Page 1

OPERATOR’S MANUAL

Chipper Shredder

Vacuum

Model Number

24A-020D000

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 368022 Cleveland, Ohio 44136-9722.

MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A.

FORM NO.

770-10535B.fm

(8/01)

Page 2

TABLE OF CONTENTS

Content Page

Important Safe Operation Practices...................................................................3

Assembling Your Chipper Shredder Vacuum ....................................................5

Know Your Chipper Shredder Vacuum..............................................................7

Operating Your Chipper Shredder Vacuum .......................................................8

Maintaining Your Chipper Shredder Vacuum.....................................................9

Troubleshooting.................................................................................................12

Parts List............................................................................................................14

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new chipper shredder vacuum. It will help you

assemble, prepare and maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the

equipment and copy the information from it in the space provided below. The information on

the model plate is very important if you need help from our Customer Support Department or

an authorized dealer.

• You can locate the model number by looking down at the rear of the chipper shredder vacuum. A

sample model plate is explained below. For future reference, please copy the model number and the

serial number of the equipment in the space below.

(Model Number)

MTD PRODUCTS INC

CLEVELAND, OHIO 44136

(Serial Number)

Copy the model number here:

Copy the serial number here:

CALLING CUSTOMER SUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, please call the Customer Support Department.

Call 1- (330) 220-4MTD (4683) or 1- (800)-800-7310 to reach a Customer Support

representative. Please have your unit’s model number and serial number ready when you

call. See previous section to locate this information. You will be asked to enter the serial

number in order to process your call.

For more details about your unit, visit our website at www.mtdproducts.com

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could

endanger the personal safety and/or property of yourself and others. Read and follow all instructions in

this manual before attempting to operate this machine. Failure to comply with these instructions may

result in personal injury. When you see this symbol - heed its warning.

WARNING: Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to State of California to cause cancer

and birth defects or other reproductiv e harm.

DANGER

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

: This machine was built to be operated according to the rules for safe operation in this

TRAINING

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe

place for future and regular reference and for

ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 16 years old to operate

this machine. Children 16 years old and over

should read and understand the operation

instructions and safety rules in this manual and

should be trained and supervised by a parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Keep bystanders, helpers, pets, and children at

least 75 feet from the machine while it is in

operation. Stop machine if anyone enters the area.

6. Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

7. Do not put hands and feet near rotating parts or in

the feeding chambers and discharge opening.

Contact with the rotating impeller can amputate

fingers, hands, and feet.

8. Never attempt to unclog either the feed intake or

discharge opening, remove or empty vacuum bag,

or inspect and repair the machine while the engine

is running. Shut the engine off and wait until all

moving parts have come to a complete stop.

Disconnect the spark plug wire and ground it

against the engine.

PREPARA TION

1. Thoroughly inspect the area where the equipment

is to be used. Remove all rocks, bottles, cans, or

other foreign objects which could be picked up or

thrown and cause personal injury or damage to the

machine.

2. Always wear safety glasses or safety goggles

during operation or while performing an adjustment

or repair, to protect eyes. Thrown objects which

ricochet can cause serious injury to the eyes.

3. Wear sturdy, rough-soled work shoes and closefitting slacks and shirts. Loose fitting clothes or

jewelry can be caught in movable parts. Never

operate this machine in bare feet or sandals. Wear

leather work gloves when feeding material in the

chipper chute.

4. Before starting, check all bolts and screws for

proper tightness to be sure the machine is in safe

working condition. Also, visually inspect machine

for any damage at frequent intervals.

5. Maintain or replace safety and instructions labels,

as necessary.

6. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and

other source s of i gnitio n.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes

before refueling.

f. Never over fill fuel tank. Fill tank to no more

than 1/2 inch below bottom of filler neck to

provide space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine

and equipment. Move machine to another

area. Wait 5 minutes before starting the

engine.

3

Page 4

i. Never store the machine or fuel container

inside where there is an open flame, spark,

or pilot light (e.g. furnace, water heater,

space heater, clothes dryer, etc.)

j. To reduce a fire hazard, keep machine free

of grass, leaves, or other debris build-up.

Clean up oil or fuel spillage and remove any

fuel soaked debris.

k. Allow machine to cool at least 5 minutes

before storing.

OPERATION

1. Do not put hands and feet near rotating parts or in

the feeding chambers and discharge opening.

Contact with the rotating impeller can amputate

fingers, hands, and feet.

2. Before starting the machine, make sure the chipper

chute, feed intake, and cutting chamber are empty

and free of all debris.

3. Thoroughly inspect all material to be shredded and

remove any metal, rocks, bottles, cans, or other

foreign objects which could cause personal injury

or damage to the machine.

4. If the impeller s trik es a fo reig n obj ect or if yo ur

machine should start making an unusual noise or

vibration, immediately shut the engine off. Allow the

impeller to come to a complete stop. Disconnect

the spark plug wire, ground it against the engine

and perform the following steps:

a. Inspect for damage.

b. Repair or replace any damaged parts.

c. Check for any loose parts and tighten to

assure continued safe operation.

5. Do not allow an accumulation of processed

material to build up in the discharge area. This can

prevent proper discharge and result in kickback of

material through the feed opening.

6. Do not attempt to shred or chip material larger than

specified on the machine or in this manual.

Personal injury or machine damage could result.

7. Never attempt to unclog either the feed intake or

discharge opening while the engine is running.

Shut the engine off, wait until all moving parts have

stopped, disconnect the spark plug wire and

ground it against the engine before clearing debris.

8. Never operate without vacuum bag and discharge

chute properly attached to the machine. Never

empty or change vacuum bag while the engine is

running. Zippered end of vacuum bag must be kept

closed at all times during operation.

9. Never operate without either the inlet nozzle or

optional hose attachment properly attached to the

machine. Never attempt to attach or change either

attachment while the engine is running.

10. Keep all guards, deflectors and safety devices in

place and operating properly.

11. Keep your face and body back and to the side of

the chipper chute while feeding material into the

machine to avoi d acci dent al kick back i njur ies.

12. Never operate this machine without good visibility

or light. Always be sure of your footing and keep a

firm hold on the handles.

13. Do not operate this machine on a gravel surface.

14. Do not operate this machine while under the

influence of alcohol or drugs.

15. Muffler and engine become hot and can cause a

burn. Do not touch.

16. Never pick up or carry machine while the engine is

running.

MAINTENANCE AND STORAGE

1. Never tamper with safety devices. Check t heir

proper operation regularly.

2. Check bolts and screws for proper tightness at

frequent intervals to keep the machine in safe

working condition. Also, visually inspect machine

for any damage and repair, if needed.

3. Before cleaning, repairing, or inspecting, stop the

engine and make certain the impeller and all

moving parts have stopped. Disconnect the spark

plug wire and ground it against the engine to

prevent unintended starting.

4. Do not change the engine governor settings or

overspeed the engine. The governor controls the

maximum safe operating speed of the engine.

5. Maintain or replace safety and instruction labels, as

necessary.

6. Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

7. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

such as a water heater, furnace, clothes dryer, etc.

8. Always refer to the operator’s manual for proper

instructions on off-season storage.

9. If the fuel tank has to be drained, do this outdoors.

10. Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

4

Page 5

WARNING - YOUR RESPONSIBILITY: Restrict the use of th is power mac hine to p ersons wh o read,

understand and fo llow th e warnings and ins tructions in this manual a nd on the mach ine.

NOTE: Not all safety labels shown may apply to your chipper shredder vacuum.

SECTION 2: ASSEMBLING YOUR CHIPPER SHREDDER VACUUM

IMPORT ANT :

in the engine. Be certain to service engine with gasoline

and oil as instructed in the separate engine manual

before operating your machine.

NOTE: Reference to right or left hand side of the

chipper shredder vacuum is observed from the

operating position.

This unit is shipped without gasoline or oil

Removing Unit From Carton

• Remove staples, break glue on top flaps, or cut

tape at carton end and peel along top flap to open

carton.

• Remove loose parts if included with unit (i.e.,

operator’s manual, etc.)

• Cut along corners, lay carton down flat, and remove

packing material.

• Roll or slide unit out of carton and check carton

thoroughly for loose parts.

