MTD 24A-070H299 Owner’s Manual

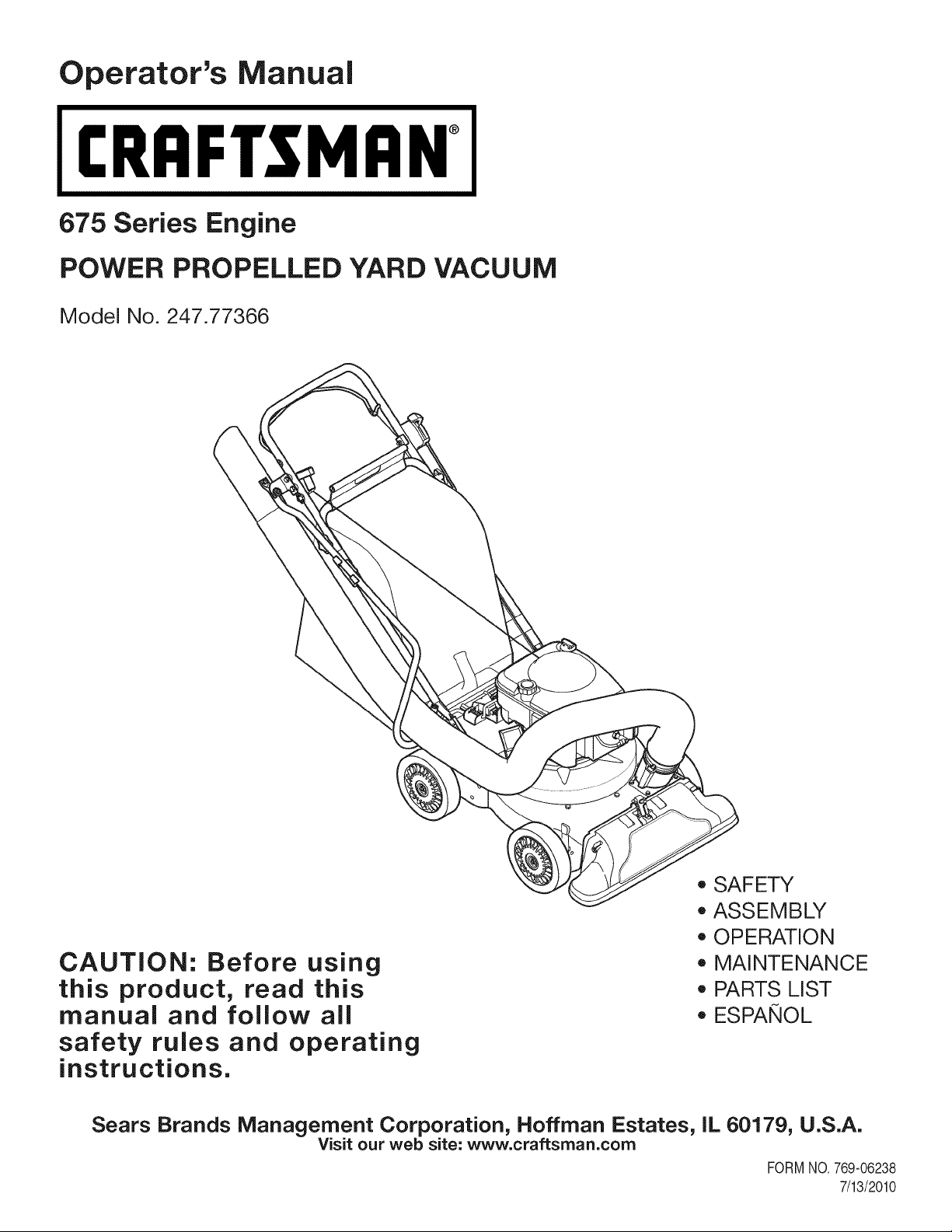

Operator's Manual

CRRF[SM ®

675 Series Engine

POWER PROPELLED YARD VACUUM

Model No. 247.77366

o SAFETY

ASSEMBLY

OPERATION

CAUTION: Before using

this product, read this

manual and follow all

MAINTENANCE

PARTS LIST

o ESPANOL

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our web site: www.craftsman.com

FORMNO.769-06238

7/13/2010

WarrantyStatement..................................Page2

SafeOperationPractices..........................Pages3-6

SafetyLabels............................................Page7

Assembly..................................................Pages8-11

Operation..................................................Pages12-15

ServiceandMaintenance.........................Pages16-21

Off-SeasonStorage..................................Page22

TroubleShooting.......................................Page23

PartsList...................................................Page24-34

RepairProtectionAgreement...................Page38

Espa_ol.....................................................Page39

ServiceNumbers......................................BackCover

CRAFTSMANTWOYEARFULLWARRANTY

FORTWOYEARSfromthedateofpurchase,thisproductiswarrantedagainstanydefectsinmaterialorworkmanship,Defectiveproductwill

receivefreerepairor freereplacementif repairisunavailable.

Thiswarrantyisvoidifthisproductiseverusedwhileprovidingcommercialservicesor ifrentedtoanotherperson.

Forwarrantycoveragedetails to obtain repairor replacement,visit the website: www.craftsman.com

This warranty covers ONLYdefects in materialandworkmanship. Warrantycoverage does NOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedto sparkplug,aircleaner,belt,and

oilfilter.

• Standardmaintenanceservicing,oilchanges,or tune-ups.

• Tirereplacementorrepaircausedby puncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireorwheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationormaintenance.

• Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedto,damagecausedbyover-speedingtheengine,orbyimpacting

objectsthatbendtheframe.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethepropergradeandamountof engineoil,orfailureto maintaintheequipmentaccordingtothe instructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedto becontaminatedoroxidized(stale).in general,fuelshouldbeused

within30 daysof itspurchasedate.

• Normaldeteriorationandwearofthe exteriorfinishes,or productlabelreplacement.

Thiswarrantygivesyou specificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

EngineSeries: 675

EngineOilType: SAE30

EngineOilCapacity: 18ounces

FuelCapacity: 1 1/2 Quarts

SparkPlug: Champion®RJ19LM

SparkPlugGap: .020"

©SearsBrands,LLC 2

Model Number.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

Thissymbolpointsoutimportantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowallinstructionsin thismanual

beforeattemptingtooperatethismachine.Failureto complywith

theseinstructionsmayresultinpersonalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothesafeopera-

tionpracticesin thismanual.Aswithanytypeofpowerequipment,

carelessnessorerroronthepartoftheoperatorcan resultin

seriousinjury.Thismachineis capableofamputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethefollowing

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorother reproductiveharm.

TRAINING

• Read,understand,andfollowallinstructionson themachineand

in themanualbeforeattemptingtoassembleandoperate.Keep

thismanualinasafeplaceforfutureandregularreferenceandfor

orderingreplacementparts.

• ReadtheOperator'sManualand followallwarningsand safety

instructions.Failuretodosocanresultin seriousinjurytothe

operatorand/orbystanders.Forquestionscall, 1-800-4MY-

HOME.

• Befamiliarwithallcontrolsandtheirproperoperation.Knowhow

tostopthemachineanddisengagethemquickly.

• Neverallowchildrenunder16yearsofageto operatethis

machine.Children16andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesinthismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultstooperatethis machinewithoutproper

instruction.

• Keepbystanders,pets,andchildrenat least75feetfromthe

machinewhileit is inoperation.Stopmachineifanyoneenters

thearea.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Donotputhandsandfeetnearrotatingpartsor inthefeeding

chambersanddischargeopening.Contactwiththerotating

impellercanamputatefingers,hands,andfeet.

• Neverattempttounclogeitherthefeed intakeordischarge

opening,removeor emptybag,orinspectandrepairthe machine

whilethe engineis running.Shuttheengineoffandwaituntilall

movingpartshavecometoa completestop.Disconnectthespark

plugwireandgroundit againsttheengine.

Your Responsibility--Restrict theuseofthispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsinthismanualandonthemachine.

SAVETHESEINSTRUCTIONS!

PREPARATION

• Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall rocks,bottles,cans,or otherforeignobjectswhich

couldbepickeduporthrownandcausepersonalinjuryor

damageto the machine.

• Alwayswearsafetyglassesorsafetygogglesduringoperation

andwhileperforminganadjustmentorrepair,to protectyour

eyes.Thrownobjectswhichricochetcan causeseriousinjuryto

theeyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesor jewelrycanbecaughtinmovable

parts.Neveroperatethismachineinbarefeetorsandals.Wear

leatherworkgloveswhenfeedingmaterialinthechipperchute.

• Beforestarting,checkallboltsandscrewsforpropertightnessto

besurethemachineisinsafeworkingcondition.Also,visually

inspectmachinefor any damageat frequentintervals.

• Maintainor replacesafetyandinstructionslabels,asnecessary.

3

SafeHandlingof Gasoline:

Toavoidpersonalinjuryorpropertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

onyourselfor yourclotheswhichcanignite.Washyour skinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Neverfillcontainersinsideavehicleor onatruckortrailerbed

withaplasticliner.Alwaysplacecontainersonthegroundaway

fromyourvehiclebeforefilling.

• Whenpractical,removegas-poweredequipmentfromthetruck

ortrailerand refuelitontheground.Ifthisisnotpossible,then

refuelsuchequipmentona trailerwithaportablecontainer,rather

thanfroma gasolinedispensernozzle.

• Keepthenozzleincontactwiththerimofthe fuel tankor

containeropeningatalltimesuntilfuelingiscomplete.Do not use

a nozzlelock-opendevice.

• Extinguishallcigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuelmachineindoors.

• Neverremovegas capor addfuel whiletheengineishotorrun-

ning.Allowenginetocoolatleasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Filltankto nomorethan1/2inchbelow

bottomoffillernecktoallowspaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitoff theengineandequipment.Move

unitto anotherarea.Wait5 minutesbeforestartingthe engine.

• Toreducefirehazards,keepmachinefreeofgrass,leaves,or

otherdebrisbuild-up.Cleanupoil orfuelspillageandremoveany

fuelsoakeddebris.

• Neverstorethemachineorfuelcontainerinsidewherethereisan

openflame,sparkor pilotlightas onawaterheater,spaceheater,

furnace,clothesdryerorothergas appliances.

OPERATION

• Donotputhandsandfeetnearrotatingpartsor in thefeeding

chambersanddischargeopening.Contactwiththe rotating

impellercanamputatefingers,hands,andfeet.

• Beforestartingthemachine,makesurethechipperchute,feed

intake,andcuttingchamberare emptyandfreeofalldebris.

• Thoroughlyinspectall materialto beshreddedandremoveany

metal,rocks,bottles,cans,orotherforeignobjectswhichcould

causepersonalinjuryor damagetothemachine.

• Iftheimpellerstrikesaforeignobjector ifyourmachineshould

startmakinganunusualnoiseorvibration,immediatelyshut

theengineoff.Allowtheimpellerto cometoacompletestop.

Disconnectthe sparkplugwire,grounditagainstthe engineand

performthefollowingsteps:

a. Inspectfordamage.

b. Repairor replaceanydamagedparts.

c. Checkfor anyloosepartsandtightento assurecontinued

safeoperation.

• Donot allowanaccumulationof processedmaterialto buildupin

thedischargearea.Thiscan preventproperdischargeandresult

inkickbackof materialthroughthefeedopening.

• Donot attempttoshredorchipmateriallargerthanspecified

on the machineor inthis manual.Personalinjuryormachine

damagecouldresult.

• Neverattempttounclogeitherthefeedintakeordischarge

openingwhilethe engineis running.Shuttheengineoff,waituntil

all movingpartshavestopped,disconnectthe sparkplugwireand

grounditagainsttheenginebeforeclearingdebris.

• Neveroperatewithoutvacuumbaganddischargechuteproperly

attachedtothe machine.Neveremptyor changevacuumbag

whilethe engineisrunning.Vacuumbagmustbekeptclosedat

all timesduringoperation.

• Neveroperatewithouteithertheinletnozzleor optionalhose

attachment(ifapplicable)properlyattachedtothemachine.

Neverattempttoattachorchangeeitherattachmentwhilethe

engineisrunning.

• Keepallguards,deflectorsand safetydevicesin placeand

operatingproperly.

• Keepyourfaceandbodybackandtothesideof the chipper

chutewhilefeedingmaterialintothemachineto avoidaccidental

kickbackinjuries.

• Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureofyourfootingand keepafirmholdonthehandles.

• Donot operatethismachineonapaved,gravelornon-level

surface.

• Donot operatethismachinewhileunderthe influenceofalcohol

or drugs.

• Mufflerandenginebecomehot andcancausea burn.Do not

touch.

• Neverpick uporcarrymachinewhiletheengineisrunning.

• Ifsituationsoccurwhicharenotcoveredinthismanual,use care

andgoodjudgement.ContactCustomerSupportforassistance

andthenameofthe nearestservicedealer.

