Page 1

Operator's Manual

I(RRFTSMRW I

6.0 Horse Power

YARD VACUUM

Model No. 247.770550

CAUTION: Before using

this product, read this

manual and follow all

Safety Rules and

Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our Sears website: www.sears.com/craftsman

Printed in U.S.A.

• Safety

• Assembly

• Operation

• Maintenance

• Parts

• Espa_ol

FORM NO. 769-00407A.fm

(10/02)

Page 2

Content Page Content Page

Warranty 2 Service and Adjustments 14

Safety 3 Storage 16

Assembly 5 Troubleshooting 17

Operation 8 Parts List 18

Maintenance 12

Limited Warranty on Craftsman Yard Vacuum

For one (1) year from the date of purchase, if this Craftsman Equipment is maintained, lubricated, and tuned up

according tothe instructions tothe operator's manual, Sears will repair or replace free of charge any parts found

to be defective in material or workmanship. Warranty service isavailable free of charge by returning Craftsman

equipment to your nearest Sears Service Center. In-home warranty service is available but a trip charge will

apply. This Warranty applies only while this product isin the United States.

This Warranty does not cover:

Expendable items which become worn during normal use, such as spark plugs, air cleaners, belts, and oil

filters.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass.

Repairs necessary because of operator abuse, including but not limited to, damage caused by objects, such

as stones or metal debris, oversized stock, impacting objects that bend the frame or crankshaft, or over-

speeding the engine.

Repairs necessary because of operator negligence, including but not limited to, electrical and mechanical

damage caused by improper storage, failure to use the proper grade and amount of engine oil, or failure to

maintain the equipment according to the instructions contained in the operator's manual.

Engine (fuel system) cleaning or repairs caused by fuel determine to be contaminated or oxidized (stale). tn

general, fuel should be used within 30 days of its purchase date.

Equipment used for commercial or rental purposes.

TO LOCATE THE NEAREST SEARS SERVICE CENTER OR TO SCHEDULE SERVICE, SIMPLY CONTACT

SEARS AT 1-800-4-MY-HOME.

This warranty gives you specific legal rights and you may also have other rights, which vary from state to state.

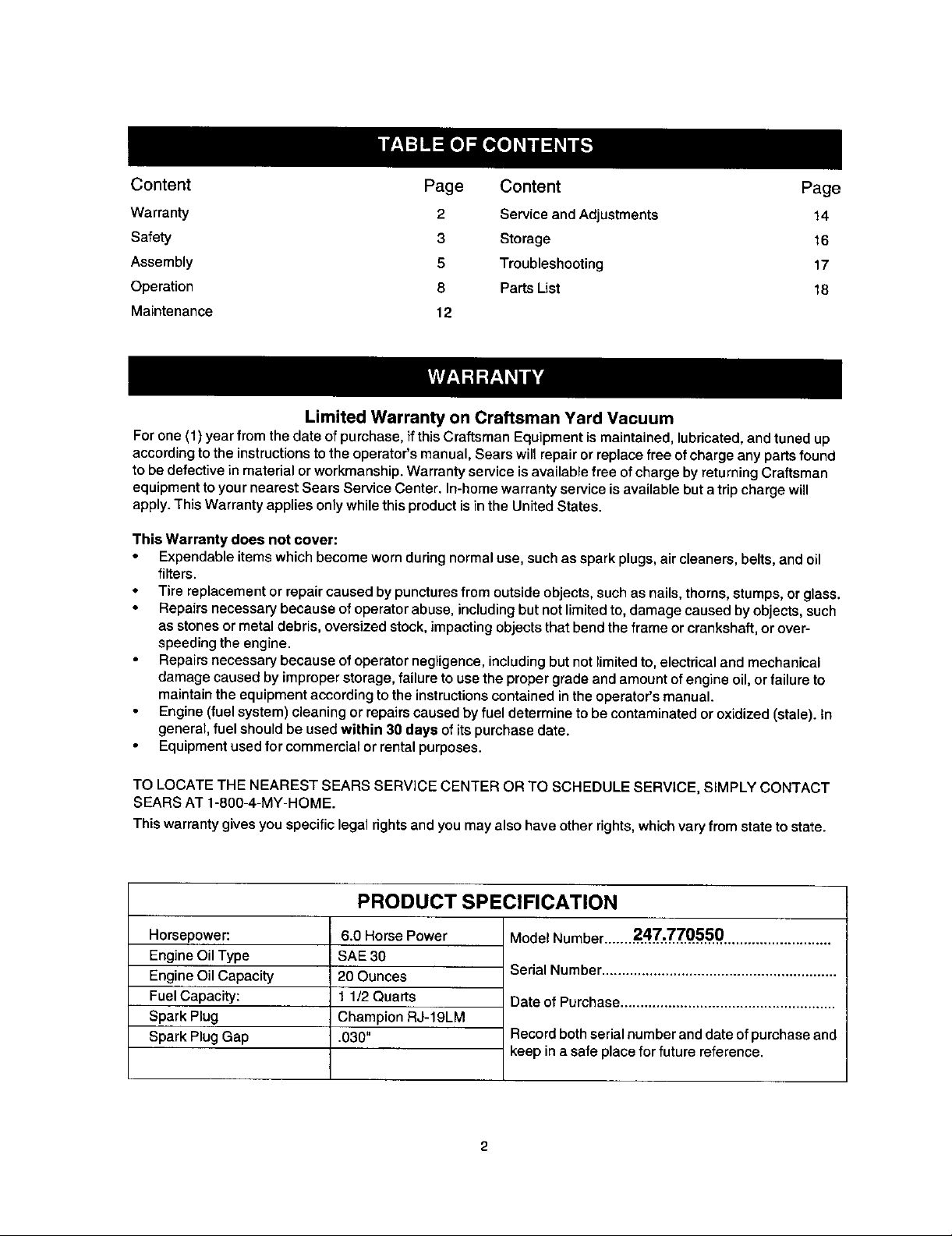

PRODUCT SPECIFICATION

Horsepower:

Engine Oil Type

Engine Oil Capacity

FuelCapacity:

Spark Plug

Spark Plug Gap

6.0 Horse Power

SAE30

20 Ounces

1 1/2 Quarts

Champion RJ-19LM

.030"

Model Number ....... ,2.,4.,7.._'_,7.,.0.5_.0............................

Serial Number ...........................................................

Date of Purchase ......................................................

