period referred to on the Emissions Compliance label indicates the number of operating

hours for which the engine has been shown to meet Federal emission requirements.

For engines less than 225 cc displacement, Category C = 125 hours, B = 250 hours and A = 500 hours.

For engines of 225 cc or more, Category C = 250 hours, B = 500 hours and A = 1000 hours.

This isa generic representation of the emission label typically found on a certified engine.

FAMILYYBSXS.3192VA 274812

37

GDOC-100182Rev.B

Page 38

Congratulations on making a smart purchase. Your new Craftsman® product is designed and

manufactured for years of dependable operation. But like all products, it may require repair

from time to time. That's when having a Repair Protection Agreement can save you money and

aggravation.

Here's what the Repair Protection Agreement* includes:

[] Expert service by our 10,000 professional repair specialists

[] Unlimited service and no charge for parts and labor on all covered repairs

[] Product replacement up to $1500 if your covered product can't be fixed

[] Discount of 25% from regular price of service and related installed parts not covered by the

agreement; also, 25% off regular price of preventive maintenance check

[] Fast help by phone - we call it Rapid Resolution - phone support from a Sears representative.

Think of us as a "talking owner's manual."

Once you purchase the Repair Protection Agreement, a simple phone call is all that it takes for you

to schedule service. You can call anytime day or night, or schedule a service appointment online.

The Repair Protection Agreement is a risk-free purchase. If you cancel for any reason during the

product warranty period, we will provide a full refund. Or, a prorated refund anytime after the

product warranty period expires. Purchase your Repair Protection Agreement today!

Some limitations and exclusions apply. For prices and additional information in the U.S.A.

call 1=800=827=6655.

*Coverage in Canada varies on some items. For full details call Sears Canada at 1=800=361=

6665.

Sears Installation Service

For Sears professional installation of home appliances, garage door openers, water heaters, and

other major home items, inthe U.S.A. or Canada call 1=800=4=MY=HOME®.

38

Page 39

Declaraci6n de garantia ....................... Pagina 39

Practicas operaci6n seguras ............... Pagina 40

Montaje ................................................ Pagina 44

Operaci6n ............................................ Pagina 48

Servicio y Mantenimiento .................... Pagina 52

Almacenamiento fuera de temporada ....Pagina 58

Soluci6n de problemas ...................... Pagina 59

Etiquetas de seguridad ....................... Pagina 7

Lista de piezas ........................................ Pagina 24

Acuerdo de Protecci6n Para

Reparaciones ....................................... Pagina 63

NOmero de servicio ..................... Cubierta posterior

ARTESANODE DOSANOS DEGARANTJA

PORDOSANOS(S)apartirdelafechadecompra,esteproductoest&garantizadocontracualquierdefectodematerialo manodeobra.Un

productodefectuosorecibir&la reparaci6no la sustituci6nsi la reparaci6nnoestAdisponible.

Paraobtenerinformaci6ndetalladacoberturade lagaranfiaparaobtenerla reparaci6no sustituci6ngratuita,visiteelsitioweb:www.craftsman.com

EstagarantiacubrelosdefectosSOLOdematerialesy fabricaci6n.Lagarantianoincluye:

• Elementosreutilizablesquepuedengastarseporel usonormaldentrodelperiododegarantia,talescomolascuchillas,bujias,filtrode

aire,pantallade desgranadoyunabolsa.

• ProductodaSosresultantesde los intentosdelusuariodemodificaci6ndelproducto,reparaci6no causadosporaccesoriosde

productos.

• Reparacionesnecesariasdebidoalaccidenteo por nooperaro mantenerelproductosegOnlas instruccionesprovistas.

• El mantenimientopreventivoo reparacionesnecesariasdebidoa unamezclaincorrectade combustible,combustiblecontaminadoo

pasado.

Estagaranfiaes inv&lidasiesteproductoseutilizaal mismotiempola prestaci6nde servicioscomercialeso si sealquilaaotrapersona.

Estagarantialeotorgaderechoslegalesespecificos,yustedtambi_npuedetenerotrosderechosquevariandeestadoa estado.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

Serie: 675

Tipode aceitedelmotor: SAE30

Capacidaddeaceitedel motor: 18onzas

Capacidaddecombustible: 1.5cuartos

Separaci6nde lasbujias: .020"

NSmerode modelo ..........................................................

N_merode serie ..............................................................

Fechade compra .............................................................

RegistrearribaelnOmerodel modelo,elnOmerode seriey lafecha

decompra

©SearsBrands,LLC 39

Page 40

Lapresenciade estesirnboloindicaquesetratade instrucciones

irnportantesde seguridadquesedebenrespetarparaevitar

ponerenpeligrosu seguridadpersonaly/omaterialy lade otras

personas.Leay sigatodaslasinstruccionesdeestemanualantes

de poneren funcionarnientoestarn_.quina.Si no respetaestas

instruccionespodriaprovocarlesionespersonales.Cuandoveaeste

sirnbolo,ipresteatenci6nala advertencia!

