Page 1

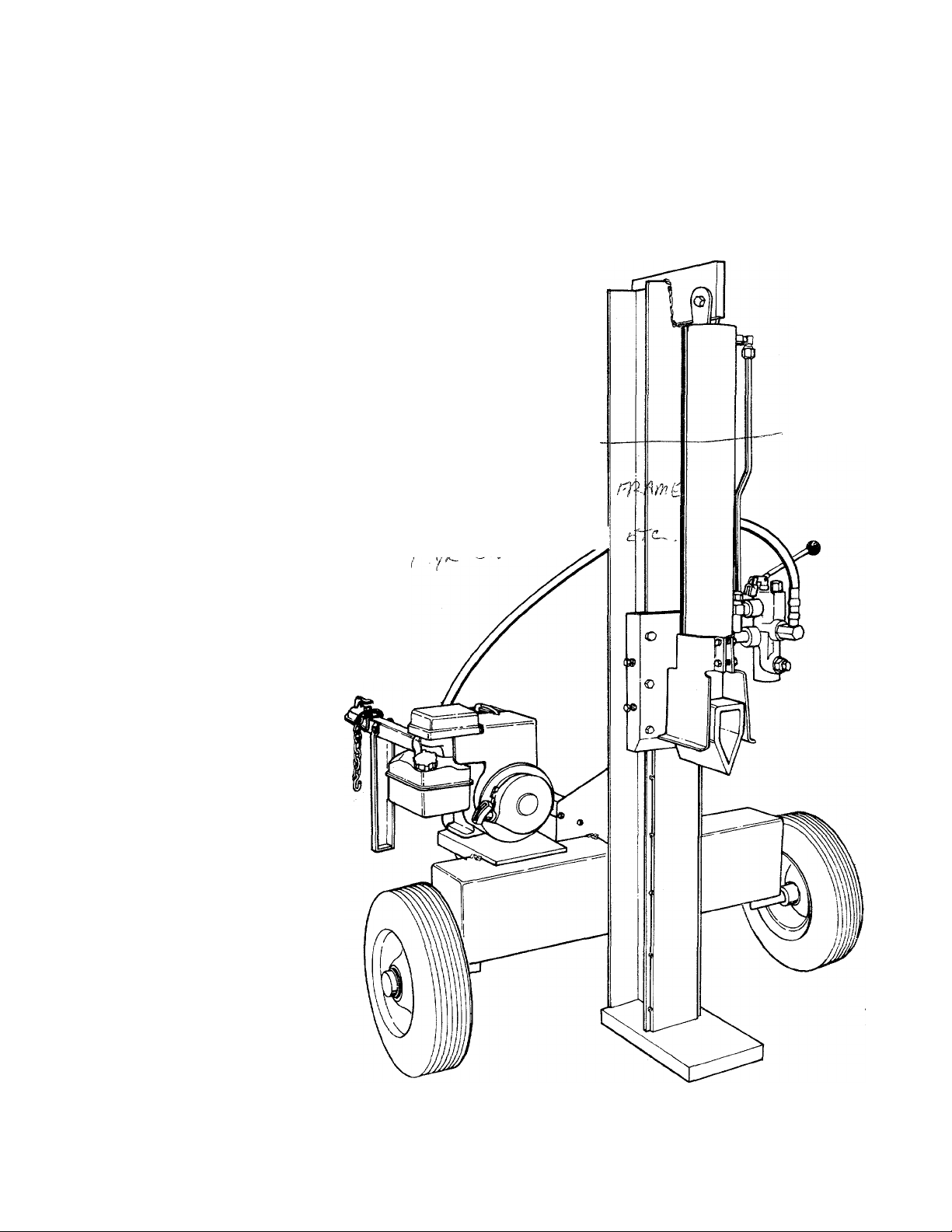

VERTICAL

DUCRR

MODEL NUMBERS

PRO/20

(248-622-003)

424/LCD/20

(248-623-003) Fro as.

IMPORTANT:

•Read this Manual

Before Attempting

to Assemble and

VP UJ

LOG SPLITTERS

V9L / '

L.t

Use

Read Safety

Rules and

Instructions

Carefully

Protect Your

Warranty —

Read Separate

Log Splitter

Information

Sheet

Carefully

(Model PRO/20 Shown)

DUERR INC. • E. 12122 DM MOUNT ROAD • MEAD, m. 99021

(509) 238-6124 - A/o/^/V M ^ OJoAb

-y7p/l

Page 2

INDEX

Rules for Safe Operation..........................................3

Assembly Instructions............................................. . 5

Operation..................................................................9

Adjustments

Maintenance...........................................................12

.........................................................

.11

Off-Season Storage.................................................13

Trouble Shooting Chart............................................13

Illustrated Parts........................................................V

Repair Parts List......................................................1

Limited Warranty......................................Back Cover

A

WARNING

This unit is equipped with an internal combustion engine and should not be used on or near any unim

proved forest-covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped

with a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should

be maintained in effective working order by the operator.

In the State of California the above is requi

Code). Other states may have similar lawi

the muffler is available through your nearest engine authorized service center or through DUERR INC.

Order Briggs and Stratton service part number 392390.

ed by law (Section 4442 of the California Public Resources

Federal laws apply on federal lands. A spark arrester for

2

Page 3

A

IMPOFnANT

RULES FOR SAFE OPERATION

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE

PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE

ATTEMPTING TO OPERATE YOUR LOG SPLITTER. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

WHEN YOU SEE THIS SYMBOL

Your log splitter was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. If you violate any of these rules, you may cause

serious injury to yourself or others.