Reoord both serial number and date of purchase and

keep in a safe place for future reference,

Page 3

WARNING: This symbol points out important safety instructions which, if not followed, could

endanger the personal safety and/or property of yourself and others. Read and follow all

instructions in this manual before attempting to operate this machine. Failure to comply with these

instructions may result in personal injury. When you see this symbol - heed its warning.

WARNING: Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to State of California to cause cancer

and birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the rulesfor safe operation inthis

manual.As withany type ofpowerequipment,carelessnessor erroron the partofthe operatorcan

resultinseriousinjury.Thismachineiscapableof amputatinghandsand feet andthrowingobjects.

Failuretoobservethe following safetyinstructionscouldresultinseriousinjuryordeath.

TRAINING

1. Read, understand, and follow all instructions on

the machine and in the manual(s) before

attempting to assemble and operate. Keep this

manual in a safe place for future and regular

reference and for ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 16 years old to

operate this machine. Children 16 years old and

over should read and understand the operation

instructions and safety rules in this manual and

should be trained and supervised by a parent.

4. Never allow adults to operate this machine

without proper instruction.

5. Keep bystanders, helpers, pets, and children at

least 75 feet from the machine while it is in

operation. Stop machine if anyone enters the

area.

6. Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

7. Do not put hands and feet near rotating parts or in

the feeding chambers and discharge opening.

Contact with the rotating impeller can amputate

fingers, hands, and feet.

8. Never attempt to unclog either the feed intake or

discharge opening, remove or empty vacuum

bag, or inspect and repair the machine while the

engine is running. Shut the engine off and wait

until all moving parts have come to a complete

stop. Disconnect the spark plug wire and ground

it against the engine.

PREPARATION

1. Thoroughly inspect the area where the

equipment is to be used. Remove all rocks,

bottles, cans, or other foreign objects which could

be picked up or thrown and cause personal injury

or damage to the machine.

2.

Always wear safety glasses or safety goggles

during operation or while performing an

adjustment or repair, to protect eyes. Thrown

objects which ricochet can cause serious injury to

the eyes.

3,

Wear sturdy, rough-soled work shoes and close-

fitting slacks and shirts. Loose fitting clothes or

jewelry can be caught in movable parts. Never

operate this machine in bare feet or sandals.

Wear leather work gloves when feeding material

in the chipper chute.

4.

Before starting, check all bolts and screws for

proper tightness to be sure the machine is in safe

working condition. Also, visually inspect machine

for any damage at frequent intervals.

5.

Maintain or replace safety and instructions labels,

as necessary.

6.

To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are

explosive. Serious personal injury can occur

when gasoline is spilled on yourself or your

clothes which can ignite. Wash your skin and

change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and

other sources of ignition.

e. Never fuel machine indoors.

d. Never remove gas cap or add while the

engine is hot or running.

e. Allow engine to cool at least two minutes

before refueling.

f. Never over fill fuel tank. Fill tank to no more

than 1/2 inch below bottom of filler neck to

provide space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine

and equipment. Move machine to another

area. Wait 5 minutes before starting the

engine.

Page 4

i. Neverstorethe machine or fuel container

insidewherethere isan openflame, spark,

or pilotlight(e.g. furnace, water heater,

space heater,clothesdryer,etc.)

j. To reducea fire hazard, keep machinefree

ofgrass,leaves, or otherdebrisbuild-up.

Cleanupoilfuel spillageand removeanyfuel

soakeddebris.

k. Allow machinetocoolat least5 minutes

beforestoring.

OPERATION

1. Do not put hands and feet near rotating parts or in

the feeding chambers and discharge opening.

Contact with the rotating impeller can amputate

fingers, hands, and feet.

2. Before starting the machine, make sure the chipper

chute, feed intake, and cutting chamber are empty

and free of all debris.

3. Thoroughly inspect all material to be shredded and

remove any metal, rocks, bottles, cans, or other

foreign objects which could cause personal injury

or damage to the machine.

4. If the impeller strikes a foreign object or if your

machine should start making an unusual noise or

vibration, immediately shut the engine off. Allow the

impeller to come to a complete stop. Disconnect

the spark plug wire, ground it against the engine

and perform the following steps:

a. Inspect for damage.

b. Repair or replace any damaged parts.

c. Check for any loose parts and tighten to

assure continued safe operation.

5. Do not allow an accumulation of processed

material to build up in the discharge area. This can

prevent proper discharge and result in kickback of

material through the feed opening.

6. Do not attempt to shred or chip material larger than

specified on the machine or in this manual.

Personal injury or machine damage could result.

7. Never attempt to unclog either the feed intake or

discharge opening while the engine is running.

Shut the engine off, wait until all moving parts have

stopped, disconnect the spark plug wire and

ground it against the engine before clearing debris.

8. Never operate without vacuum bag and discharge

chute properly attached to the machine. Never

empty or change vacuum bag while the engine is

running. Rear end of vacuum bag must be kept

closed at all times during operation.

9. Never operate without either the inlet nozzle or

optional hose attachment properly attached to the

machine. Never attempt to attach or change either

attachment while the engine is running.

10. Keep all guards, deflectors and safety devices in

place and operating properly.

11. Keep your face and body back and to the side of

the chipper chute while feeding material into the

machine to avoid accidental kickback injuries.

12. Never operate this machine without good visibility

or light. Always be sure of your footing and keep a

firm hold on the handles.

13. Do not operate this machine on a gravel surface.

14. Do not operate this machine while under the

influence of alcohol or drugs.

15. Muffler and engine become hot and can cause a

burn. Do not touch.

16. Never pick up or carry machine while the engine is

running.

MAINTENANCEANDSTORAGE

1. Never tamper with safety devices. Check their

proper operation regularly.

2. Check bolts and screws for proper tightness at

frequent intervals to keep the machine in safe

working condition. Also, visually inspect machine

for any damage and repair, if needed.

3. Before cleaning, repairing, or inspecting, stop the

engine and make certain the impeller and all

moving parts have stopped. Disconnect the spark

plug wire and ground it against the engine to

prevent unintended starting.

4. Do not change the engine governor settings or

overspeed the engine. The governor controls the

maximum safe operating speed of the engine.

5. Maintain or replace safety and instruction labels, as

necessary.

6. Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

7. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

such as a water heater, furnace, clothes dryer, etc.

8. Always refer to the operator's manual for proper

instructions on off-season storage.

