MTD 24A-020E762 Owner’s Manual

Safety • Assembly • Operation • Maintenance •Troubleshooting • Parts Lists •Warranty

OF A O AL

\

\

\

Chipper Shredder Vacuum - IVlodel Series 020

iMPORTANT

READ SAFETY RULES AND iNSTRUCTiONS CAREFULLY BEFORE OPERATION

Warning: Thisunitisequippedwithan internalcombustionengineandshouldnotbeusedonor nearanyunimprovedforest-covered,brush-

coveredor grass-coveredlandunlesstheengine'sexhaustsystemisequippedwitha sparkarrestermeetingapplicablelocalor statelaws(if any).

If a sparkarresterisused,itshouldbemaintainedineffectiveworkingorderbytheoperator.IntheStateofCaliforniatheaboveisrequiredbylaw

(Section4442oftheCaliforniaPublicResourcesCode).Otherstatesmayhavesimilarlaws.Federallawsapplyonfederallands.A sparkarrester

forthemufflerisavailablethroughyournearestengineauthorizedservicedealeror contacttheservicedepartment,RO.Box361131Cleveland,

Ohio44136-0019.

FORMNO.769-03188

PRINTEDIN U.S.A.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136=0019

5/30/2007

This Operator's IVlanual is an important part of your new chipper shredder vacuum, it will help you assem=

ble, prepare and maintain the unit for best performance. Please read and understand what it says.

Table of Contents

Customer Support .............................................. 2

Safety Labels ...................................................... 3

Safe Operation Practices ................................... 4

Setting UpYour Chipper Shredder Vacuum ..... 6

Operating Your Chipper Shredder Vacuum .... 10

Finding and Recording Model Number

BEFOREYOUSTARTASSEMBLING

YOURNEW EQUIPMENT,

pleaselocate themodel plateon the equipment and copy

the informationto the samplemodel plate providedto the

right.Youcan locatethe model plate by standing behindthe

unitand looking downat the frame belowthe engine.This

informationwill benecessary to usethe manufacturer'sweb

site and/or obtain assistancefrom the Customer Support

Departmentor an authorizedservice dealer.

Maintaining Your Chipper Shredder Vacuum. 14

Troubleshooting ................................................ 18

Parts List ........................................................... 20

Warranty ............................................................ 24

Espa_ol .............................................................. 25

Model Number

®

www.mtdproducts.com

Serial Number

MTD LLC

P.O. BOX 361131

CLEVELAND, OH 44136

330 =220 =4683

800=800=731 0

Customer Support

Please do NOTreturn the unit to the retailer from which it was

purchased, without first contacting Customer Support.

Ifyou havedifficulty assemblingthis productor haveany questionsregardingthe controls,operation,or maintenanceof this

unit,you can seek helpfrom the experts.Choosefrom the optionsbelow:

1. Visitmtdproducts.com. Clickonthe CustomerService tab.

2. Phonea Customer Support Representativeat 1.800.800.7310. Spanishspeakingagents are available.

3. Theengine manufacturer isresponsible for allengine-relatedissueswith regards to performance,power-rating,specifica-

tions,warrantyand service. Pleaserefer tothe enginemanufacturer'sOwner's/Operator'sManual, packedseparatelywith

your unit,for more information.

2

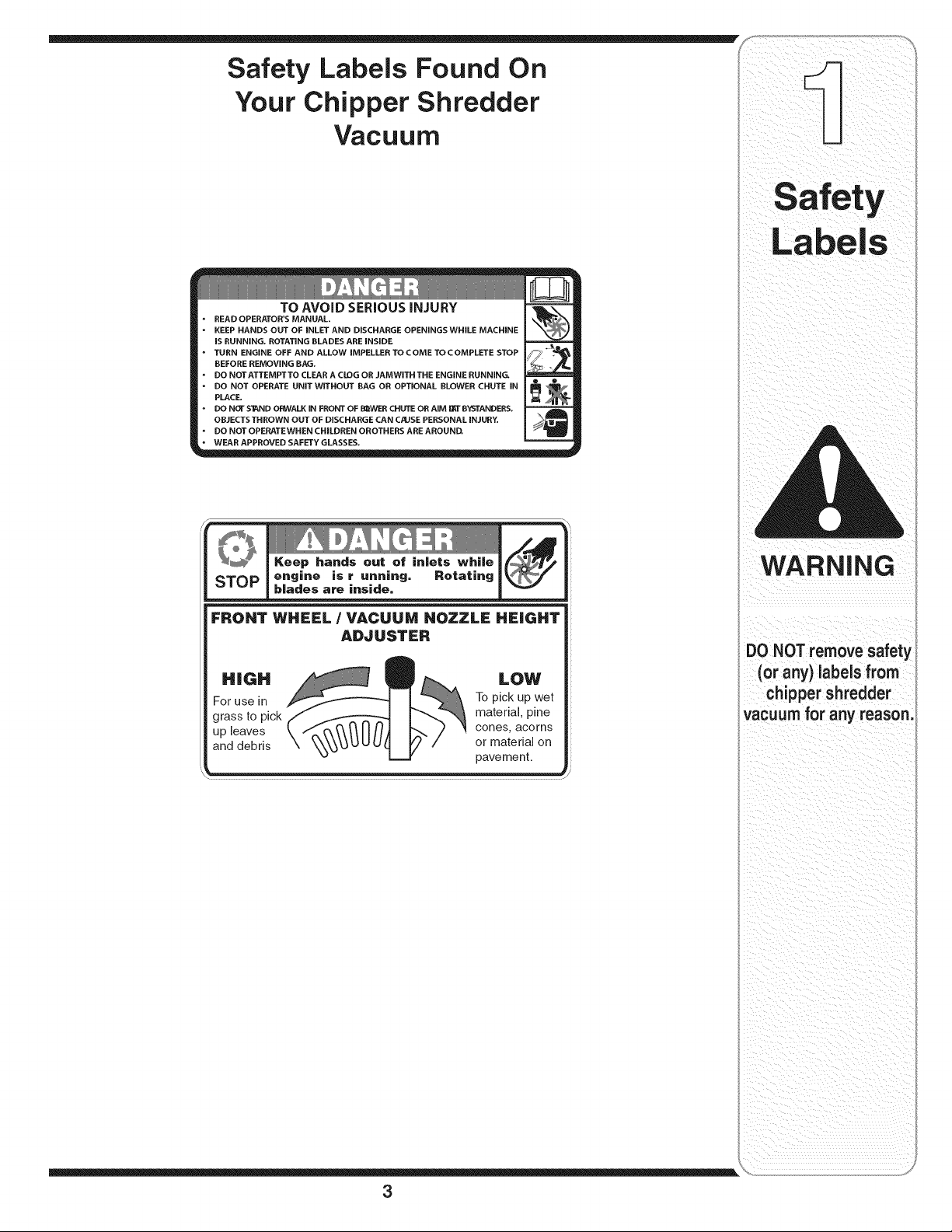

Safety Labels Found On

Your Chipper Shredder

Vacuum

READ OPERATOR'S MANUAL.

