Page 1

DUSRR

MODEL NUMBER

424/LCD/22

(249-623-003)

IMPORTANT:

•Read this Manual

Before Attempting

to Assemble and

LOG SPLITTER

Use

•Read Safety

Rules and

Instructions

Carefully

•Protect Your

Warranty —

Read “Important

Information for

Log Splitter

Users” (Page 2)

Carefully

DUERR INC. E. 12122 DAY MOUNT ROAD • MEAD, WA. 99021

(509) 238-6124

Page 2

IMPORTANT INFORMATION FOR LOG SPLITTER USERS

ALWAYS:

Use clean fluid and check fluid level regularl/

Use Dexron II Automatic Transmission Fluid

Use a fiiter (clean or replace regularly)

Use a breather cap on fluid reservoir

Keep end of reservoir return tube below fluid levei

Make certain pump is mounted and aligned properly

Use a flexible “spider” type coupling between engine

and pump driveshafts

Keep hoses clear and unblocked

Bleed air out of hoses before operating

Flush and clean hydraulic system before start jp after

any malfunction or servicing

Use “pipe dope” on aii hydraulic fittings

Aliow time for warmup before splitting wood

Prime the pump before initial startup by turni ig over

the engine with spark plug disconnected

Split wood with the grain (lengthwise) only

NEVER:

Use fluid below 0° F., or above 150° F.

Use a solid engine/pump coupling

Force pump when mounting

Operate through reiief valve for more than several

seconds

Attempt to adjust unloading or relief vaive settings

without pressure gauges

Operate with air in hydraulic system

Use Teflon tape on hydraulic fittings

Warm up engine apart from pump in cold weather

Attempt to cut wood across the grain

CONDITIONS WHICH WILL VOID YOUR WARRANTY

1. Failure to maintain proper fluid level ir reservoir will void your warranty, causing permanent damage to

pump by aliowing air to be drawn into pump. Fiuid will become foamy. Refer to “Initial Preparation” in the

Operation Section of this manuai.

2. Changing the relief valve setting or pressure adjustment of control valve without proper knowiedge and

instruction from the factory wiil void your warranty. A very minor adjustment couid destroy the structural and

safety limits for which the unit was desic ned. The system will produce more power than the structure will

withstand. Higher pressure could cause :he hoses to burst, cylinder to rupture and intense fluid reieases,

which could result in serious personal injury.

3. Disassembling the pump wiii void your warranty. If replacment is necessary, merely disconnect and replace.

Do not attempt to adjust pump settings, as they are adjusted by the manufacturer at the factory.

4. Use of incorrect hydraulic fluid will void your warranty. Use only Dexron II automatic transmission fluid.

Any other type of fluid must be approved by a direct factory representative.

5. The flexible pump coupler must be inspected regularly. Allowing the coupler to deteriorate will void your

warranty. Deterioration of spider insert and prolonged use after deterioration will destroy pump bearings and

engine bearings, along with total destruction of coupler hubs.

6. Improper beam lubrication will cause p emature wear and looseness. Lubricate the beam regularly. Lack

of lubrication will void your warranty.

7. Improper adjustment of splitting wedge: will void your warranty. Become familiar with the proper tolerance

required for adjustment of the splitting wedge as instructed in the adjustment section of this manual.

a. If wedge is too loose, cylinder beam ind wedge wear will result. Allowing the wedge to loosen and be

used under operating stress will cause damage which will not be covered under warranty.

b. If wedge is too tight, severe beam damage will result which will not be covered under warranty.

8. Warranty card must be mailed or delivered directly to factory. Proper information must be completed and

mailed as per instructions. No warranty ecords on file may result in delay.

9. Do not overheat the hydraulic system. Excessive heat will destroy the hydraulic system with hardened 0-rings

and excessive friction.

10. Do not attempt to start in temperatures under 20° F. without pre-heating fluid in reservoir. Excessively

cold fluid cannot circulate and draw into pump. Warranty will be void.

11. Repair any leaks in hydraulic system in mediately. Unattended leaks will cause air to enter system and/or

decrease fluid level in reservoir, causing di image to the hydraulic system which will not be covered by warranty.

Page 3

A

A

IMPORTANT

RULES FOR SAFE OPERATION

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL

SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE AT

TEMPTING TO OPERATE YOUR LOG SPLITTER. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL IN

JURY. WHEN YOU SEE THIS SYMBOL-^HEED ITS WARNING.

DANGER

AC

Your log splitter was built to be operated according to the rules for safe operation in this manual. As

with any type of power equipment, carelessness or error on the part of the operator can result in serious

injury. If you violate any of these rules, you may cause serious injury to yourself or others.

TRAINING

Before operating this splitter, read and understand this manual

completely. Become familiar with it for your own safety. To fail

to do so may cause serious injury. Do not allow anyone to operate

your splitter who has not read this manual. Keep this manual in

a safe place for future and regular reference and for ordering

replacement parts.

2. Never use your splitter for any other purpose than splitting wood.

It is designed for this use and any other use may cause an injury.

Your log splitter is a precision piece of power equipment, not a

playtoy. Therefore, excercise extreme caution at all times.

3. Never allow children to operate your log splitter. Do not allow adults

to operate it without proper instruction. Only persons well ac

quainted with these rules of safe operation should be allowed to

use your log splitter.

4. Only the operator is to be near your log splitter during use. Keep

all others, including pets and children, a minimum of 20 feet away

from your work zone. Flying wood can be hazardous. If a helper

is assisting in loading logs, never activate the control until the helper

is clear of the area. More accidents occur when more than one

person operates the log splitter than at any other time.

5. No one should operate this unit while intoxicated or while taking

medication that impairs the senses or reactions. A clear mind is

essential for safety. Never allow a person who is tired or other

wise not alert to use your splitter.

8. Only operate your splitter on level ground and not on the side of

a hill. It could tip, or rolling logs or poor footing could cause an

accident. Operating the splitter on level ground also prevents the

spillage of gasoline from the fuel tank.

9. Never attempt to move the log splitter over hilly or uneven terrain

without a tow vehicle or adequate help.

10. Always block the wheels to prevent movement of log splitter while

in operation.

11. Check the fuel before starting the engine. Gasoline is an extreme

ly flammable fuel. Do not fill the gasoline tank indoors, when the

engine is running, or while the engine is still hot. Replace gasoline

cap securely and wipe off any spilled gasoline before starting the

engine as it may cause a fire or explosion.

12. Both ends of each log must be cut as square as possible to help

prevent the log from riding out of the splitter during operation.