4

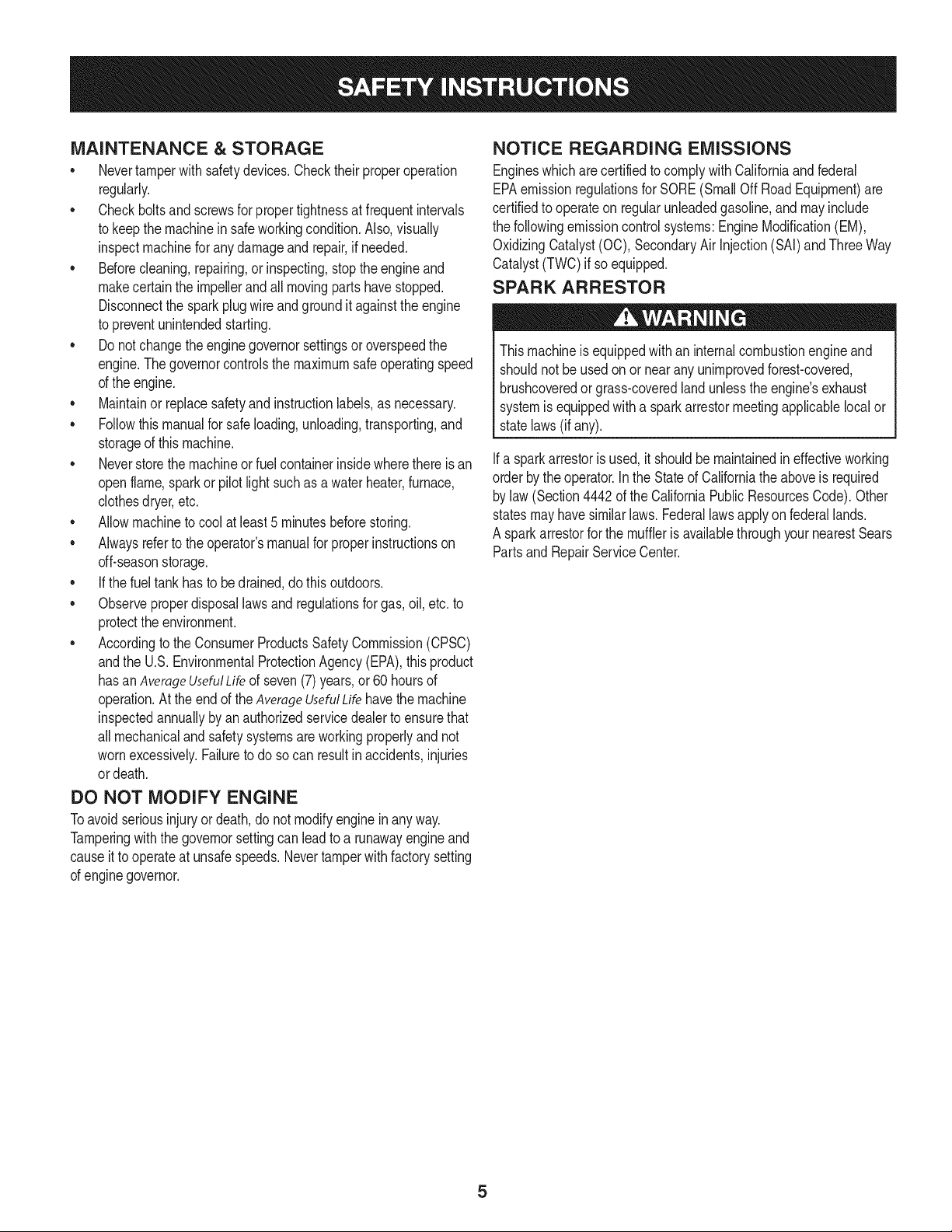

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.

• Checkboltsandscrewsforpropertightnessat frequentintervals

tokeepthe machinein safeworkingcondition.Also,visually

inspectmachineforanydamageandrepair,ifneeded.

Beforecleaning,repairing,or inspecting,stopthe engineand

makecertaintheimpellerandallmovingpartshavestopped.

Disconnectthe sparkplugwireandgrounditagainsttheengine

topreventunintendedstarting.

Donotchangetheenginegovernorsettingsor overspeedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

oftheengine.

Maintainor replacesafetyandinstructionlabels,asnecessary.

Followthismanualfor safeloading,unloading,transporting,and

storageof thismachine.

Neverstorethemachineorfuelcontainerinsidewherethereis an

openflame,sparkorpilotlightsuchasa waterheater,furnace,

clothesdryer,etc.

Allowmachinetocoolatleast5minutesbeforestoring.

• Alwaysrefertotheoperator'smanualfor properinstructionson

off-seasonstorage.

• If thefueltankhasto bedrained,dothisoutdoors.

• Observeproperdisposallawsand regulationsforgas,oil,etc.to

protecttheenvironment.

• Accordingto theConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeofseven(7)years,or60hoursof

operation.Atthe endoftheAverageUsefulLifehavethe machine

inspectedannuallybyanauthorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failuretodo socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyengineinanyway.

Tamperingwiththegovernorsettingcanleadto arunawayengineand

causeittooperateatunsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOff RoadEquipment)are

certifiedto operateon regularunleadedgasoline,andmayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if so equipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbeusedonor nearanyunimprovedforest-covered,

brushcoveredor grass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(ifany).

Ifasparkarrestorisused,itshouldbemaintainedin effectiveworking

orderbytheoperator.IntheStateof Californiathe aboveis required

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorfor themufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

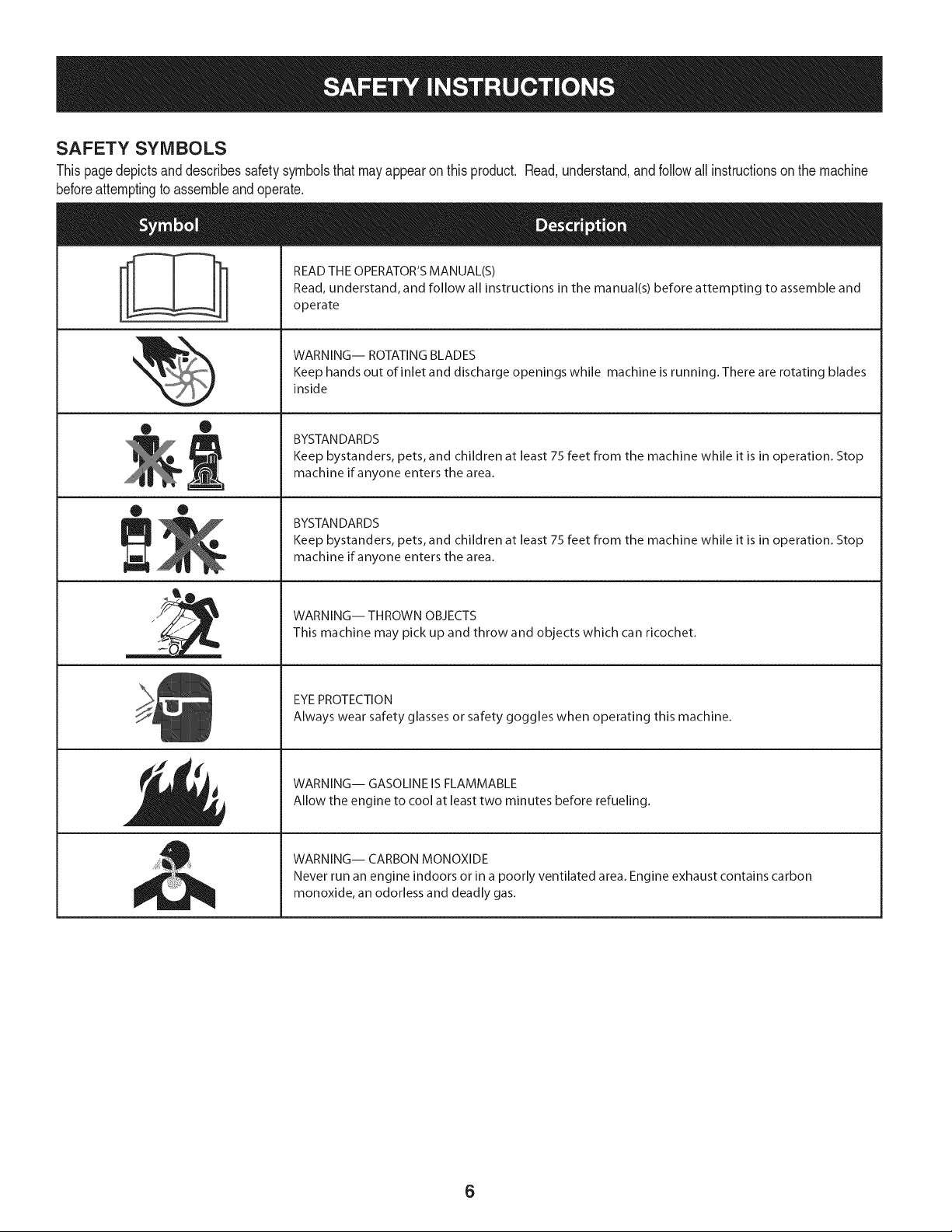

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine isrunning. There are rotating blades

inside

• ®

® •

llm

il

BYSTANDARDS

Keep bystanders, pets, and children at least 75 feet from the machine while it is in operation. Stop

machine if anyone enters the area.

BYSTANDARDS

Keep bystanders, pets, and children at least 75 feet from the machine while it is in operation. Stop

machine if anyone enters the area.

WARNING-- THROWN OBJECTS

This machine may pick up and throw and objects which can ricochet.

EYEPROTECTION

Always wear safety glasses or safety goggles when operating this machine.

WARNING-- GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

6

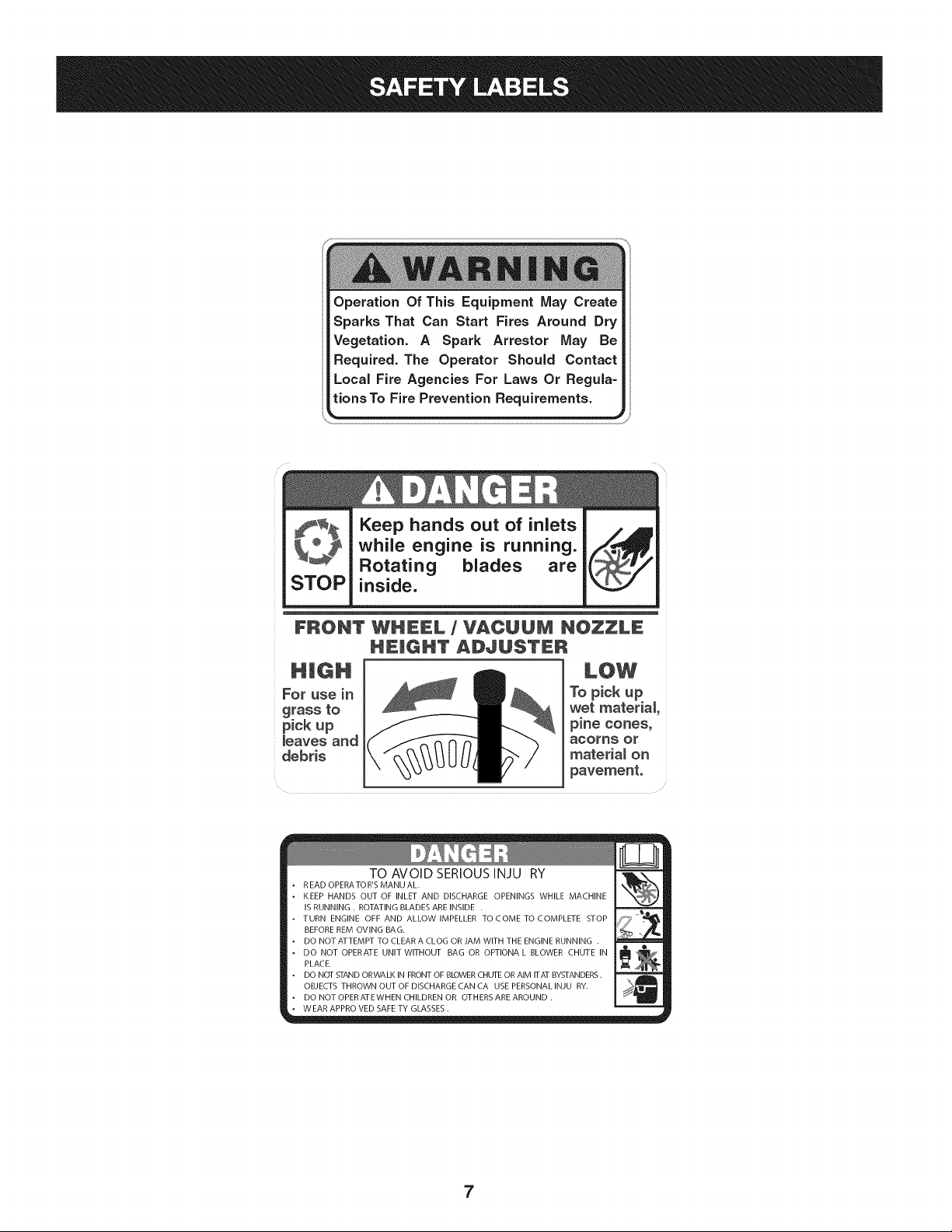

Operation Of This Equipment May Create

Sparks That Can Start Fires Around Dry

Vegetation. A Spark Arrestor May Be

Required. The Operator Should Contact

Local Fire Agencies For Laws Or Regula=

tions To Fire Prevention Requirements.

