Page 1

ASSEMBLY

OPERATION

PARTS

MAINTENANCE

FIFTY CENTS

MODEL

NOS.

249-670A

249-680A

POWER

IMPORTANT:

READ SAFETY RULES

& INSTRUCTIONS

\

VACUUMS

PRINTED IN U.S.A.

1

FORM No. 770-8250

Page 2

LIMITED WARRANTY

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm,

any part or parts found to be defective in material or workmanship. Transportation charges

under this warranty must be paid by the purchaser unless return is requested by MTD

PRODUCTS INC.

This warranty will not apply to any part which has become inoperative due to misuse,

excessive use, accident, neglect, improper maintenance, alterations, or unless the unit

has been operated and maintained in accordance with the instructions furnished. This

warranty does not apply to the engine, motor, battery, battery charger or component parts

thereof. Please refer to the applicable manufacturer’s warranty on these items.

This warranty will not apply where the unit has been used commercially.

Warranty service is availabie through your iocal authorized service dealer or distributor. If

you do not know the dealer or distributor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will not be accepted by the factory unless prior written

permission has been extended by MTD.

This warranty gives you specific legal rights. You may also have other rights which vary

from state to state.

WARNING TO PURCHASERS

OF INTERNAL COMBUSTION ENGINE EQUIPPED

MACHINERY OR DEVICES IN THE STATE OF CALIFORNIA

The equipment which you have just purchased does not have a spark arrester. If this equipment is used on

any forest covered land, brush covered land, or grass covered unimproved land in the State of California,

before using on such land, the California law requires that a spark arrester be provided. In addition, spark

arrester is required by law to be in effective working order. The spark arrester must be attached to the

exhaust system and comply with Section 4442 of the California Public Resources Code.

Page 3

IMPORTANT

It is suggested that this manual be read in its entirety before attempting to assemble or operate. Keep this

manual in a safe place for future reference and for ordering replacement parts.

This unit is shipped WITHOUT GASOLINE or OIL. After assembly, see operating section of this manuai for

proper fuel and amount.

SAFE OPERATION PRACTICES FOR POWER VACUUMS

1. Read the operating and service instructing

manual carefully. Be thoroughly familiar with

the controls and proper use of the power

vacuum.

2. Never allow children to operate this power

vacuum.

3. Keep the area of operation clear of all per

sons, particularly small children and pets.

4. Check fuel before starting engine. Do not fill

fuel tank indoors, when engine is running, or

while engine is hot. Wipe off any spilled fuel

before starting engine.

5. Do not change engine governor settings.

6. Do not put hands near rotating parts for

any reason.

7. If the power vacuum should start to vibrate

abnormally, stop the engine and check

immediately for the cause. Vibration is

generally a warning of trouble.

8. Before cleaning, repairing or inspecting make

certain all moving parts have come to a

complete stop. Disconnect spark plug wire

and keep wire away from plug to prevent

accidental starting. Also keep throttle control

lever in the stop position.

9. If the power vacuum should become blocked

with debris at any point shut engine off and

wait until the impeller comes to a complete

stop before attempting to remove the

obstruction. Disconnect spark plug wire to

prevent accidental starting.

10. Check all bolts for tightness at frequent

periods.

11.

Never store this power vacuum with fuel in the

tank. Allow engine to cool before starting in

any enclosure.

12.

Keep bag and equipment free of debris when

not in use.

13. Never operate this power vacuum unless air

duct and vacuum bag are properly affixed

in their place. Large zippered end of bag must

be closed when operating to prevent objects

from being blown out.

14. Never empty vacuum bag when engine is

running.

15. Never change inlet nozzle or auxiliary hose

attachment when engine is running.

16. The manufacturer recommends that the

operator wear safety glasses or some other

suitable eye protection when operating this

machine.

17. Check the vacuum bag frequently for wear and

replace when necessary.