A

OPERATION

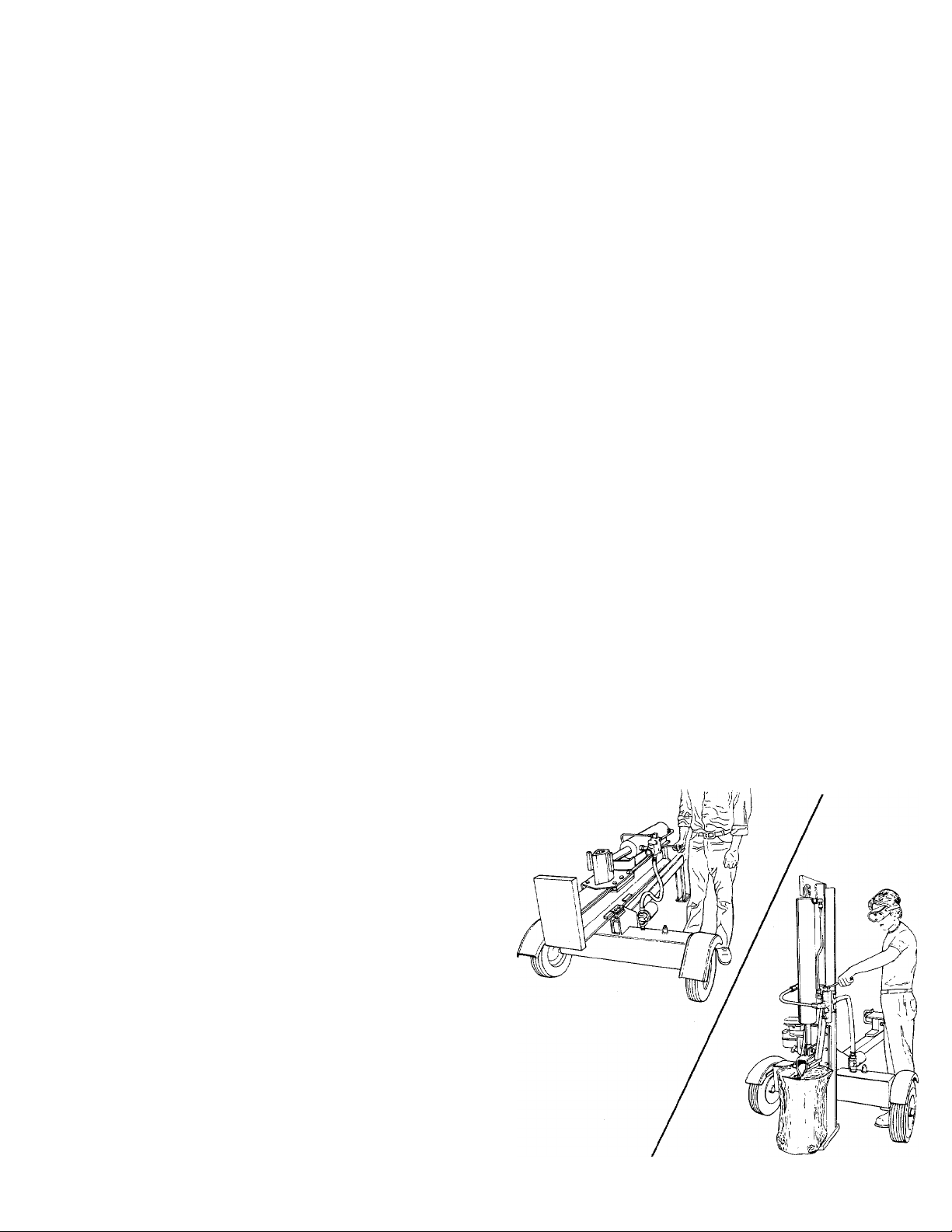

1. Stand behind the reservoir tank when operating. See illustrations.

A

A

PREPARATION

1.

Never wear loose clothing or jewelry that can be caught by mov

ing parts of your log splitter and pull you into it. Keep clothing

away from all moving parts of your log splitter.

Wear proper head gear to keep hair away from moving parts.

Always wear protective hearing devices as needed.

3.

Always wear safety shoes. A dropped log can seriously injure your

foot.

4. Always wear safety glasses or goggles while operating your split

ter. A piece of splitting log could fly off and hit your eyes.

5. If you wear gloves, be sure they are tight fitting without loose cuffs

or draw strings.

6. Use your log splitter in daylight, or under good artificial light.

7. Never operate your splitter on slippery, wet, muddy or icy sur

faces. Safe footing is essential in preventing accidents. Never

operate your splitter while attached to a towing vehicle.

Page 4

2. Know how to stop the unit and disengage the con :rols.

3. Never place hands or feet between log and splitting wedge or be

tween log and end plate during forward or reverse stroke. To do

so may result in crushed or amputated fingers or tot s, or worse,

you may lose an arm or foot.

4. Do not straddle the splitter when using it. A siip in any position

could result in a serious injury.

5. Do not step over your iog splitter when the engine is unning. You

may trip or accidentally activate the splitting wedgn if you step

over. If you need to get to the other side, walk arDund.

6. Never try to split two logs on top of each other. One may fly out

and injure you.

7. When loading the log splitter, place your hands on the side of the

log, not at the ends. Never attempt to load your splitter while the

splitting wedge is in motion. You may get caught b/ the wedge

and injured.

8. Only use your hand to operate the splitting wedge or control lever.

Never use your foot or a rope or any other extension device. This

could result in your ability to stop your splitter quickly enough

and cause injury.

9. Always keep fingers away from any cracks that op( n in the log

during splitting operation. They can quickly close <nd pinch or

amputate your fingers.

10. Never attempt to split woods across the grain. Some t pes of wood

may burst or fly out of your splitter and result in i ijury to you

or a bystander.

11. For logs that are not cut square, the longest porticn of the log

should be rotated down and the most square end pi iced against

the splitting wedge.

12. Keep your work area clean. Immediately remove split wood around

your splitter so that you do not stumble over it. Clean chips and

dirt off end plate (wood platform) after each log is split, or whenever

necessary to maintain flat contact between wood a id end plate

(platform).

13. Never move the log splitter while the engine is rut ning.

14. Never leave your log splitter unattended with the ent ine running.

Shut off the engine if you are leaving your splitter, evt :n for a short

period of time. Someone could accidentally activate the splitting

wedge and be injured.

15. Do not run engine in an enclosed area. Exhaust gasej contain car

bon monoxide. This odorless gas can be deadly when inhaled.

16. Be careful not to touch the muffler after the engine has been run

ning as it is HOT.

17. If the equipment should start to vibrate abnormally, st( >p the engine

and check immediately for the cause. Vibration is geni ¡rally a warn

ing of trouble.

18. When cleaning, repairing or inspecting, make certain all moving

parts have stopped. Disconnect the spark plug wire ind keep the

wire away from the plug to prevent accidental sta ting.

MAINTENANCE

A

Do not operate your splitter in poor mechanical condition or when

in need of repair.

Periodically check that all nuts, bolts, screws, hose clamps and

hydraulic fittings are tight to be sure equipment is in >afe working

condition. Where appropriate, check all safety guards and shields

to be sure they are in the proper position. Never operite your split

ter with safety guards, shields or other protective featu es removed.

These safety devices are for your protection.

NOTE: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-covered

or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting iipplicable local or state laws (if any). If

a spark arrester is used, it shouid be maintained in effect ve working order by the operator.

In the State of California the above is required by law (Seition 4442 of the California Public Resources Code). Other states may have similar

laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer

or through DUERR INC.

3. Replace all damaged or worn parts such as hydraulic hoses and

fittings immediately with manufacturer approved replacement parts.

4. Do not change the engine governor settings or overspeed the,

engine. This increases the hazard of personal injury. The max

imum engine speed is preset by the manufacturer and is within

safety limits.

5. Do not alter your splitter in any manner such as attaching a rope

or extension to the control lever or adding to the width or height

of the wedge. Such alterations may cause your splitter to be unsafe.

6. Perform all recommended maintenance procedures before you use

your splitter.

7. Do not service or repair your log splitter without disconnecting

the spark plug wire.

8. Never store the equipment with gasoline in the tank inside of a

building where ignition sources are present, such as hot water

and space heaters, clothes dryers and the like. Allow the engine

to cool before storing in any enclosure.

9. Always store gasoline in an approved, tightly sealed container.

Store the container in a cool, dry place. Do not store in a building

where ignition sources are present.

10. To reduce fire hazard, keep engine free of grass, leaves, wood

chips, and excessive grease and oil.

11. The hydraulic system of your log splitter requires careful inspec

tion, along with the mechanical parts. Be sure to replace frayed,

kinked, or otherwise damaged hydraulic components.

12. Fluid escaping from a very small hole can be almost invisible. Do

not check for leaks with your hand. Escaping fluid under pressure

can have sufficient force to penetrate skin, causing serious per

sonal injury. Leaks can be located by passing a piece of card

board or wood over the suspected leak and looking for

discoloration.

13. Should it become necessary to loosen or remove any hydraulic,

fitting or line, be sure to relieve all pressure by shutting off the

engine and moving the control handle back and forth several times.

14. Do not remove the cap from the hydraulic tank or reservoir while

your log splitter is running. Hot oil under pressure could cause

injury.