KEEP HANDS OUT OF iNLET AND DISCHARGE OPENINGS WHILE MACHINE

iS RUNNING. ROTATING BLADES ARE iNSiDE

TURN ENGINE OFF AND ALLOW iMPELLER TOCOME TO COMPLETE STOP

BEFORE REMOVING BAG.

DO NOT ATTEMPT TO CLEAR A CLOG OR JAMWITH THE ENGINE RUNNING.

DO NOT OPERATE UNiT WITHOUT BAG OR OPTIONAL RLOWER CHUTE iN

DO N(_" S'I_ND ORWALK IN FRONT OF IE_WER CHUTE OR AIM I[_T BYSTANDERS.

• PLACE.

OBJECTSTHROWN OUT OF DISCHARGE CAN CPJSE PERSONAL iNJURY, i _

I " DONOTOPERATEWHENCNILDRENOROTHERSAREAROUND.

• WEAR APPROVED SAFETYGLASSES.

TO AVOID SERIOUS iNJURY

FRONT WHEEL / VACUUM NOZZLE HEIGHT

ADJUSTER

HiGH LOW

For use in To pick up wet

grass to pick material, pine

up leaves cones, acorns

and debris or material on

pavement.

WARNING

DO NOT removesafety

(or any) labels from

chippershredder

vacuumfor any reason.

3

WARNING: EngineExhaust,some of its constituents, andcertain vehiclecompo-

nentscontain or emit chemicals knownto Stateof Californiato cause cancerand

birth defectsor other reproductiveharm.

DANGER: This machinewas builtto beoperated accordingto the rulesfor safeoperation in this

manual.As with anytype of powerequipment,carelessness or error on the part ofthe operator can

result inseriousinjury.This machine iscapable of amputatinghands andfeet andthrowing objects.

Failureto observethe followingsafetyinstructionscould resultinserious injuryor death.

WARNING

Thissymbolpoints

out importantsafety

instructionswhich,if

notfollowed,could

endangerthe personal

i safetyand/or property

I ofyourselfandothers.

Readandfollowall

instructionsinthis

manualbeforeat-

temptingto operate

i this machine.Failure

I to complywith these

instructionsmayresult

i in personalinjury.When

youseethis symbol.

i HEED ITS WARNING!

i Your Responsibility

Restrictthe use

ofthis powermachine

to personswho read.

i understand

andfollow thewarnings

and instructions

i inthis manual

and on the machine.

Training

1. Read,understand,and followall instructionsonthe ma- 1.

chineandin the manual(s)beforeattemptingtoassemble

andoperate.Keepthis manualina safe placefor future

andregularreferenceandfor orderingreplacementparts.

2. Befamiliarwith allcontrolsandtheir properoperation. 2.

Knowhowtostopthe machineanddisengagethem

quickly.

3. Neverallowchildrenunder 16yearsoldto operatethis

machine.Children16yearsoldandovershouldreadand 3.

understandthe operationinstructionsandsafetyrulesin

thismanualand shouldbetrainedandsupervisedbya

parent.

4. Neverallowadultstooperatethismachinewithoutproper

instruction. 4.

5. Keepbystanders,helpers,pets,and childrenat least

75feetfromthe machinewhile it isin operation.Stop

machineif anyoneentersthe area.

6. Neverrunan engineindoorsor in a poorlyventilatedarea. 5.

Engineexhaustcontainscarbon monoxide,anodorless

anddeadly gas. 6.

7. Do notputhands andfeet nearrotatingpartsorin the

feedingchambersanddischargeopening.Contactwith

the rotatingimpellercanamputatefingers,hands,and

feet.

8. Neverattemptto unclogeitherthefeed intakeordis-

chargeopening,removeor emptyvacuumbag,or inspect

andrepairthe machinewhilethe engineis running.Shut

theengineoffand waituntilall movingparts havecome

toa completestop.Disconnectthe sparkplugwireand

groundit againstthe engine.

Preparation

Thoroughlyinspecttheareawherethe equipmentisto

beused.Removeallrocks,bottles,cans,orotherforeign

objectswhichcouldbe pickedupor thrownandcause

personalinjuryor damageto themachine.

Alwayswearsafetyglassesorsafetygogglesduringopera-

tionor whileperforminganadjustmentor repair,to protect

eyes.Thrownobjectswhichricochetcancauseserious

injurytothe eyes.

Wearsturdy,rough-soledworkshoesand close-fitting

slacksandshirts. Loosefittingclothesorjewelrycan be

caughtinmovableparts.Neveroperatethis machine

in barefeet or sandals.Wearleatherworkgloveswhen

feedingmaterialin thechipperchute.

Beforestarting,checkallboltsandscrewsfor propertight-

nessto besurethe machineisin safeworkingcondition.

Also,visuallyinspectmachinefor anydamageatfrequent

intervals.

Maintainorreplacesafetyandinstructionslabels,as

necessary.

Toavoidpersonalinjuryor propertydamageuseextreme

careinhandlinggasoline.Gasolineisextremelyflammable

andthe vaporsareexplosive.Seriouspersonalinjurycan

occurwhengasolineis spilledonyourselforyourclothes

whichcanignite.Washyour skinandchangeclothes

immediately.

a. Useonlyanapprovedgasolinecontainer.

b. Extinguishallcigarettes,cigars, pipes,andother

sourcesofignition.

c. Neverfuelmachineindoors.

d. Neverremovegascap oradd fuelwhiletheengineis hot

or running.

e. Allowengineto coolat leasttwo minutesbeforerefuel-

ing.

f. Neveroverfillfueltank. Filltankto nomorethan1/2

inchbelowbottomoffiller neckto providespacefor fuel

expansion.

g. Replacegasolinecap andtightensecurely.

h. If gasolineis spilled,wipeitoff theengineandequip-

ment.Movemachinetoanotherarea.Wait5 minutes

beforestartingtheengine.

i. Neverstorethe machineorfuel containerinsidewhere

there is an openflame,spark,orpilotlight (e.g.furnace,

waterheater,spaceheater,clothesdryer,etc.).

j. Toreduceafire hazard,keepmachinefreeofgrass,

leaves,orotherdebrisbuild-up.Cleanupoilor fuel

spillageandremoveanyfuel soakeddebris.

k. Allowmachinetocoolat least5 minutesbeforestoring.