- A HEED ITS WARNING.

DANGER

A

TRAINING

A

1. Before operating this splitter, read and understand this

manual completely. Become familiar with it for your own

safety To fail to do so may cause serious injury. Do not

allow anyone to operate your splitter who has not read

this manual. Keep this manual in a safe place for future

and regular reference and for ordering replacement parts.

2. Never use your splitter for any other purpose than

splitting wood. It is designed for this use and any other

use may cause an injury. Your log splitter is a precision

piece of power equipment, not a playtoy. Therefore,

exercise extreme caution at all times.

Never allow children to operate your log splitter. Do not

^ allow adults to operate it without proper instruction.

Only persons well acquainted with these rules of safe

operation should be allowed to use your log splitter.

4. Only the operator is to be near your log splitter during use.

Keep all others, including pets and children, a minimum

of 20 feet away from your work zone. Flying wood can

be hazardous. If a helper is assisting in loading logs, never

activate the control until the helper is clear of the area.

More accidents occur when more than one person

operates the log splitter than at any other time.

5. No one should operate this unit while intoxicated or while

taking medication that impairs the senses or reactions.

A clear mind is essential for safety. Never allow a

person who is tired or otherwise not alert to use your

splitter.

Never operate your splitter on slippery, wet muddy or icy

surfaces. Safe footing is essential in preventing accidents.

Never operate your splitter while attached to a towing

vehicle.

Only operate your splitter on level ground and not on the

side of a hill. It could tip, or rolling logs or poor footing

could cause an accident. Operating the splitter on level

ground also prevents the spillage of gasoline from the

fuel tank.

9.

Never attempt to move the log splitter over hilly or uneven

terrain without a tow vehicle or adequate help.

10.

Always block the wheels to prevent movement of log

splitter while in operation.

Check the fuel before starting the engine. Gasoline is an

11.

extremely flammable fuel. Do not fill the gasoline tank

indoors, when the engine is running, or while the engine

is still hot. Replace gasoline cap securely and wipe off

any splilled gasoline before starting the engine as it may

cause a fire or explosion.

12.

Both ends of each log must be cut as square as

possible to help prevent the log from riding out of the

splitter during operation.

OPERATION

A

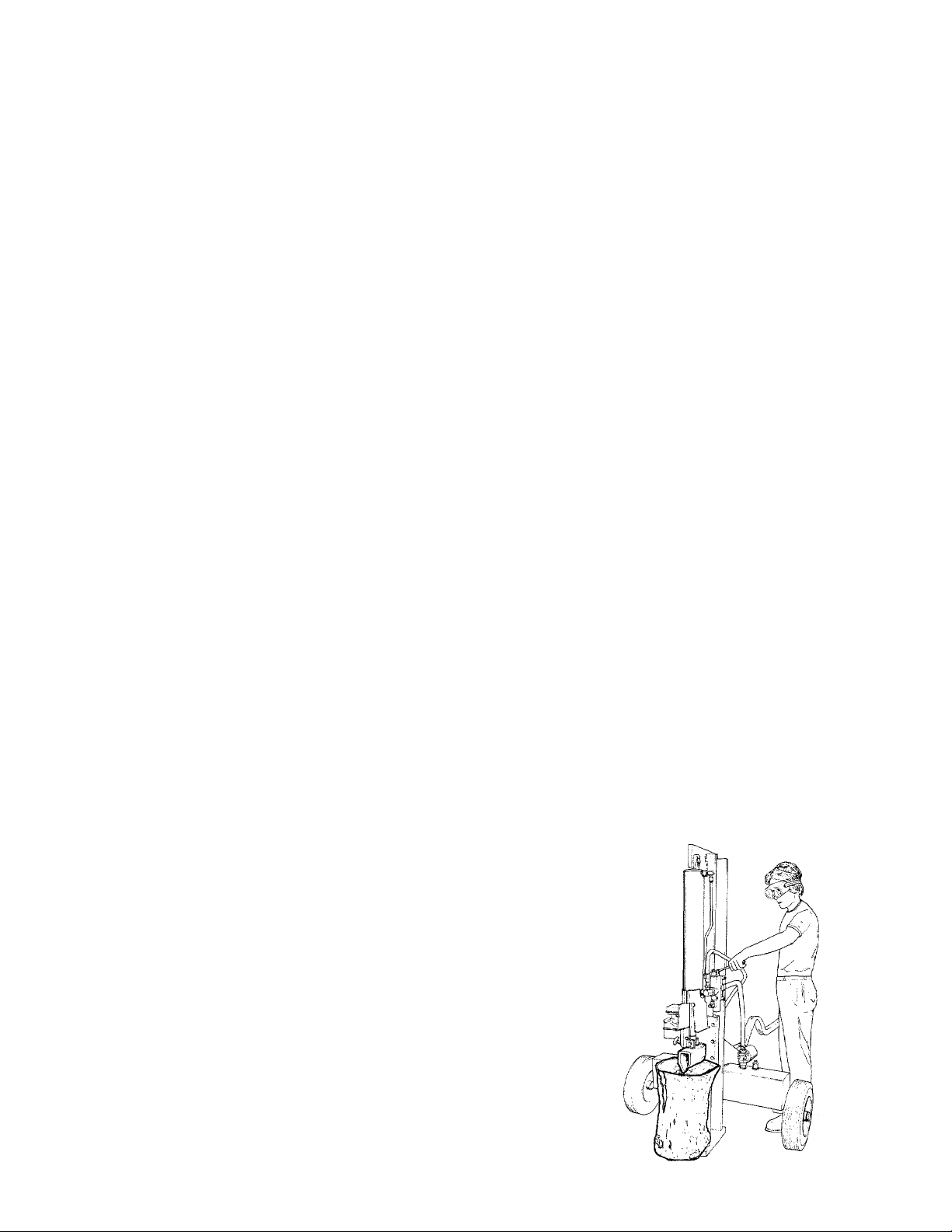

1. Stand behind the reservoir tank when operating. See

illustration.