15. The pressure relief valve on your splitter is preset at the factory.

Do not adjust the valve. Only a qualified service technician should

perform this adjustment.

16. Completely drain fuel tank prior to storage. This guards against

accumulation of fuel fumes which could result in a fire hazard.

17. Never store log splitter outside without a waterproof cover. Rain

will cause rust on the inside of the cylinder.

A

TOWING

This unit should not be towed on any street, highway or public

road without checking the existing federal, local or state vehicle

requirements. Any licensing or modifications such as taillights,

etc., needed to comply with the existing federal, local or state

vehicle requirements is the sole responsibility of the purchaser.

Before towing, be certain the log splitter is correctly and securely

2.

attached to the towing vehicle, and the safety chains are in place.

Leave slack in chains for turning allowance.

3.

Do not allow anyone to sit or ride on your splitter. They can easily

fall off and be seriously injured.

4

Page 5

IMPORTANT

This unit has been shipped without

gasoiine or oil in the engine. After

assembiy, refer to separate engine

manual for proper fuel and engine oil

information.

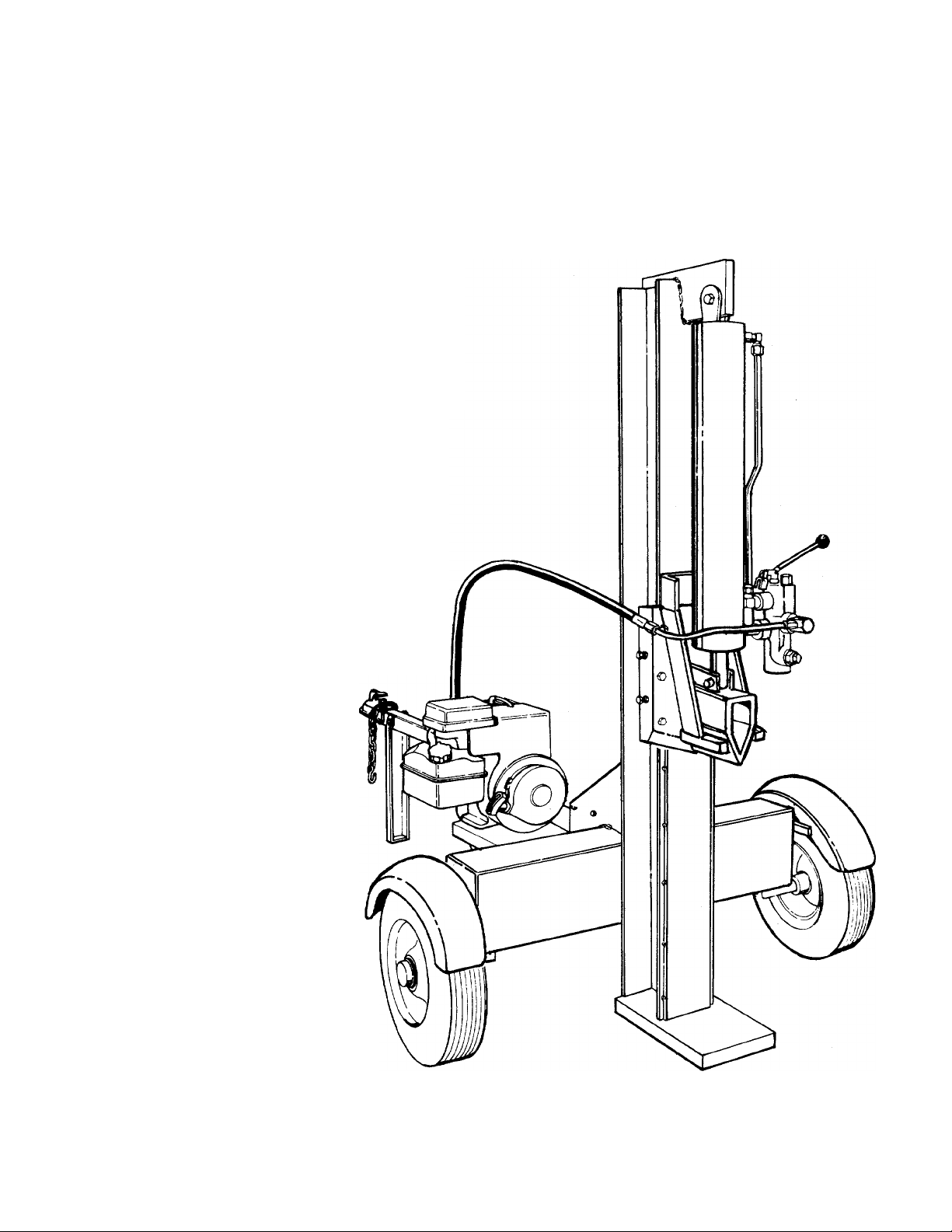

„ . . „ Beam Support/

Engine and Reservoir Latch Bracket

Pump Assembly Tank Assembly I

ASSEMBLY

UNPACKING

Remove the log splitter parts from the cartons by cut

ting the corners of the cartons. Make certain all parts

and literature have been removed from the cartons

before the cartons are discarded.

All hardware for assembly of the log splitter has been

placed in position on the various parts.

s FIGURE 1.

Wedge, Beam and

Cylinder Assembly

-Hitch

Assembly Tongue Assembly

Beam

Hinge

Bracket

-Parts in Cartons (See figure 1)

Carton marked 1 of 2:

Reservoir Tank Assembly

Engine and Pump Assembly (Bolted to bottom of

carton)

Beam Hinge Bracket

Fenders (Not Shown)

Carton marked 2 of 2:

Tongue Assembly

Wedge, Beam and Cylinder Assembly

Hitch Assembly

Beam Support/Latch Bracket

Tools Required for Assembly

(2) 9/16" Wrenches*

(2) 1/2" Wrenches*

(1) Adjustable Wrench

(1) Knife (to remove cable tie)

(1) Screwdriver

*Adjustable Wrenches may be used.

Other Materials Required for Assembly:

Engine Oil

Unleaded Gasoline (regular grade gasoline is an

acceptable substitute)