4

Operation

1. Donotputhandsandfeetnearrotatingpartsor in the

feedingchambersanddischargeopening.Contactwith the

rotatingimpellercanamputatefingers,hands,andfeet.

2. Beforestartingthe machine,makesurethechipperchute,

feedintake,andcuttingchamberare emptyandfreeofall

debris.

3. Thoroughlyinspectallmaterialto beshreddedandremove

any metal,rocks,bottles,cans,orotherforeignobjects

whichcouldcausepersonalinjuryordamageto the

machine.

4. Ifthe impellerstrikesa foreignobjector ifyour machine

shouldstart makinganunusualnoiseor vibration,

immediatelyshuttheengineoff.Allowthe impellertocome

to a completestop.Disconnectthesparkplugwire,ground

itagainstthe engineandperformthe followingsteps:

a. Inspectfordamage.

b. Repairorreplaceanydamagedparts.

c. Checkfor anyloosepartsand tightento assure

continuedsafeoperation.

5. Donotallow anaccumulationof processedmaterialtobuild

upinthedischargearea.Thiscan preventproperdischarge

andresult in kickbackofmaterialthroughthefeedopening.

6. Donotattemptto shredorchipmateriallargerthan

specifiedonthe machineor inthismanual.Personalinjury

or machinedamagecouldresult.

7. Neverattemptto unclogeitherthefeed intakeordischarge

openingwhilethe engineisrunning.Shuttheengineoff,

wait until all movingpartshavestopped,disconnectthe

sparkplugwireandgrounditagainsttheenginebefore

clearingdebris.

8. Neveroperatewithoutvacuumbagand dischargechute

properlyattachedto the machine.Neveremptyor change

vacuumbagwhilethe engineisrunning.Zipperedend

of vacuumbag mustbekeptclosedatalltimes during

operation.

9. Neveroperatewithouteitherthe inlet nozzleoroptional

hoseattachmentproperlyattachedto the machine.Never

attemptto attachorchangeeitherattachmentwhilethe

engineis running.

10.Keepall guards,deflectorsandsafetydevicesinplaceand

operatingproperly.

11.Keepyourface andbodybackand to theside ofthe chipper

chutewhilefeedingmaterialintothe machineto avoid

accidentalkickbackinjuries.

12.Neveroperatethis machinewithoutgoodvisibility or light.

Alwaysbe sure ofyourfootingand keepafirm holdonthe

handles.

13.Donotoperatethismachineon a gravelsurface.

14.Donotoperatethismachinewhile undertheinfluenceof

alcoholordrugs.

15.Mufflerandenginebecomehotandcan causea burn.Do

nottouch.

16.Neverpickupor carrymachinewhilethe engineis running.

Maintenance & Storage

1. Nevertamperwithsafetydevices.Checktheirproper

operationregularly.

2. Checkboltsand screwsfor propertightnessatfrequent

intervalstokeepthe machinein safeworkingcondition.

Also,visuallyinspectmachinefor anydamageand repair,

if needed.

3. Beforecleaning,repairing,or inspecting,stoptheengine

andmakecertaintheimpellerand all movingpartshave

stopped.Disconnectthesparkplugwire and groundit

againsttheengineto preventunintendedstarting.

4. Do notchangetheenginegovernorsettingsor overspeed

theengine.The governorcontrolsthemaximumsafe

operatingspeedoftheengine.

5. Maintainor replacesafetyandinstructionlabels,as

necessary.

6. Followthismanualforsafe loading,unloading,transport-

ing,andstorageofthis machine.

7. Neverstorethemachineorfuel containerinsidewhere

thereisan openflame,sparkor pilotlightsuchasa water

heater,furnace,clothesdryer,etc.

8. Alwaysreferto theoperator'smanualforproperinstruc-

tionsonoff-seasonstorage.

9. Ifthefueltank hasto be drained,do this outdoors.

10.Observeproperdisposallawsandregulationsfor gas,oil,

etc.toprotecttheenvironment.

Do not modify engine

Toavoidseriousinjuryordeath,donotmodifyengineinany

way.Tamperingwiththegovernorsettingcan leadto arunaway

engineandcauseit tooperateatunsafespeeds.Nevertamper

withfactorysettingofenginegovernor.

Notice regarding Emissions

Engineswhicharecertifiedto complywithCaliforniaand

federalEPAemissionregulationsforSORE(SmallOff Road

Equipment)arecertifiedto operateonregularunleadedgaso-

line,and mayincludethefollowingemissioncontrolsystems:

EngineModification(EM)andThreeWayCatalyst(TWO)ifso

equipped.

Your Responsibility

Restrictthe useofthispowermachineto personswhoread,

understandandfollowthe warningsandinstructionsinthis

manualandonthe machine.

Practices

WARNING

Thissymbol points

out importantsafety

instructions,which if

notfollowed,could

endangerthe personal

safety and/or property

of yourselfand others.

Readand followall

instructions inthis man-

ual beforeattemptingto

operatethis machine.

Failureto comply with

these instructionsmay

result inpersonalinjury.

Whenyou seethis

symbol.

HEED iT S WARNING!

Your Responsibility

Restrictthe use

of this power machine

to personswho read.

understand

and followthe warnings

and instructions

in this manua

and on the machine.