9. If the fuel tank has to be drained, do this outdoors.

10. Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

4

Page 5

20-oz. Bottle

of Engine Oil

NOTE: Reference to right and left hand side of the

Yard Vacuum is observed from the operating

position. See Figure 1.

This Yard Vacuum has been completely assembled

at the factory, except for the handle, bag, and blower

chute. These parts are shipped loose in the carton.

A pair of safety glasses and a 20-oz. bottle of engine

oil are also included in the carton. See Figure 1.

REMOVINGUNITFROMCARTON

Cut the cornersof the carton.

ly

Remove allloose parts.

Remove packing material.

Lift unit from the rear to discard packingmaterial

from under unit and roll unit out of carton.

Check carton thoroughly for any other loose

parts.

uts

_ Upper

Blowe Handle

Chute /

Rope

Guide

Nut

LOOSEPARTSINCARTON(SeeFigure1)

Handle Assembly

• Hose Assembly

Bag

Blower Chute

Safety Glasses (Not Shown)

A 20-oz. Bottle of Engine Oil (may be located in

bag)

Operator's Manual

DISCONNECTINGSPARKPLUG

Before proceeding with assembly of your new Yard

Vacuum, disconnect the spark plug wire from the

spark plug and ground onto the retaining post on the

engine. This will prevent accidental starting of the

engine. See Figure 2.

Retaining Post

O

Spark

Carriage

Screw

Figure I

IMPORTANT: This unit is shipped without gasoline or

oil in the engine. After assembly, see OPERATION

section of this manual for proper fuel and engine oil

fill-up.

Plug Wire

Figure 2

ATTACHINGTHEHANDLE

Unfold the upper handle until it aligns with lower

handle. Make sure the rope guide is on the right

side of upper handle. See Figure 1.

5

Page 6

• Secure the two handles by tightening the upper

wingnuts (carriage bolts must be seatedproperly

into the handle).

• Remove the hairpin clips from the handle

brackets and removethe carriage bolts and wing

nuts from the lower handle. See Figure 3.

Place the bottom holes in lower handle over the

pins on handle brackets and secure with hairpin

clips,

Insert carriage bolts through upper hole in lower

handle from the outside and secure with wing

Figure 3

Loosen the wing nut that secures the rope guide

to the right side of upper handle.

Pull the starter rope out of the engine slowly and

slip the starter rope into the rope guide. Tighten

the wing nut,

AttachingTheHoseAssembly

Slide hose adapter of hose assembly into the

base adapter located on the left front of the Yard

Vacuum. See Figure 4.

• Pull spring loaded pin out on the base and align

pin with the first hole in the hose adapter.

• Release the pin to lock the hose in place.

• Connect the hose handle near nozzle end of

hose to the side bracket on the upper handle.

Refer to Figure 7.

Snap hose handle to the lower handle bracket to

secure in place and lay hose tubing on side

bracket hanger next to chipper chute. Refer to

Figure 7.

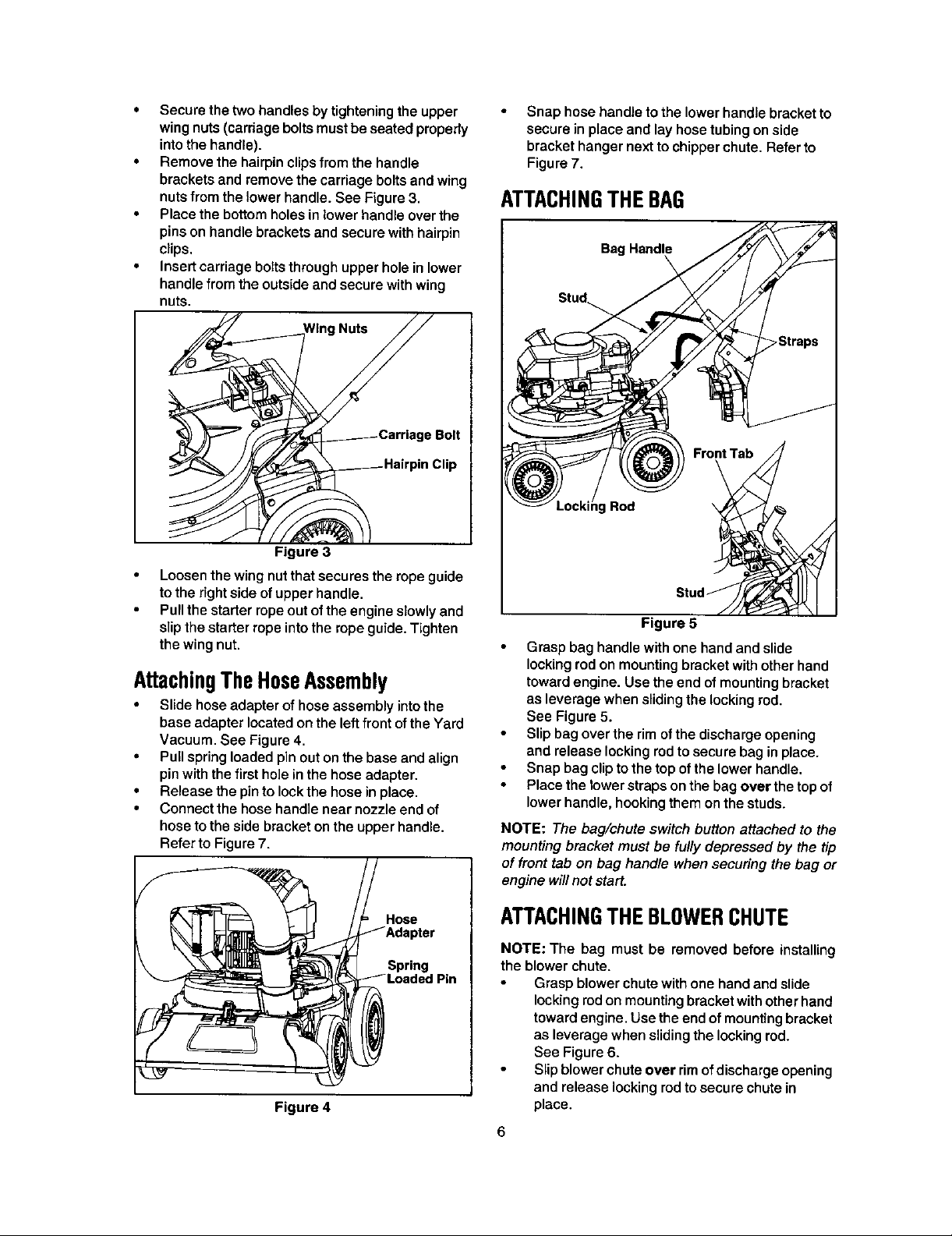

ATTACHINGTHEBAG

Figure 5

Grasp bag handle with one hand and slide

locking rod on mounting bracket with other hand

toward engine. Use the end of mounting bracket

as leverage when sliding the locking rod,

See Figure 5.