Approximately 7.6 Gallons of Dexron II Automatic

Transmission Fluid

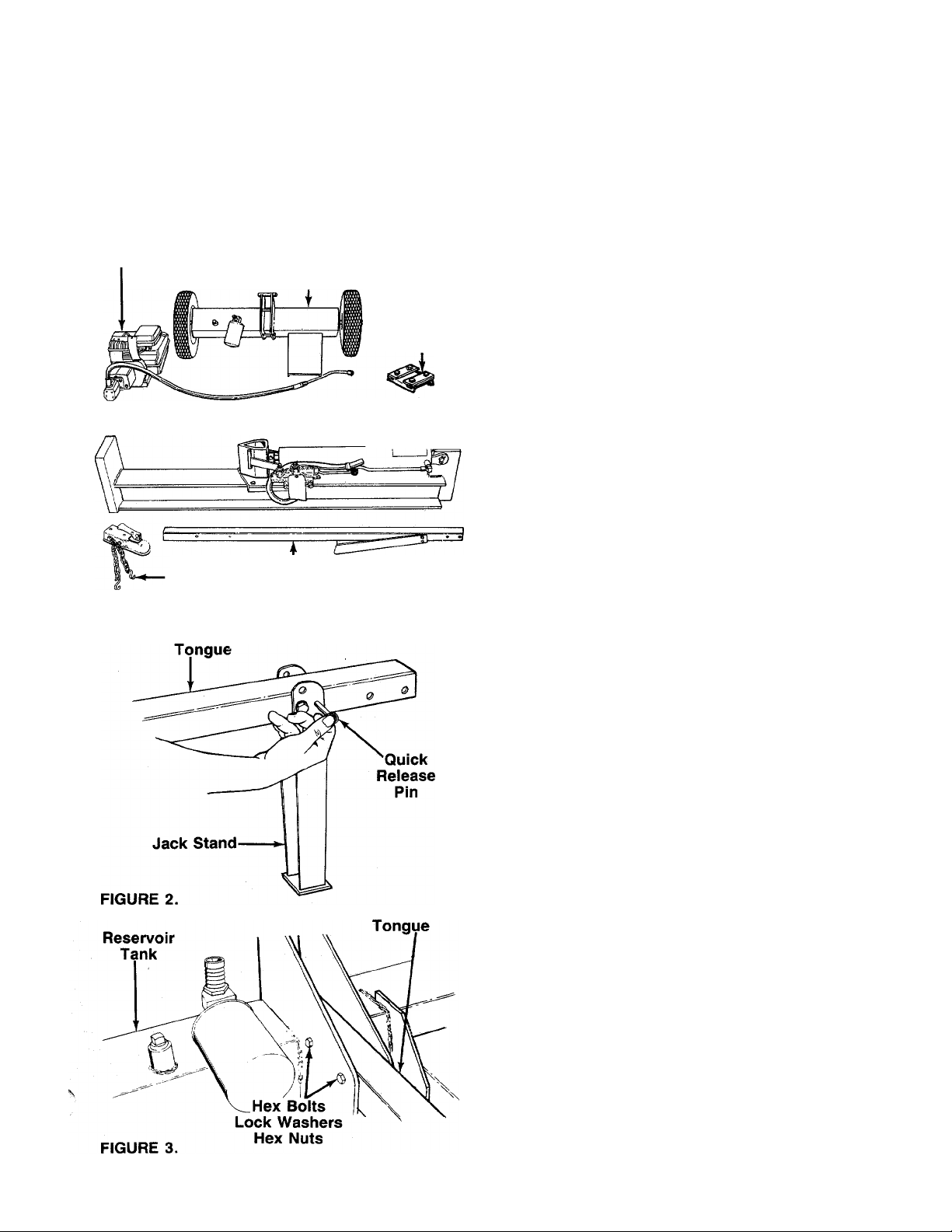

ATTACHING TONGUE TO RESERVOIR TANK

—1. The tongue is shipped with the jack stand already

attached to the tongue. The jack stand is in the

transport position. Remove the quick release pin.

Pivot the jack stand to the operating position (90°),

and secure with the quick release pin. See figure 2.

2. Remove the two hex bolts, lock washers and hex

nuts on the front of the reservoir tank. Two 9/16"

wrenches are required. Place the tongue in posi

tion, and secure with hardware just removed. See

figure 3.

Page 6

Hex Nuts

INSTALLING THE HITCH

1. Using two 9/16" wrenches, remove the two long

hex bolts, lock washers and hex nuts which are

assembled through the sides of the hitch. Do not

remove the chain and spacer from the one hex

bolt.

2.--Place the hitch in position on the end of the tongue

-------

as shown in figure 4. Secure with hardware just

removed.

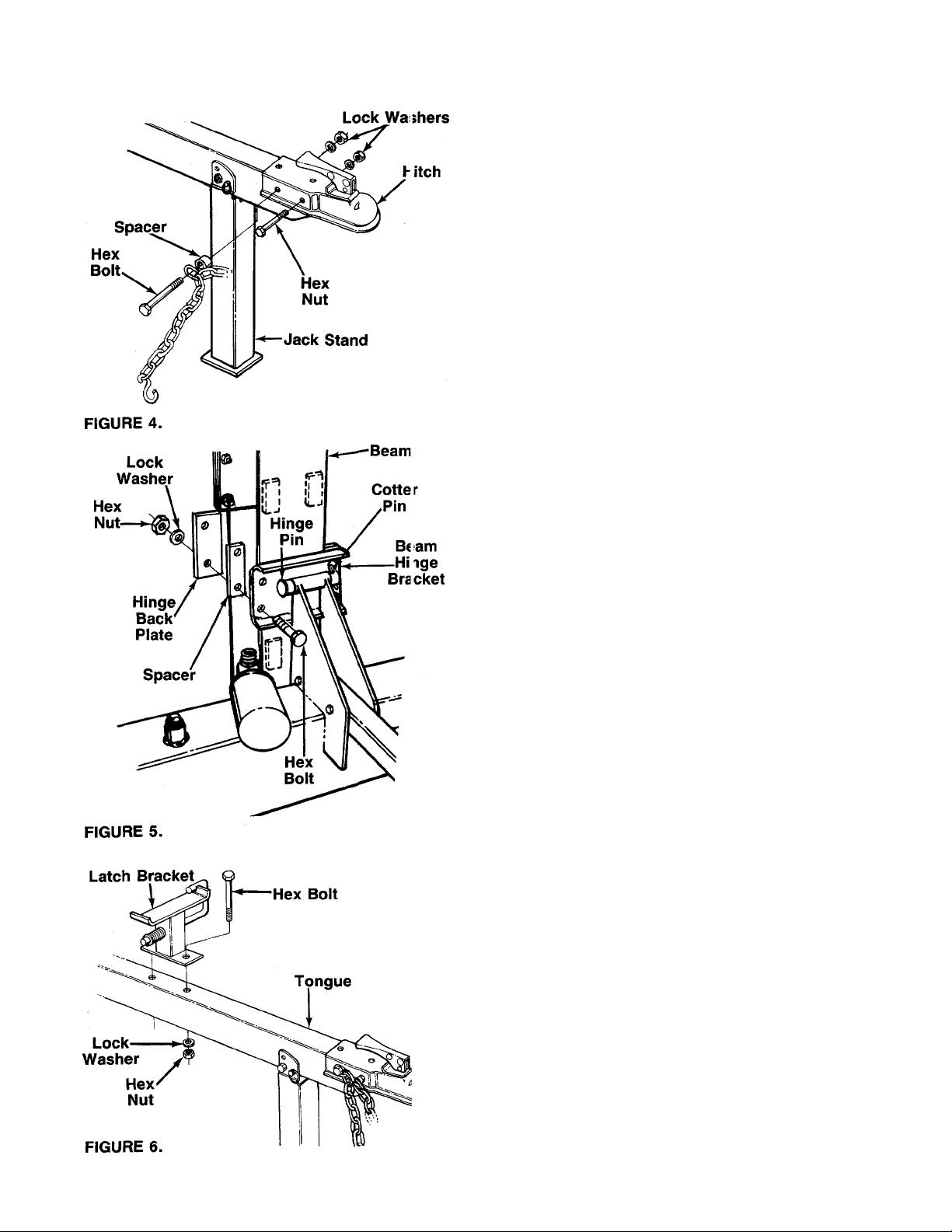

ATTACHING THE WEDGE, BEAM AND CYLINDER ASSEMBLY

1. Stand the wedge, beam and cylinder assembly

upright.

2. Remove the cotter pin from the hinge pin, located

on top of the reservoir tank assembly. Place the

beam hinge bracket in position on the reservoir

-------

tank assembly as shown in figure 5. Secure with

hinge pin and cotter pin just removed.

3. Using two 9/16" wrenches, remove two hex bolts,

lock washers, hex nuts and the hinge back plate

and spacer from one side of the beam hinge

bracket. Move the reservoir tank assembly in posi

tion against the beam, sliding one edge of the

beam into the beam hinge bracket. See figure 5.

4. Place the spacer beside the beam. Secure with the

hinge back plate, hex bolts, lock washers and hex

nuts. Tighten securely.

Beam Support/

ATTACHING THE BEAM SUPPORT/LATCH BRACKET

1. Remove the two hex bolts, lock washers and hex

nuts from the tongue, using two 9/16" wrenches.

2. With the beam still in the upright position, place

the beam support/latch bracket on the tongue as

--------shown in figure 6. Secure with hex bolts, lock

washers and hex nuts just removed. Tighten

securely.

Page 7

ATTACHING THE ENGINE AND PUMP ASSEMBLY

1. Using two V2" wrenches, remove the four hex

bolts, lock washers and hex nuts which secure the

base of the engine to the bottom of the shipping

carton.

Piace the engine and pump assembly in position

2.

on the engine mounting bracket as shown in figure

-7. Secure with hardware just removed. Tighten

securely.