Page 4

ASSEMBLY

INSTRUCTIONS

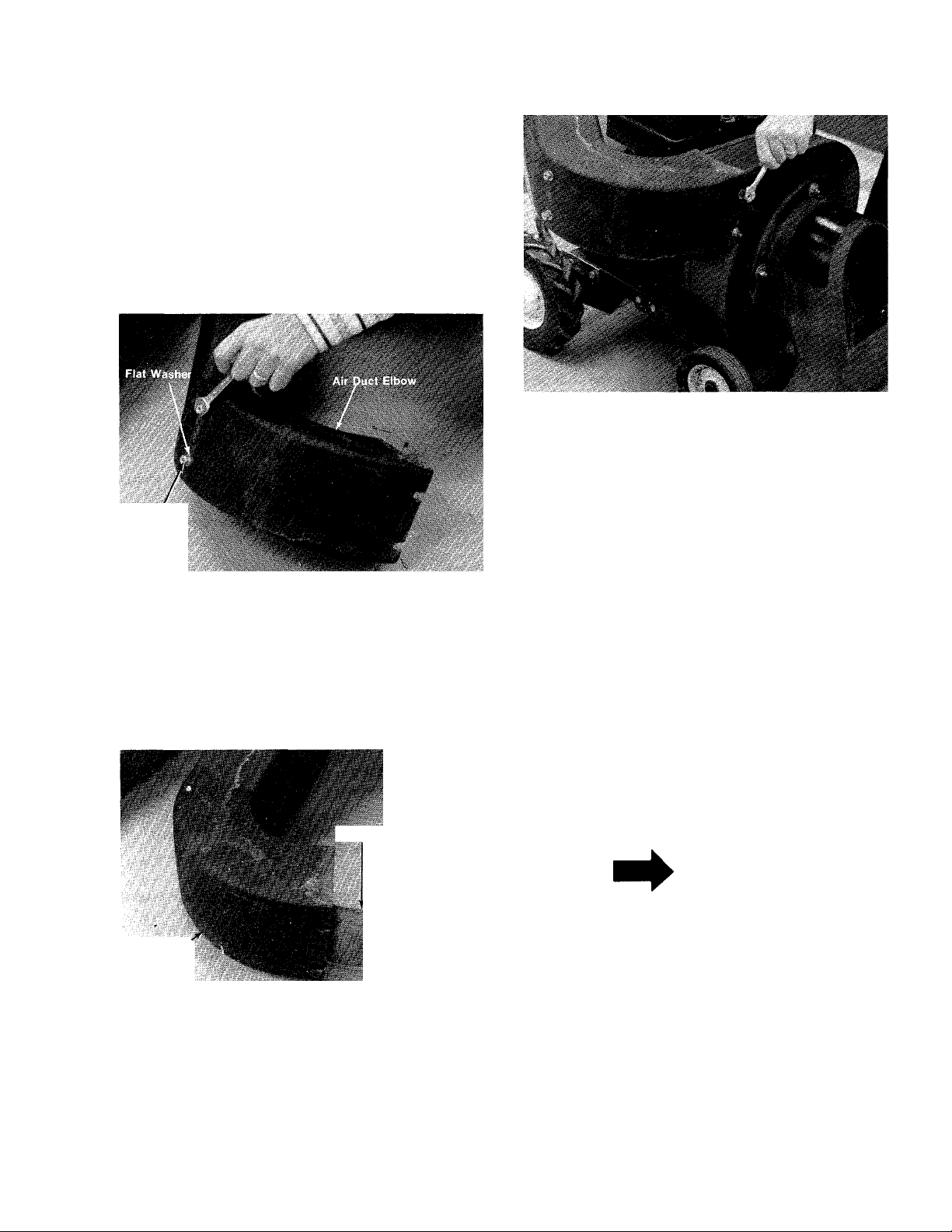

(Refer to figures 1, 2 and 3)

1. Place the upper handle in position and fasten

with four (4) hex screws and hex centerlock

nuts provided.

2. Place the air duct liner (studded end first) into

the elbow of air duct. See figure 1.

Hex Nut

FIGURE 1.