5

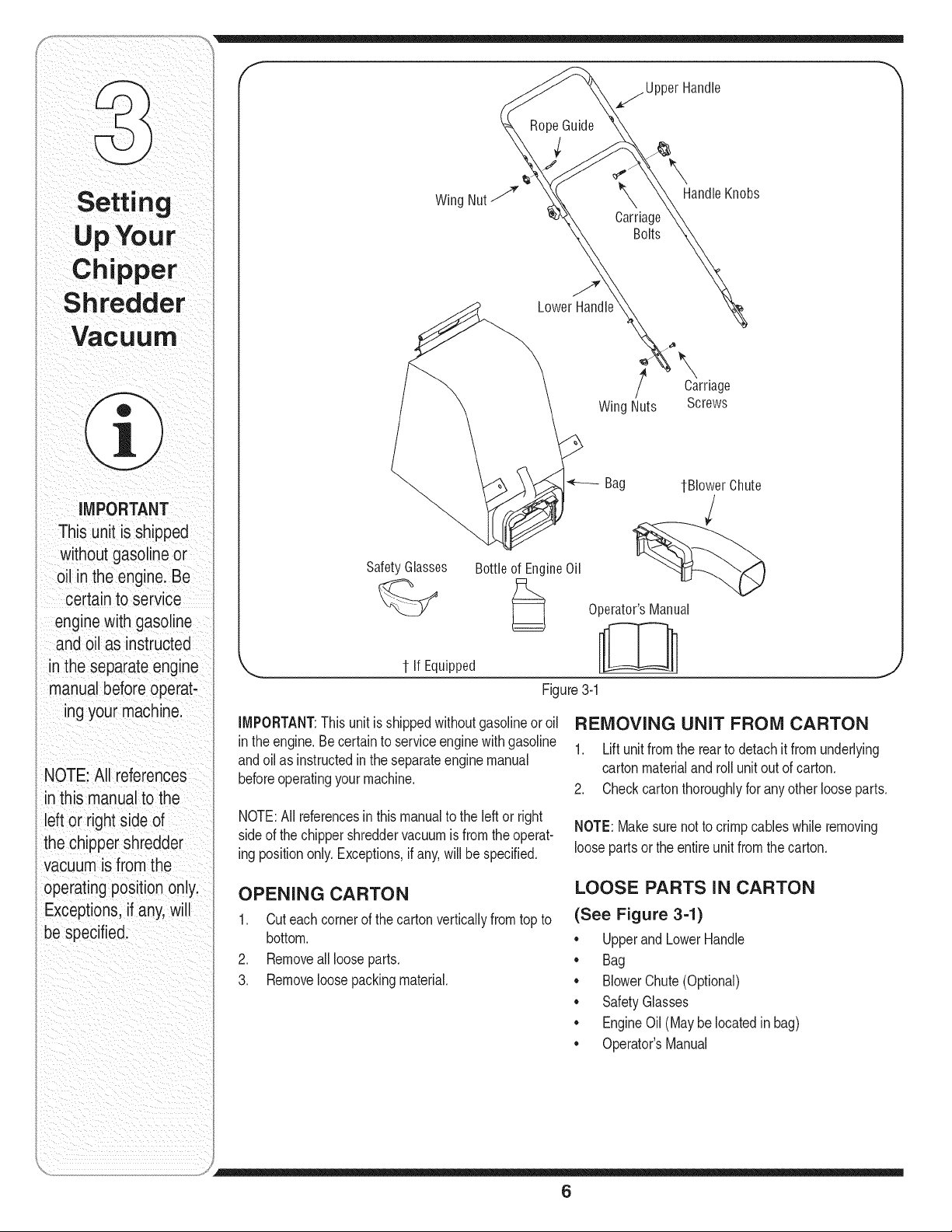

IMPORTANT

This unit is shipped

without gasoline or

oil in the engine.Be

certainto service

enginewith gasoline

and oil as instructed

inthe separateengine

manual beforeoperat-

ingyour machine.

NOTE:All references

in this manualto the

left or rightside of

thechipper shredder

vacuum isfrom the

operatingposition only.

Exceptions,if any,will

i be specified.

f

RopeGuide

WingNutJ

Lower Handle

SafetyGlasses Bottleof EngineOil

_'_ _ _ Operator'sManual

1-If Equipped Ih_ll

Figure3-1

IMPORTANT:Thisunitis shippedwithoutgasolineoroil

in theengine.Becertainto serviceenginewithgasoline

andoilas instructedintheseparateenginemanual

beforeoperatingyourmachine.

NOTE:Allreferencesinthismanualtotheleft or right

sideof thechippershreddervacuumisfromtheoperat-

ingpositiononly.Exceptions,ifany,willbe specified.

OPENING CARTON

1. Cuteachcornerofthecartonverticallyfromtopto

bottom.

2. Removealllooseparts.

3. Removeloosepackingmaterial.

,_j Upper Handle

J_

\

_X, HandleKnobs

Carriage

Bolts

/_ Carriage

WingNuts Screws

4F--_ Bag tBIower Chute

REMOVING UNIT FROM CARTON

1. Lift unitfromthe reartodetachitfromunderlying

cartonmaterialandrollunitoutofcarton.

2. Checkcartonthoroughlyforanyother looseparts.

NOTE:Makesure notto crimpcableswhileremoving

loosepartsortheentireunitfromthecarton.

LOOSE PARTS IN CARTON

(See Figure 3-1)

• UpperandLowerHandle

• Bag

• BlowerChute(Optional)

• SafetyGlasses

• EngineOil(Maybe locatedinbag)