Keep hands out of inlets

while engine is running.

Rotating blades are

STOP

inside.

FRONT WHEEL / VACUUM NOZZLE

HEmGHT ADJUSTER

For use in

grass to

pickup

_eaves and

debris

R EAD OPERA TO R'S MANU AL.

KEEP HANDS OUT OF INLET AND DISCHARGE OPENINGS WHILE MACHINE

IS RUNNING . ROTATING BLADES ARE INSIDE .

TURN ENGINE OFF AND ALLOW IMPELLER TOCOME TOCOMPLETE STOP

BEFORE REM OVlNG BAG.

DO NOT ATTEMPT TO CLEAR A CLOG OR JAM WITH THE ENGINE RUNNING .

DO NOT OPERATE UNIT WITHOUT BAG OR OPTIONA L BLOWER CHUTE IN

PLACE.

DO NOT STAND ORWALK IN FRONT OF BLOWER CHUTE OR AIM ITAT BYSTANDERS.

OBJECTS THROWN OUT OF DISCHARGE CAN CA USE PERSONAL INJU RY.

DO NOT OPERATEWHEN CHILDREN OR OTHERS ARE AROUND .

WEAR APPRO VED SAFE TY GLASSES.

TO AVOID SERIOUSINJU RY

To pick up

wet material

pine cones_

acorns Or

materia_ on

pavement.

7

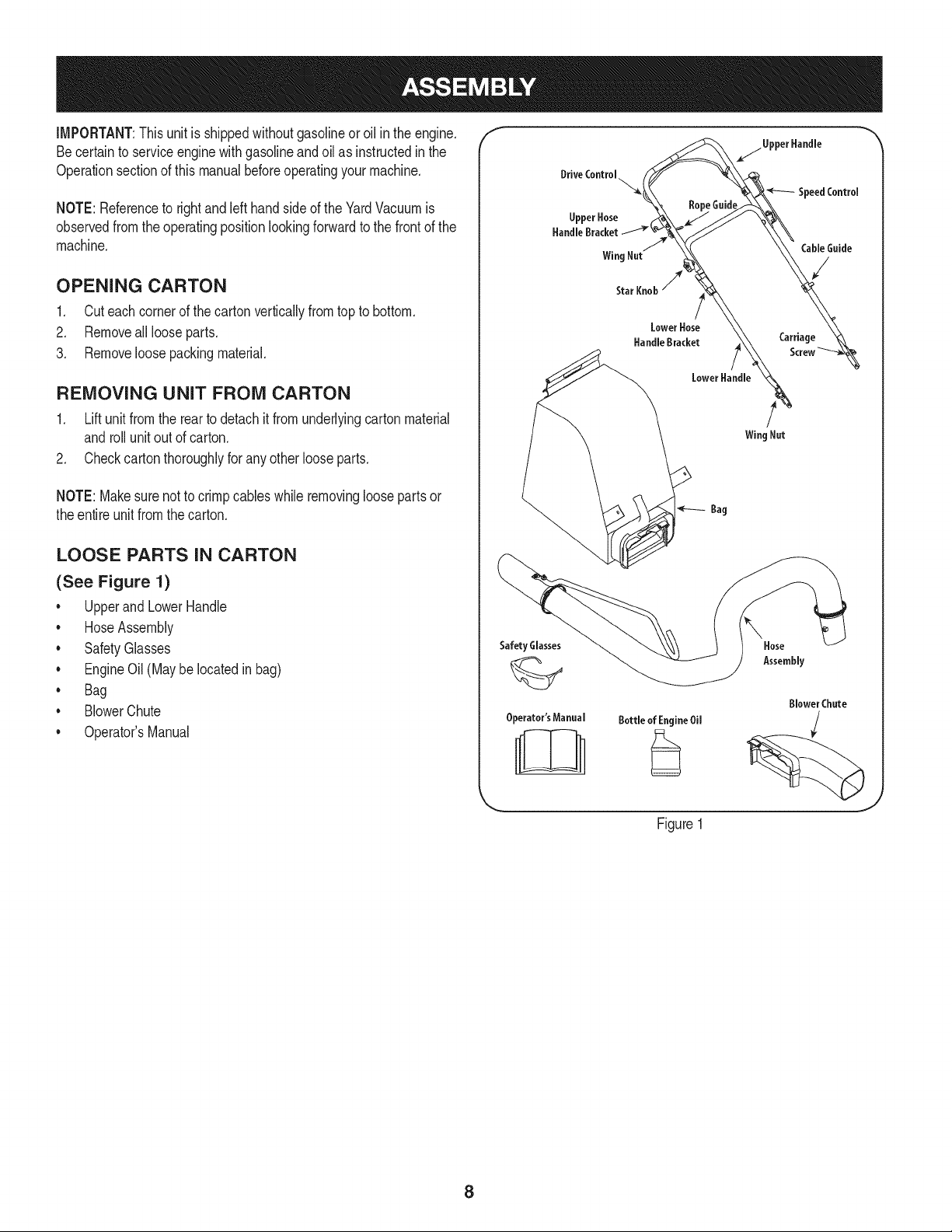

IMPORTANT:Thisunit isshippedwithoutgasolineoroil intheengine.

Becertainto serviceenginewithgasolineandoilasinstructedinthe

Operationsectionofthis manualbeforeoperatingyourmachine.

NOTE:Referenceto rightandlefthandsideofthe YardVacuumis

observedfromtheoperatingpositionlookingforwardto the frontof the

machine.

OPENING CARTON

1. Cuteachcornerofthecartonverticallyfromtop to bottom.

2. Removeall looseparts.

3. Removeloosepackingmaterial.

REMOVING UNIT FROM CARTON

1. Liftunit fromthe reartodetachitfromunderlyingcartonmaterial

androllunit outofcarton.

2. Checkcartonthoroughlyforanyotherlooseparts.

NOTE:Makesurenottocrimpcableswhileremovingloosepartsor

theentire unitfromthecarton.

LOOSE PARTS IN CARTON

f

(See Figure 1)

• UpperandLowerHandle

• HoseAssembly

• SafetyGlasses

• EngineOil(Maybelocatedinbag)

• Bag

• BlowerChute

• Operator'sManual

Safety Glasses

Operator'sManual

\

Hose

Assembly

BlowerChute

Bottle of EngineOil

J

Figure1

8

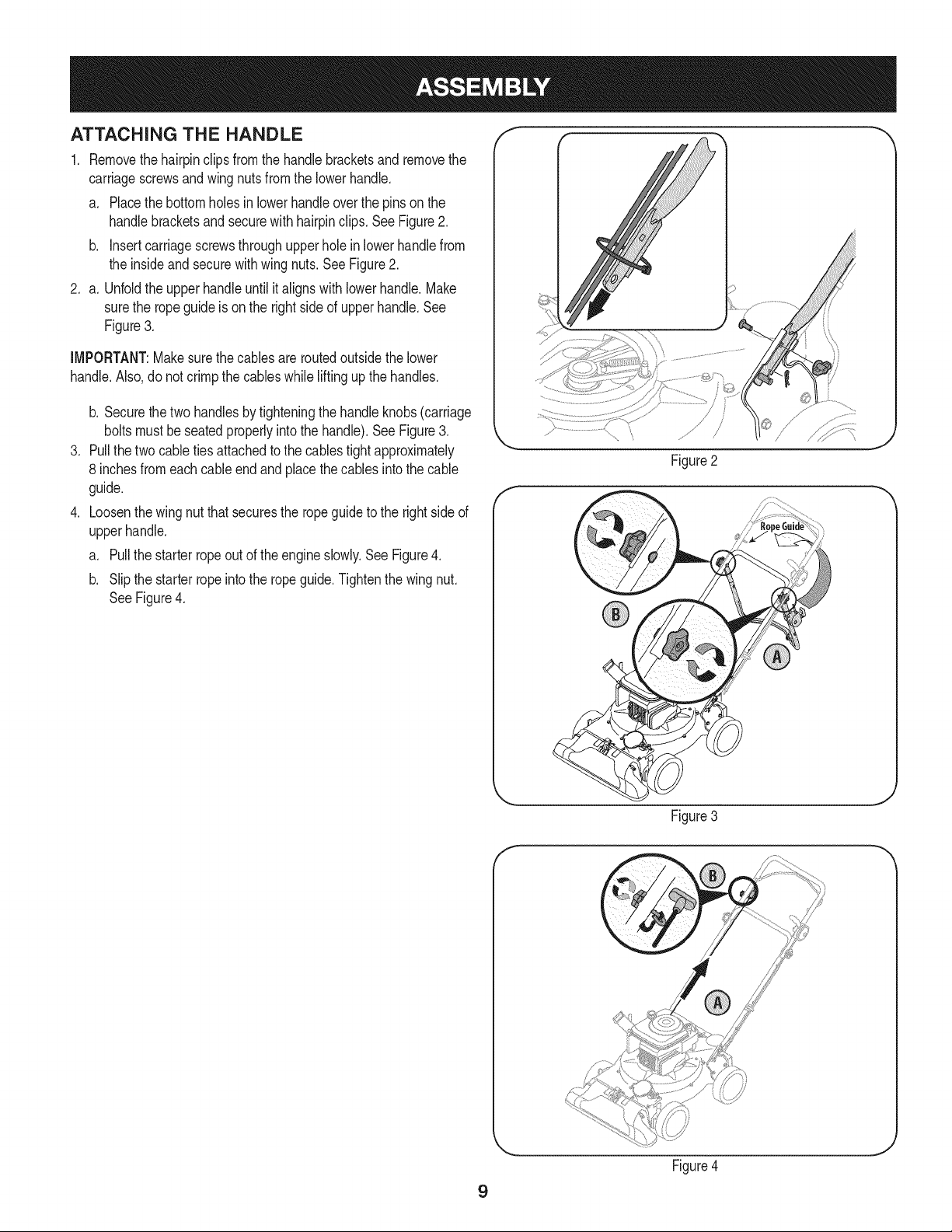

ATTACHING THE HANDLE

1. Removethehairpinclipsfromthehandlebracketsand removethe

carriagescrewsandwingnutsfromthelowerhandle.

a. Placethebottomholesinlowerhandleoverthepinsonthe

handlebracketsand securewith hairpinclips. SeeFigure2.

b. insertcarriagescrewsthroughupperholeinlowerhandlefrom

theinsideandsecurewithwingnuts.SeeFigure2.

2. a. Unfoldtheupperhandleuntilitalignswithlowerhandle.Make

surethe ropeguideis ontherightsideofupperhandle.See

Figure3.

IMPORTANT:Makesurethecablesareroutedoutsidethelower

handle.Also,donotcrimpthecableswhile liftingupthehandles.

b. Securethetwohandlesbytighteningthe handleknobs(carriage

boltsmustbeseatedproperlyintothehandle).See Figure3.

.

Pullthetwo cabletiesattachedto thecablestightapproximately

8 inchesfromeachcableendandplacethecablesintothecable

guide.

.

Loosenthewingnutthatsecurestheropeguideto the rightsideof

upperhandle.

a. Pullthestarterropeoutoftheengineslowly.SeeFigure4.

b. Slipthestarterropeintotheropeguide.Tightenthewingnut.

SeeFigure4.