3. Insert studs of air duct liner through holes in

air duct. Thread on two (2) flat washers and

hex nuts (provided) several turns—do not

tighten. See figure 2.

Air Duct I in»r

FIGURE 3.

5. Secure the two (2) hex nuts onto the air duct

liner studs at the air duct elbow.

6. Slide the vacuum bag over the back of the

upper handle and snap the four flaps to hold

the bag.

7. Fasten the deflector on the top of the air duct

with three hex screws, flat washers and hex

nuts. (Seefigure!.)

8. Slide the bag over the air duct.

9. Fasten the nozzle to the front of the vacuum

with four flat washers and thumb nuts

provided.

10. Use the following steps on the self propelled

unit only.

11. Fasten the throttle control to the right hand

side of the upper handle with one hex screw

and hex center iocknut provided.

12. Secure throttle control cable to the lower

handle with the cable clip provided.

Air Duct

FIGURE 2.

4. Place the air duct in position on the blower

housing and fasten with four (4) flat washers

and hex nuts provided. See figure 3.

NOTE

Cable clip must be assembled to

lower handle with the open end

towards the engine. This will pre

vent wear to the bag.

13. Place ferrule through control lever.

.r

14. Place flat washer over ferrule and thread

control rod into ferrule about eight or nine

turns.

15. Hook formed end of controi rod in the shifting

finger.

16. Place curved face of spacer towards the

outside of upper handle left hand side.

Page 5

17. Fasten control lever in position with hex

screw and two hex nuts provided.

18. Engage and disengage control lever, check for

free pivoting action. It may be necessary to

readjust the control rod.

OPERATION

3. After two or three full firm pulls on recoil (or

as soon as engine fires), move speed control

to run position.

4. Operate a new engine at intermediate speeds

and light toad for the first few hours as you

would a new automotive engine.

1. Service engine with gas and oil. See engine

manual packed with vacuum for complete

instructions for care and maintenance of

engine. READ DIRECTIONS CAREFULLY.

START ENGINE

After the engine has been properly fueled and

oiled (refer to engine operating and maintenance

instructions), start engine in the foiiowing

manner.

PUSH MODEL

1. Move throttle control lever on engine to

START position.

2. Crank engine. Pull recoil with a quick firm

pull. Do not pull out so far that rope stops

with a jerk as this will cause rope failure. Do

not allow rope and handle to snap back into

place.

5. To stop engine, move speed control lever on

engine to STOP position.

6. If carburetor needs adjustment to start or for

operation, see “Carburetor Readjustment^’

section.

SELF PROPELLED MODEL

1. Place drive engagement lever in the neutral

position (towards the operator).

2. Move throttle control lever on handle to

START position.

3. Crank engine. Pull recoil with a quick firm

pull. Do not pull out so far that rope stops

with a jerk as this will cause rope failure. Do

not allow rope and handle to snap back into

place.

Page 6

249-670A

249-680A

IF YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

air escape located on the

upper right hand side. This

should be open when the

bag becomes half full.

EXPLODED VIEW OF UPPER HANDLE

Page 7

PARTS LIST FOR MODELS 249-670A AND 249-680A

REF.

PART

NO.

NO.

720-0142

1

710-0606 HexScr. 1/4-20x1.50” Lg.*

2

COLOR

CODE

DESCRIPTION

Grip(680A)

(680A)

711-0596

3

736-0108

4

Control Rod (680A)

FI. Wash. .510” I.D. x .75”

O.D. (680A)

711-0179

5

712-0107

6

Adj. Ferrule (680A)

Hex Center L-Nut 1^-20 Thd.

(680A)

736-0173

7

Flat Wash. .28” I.D. x .75”

O.D. X .063

710-0289

8

731-0404

9

10

13316

710-0106

11

12234

12

712-0107

13

764-0127

14

12104

15

712-0107 Hex Center L-Nut V4-20 Thd.