• Operator'sManual

6

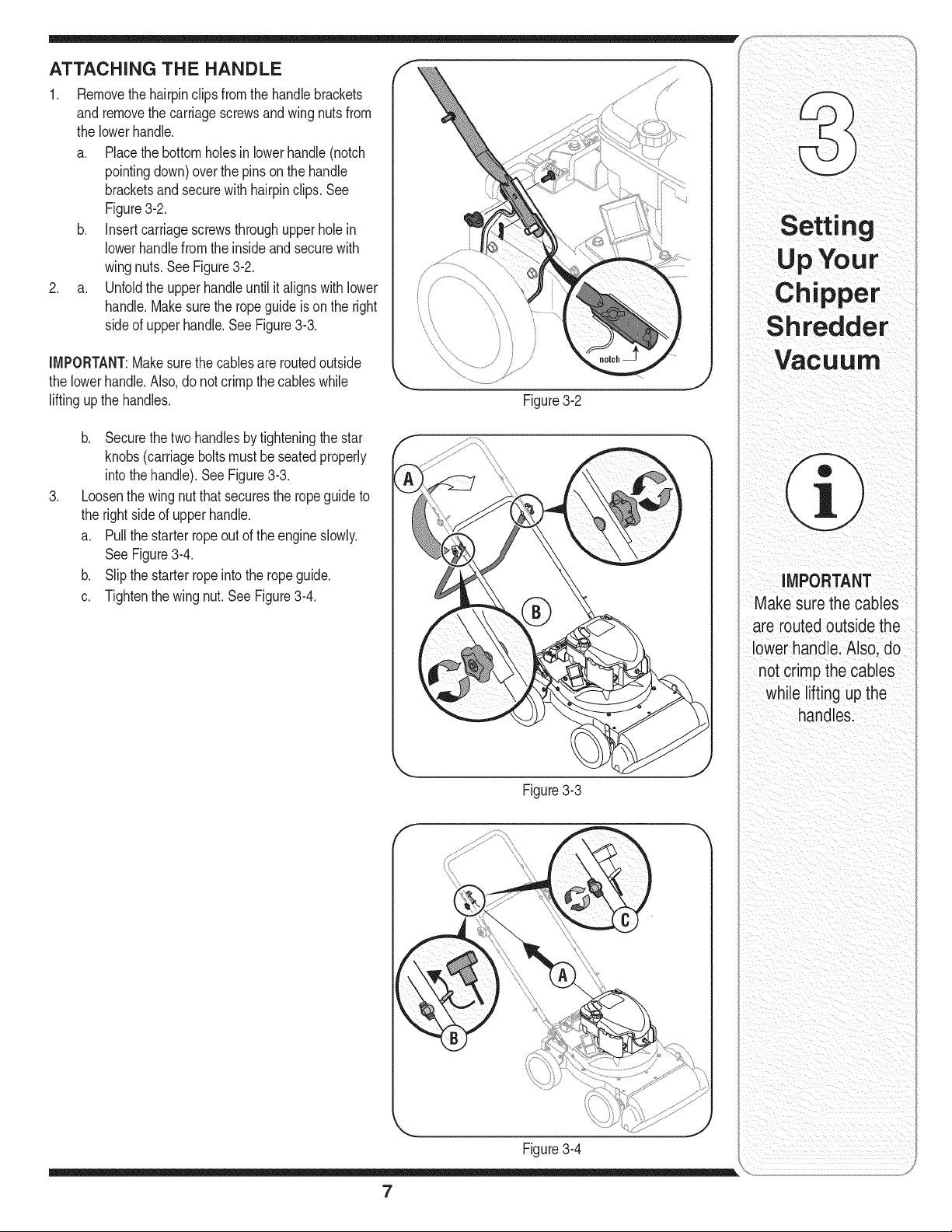

ATTACHING THE HANDLE

1. Removethe hairpinclipsfromthehandlebrackets

and removethecarriagescrewsandwingnutsfrom

thelowerhandle.

a. Placethebottomholesinlowerhandle(notch

pointingdown)overthepinsonthehandle

bracketsandsecurewithhairpinclips.See

Figure3-2.

b. insertcarriagescrewsthroughupperholein

lowerhandlefromtheinsideandsecurewith

wingnuts.SeeFigure3-2.

2. a. Unfoldthe upperhandleuntilitalignswithlower

handle.Makesuretheropeguideisonthe right

sideofupperhandle.SeeFigure3-3.

iMPORTANT:Makesurethe cablesare routedoutside

thelowerhandle.Also,donotcrimpthecableswhile

lifting upthehandles.

b. Securethetwohandlesbytighteningthe star

knobs(carriageboltsmustbeseatedproperly

intothehandle).SeeFigure3-3.

.

Loosenthewingnutthatsecuresthe ropeguideto

therightsideofupperhandle.

a. Pullthestarterropeout oftheengineslowly.

See Figure3-4.

b. Slipthestarterropeintothe ropeguide.

c. Tightenthe wingnut.See Figure3-4.

f

........

upyo,.,

Chipper

Shredder

\

Figure3-2

IMPORTANT

Makesure the cables

are routedoutsidethe

lowerhandle. Also do

not crimpthe cables

while lifting upthe

handles.

Figure3-3

Figure3-4

7

Up Your

f

_, ATTACHING THE BAG

1. Graspbaghandlewithonehandandslidelocking

rodonmountingbracketwithotherhandtoward

engine.Usethe endofmountingbracketas leverage

whenslidingthelockingrod.

2. Slipbagovertherimof thedischargeopeningand

releaselockingrodtosecurebaginplace.See

Figure3-5.

3. Snapbagcliptothe topof thelowerhandle.

4. Placelowerstrapsonthebagoverthetopof lower

handle,hookingthemonthe studs.SeeFigure3-6.

Chipper

Shredder

NOTE: The bag/chute

i switchbuttona_tachedto

themountingbracketmust

befullydepressedby the

i tipof fronttab ontheblower

chuteor enginewillnot

sta"t.

NOTE:Thebag/chuteswitchbuttonattachedtothe

mountingbracketmustbefullydepressedbythetip of

fronttabon baghandlewhensecuringthe bagor engine

willnotstart.