Figure2

J

Figure3

J

Figure4

9

f

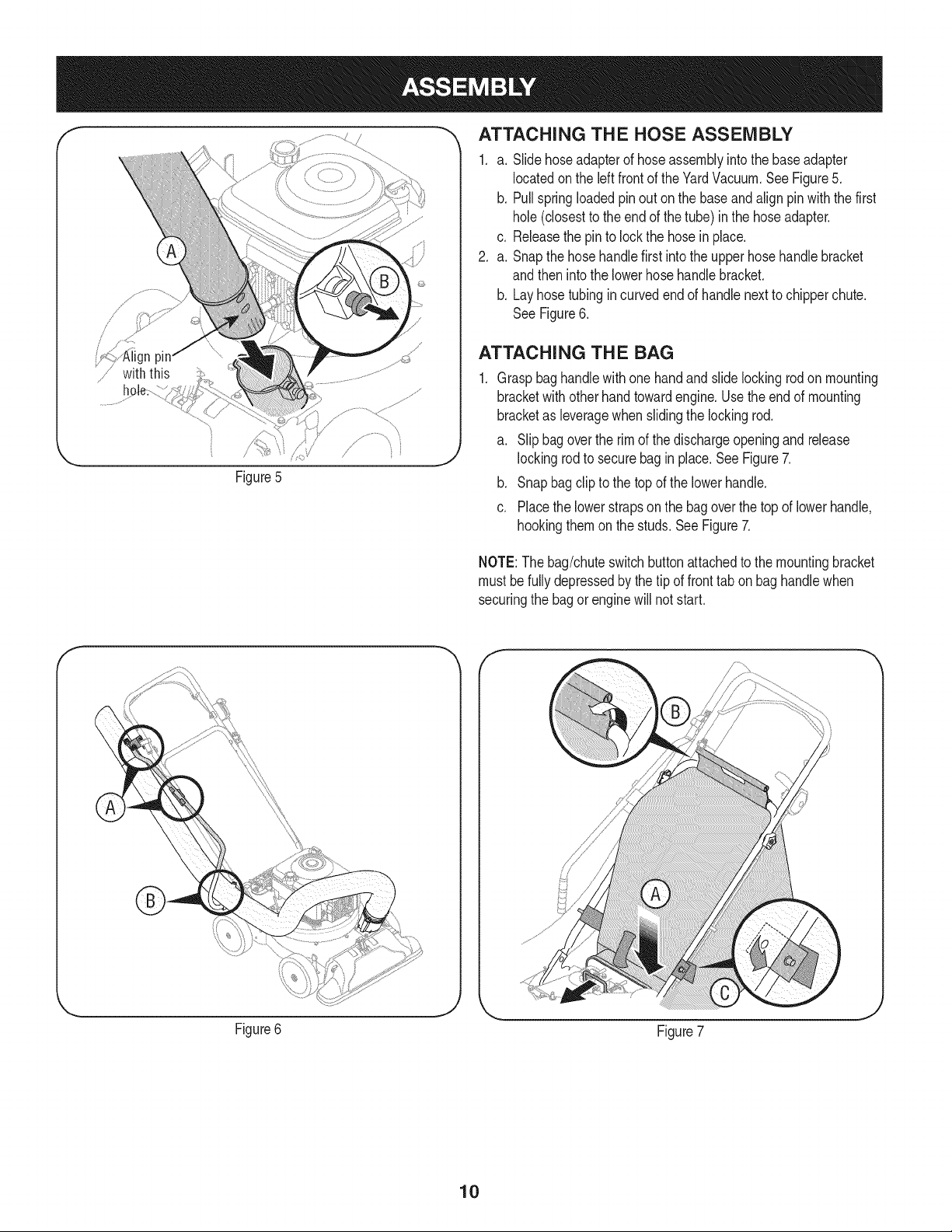

_, ATTACHING THE HOSE ASSEMBLY

1. a. Slidehoseadapterof hoseassemblyintothebaseadapter

locatedon theleftfrontof theYardVacuum.SeeFigure5.

b. Pullspringloadedpinouton thebaseandalignpinwiththe first

hole(closesttotheendofthetube)inthehoseadapter.

c. Releasethepintolockthehosein place.

2. a. Snapthehosehandlefirstintotheupperhose handlebracket

andthenintothelowerhosehandlebracket.

b. Layhosetubingincurvedendof handlenextto chipperchute.

SeeFigure6.

ATTACH ING TH E BAG

Graspbaghandlewithonehandandslidelockingrodonmounting

bracketwithotherhandtowardengine.Usetheendofmounting

bracketas leveragewhenslidingthelockingrod.

a. Slipbagovertherim of thedischargeopeningandrelease

lockingrodto securebagin place.SeeFigure7.

Figure5

b. Snapbagclipto thetopofthelowerhandle.

c. Placethelowerstrapsonthebagoverthe topof lowerhandle,

hookingthemon thestuds.SeeFigure7.

NOTE:The bag/chuteswitchbuttonattachedto themountingbracket

mustbefullydepressedby thetipof fronttabon baghandlewhen

securingthebagorenginewillnotstart.

Figure6

Figure7

10

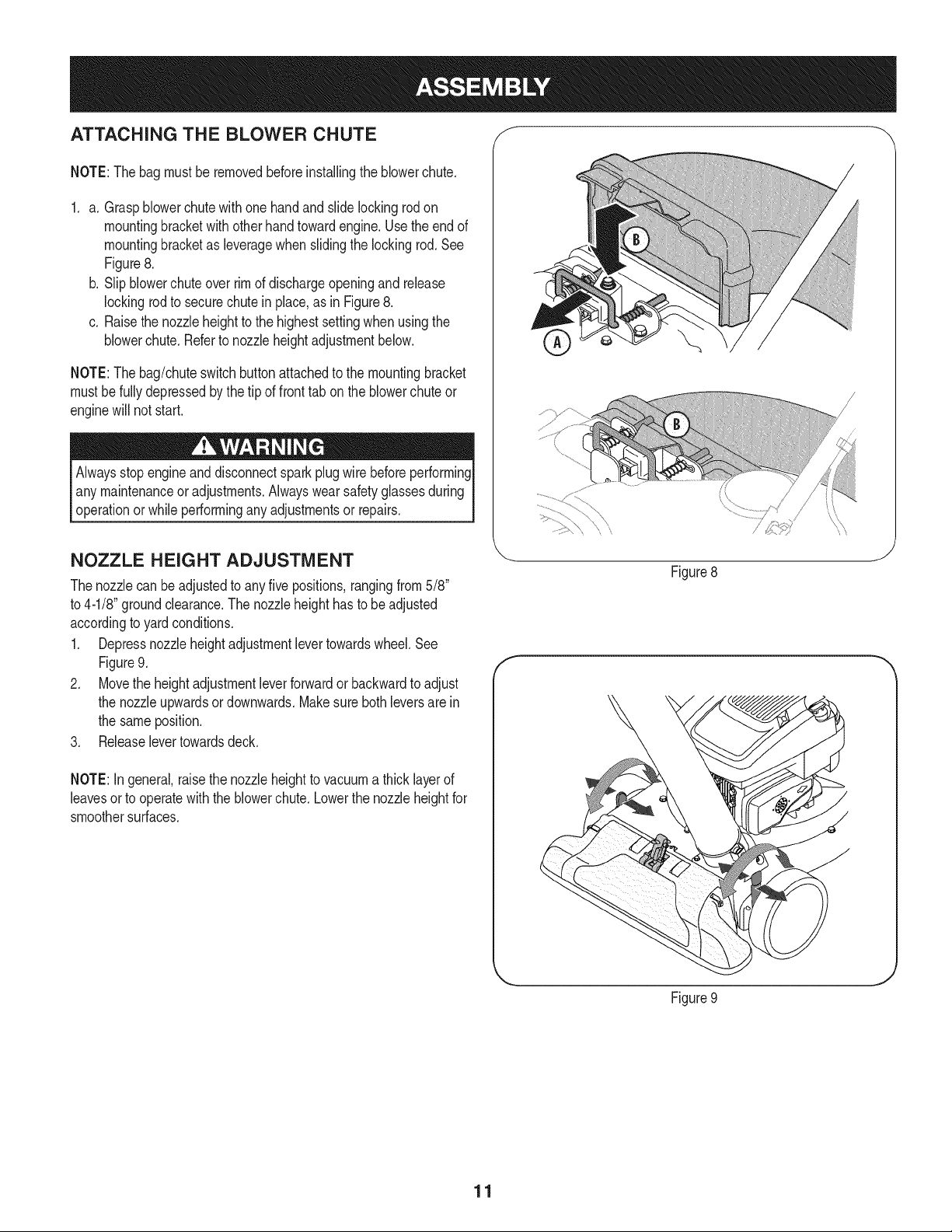

ATTACHING THE BLOWER CHUTE f

NOTE:Thebagmust beremovedbeforeinstallingtheblowerchute.

1. a. Graspblowerchutewithonehandandslidelockingrodon

mountingbracketwithotherhandtowardengine.Usetheendof

mountingbracketas leveragewhenslidingthelockingrod.See

Figure8.

b. Slipblowerchuteoverrimof dischargeopeningandrelease

lockingrodto securechuteinplace,asin Figure8.

c. Raisethe nozzleheighttothehighestsettingwhenusingthe

blowerchute.Refertonozzleheightadjustmentbelow.

NOTE:Thebag/chuteswitchbuttonattachedtothemountingbracket

mustbefullydepressedbythetip of fronttab onthe blowerchuteor

enginewillnotstart.

Alwaysstopengineanddisconnectsparkplugwirebeforeperforming

anymaintenanceoradjustments.Alwayswearsafetyglassesduring

operationorwhileperforminganyadjustmentsor repairs.

NOZZLE HEIGHT ADJUSTMENT

Thenozzlecan beadjustedtoanyfivepositions,rangingfrom5/8"

to4-1/8"groundclearance.Thenozzleheighthastobe adjusted

accordingtoyardconditions.

1. Depressnozzleheightadjustmentlevertowardswheel.See

Figure9.

2. Movetheheightadjustmentleverforwardor backwardto adjust

thenozzleupwardsordownwards.Makesure bothleversarein

thesameposition.

3. Releaselevertowardsdeck.

\\

J

Figure8

f

NOTE:In general,raisethe nozzleheighttovacuumathicklayerof

leavesortooperatewiththeblowerchute.Lowerthenozzleheightfor

smoothersurfaces.

J

Figure9

11

f

Drive Control

Speed Thr( Control Choke Control

Starter

Bag

Lower

Hose

Bracket

Bag Handle

HoseAssembl'

Hose

Blower Chipper

Chute Chute

NozzleHeig

Adjustment Lever

Figure10

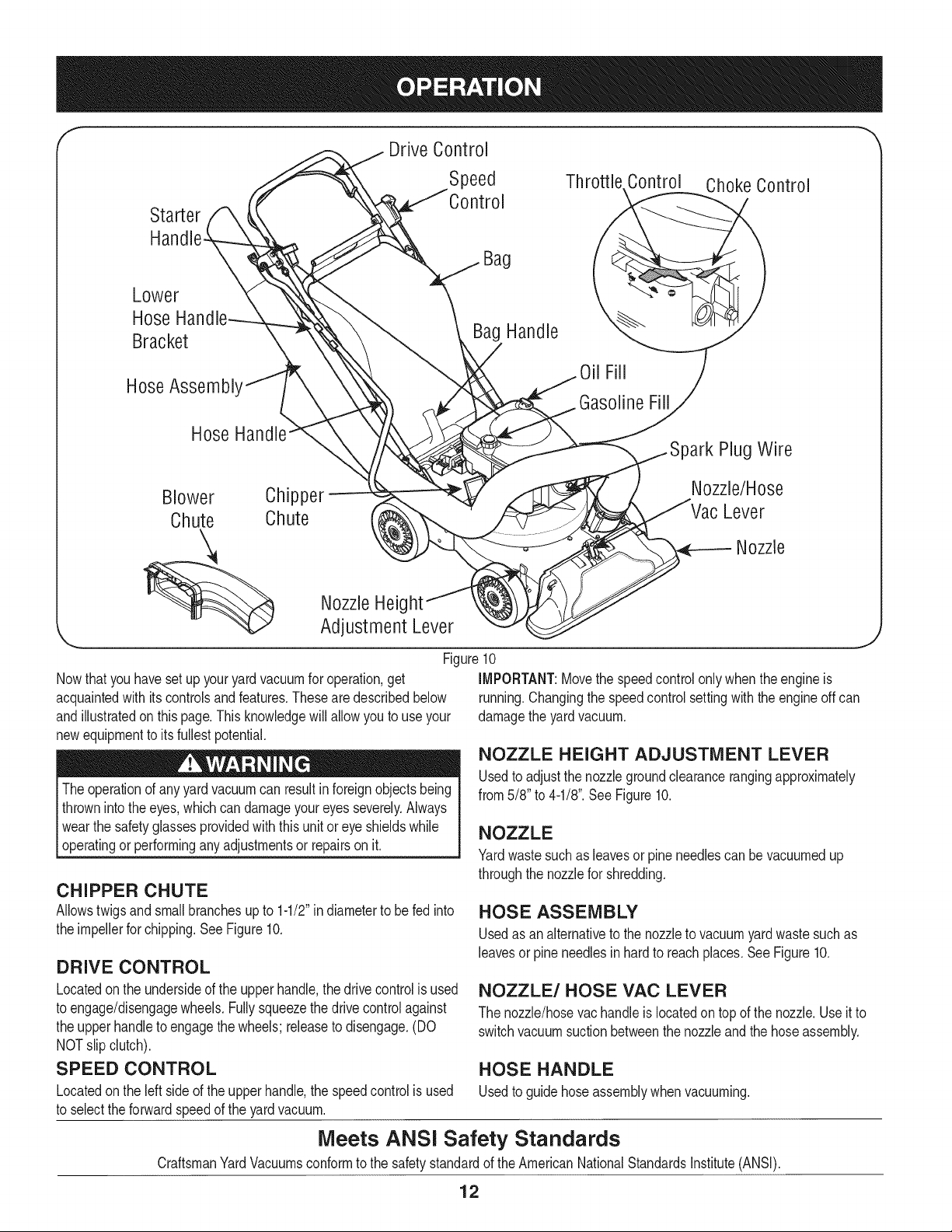

Nowthat youhavesetup youryardvacuumforoperation,get

acquaintedwith itscontrolsandfeatures.Thesearedescribedbelow

andillustratedon thispage.Thisknowledgewill allowyoutouseyour

newequipmenttoitsfullestpotential.