16

Hex Scr. 1/4-20 X .50” Lg.*

Air Duct

Air Duct Liner

HexScr. 1/4-20x1.25” Lg.*

Upper Handle

Hex Center L-Nut V4-20 Thd.

Vacuum Bag

Deflector

(680A)

746-0202

17

Throttle Control Ass’y-—

Comp. (680A)

710-0606

18

Hex Scr. 1/4-20 X1.50” Lg.*

(680A)

19

20

21

23

748-0210

12226

746-0229

731-0344

Spacer (680A)

Control Lever(680A)

Conduit and Wire

Plastic Label

NEW

PART

*For faster service obtain standard nuts, bolts and washers

locally. If these items cannot be obtained locally, order by

part number and size as shown on parts list.

(436—Radiant Yellow)

When ordering parts, Ifcoior or finish is important use the

appropriate color code shown above (e.g. Radiant

Yellow Finish—12236 (436).)

This instruction manuai covers various

modeis and all specifications shown do not

necessariiy appiy to your modei. Specifica

tions subject to change without notice or

obligation.

NOTE

NOTE; The engine is not under warranty by

the vacuum manufacturer.. .If repairs or

service is needed on the engine, please

contact your nearest author

ized engine service outiet.

Check the “Yellow Pages” of

your telephone book under

“Engines—Gasoline.”

Find It Fast

In The

Yellow Pages

Page 8

249-670A

249-680A

NOTE

Cable clip must be assembled to

lower handle as shown, with open

end towards the engine. This will

EXPLODED VIEW OF FRAME

8

Page 9

PARTS LIST FOR MODELS 249-670A AND 249-680A

REF.

PART

NO.

NO.

1 710-0258

COLOR

CODE

DESCRIPTION

Hex Scr. V4-20X.62” Lg.‘

(680A)

2 736-0329

Spring L-Wash. V4”Scr.*

(680A)

3 712-0116

Hex Ins. L-Nut 3/8-24 Thd.

(680A)

4 736-0117

714-0127

5

FI.-Wash. (680A)

Cotter Pin 1/16” Dia. X.75”

(680A)

6 754-0176

“V”-Belt 1/4” X 22.76” Lg.

(680A)

7 710-0938

Set Scr 1/4-28 X .25” Lg.

(680A)

711-0614

8

9 756-0194

10 12206

11

732-0157

12

712-0429

P.T.O. Sheave (680A)

Idler Pulley (680A)

Idler Brkt. Ass’v. (680A)

Spring .38”O.D. (680A)

Hex Ins. L-Nut 5/16-18 Thd.

(680A)

13 738-0140

Shoulder Bolt .437” Dia. x

.180 (680A)

14

711-0596

15 12231

16 712-0429

Control Rod (680A)

Shifting Finger(680A)

Hex Ins. L-Nut 5/16-18 Thd.

(680A)

17

12213 —463

18 732-0237

19 714-0474

Pivot Brkt. Ass’y. (680A)

Compression Spring (680A)

Cotter Pin 1 /8” Dia. x .75”

Lg.‘(680A)

20 736-0300

21

714-0137

FI.-Wash. (680A)

Hi-Pro-Key 3/16” X 3/4” Dia.

x1.062”Lg.(680A)

22

12216

23 711-0594

24

720-0132 Grip

25

12208

Shifting Yoke Ass’y. (680A)

Shifting Fork Rod (680A)

Index Handle Ass’y.

26 732-0231 Torsion Spring

27

712-0107

28 12240

29

748-0161

—463 Pivot Brkt. Ass’y.—R.H.

30 748-0164

31

736-0116 Fi .-Wash. (680A)

32

716-0115

Hex Center L-Nut V4-20 Thd.

Clutch Collar(680A)

Sprocket 10 Teeth (680A)

Snap Ring for .625” Dia.

(680A) ■

33

34

35

36

37

38

756-0195

736-0160

748-0742

710-0136

12241

—463 Pivot Brkt. Ass’y.—L.H.