ATTACHING THE FENDERS

1. Using two Vz" wrenches, remove the hex nuts, lock

washers, flat washers and hex bolts from the

fender support brackets.

2. Place the fenders in position against the fender

support brackets. Insert hex bolts through holes

in support brackets and fenders. Secure with flat

washers, lock washers and hex nuts. See figure

--------

8. Tighten securely.

FIGURE 8.

©

FIGURE 9.

ATTACHING THE CONTROL HANDLE

1.

The control handle and the return hose are

attached to the metal pressure tube with a cable

tie for shipping purposes only. Cut and remove the

cable tie.

2.

The bottom of the control handle is already at

tached to the valve with a cotter pin and clevis pin.

Remove the second cotter pin and clevis pin which

are attached to the valve only. Place the handle

in position, and secure using the second cotter pin

-and clevis pin. See figure 9.

Page 8

Filter

Head

FIGURE 10.

'Control

Valve

Reservoir

Tank

Suction

Control

Valve

*ump

Hose

ATTACHING THE HOSES Suction Hose

1. The suction hose is attached to the reservoir tank,

beneath the engine mounting plate. Loosen the

hose clamp on the free end of the hose using a

screwdriver.

2.--Attach the end of the hose to the fitting on the bot-

--------tom of the pump. See figure 10. Place the hose

clamp at the base of the fitting, and tighten

securely.

Return Hose

1. The return hose is attached to the bottom of the

valve. Loosen the hose clamp on the free end of

the hose using a screwdriver.

2. Attach the end of the hose to the fitting on top of

the filter head. See figure 10. Place the hose clamp

at the base of the fitting, and tighten securely.

Pressure Hose

The pressure hose is attached to the top of the pump.

-Route the hose as shown in figure 11. Place the metal

pressure tube in position on the fitting on top of con

trol valve. Secure with the compression nut on the

pressure tube, using an adjustable wrench.

Metal

Pressure

Tjbe

FIGURE 11.

OPERATION

INITIAL PREPARATION

1. Place the log splitter on a firm, level surface.

2. Service engine with gasoline and oil as instructed

in the separate engine manual packed witf your

log splitter.

3. Lubricate the beam area where splitting wed( le will

slide with engine oil (DO NOT USE GREASE).

Make certain to oil both front and back of the beam

face.

4. Fill the reservoir tank as follows.

a. Remove reservoir vent plug. See figure 12.

Using Dexron II automatic transmission fluid,

fill reservoir to the top. Replace vent plug

securely.

FINAL ASSEMBLY

1. Make certain all nuts, bolts and hose clamps are

tightened securely.

2. Before operating the log splitter, make certain to

follow “Initial Preparation” instructions, below.

b. Disconnect the spark plug wire. Prime the

pump by pulling the recoil starter, to turn the

engine over, approximately 10 times. Recon

nect the spark plug wire.

Page 9

TO STOP ENGINE

1. Move throttle control lever to OFF position.

2. Disconnect spark plug wire from spark plug to pre

vent accidental starting while equipment is unat

tended.

USING THE LOG SPLITTER

Use the log splitter only on a level, hard surface.

Never stand next to the splitting wedge when

operating the log splitter. Always stand behind the

reservoir tank. See figures 14 and 15. Never attempt

to cut a log in half sideways. Always split the log

lengthwise. Maximum length of log to be split is 24".

If all logs are of a smaller length, refer to “Log

Dislodger” in Adjustment Section.

At

Always use the log splitter in the

vertical position only when splitting

heavy logs.

The control handle has three positions:

FORWARD—Push the control handle down for vertical

operation, push it forward for horizontal OperationSplitting wedge moves, toward the end plate. Con

trol handle will return to neutral position as soon as

handle is released.

NEUTRAL (Middle position)—Splitting wedge stops

in place.

REVERSE—Push the control handle upward for ver-

ical operation, push it toward the rear for horizontal

operation—Splitting wedge returns. The control han

dle will lock in the reverse position, and will return

to neutral automatically when the reverse stroke is

complete.

TO OPERATE LOG SPLITTER:

1. Set throttle at maximum speed.

2. Place the log upright, on top of end plate for ver

tical operation, and on top of beam for horizontal

operation.

3. Push the control handle in forward position until

the splitting wedge just contacts the log. Release

the control handle.

4. Step behind the reservoir tank (see figures 14

or 15) and push the control handle in forward posi

tion until the log is split.

5. Move the control handle to reverse position to

return the splitting wedge.

10

Page 10

Start engine. Use the control handle to 3xtend

c.

the wedge to the far extended position. Leave

the wedge in this position (do not retract).

Refill tank to within IV2" to 2" from the top of

d.

the tank. Total capacity of system is e pprox-

imately 7.6 gallons.

Now retract the wedge. Extend and retract the

e.

wedge fully 10 to 12 complete cycles to temove

trapped air in the system (system is “self

bleeding”).

Refill the reservoir to within 1V2" to 2" from

the top of the tank. Much of the original fluid

has been drawn into the cylinder and hoses.

Make certain to refill the reservoir, to prevent

extreme damage to the hydraulic pump. Failure

to refill the tank will void your warranty.

IMPORTANT

Reservoir tank must be full as

instructed. Low fluid level will damage

the pump and void your warranty.

3. Lubricate the beam area where splitting wedge will

slide with engine oil (DO NOT USE GREASE).

Make certain to oil both front and back of the beam

face.

4. Fill gasoline tank as instructed in separate engine

manual.

5. Attach spark plug wire to spark plug.

NOTE

Some fluid may overflow from the

vent plug as the system builds heal

and the fluid expands and seeks its

own level.

WARNiNG 1

Do not operate the log splitter withou :

A

the proper amount of transmissior

fuild in the reservoir tank.

♦♦♦♦♦♦♦♦

BEFORE STARTING

Before each use, check the following:

1. Place log splitter on a firm, level surface.

a. Vertical operation: Loosen the four bDits on

the beam hinge bracket. Refer to figure 5. Pull

the locking rod out and pivot it down to lelease

the beam. Move the beam as far from the hitch

as possible, then place the beam in the vertical

position. Tighten the hex nuts and bolts on the

beam hinge bracket so the log splittsr and

beam sit flat on the ground.

b. Horizontal operation: Make certain the beam

is adjusted to sit as far over the tongue as possi

ble (beam hinge bracket is against the stop as

shown in figure 15).

TO START ENGINE

1 Place throttle control lever on the engine in FAST

position. See figure 13.

2. Place choke lever In CHOKE position (a warm

engine may not require choking).

3. Grasp starter handle and pull rope out slowly until

engine reaches start of compression cycle (rope

will pull slightly harder at this point). Let the rope

rewind slowly.

NOTE

When restarting a warm engine, be care

ful to keep away from muffler and other

heated surfaces on the engine.

4. Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on the starter handle. Let the rope

rewind slowly. Do not let starter handle snap back

against starter.

5. Repeat preceding instructions 3 and 4 until engine

fires. When engine starts, move choke lever

halfway between CHOKE and RUN.

6. Move throttle control lever to IDLE position for a

few minutes warm-up. Gradually move choke lever

to RUN position as engine warms up.

NOTE

A

WARNING

Beam must be positioned as shown ir

figure 15 when operating in the hori

zontal position.

2. Remove the vent plug and check the fluid level.

Fluid level should be 1V2" to 2" from the to 3 of the

tank.

In order to idle smoothly, a new

engine may require 3 to 5 minutes

running above slow idle speed. Idle

speed has been adjusted to be correct

after this break-in period.

7. If weather is cold, run wedge up and down beam

6 to 8 times to circulate the hydraulic fluid, which

will warm and thin the fluid.

Page 11

A

If the fluid becomes excessively hot at

any time during operation, stop the unit

and allow the fluid to cool down. Maxi

mum performance will not be obtained

from your log splitter if the fluid is too

hot. Use extreme caution as contacting

hot fluid could result in serious personal

injury.