Figure3-6

8

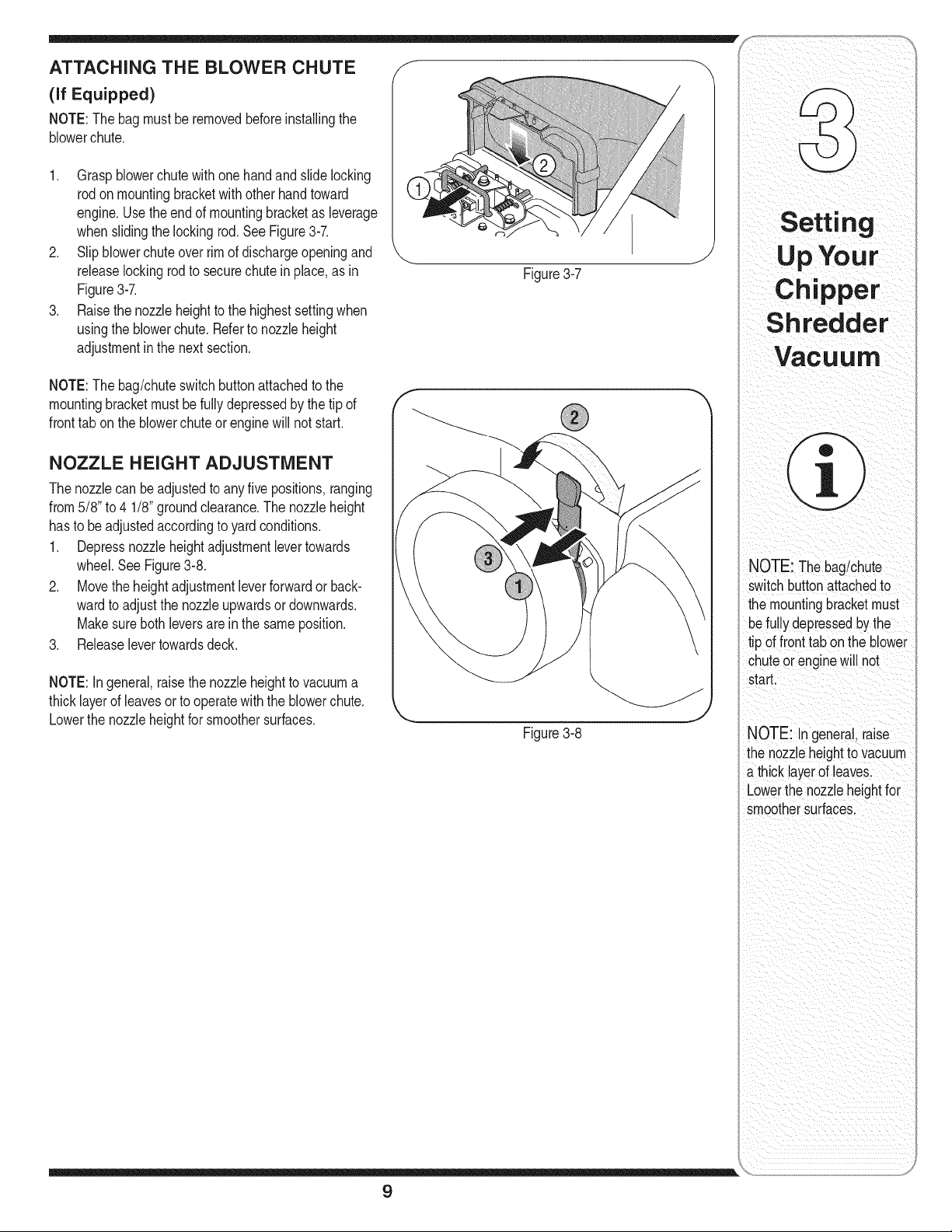

(if Equipped)

NOTE:The bagmustbe removedbeforeinstallingthe

blowerchute.

1. Graspblowerchutewithonehandandslidelocking

rodonmountingbracketwithotherhandtoward

engine.Usetheendof mountingbracketasleverage

whenslidingthelockingrod.SeeFigure3-7.

2. Slip blowerchuteoverrimof dischargeopeningand

releaselockingrodto securechutein place,asin

Figure3-7.

3. Raisethenozzleheighttothehighestsettingwhen

usingthe blowerchute.Referto nozzleheight

adjustmentin thenextsection.

NOTE:The bag/chuteswitchbuttonattachedtothe

mountingbracketmustbefullydepressedby thetip of

fronttabontheblowerchuteorenginewill notstart.

NOZZLE HEIGHT ADJUSTMENT

Thenozzlecanbeadjustedto anyfivepositions,ranging

from5/8"to 4 1/8"groundclearance.Thenozzleheight

hastobeadjustedaccordingto yardconditions.

1. Depressnozzleheightadjustmentlevertowards

wheel.SeeFigure3-8.

2. Movetheheightadjustmentleverforwardorback-

wardto adjustthenozzleupwardsor downwards.

Makesurebothleversareinthe sameposition.

3. Releaselevertowardsdeck.

NOTE:Ingeneral,raisethenozzleheighttovacuuma

thicklayerofleavesortooperatewiththe blowerchute.

Lowerthenozzleheightforsmoothersurfaces.

Figure3-7

Figure3-8

J

Chipper

Shredder

c

NOTE: The bag/chute

switchbuttonattachedto

the mountingbracketmust

uefullydepressedby the

tip of fronttabon theblower

chuteor enginewillnot

start.

NOTE: In general,raise

thenozzleheighttovacuum

athicklayerofleaves.

Lowerthenozzleheightfor

smoothersurfaces.

9

Know Your Chipper Shredder Vacuum

Bag

WARNING

i The operation of any

chipper shredder

vacuum can result

inforeign objects

being thrown into

the eyes, whichcan

damage your eyes

severely. Alwayswear

the safety glasses

providedwith this

unit or eye shields

while operating or

while performing

i any adjustments or

repairs.

Starter

Handle

Blower

Chutet

"_ Chipper

Chute

_" NozzleHeight

Adjustment Lever

tlf Equipped

Figure4-1

Nowthatyouhavesetupyouryardvacuumfor

operation,getacquaintedwithits controlsandfeatures.

Thesearedescribedbelowandillustratedonthis page.

Thisknowledgewillallowyoutouseyournewequip-

mentto itsfullestpotential.

_ WARNING:Theoperation of any

which candamageyour eyesseverely.Always wear

the safety glasses providedwith this unit or eye

shields whileoperating or while performingany

adjustments or repairs.

CHIPPER CHUTE

Allowstwigsandsmallbranchesupto 1-1/2"in diameter

tobefedinto theimpellerforchipping.SeeFigure4-1.

NOZZLE

Yardwastesuchas leavesor pineneedlescanbe

vacuumedupthroughthenozzleforshredding.

BAG

Collectsshreddedmaterialfedthroughthechipper

chuteor vacuumedthroughthe nozzle.

chipper shreddercanresultinforeign

objects being thrown intothe eyes,

J

BagHandle

Fill

GasolineFill

BLOWER CHUTE

(if Equipped)

Whenattachedtounit,theblowerchuteisusedto

dischargeyardwastesuchasleaves,pineneedle,or

smalltwigsacrossyard.

BAG HANDLE

Usedtograspbagin ordertoassistinattaching,remov-

ing,andemptyingbag.SeeFigure4-1.

NOZZLE HEIGHT ADJUSTMENT

LEVER

Usedtoadjustthenozzlegroundclearanceranging

approximatelyfrom5/8" to4 1/8".

STARTER HANDLE

Thestarterhandleisattachedtotherightupperhandle.