Theoperationofanyyard vacuumcan resultinforeignobjectsbeing

thrownintothe eyes,whichcandamageyoureyesseverely.Always

Iwearthe safetyglassesprovidedwiththisunit oreye shieldswhile

[operatingor performinganyadjustmentsor repairsonit.

CHIPPER CHUTE

Allowstwigsandsmallbranchesupto 1-1/2"in diametertobe fedinto

theimpellerforchipping.SeeFigure10.

DRIVE CONTROL

Locatedon theundersideof the upperhandle,thedrivecontrolisused

toengage/disengagewheels.Fullysqueezethedrivecontrolagainst

theupperhandletoengagethewheels;releasetodisengage.(DO

NOTslipclutch).

SPEED CONTROL

Locatedon theleftsideoftheupperhandle,thespeedcontrolis used

toselectthe forwardspeedof the yardvacuum.

Oil Fill

GasolineFill

)ark PlugWire

Nozzle/Hose

Lever

Nozzle

J

iMPORTANT:Movethespeedcontrolonlywhenthe engineis

running.Changingthespeedcontrolsettingwiththeengineoffcan

damagetheyardvacuum.

NOZZLE HEIGHT ADJUSTMENT LEVER

Usedtoadjustthenozzlegroundclearancerangingapproximately

from5/8"to 4-1/8".See Figure10.

NOZZLE

Yardwastesuchasleavesorpineneedlescan bevacuumedup

throughthe nozzlefor shredding.

HOSE ASSEMBLY

Usedasanalternativeto thenozzletovacuumyardwastesuchas

leavesor pineneedlesinhardto reachplaces.SeeFigure10.

NOZZLE/HOSE VAC LEVER

Thenozzle/hosevachandleislocatedon topofthe nozzle.Useit to

switchvacuumsuctionbetweenthenozzleandthehoseassembly.

HOSE HANDLE

Usedtoguidehoseassemblywhenvacuuming.

Meets ANSI Safety Standards

CraftsmanYardVacuumsconformto the safetystandardof theAmericanNationalStandardsinstitute(ANSi).

12

BAG HANDLE

Usedtograspbaginorderto assistinattaching,removing,and

emptyingbag.SeeFigure10.

BAG

Collectsshreddedmaterialfed throughthechipperchuteorvacuumed

throughthenozzleorhose.

BLOWER CHUTE

Whenattachedtounit,theblowerchuteisusedtodischargeyard

wastesuchas leaves,pineneedle,or smalltwigsacrossyard.

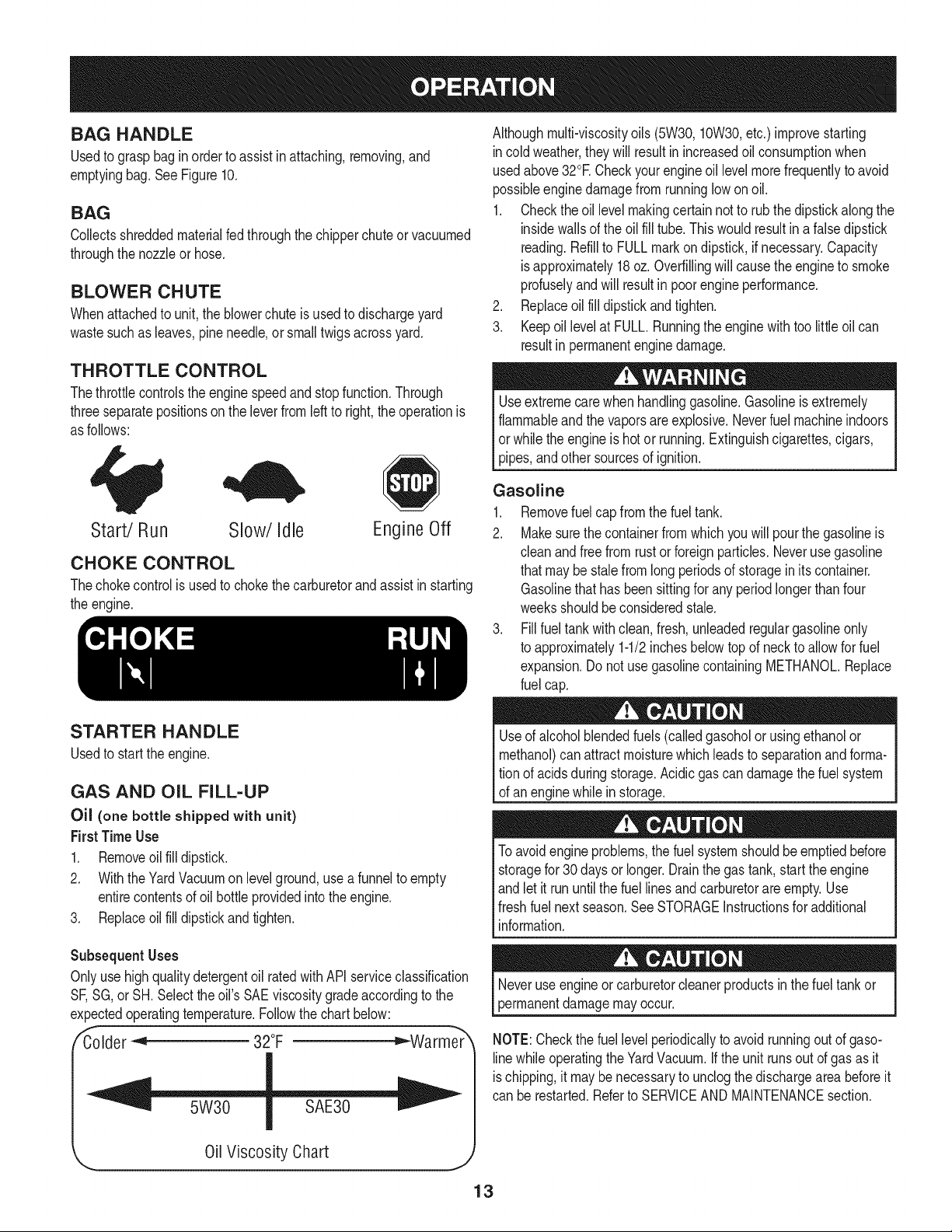

THROTTLE CONTROL

Thethrottlecontrolsthe enginespeedandstopfunction.Through

threeseparatepositionson theleverfromleftto right,theoperationis

asfollows:

Start/Run Slow/Idle EngineOff

CHOKE CONTROL

Thechokecontrolisusedtochokethecarburetorandassistinstarting

theengine.

Althoughmulti-viscosityoils (5W30,10W30,etc.) improvestarting

incoldweather,theywill resultinincreasedoilconsumptionwhen

usedabove32°ECheckyourengineoillevelmorefrequentlyto avoid

possibleenginedamagefromrunninglowonoil.

1. Checktheoillevelmakingcertainnotto rubthedipstickalongthe

insidewallsof the oilfill tube.Thiswouldresultinafalsedipstick

reading.RefilltoFULLmarkondipstick,ifnecessary.Capacity

isapproximately18oz.Overfillingwillcausetheenginetosmoke

profuselyandwillresultin poorengineperformance.

2. Replaceoilfilldipstickandtighten.

3. KeepoillevelatFULL.Runningtheenginewithtoolittleoilcan

resultin permanentenginedamage.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableand thevaporsare explosive.Neverfuel machineindoors

or whiletheengineishotor running.Extinguishcigarettes,cigars,

pipes,andothersourcesof ignition.

Gasoline

1. Removefuelcapfromthefueltank.

2. Makesurethecontainerfromwhichyouwillpourthegasolineis

cleanandfreefromrustorforeignparticles.Neverusegasoline

thatmaybe stalefromlongperiodsof storageinitscontainer.

Gasolinethathasbeensittingforanyperiodlongerthanfour

weeksshouldbeconsideredstale.

3. Fillfueltankwithclean,fresh,unleadedregulargasolineonly

toapproximately1-1/2inchesbelowtopof necktoallowforfuel

expansion.DonotusegasolinecontainingMETHANOL.Replace

fuelcap.

STARTER HANDLE

Usedto startthe engine.

GAS AND OiL FILL-UP

Oil (one bottle shipped with unit)

First TimeUse

1. Removeoilfilldipstick.

2. WiththeYardVacuumon levelground,useafunnelto empty

entirecontentsofoilbottleprovidedintotheengine.

3. Replaceoilfill dipstickandtighten.

Subsequent Uses

Onlyuse highqualitydetergentoil ratedwithAPIserviceclassification

SF,SG,or SH.Selecttheoil'sSAEviscositygradeaccordingto the

expectedoperatingtemperature.Followthe chartbelow:

/_Colder_ 32°F _Warme_

0il Viscosity Chart

J

Useofalcoholblendedfuels(calledgasoholor usingethanolor

methanol)canattractmoisturewhichleadsto separationandforma-

tionofacidsduringstorage.Acidicgascandamagethe fuelsystem

of anenginewhilein storage.

Toavoidengineproblems,thefuelsystemshouldbeemptiedbefore

storagefor30 daysorlonger.Drainthe gastank,starttheengine

andletitrununtilthefuellinesandcarburetorareempty.Use

freshfuelnextseason.SeeSTORAGEInstructionsfor additional

nformaton.

mayoccur.

NOTE:Checkthefuellevel periodicallyto avoidrunningoutofgaso-

linewhileoperatingthe YardVacuum.Iftheunitrunsout of gasasit

ischipping,it maybe necessarytounclogthedischargeareabeforeit

canbe restarted.RefertoSERVICEANDMAINTENANCEsection.

13

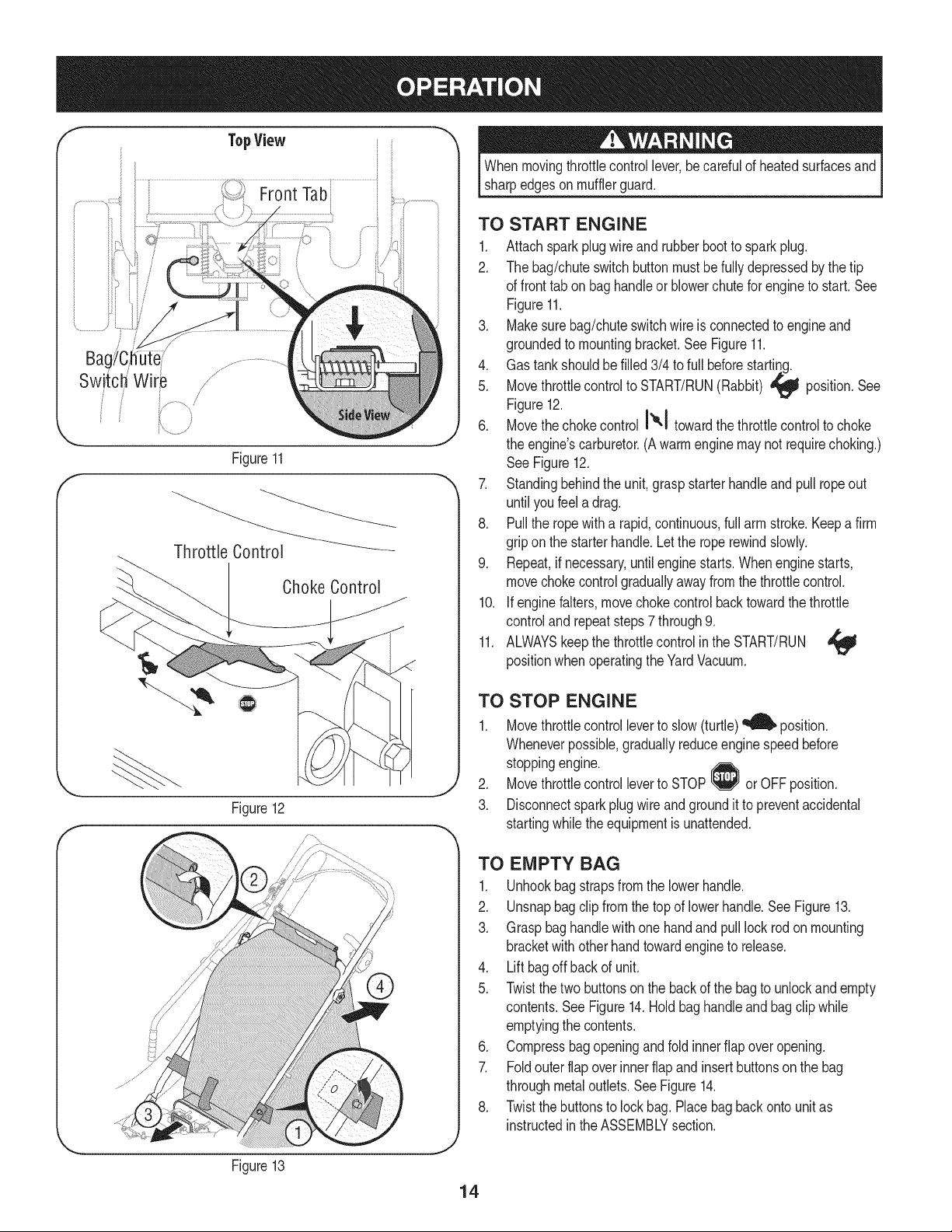

BagYC_hutei/

SwitchWire /

/

TopView

iiii FrontTab i ..............................