A

PREPARATION

1. Never wear loose clothing or jewelry that can be caught by

moving parts of your log splitter and pull you into it. Keep

clothing away from all moving parts of your log splitter.

2. Wear proper head gear to keep hair away from moving

parts. Always wear protective hearing devices as needed.

3. Always wear safety shoes. A dropped log can seriously

injure your foot.

4. Always wear safety glasses or goggles while operating

your splitter. A piece of splitting log could fly off and hit

your eyes.

If you wear gloves, be sure they are tight fitting without

loose cuffs or draw strings.

6. Use your log splitter in daylight, or under good artificial

light.

Page 4

2. Know how to stop the unit and disengage the cor trols.

3. Never place hands or feet between log and splitting v /edge

or between log and end plate during forward or reverse

stroke. To do so may result in crushed or ampi fated

fingers or toes, or worse, you may lose an arm or foot.

4. Do not straddle the splitter when using it. A slip in any

position could result in a serious injury.

5. Do not step over your log splitter when the eng ne is

running. You may trip or accidentally activate the

splitting wedge if you step over. If you need to (¡et to

the other side, walk around.

6. Never try to split two logs on top of each other. Dm! may

fly out and injure you.

7. When loading the log splitter, place your hands on th s side

of the log, not at the ends. Never attempt to loac your

splitter while the splitting wedge is in motion. Yon may

get caught by the wedge and injured.

8. Only use your hand to operate the splitting weege or

control lever. Never use your foot or a rope or any other

extension device. This could result in your ability to stop

your splitter quickly enough and cause injury.

9. Always keep fingers away from any cracks that open in

the log during splitting operation. They can quickly close

and pinch or amputate your fingers.

10. Never attempt to split wood across the grain. Some types

of wood may burst or fly out of your splitter and result

in injury to you or a bystander.

11. For logs that are not cut square, the longest portion of the

log should be rotated down and the most square end

placed against the splitting wedge.

12. Keep your work area clean. Immediately removí split

wood around your splitter so that you do not stumble

over it. Clean chips

after each log is split, or whenever necessary to main

tain flat contact between wood and end plate (platlorm).

13. Never move the log splitter while the engine is running.

14. Never leave your log splitter unattended with the e ngine

running. Shut off the engine if you are ieaving your s plittei;

even for a short period of time. Someone could ac ;identally activate the splitting wedge and be injured.

15. Do not run engine in an enclosed area. Exhaust gases

contain carbon monoxide. This odorless gas cm be

deadly when inhaled.

16. Be careful not to touch the muffler after the engir e has

been running as it is HOT.

17. If the equipment should start to vibrate abnormally, stop

the engine and check immediately for the cause. Vi! ¡ration

is generally a warning of trouble.

18. When cleaning, repairing or inspecting, make certain all

moving parts have stopped. Disconnect the spark plug

wire and keep the wire away from the plug to prevent

accidental starting.

and dirt off end plate (wood pleiform)

MAINTENANCE AND STORAGE

▲

1. Do not operate your splitter in poor mechanical

condition or when in need of repair.

2. Periodically check that all nuts, bolts, screws, hose c lamps

and hydraulic fittings are tight to be sure equiprr ent is

in safe working condition. Where appropriate, chuck all

safety guards and shields to be sure they are ;n the

proper position. Never operate your splitter with safety

guards, shields or other protective features removed.

These safety devices are for your protection.

3. Replace all damaged or worn parts such as hydraulic

hoses and fittings immediately with manufacturer approv

ed replacement parts.

4. Do not change the engine governor settings or overspeed

the engine. This increases the hazard of personal injury.

The maximum engine speed is preset by the manufac-"

turer and is within safety limits.

5. Do not alter your splitter in any manner such as attaching

a rope or extension to the control lever or adding to the

width or height of the wedge. Such alterations may cause

your splitter to be unsafe.

6. Perform all recommended maintenance procedures before

you use your splitter.

7. Do not service or repair your log splitter without

disconnecting the spark plug wire.

8. Never store the equipment with gasoline in the tank

inside of a building where ignition sources are present,

such as hot water and space heaters, clothes dryers and

the like. Allow the engine to cool before storing in any

enclosure.

9. Always store gasoline in an approved, tightly sealed

container. Store the container in a cool, dry place. Do

not store in a building where ignition sources are present.

10. To reduce fire hazard, keep engine free of grass, leaves,

wood chips, and excessive grease and oil.

11. The hydraulic system of your log splitter requires careful

inspection, along with the mechanical parts. Be sure to

replace frayed, kinked, or otherwise damaged hydraulic

components.

12. Fluid escaping from a very small hole can be almost

invisible. Do not check for leaks with your hand.

Escaping fluid under pressure can have sufficient force

to penetrate skin, causing serious personal injury. Leaks

can be located by passing a piece of cardboard or wo'’'"

over the suspected leak and looking for discoloratic

13. Should it become necessary to loosen or remove any

hydraulic fitting or line, be sure to relieve all pressure

by shutting off the engine and moving the control

handle back and forth several times.