Slip bag over the rim of the discharge opening

and release locking rod to secure bag in place.

Snap bag clip to the top of the lower handle,

Place the lower straps on the bag over the top of

lower handle, hooking them on the studs.

NOTE: The bag/chute switch button attached to the

mounting bracket must be fully depressed by the tip

of front tab on bag handle when securing the bag or

engine will not start.

Figure 4

Hose

Spring

ATTACHINGTHEBLOWERCHUTE

NOTE: The bag must be removed before installing

the blower chute.

Grasp blower chute with one hand and slide

locking rod on mounting bracket with other hand

toward engine. Use the end of mounting bracket

as leverage when sliding the locking rod.

See Figure 6.

Slip blower chute over rim of discharge opening

and release locking rod to secure chute in

place.

6

Page 7

• Raise the nozzle height to the highest setting

when using the blower chute. Refer to nozzle

height adjustment in the ADJUSTMENT section.

NOTE: The bag/chute switch button attached to the

mounting bracket must be fully depressed by the tip of

front tab on the blower chute or engine will not start.

Blower

Front

Tab

Locking

Rod

king

Rod

Figure 6

7

Page 8

Know Your Yard Vacuum

Read this operator'smanualand safety rules before operatingyour Yard Vacuum. Compare the illustrations

betow with your equipment to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

The operation of any Yard Vacuum can result in foreign objects being thrown into the eyes,

which can result in severe eye damage. Always wear safety glasses, provided with the

Yard Vacuum, for operating this equipment or while performing any adjustments or repairs on

Starter

Bag Handle

Throttle Control

Nozzle/Hose

Vac Handle

Blower Chute

Choke Control

Nozzle Height

Adjustment Lever

OPERATINGCONTROLS(seeFigure7)

Chipper Chute

Allows twigs and small branches up to 1 1/2" in

diameter to be fed into the impeller for chipping.

Nozzle

Yard waste such as leaves and pine needles can be

vacuumed up through the nozzle for shredding.

Bag

Collects shredded material fed in through the chipper

chute or vacuumed in through the nozzle.

Blower Chute

When attached to unit, the blower chute is used to

blow or scatter yard waste such as leaves, pine

needle, or small twigs across yard.

Bag Handle

Used to grasp bag in order to assist in attaching,

removing, and emptying bag.

Spark Plug Wire \

t

Nozzle

Figure 7

Nozzle Height Adjustment Lever

Used to adjust the nozzle ground clearance ranging

from 5/8" to 4 1/8".

Throttle Control

This lever controls the engine speed and stop

function. Through three separate positions on the

lever from left to right, the operation is as follows:

Start/ Slow/ Engine

Run Idle Off

Choke Control

The choke control is used to choke of the carburetor

and assist in starting the engine.

Starter Handle

Used to start the engine.

Meets ANSI safety standards

Craftsman Yard Vacuums conform to the safety standard of the American National Standards Institute (ANSI),

8

Page 9

Hose Assembly

Used asan alternative to the nozzletovacuum yard

waste suchas leavesor pine needlesin hardto

reachplaces.

Hose Handle

Used to guidehoseassemblywhenvacuuming.

Nozzle/Hose Vac Handle

The nozzle/hose vac handle is located on top of the

nozzle and it is used to regulate the vacuum between

the nozzle and the hose assembly.

GASANDOILFILL-UP

Oil (one 20-oz. bottle shipped with unit)

Only use high quality detergent oil rated with API

service classification SF, SG, or SH. Select the oil's

SAE viscosity grade according to the expected

operating temperature. Follow the chart below.

Colder _- 32°F _ Warmer

5W_ SAE 30

Fill fuel tank with clean, fresh, unleaded regular,

unleaded premium or reformulated automotive

gasoline only. DO NOT use Ethyl or high octane

gasoline. Do not use gasoline containing

METHANOL. Replace fuel cap.

To avoid engine problems, the fuel system should

be emptied before storage for 30 days or longer.

Drain the gas tank, start the engine and let it run

until the fuel lines and carburetor are empty. Use

fresh fuel next season. See STORAGE section

for additional information.

WARNING: Use extreme care when

a,

handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

Never fuel machine indoors or while the

engine is hot or running. Extinguish

cigarettes, cigars, pipes, and other

sources of ignition.

Check the fuel level periodically to avoid running

out of gasoline while operating the Yard Vacuum.

If the unit runs out of gas as it is chipping, it may

be necessary to unclog the unit before it can be

restarted. Refer to SERVICE AND

ADJUSTMENT section.

Oil Viscosity Chart

NOTE: Although multi-viscosity oils (5W30, 10W30,

etc.) improve starting in cold weather, they will result

in increased oil consumption when used above 32°F.

Check your engine oil level more frequently to avoid

possible engine damage from running low on oil.

Remove oil fill dipstick.

With the Yard Vacuum on level ground, use a

funnel to fill engine with oil to FULL mark on

dipstick. Capacity is approximately 20 oz. Be

careful not to overfill. Overfilling will cause the

engine to smoke profusely and will result in poor

engine performance. The oil bottle packaged 1.

with your Yard Vacuum contains 20 oz. of oil.

Check the oil level making certain not to rub the 2.

dipstick along the inside walls of the oil fill tube.

This would result in a false dipstick reading. Refill

to FULL mark on dipstick, if necessary. Replace 3.

dipstick and tighten.

• Check oillevelthree times prior to starting engine

to be certain you've gotten an accurate dipstick 4.

reading. Running the engine with too little oil can

result in permanent engine damage. 5.

Gasoline

Remove fuel cap from the fuel tank.

Make sure the container from which you will pour

the gasoline is clean and free from rust or foreign

particles. Never use gasoline that may be stale

from long periods of storage in its container.

Gasoline that has been sitting for any period

longer than four weeks should be considered

stale.

TOSTOPENGINE

Move throttle control lever to STOP or OFF

position.