714-0115

Drive Pulley (680A)

Fl.-Wash. (680A) '

Flange Bearing (680A)

Hex Scr. 1/4-20x1.75” Lg.*

Cotter Pin 1/8” Dia. X 1.00”

Lg.*

39

736-0116 Fl.-Wash.

40 12217

41

734-0225

42

748-0176

43

736-0116 Fl.-Wash.

44

714-0115

—463

Front Axle Ass’y.

Front Wheel Ass’y.—Comp.

Flange Bearing .630” I.D.

Cotter Pin 1/8” Dia. X 1.00”

Lg.*

45 712-0107

Hex Center L-Nut V4-20 Thd.

(680A)

46

736-0329

12227

47

48

710-0118 Hex Scr. 5/16-18 x.75” Lg.

—463

L-Wash. 1/4” Scr.* (680A)

Bearing Support Brkt. (680A)

(680A)

NEW

PART

REF

NO.

PART

NO.

COLOR

CODE

DESCRIPTION

49 736-0119 L-Wash. 5/16” Scr.* (680A)

50 12211 —463 Gear Box Mtg. Brkt. Ass’y.

(680A)

51 736-0119 L-Wash. 5/16” Scr.* (680A)

52

710-0118 Hex Scr. 5/16-18 X.75” Lg.*

(680A)

53 736-0329 L-Wash. 1/4” Scr.* (680A)

54 12222

712-0267

55

—463 Gear Box Brace (680A)

Hex Nut 5/16-18 Thd. *

(680A)

56 736-0119 L-Wash. 5/16” Scr. (680A)

57

710-0258 Hex Scr. V4-20X.62” Lg.*

(680A)

58 710-0148 Hex Wash. Hd. F-TappScr. #8

-32 X .38” Lg. (680A)

59 717-0325

Gear Box Ass’y.—Comp.

(680A)

60 714-0126 #9 Hi-Pro-Key 3/16” X 3/4” Dia.

(680A)

61 713-0118 Chain #41 X 61 Links (680A)

62

713-0723

#41 Master Link V2” Pitch

Type II (680A)

63

710-0118

64

736-0119 L-Wash. 5/16” Scr.*

712-0267

65

66 736-0119

67 12224

68 12200 —463

69 748-0227

Hex Scr. 5/16-18 X.75” Lg.*

Hex Nut 5/16-18Thd.*

L-Wash. 5/16” Scr.*

Index Plate Ass’y.

Engine Mtg. Frame Ass’y.

Hex Flange Bearing .630” I.D.

70 736-0116 Fl.-Wash.

71

710-0258 Hex Scr. 1/4-20 X.62” Lg.*

72

736-0211 Fl.-Wash.

73 734-0576

75

710-0118

76

736-0119

77

712-0287

78 736-0329

79

710-0258

Rear Wheel Ass’y.—Comp.

Hex Scr. 5/16-18 X.75” Lg.*

L-Wash. 5/16” Scr.*

Hex Nut 1/4-20 Thd.* (680A)

L-Wash. 1/4” Scr.*(680A)

Hex Scr. 1/4-20 X.62” Lg.*

(680A)

80 12232

712-0107

81

82 726-0178

83

738-0185

717-0353

Chain Guard (680A)

Hex Center L-Nut V4-20 Thd.

Cable Tie (680A)

Rear Axle (670A)

Differential Ass’y.—Comp.

(680A)

84

12233 Lower Handle

712-0107

85

86 714-0229

Hex Center L-Nut V4-20 Thd.

#2 Woodruff Key 3/32 x V2”

Dia. Hdn. (680A)

87

748-0136

Pinion Gear .50” I.D. x 14

Teeth (680A)

88

711-0593

89 715-0246

Drive Shaft (680A)

Spring Pin Spirol 3/16” Dia. x

1.25 (680A)

90

748-0135

Bevel Gear .62” I.D. 28 Teeth

(680A)

91 08187

92

748-0110

Gear Box Cover (680A)

Flange Bearing .630” i.D.

(680A)

93 08189 Gear Box (680A)

94

748-0108

Flange Bearing .503” i.D.