14. Do not remove the cap from the hydraulic tank or

reservoir while your log splitter is running. Hot oil under

pressure could cause injury.

15. The pressure relief valve on your splitter is preset at the

factory. Do not adjust the valve. Only a qualified service

technician should perform this adjustment.

16. Completely drain fuel tank prior to storage. This guards

against accumulation of fuel fumes which could result

in a fire hazard.

17. Never store log splitter outside without a waterproof cover.

Rain will cause rust on the inside of the cylinder

TOWING

A

1. This unit should not be towed on any street, highway or

public road without checking the existing federal, local

or state vehicle requirements. Any licensing or modifica

tions such as taillights, etc., needed to comply with the

existing federal, local or state vehicle requirements is the

sole responsibility of the purchaser.

2. Before towing, be certain the log splitter is correctly and

securely attached to the towing vehicle, and the safr ' "

chains are in place. Leave slack in chains for turnr

allowance.

3. Do not allow anyone to sit or ride on your splitter. They

can easily fall off and be seriously injured.

Page 5

IMPORTANT

ASSEMBLY

This unit has been shipped without

gasoline or oil in the engine. After

assembly, refer to separate engine

manual for proper fuel and engine oil

information.

Reservoir Tank

Assembly

Wedge and Beam Assembly

__________Jl_______

Tongue Assembly

\

Pivot

Latch

\ Hydraulic-

Assembly

Cylinder and

Valve Assembly

FIGURE 1

FIGURE 2

Hydraulic

Filter

Head

Filter

Engine and

Pump Assembly

Hoses

Wheels

Hub Cap

Stripper

Assembly

UNPACKING

Remove all parts from the carton. Make certain all

parts and literature have been removed from the

carton before the carton is discarded.

NOTE

All hardware for assembly of the log

splitter has been placed in position on

the various parts.

Other Materials Required for Assembly:

Wheel Bearing Grease

Loc-tite Hydraulic Sealer or Equivalent

Engine Oil

Unleaded Gasoline (regular grade gasoline is an

acceptable substitute)

Approximately 6-1/2 Gallons of 10 Weight AW type

fluid or Dexron 11 Automatic Transmission Fluid

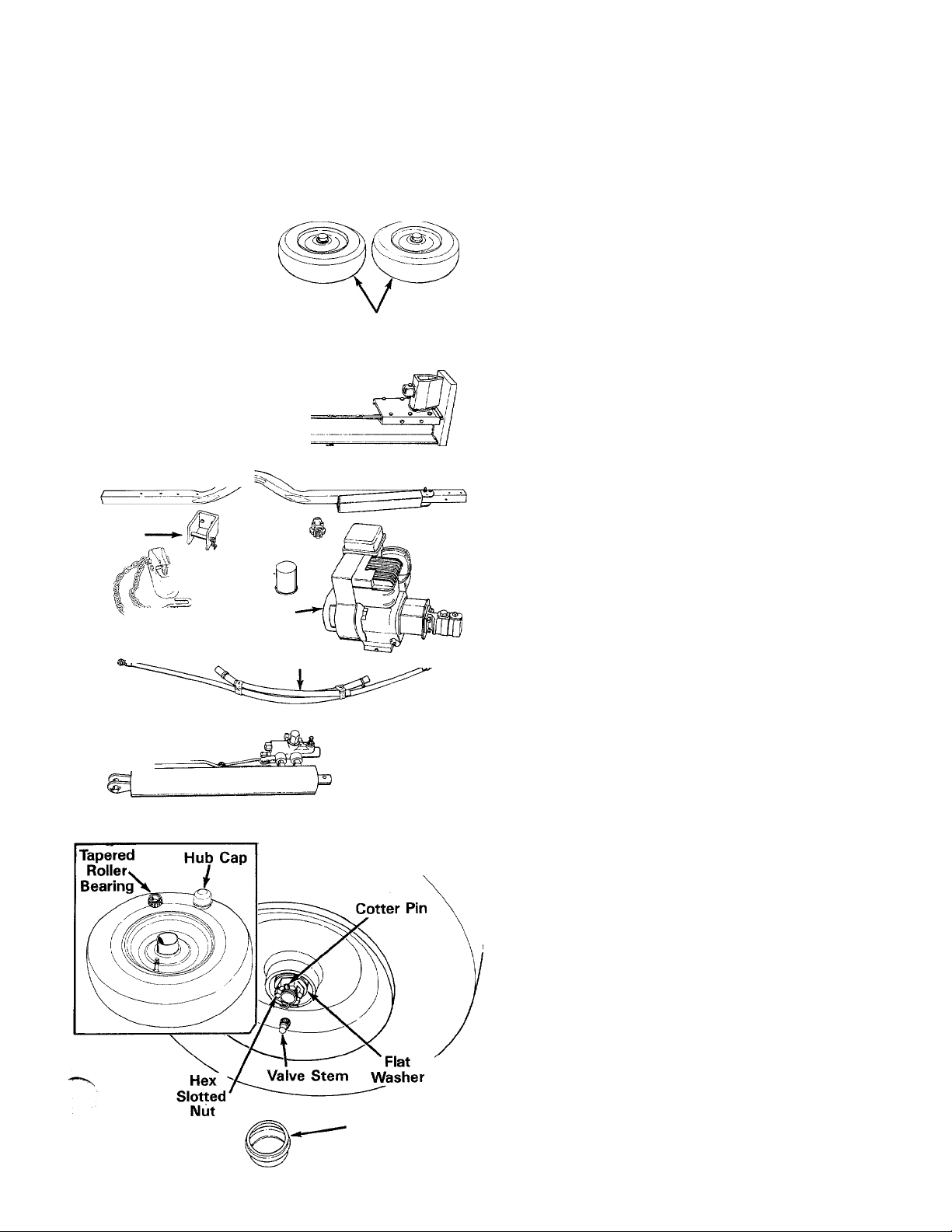

Loose Parts in Carton: (See figure 1)