WARNING

TO TRANSPORT LOG SPLITTER

1. Lower the beam to its horizontal position. Make

certain the beam is latched securely with the lock

ing rod.

2. Remove the quick release pin which secures the

jack stand. Pivot it up against the tongue, and

secure with the quick release pin.

3. Attach the hitch to a towing vehicle, making cer

tain to latch securely. Attach the safety chains to

the towing vehicle.

ADJUSTMENT

At WARNING (

Always stop the engine and disconnect

the spark plug wire before performing

any adjustments.

LOG DISLODGER

If the logs to be split are all of a standard length less

than 24", adjust the log dislodger as follows. See figure

15.

1. Remove the hex bolts, lock washers and hex nuts

which secure the log dislodger to the beam.

2. Move the log dislodger to the hole desired. Secure

with hardware just removed. Tighten securely.

Adjusting the log dislodger to accommodate smaller

logs will shorten the time required for the wedge to

make a complete cycle.

SPLITTING WEDGE

As normal wear occurs, periodically adjust the bolts on

the slide plate (beneath the splitting wedge) as follows

to eliminate the excess space between the wedge plate

and the beam. See figure 16.

1. Loosen the three hex bolts on top of the slide plate

(beneath the splitting wedge).

2. Back the two adjustment bolts on the side of the

slide plate out slowly until the wedge assembly will

slide on the beam. Tighten the lock nuts securely

against the base of the slide plate to hold the bolts

in this position.

3. Retighten the three hex bolts on top of the slide

plate.

CARBURETOR ADJUSTMENT

i WARNING i

A

If any adjustments are made to the

engine while the engine is running

(e.g. carburetor), keep clear of all moving

parts. Be careful of heated surfaces and

muffler.

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude or

load. Improper adjustment will cause stalling when split

ter is under load, hard starting and higher fuel con

sumption.

Refer to the separate engine manual packed with your

log splitter for carburetor adjustment information.

^ ^ ^ ^ ^ ^ ^ ▼

NOTE

A DIRTY AIR CLEANER WILL CAUSE

ENGINE TO RUN ROUGH. BE CERTAIN

AIR CLEANER IS CLEAN AND AT

TACHED TO THE CARBURETOR

BEFORE ADJUSTING CARBURETOR.

DO NOT MAKE UNNECESSARY

ADJUSTMENTS. FACTORY SETTINGS

ARE SATISFACTORY FOR MOST

APPLICATIONS AND CONDITIONS.

MAINTENANCE

Ac Varn*ng

Always stop the engine and disconnect

the spark plug wire before performing

any maintenance or repairs.

11

Page 12

RESERVOIR FLUID

Check the hydraulic fluid level in the log splitter eservoir tank before each use. Fluid level should be 1V2"

to 2" from the top of the tank.

Change the hydraulic fluid in the reservoir ever / 100

hours of operation. Disconnect the suction hose from

the bottom of the reservoir tank, and drain the fliiid in

to a suitable container. Refill using only Dexron II

automatic transmission fluid, as instructed in ths “In

itial Preparation” section of this manual, pages B and

9. Also, make certain to change the hydraulic liter.

NOTE

Drain the fluid and flush the reservoir

tank and hoses with kerosene whenever

any repair work is performed on the

tank, hydraulic pump or valve. Con

taminants in the fluid will damage the

hydraulic components. (Should be per

formed by an authorized service dealer.)

conditions. Poor engine performance and flooding usually indicates that the air cleaner should be ser viced. To service the air cleaner refer to the separate engine manual packed with your unit.

The spark plug should be cleaned and the gap reset

once a season. Spark plug replacement is recommend

ed at the start of each season; check engine manual

for correct plug type and gap specification.

Clean the engine regularly with a cloth or brush. Keep

the cooling system (blower housing area) clean to per

mit proper air circulation which is essential to engine

performance and life. Be certain to remove ail dirt and

combustible debris from muffler area.

FLEXIBLE PUMP COUPLER

The flexible pump coupler is a nylon “spider” insert,

located between the pump and engine shaft. The align

ment is very critical. Over a period of time, the coupler

will harden and deteriorate. For a replacement flexible

pump coupler, order part number 717-0891.

A

Use extreme caution when working with

kerosene, as it is an extremely flammable

fluid.

t WARNING 1

HYDRAULIC FILTER

Change the hydraulic filter every 50 hours of ope ation.

Use only a 10 micron hydraulic filter. Order part number

723-0405.

BEAM AND SPLITTING WEDGE

Lubricate both sides of the beam where it contacts the

splitting wedge with engine oil before each use to ob

tain years of service. However, normal wear will accur.

The wedge plate on the log splitter is designed 30 the

gibs on the side of the wedge plate can be easily re

moved and rotated and/or turned over for even wear.

Make certain to readjust the adjustment bolts so wedge

moves freely, but no excess space exists betwesn the

wedge plate and beam.

HOSE CLAMPS

Check the hose clamps on the suction hose (attached

to bottom of the pump) for proper tightness befons each

use. Check the hose clamps on the return hose ct least

once a season.

ENGINE

Refer to the separate engine manual for all e ngine

maintenance instructions.

Maintain engine oil as instructed in the seaarate

engine manual packed with your unit. Read and follow

instructions carefully.

Service air cleaner every 25 hours under normal con

ditions. Clean every few hours under extremely dusty

A

I WARNING \

Never hit the pump shaft in any manner,

as any blow will cause permanent

damage to the pump.

When replacing the flexible pump coupling, proceed

as follows.

1. Place the coupling half onto the engine shaft. Make

certain there is clearance between the coupling

half and the engine. Tighten the set screw.

2. Mount the pump onto the coupling support bracket.

Tighten securely.

3. Carefully slide coupling half onto pump shaft (make

certain set screw is loose). Slide the key into place

on the shaft.

4. Install the nylon “spider” insert into coupling half

on the engine shaft.

5. Place the coupling shield in position on the hex

bolts. Rotate the keyway on the pump shaft so it

is toward the bottom.

6. Attach the coupiing support bracket to the hex

bolts, carefully sliding the coupling half over the

“spider” insert. Secure coupling shield and coup

ling support bracket with lock washers and hex

nuts. Tighten securely.

7. Adjust the two coupling halves (steel) so there is

between .010" and .060" clearance between the

two halves (at least the thickness of a matchbook

cover, up to 1/16" maximum). See figure 17.

Tighten the set screw in the coupling half on the

pump shaft.

12

Page 13

NOTE

Make certain proper clearance is ob

tained before tightening set screw.

PUMP

A

Ì WARNING t

DO NOT DRAIN FUEL WHILE

SMOKING, OR IF NEAR AN OPEN FIRE.

2. Drain all the oil from the crankcase (this should be

done after the engine has been operated and is

still warm) and refill the crankcase with fresh oil.

3. Protect the inside of the engine for storage as

follows.

Remove spark plug, pour approximately V2 ounce

(approximately one tablespoon) of engine oil into

cylinder and crank slowly to distribute oil. Replace

spark plug.

4. Clean the engine and the entire log splitter

thoroughly.

5. Wipe unit with an oiled rag to prevent rust,

especially wedge and beam.

TIRE PRESSURE

Check sidewall of tire for manufacturer’s recommended

maximum tire pressure. If this information does not ap

pear on your tire, maximum tire pressure under any cir

cumstances is 30 p.s.i. Equal pressure should be

maintained on both tires.

INSTALLATION OF TIRE TO RIM

i WARNING i

A

The following procedure must be fol

lowed when removing or installing a

tire to the rim.

1. Be certain rim is clean and free of rust.

2. Lubricate both the tire and rim generously.

3. Never inflate to over 30 p.s.i. to seat beads. Ex

cessive pressure when seating beads may cause

tire/rim assembly to burst with force sufficient to

cause serious injury.

^ ^ ^ ^ ^ ^

NOTE

When storing any type of power

equipment in an unventilated or metal

storage shed, care should be taken to

rustproof the equipment by coating with

a light oil or silicone.