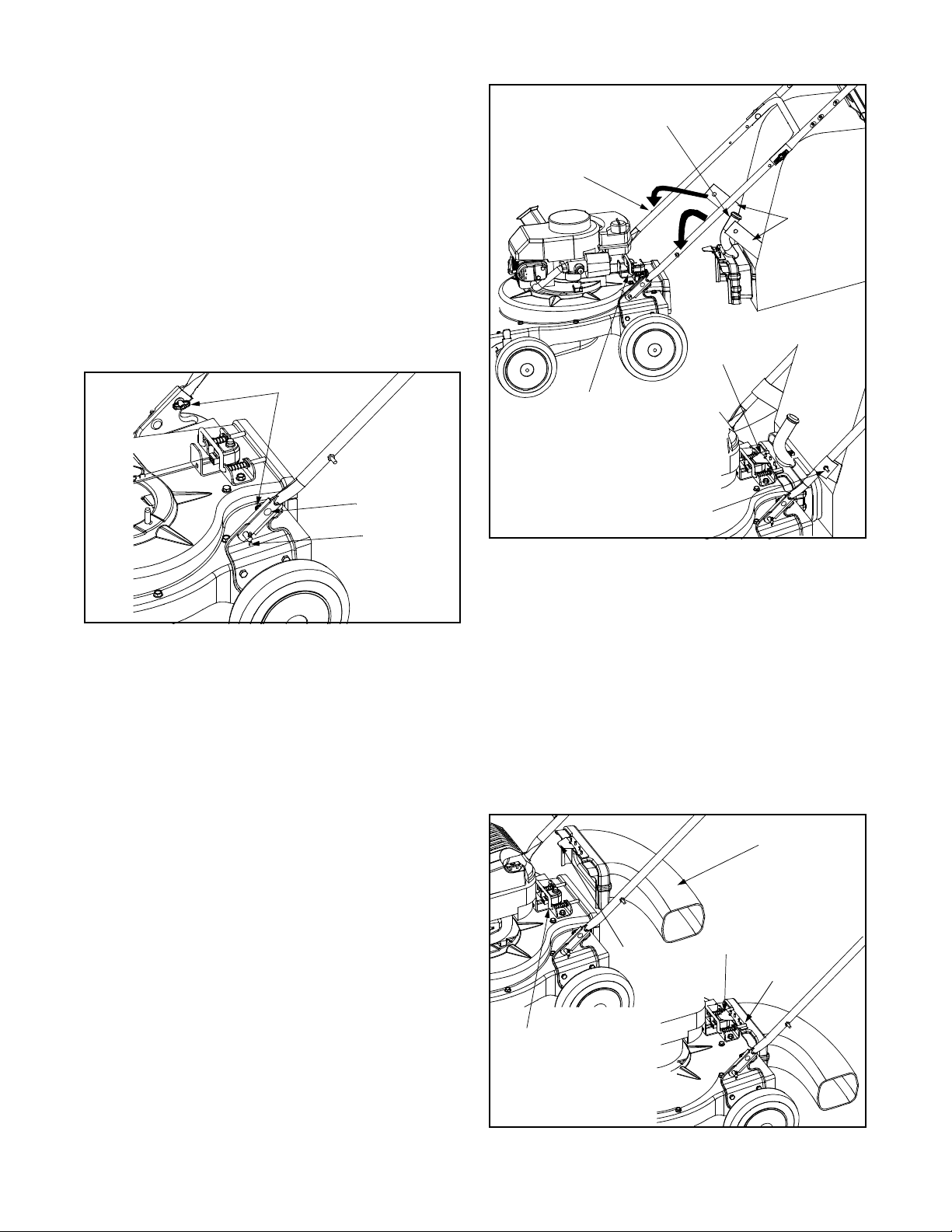

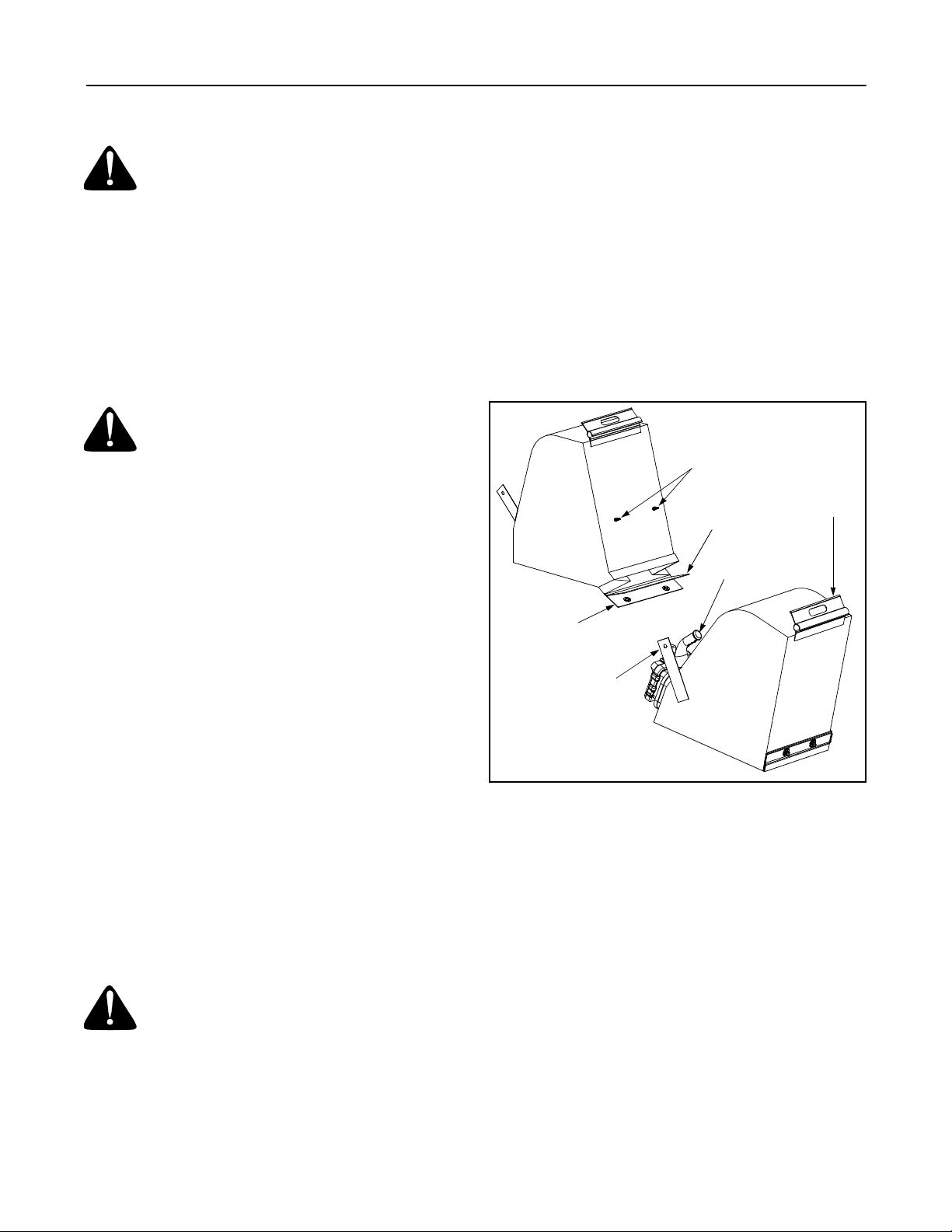

Loose Parts In Carton (See Figure 1)

• Handle Assembly

• Bag

• Blower Chute (If Equipped)

Upper

Handle

Blower Chute

Wing

Nuts

Bag

Lower

Handle

Disconnecting Spark Pl ug Wire

Before setting up your chipper shredder vacuum,

disconnect the spark plug wire from the spark plug and

ground to a stud on the engine.

Wing

Nuts

Carriage

Screw

Figure 1

5

Page 6

Attaching The Handle

• Unfold the upper handle until it aligns with the lower

handle.

• Secure the two handles by tightening the wing nuts

(carriage bolts must be seated properly into the

handle). See Figure 1.

• Remove the hairpin clips from the handle brackets

on the chipper shredder vacuum and remove the

carriage bolts and wing nuts from the lower handle.

See Figure 2.

• Place each bottom hole in lower handle over pins

on handle brackets and secure with hairpin clips.

• Insert carriage bolts thru upper hole in lower handle

from the outside and secure with wing nuts.

Bag Handle

Stud

Straps

Front Tab

Wing Nuts

Carriage Bolt

Hairpin Clip

Figure 2

Attaching The Bag

• Grasp bag handle with one hand and slide locking

rod on mounting bracket with other hand toward

engine. Use the end of mounting bracket as

leverage when sliding the locking rod.

See Figure 3.

• Slip bag over the rim of the discharge opening and

release locking rod to secure bag in place.

• Place the straps on the bag over the lower handle,

hooking them on the studs.

• Snap bag clip to the top of the lower handle.

Locking Rod

Stud

Figure 3

Attaching The Blower Chute (If E quippe d)

• Grasp blower chute with one hand and slide locking

rod on mounting bracket with other hand toward

engine. Use the end of mounting bracket as

leverage when sliding the locking rod. See Figure 4.

• Slip blower chute over rim of the discharge opening

and release locking rod to secure chute in place.

Make sure the safety switch button is fully

depressed by the front tab on the blower chute.

• Raise the nozzle height to the highest setting when

using the blower chute. Refer to nozzle height

adjustment in the OPERATION section.

Blower

Chute

NOTE: The safety switch button attached to the

mounting bracket mu st be fully dep ressed by the fr ont

tab on the bag handle when securing the bag or the

engine will not start.