(1) Reservoir Tank Assembly

(2) Wheels

(1) Wedge and Beam Assembly

(1) Tongue Assembly

(1) Pivot Latch

(1) Hitch Assembly

(1) Engine and Pump Assembly

(3) Hoses (taped together)

(1) Cylinder and Valve Assembly

(1) Stripper Assembly (two halves)

(2) Fenders (Not Shown —Model 424/LCD/20)

(1) Filter Head^

(1) Hydraulic Filter*

*May be already assembled to the reservoir tank.

INSTALLATION OF WHEELS

Attach the wheels to the reservoir tank as follows.

See figure 2.

1. Pry off the hub caps which are attached to the

wheels. Remove one tapered roller bearing from

inside each wheel. See inset, figure 2.

2. Remove the cotter pin, hex slotted nut and one

flat washer from each axle (leave spacers and

two flat washers in place on axles).

3. Place one wheel on each axle, with the valve

stem facing outward.

4. Pack the tapered roller bearings with wheel

bearing grease, and place one on each axle.

5. Place one flat washer removed in step 2 on each

axle. Secure with hex slotted nut. Tighten

slotted nut until snug, then back off approx

imately 1/3 turn or until one of the slots on the

slotted nut lines up with the hole in the axle.

6. Check the assembly of the wheels. There should

be no side to side play, and the wheels should

spin freely.

7. Place hub caps in position on wheels and tap

on with a rubber mallet or plastic hammer.

Page 6

Fender

Lock Washer

FIGURE 3

ATTACHING THE FENDERS (Model 424/LCD/20)

1. Remove the hex nuts, lock washers, flat washers

and hex bolts from the fender support brackets.

Place the fenders in position against the fender

support brackets. Insert hex bolts through holes

in support brackets and fenders. Secure with flat

washers, lock washers and hex nuts. See figure

3. Tighten securely.

INSTALLING THE HYDRAULIC FILTER (If not already assembled)

If the hydraulic filter head and hydraulic filter have

not already been installed on the reservoir tank at

the factory, proceed as follows.

1. Place Loc-tite hydraulic sealer or equivalent on

the threads on the fitting on top of the

reservoir tank.

Thread hydraulic filter head onto fitting on top

of the reservoir tank as shown in figure 4, in

set. The direction arrow on the filter head must

point down toward the tank. Filter head must

be positioned as shown.

Oil the gasket on the top of the hydraulic filter

using automatic transmission fluid. Thread the

hydraulic filter onto the hydraulic filter head as

shown in figure 4. Tighten by hand.

Hydraulic Filter

FIGURE 4

Hex Bolts

Hex Nuts

ATTACHING THE WEDGE AND BEAM ASSEMBLY

The beam has been shipped with the wedge

down against the end plate, and tightened in this

position. Stand the beam upright, making

certain the wedge is down against the end of

the beam.

A

Do not attempt to stand beam upright

if the wedge is not against the end of

the beam, to avoid personal injury.

(Move wedge so it is against end of

beam).

Remove the pivot pin from the bracket on the

2.

beam by removing the cotter pin. See figure 4.

Roll the reservoir tank in position against the

3.

beam. Secure beam to tank using pivot pin and

cotter pin just removed.

ATTACHING TONGUE TO RESERVOIR TANK

1. The tongue is shipped with the jack stand

already attached to the tongue. The jack stand

is in the transport position. Remove the spring

pin and clevis pin. Pivot the jack stand to the

_ operating position and replace the clevis pin and

spring pin. See figure 5.

2. Remove the two hex bolts, lock washers and he.

nuts on the front of the reservoir tank. Place the

tongue in position and secure with hardware

just removed. See figure 4.

WARNING

Page 7

FIGURE 6

FIGURE 7

Hose Clamp

Hex Bolts

Lock Washers

Hex Nuts

Suction Hose

Pump

INSTALLING THE HITCH

1. Remove the two long hex bolts, lock washers

and hex nuts which are assembled through the

sides of the hitch. Do not remove the chain and

spacer from the one hex bolt.

2. Place the hitch in position on the end of the

tongue. Secure with hardware just removed. See

figure 5.

INSTALLATION OF PIVOT LATCH

1. Remove the two hex bolts, lock washers and

hex nuts on the pivot latch.

2. With the beam still in the upright position, place

the pivot latch on the beam as shown in figure

6. Secure with hex bolts, lock washers and hex

nuts just removed. The heads of the bolts must

be inside the pivot latch.

ATTACHING THE ENGINE AND PUMP ASSEMBLY

1. Remove the four hex bolts, lock washers and

hex nuts from the engine mounting bracket

(attached to the reservoir tank).

Place the engine and pump assembly in position

as shown in figure 7. Secure with hardware just

removed. Tighten securely.

ATTACHING THE SUCTION HOSE

1. The suction hose is 3/4" by 20" long. Loosen

the hose clamps on each end of the hose

using a screwdriver.