6. The tongue can be removed and reattached in an

upright position as shown in figure 18 to take less

space when storing.

7. Store unit in a clean, dry area.

OFF-SEASON STORAGE

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. Follow

these instructions.

1. Drain the fuel tank. Start the engine, and let it run

until the fuel lines and carburetor are empty.

FIGURE 18.

13

Page 14

Trouble Shooting Guide

Trouble

Engine fails to start

Engine runs erratic

Engine overheats

Possible Cause(s|

1. Fuel tank empty, or stale fuel.

2. Blocked fuel life.

3. Spark plug wins disconnected.

4. Faulty spark pi jg.

1. Unit running on CHOKE.

2. Spark plug wins loose.

3. Blocked fuel lir e or stale fuel.

4. Water or dirt ir fuel system.

5. Dirty air cleane r.

6. Carburetor out of adjustment.

1. Engine oil leve low.

2. Air flow restricled.

3. Carburetor not adjusted properly.

Corrective Action

1. Fill tank with clean, fresh gasoline.

2. Clean fuel line.

3. Connect wire to spark plug.

4. Clean, adjust gap or replace.

1. Move choke lever to OFF position.

2. Connect and tighten spark plug

wire.

3. Clean fuel line; fill tank with clean

fresh gasoline.

4. Drain fuel tank. Refill with fresh

fuel.

5. Clean air cleaner as instructed in

separate engine manual.

6. Adjust carburetor (see Carburetor

Adjustment in separate engine

manual).

1. Fill crankcase with proper oil.

2. Remove blower housing and

clean as instructed in

separate engine manual.

3. Adjust carburetor (see Carburetor

Adjustment in separate engine

manual).

Will not split logs

Leaking cylinder

Reservoir fluid level low.

1. Broken seals.

2. Scored cylinder.

Check and fill reservoir tank as

instructed in Operation section

of this manual.

1. Replace seals.*

2. Replace cylinder.*

NOTE: For repairs beyond the minor adjustments listed above, please contact your nearest authorized service

dealer.

* Should be performed by an authorized ser/ice dealer only.

14

Page 15

HOW YOUR LOG SPLITTER OPERATES

Cylinder

Breather

Cap Unloading

Jl--, Valve

Reservoir

High Volume

Low Pressure

Gear Section

THE PUMP

A two-stage log splitter pump has one large and one

small gear section, using common inlet and outlet ports.

Below a preset pressure (called unloading pressure)

a check valve between the two gear sections allows

both flows to combine. Together, the two gear sections

create a large volume flow which produces rapid

cylinder movement under low load conditions.

Above unloading pressure, a pilot pressure line (which

simulates actual pressure at the cylinder) activates the

unloading valve, which causes the flow to bypass the

large gear section and return to the pump inlet area.

The small gear section is now operating alone, and will

generate the higher pressure necessary for the actual

log splitting operation.

The original factory setting for the unloading valve is

designed to provide maximum flow while remaining

below engine stalling load. Note: Splitting capabiiity

is not affected by the setting of the unloading valve.

Do not attempt to adjust or reset it without a

pressure gauge (should be performed by an

authorized service dealer only).

THE DIRECTIONAL VALVE AND CYLINDER

From the pump, oil flows to a four way, three position

directional valve. At the neutral position this valve

directs the flow back to the oil reservoir, bypassing the

cylinder. When the directional valve is directing the flow

to the back of the cylinder, the cylinder rod extends

quickly until it meets significant resistance. Upon

reaching unloading pressure, movement of the shaft

Cylinder

Directional

Valve

Relief Valve

Pilot

Pressure

Line

Pump

Low Volume

High Pressure

Gear Section

will slow but will continue forward. If the pressure

reaches a preset maximum (called relief valve pressure)

the relief valve, located within the directional valve, will

allow the flow to bypass the cylinder and return to the

reservoir. This can happen when the cylinder rod meets

excessive resistance, or when it reaches the end of its

stroke and can move no farther.

Note: Never operate at relief valve pressure for more

than a few seconds.

When the directional valve is directing the flow to the

front of the cylinder, the rod will retract quickly since

it is encountering no resistance. The relief valve will

momentarily bypass the flow at the end of the return

stroke but the directional valve should then automatical

ly return to the neutral position, directing the flow direct

ly into the reservoir. This serves to protect the pump

from possible damage due to prolonged operation at

relief valve pressure.

Because of the potential for system damage, the relief

valve is carefully and precisely preset by the

manufacturer.

Note: The user should not attempt to adjust or

change the setting of the relief valve.

OPERATIONAL PROBLEMS

If you have trouble with your log splitter, please refer

to the Hydraulic Trouble Shooting Guide on page 16.

Note: Readjustment of valves or disassembly of

pump should be performed by an authorized ser

vice dealer only.

15

Page 16

HYDRAULIC TROUBLE SHOOTING GUIDE

Problem Probable Cau!>e(s)

Cylinder rod wjll not

move

Slow cylinder shaft

speed while

extending and

retracting

Engine runs but

wood will not split,

or wood splits too

slowly

A Broken driveshaft

B Loose shaft coupling

C Gear sections damac ed

D Damaged relief valve

E Hydraulic lines block ;d

F Too little oil to pump

G Damaged directional valve

H Blocked directional v jIve

A Gear sections damac ed

B Excessive pump inie vacuum

C Slow engine speed

D Damaged relief valve

E Too little oil to pump

F Air in oil

G Directional valve leaking internally

H Internally damaged cylinder

A Small gear section d imaged

B Pump check valve leaking

C Excessive pump inIe: vacuum

D Low relief valve setti ig

E Too little oil to pump

F Air in oil

G Directional valve leal:ing internally

H Overloaded cylinder

1 Internally damaged c ylinder

Corrective Action

A Return pump for authorized repair

B Correct engine/pump alignment as necessary

C Return pump for authorized repair

D Return directional valve for authorized repair

E Flush and clean hydraulic system

F Add oil to reservoir

G Return directional valve for authorized repair

H Flush and clean hydraulic system; return

directional valve for authorized repair

A Return pump for authorized repair

B Make certain pump inlet hoses are clear

and unblocked—use short, large

diameter inlet hoses

C Return engine for authorized repair

D Return directional valve for authorized repair

E Add oil to reservoir

F Add oil, clean reservoir, make certain oil

return tube is below oil level

G Return directional valve for authorized repair

H Return cylinder for authorized repair

A Return pump for authorized repair

B Return pump for authorized repair

C Make certain pump inlet hoses are

clear and unblocked; use short, large

diameter inlet hoses

D Adjust valve while using pressure gauge*

E Add oil to reservoir

F Add oil, clean reservoir, make certain oil

return tube is below oil level

G Return directional valve for authorized repair

H Do not attempt to split wood against the grain

1 Return cylinder for authorized repair

Engine stalls during

splitting

Engine will not turn

or stalls under low

load conditions

Leaking pump shaft

seal

'Should be performed by an authorized service dealer only.

A Low horsepower/wec k engine

B High relief valve sett ng

C High unioading valve setting

D Overloaded cylinder

A Engine/pump misalic nment

B Frozen or seized pump

C Low horsepower/wee k engine

D Hydraulic lines blocked

E Blocked directional \ alve

A Broken driveshaft

B Engine/pump misalic nment

C Gear sections damaged

D Poorly positioned sh ift seal

E Plugged oil breather

A Return engine for authorized repair

B Adjust valve while using pressure gauge*

C Adjust valve while using pressure gauge*

D Do not attempt to split wood against the grain

A Correct alignment as necessary

B Return pump for authorized repair

C Return engine for authorized repair

D Flush and clean hydraulic system

E Flush and clean hydraulic system; return

directional valve for authorized repair

A Return pump for authorized repair

B Correct alignment as necessary

C Return pump for authorized repair

D Return pump for authorized repair

E Make certain reservoir is properly vented

16

Page 17

424/LCD/22 (Model 623) Pft¿:s^uR£

30ÛÛ то 3<3.ûû FS I

Î1

Page 18

424/LCD/22 (Model 623)

PARTS LIST FOR MODEL 623 LOG SPLITTER

REF.