6

Locking

Rod

Front

Tab

Figure 4

Front

Tab

Locking

Rod

Page 7

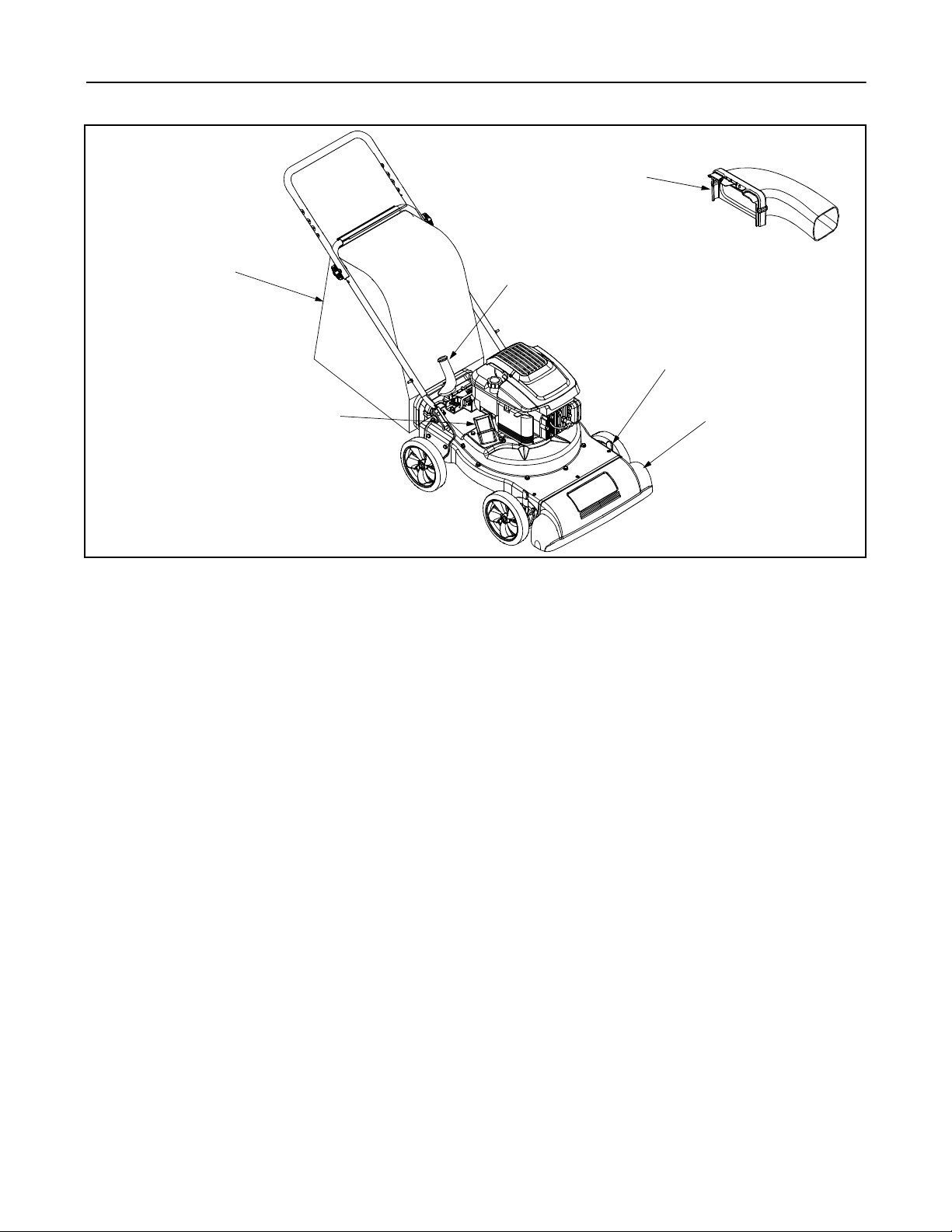

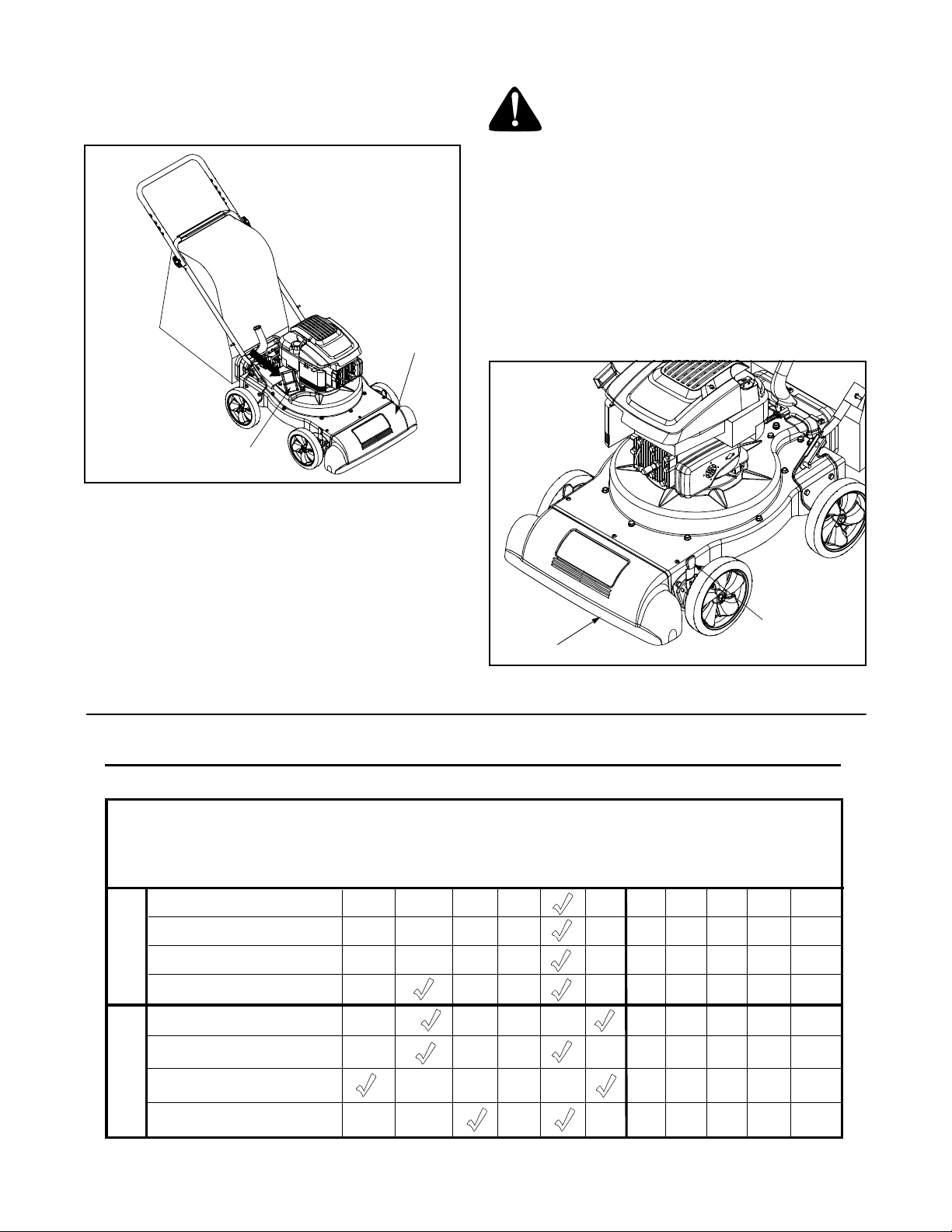

SECTION 3: KNOW YOUR CHIPPER SHREDDER VACUUM

Blower Chute

Bag

Chipper

Chute

Figure 5

Read this operator’s manual and safety rules before

operating your chipper shredder vacuum. Compare the

illustrations in Figure 5 with your unit to familiarize

yourself with the location of various controls and

adjustments. Save this manual for future reference.

Bag

Collects shredded material fed through the chipper

chute or vacuumed through the nozzle. See Figure 5.

Bag Handle

Used to grasp bag in order to assist in attaching,

removing, and emptying bag. See Figure 5.

Chipper Chute

Allow twigs and small branches up to 1 1/2” in diameter

to be fed into the impeller for chipping. See Figure 5.

Blower Chute (If Equipped)

When attached to unit the blower chute is used to blow

or scatter yard waste such as leaves, pine needles, or

small twigs across yard. See Figure 5.

Nozzle Height Adjustment Lever

Used to adjust the nozzle ground clearance ranging

approximately 5/8” to 4 1/8”.

Bag Handle

Nozzle Height

Adjustment Lever

Nozzle

Nozzle

Yard waste such as leaves and pine needles can be

vacuumed up through the nozzle for shredding.

Starter Handle (Not Shown)

The starter handle is attached to the right upper handle.

Stand behind unit and pull the starter handle to start

engine. Se e Figur e 5.

Throttle Control Lever (Not Shown)

The throttle control lever is located on the engine. It

controls the engine’s speed and stops the engine. See

separate engine manual packed with unit for details.

Engine Controls

See the separate engine manual for the location and

function of the controls on the engine.

Stopping Engine

• Move throttle control lever to STOP or OFF

position.

• Disconnect spark plug wire from spark plug and

ground against the engine.

7

Page 8

SECTION 4: OPERATING YOUR CHIPPER SHREDDER VACUUM

WARNING: The operation of any chipper

shredder vacuum can result in foreign

objects being throw n into th e eyes, which

can damage your eyes severely. Always

wear the safety glasse s provided with this

unit or eye shields before chipping or

blowing and while performing any

adjustments or repairs.

Gas And Oil Fill-Up

Service the engine with gasoline and oil as instructed in

the separate engine manual packed with your chipper

shredder vacuum. Read instructions carefully.

WARNING: Never fill fuel tank indoors with

engine running or until the engine has

been allowed to cool for at least two

minutes after running.

Starting Engine

• Attach spark plug wire to spark plug. Make certain

the metal cap on the end of the spark plug is

fastened securely over the metal tip on the spark

plug.

• Make sure safety swi tch wire is conne cted to

engine and properly grounded.

• Engines with choke lever:

Move choke lever on engine to CHOKE position. (A

warm engine may not require choking).

Engines with primer:

Prime engine as instructed in separate engine

manual.

• The throttle control is located on the engine. Move

engine throttle control lever to FAST or ON position.

• Stand behind unit, grasp starter handle and pull

rope out slowly until engine reaches start of

compression cycle (rope will pull slightly harder at

this poin t).

• Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on starter handle. Let rope rewind

slowly.

• Repeat previous steps until engine fires. When

engine starts, move choke control (if equipped)

gradually to RUN position.

WARNING: Never run the engine indoors

or in a poorly ventilated area. Engine

exhaust contains carbon monoxide, an

odorless and deadly gas.

To Empty Bag

• Unhook bag straps from the lower handle and

unsnap bag clip from the top of lower handle.

See Figure 6.

• Grasp bag handle with one hand and pull lock rod

on mounting bracket with other hand toward engine

to release.

• Remove bag from rim of the discharge opening.

Refer to Figure 3.

• Twist the two buttons on the back of the bag to

unlock and empty contents. See Figure 6.

• Hold bag handle and bag clip while emptying the

contents.

• Compress bag opening and fold inner flap over

opening.

• Fold outer flap over inner flap and insert buttons on

the bag through metal outlets.

• Twist the buttons to lock bag.

Buttons

Bag Clip

Inner Flap

Bag Handle

Outer Flap

Strap

Figure 6

To Remove Blower Chute (If Equipped)

• Grasp blower chute with one hand and pull lock rod

on mounting bracket with other hand toward engine

to release. Refer to Figure 4.

• Remove blower chute from rim of the discharge

opening.

Using the Chipper Shre dder Vac uum

Place both hands on top of upper handle to push unit

over yard waste. Yard waste such as leaves and pine

needles can be vacuumed up through the nozzle for

shredding. After material has been shredded by the flail

blades on the impeller assembly, it will be discharged

into catcher bag or through blower chute. Do not

attempt to sh red or chi p any materia l other than

vegetation found in a normal yard (i.e. branches,

leaves, twigs, etc.) Avoid fibrous plants such as tomato

8

Page 9

vines until they are thoroughly dried out. Materials such

as stalks or heavy branches up to 1 1/2” in diameter

may be fed into the chipper chute. See Figure 7.

Nozzle

Chipper

Chute

Figure 7

IMPORT ANT :

The flail screen is located inside the

housing in the discharge area. If the flail screen

becomes clogged, remove and clean as instructed in

SECTION 5: MAINTAINING YOUR CHIPPER

SHREDDER VACUUM. For best performance, it is also

important to keep the chipper blade sharp.

WARNING: Do not at any time make any

adjustments without first stopping engine

and disconnecting spark plug wire.

Nozzle Height Adjustment

The nozzle can be adjusted to any five positions,

ranging from 5/8” to 4 1/8” ground clearance. The

nozzle height has to be adjusted according to the

conditions. Move the height adjustment levers forward

or backward to adjust the nozzle upwards or

downwards. See Figure 8.

NOTE: In general, r ai se th e nozzle height to v acuum a

thick layer of leaves or to operate with the blower chute

and lower the nozzle height for smoother surfaces.