Standbehindunitandpullthe starterhandleto start

engine.SeeFigure4-1.

ENGINE CONTROLS

Seetheseparateenginemanualforthelocationand

functionofthecontrolsonthe engine.

10

,__ WARNING:Useextremecarewhenhan-

the engineis hotor running.Extinguishcigarettes,

cigars,pipes,andothersourcesof ignition.

dlinggasoline. Gasolineisextremely

flammableand the vaporsare explosive.

Neverfuel machineindoorsor while

GAS AND OiL FILL-UP

1. Checkoil levelandaddoil ifnecessary.Followengine

manualforthis.SeeFigure4-1for locationofthe oil

fill.

2. Servicethe enginewith gasolineasinstructedinthe

enginemanual.SeeFigure4-1forlocationofgas fill.

f

ChokeControl

_ WARNING:Neverfill fuel tank indoors

with enginerunningor until the engine

hasbeen allowed to coolfor at leasttwo

minutesafterrunning.

TO START ENGINE

IMPORTANT:Thebag/chuteswitchbuttonmustbefully

depressedbythetipoffronttabonbaghandleorblower

chuteforenginetostart.

1. Attachsparkplugwireand rubberbootto sparkplug.

2. Makesuresafetyswitchwireisconnectedtoengine

and properlygroundedto mountingbracket.

3. Engineswith chokelever:

Movechokeleveronengineto CHOKEposition.(A

warmenginemaynotrequirechoking).

Engineswithprimer:

Primeengineasinstructedinseparateenginemanual.

4. The throttlecontrolleverislocatedontheengine.

MoveenginethrottlecontrollevertoFASTor START

position.SeeFigure4-2.

5. Standingbehindthe unit,graspstarterhandleandpull

ropeoutslowlyuntilenginereachesstartofcompres-

sioncycle(ropewillpullslightlyharderatthis point).

See Figure4-3.

6. Pullropewitharapid,continuous,fullarmstroke.

Keepa firmgriponstarterhandle.Let roperewind

slowly.

7. Repeatthepreviousstepsuntilenginefires.When

enginestarts,movechokecontrol(ifequipped)

graduallyto RUNposition.

Figure4-2

Figure4-3

8. If enginefalters,movechokecontrolbacktowardthe

throttlecontrolandrepeatsteps5 through7.

9. ALWAYSkeepthe throttlecontrolinthe START/RUN

positionwhenoperatingtheYardVacuum.

__i= ARNING:Neverrun the engine

monoxide,anodorless and deadly gas.

indoorsor ina poorly ventilated area.

Engineexhaustcontainscarbon

WARNING

Useextreme care

when handling

gasoline.Gasoline is

extremely flammable

and the vapors are

explosive. Never fuel

machine indoors

or while the engine

is hot or running.

Extinguish cigarettes,

cigars, pipes, and

other sources of

ignition.

Never fill fuel tank

indoors with engine

running or until the

engine has been

allowed to cool for

at least two minutes

after running.

Never run the engine

indoors or ina poorly

ventilated area. En-

gine exhaust contains

carbon monoxide, an

odorless and deadly

gas.

11

Operating

WARNING

When movingthrottle

I control lever,be care-

i ful of heated surfaces

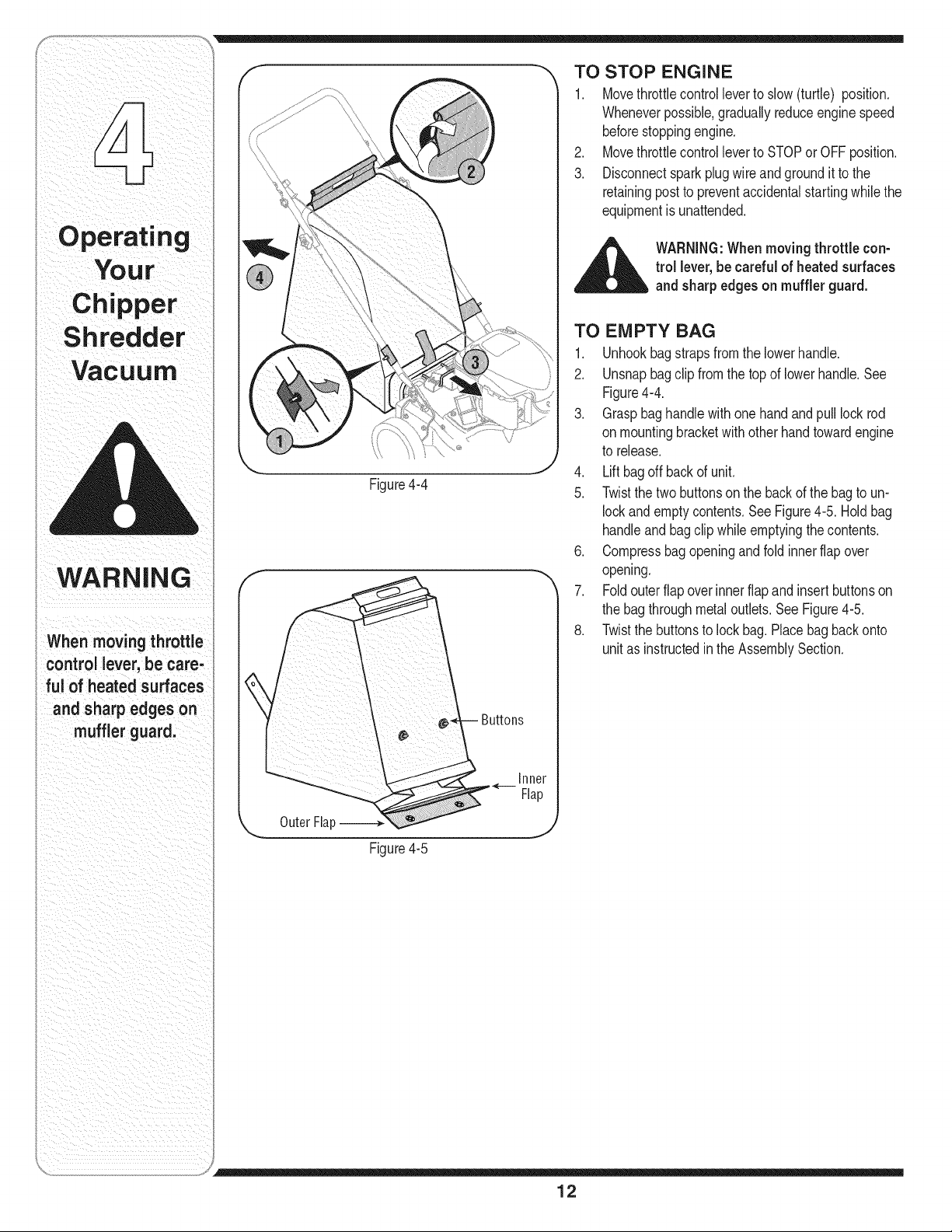

Figure4-4

TO STOP ENGINE

1. Movethrottlecontrollevertoslow(turtle) position.

Wheneverpossible,graduallyreduceenginespeed

beforestoppingengine.