Disconnect spark plug wire and ground it to the

post to prevent accidental starting while the

equipment is unattended.

lever, be careful of heated surfaces and

WARNING: When moving throttle control

sharp edges on muffler guard.

TOSTARTENGINE

Attach spark plug wire and rubber boot to spark

plug.

The bag/chute switch button must be fully

depressed by the tip of front tab on bag handle

or blower chute for engine to start.

Make sure bag/chute switch wire is connected to

engine and grounded to mounting bracket.

Gas tank should be filled 3/4 to full before start-

ing.

Move throttle control to START/RUN position.

See Figure 8.

6.

Move the choke control toward the throttle

control to choke the engine's carburetor. (A

warm engine may not require choking.) See

Figure 8.

Page 10

Throttle Control

Buttons

Choke Control

Figure 8

7. Standing behind the unit, grasp starter handle

and pull rope out until you feel adrag.

8. Pull the rope with a rapid, continuous, futl arm

stroke. Keep a firm grip on the starter handle.

Let the rope rewind slowly.

9. Repeat, if necessary, until engine starts. When

engine starts, move choke control gradually

away from the throttle control.

10. If engine falters, move choke control back

toward the throttle control and repeat steps 7-9.

11. ALWAYS keep the throttle control in the START/

RUN position when operating the Yard Vacuum.

TOEMPTYBAG

• Unhook bag straps from the lower handle and

unsnap bag clip from top of the lower handle.

See Figure 9.

Grasp bag handle with one hand and pull lock rod

on mounting bracket with other hand toward

engine to release.

Remove bag from over the rim of the discharge

opening. Refer to Figure 4.

Twist the two buttons on the back of the bag to

unlock and empty contents. See Figure 9.

Hold bag handle and bag clip while emptying the

contents.

• Compress bag opening and fold inner flap over

opening.

Fold outer flap over inner flap and insed buttons

on the bag through metal outlets.

Twist the buttons to lock bag.

Inner Flap Bag

Handle

Figure 9

Clip

TOREMOVEBLOWERCHUTE

Grasp blower chute with one hand and pull lock

rod on mounting bracket with other hand toward

engine to release. Refer to Figure 6.

Remove blower chute from over the rim of the

discharge opening.

UsingtheNozzleVacuum

• Place nozzle/hose vac handle in the top position

on the nozzle to vacuum through nozzle. See

Figure 10.

The spring loaded pin must be in the first hole of

the hose adapter to operate the nozzle vac.

Place both hands on top of upper handle to push

unit over yard waste.

Yard waste such as leaves and pine needles can be

vacuumed up through the nozzle for shredding. After

material has been shredded by the flail blades on the

impeller assembly, it will be discharged into catcher

bag or through blower chute. Do not attempt to shred

or chip any material other than vegetation found in a

normal yard (i.e. branches, leaves, twigs, etc.) Avoid

fibrous plants such as tomato vines until they are

thoroughly dried out. Materials such as stalks or

heavy branches up to 1 1/2" in diameter may be fed

into the chipper chute.

WARNING: Do not attempt to shred,

A

chip, or vacuum any material larger than

specified on the machine or in this

manual. Personal injury or damage to

the machine could result.

10

Page 11

Nozzle/Hose\_

MacHandle \ --

Spring Loaded Pin

(First Hole)

Figure 10

IMPORTANT: The flail screen is located inside the

housing in the discharge area. If the flail screen

becomes clogged, remove and clean as instructed in

SECTION 5: MAINTAINING YOUR YARD VACUUM.

For best performance, it is also important to keep the

chipper blade sharp.

adjustments without first stopping engine

WARNING: Do not at any time make any

and disconnecting spark plug wire.

NozzleHeightAdjustment

The nozzle can be adjusted to any six positions,

ranging from 5/8" to 4 1/8" ground clearance. The

nozzle height has to be adjusted according to the

conditions. Move the height adjustment levers forward

or backward to adjust the nozzle upwards or

downwards. See Figure 12.

NOTE: In general, raise the nozzle height to vacuum a

thick layer of leaves or to operate with the blower chute

and lower the nozzle height for smoother surfaces.

Nozzle" Adjustment

Lever

Figure 12

UsingtheHoseAssembly

Place nozzle/hose vac handle inthe bottom

position on the nozzle to redirect vacuum to the

hose assembly. See Figure 11.

The spring loaded pin must be in the second hole of

the hose adapter to operate the hose assembly.

Unhook the hose from upper handle bracket and

grasp the hose handle to guide while vacuuming

yard waste such as leaves or pine needles in hard

to reach places.

Nozzle/Hose

Vac Handle

Spring

(Second Hole)

Figure 11

11

Page 12

MAINTENANCE a.J _ ,_#_

SCHEDULE ,_o_'=_._._ _...

I-

O Lubrication _

E3

o

Clean equipment _

Check engine oil

LU Change engine oil _ _

z

Service air cleaner

z

ug

Service spark plug _ <_//

Service muffler '_

Clean engine _ _:_

GENERALRECOMMENDATIONS

Always observe safety rules when performing any

maintenance.

• The warranty on this Yard Vacuum does not

cover items that have been subjected to operator

abuse or negligence. To receive full value from

the warranty, operator must maintain the

equipment as instructed in this manual.

Some adjustments will need to be made

periodically to maintain your equipment properly.

Follow the maintenance schedule.

• Periodically check all fasteners and make sure

they are tight.

WARNING: Always stop the engine and

&

disconnect and ground the spark plug

wire before performing any maintenance

or adjustments,

LUBRICATION

Wheels- Place a few drops of SAE 30 oil on each

shoulder screw once a season.

Refer to Figure 7.

Nozzle height adjustment levers- Lubricate

nozzle height adjustment levers with light oil.

Refer to Figure 7,

Locking Rod- Lubricate the lock rod and

compression springs which attach to the

mounting bracket. Refer to Figure 5,

CLEANEQUIPMENT

Clean the Yard Vacuum thoroughly after each

use.

Wash the bag periodically with water. Allow to

dry thoroughly in the shade.

Ifthe flail screen becomes clogged, remove and

clean as instructed in the SERVICE AND

ADJUSTMENT section.

NOTE: Cleaning with a forceful spray of water is not

recommended as it could contaminate the fuel

system.

CHECKENGINEOIL

Remove oil fill dipstick.

Check oil level on dipstick. Level should be at

FULL mark.

Replace dipstick and tighten.