2. Attach one end of the hose to the fitting on the

bottom of the pump. Attach the other end to

the reservoir tank. See figure 7.

Place hose clamps at the base of the fittings,

3.

and tighten securely.

FIGURE 8

ADJUSTING THE SPLITTING WEDGE

The adjustment bolts on the splitting wedge were

tightened at the factory to hold the wedge in a sta

tionary position for shipping. Adjust these bolts as

■follows. See figure 8.

1. Loosen the three hex bolts on top of the slide

plate (beneath the splitting wedge).

2. Back the two adjustment bolts on the side of the

slide plate out slowly until the wedge assembly

will slide on the beam. Tighten the lock nuts

securely against the base of the slide plate to

hold the bolts in this position.

3. Retighten the three hex bolts on top of the slide

plate.

Page 8

iNSTALLING THE CYLINDER AND VALVE ASSEMBLY

1. Lower the beam to the horizontal position as

follows.

a. Remove the spring pin from the pivot latch

on the back side of the beam. Remove the

clevis pin.

— b. Lower the beam so the tongue is inside the

pivot latch. Secure with clevis pin and spring

pin.

2. Remove one hairpin clip from the clevis pin on

the end of the cylinder. Place the cylinder in

position on the log splitter, and secure with

clevis pin and hairpin clip just removed. See

figure 9.

3. Remove the large hex bolt, lock washer and hex

nut on the end of the wedge assembly. Secure

the other end of the cylinder assembly with the

hardware just removed. See figure 10.

ATTACHING THE CONTROL HANDLE

The bottom of the control handle is already attach

ed to the valve with a cotter pin. Remove the second

cotter pin which is attached to the valve only. Place

the handle in position and secure using the second

cotter pin. See figure 10.

INSTALLING THE RETURN HOSE

1. Move the beam to the operating (upright)

position by removing the spring pin and clevis

pin from the pivot latch. Place the beam upright,

and replace clevis pin and spring pin in pivot

latch for safekeeping.

2. The return hose is 3/4" by 30" long. Loosen the

hose clamps on each end of the hose using a

screwdriver.

3. Attach one end of the hose to the fitting on the

hydraulic filter head (located on top of the reser

voir tank). Attach the other end to the fitting

beneath the valve. See figure 11.

4. Make certain the hose is adjusted so it is

relaxed and in the proper position (do not allow

hose to twist). Place hose clamps at the base

of the fittings, and tighten securely.

INSTALLING THE PRESSURE HOSE

1. The pressure hose is 1/2" x 54" long. Place

Loc-tite hydraulic sealer or equivalent on the

threads on both ends of the pressure hose.

2. Thread one end of the hose into the fitting on

top of the pump. See figure 11.

3. Thread the other end of the hose into the

fitting on top of the valve. Adjust hose so it is

relaxed and in the proper position as shown in

figure 11. Do not allow hose to twist. Then

tighten securely.

8

Page 9

FIGURE 12

ATTACHING THE STRIPPER ASSEMBLY

1. Remove the four hex bolts and hex lock nuts

which are holding the two stripper halves

together.

2. Slip one stripper half over the pipe flange on the

cylinder. Place the other stripper half on the

other side of the cylinder. See figure 12.

3. Put two hex bolts through the top of the stripper

halves, and start hex nuts on the bolts. Start the

hex bolts and nuts through the bottom of the

stripper halves in the same manner.

4. Make certain the cylinder is against the stops

located on the inside of the stripper halves.

Tighten all four nuts and bolts equally.

FINAL ASSEMBLY

1. Make certain all nuts, bolts and hose clamps are

tightened securely.

2. Before operating the log splitter, make certain to

follow the "Initial Preparation" instructions in the

Operation section.

OPERATION

INITIAL PREPARATION

1. On a firm, level surface, remove the spring pin

and clevis pin from the pivot latch. Place the

beam in the vertical position. Replace clevis pin

and spring pin in pivot latch for safekeeping.

Make certain the beam is straight up and down,

against the reservoir tank.

2. Service engine with gasoline and oil as in

structed in the separate engine manual packed

with your log splitter.

3. Lubricate the beam area where beam will slide

with engine oil (DO NOT USE GREASE). Make

certain to oil both front and back of the beam

face. Pour some oil directly into the wedge

assembly.

4. Fill the reservoir tank as follows.

a. Remove reservoir vent plug. See figure 13.

Using 10 Weight AW type fluid or Dexron II

automatic transmission fluid, fill reservoir

to the top. Replace vent plug securely.

b. Disconnect the spark plug wire and ground

against the engine. Prime the pump by

pulling the recoil starter, to turn the engine

over, approximately 10 times. Reconnect the

spark plug wire.

c. Start engine. Use the control handle to extend

the wedge to the far extended position. Leave

the wedge in this position (do not retract).

d. Refill tank to within 1-1/2" to 2" from the top

^ ^ of the tank. Total capacity of system is

approximately 6-1/2 gallons.

e. Now retract the wedge. Extend and retract

the wedge fully 10 to 12 complete cycles to

remove trapped air in the system (system is

"self-bleeding").

f. Refill the reservoir to within 1-1/2" to 2" from

the top of the tank. Much of the original fluid

has been drawn into the cylinder and hoses.

Make certain to refill the reservoir, to prevent

extreme damage to the hydraulic pump.

Failure to refill the tank will void your

warranty.

NOTE

Some fluid may overflow from the

vent plug as the system builds heat

and the fluid expands and seeks its

own level.

WARNING

ik

Do not operate the log splitter without

the proper amount of transmission

fluid in the reservoir tank.