Nozzle Height

Nozzle

Adjustment

Lever

Figure 8

SECTION 5: MAINTAINING YOUR CHIPPER SHREDDER VACUUM

Customer Responsibilities

s

s

r

r

u

o

h

0

0

1

y

r

e

O

n

e

o

g

s

a

r

a

o

e

t

s

s

a

e

r

e

o

f

c

e

n

B

SERVICE

DATES

MAINTENANCE

SCHEDULE

Lubricate Wheels

T

C

Lubricate Nozzle Levers

U

D

O

Lubricate Locking Rod

R

P

Check Chipper Blade

Change Oil

E

Check Air Filter

N

I

G

N

Clean Engine

E

Check Spark Plug

e

s

u

h

c

a

e

e

r

o

f

e

B

E

s

r

u

o

h

5

2

y

r

e

v

u

o

h

0

5

y

r

e

v

v

E

E

9

Page 10

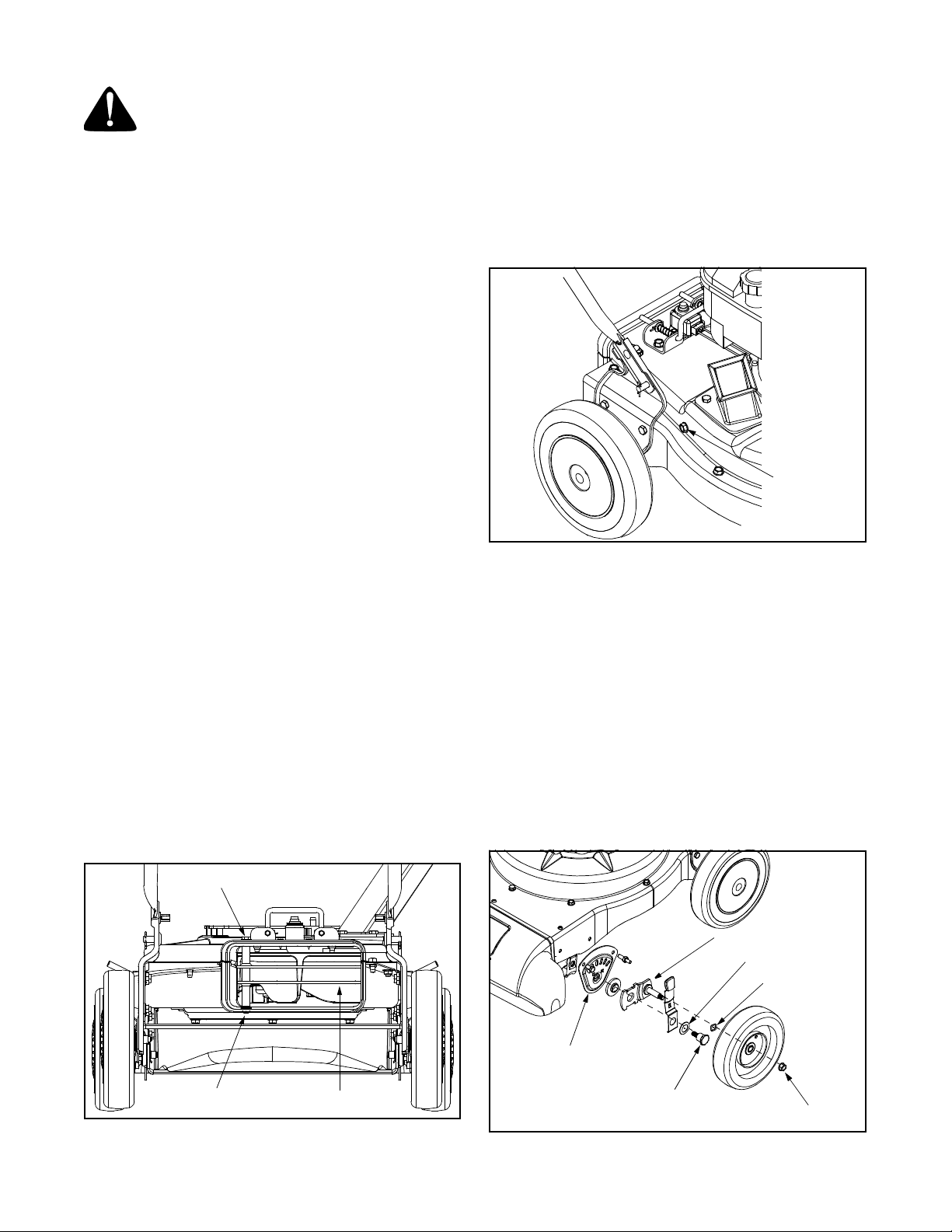

WARNING: Always stop engine and

disconnect spark plug wire before

cleaning, lubricating or doing any kind of

maintenance on your machine.

Lubrication

Wheels: Lubricate each wheel shoulder screw once a

season with light oil. Refer to Figure 5.

Nozzle height adjustment levers: Lubricate the pivot

points of the nozzle height adjustment levers once a

season with light oil. Refer to Figure 5.

Engine: Follow the separate engine manual packed

with you unit for lubrication instructions.

Maintenance

Engine

Refer to the separate engine manual for all engine

maintenance instructions.

• Check engine oil level before each use as

instructed in the separate engine manual packed

with your unit. Read and follow instructions

carefully.

• Clean air cleaner every 25 hours under normal

conditions or once a season. Clean every few hours

under extr emely dusty co nditions. To service th e air

cleaner, refer to the separate engine manual

packed with your unit.

• The spar k plug should be cleaned and the gap

reset once a season. Check engine manual for

correct plug type and gap specifications.

• Remove the bag or blower chute from the unit as

instructed in the OPERATION section to obtain

access to flail screen. See Figure 9.

• Remove hex screw on right side of unit that

attaches to the fail screen. See Figure 10.

• Remove hex screw and flat washer on top of rear

housing mounting bracket and the lock nut that

secures flail screen. See Figure 9.

• Remove and clean the screen by scraping or

washing with water. Reinstall the flail screen.

Remove

Hex Screw

Figure 10

Sharpening Or Replacing Chipper Blad e

Because the engine on this unit has a tapered

crankshaft, a special impeller tool (part number 753-

0900) is required to remove the impeller assembly. For

further assistance, contact your local service dealer.

Removing The Flail Scr een

If the discharge area becomes clogged, remove the flail

screen and clean area as follows:

• Stop the engine and make certain the chipper

shredder vacuum has come to a complete stop.

• Disconnect spark plug wire from spark plug and

ground against the engine.

Hex Screw & Flat Washer

Lock Nut

Flail Screen

Figure 9

NOTE: When tipping the unit, empty the fuel ta nk and

keep spark plug side up.

• Disconnect the spark plug wire and ground it away

from the spark plug.

• Remove the lock nuts, front wheels, and wave

washers that attach to the pivot arm assemblies.

See Figure 11.

Pivot Arm Assembly

Bell Washer

Wave Washer

Height Adjustment

Bracket

Shoulder

Screw

Figure 11

Lock Nut

10

Page 11

• Remove the sho ulder scr ews and be ll wash ers that

go through the pivot arms and height bracket

adjusters to the front support brace.

• Remove the three screws on the upper housing

that secure th e nozzle cover and the nin e screws

that secure the lower housing to the upper housing.

See Figure 12.

Housing

Screw

Nozzle

Screws

Lower Housing

Screws

Figure 12

• Remove lock nut that secures flail screen to the

lower housing. The flail screen does not have to be

removed.

• Remove the hex bolt, lock washer, and flat washer

that secure the impeller assembly to the crankshaft.

See Figure 13.

• Apply lubricant to the threads of impeller removal

tool and then thread the tool into the crankshaft.

Stop when the impeller assembly can move on the

crankshaft.

• Remove the impeller assembly from the crankshaft.

Unthread the impeller removal tool from the

impeller assembly.

• Remove the blade using a 3/16” allen wrench on

the outside of the blade and 1/2” wrench on the

impeller assembly.

• Replace or sharpen chipper blade.

• When sharpening blade, protect hands by using

gloves and follow the original angle of grind.

• Reassemble by performing the previous steps in

reverse order.

• Tighten blade screws to 210-250 in-lbs.

Tighten impeller bolt to 375-425 in-lbs.

NOTE: Make certain chipper blade is reassembled with

the sharp edge facing upward. See Figure 14.

Flail

Blade

Chipper

Blade

Impeller

Assembly

Figure 14

Chipper

Blade

BOTTOM VIEW

Figure 13

Upper

Housing

Impeller

Assembly

Hex Bolt

Lock Washer

Flat Washer

Flail

Blade

Storing Y our Chipper Shredder V acuum

• Clean the equipment thoroughly.

• Wipe equipment with a oiled rag to prevent rust.

• Refer to engine manual for correct engine storage

instructions

• Store unit in a clean, dry area. Do not store next to

corrosive materials such as fertilizer.

11

Page 12

SECTION 6: TROUBLESHOOTING

Problem Cause Remedy

Engine fails to start 1. Spark plug wire disconnected.

2. Fuel tank empty or stale fuel.

3. Throttle control lever not in correct

starting position. (If Equipped)

4. Choke not in CHOKE posit ion.

5. Blocked fuel line.

6. Faulty spark plug.

Engine runs er ratic 1. Spark plug wire loos e.

2. Unit running on CHOKE.

3. Blocked fuel line or stale fuel.

4. Water or dirt in fuel system.

5. Dirty air cleaner.

6. Carburetor out of adjustment.

Too much vibration 1. Loose parts or damaged impeller. 1. See authorized service dealer.

Engine overheats 1. Engine oil level low.

2. Dirty air cleaner.

3. Carburetor not adjusted properly.

Occasional skip (hesitates)

at high speed

Unit does not discharge 1. Discharge chute clogged.

Rate of discharge slows

considerably or

composition of discharged

material changes.

NOTE: For repairs beyond the minor adjustments listed above, contact your nearest authorized service dealer.

1. Spark plug gap too close. 1. Adjust gap to .030”.

2. Foreign object lodged in impeller.

3. Low engine RPM

4. Vacuum bag is full.

1. Low engine RPM.

2. Chipper blade dull.

1. Connect wire to spark plug.

2. Fill tank with clean, fresh gasoline.

3. Move throttle lever to FAST position.

4. Move choke to CHOKE position.

5. Clean fuel line.

6. Clean, adjust gap, or replace.

1. Connect and tighten spark plug wire.

2. Move choke lever (if equipped) to OFF

position.

3. Clean fuel line; fill tank with clean, fresh

gasoline

4. Drain fuel tank. Refill with fresh fuel.

5. Clean or replace air cleaner.

6. See authorized service dealer.

1. Fill crankcase with proper oil.

2. Clean or replace air cleaner.

3. See authorized service dealer.

1. Stop engine immediately and

disconnect spark plug wire. Clean flail

screen and inside of discharge opening.

2. Stop engine and disconnect spark plug

wire. Remove lodged object.

3. Always run engine at full throttle.

4. Empty bag.

1. Always run engine at full throttle.

2. Replace chipper blade or see your

authorized service dealer.

12

Page 13

NOTES

13

Page 14

Model 24A-020D000

16

12

19

15

13

11

1

2

3

4

5

10

13

39

6

8

7

9

14

17

18

7

20

5

35

37

36

26

34

23

33

21

24

27

28

7

16

22

30

29

25

31

32

36

38

36

14

Page 15

Model 24A-020D000

Ref.

No.