CHANGEENGINEOIL

Only use high quality detergent oil rated with API

service cTassification SF, SG, or SH. Select the

oil's SAE viscosity grade according to the

expected operating temperature. Refer to

operation section for viscosity chart.

Stop engine and wait several minutes before

checking oil level. With engine on level ground,

the oil must be to FULL mark on dipstick.

Change engine oil after the first five hours of

operation, and every twenty-five hours

thereafter.

12

Page 13

TODRAINOIL

Drain oil while engine is warm. Follow the instructions

given below.

Drain the gas tank, start the engine and let it run

until the fuel line and carburetor are empty.

Remove oil fill dipstick.

• Tip unit on its side to drain through the oil fill tube.

• When engine is drained of all oil, refill with

approximately 20 oz. of fresh oil. Refer to Gas

And Oil Fill-up in OPERATION section.

Replace dipstick.

SERVICEAIRCLEANER

The air cleaner prevents damaging dirt, dust, etc.,

from entering the carburetor and being forced into the

engine and is important to engine life and

performance. The air cleaner consists of a foam filter.

Never run the engine without an air cleaner

completely assembled.

TOService Air Cleaner:

Remove foam filter from plastic housing on top of

engine.

Wash in water and detergent solution, and

squeeze (do not twist) until all dirt is removed.

Rinse thoroughly in clear water.

Wrap in a clean cloth and squeeze (do not twist)

until completely dry, or allow to air dry.

Saturate with engine oil and squeeze to distribute

oil and remove excess oil.

Replace foam filter in plastic housing

NOTE: ff the foam filter is tom or damaged in any

way, replace it.

_lb ARNING: WARNING: Temperature ofmuffler end nearby areas may exceed

150 ° F(65°C). Avoid these areas.

SERVICESPARKPLUG

Clean the spark plug and reset the gap to .030" at

least once a season or every 50 hours of

operation. See Figure 13. Spark plug

replacement is recommended at the start of each

season. Refer to engine parts list for correct

spark plug type.

NOTE: Do not sandblast spark plug. Spark plug

should be cleaned by scraping or wire brushing and

washing with a commercial solvent.

Figure 13

SERVICEMUFFLER

Inspect muffler periodically, and replace if

necessary.

If your engine is equipped with a spark arrester

screen assembly, remove after every 50 hours of

use for cleaning and inspection. Replace if

damaged.

WARNING: Do not operate the Yard

&

Vacuum without a muffler or tamper with

the exhaust system. Damaged mufflers

or spark arresters could create a fire

hazard.

CLEANENGINE

Clean engine by removing dirt and debris with a

cloth or brush.

Frequently remove grass clippings, dirt, and

debris from cooling fins, air intake screen, levers,

and linkage. This will help ensure adequate

cooling and engine speed.

13

Page 14

adjustment to the unit without first

WARNING: Do not at any time make any /_,

stopping engine and disconnecting

spark plug wire.

NozzleHeightAdjustment

The nozzle can be adjusted to any six positions,

ranging from 5/8" to 4 1/8" ground clearance. The

nozzle height has to be adjusted according to the

conditions. Move the height adjustment levers

forward or backward to adjust the nozzle upwards or

downwards. See Figure 14.

NOTE: In general, raise the nozzle height to vacuum

a thick layer of leaves or to operate with the blower

chute and lower the nozzle height for smoother

surfaces.

WARNING: Do not attempt to alter the

engine speed by tampering with the

engine's governor linkage. Doing so

could result in serious personal injury

and damage to the engine. The engine

RPM has been set at the factory.

REMOVINGTHEFLAILSCREEN

If the discharge area becomes clogged, remove the

flail screen and clean areaas follows.

Stop the engine. Make certain the chipper

shredder vacuum has come to a complete stop.

Disconnect and ground the spark plug wire

before unclogging the discharge chute.

Remove the vacuum bag or blower chute from

the unit as instructed in the OPERATION section

to obtain access to flail screen. See Figure 15.

tex Screw & Flat Washer /,

f

ght

Nozzle

Adjustment

Lever

Figure 14

CARBURETORADJUSTMENT

WARNING: If any adjustments (e.g.

carburetor) are made to the engine

while the engine is running, keep clear

of all moving parts. Be careful of heated

surfaces and muffler.

The carburetor has been pre-set at the factory and

should not require adjustment. If your engine does

not operate properly due to suspected carburetor

problems, take your Yard Vacuum to a Sears Service

Center for repair and adjustment.

ENGINESPEED

The engine speed on your Yard Vacuum has been

set at the factory. Do not attempt to increase the

engine RPM. Ifyou think that the engine is running

too fast or too slow, take your Yard Vacuum to the

nearest Sears Service Center for repair and adjust-

ment.

REAR VIEW

Figure 15

Remove hex screw on right side of unit that

attaches to the flail screen. See Figure 16.

Hex Screw

Figure 16

• Remove hex screw and flat washer on top of rear

housing near mounting bracket and the lock nut

that secures flail screen. See Figure 15.

• Remove and clean the screen by scraping or

washing with water. Reinstall the screen.

14

Page 15

SHARPENINGORREPLACINGCHIPPER

BLADE

Because the engine on this unit has a tapered

crankshaft, a special impeller removal tool (part

number 753-0900) is required to remove the impeller

assembly. For further assistance, contact your Sears

Service Center.

NOTE: When tipping the unit, empty the fuel tank and

keep engine spark plug side up.

Disconnect and ground the spark plug wire.

Remove the front hubcaps, lock nuts, front

wheels, and wave washers that attach to the pivot

arm assemblies. See Figure 17,

Remove the shoulder screws and bell washers

that go through the pivot arms and height bracket

adjusters to the front support brace.

Remove lock nut that secures flail screen to the

lower housing. The flail screen does not have to

be removed. Refer to Figure 15.

Remove the hex bolt, lock washer, and flat

washer that secure the impeller assembly to the

crankshaft. See Figure 19.

Upper

Dhippm

Blade

._._ Housing

Impeller

JAssembly

ex Bolt

"Lock Washer

Fiat Washer

Pivot Arm Assembly

Bell Washer

Wave Washer

Bracket

Screw Lock

Figure 17

Remove the three screws on the upper housing

that secure the nozzle cover and the nine screws

that secure the lower housing to the upper

housing. See Figure 18.

Housing

o 0

BOTTOM VIEW

Figure 19

Apply lubricant to the threads of impeller removal

tool and then thread the tool into the crankshaft.

Stop when the impeller assembly can move on

the crankshaft.