BEFORE STARTING

Before each use, check the following:

1. On a firm level surface, remove the spring pin

and clevis pin from the pivot latch. Place the

beam in the vertical position. Replace clevis pin

and spring pin in pivot latch for safekeeping.

Make certain the beam is straight up and down,

against the reservoir tank.

Page 10

Remove the vent plug and check the fluid 13vel.

2.

Fluid level should be 1-1/2" to 2" from the top

of the tank.

IMPORTANT

Reservoir tank must be full as

instructed. Low fluid level will damage

the pump and void your warranty.

3. Lubricate the beam area where beam will slide

with engine oil ( DO NOT USE GREASE), f/lake

certain to oil both front and back of the Learn

face. Pour some oil directly into the W3dge

assembly.

4. Fill gasoline tank as instructed in the sep arate

engine manual.

5. Make certain wearing surfaces of beam are

lubricated with engine oil.

TO START ENGINE

1. Place throttle control lever on the engine in -AST

position. See figure 14.

2. Place choke lever in CHOKE position.

NOTE

A warm engine may not require

choking.

Grasp starter handle and pull rope out s owly

3.

until engine reaches start of compression

cycle (rope will pull slightly harder at this point).

Let the rope rewind slowly.

Pull rope with a rapid, continuous, full arm

4.

stroke. Keep a firm grip on the starter handle.

Let the rope rewind slowly. Do not let s arter

handle snap back against starter.

Repeat preceding instructions 3 and 4 until

5.

engine fires. When engine starts, move choke

lever halfway between CHOKE and RUN.

Move throttle control lever to IDLE positic-nfor

6.

a few minutes warm-up. Gradually move c hoke

lever to RUN position as engine warms jp.

TO STOP ENGINE

1. Move throttle control lever to OFF position.

2. Disconnect spark plug wire from spark plug and

ground against the engine to prevent

accidental starting while equipment /'

unattended.

USING THE LOG SPLITTER

WARNING

A

Use the log splitter only on a level, hard surface.

Never stand next to the splitting wedge when

operating the log splitter. Always stand behind the

reservoir tank. See figure 15. Never attempt to cut

a log in half sideways. Always split the log

lengthwise.

The log splitter is designed to be used in the vertical

position only. Do not split logs with the beam

horizontal. Maximum length of log to be split is 24".

The control handle has three positions:

FORWARD (push the control handle down) —

Splitting wedge moves toward the end plate.

Control handle will return to neutral position as

soon as handle is released.

NEUTRAL (Middle positon) — Splitting wedge stops

in place.

REVERSE (Push the control handle upward) —

Splitting wedge returns. The control handle will

lock in the reverse position, and will return

neutral automatically when the reverse strc

NOTE

In order to idle smoothly, a new

engine may require 3 to 5 minutes

running above slow idle speed. Idle

speed has been adjusted to be correct

after this break-in period.

If weather is cold, run wedge up and down

7.

beam 6 to 8 times to circulate the hyd aulic

fluid, which will warm and thin the fluic.

TO OPERATE LOG SPLITTER:

1. Set throttle as maximum speed (3450-3600

RPM).

10

Page 11

2. Place the log upright, on top of end plate.

3. Press the control handle down (forward position)

until the splitting wedge just contacts the log.

Release the control handle.

STEP BEHIND THE RESERVOIR TANK (see

figure 15) and press the control handle down

until the log is split.

5. Move the control handle upward to return the

splitting wedge.

The wedge should take approximately 14 seconds

to make a complete cycle. This speed may vary

depending on throttle setting and temperature of

hydraulic fluid.

‘■NOTE

If the control handle kicks out of

reverse too soon, it can be adjusted.

Refer to Adjustment section of this

manual.

TO TRANSPORT LOG SPLITTER

1. Lower the beam to its horizontal position.

Make certain the pivot latch is latched

securely with the clevis pin and spring pin.

2. Remove the spring pin and clevis pin which

secure the jack stand. Pivot it up against the

tongue, and secure with spring pin and clevis

pin.

3. Attach the hitch to a towing vehicle, making

certain to latch securely. Attach the safety

chains to the towing vehicle.

■Adjustments

«PUTTING WEDGE

As normal wear occurs, periodically adjust the bolts

on the slide plate (beneath the splitting wedge) as

follows to eliminate the excess space between the

wedge plate and the beam. Refer to figure 8.

1. Loosen the three hex bolts on top of the slide

plate (beneath the splitting wedge).

Back the two adjustment bolts on the side of the

2.

slide plate out slowly until the wedge assembly

will slide on the beam. Tighten the lock nuts

securely against the base of the slide plate to

hold the bolts in this position.

Retighten the three hex bolts on top of the slide

3.

plate.

CARBURETOR ADJUSTMENT

A

If any adjustments are made to the

engine while the engine is running

(e.g., carburetor), keep clear of all

moving parts. Be careful of heated

surfaces and muffler.

-'"^or carburetor adjustment may required to comisate for differences in fuel, temperature, altitude

and load. Improper adjustment will cause stalling

when splitter is under load, hard starting and higher

fuel consumption.

WARNING

Refer to the separate engine manual packed with

your log splitter for carburetor adjustment

information.

REVERSE LOCKOUT ADJUSTMENT

WARNING

A

This adjustment should be made by

an authorized service dealer only.

The spring detent for the reverse lockout can be

adjusted by turning the adjustment screw shown in

figure 16. If it is not tight enough, the control han

dle will kick out of reverse too soon, before the return

stroke is completed. If it is adjusted too tight, the

control handle will not kick out of reverse, and could

cause damage to the pump, hoses, and serious

personal injury.