/

Figure11

ChokeControl

Whenmovingthrottlecontrollever,becarefulof heatedsurfacesand

sharpedgesonmufflerguard.

TO START ENGINE

1. Attachsparkplugwire andrubberbootto sparkplug.

2. Thebag/chuteswitchbuttonmustbefullydepressedbythe tip

offronttabon baghandleor blowerchutefor enginetostart.See

Figure11.

3. Makesurebag/chuteswitchwire is connectedto engineand

groundedtomountingbracket.SeeFigure11.

4. Gastankshouldbe filled3/4tofull beforestarting.

5. Movethrottlecontrolto START/RUN(Rabbit) ,_ position.See

Figure12.

6. MovethechokecontrolI'_'1 towardthethrottlecontroltochoke

theengine'scarburetor.(Awarmenginemaynotrequirechoking.)

See Figure12.

7. Standingbehindtheunit,graspstarterhandleandpullropeout

untilyoufeel adrag.

8. Pullthe ropewitha rapid,continuous,fullarmstroke.Keepa firm

griponthestarterhandle.Letthe roperewindslowly.

9. Repeat,ifnecessary,untilenginestarts.Whenenginestarts,

movechokecontrolgraduallyawayfromthe throttlecontrol.

10. if enginefalters,movechokecontrolbacktowardthethrottle

controland repeatsteps7 through9.

11. ALWAYSkeepthethrottlecontrolinthe START/RUN

positionwhenoperatingtheYardVacuum.

TO STOP ENGINE

1. Movethrottlecontrolleverto slow(turtle)_ position.

Wheneverpossible,graduallyreduceenginespeedbefore

stoppingengine.

2. Movethrottlecontrolleverto STOP or OFFposition.

Figure12

f

3. Disconnectsparkplugwireand groundittopreventaccidental

startingwhiletheequipmentisunattended.

TO EMPTY BAG

1. Unhookbagstrapsfromthelowerhandle.

2. Unsnapbagclip fromthetopoflowerhandle.See Figure13.

3. Graspbaghandlewithonehandandpulllock rodonmounting

bracketwithotherhandtowardengineto release.

4. Liftbagoffbackof unit.

5. Twistthetwobuttonsonthebackof thebagto unlockandempty

contents.SeeFigure14.Holdbaghandleandbagclipwhile

emptyingthecontents.

6. Compressbagopeningandfold innerflap overopening.

7. Foldouterflapoverinnerflapand insertbuttonsonthebag

throughmetaloutlets.SeeFigure14.

8. Twistthebuttonsto lockbag.Placebagbackontounitas

instructedintheASSEMBLYsection.

J

Figure13

14

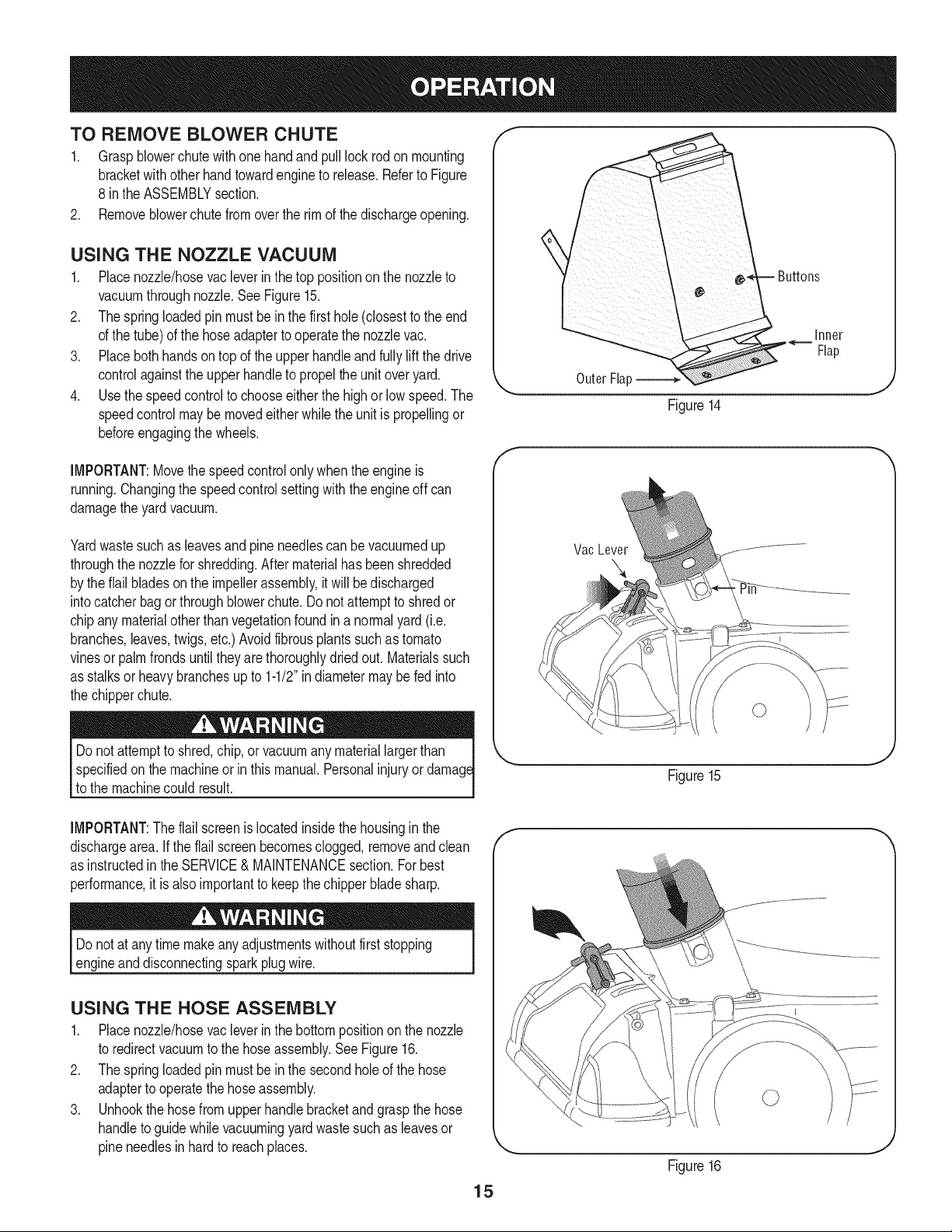

TO REMOVE BLOWER CHUTE

1. Graspblowerchutewithone handandpull lockrodonmounting

bracketwithotherhandtowardengineto release.Referto Figure

8 intheASSEMBLYsection.

2. Removeblowerchutefromovertherimofthe dischargeopening.

USING THE NOZZLE VACUUM

1. Placenozzle/hosevacleverinthe top positionon thenozzleto

vacuumthroughnozzle.SeeFigure15.

2. Thespringloadedpinmustbein the firsthole(closesttotheend

ofthetube)ofthehoseadaptertooperatethenozzlevac.

3. Placebothhandsontop oftheupperhandleandfullyliftthedrive

controlagainsttheupperhandletopropeltheunitoveryard.

4. Usethe speedcontrolto chooseeitherthe highorlow speed.The

speedcontrolmaybemovedeitherwhiletheunitis propellingor

beforeengagingthewheels.

IMPORTANT:Movethe speedcontrolonlywhentheengineis

running.Changingthe speedcontrolsettingwiththeengineoffcan

damagetheyardvacuum.

Inner

Flap

OuterFlal:

Figure14

Yardwastesuchas leavesandpineneedlescanbevacuumedup

throughthenozzleforshredding.Aftermaterialhasbeenshredded

bytheflail bladesontheimpellerassembly,itwill bedischarged

intocatcherbagorthroughblowerchute.Donotattempttoshredor

chipany materialotherthanvegetationfoundin a normalyard(i.e.

branches,leaves,twigs,etc.)Avoidfibrousplantssuchastomato

vinesor palmfrondsuntiltheyare thoroughlydriedout.Materialssuch

asstalksor heavybranchesupto 1-1/2"indiametermaybefedinto

thechipperchute.

specifiedonthe machineorin thismanual.Personalinjuryor

to themachinecould result.

IMPORTANT:Theflailscreenis locatedinsidethe housinginthe

dischargearea.if the flailscreenbecomesclogged,removeandclean

asinstructedin theSERVICE&MAINTENANCEsection.Forbest

performance,itis alsoimportanttokeepthechipperbladesharp.

Donotat anytimemakeanyadjustmentswithoutfirststopping

engineanddisconnectingsparkplugwire.

Vac Lever

Figure15

F

USING THE HOSE ASSEMBLY

1. Placenozzle/hosevacleverinthe bottompositionon thenozzle

toredirectvacuumtothehoseassembly.SeeFigure16.

2. Thespringloadedpinmustbein the secondholeof thehose

adaptertooperatethe hoseassembly.

3. Unhookthehosefromupperhandlebracketandgraspthehose

handletoguidewhilevacuumingyardwastesuchas leavesor

pineneedlesin hardto reachplaces.

Figure16

15

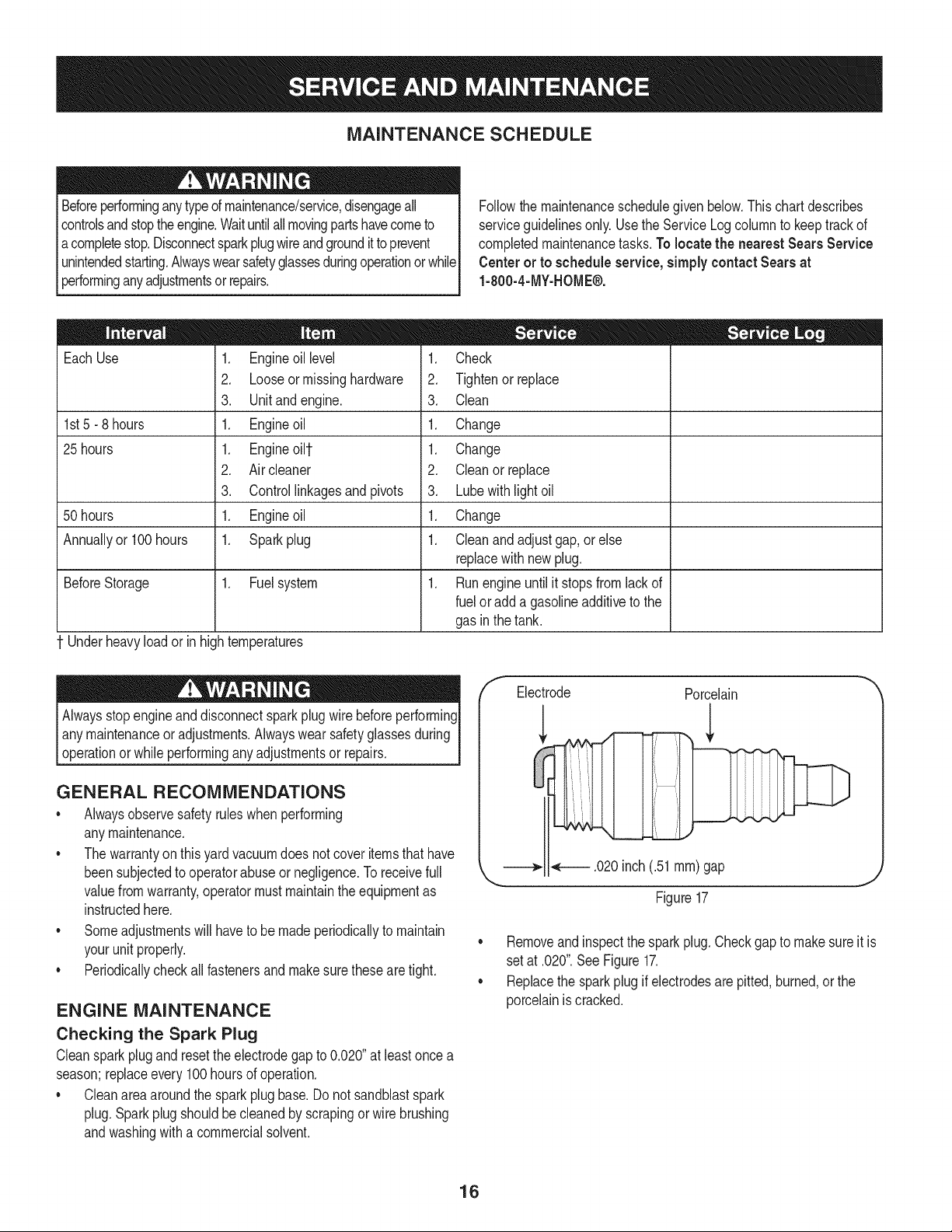

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgroundittoprevent

unintendedstarting.Alwayswearsafetyglassesduringoperationorwhile

performinganyadjustmentsorrepairs.