(680A)

95

710-0442

Hex Scr. 5/16-18 X1.50 Lg. *

NEW

PART

Page 10

249-670A

249-680A

EXPLODED VIEW OF DRIVE ASSEMBLY

10

Page 11

PARTS LIST FOR MODELS 249-670A AND 249-680A

COLOR

CODE

—436

—436

DESCRIPTION

HexScr. 1/4-20x1.25” Lg.*

Part of Engine

Woodruff Key (680A)

Sq. Key V4” X2.00” Lg.

L-Wash. 5/16” Scr.*

Hopper to Engine Mtg. Plate

Gasket Strip—Pressure Sen.

Vane Plate Ass’yAir Vane

Blower Housing Ass’yNozzle

FI.-Wash. .344” I.D. x .88”

1

PART

NO.

710-0106

REF.

NO.

2

3 714-0108

4

714-0114

5

712-0267 Hex Nut 5/16-18” Thd.*

6

736-0119

7 11452

8

721-0128

9 12203

10 12230 —436

11

13320 —436

12

731-0211

13

736-0159

O.D. X .063

14

712-0254

15 710-0239

Thumb Nut 5/16-18 Thd.

Hex Scr. 3/8-24x1.75” Lg.

H.T.

736-0217 L-Wash. 3/8” Scr. Heavy Duty

16

712-0107

17

Hex Center L-Nut V4-20 Thd.

18 736-0211 Fl.-Wash. .285” I.D. x 1.25”

O.D. X .060

19 721-0129 Dust Pad—Pressure Sensitive

712-0241 Hex Nut 3/8-24” Thd.*

20

736-0217 L-Wash. 3/8” Scr. Heavy Duty

21

22

710-0118

23 736-0119

24

736-0119

25 710-0409

Hex Scr. 5/16-18 x.75” Lg.*

L-Wash. 5/16” Scr.*

L-Wash. 5/16” Scr.*

Hex Scr. 5/16-24 x 1.75” Lg. *

26 711-0591 Engine Spacer

27

28

29

30

736-0119

712-0267

749-0326

12228

L-Wash. 5/16” Scr.*

Hex Nut 5/16-18Thd.*

Engine

Engine Brace (249-670)

Engine Brace (249-680)

NEW

PART

N

*For faster service obtain standard nuts, bolts, and washers locally. If these items cannot be obtained lo

cally, order by part number and size as shown on parts list.

(436—Radiant Yellow)

When ordering parts, if color or finish is important use

the appropriate color code shown above (e.g. Radiant

Yellow Finish—12236 (436).)

NOTE; The engine is not under warranty by

the vacuum manufacturer.. .If repairs or

service is needed on the engine, please

contact your nearest author

ized engine service outlet.

Check the “Yellow Pages” of

your telephone book under

“Engines—Gasoline.”

Find It Fast

Yellow Pages

11

In The

Page 12

249-680A

(ONLY)

SHORT SHAFT

Lubricate with 2 oz.

Temp. Grease 450“F.

Part No. 737-0120.

FIGURE 4.

MODEL 717-0353 DIFFERENTIAL ASSEMBLY

PARTS LIST FOR FIGURE 4 MODEL 249-680A

REF.

NO.

PART

NO.

Qty.

Req’d.

DESCRIPTION

NEW

PART

1 715-0247 2 Spring Pin Spir. 3/16” Dia. x

1.00” Lg.

2

748-0185

3

738-0218

4

736-0188

2

Gear—Double “D” Hole

1 Shaft—Long 15.38” Lg.

2 FI-Wash. .760I.D.X1.49O.D.

5 717-0341 2 Housing Half

6

736-0119

7

710-0526

8 736-0187

9

748-0158

10

711-0276

11

712-0237

09054 1

12

13 738-0217 1

*For faster service obtain standard nuts, bolts and washers locally. If these Items cannot be obtained locally, order by part

number and size as shown on parts list.