1. 725-1700 Switch Cover

2. 725-3166 Safety Switch

3. 71 0-0224 Hex Washer Screw #10-16 x.50

4. 629-0920 Wire Harness

5. 710-0604A Hex Washer Screw 5/16-18 x.625

6. 714-0104 Cotter Pin

7. 736-0264 Flat Washer.330 ID x.630 OD

8. 732-0962 Compression Spring

9. 781-0778A Mounting Bracket

10. 747-1153 Lock Rod

11. 710-3008 Hex Cap Screw 5/16-18 x.75

12. 681-0122 Chipper Chute Assembly

13. 726-0454 U-Clip Lock Nut 5/16-18

14. 736-0607 External Lock Washer 5/16

15. 710-0502A Hex Washer Screw 3/8-16 x 1.25

16. 710-0969 Screw #12-16 x 1.0

17. 710-3195 Hex Cap Screw 5/16-18 x 4.5

18. 710-3025 Hex Cap Screw 5/16-18 x.625

19. 710-0604A Hex Washer Screw 5/16-18 x.625

20. 781-1085 Upper Housing

Part No. Part Description

Ref.

No.

21. 710-1054 Hex Screw 5/16-24 x 1.0

22. 781-049 0 Chipper Blad e

23. 736-0119 Lock Washer 5/16

24. 712-0411 Hex Lock Nut 5/16-24

25. 681-0152 Impeller Assembly

26. 719-0329 Flail Blade

27. 781-0735 Pin Clip

28. 711-1401 Clevis Pin

29. 715-0166 Spiral Pin

30. 736-0247 Flat Washer.375 ID x 1.25 OD

31. 736-0217 Lock Washer 3/8

32. 710-0818 Hex Cap Screw 3/8-24 x 2.0

33. 681-0154 Screen Assembly

34. 710-3038 Hex Cap Screw 5/16-18 x.875

35. 781-0721A Lower Housing

36. 712-3004A Lock Nut 5/16-18

37. 731-2265 Nozzle Cover

38. 712-0158 Lock Nut 5/16-18

39. 731-1613 Safety Switch Cover

Part No. Part Description

15

Page 16

Model 24A-020D000

1

2

23

11

4

12

15

5

3

7

13

14

16

32

31

30

6

8

9

9

11

10

9

19

20

22

18

14

28

21

29

24

26

25

16

17

27

16

Page 17

Model 24A-020D000

Ref.

No.

1. 74 9-14 23 Upper Handle

2. 720-0314 Handle Knob 5/16-18

3. 710-1174 Carriage Bolt

4. 749-0907B Lower Handle

5. 664-0090 Bag Assembly

6. 711-1293 Studs

7. 712-0397 Wing Nut 1/4-20

8. 710-0703 Carriage Screw 1/4-20 x.75

9. 726-0453 Lock U-Clip Nut 3/8-16

10. 781-0777 Rear Wheel Support Brace

11. 712-3004A Flange Lock Nut 5/16-18

12. 714-0104 Cotter Pin

13. 681-0155 Handle Bracket Ass’y LH

14. 710-3025 Hex Cap Screw 5/16-18 x.625

15. 736-0105 Bell Washer.401 ID x.870 OD

16. 734-1987 Wheel 8 x 8.1

Part No. Part Description

681-0156 Hndle Brkt Ass’y RH (Not Shown)

Ref.

No.

17. 738-1015 Shoulder Screw 3/8-16

18. 781-072 5A Front Wheel Support Brace

19. 781-078 5 Height Adjustment Brac ket

20. 738-1185 Stud 5/16-18 .56 x .75

21. 741-075 1 Height Adjustment Bearing

22. 682-0113 Pivot Arm Assembly

23. 720-042 6 Height Adjustment Knob

24. 732-1026 Spring Lever

25. 736-0741 Bell Washer .760 ID x .25OD

26. 738-1173 Shoulder Screw .750 ID x .625 OD

27. 712-0431 Flange Lock Nut 3/8-16

28. 736-0314 Thrust Washer .375 ID x .70 OD

29. 736-0232 Wave Washer .531 ID x .781 OD

30. OEM-290-012 Blower Chute Ass’y (If Equipped)

31. 764-0507 Bag

32. 631-0083 Chute Assembly

Part No. Part Description

17

Page 18

ÍNDICE

Contenido Página

Medidas importantes de seguridad....................................................................19

Montaje de la cortadora trituradora aspiradora .................................................21

Conozca las propiedades de la cortadora trituradora aspiradora.......................22

Funcionamiento de la cortadora trituradora aspiradora .....................................23

Mantenimiento de la cortadora trituradora aspiradora .......................................24

Guía para la solución de problemas...................................................................27

Lista de las piezas..............................................................................................14

BÚSQUEDA DEL NÚMERO DE MODELO

Este manual de operación es una parte importante de la nueva cortadora trituradora aspiradora. Le

ayudará a montar, preparar y mantener la unidad para obtener los mejores resultados. Por favor lea y

comprenda el contenido del manual.

Antes de comenzar el montaje del equipo nue vo , por favor encuentre la placa del

modelo del equipo y copie la información contenida en la misma en el espacio provisto a

continuación. La información contenida en la placa del modelo es muy importante en caso

de necesitar ayuda de nuestro Departamento de Asistencia al Cliente o de un distribuidor

autorizado.

• Para encontrar el número de modelo mire hacia abajo de la parte posterior de la cortadora trituradora

aspiradora. A continuación se explica un ejemplo de placa de modelo. Para referencias futuras, por

favor copie el número de modelo y el número de serie del equipo en el espacio a continuación.

(Número de modelo)

MTD PRODUCTS INC

CLEVELAND, OHIO 44136

(Número de serie)

Copie el número del modelo en este espacio:

Copie el número de serie en este espacio:

SERVICIO TELEFÓNICO DE ASISTENCIA AL CLIENTE

En caso de tener problemas para ensamblar este producto o de tener dudas con respecto a los controles,

funcionamiento o mantenimiento del mismo, por favor comuníquese con el Departamento de asistencia al

cliente.

Llame al 1- (330) 220-4MTD (4683) o 1- (800)-800-7310 para comunicarse con un

representante de asistencia al cliente. Por favor cuando llame tenga a la vista el número de

modelo y el número de serie de su unidad. Consulte la sección anterior para obtener esta

información. Se le solicitará que ingrese el número de serie para poder procesar su llamada.

Si desea más información sobre la máquina visite nuestro sitio web en www.mtdproducts.com

18

Page 19

SECCIÓN 1: MEDIDAS IMPORTANTES DE SEGURIDAD

ADVERTENCIA: L a presenc ia de es te símbo lo indic a que se trata de instrucci ones im portantes de

seguridad que debe respetar para evitar poner en riesgo su segu ridad personal y / o materi al y de otras personas.

Lea y siga todas l as instru cciones conteni das en este manual antes de intentar p oner esta máquina en

funcionamiento. D e no hacerlo puede oc asionar lesiones. C uando e ncuentre este símbol o - resp ete la

advertencia que apar ece a co ntinuación d el mismo.

ADVERTENCIA: El escape del motor de este produc to, alg unos de sus componen tes y algunos

componentes del v ehículo con tienen o emiten p roducto s químicos que el estado de Calif ornia con sidera que

pueden producir cán cer , def ectos d e nacimi ento u ot ros prob lemas reproduct ivo s.

PELIGRO: Esta máquina e stá dise ñada para ser ut ilizada respetand o las reg las de segu ridad contenida s en

este manual. Al i gual que con todo s los e quipos e léctricos s i el ope rador es d escuidad o o com ete errores puede

ocasionar lesiones graves . Esta máquin a puede amputar m anos y pies y a rrojar obje tos. De no respetar l as

instrucciones d e segurid ad sigui entes se pueden producir l esiones graves o la muer te.

CAPACITACIÓN

1. Lea, comprenda y respete todas las instrucciones que figuran

en la máquina o en este(os) manual(es) antes de proceder al

montaje y operación del equipo. Guarde este manual en un

lugar seguro para referencias futuras y regulares y para solicitar

repuestos.

2. Familiarícese con todos los controles y con el uso adecuado de

los mismos. Sepa cómo detener la máquina y cómo

desengranar los controles rápidamente.

3. Nunca permita que niños menores de 16 años operen esta

máquina. Los niños de 16 años y más deben leer y comprender

las instrucciones de operación y las reglas de seguridad

contenidas en este manual y deben ser capacitados y

supervisados por uno de los padres.

4. Nunca permita que adultos sin conocimientos acerca de la

máquina operen la misma.

5. Mantenga a los observadores, ayudantes, mascotas y a los

niños por lo menos a 75 pies de la máquina mientras la misma

está en funcionamiento. Detenga la máquina si alguien entra en

la zona.

6. Nunca encienda un motor en espacios cerrados o en una zona

con poca ventilación. El escape del motor contiene monóxido de

carbono, un gas inodoro y letal.

7. No ponga las manos o los pies cerca de las piezas rotatorias o

en las cámaras de alimentación ni en la abertura de descarga.

El contacto con el motor rotatorio puede producir la amputación

de dedos, manos o pies.

8. Nunca trate de destapar la toma de alimentación o la abertura

de descarga, ni trate de sacar o vaciar la bolsa de la aspiradora,

ni de revisar y reparar la máquina mientras el motor está en

marcha. Apague el motor y espere hasta que todas las piezas

que se mueven se hayan detenido por completo. Desconecte el

cable de la bujía y póngalo de manera que haga masa contra el

motor.

PREPARACIÓN

1. Revise minuciosamente la zona donde se utilizará el equipo.

Retire todas las piedras, botellas, latas u otros objetos extraños

que puedan ser levantados o arrojados causando lesiones o

daños a la máquina.

2. Para protegerse los ojos utilice siempre anteojos o antiparras de

seguridad mientras opera la máquina o mientras la ajusta o

repara. Los objetos arrojados que rebotan pueden lesionar

gravemente la vista.

3. Utilice zapatos de trabajo resistentes, de suela fuerte y

pantalones y camisas ajustados. Las prendas sueltas o las

alhajas pueden quedar atrapadas en las piezas movibles.

Nunca opere esta máquina estando descalzo o con sandalias.

Utilice guantes de trabajo de cuero cuando alimente material

por el canal de la cortadora.

4. Antes de encender la máquina controle que todos los pernos y

tornillos estén bien ajustados para comprobar que la máquina

se encuentra en condiciones seguras de operación Además

realice una inspección visual de la máquina a intervalos

frecuentes para controlar si la misma está dañada.

5. Mantenga o reemplace las etiquetas de seguridad e

instrucciones según sea necesario.

6. Sea sumamente cuidadoso al manipular la gasolina. La

gasolina es altamente inflamable y los vapores son explosivos.