EachUse

1. Engineoil level

2. Looseormissinghardware

3. Unitandengine.

1st5 - 8 hours

25 hours

1. Engineoil

1. Engineoilt

2. Aircleaner

3. Controllinkagesandpivots

50 hours

Annuallyor100hours

1. Engineoil

1. Sparkplug

BeforeStorage 1. Fuelsystem

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Change

2. Cleanor replace

3. Lubewithlight oil

1. Change

1. Cleanandadjustgap,orelse

1. Runengineuntilit stopsfromlackof

Underheavyloador inhightemperatures

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumntokeeptrackof

completedmaintenancetasks.To locate the nearest SearsService

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

= =

replacewithnewplug.

fuelor addagasolineadditiveto the

gasin thetank.

Alwaysstopengineanddisconnectsparkplugwirebeforeperforming

Ianymaintenanceoradjustments.Alwayswearsafetyglassesduring

_operationor whileperforminganyadjustmentsor repairs.

GENERAL RECOMMENDATIONS

• Alwaysobservesafetyruleswhenperforming

anymaintenance.

• Thewarrantyon thisyardvacuumdoesnotcoveritemsthat have

beensubjectedtooperatorabuseor negligence.Toreceivefull

valuefromwarranty,operatormustmaintaintheequipmentas

instructedhere.

• Someadjustmentswillhavetobemadeperiodicallyto maintain

yourunit properly.

• Periodicallycheckallfastenersand makesurethesearetight.

ENGINE MAINTENANCE

Checking the Spark Plug

Cleansparkplugandresettheelectrodegapto0.020"atleastoncea

season;replaceevery100hoursofoperation.

• Cleanareaaroundthesparkplugbase.Donotsandblastspark

plug.Sparkplugshouldbecleanedbyscrapingorwirebrushing

andwashingwitha commercialsolvent.

/f Electrode Porcelain

.020inch(.51ram)gap

J

Figure17

• Removeandinspectthesparkplug.Checkgaptomakesureit is

setat .020".SeeFigure17.

• Replacethesparkplugifelectrodesare pitted,burned,or the

porcelainiscracked.

16

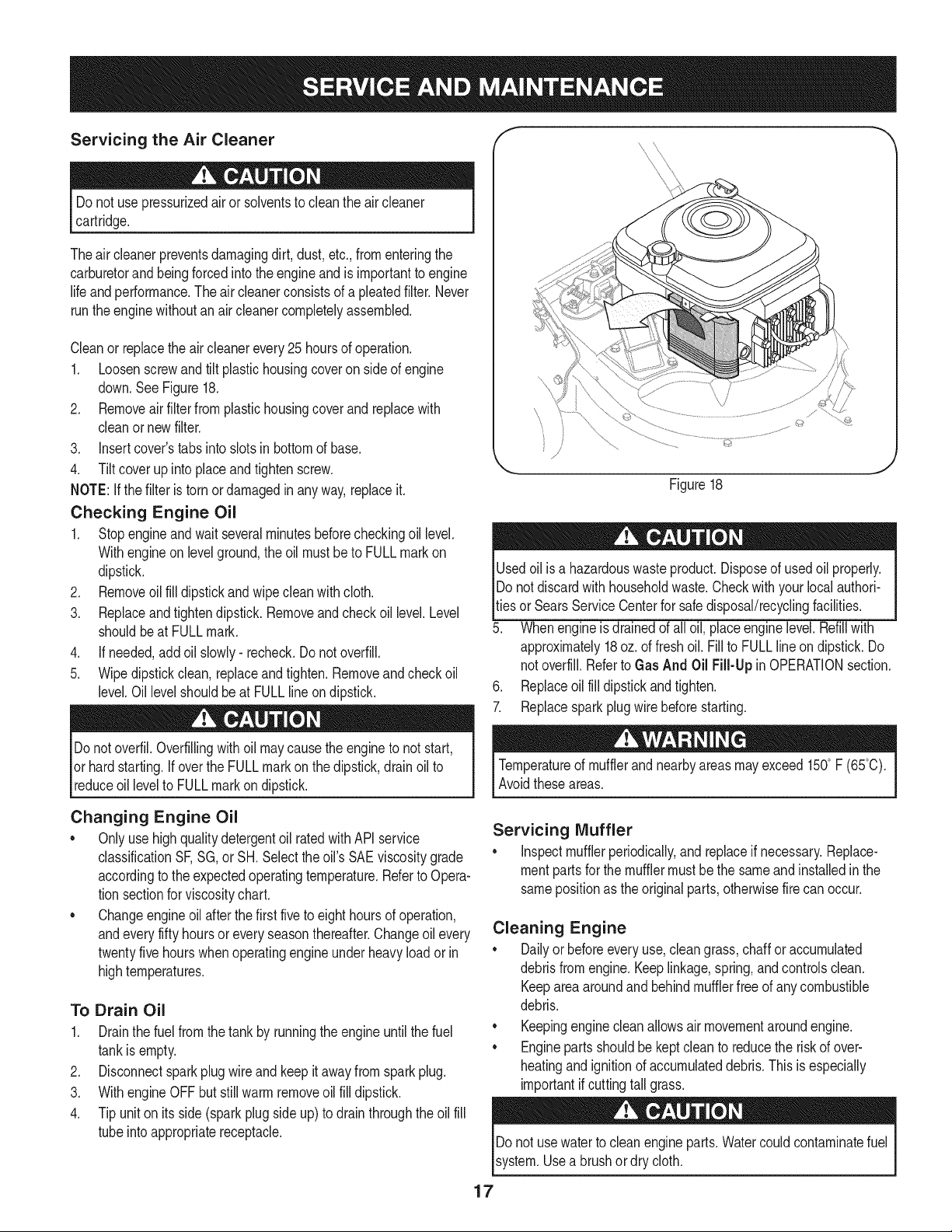

Servicing the Air Cleaner

Donotuse pressurizedairorsolventstocleantheaircleaner

cartridge.

Theair cleanerpreventsdamagingdirt, dust,etc.,fromenteringthe

carburetorand beingforcedintotheengineandis importantto engine

lifeandperformance.Theair cleanerconsistsofa pleatedfilter. Never

runtheenginewithoutan aircleanercompletelyassembled.

Cleanor replacetheair cleanerevery25hoursofoperation.

1. Loosenscrewandtilt plastichousingcoveronsideofengine

down.SeeFigure18.

2. Removeairfilterfromplastichousingcoverandreplacewith

cleanor newfilter.

3. insertcover'stabsintoslotsin bottomofbase.

4. Tiltcoverupintoplaceandtightenscrew.

NOTE:Ifthefilteristornordamagedinanyway,replaceit.

Checking Engine Oil

1. Stopengineandwaitseveralminutesbeforecheckingoil level.

Withengineonlevelground,the oilmustbeto FULLmarkon

dipstick.

2. Removeoilfilldipstickandwipecleanwithcloth.

3. Replaceandtightendipstick.Removeandcheckoillevel.Level

shouldbeatFULLmark.

4. Ifneeded,addoil slowly- recheck.Do notoverfill.

5. Wipedipstickclean,replaceandtighten.Removeandcheckoil

level.Oil levelshouldbe atFULLlineondipstick.

f

x \

\

©

J

Figure18

Usedoil is ahazardouswasteproduct.Disposeofusedoilproperly.

IDo notdiscardwithhouseholdwaste.Checkwithyourlocalauthori-

_tiesorSearsServiceCenterfor safedisposal/recyclingfacilities.

5. Whenengineisdrainedofall oil,placeenginelevel.Refillwith

approximately18oz.offreshoil.Fillto FULLlineondipstick.Do

notoverfill.RefertoGasAnd Oil Fill-Up inOPERATIONsection.

6. Replaceoilfilldipstickandtighten.

7. Replacesparkplugwirebeforestarting.

Donotoverfil.Overfillingwithoil maycausetheenginetonotstart,

or hardstarting.Ifoverthe FULLmarkonthedipstick,drainoilto

reduceoillevelto FULLmarkondipstick.

Changing Engine Oil

• OnlyusehighqualitydetergentoilratedwithAPIservice

classificationSF,SG, orSH.Selecttheoil's SAEviscositygrade

accordingtothe expectedoperatingtemperature.Referto Opera-

tionsectionforviscositychart.

• Changeengineoilafterthefirst fivetoeighthoursofoperation,

andeveryfiftyhoursoreveryseasonthereafter.Changeoilevery

twentyfivehourswhenoperatingengineunderheavyloadorin

hightemperatures.

To Drain Oil

1. Drainthefuelfromthetankbyrunningtheengineuntil thefuel

tankisempty.

2. Disconnectsparkplugwireandkeepit awayfromsparkplug.

3. WithengineOFFbutstillwarmremoveoil filldipstick.

4. Tipuniton itsside(sparkplugside up)to drainthroughtheoilfill

tubeinto appropriatereceptacle.

Temperatureof mufflerandnearbyareasmayexceed150°F (65°C).

Avoidtheseareas.

Servicing Muffler

• inspectmufflerperiodically,andreplaceif necessary.Replace-

mentpartsforthemufflermustbe the sameandinstalledinthe

samepositionastheoriginalparts,otherwisefirecanoccur.

Cleaning Engine

• Dailyor beforeeveryuse,cleangrass,chafforaccumulated

debrisfromengine.Keeplinkage,spring,andcontrolsclean.

Keepareaaroundand behindmufflerfreeofanycombustible

debris.

• Keepingenginecleanallowsairmovementaroundengine.

• Enginepartsshouldbekeptcleanto reducetheriskofover-

heatingandignitionofaccumulateddebris.Thisisespecially

importantifcuttingtallgrass.

Donot usewatertocleanengineparts.Watercouldcontaminatefuel

system.Useabrushordry cloth.

17

Carburetor Adjustment f ..../ _,

Thecarburetoronthis engineisnotuseradjustable.ContactSears /

Parts&Repairforadjustment,

Engine Speed

/

Donot,attempttoaltertheenginespeedbytamperingwiththe

enginesgovernorlinkage.Doingsocouldresultinseriouspersonal

Iinjuryanddamagetotheengine.TheengineRPMhasbeensetat

thefactory.

LUBRICATION

• Wheels- Placea fewdropsofSAE30 oiloneachshoulderscrew

oncea season.

• Nozzleheight adjustment levers- Lubricatenozzleheight

adjustmentleverswith lightoil.

• Locking Rod-Lubricatethelock rodandcompressionsprings

Figure19

whichattachto the mountingbracket.

• Nozzle/HoseVacLever: Lubricatethe nozzle/hosevacleveron

topof the nozzleonceaseasonwithlightoil.

CLEANING EQUIPMENT

Cleanundersideof theyardvacuumonceaseasontopreventbuild-up

ofdebris.Followstepsbelowforthisjob.

1. Disconnectandgroundsparkplugwire.Emptythefueltankby

runningengineuntiltankisdry.

2. Tiptheyardvacuumsothatitrestson itsside,keepingthe

mufflersidedown.Holdyardvacuumfirmly.

3. Scrapeandcleanthe undersideofthedeckandnozzlewitha

suitabletool.Donotspraywithwater.

f

IMPORTANT:Donotusea pressurewasherorgardenhosetoclean

yourunit.Thesemaycausedamageto bearings,orthe engine.The

useof waterwillresultin shortenedlifeandreduceserviceability.