2 L-Wash.5/16” Scr.*

2 Hex Scr. 5/16-24 x 4.00” Lg.*

2 FI-Wash. .6401.D. x 1.24 O.D.

2 Gear—Round Hole

1

Drive Pin

2 Hex Cent. L-Nut 5/16-24 Thd.

Sprocket—40 Tooth

Shaft—Short 8.31” Lg.

12

High

Order

Page 13

Page 14

PARTS INFORMATION

POWER EQUIPMENT PARTS AND SERVICE

Parts and service for all MTD manufactured power equipment are

available through the authorized service firms listed below. All orders

should specify the model number of your unit, parts number,

description of parts and the quantity of each part required.

ALABAMA BIRMINGHAM

Auto Electric & Carburetor Co. .. 2625 4th Ave. S..............

ARKANSAS NORTH LITTLE ROCK

Sutton’s Lawn Mower Shop .... Rt. 4 Box 368

...............

FORT SMITH

Mity Mile Motors, Inc......................2515 Towson Ave. . ..

CALIFORNIA PORTERVILLE

Billious

...........................................

75 North D Street....

SAN BERNARDINO

Lawn Mower Supply Co. ....... 25608 E. Baseline ...

SAN FRANCISCO

J.W. Jewett Co

.................................

981 Folsom St

.............

SACRAMENTO

Luttig & Severson

...............................

2030 28th St

.............

COLORADO DENVER

South Denver Lawn Equip

............

527 West Evans

FLORIDA JACKSONVILLE

Radco Distributors

....................................

2403 Market St

CORAL GABLES

Moz-AII of Florida, Inc

...................

365 Greco Ave

............

GEORGIA EAST POINT

East Point Cycle & Key............................. 2834 Church St

ILLINOIS LYONS

Keen Edge Co

................................

8615 Ogden Ave

............

INDIANA ELKHART

Parts & Sales Inc

............................

2101 Industrial Pkwy.

IOWA DUBUQUE

Power Lawn & Garden Equip. ... 2551 J.F. Kennedy ..

LOUISIANA NEW ORLEANS

Suhren Engine Co......................................8330 Earhart Blvd. . .

MARYLAND TAKOMA PARK

Center Supply Co

..................

6867 New Hampshire Ave.

MASSACHUSETTS SPRINGFIELD

Morton B. Collins Co

.....................

300BirnieAve................

MICHIGAN MOUNT CLEMENS

Power Equipment Dist................... 36463 South Gratiot .

LANSING

Lorenz Service Co........................... 2500 S. Pennsylvania

MINNESOTA MINNETONKA

Hance Distributing Inc

....................

11212 Wayzata Blvd..

ST. PAUL

Power Tools Inc

...................

3771 Sibley Memorial Hwy.

MISSISSIPPI BILOXI

Biloxi Sales & Service, Inc

...............

506 Caillavet St

MISSOURI KANSAS CITY

Automotive Equip. Service

...........

3117 Holmes St. ....

ST. JOSEPH

Ross-Frazier Supply Co

..................

8th and Monteray ...

ST. LOUIS

Henzier, Inc.......................................2015 Lemay Ferry Rd.

NEW JERSEY BELLMAWR

Lawnmower Parts Inc.............717 Creek Rd., P.O. Box 7

RUTHERFORD

Feld Distributor

NEW YORK

Gamble Dist., Inc.

................................

CARTHAGE

........

28 Glen Rd

West End Ave.

..................

...........

..........

.35233

.72117

.72901

.93257

.92410

.94107

.95818

.80223

.32206

............

.33146

.30344

............

.60534

.46514

.52001

.70118

.20012

.01107

.48043

.48900

.55343

.55122

.39533

.64109

.64503

.63125

.08030

.07070

.13619

BRIGGS AND STRATTON, TECUMSEH AND PEERLESS PARTS AND

SERVICE

Briggs & Stratton, Tecumseh and Peerless parts and service should h

handled by your nearest authorized engine service firm. Check I

yellow pages of your telephone directory under the listii.^

Engines—Gasoline, Briggs & Stratton or Tecumseh Louson.