Remove the impeller assembly from the

crankshaft. Unthread the impeller removal tool

from the impeller assembly.

Remove the chipper blade using a 3/16" allen

wrench on the outside of the blade and 1/2"

wrench on the underside of impeller assembly.

Replace or sharpen chipper blade.

When sharpening blade, protect hands by using

gloves and follow the original angle of grind.

Reassemble by performing the previous steps in

reverse order.

• Tighten blade screws to 210 - 250 in-lbs.

• Tighten impeller bolt to 375 - 425 in-lbs.

NOTE: Make certain chipper blade is reassembled

with the sharp edge facing upward. See Figure 20.

• Chipper

_Flall

Blade

Screws

Figure 18

Lower Housing

Screws

_lmpeller

_r _L_/ Assembly

Figure 20

15

Page 16

PrepareyourCraftsmanYardVacuumforstorageat

theendoftheseasonoriftheunitwillnotbeusedfor

30daysorlonger.Ayearlycheck-upbyyourlocal

SearsServiceCenterisagoodwaytoensurethatthe

unitrunsproperlynext season.

YardVacuum

Clean the equipment thoroughly.

Wipe equipment with an oiled rag to prevent rust.

Use a light oil or silicone to wipe.

Service the engine following instructions below.

Store unit in a clean, dry area. Do not store next to

corrosive materials such as fertilizer.

Engine

IMPORTANT: It is important to prevent gum deposits

from forming in essential fuel system parts such as

the carburetor, fuel filter, fuel hose, or tank during

storage. Also, alcohol blended fuels (called gasohol or

using ethanol or methanol) can attract moisture which

leads to separation and formation of acids during

storage. Acidic gas can damage the fuel system of an

engine while in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. Follow

these instruction:

Drain the fuel tank.

Start the engine and let it run until the fuel lines

and carburetor are empty.

Drain carburetor.

Never use engine or carburetor cleaner products

in the fuel tank or permanent damage may occur.

NOTE: Fuel stabilizer is an acceptable altemative in

minimizing the formation of fuel gum deposits during

storage.

Add stabilizer to gasoline in fuel tank or storage

container.

• Always follow the mix ratio found on stabilizer

container.

• Run engine at least 10 minutes after adding

stabilizer to allow the stabilizer to reach the

carburetor.

• Do not drain the gas tank and carburetor if using

fuel stabilizer. Drain all the oil from the

crankcase (this should be done after the engine

has been operated and is still warm) and refill the

crankcase with fresh oil.

If you have d rained the fuel tank, protect the inside of

the engine as follows:

Remove spark plug, pour approximately 1/2

ounce (approximately one tablespoon) of engine

oil into cylinder and crank slowly to distribute oil.

Replace spark plug.

Other

Do not store gasoline from one season to

another.

Replace the gasoline can if it starts to rust. Rust

and/or dirt in the gasoline will cause problems.

Store unit in a clean, dry area. Do not store next

to corrosive materials, such as fertilizer.

NOTE: If storing in an unventilated or metal storage

shed, be certain to rustproof the equipment by coat-

ing with a light oil or silicone.

16

Page 17

Problem Possible Cause(s) Corrective Action

Enginefailstostart 1. Fueltankemptyorstalefuel. 1.

Filltank with clean, fresh gasoline. Fuel will not

last over thirty days unless a fuel stabilizer is

added.

2. Spark plugwire disconnected.

3. Cannot pull recoilcord.

2. Connect wire to spark plug.

3. Obstruction lodged in impeller. Disconnect

spark plug wire and remove lodged object.

4. Choke not in ON position.

5. Faulty spark plug.

6. Safety switch not depressed.

4. Move CHOKE to ON position.

5. Clean, adjust gap or replace.

6. Safety switch must be depressed bythe front

tab on the bag handle when securing the bag.

7. Safety switch wire is not

connected to engine or not

properly grounded.

Lossofpower;

operation erratic

Too much vibration

Engine overheats 1. Carburetor not adjusted 1.

Unit does not 1. Discharge chute clogged. 1.

discharge

Rate of discharge

slows considerably or

1. Spark plug wire loose.

2. Unit running on CHOKE.

3. Blocked fuel line or stale fuel.

4. Water or dirt in fuel system.

5. Carburetor out of adjustment.

6. Lowengine RPM.

1. Loose parts or damaged

impeller.

2. Engine oil level low 2.

2. Foreign object lodged in

impeller.

3. Lowengine RPM.

4. Vacuum bag is full.

1. Lowengine RPM.

2. Chipper blade dull.

composition of

7. Connect safety switch wire to engineconnector

and ground to mounting bracket.

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF position.

3. Clean fuel line; fill tank with clean fresh

gasoline. Fuel will not last over thirty days

unless a fuel stabilizer is used.

4. Disconnect fuel line at carburetor to drain fuel

tank. Refill with fresh fuel.

5. Contact your Sears Service Center.

6. Always run engine at full throttle.

1. Stop engine immediately and disconnect spark

plug wire. Have unit serviced by a Sears

Service Center.

Contact your Sears Service Center.

Fill crankcase with proper selection of oil.

Stop engine immediately and disconnect spark

plug wire. Clean flail screen and inside of

discharge opening. Bee Maintenance section of

this manual.

2.

Stop engine immediately and disconnect spark

plug wire. Remove lodged object.

3.

Always run engine at full throttle.

4.

Empty bag.

1.

Always run engine at full throttle.

2.

Replace chipper blade or see your Sears

Service Center.

discharged material

changes

NOTE: For repairs beyond the minor adjustments listed above, please contact your local Sears Service Center.

17

Page 18

Sears Craftsman 6.0 H.P. Yard Vacuum Model 247.770550

-11

7

17

/

15

48

47

33 34 35

51

4O

19

18

Page 19

Sears Craftsman 6.0 H.P. Yard Vacuum Model 247.770550

Ref.

No.

2. 749-1423

3. 720-0279

4, 712-3004A

5. 710-1205

6. 781-1056

7. 710-0528

8. 720-0314

9. 710-1174

11. 710-0604A

12. 681-0174

13. 749-0907B

14. 711-1293

15. 710-0703

16. 712-0397

17, 751B282454

18. 725-1700

19. 725-3166

20. 731-1613

21. 710-0224

22. 629-0920

23. 714-0104

24. 736-0264

25. 732-0962

26. 781-0778A

27, 747-1153

28. 710-3195

29. 710-3025

Part No.