Estarn_.quinarueconstruidaparaseroperadadeacuerdocon

lasreglasde seguridadcontenidasenestemanual.AIigualque

concualquiertipodeequipornotorizado,undescuidoo errorpor

partedeloperadorpuedeproducirlesionesgraves.Estarn_.quina

escapazde arnputarrnanosy piesy dearrojarobjetoscongran

fuerza.De norespetarlasinstruccionesde seguridadsiguientesse

puedenproducirlesionesgraveso la rnuerte.

PROPOSICION 65 DE CALIFORNIA

Elescapedel motordeesteproducto,algunosde suscornponentes

y algunoscornponentesdelvehiculocontieneno liberansustancias

quirnicasqueelestadode Californiaconsideraque puedenproducir

c_.ncer,defectosde nacirnientouotrosproblernasreproductivos.

CAPACITACION

• Lea,entienday curnplatodaslasinstruccionesincluidasen

la rnAquinayen los rnanualesantesde rnontarlayutilizarla.

Guardeestemanualenun lugarseguroparaconsultasfuturasy

regulares,asi cornoparasolicitarrepuestos.

• Leael ManualdelOperadory sigatodaslasadvertenciase

instruccionesdeseguridad.El fracasodehacerasi puedecausar

la heridaseriaal operadory/opersonaspresentes.ParaIlarnada

de preguntas,1-800-659-5917.

• Farniliaricesecontodosloscontrolesysuoperaci6nadecuada.

Sepac6rnodetenerla rn_.quinayc6rnodesengranarloscontroles

r_.pidarnente.

• No perrnitanuncaquelosniffosrnenoresde 16afrosutilicen

estarn_.quina.Losniffosde 16afrosy rn_.srnayoresdeben

leerycornprenderlasinstruccionesde operaci6nylas reglas

de seguridadcontenidasen estemanual,y tarnbi_ndebenser

capacitadosy estarsupervisadosporunode lospadres.

• Nuncaperrnitaquelosadultosoperenestarn_.quinasin recibir

antesla instrucci6napropiada.

• MantengaalostranseQntes,ayudantes,rnascotasy niffosal

rnenosa75piesde la rn_.quinarnientrasest,.operando.Detenga

la rn_.quinasialguienentraenla zona.

• Nuncaenciendaun motorenespacioscerradoso enunazona

conpocaventilaci6n.Elescapedel motorcontienernon6xidode

carbono,un gasinodoroy letal.

• No pongalas rnanosolospiescercadelaspiezasrotatoriaso

en lasc_.rnarasde alirnentaci6nnien laaberturade descarga.El

contactocon el motorrotatoriopuedeproducirla arnputaci6nde

dedos,rnanosopies.

• Nuncatratededestapar[atornade alirnentaci6no la aberturade

descarga,nitratede sacaro vaciarla bolsade laaspiradora,ni

de revisaryrepararlarn_.quinarnientrasel motorest,.enrnarcha.

Su responsabilidad--Restrinja el usode estarn_.quina

rnotorizadaa laspersonasque lean,cornprendany respetenlas

advertenciase instruccionesqueaparecenenestemanualyen la

rn_.quina.

iGUARI)E ESTASINSTRUCCIONES!

Apagueel motoryesperehastaquetodaslaspiezasrn6vilesse

hayandetenidoporcornpleto.Desconecteel cablede labujiay

p6ngalode rnaneraquehagarnasacontrael motor.

PREPARATIVOS

• Inspeccionerninuciosarnenteel _.readondeutilizar_,el equipo.

Retiretodaslas piedras,botellas,latasu otrosobjetosextra_os

que puedanserlevantadoso arrojadoscausandolesiones

personaleso da_osa larn_.quina.

• Paraprotegerselosojosutilicesiernpreanteojoso antiparras

de seguridadrnientrasoperala rn_.quinao rnientraslaajusta

o repara.Losobjetosarrojadosquerebotanpuedenlesionar

gravernentelavista.

• Utilicezapatosdetrabajoresistentes,desuelafuerte,asi corno

pantalonesy carnisasajustados.Las prendassueltaso las

alhajaspuedenquedaratrapadasen laspiezasrn6viles.Nunca

utilicela rn_.quinadescalzoocon sandalias.Utiliceguantesde

trabajodecuerocuandoalirnentematerialporelcanaldela

cortadora.

• Antesde encenderlarn_.quinacontrolequetodoslospernosy

tornillosest_nbienajustadosparacornprobarquela rn_.quinase

encuentraen condicionessegurasdeoperaci6n.Adern_.s,realice

una inspecci6nvisualde larn_.quinaa intervalosfrecuentespara

controlarsila rnisrnaest,.da_ada.

• Mantengao reernplacelasetiquetasdeseguridadeinstrucciones

segQnseanecesario.

Manejosegurode la gasolina