SYRACUSE

GTP Leisure Products Inc

............

420 Marcellus St

.............

13204

NORTH CAROLINA GREENSBORO

Dixie Sales Company

.....................

327 Battleground Ave. 27402

GOLDSBORO

Smith Hardware Co

........................

515 N. George St

.........

27530

OHIO WADSWORTH

National Central .............................

687 Seville Rd

..............

44281

CLEVELAND

Bleckrie, Inc.....................................7900 Lorain Ave...........44102

CARROLL

Stebe’s Mid-State Mower Supply. Box 366-71 High St. ..43112

YOUNGSTOWN

Burton Supply Co

....................

1301 Logan Ave. Box 929 . 44501

OKLAHOMA MUSKOGEE

Victory Motors, Inc

.........................

605 S. Cherokee

..........

74401

OKLAHOMA CITY

Forest Sales Inc

...............................

1039 NW 63rd St

..........

73116

ADA

AdaAuto Supply

..............................

301 E.12th St

................

74820

OREGON PORTLAND

Kenton Supply Co

..........................

8216 N. Denver Ave. . .97217

PENNSYLVANIA CHESTER

Stull Equipment Corp.....................742 W. Front St

............

19013

HARRISBURG

EECO Inc

.........................................

4021 N. 6th St...............17110

PHILADELPHIA

Thompson Rubber Co

..................

5222-24 N Fifth St. ...19120

PITTSBURGH

BluemontCo....................................11125 Frankstown Rd. 15235

TENNESSEE KNOXVILLE

Master Repair Service

...................

2423 Broadway, N.E. .3791’

MEMPHIS

Memphis Cycle & Supply Co. ... 421 Monroe Ave

American Sales & Service, Inc. . .1922 Lynnbrook

................

..............

381u

38116

TEXAS DALLAS

Marr Brothers, Inc

.....................

423 E. Jefferson

.................

75203

HOUSTON

Bullard Supply Co

..........................

2409 Commerce St.. . . 77003

SAN ANTONIO

Catto & Putty, Inc.................................P.O. Box 2408 .78206

FORT WORTH

Woodson Sales Corp..................... 1702 N. Sylvania

.............

76111

UTAH SALT LAKE CITY

A-1 Engines. Mower Co

...............

437 E. 9th St

...................

84111

VERMONT BURLINGTON

Vermont Hdwe. Co. Inc

...............

180 Flynn Ave

..................

05401

VIRGINIA RICHMOND

RBI Corp........................................963 Myers St

....................

23260

WASHINGTON SEATTLE

Bailey’s Inc

..........................................

1414 14th Ave.98122

WEST VIRGINIA CHARLESTON

Young's, Inc

.....................................

233 Virginia St., E. .. .25301

WISCONSIN APPLETON

Automotive Supply Co

...................

123 S. Linwood Ave. . .54911

WARRANTY PARTS AND SERVICE POLICY

The purpose of warranty is to protect the customer from defects in workmanship and materials, defects which are NOT detected at the time of

monufacture. It does not provide for the unlimited and unrestricted replacement of parts. Use and maintenance are the responsibility of the

customer. The manufacturer cannot assume responsibility for conditions which it has no control. Simply put, if it's the manufacturer's fault, it's

the manufacturer's responsibility; if it's the customer's fault, it's the customer's responsibility.

CLAIMS AGAINST THE MANUFACTURER'S

WARRANTY INCLUDES

1. Replacement of Missing Parts on new equipment.

2. Replacement of Defective Parts within the warranty period.

3. Repair of Defects within the warranty period.

All claims MUST be substantiated with the following information:

1. Model Number of unit involved.

2. Date unit was purchased or first put into service.

3. Date of failure.

4. Nature of failure.

MTD PRODUCTS INC • 5389 WEST 13,0th STREET • P.O. BOX 2741 CLEVELAND OHIO 44111

Loading...

Loading...