2. MovethrottlecontrollevertoSTOPorOFFposition.

3. Disconnectsparkplugwireandgroundit to the

retainingpostto preventaccidentalstartingwhilethe

equipmentisunattended.

__k WARNING:Whenmoving throttle con-

trol lever,becarefulof heatedsurfaces

and sharpedgeson mufflerguard.

TO EMPTY BAG

1. Unhookbagstrapsfromthelowerhandle.

2. Unsnapbagclipfromthetop oflowerhandle.See

Figure4-4.

3. Graspbaghandlewithonehandandpulllockrod

onmountingbracketwithotherhandtowardengine

torelease.

4. Lift bagoff backofunit.

5. Twistthetwo buttonson thebackofthebagtoun-

lockandemptycontents.SeeFigure4-5.Hold bag

handleandbagclipwhileemptyingthecontents.

6. Compressbagopeningand foldinnerflapover

opening.

7. Foldouterflapoverinnerflap andinsertbuttonson

thebagthroughmetaloutlets.SeeFigure4-5.

8. Twistthebuttonstolockbag.Placebagbackonto

unitas instructedintheAssemblySection.

i and sharpedges on

muffler guard.

Buttons

Outer Fla

Figure4-5

12

TO REMOVE BLOWER CHUTE

(if Equipped)

1. Graspblowerchutewithonehandandpulllock rod

on mountingbracketwithother handtowardengine

to release.Referto Figure4-6.

2. Removeblowerchutefromovertherimofthe

dischargeopening.

Placebothhandson topof upperhandleto pushunitover

yardwaste.Yardwastesuchasleavesandpineneedles

canbevacuumedupthroughthe nozzlefor shredding.

Aftermaterialhasbeenshreddedbytheflail bladeson

theimpellerassembly,itwillbedischargedintocatcher

bagorthroughblowerchute.Donotattempttoshredor

chipanymaterialotherthanvegetationfoundina normal

yard(i.e.branches,leaves,twigs,etc.)Avoidfibrous

plantssuchastomatovinesuntiltheyarethoroughly

driedout.Materialssuchasstalksor heavybranchesup

to 1-1/2"in diametermaybefedintothe chipperchute.

0 perat ing

Figure4-6

__i= ARNING:Donot attempt to shred,

manual. Personalinjuryor damageto the machine

couldresult.

IMPORTANT:Theflailscreenislocatedinsidethe

housinginthe dischargearea.Iftheflail screenbecomes

clogged,removeandcleanasinstructedintheMainte-

nancesection.Forbestperformance,it isalso important

to keepthechipperbladesharp.

__i= WARNING:Donot at anytime make

chip,or vacuumany materiallarger

thanspecifiedon the machineor inthis

anyadjustments without first stopping

engineand disconnecting sparkplug

wire.

Do not attempt

to shred,chip, or

vacuum any material

larger than specified

on the machine or in

this manual. Personal

injury or damageto

the machine could

result.

Do notat any time

makeany adjust-

ments withoutfirst

stoppingengine and

disconnecting spark

plugwire.

13

WARNING

I Alwaysstop engine,

disconnectspark

plug, and ground

} against engine before

i cleaning, lubricating

} or doing any kind of

i maintenance onyour

machine.

A_. WARNING:Alwaysstop engine, LUBRiCATiON

disconnect sparkplug, and ground

against enginebeforecleaning, (rearwheel)andpivotarmaxle(frontwheel)oncea

lubricating or doing any kindof

maintenanceonyourmachine.

GENERAL RECOMMENDATIONS

• Alwaysobservesafetyruleswhenperforming

anymaintenance.

• Thewarrantyon thisyardvacuumdoesnotcover

itemsthathavebeensubjectedtooperatorabuse

ornegligence.Toreceivefullvaluefromwarranty,

operatormustmaintaintheequipmentas

instructedhere.

• Someadjustmentswill havetobe madeperiodi-

callytomaintainyourunitproperly.

• Periodicallycheckallfastenersand makesure

thesearetight.

• Wheels:Lubricateeachwheelshoulderscrew

seasonwithlightoil.

• Nozzleheight adjustment levers:Lubricatethe

pivotpointsofthenozzleheightadjustmentlevers

oncea seasonwithlightoil.

• Locking Rod: Lubricatethe lockingrodwith lightoil

toeasetheapplicationofattachingonor removing

bag.

• Engine: Followtheseparateenginemanualpacked

withyourunitforlubricationinstructions.

EQUIPMENT CARE

• CleantheYardVacuumthoroughlyaftereachuse.

• Washbagperiodicallywithwater.Allowtodry

thoroughlyinshade.

• If the flailscreenbecomesclogged,removeand

cleanas instructedbelow.

NOTE:Cleaningwithaforcefulsprayofwaterisnot

recommendedasitcould contaminatethefuelsystem.

ENGINE CARE

RefertotheMaintenancesectionofthe EngineOwner/

Operatormanualpackedwithyourunit. Readandfollow

instructionscarefully.

• Checkengineoil levelbeforeeachuseas

instructedin theseparateenginemanual.

Cleanor replaceair cleanerevery25 hoursunder

normalconditions.Cleaneveryfewhoursunder

extremelydustyconditions.Toservicetheair

cleaner,refertotheseparateenginemanual.

• Thesparkplug shouldbe cleanedandthegap

resetoncea season.Refertotheseparateengine

manualforcorrectplugtypeandgapspecifications.

• Cleanengineregularlywitha clothorbrush.Keep

areaaroundenginecleantopermitproperair

circulation.Removeall grass,dirtandcombustible

debrisfrommufflerarea.

14

Loading...

Loading...