Se puede lesionar gravemente si derrama gasolina sobre usted

o sobre la ropa ya que se puede encender. Lave la piel y

cámbiese de ropa de inmediato.

a. Utilice sólo recip ientes pa ra gasol ina autori zados.

b. Apague todos los cigarrillos, cigarros, pipas y otras

fuentes de combustión.

c. Nunca cargue combustible en la máquina en un espacio

cerrado.

d. Nunca saque la tapa del gas ni agregue combustible

mientras el motor está caliente o en marcha.

e. Deje que el motor se enfríe por lo menos dos minutos

antes de volver a cargar combustible.

f. Nunca recargue el tanque de combustible. Llene el

tanque no más de 1/2 pulgada por debajo de la base del

cuello del filtro para dejar espacio para la dilatación del

combustible.

g. Vuelva a colocar la tapa de la gasolina y ajústela bien.

h. Limpie la gasolina derramada sobre el motor y el

equipo. Traslade la máquina a otra zona. Espere 5

minutos antes de encender el motor.

i. Nunca almacene la máquina o el recipiente de

combustible en un espacio cerrado donde haya fuego,

chispas o luz piloto (por ejemplo, hornos, calentadores

de agua, calefactores, secadores de ropa, etc.)

j. Para reducir el riesgo de incendio mantenga la máquina

limpia de pasto, hojas y de acumulación de otros

escombros. Limpie los derrames de aceite o

combustible y saque todos los escombros embebidos

con combustible.

k. Deje que la máquina se enfríe por lo menos 5 minutos

antes de guardarla.

FUNCIONAMIENTO

1. No ponga las manos o los pies cerca de las piezas rotatorias o

en las cámaras de alimentación ni en la abertura de descarga.

El contacto con el motor rotatorio puede producir la amputación

de dedos, manos o pies.

19

Page 20

2. Antes de encender la máquina compruebe que el canal de la

cortadora, la toma de alimentación y la cámara de corte están

vacías y sin escom bros.

3. Inspeccione minuciosamente todo el material que desea triturar

y saque los objetos metálicos, piedras, botellas, latas u otros

objetos extraños que pueden ocasionar lesiones o dañar la

máquina.

4. Si el motor golpea un objeto extraño o si la máquina produce un

sonido poco común o una vibración al encenderla, apague el

motor de inmediato. Deje que el motor se detenga por completo.

Desconecte el cable de la bujía, póngalo de manera que haga

masa contra el motor y siga estos pasos:

a. Inspeccione la máquina para ver s i está da ñada.

b. Repare o reemplace las piezas dañadas.

c. Controle si hay piezas flojas y ajústelas para asegurar

que la máquina funcione de manera segura y continua.

4. No permita que se acumule material procesado en la zona de

descarga. El mismo puede obstaculizar la descarga adecuada y

provocar el retorno del material a través de la abertura de

alimentación.

5. No intente triturar ni picar material de mayor tamaño al

especificado en la máquina o en este manual. Se podrían

producir lesiones o daños.

6. Nunca trate de destapar la toma de alimentación o la abertura

de descarga mientras el motor está en marcha. Apague el

motor y espere hasta que todas las piezas que se mueven se

hayan detenido por completo, desconecte el cable de la bujía y

póngalo de manera que haga masa contra el motor antes de

sacar los escombros.

7. Nunca opere la máquina sin que la bolsa de la aspiradora y el

canal de descarga estén conectados a la máquina como

corresponde. Nunca vacíe ni cambie la bolsa de la aspiradora

mientras el motor está en marcha. El extremo con cierre de la

bolsa de la aspiradora debe quedar cerrado todo el tiempo

mientras la máquina está en funcionamiento.

8. Nunca ponga la máquina en funcionamiento si el pico de

ingreso o la unión opcional para la manguera no están

conectados a la máquina adecuadamente. Nunca intente

conectar o cambiar ninguna de estas uniones mientras el motor

está en marcha.

9. Mantenga todos los protectores, desviadores y dispositivos de

seguridad en su lugar y en buenas condiciones.

10. Mientras alimenta material dentro de la máquina mantenga su

rostro y su cuerpo detrás y hacia un costado del canal de la

cortadora para evitar lesiones por retrocesos accidentales.

11. Nunca opere esta máquina sin buena visibilidad o iluminación.

Siempre debe estar seguro de que está bien afirmado y

sostenga bien las manijas.

12. No opere esta máquina en superficies con grava.

13. No opere esta máquina estando bajo los efectos del alcohol o

de drogas.

14. El silenciador y el motor se calientan y producen una

quemadura. No los toque.

15. Nunca levante o transporte la máquina cuando el motor está

encendido.

MANTENIMIENTO Y ALMACENAMIENTO

1. Nunca manipule los dispositivos de seguridad de manera

imprudente. Controle periódicamente que funcionen de forma

adecuada.

2. Controle frecuentemente que todos los pernos y tornillos estén

bien ajustados para comprobar que la máquina se encuentra en

condiciones seguras de operación. Además realice una

inspección visual de la máquina para controlar si la misma está

dañada y repárela de ser necesario.

3. Antes de limpiar, reparar o inspeccionar la máquina, detenga el

motor y compruebe que el mismo y todas las partes que se

mueven se hallan detenido. Desconecte el cable de la bujía y

póngalo de manera que haga masa contra el motor para evitar

que se encienda de manera accidental.

4. No cambie la configuración del regulador del motor ni acelere

demasiado el mismo. El regulador controla la velocidad máxima

segura de operación del motor.

5. Mantenga o reemplace las etiquetas de seguridad e

instrucciones según sea necesario.

6. Siga las instrucciones de este manual para cargar, descargar,

transportar y almacenar de manera segura esta máquina.

7. Nunca almacene la máquina o el recipiente de combustible en

un espacio cerrado donde haya fuego, chispas o luz piloto como

por ejemplo, calentadores de agua, hornos, secadores de ropa,

etc.

8. Consulte siempre el manual de operación para las instrucciones

adecuadas para el almacenamiento fuera de temporada.

9. Si debe vaciar el tanque de combustible, hágalo al aire libre.

10. Respete las normas referentes a la disposición correcta y las

reglamentaciones sobre gas, combustible, etc. para proteger el

medio ambiente.

ADVERTENCIA: - SU RESPONSABILIDAD:

Sólo permita que usen esta máquina eléctrica

las personas que lean, comprendan y respeten

las advertencias y las instrucciones que

aparecen en este manual y en la máquina.

NOTA: Es posible que no todas las etiquetas de seguridad

que se enseñan correspon dan a es ta cortado ra triturado ra.

20

Page 21

SECCIÓN 2: MONTAJE DE LA CORTADORA TRITURADORA ASPIRADORA

IMPORTANTE: Esta unidad se env ía sin gasolina ni aceite en el

motor. Antes de operar la máquina cargue el motor con gasolina y

aceite como se indica en el manual separado del mismo.

NOTA: Las referencias a los lados derecho o izquierdo de la

cortadora trituradora aspiradora se hacen observando la máquina

desde la posición de operación.

Extracción de la unidad de la c aja

• Saque las grapas, rompa el pegamento de las aletas superiores

o corte la cinta del extremo de la caja tire a lo largo de la aleta

superior para abrir la caja.

• Saque las piezas sueltas que se incluyen junto con la unidad (es

decir, el manual de operación, etc.)

• Corte a lo largo de las esquinas, extienda la caja plana hacia

abajo y saque el material de embalaje.

• Haga rodar o deslice la unidad fuera de la caja y revise

minuciosamente la caja para controlar si hay piezas sueltas.

Montaje de la manija

• Despliegue la manija superior hasta que quede alineada con la

manija inferior.

• Para sujetar las dos manijas ajuste las tuercas de mariposa (los

pernos del carro deben estar colocados de forma adecuada en

la manija). Ver Figura 1.

• Saque los broches de horquilla de los soportes de la manija de

la cortadora trituradora aspiradora y saque los pernos del carro

y las tuercas de mariposa de la manija inferior. Ver Figura 2.

• Coloque los agujeros inferiores de la manija inferior sobre los

pernos de los soportes de la manija y asegúrelos con broches

de orquilla.

• Inserte los pernos del carro desde el lado de afuera a través del

agujero superior de la manija inferior y asegúrelos con tuercas

de mariposa.

Piezas sueltas en la caja (Ver Figura 1)

• Montaje de la manguera

• Bolsa

• Canal de soplado (Si está incluido)

Desconexión del cable de la bujía

Antes de instalar la cortadora trituradora aspiradora desconecte el

cable de la bujía de la misma y póngalo de manera que haga masa

con un perno del motor.

Tuercas de mariposa

Bulón del carro

Broche de

horquilla

Canal

de soplado

A mariposa

Tuercas

A mariposa

Tuercas

Inferior

Manija

Carro

Tornillo

Superior

Manija

Bolsa

Figura 2

Colocación de la bolsa

Manija de la bolsa

Perno

Tiras

Aleta delantera

Varilla de seguridad

Perno

Figura 1

Figura 3

21

Page 22

• Sostenga la manija de la bolsa con una mano y deslice la varilla

de seguridad del soporte de montaje hacia el motor con la otra

mano. Use el extremo del soporte de montaje como palanca

cuando deslice la varilla de seguridad.

Ver Figura 3.

• Deslice la bolsa por encima del borde de la abertura de

descarga y suelte la varilla de seguridad para ajustar la bolsa en

su lugar.

• Coloque las tiras de la bolsa por encima de la manija inferior

enganchándolas en los pernos.

• Una el broche de la bolsa a presión con la parte superior de la

manija inferior.

NOTA: El botón del interruptor de seguridad unido al soporte de

montaje debe quedar presionado totalmente por la aleta delantera de

la manija de la bolsa cuando ajuste la bolsa o el motor no arrancará.

Instalación del canal de soplado(Si está incluido)

• Tome el canal de soplado con una mano y deslice la varilla de

seguridad del soporte de montaje hacia el motor con la otra

mano. Use el extremo del soporte de montaje como palanca

cuando deslice la varilla de seguridad. Ver Figura 4.

• Deslice el canal de soplado por encima del borde de la abertura

de descarga y suelte la varilla de seguridad para ajustar el canal

en su lugar. Compruebe que el botón del interruptor de

seguridad quede presionado totalmente por la aleta delantera

del canal de soplado.

Aumente la alt ura del pico al máxi mo cuan do util ice el canal

•

de soplado. Consulte las instrucciones para ajustar la altura

del pico en la sección FUNCIONAMIENTO.