4. Puttheyardvacuumbackonitswheelson theground.

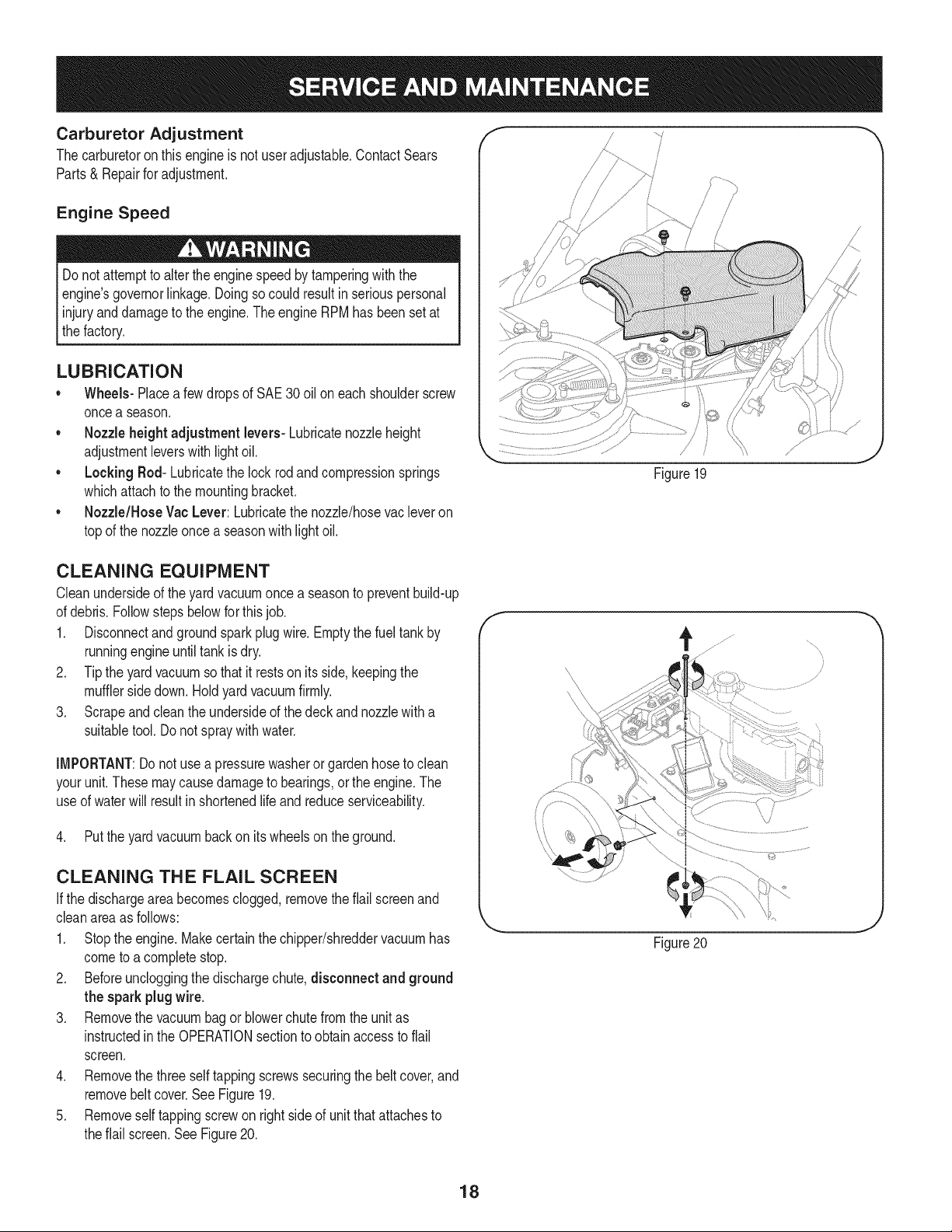

CLEANING THE FLAIL SCREEN

Ifthedischargeareabecomesclogged,removetheflailscreenand

cleanareaasfollows:

1. Stoptheengine.Makecertainthe chipper/shreddervacuumhas

cometoa completestop.

2. Beforeuncloggingthedischargechute,disconnect and ground

the spark plugwire.

3. Removethevacuumbagorblowerchutefromthe unitas

instructedin theOPERATIONsectiontoobtainaccesstoflail

screen.

4. Removethethreeselftappingscrewssecuringthebeltcover,and

removebeltcover.SeeFigure19.

5. Removeselftappingscrewon rightsideof unitthatattachesto

theflail screen.SeeFigure20.

/

J

Figure20

18

6. Removehexscrewontopofrearhousingnearmountingbracket

andtheflangelocknutthatsecuresflailscreen.SeeFigure20.

7. Removeandcleanthe screenby scrapingorwashingwithwater.

SeeFigure21.

8. Reinstallthescreen.

Beforeperforminganytypeof maintenanceon themachine,waitfor

all partsto stopmovinganddisconnectandgroundthesparkplug

wire. Failuretofollowthisinstructioncould resultinpersonalinjuryor

propertydamage.

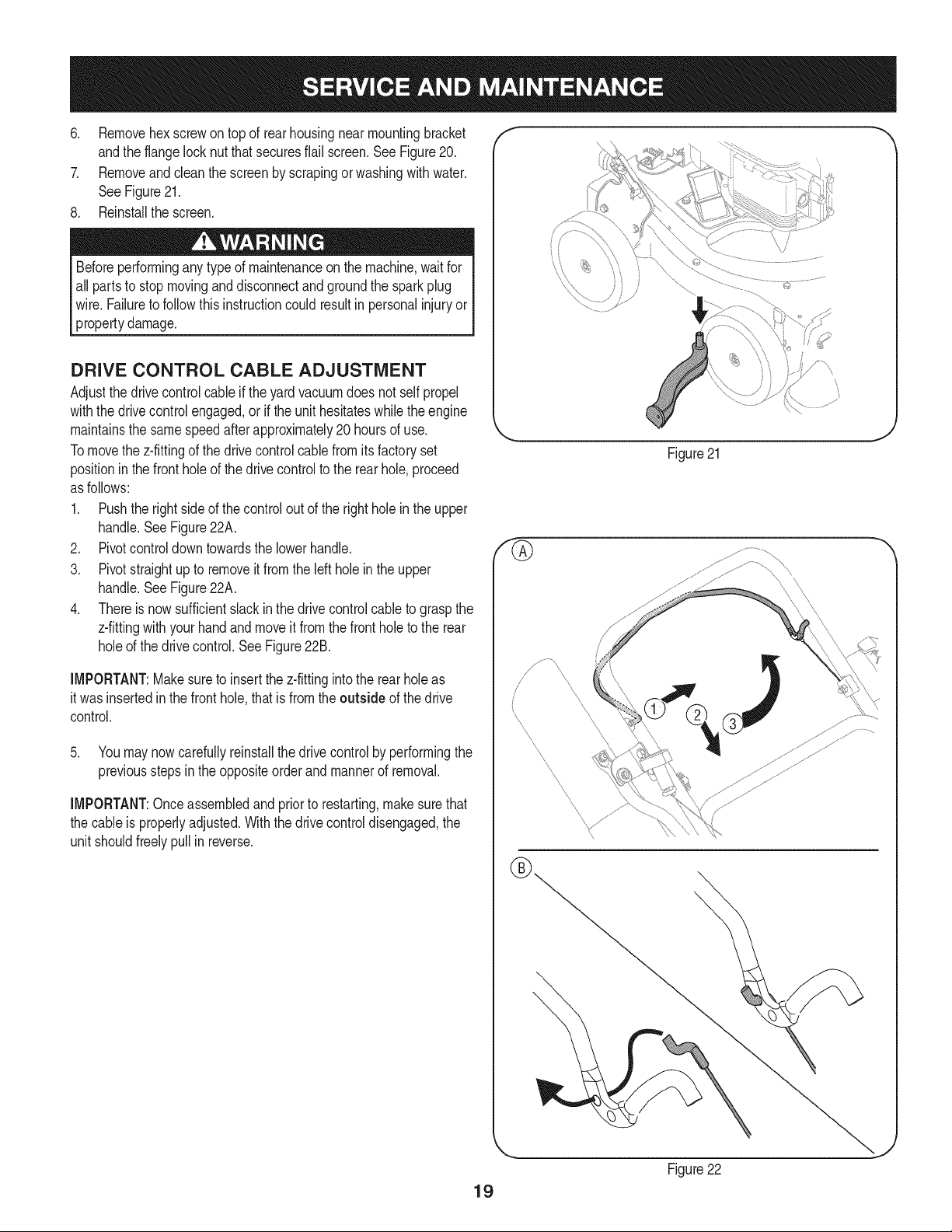

DRIVE CONTROL CABLE ADJUSTMENT

Adjustthedrivecontrolcableif theyardvacuumdoesnot selfpropel

withthedrivecontrolengaged,orif the unithesitateswhiletheengine

maintainsthe samespeedafterapproximately20 hoursofuse.

Tomovethe z-fittingof thedrivecontrolcablefromitsfactoryset

positioninthefrontholeof the drivecontroltotherearhole,proceed

asfollows:

1. Pushtherightsideof thecontroloutofthe rightholeintheupper

handle.SeeFigure22A.

2. Pivotcontroldowntowardsthelowerhandle.

3. Pivotstraightupto removeitfromtheleftholein theupper

handle.SeeFigure22A.

4. Thereisnowsufficientslackinthedrivecontrolcableto graspthe

z-fittingwithyourhandandmoveitfromthe frontholeto the rear

holeofthedrivecontrol.SeeFigure22B.

f

\

J

Figure21

IMPORTANT:Makesureto insertthez-fittingintothe rearholeas

itwasinsertedinthefronthole,thatis fromthe outside ofthedrive

control.

5. Youmaynowcarefullyreinstallthe drivecontrolbyperformingthe

previousstepsintheoppositeorderandmannerof removal.

IMPORTANT:Onceassembledand priorto restarting,makesurethat

thecableis properlyadjusted.Withthedrivecontroldisengaged,the

unitshouldfreelypullin reverse.

\

19

Figure22

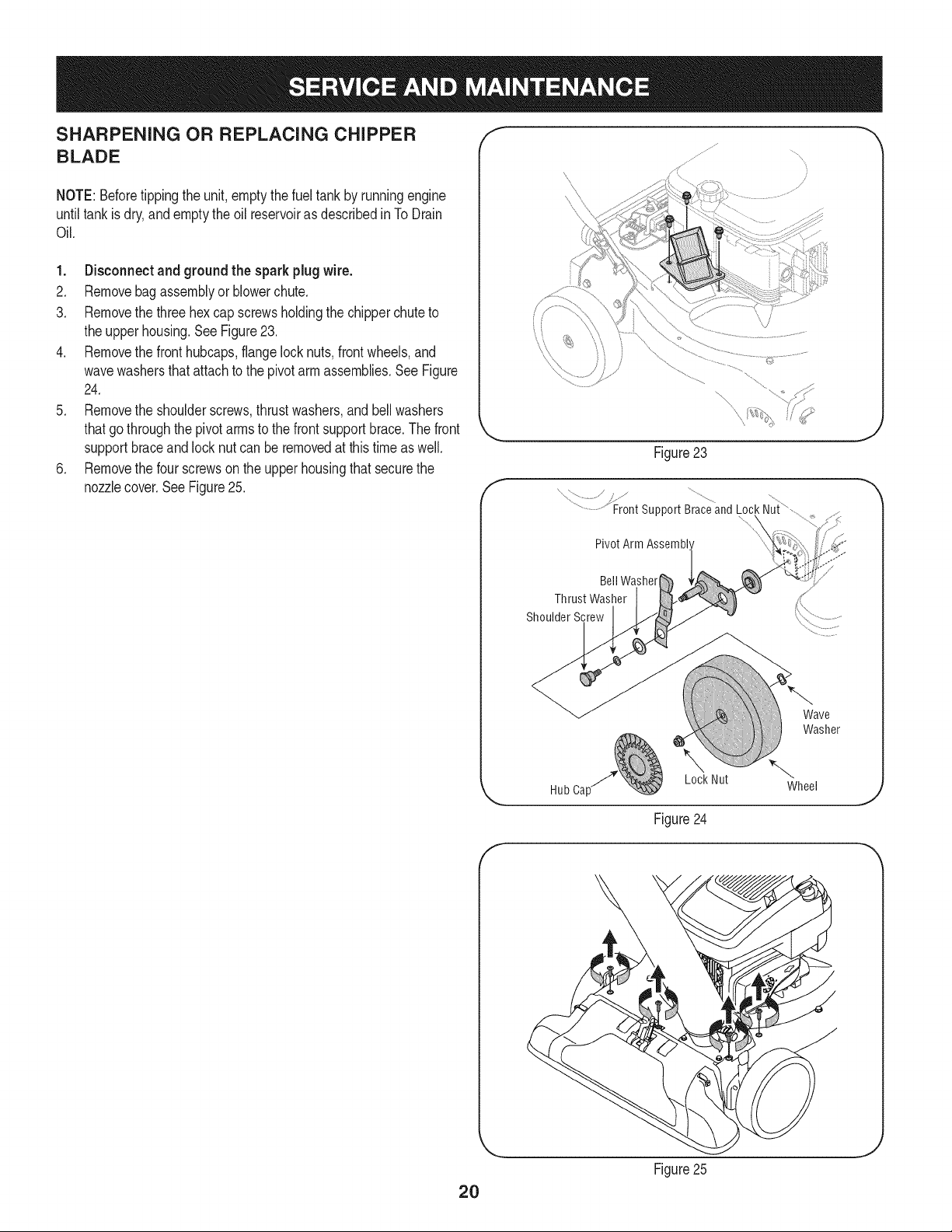

SHARPENING OR REPLACING CHIPPER

BLADE

NOTE:Beforetippingthe unit,emptythefueltankbyrunningengine

untiltankisdry,andemptythe oil reservoiras describedinTo Drain

Oil.

1. Disconnectand groundthesparkplugwire.

2. Removebagassemblyor blowerchute.

3. Removethethreehexcapscrewsholdingthechipperchuteto

theupperhousing.SeeFigure23.

4. Removethefronthubcaps,flangelocknuts,frontwheels,and

wavewashersthatattachtothepivotarmassemblies.SeeFigure

24.

5. Removethe shoulderscrews,thrustwashers,andbellwashers

thatgothroughthepivotarmstothefrontsupportbrace.Thefront

supportbraceandlocknutcanberemovedatthistimeaswell.

6. Removethefourscrewsontheupperhousingthatsecurethe

nozzlecover.SeeFigure25.

f

J

Figure23

x /

..........................Front support Braceand Lock Nui,

PivotArm Assembl'

BellWasher

Thrust Washer

Shoulder Screw

2O

Wave

Washer

Lock Nut

HubCa[ Wheel

J

Figure24

f

J

Figure25

Loading...

Loading...