NO.

10

11 781-0386

12

21 732-0583

31

T34 727-0440

r 35

41

PART

NO.

1 712-0299

714-0162

2

734-0873

3

734-1016 Wheel Ass’y- Comp.

4

734-0872

734-1017

734-0255

736-0351

5

741-0107

6

736-0921

7

737-0192

8

737-0238

9

750-0442

710-3104 N

712-3034 N

13

14 710-1010

710-1018

15

710-1032 N

16

17 712-0239

712-0333

18

712-3001

19

736-0192

20

22 750-0750 N

781-0393 N

23

781-0345 N

24

781-0350 N

25

781-0351 N

26

781-0352 N

27

781-0356

28

714-0203 N

29

30 715-0206

717-0893 N

717-0942

32

727-0307

33

737-6'i?1-£

37 737-0235

710-0521

39

710-0615A N

40

710-3130

42 711-0820

CODE

Hex Castle Nut 3/4-16 Thd. 43

Cotter pin 5/32" Dia.

Hub Cap

Tire Only

Rim Only

Air Valve

FI-Wash. .76" I.D. x 1.5" O.D. 51 736-0185

Roller Bearing

L-Wash. 1/2" I.D.*

90° Solid Male Adaptor 54

Pipe Nipple 1/2 NPT

Spacer 1.56" Lg. 56 781-0388 N Beam Support Ass’y.

N

Stripper Ass’yHex Bolt 1/2-13 X 21/4" Lg. 58 723-0406

(Grade 5)

Hex Nut 1/2-13 Thd. (Grade 5) 60 727-0309

Hex Bolt 1/2-20 X 3" Lg. 62

(Grade 8) 64 710-0520 Hex Bolt 3/8-16 X 1.5" Lg. (Gr! 5)

Hex Bolt 1/2-20 X 2.75" Lg.

(Grade 8) 68 738-0736 Hinge Pin

Hex Bolt 3/8-24 x 1.5" Lg.

Hex L-Nut 1/2-20 Thd.

Hex Nut 1/2-20 Thd. 72 781-0377 N Beam Hinge Spacer

Hex Jam Nut 3/8-24 Thd.

(Grade 5) 74 710-0237 Hex Bolt 5/16-24 x .62" Lg.

FI-Wash. .53" I.D. x .94" O.D.

Comp. Spring 4" Lg.

Spacer 1/2" I.D. x .86" Lg. 77 714-0122 Sq.-Key 3/16" x .75"

Wedge Ass’y. 78 717-0891 Flexible Coupling

Pusher Back Plate

Fixed Side Gib

Adjustable Gib

Adjustable Gib Shim 82 727-0427 N Suction Hose 1" I.D.

N Floating Gib Plate i lT83

External Cotter Pin 84 736-0119 L-Wash. 5/16" I.D.*

Cylinder Mounting Pin

N

Hydraulic Cylinder 86 781-0098

Control Valve 87 710-0157 Hex Bolt 5/16-24 x .75" Lg.

N

Metal Pressure Tube

N Pressure Tube 89

Zi>5

90° Solid Male Adaptor5(/<p c^aa

3/4" Hose Barb.

Hex Bolt 3/8-16 X 3" Lg.

(Grade 8) 93 781-0271

Hex Bolt 3/8-16 X 5" Lg. 94 781-0312 Strainer Ass’y.

Hex Bolt 3/8-16 X 3.25" Lg.

(Grade 8) 96 720-0231 N

Quick Release Pin 97

N

DESCRIPTION

REF.

NO.

/90

PART

NO.

712-0375

44 712-0798

45 713-0338

46 715-0249

47

727-0311

49 736-0116

736-0169 L-Wash. 3/8" I.D.*

50

52 750-0507 Spacer .27" Lg.

53 781-0358 N

781-0368 Tongue Tube

781-0370 N Locking Rod

55

57 723-0405

59

726-0146

781-0339

66 714-0470 Cotter Pin 1/8" Dia.

70 781-0373

71 781-0375 N Beam Hinge Back Plate

710-0117 Hex Bolt 5/16-24 X 1" Lg.

73

710-0363

75

76 712-0123

79 717-0936

80 719-0281

726-0132

81

727'0432-0

781-0097 Rear Coupling Support Brkt.

85

88 710-0409

—

736-0159 FI-Wash. .344" I.D. x .875" O.D.

737-0236 L-Vent Pipe Plug

91

92 735-0639 Spark Plug Boot

781-0376 N Tank Ass’y.

95

747-0709

CODE

Hex L-Nut 3/8-16 Thd.

Hex Nut 3/8-16 Thd.

Chain—Tow Hitch

Spring Roll Pin 5/32" Dia.

Hitch Coupler

FI-Wash. .635" I.D. x .93" O.D.

FI-Wash. .406" I.D. x .75" O.D.

Jack Stand Ass’y.

Filter Element

Filter Head

Adj. Hose Clamp

Return Hose 3/4" I.D. x 30" Lg.

N

Vertical Beam Ass’y.

N Beam Hinge

Hex Bolt 5/16-24 x 4" Lg.

Hex Nut 5/16-24 Thd.

N Two Volume Pump

Coupling Shield

Hose Clamp 5/8"

S33N

High Pressure Hydraulic Hose45®*’

Front Coupling Support Brkt.

Hex Bolt 5/16-24 x 1.75" Lg.

Engine

Fender

Ball Knob

N

Control Handle

DESCRIPTION

*For faster service obtain standard nuts, bolts and washers locally.

If these items cannot be obtained locally, order by part number and

size as shown on parts list.

19

NOTE: The engine is not under warranty by

the log splitter manufacturer...If repairs or

service is needed on the engine, please

contact your nearest author

ized engine service outlet.

Check the “Yellow Pages” of

your telephone book under

“Engines—Gasoline.”

Find If Fast

In The

Yellow Pages

Page 19

18 MONTH LIMITED WARRANTY

NON-COMMERCIAL

NON-TRANSFERABLE

Limited to Models PRO/20 and 424/LCD/22 Log Splitters

For 18 months from the date of original retail purchase, DUERR INC. will either repair or replace,

at its option, free of charge, F.O.B. factory or authorized service firm, any part or parts found

to be defective in material or workmanship. Transportation charges for the movement of any

power equipment unit or attachment aie the responsibility of the purchaser. Transportation

charges for any parts submitted for replacement under this warranty must be paid by the pur

chaser unless such return is requested by DUERR INC.

Warranty on units used commercially i{; limited to ninety (90) days.

This warranty will not apply to any part which has become inoperative due to normal wear,

misuse, excessive use, accident, negle:t, improper maintenance, alterations, modifications,

or unless the unit has been operated ard maintained in accordance with the instructions fur

nished. This warranty does not apply to t ie engine, pump, cylinder^jr component parts thereof.

Please refer to the applicable manufadurer’s warranty on these items?

Warranty service is available through your local authorized service dealer or distributor. If you

do not know the dealer or distributor in your area, please write to the Customer Service Depart

ment of DUERR INC.

Walve.

The return of a complete unit will not be i ccepted by the factory unless prior written permission

has been extended by DUERR, INC.

This warranty gives you specific legal rights. You may also have other rights which vary from

state to state. x

XtoMlESnC. UUKftiAKyr/ * ]? Mo.

futnp CVuiObER.* I /R.. From PuR. t)ATE\ o __

nJKL>.E= 3 XRS. OF TF№ OF liaise

Fill Out

Completely

and Retain

For Your

Records

Please

Complete

Warranty

Card and Mail

Date of Purchase Dealer Telephone Number

Purchased From

City State Zip

Model Number

Address

Serial Number

FORM NO. 770-6746D

(R880823)

DUERR INC. • MEAD, WASHINGTON 99021

Loading...

Loading...