De soplado

Canal

Frente

Aleta

Frente

Aleta

De seguridad

Varilla

De seguridad

Varilla

Figura 4

SECCIÓN 3: CONOZCA LAS PROPIEDADES DE LA CORTADORA

TRITURADORA ASPIRADORA

Canal de soplado

Bolsa

Cortadora

Canal

Manija de la bolsa

Altura del pico

Palanca de ajuste

Pico

Figura 5

Lea este manual de operación y las reglas de seguridad antes de

poner la cortadora trituradora aspiradora en funcionamiento.

Compare las ilustraciones en Figura 5 con su unidad para

familiarizarse con la ubicación de los distintos controles y ajustes.

Guarde este manual para referencias futuras.

Bolsa

Junta el material triturado que ingresó a través del canal de picado o

que fue aspirado a través del pico. Ver Figura 5.

Manija de la bolsa

Se utiliza para tomar la bolsa para colocarla, sacarla y vaciarla. Ver

Figura 5.

Canal de la cortadora

Permita que las ramas pequeñas de hasta 1 1/2” de diámetro

ingresen al motor para picarlas. Ver Figura 5.

22

Page 23

Canal de soplado (Si está incluido)

Cuando se lo une a la unidad el canal de soplado se utiliza para

soplar o esparcir por los patios los desechos que se acumulan en los

mismos como por ejemplo las hojas, las agujas de los pinos o las

ramas pequeñas. Ver Figura 5.

Palanca de ajuste de l a altura del pico

Se utiliza para ajustar la distancia entre el suelo y el pico que

varía aproximadamente de 5/8” a 4 1/8”

.

Pico

Los desechos que se acumulan en los patios como por ejemplo las

hojas o las agujas de los pinos se pueden aspirar con el pico para

picarlos.

Manija del arrancador (No se enseña)

La manija del arrancador está unida a la manija superior derecha.

Para encender el motor párese detrás de la unidad y tire de la manija

del arrancador. Ver Figura 5.

Palanca de contro l del regu lador (No se enseña)

La palanca de control del regulador está ubicada en el motor.

Controla la velocidad del motor y lo detiene. Si desea más detalles,

consulte el manual del motor que viene por separado y embalado con

la unidad.

Controles del moto r

Consulte el manual del motor que viene por separado si desea

conocer la ubicación el funcionamiento de los controles del motor.

Detención del motor

• Mueva las palancas de control del regulador a la posición STOP

(detención) u OFF (apagado).

• Desconecte el cable de la bujía y póngalo de manera que haga

masa contra el motor.

SECCIÓN 4: FUNCIONAMIENTO DE LA CORTADORA TRITURADORA

ASPIRADORA

ADVERTENCIA: Al operar la cortadora

trituradora aspiradora puede ser que objetos

extraños sean arrojados a los ojos lo cual puede

dañarlos gravemente. Utilice siempre los anteojos de

seguridad provistos con esta unidad o protectores

para ojos antes de picar o soplar el material y

mientras realiza ajustes o reparaciones.

Carga de gas y aceite

Cargue el motor con gasolina y aceite como se indica en el manual

separado del mismo que viene embalado con la cortadora trituradora

aspiradora. Lea cuidadosamente las instrucciones.

ADVERTENCIA: Nunca cargue el tanque de

combustible en espacios cerrados con el motor en

marcha o hasta que haya dejado que el mismo se

enfríe por lo menos dos minutos después de haber

estado en marcha.

Encendido del motor

• Conecte el cable de la bujía a la misma. Compruebe que la tapa

metálica del extremo de la bujía esté bien ajustada sobre la

punta metálica de la bujía.

• Compruebe que el cable del interruptor de seguridad esté

conectado al motor y que haga descarga a tierra como

corresponde.

• Motores con palanca de obturación:

Mueva la palanca de obturación del motor a la posición CHOKE

(obturación). (Si el motor está tibio la obturación puede no ser

necesaria).

Motores con cebador:

Utilice el cebador del motor como se explica en el manual por

separado del motor.

• El control del regulador está ubicado en el motor. Mueva las

palancas de control del regulador del motor a la posición FAST

(rápido) o START (encendido).

• Párese detrás de la unidad, tome la manija del arrancador y

saque cuerda lentamente hasta que el motor alcance el

comienzo del ciclo de compresión (la cuerda tirará un poco más

fuerte en este punto).

• Tire de la cuerda de manera rápida y continua. Apriete bien la

manija del arrancador. Deje que la soga se enrosque

lentamente.

• Repita los pasos anteriores hasta que se encienda el motor.

Cuando se enciende el motor mueva el control de obturación (si

está incluido) gradualmente hasta la posición RUN (en marcha).

ADVERTENCIA: Nunca encienda el motor en

espacios cerrados o en una zona poco ventilad a. El

escape del motor contiene monóxido de carbono, un

gas inodoro y letal.

Descarga de la bolsa

• Desenganche las tiras de la bolsa de la manija inferior y

desabroche el broche de la bolsa de la parte superior de la

manija inferior.

Ver Figura 6.

• Tome la manija de la bolsa con una mano y tire de la varilla de

seguridad del soporte de montaje hacia el motor con la otra

mano para soltarla.

• Saque la bolsa del borde de la abertura de descarga. Consulte

Figura 3.

Botones

Broche de

la bolsa

Aleta interior

Manija de

la bolsa

Aleta exterior

Tira

Figura 6

23

Page 24

• Gire los dos botones de la parte posterior de la bolsa para

abrirla y vaciar el contenido. Ver Figura 6.

• Sostenga la manija y el broche de la bolsa mientras vacía el

contenido.

• Comprima la abertura de la bolsa y doble la aleta interior sobre

la abertura.

• Doble la aleta exterior sobre la aleta interior e inserte los

botones de la bolsa a través de las salidas metálicas.

• Gire los botones para cerrar la bolsa.

Extracción del canal de soplado (Si está incluido)

• Tome el canal de soplado con una mano y tire de la varilla de

seguridad del soporte de montaje hacia el motor con la otra

mano para soltarlo. Consulte Figura 4.

• Saque el canal de soplado del borde de la abertura de

descarga.

Funcionamiento de la cortadora trituradora

aspiradora

máquina para triturar o picar el material integrante de la vegetación

que se encuentra en un patio normal (es decir, ramas, hojas, ramas

pequeñas, etc.) Evite las plantas fibrosas como por ejemplo las de

tomates hasta que estén totalmente secas. Se pueden introducir

materiales como por ejemplo troncos o ramas pesadas de hasta 1 1/

2” de diámetro en el canal de la cortadora. Ver Figura 7.

IMPORTANTE: La pantalla de desgranado está ubicada dentro de

la caja en la zona de descarga. Si se tapa la pantalla de desgranado,

sáquela y límpiela como se indica en SECCIÓN 5: MAINTAINING

YOUR CHIPPER SHREDDER VACUUM. Para obtener el mejor

resultado es importante también mantener afilada la hoja de la

cortadora.

ADVERTENCIA: Siempre detenga el motor y

desconecte el cable de la bujía antes de realizar

cualquier ajuste.

Ajuste de la altura del pico

Puede ajustar el pico en cinco posiciones que varían desde 5/8” a 4

1/8” de distancia del suelo. Debe ajustar la altura del pico según las

condiciones. Mueva las palancas para ajustar la altura hacia

adelante o hacia atrás para ajustar el pico hacia arriba o hacia abajo.

Ver Figura 8.

NOTA: En general, levante la altura del pico para aspirar una capa

gruesa de hojas o para usar el canal de soplado y baje la altura del

pico para las superficies más lisas.

Pico

Cortadora

Canal

Figura 7

Coloque ambas manos en la parte superior de la manija superior

para desplazar la unidad por encima de los desechos acumulados en

el patio. El desecho que se acumula en los patios como por ejemplo

las hojas y las agujas de los pinos pueden aspirarse a través del pico

para triturarlos. Después que ha triturado el material con las hojas de

desgranar del montaje del motor, el mismo será descargado a la

bolsa colectora o a través del canal de soplado. Sólo utilice la

Pico

Figura 8

Altura del pico

Ajuste

Palanca

SECCIÓN 5: MANTENIMIENTO DE LA CORTADORA TRITURADORA

ASPIRADORA

ADVERTENCIA: Detenga siempre el motor y

desconecte el cable de la bujía antes de limpiar y

lubricar la máquina o de realizar todo tipo de

mantenimiento de la misma.

Lubricación

Ruedas: Lubrique los tornillos con reborde de las ruedas una vez por

temporada con aceite liviano. Consulte Figura 5.

Palancas de ajuste de la altura del pico: Lubrique los puntos

giratorios de las palancas de ajuste de la altura del pico una vez por

temporada con aceite liviano. Consulte Figura 5.

Motor: Siga las instrucciones de lubricación del manual separado del

motor que viene embalado con la unidad.

Mantenimiento

Motor

Consulte el manual separado del motor para conocer todas las

instrucciones de mantenimiento del mismo.

• Controle el nivel de aceite del motor antes de cada uso como

se indica en el manual separado del mismo que viene embalado

con la unidad. Lea y siga las instrucciones cuidadosamente.

24

Page 25

• Limpie el depurador de aire cada 25 horas en condiciones

b

normales o una vez por temporada. Limpie a intervalos de

pocas horas cuando haya mucho polvo. Para realizar el control

del depurador de aire consulte el manual separado del motor

que viene embalado con la unidad.

Responsabilidades del cliente

MANTENIMIENTO

PROGRAMACIÓN

O

Lubrique las ruedas

T

C

Lubrique las palancas del pico

U

D

O

Lubrique la varilla de seguridad

R

P

Controle la hoja de la cortadora

Cambie el aceite

R

Controle el filtro de aire

O

T

O

Limpie el motor

M

Controle la bujía

e

d

o

s

s

u

e

t

a

n

d

A

a

c

C

La bujía debe limpiarse y se debe reponer la distancia disruptiva una

vez por temporada. Consulte el manual del motor para conocer las

especificaciones para el tipo de bujía y para la distancia disruptiva.

l

e

d

e

c

a

o

t

n

e

i

m

CONTROL

a

n

FECHAS

s

s

a

r

o

h

5

2

a

d

a

C

s

a

a

r

o

h

h

0

0

0

5

1

a

a

d

d

a

a

C

r

r

o

o

p

a

z

d

e

a

v

r

s

o

e

a

t

p

n

n

m

m

A

U

l

e

a

t

Extracción de la pantalla de desgranado

Si la zona de descarga se tapa, saque la pantalla de desgranado y

limpie la zona como se indica a continuación:

• Detenga el motor y compruebe que la cortadora trituradora

aspiradora se haya detenido por completo.

• Desconecte el cable de la bujía y póngalo de manera que haga

masa contra el motor.