Part Description No.

Ref.

Upper Handle 30,

Knob 31.

Flange Lock Nut 5/16-18 32.

Eye Bolt 33,

Upper Handle Bracket 34.

Hex Cap Screw 5/16-18 x 1.25 35.

Handle Knob 5/16-18 36,

Carriage Bolt 37.

Hex Washer Screw 5/16-18 x,625 38.

Lower Handle Bracket 39.

Lower Handle 40,

Studs 41.

Carriage Screw 1/4-20 x.75 42.

Wing Nut 1/4-20 43.

Shroud 44.

Switch Cover 45.

Safety Switch 46.

Safety Switch Cover 47.

Hex Washer Screw #10-16 x.50 48.

Wire Harness 49.

Cotter Pin 50.

Flat Washer.330 ID x.630 OD 51.

Compression Spring 52.

Mounting Bracket 53.

Lock Rod 54.

Hex Cap Screw 5/16-18 x 4.5 55.

Hex Cap Screw 5/16-18 x.625 56.

Part No.

710.0502A

710-0751

;731-2484

716-0104

732-3035

711-1571

736-3020

710-0969

710-0425

781-1042

726-0454

710-3008

681-0122

738-1167

736-0371

781-1058

712-3027

748-0457

731-2478

710-3288

723-0295

749-1270

764-0648

07071

731-2292

736-0607

712-9161

Part Description

Hex Washer Screw 8/8-16 x t.25

Hex Cap Screw 1/4-20 x .620

Hose Base Adapter

E Ring .500 Dia

Compression Spring

Clevis Pin

Flat Washer _271 ID x .630 OD

Screw #12-16 x 1.0

Machine Screw #10 - 24 x ,625

Upper Housing

U-Clip Lock Nut 5/16-18

Hex Cap Screw 5/16-18 x.75

Chipper Chute Assembly

Stud 5/16-18 x .56

Flat Washer .343 ID x .860 OD

Hose Bracket Hanger

Hex Flange Nut 1/4-20

Spacer

Hose Nozzle

Hex Cap Screw 1/4-20 x 2.625

Adjustment Clamp

Nozzle Handle

Vacuum Hose

Handle Grip

Hose Adapter

External L-Washer 5/16

Hex Lock Nut #10 -24

NOTE: For painted parts, please refer to the list of color codes below. Please add the applicable color code, wherever needed,

to the part number to order a replacement part. For instance, if a part, numbered 700-xxxx, is painted polo green, the part num-

ber to order would be 700-xxxx-0689.

Polo Green: 0689

Oyster Grey: 0662

Powder Black: 0637

19

Page 20

Sears Craftsman 6.0 H.P. Yard Vacuum Model 247.770550

41 39

23

/

19

15

36

32_

45

46

49

53

44

51

54

20

Page 21

Sears Craftsman 6.0 H.P. Yard Vacuum Model 247.770550

Ref.

No,

1. 664-0094

2, 661-0154

3. 710-1054

4. 731-0490

5. 681-0152

6. 781-0735

7. 719-0329

8. 715-0166

9. 711-1401

10. 736-0247

11. 736-0217

12. 710-0818

13, 710-3038

14. 781-0721A

15. 712-3004A

16. 712-3027

17. 736-0142

18. 714-0225

19, 711-1560

20. 731-2294

21. 781-1064

22. 732-1156

23. 726-0106

24. 711-1551

25, 712-0161

26. 736-0400

27. 731-2485

28. 710-1156

29. 750-1294

30. 732-3118

31. 732-1151

Part No.

Part Description No. Part No.

Ref.

Bag Assembly 32, 732-1150

Screen Assembly 33. 731-2294

Hex Screw 5/16-24 x 1.0 34. 711-1582

Chipper Blade 35. 781-0725A

Impeller Assembly 36. 781-0777

Pin Clip 37. 681-0155

Flail Blade 661-0156

Spiral Pin 38. 714-0104

Clevis Pin 39. 710-3925

Flat Washer,375 ID x 1.25 OD 40. 736-0195

Lock Washer 3/8 41. 734-1992

Hex Cap Screw 3/8-24 x 2.0 42. 736-0232

Hex Cap Screw 5/16-18 x .875 43. 738-1015

Lower Housing 44, 731-0981A

Flange Lock Nut 5/16-18 45. 781-0785

Hex Flange Nut 1/4-20 46. 738-1185

Flat Washer .261 ID x .50 OD 47. 741-0751

Cotter Pin 48. 682-0113

Pivot Rod 49. 729-0426

Nozzle 50, 732-1026

Base Adapter Door 51, 736-0741

Torsion Spring 62. 738-1173

Cap Speed Nut 1/4 53. 734-1978

Pivot Rod 54. 712-0431

Hex Lock Nut #10-24 55. 726-0453

Flat Washer .194 ID x .62 OD 56. 712-0158

Nozzle Door Lever 57. 736-0314

Hex Screw #10-24 x 1,25 58. OEM-290-012

Shoulder Spacer 59. 764-0631

Extension Spring 60. 631-0383

Torsion Spring LH

Part Description

Torsion Spring RH

Nozzle Door

Rod .25 x 1.25 Lg

FrontWheel Support Brace

Rear Wheel Support Brace

Handle Bracket Ass"y LH

Handle Brkt Ass"y RH (Not Shown)

Cotter Pin

Hex Cap Screw 5/16-18 x,625

Bell Washer.401 ID x.870 OD

Wheel 9 x 2

Wave Washer .531 ID x ,781 OD

Shoulder Screw 3/8-16

Hubcap

Height Adjustment Bracket

Stud 5/16-18.56 x .75

Height Adjustment Bearing

Pivot Arm Assembly

Height Adjustment Knob

Spring Lever

Bell Washer .760 ID x .25 OD

Shoulder Screw .750 ID x .625 OD

Wheel 8 x 2

Flange Lock Nut 3/8-16

Lock Nut3/8-16

Hex Lock Nut 5/16-18

Thrust Washer .375 ID x .70 OD

Blower Chute (If Equipped)

Bag

Chute Assembly

NOTE: For painted parts, please refer to the list of color codes below. Please add the applicable color code, wherever needed,

to the part number to order a replacement part. For instance, if a part, numbered 700-xxxx, is painted polo green, the part num-

ber to order would be 700-xxxx-0689.

Polo Green: 0689

Oyster Grey: 0662

Powder Back: 0637

21

Loading...

Loading...