Tornillo de cabeza

hexagonal y Arandela plana

Tuerca de

seguridad

Figura 9

• Saque la bolsa o el canal de soplado de la unidad como se

indica en la sección de FUNCIONAMIENTO para acceder a la

pantalla de desgranado. Ver Figura 9.

• Saque el tornillo de cabeza hexagonal del lado derecho de la

unidad que se une a la pantalla de desgranado. Ver Figura 10.

• Saque el tornillo de cabeza hexagonal y la arandela plana de la

parte superior del soporte de montaje de la caja posterior y la

tuerca de seguridad que une la pantalla de desgranado. Ver

Figura 9.

Pantalla de

desgranado

• Saque la pantalla y límpiela con un cepillo o lávela con agua.

Vuelva a colocar la pantalla de desgranado.

Saque

Tornillo de ca

Figura 10

Afilado o recambio de las hojas de la

cortadora

Debido a que el motor de esta unidad tiene un cigüeñal ahusado, se

necesita una herramienta para motores especial (pieza número 753-

0900) para sacar el montaje del motor. Si necesita más ayuda

comuníquese con el distribuidor de su zona autorizado para realizar

el mantenimiento.

NOTA: Cuando incline la unidad, vacíe el tanque de combustible y

mantenga el lado de la bujía hacia arriba.

• Desconecte el cable de la bujía y conéctelo a tierra lejos de la

misma.Saque las tuercas de seguridad, las ruedas delanteras y

las arandelas ondulatorias que van unidas a los montajes del

brazo giratorio. Ver Figura 11.

25

Page 26

Montaje del brazo giratorio

Arandela de campana

Arandela ondulatoria

Ajuste de la altura

Soporte

Con reborde

Tornillo

Tuerca de seguridad

Figura 11

• Saque los tornillos con reborde y las arandelas de campana

que pasan por los brazos giratorios y los adaptadores de los

soportes de altura hasta la traba de sostén delantera.

• Saque los tres tornillos de la caja superior que unen la cubierta

del pico y los nueve tornillos que unen la caja inferior a la

superior. Ver Figura 12.

• Cuando afile las hojas, protéjase las manos mediante el uso de

guantes y siga el ángulo original de molido.

• Para realizar el reensamblado siga los pasos anteriores pero en

orden inverso.

• Ajuste los tornillos de la hoja con un par de torsión de 210-250

in-lbs.

Ajuste el perno del motor con un par de torsión de 375-425 inlbs.

Superior

Cortadora

Caja

Hoja

Motor

Montaje

Bulón hexagonal

Arandela de segurid

Arandela plana

Caja

Tornillo

Pico

Tornillos

Caja inferior

Tornillos

Figura 12

• Saque la tuerca de seguridad que une la pantalla de

desgranado a la caja inferior. No es necesario sacar la pantalla

de desgranado.

• Saque el bulón hexagonal, la arandela de seguridad y la

arandela plana que unen el montaje del motor al cigüeñal. Ver

Figura 13.

• Aplique lubricante a las roscas de la herramienta que se usa

para sacar el motor y luego enrosque la herramienta en el

cigüeñal. Deténgase cuando el montaje del motor se pueda

mover en el cigüeñal.

• Saque el montaje del motor del cigüeñal. Desenrosque del

montaje del motor la herramienta que se utiliza para sacarlo.

• Saque la hoja mediante el uso de una llave allen de 3/16” en el

lado exterior de la hoja y de una llave de 1/2" en el montaje del

motor.

• Cambie o afile las hojas de la cortadora.

De desgranar

Hoja

VISTA DE LA BASE

Figura 13

NOTA:

con el filo hacia arriba. Ver Figura 14.

Compruebe que se reensamblen las hojas de la cortadora

De desgranado

Hoja

Cortadora

Hoja

Motor

Montaje

Figura 14

Almacenamiento de la cortadora tritur adora

aspiradora

• Limpie el equipo por completo.

• Limpie el equipo con un trapo con aceite para evitar que se

oxide.

• Consulte el manual del motor para conocer las instrucciones

para el almacenamiento correcto del mismo

• Almacene la unidad en una zona limpia y seca. No la almacene

cerca de materiales corrosivos como por ejemplo fertilizantes.

26

Page 27

SECCIÓN 6: GUÍA PARA LA SOLUCIÓN DE PROBLEMAS

Problema Causa Solución

El motor no arranca 1. Se ha desconectado el cable de la bujía.

El motor funciona de manera

errática

Demasiada vibración 1. Hay partes que están flojas o el motor está

El motor recalienta 1. El nivel de aceite del motor es bajo.

Saltos ocasionales (duda) a alta

velocidad

La unidad no descarga 1. El canal de descarga está tapado.

Tasa de descarga se reduce de

manera considerable o cambia la

composición del material

descargado.

2. El tanque de combustible está vacío o el

combustible es viejo.

3. La palanca de control del regulador no está

en la posición de arranque correcta. (Si está

incluida)

4. La palanca de obturación no está en la

posición CHOKE (obturación).

5. La línea del combustible está bloqueada.

6. La bujía no funciona correctamente.

1. El cable de la bujía está flojo.

2. La unidad está funcionando en la posición

CHOKE (obturación).

3. La línea del combustible está tapada o el

mismo es viejo.

4. Agua o suciedad en el sistema del

combustible.

5. El depurador de aire está sucio.

6. Es necesario ajustar el carburador.

dañado.

2. El depurador de aire está sucio.

3. El carburador no está ajustado

correctamente.

1. La distancia disruptiva de la bujía es mu y

poca.

2. Hay un objeto extraño en el motor.

3. RPM del motor son bajas

4. La bolsa de la aspiradora está llena.

1. RPM del motor son bajas.

2. La hoja de la cortadora está desafilada.

NOTA: Si debe realizar reparaciones más importantes que las enunciadas anteriormente comuníquese con el distribuidor autorizado para el

mantenimiento más cercano

.

1. Conecte el cable a la bujía.

2. Llene el tanque con gasolina limpia y fresca.

3. Mueva la palanca del regulador a la posición

FAST (rápido).

4. Ponga la palanca de obturación en la posición

CHOKE (obturación).

5. Limpie la línea del combustible.

6. Límpiela, ajuste la distancia disruptiva o

cámbiela.

1. Conecte y ajuste el cable de la bujía.

2. Cambie la palanca de obturación (si está incluida)

a la posición OFF (apagado).

3. Limpie la línea del combustible; llene el tanque

con gasolina limpia y fresca

4. Vacíe el tanque del combustible. Vuelva a llenarlo

con combustible fresco.

5. Limpie o cambie el depurador de aire.

6. Consulte al distribuidor autorizado para el

mantenimiento.

1. Consulte al distribuidor autorizado para el

mantenimiento.

1. Llene el cárter con aceite adecuado.

2. Limpie o cambie el depurador de aire.

3. Consulte al distribuidor autorizado para el

mantenimiento.

1. Ajuste la distancia disruptiva a 0,030”.

1. Detenga el motor de inmediato y desconecte el

cable de la bujía. Limpie la pantalla de

desgranado y el interior de la abertura de

descarga.

2. Detenga el motor y desconecte el cable de la

bujía. Saque el objeto extraño del motor.

3. Siempre accione el motor con el regulador al

máximo.

4. Vacíe la bolsa.

1. Siempre accione el motor con el regulador al

máximo.

2. Cambie la hoja de la cortadora o consulte al

distribuidor autorizado para el mantenimiento.

27

Page 28

282930

Page 29

Page 30

Page 31

DEL FABRICANTE

GARANTÍA LIMITADA

La garantía limitada que se extiende a continuación es

otorgada por la empresa MTD PRODUCTS INC (“MTD”)

con respecto a mercaderías nuevas compradas y

utilizadas en los Estados Unidos, sus posesiones y

territorios.

MTD garantiza este producto por defectos materiales y de

fabricación por un período de dos (2) años a partir de la

fecha de la compra original y reparará o cambiará sin

cargo cuando lo considere pertinente todas las piezas con

defectos materi ales o de f a bricación. Esta garantía limitada

sólo será aplicable si el producto ha sido utilizado y

mantenido según lo e sta blecido en el Manual de operaci ón

provisto junto con el producto y no ha sufrido usos

inadecuados, abuso, usos comerciales, descuidos,

accidentes, mantenimiento incorrecto, alteraciones,

vandalismo, robo, incendio, agua producto de otros

peligros o desastres naturales. El daño resultante por la

instalación o el uso de accesorios o uniones no aprobados

por MTD Products Inc. para su uso con el(los) producto(s)

incluido(s ) en este manual anula rá la garantía en lo que

respecta a esos daños.

Las piezas o componentes desgastables normales están

sujetos a condiciones diferentes como se indica a

continuación: Todas las fallas de las pieza s o compon ent es

desgastables nor males estarán cubiertas para el producto

por un período de 90 días sin impor tar la ca usa. Desp ués

de los 90 días, pero dentro del per íodo de dos años, las

fallas de las p iez as d es gas tables normales serán cubiertas

SOLO SI fueron causadas po r los de fectos materiales o de

fábrica de OTRAS piezas componentes. Las piezas o

componentes desgas tables normales incluyen pero no se

limitan a correas, hojas, adaptadores para hojas, bolsas

para pasto, r uedas para la plataforma, asientos, zapatos

anti deslizantes para la máquina de sacar nieve, placas y

gomas de corte. Las baterías están cubiertas por una

garantía de reposición limitada de 90 días.

OBTENCIÓN DEL SERVICIO DE MANTENIMIENTO: El

servicio de la garantía está disponible, CON PRUEBA DE

COMPRA A TRAVÉS DEL DISTRIBUIDOR LOCAL

AUTORIZADO PARA EL MANTENIMIENTO. Para ubicar al

distribuidor de s u zona, por favor c ont role s i existe una lista

en las Páginas amarillas o comuníquese con el

Departamento de asistencia al cliente de MTD

PRODUCTS INC llamando al 1-800-800-7310 o

escribiendo al apartado postal P.O. Box 368022,

Cleveland, Ohio 44136-9722.

Esta garantía limitada no lo cubrirá en los siguientes

casos:

a. El motor y las piezas componentes presentes. Estos

artículos tienen una garantía diferente a cargo del

fabricante. Por favor para estos artículos consulte la

garantía aplicable del fabricante.

b. Las bombas para el corte de madera, las válvulas y

los cilindros tienen una garantía independiente de un

año.

c. Los artículos necesarios para el mantenimiento de

rutina como por ejemplo lubricantes, filtros, afiladores

de hojas, las adaptaciones y los ajustes como por

ejemplo los ajustes de los frenos, del embrague o de