If adjustment is needed, an authorized service dealer

should make the adjustment using a pressure gauge

as shown in figure 16. The reverse lockout should

kick out at 1400 p.s.i.

A

When adjusting the reverse lockout,

do not overtighten the adjustment

screw to avoid damage to the log

splitter and possible serious personal

injury.

PRESSURE ADJUSTMENT

WARNING

WARNING

A

This adjustment should be made by

an authorized service deafer only.

The pressure is preset at the factory and should not

require adjustment. The pressure should be between

3000 and 3100 p.s.i. An adjustment screw is located

on the valve and should be adjusted by an authoriz

ed service dealer only, using a pressure gauge as

shown in figure 16.

Any adjustment of the pressure without instruction

from the factory will automatically void your

warranty.

11

_________

Page 12

MAINTENANCE

A

Always stop the engine and dis

connect the spark plug wire before

performing any maintenance or

adjustments.

RESERVOIR FLUID

Check the hydraulic fluid level in the log splitter

reservoir tank before each use. Fluid level should be

1-1/2" to 2" from the top of the tank.

Change the hydraulic fluid in the reservoir every 100

hours of operation. Disconnect the suction hos(j from

the bottom of the reservoir tank, and drain thu fluid

into a suitable container. Refill using only 10 V/eight

AW type fluid or Dexron II automatic transmission

fluid, as instructed in the "Initial Preparation' sec

tion of this manual, page 9. Also, make certain to

change the hydraulic filter.

Drain the fluid and flush the reservoir

tank and hoses with kerosene

whenever any repair work is perform

ed on the tank, hydraulic pump or

valve. Contaminants in the fluid will

damage the hydraulic components.

WARNING

NOTE

WARNING

A

Use extreme caution when working

with kerosene, as it is an extremely

flammable fluid.

HOSE CLAMPS

Check the hose clamps on the suction hose (attached

to bottom of the pump) for proper tightness before

each use. Check the hose clamps on the return hose„

at least once a season.

ENGINE

Change the engine oil after first 5 hours of opera

tion. Thereafter, change every 25 hours. Check

engine oil level every 5 hours, or each time the log

splitter is used. Service air cleaner every 25 hours.

Refer to separate engine manual for complete instruc

tions for care and maintenance of the engine.

FLEXIBLE PUMP COUPLER

The flexible pump coupler is a nylon "spider" insert,

located between the pump and engine shaft. The

alignment is very critical. Over a period of time, the

coupler will harden and deteriorate. To replace,

remove the engine, slide it back and replace the

coupler. Do not loosen or remove pump. Replace

engine, leaving engine mounting bolts loose. Align

coupler, then tighten engine bolts. Make certain

coupler is tight.

For a replacement flexible pump coupler, order pp'-'“

number 717-0891.

TIRE PRESSURE

Check sidewall of tire for manufacturer's recommend

ed maximum tire pressure. If this information does

not appear on your tire, maximum tire pressure under

any circumstances is 30 p.s.i. Equal pressure should

be maintained on both tires.

HYDRAULIC FILTER

Change the hydraulic filter every 50 hours of c peration. Use only a 10 micron hydraulic filter. Order part

number 723-0405.

BEAM AND SPLITTING WEDGE

Lubricate both sides of the beam where it contacts

the splitting wedge with engine oil before each use

to obtain years of service. However, normal we jr will

occur. The wedge plate on the log splitter is design

ed so the gibs on the side of the wedge plats can

be easily removed and rotated and/or turned over for

even wear. Make certain to readjust the adjusi ment

bolts so wedge moves freely, but no excess space

exists between the wedge plate and beam.

INSTALLATION OF TIRE TO RIM

A

The following procedure must be

followed when removing or installing

a tire to the rim.

1.

Be certain rim is clean and free of rust.

2.

Lubricate both the tire and rim generously.

Never inflate to over 30 p.s.i. to seat beao„.

3.

Excessive pressure when seating beads may

cause tire/rim assembly to burst with force

sufficient to cause serious injury.

12

WARNING

Page 13

OFF-SEASON STORAGE

If the machine is to be inoperative for a period longer

than 30 days, prepare for storage as folllows.

Clean the engine and the entire unit thoroughly.

Wipe the entire machine with an oiled rag to

protect the surfaces.

Refer to the engine manual for correct engine

3.

storage instructions. The engine must be

completely drained of fuel to prevent gum

deposits from forming on essential carburetor

parts and fuel tank.

The tongue can be removed and reattached in

4.

an upright position as shown in figure 17 to take

less space when storing.

Store unit in a clean, dry area.

5.

NOTE

When storing any type of power

equipment in an unventilated or metal

storage shed, care should be taken to

rustproof the equipment. Using a light

oil or silicone, coat the equipment,

especially all moving parts.

SYMPTOM POSSIBLE CAUSE(S) SOLUTION

1. Engine fails to start

2. Hard starting or loss of

power

3. Engine overheats

4. Will not split logs

5. Leaking cylinder

TROUBLE SHOOTING CHART

A. Check fuel tank for gas.

B. Spark plug lead wire

disconnected.

C. Faulty spark plug.

A. Spark plug wire loose.

B. Dirty air cleaner. B. Clean air cleaner as described in

A. Carburetor not adjusted

properly.

B. Air flow restricted.

C. Engine oil level low.

A. Reservoir fluid level low.

B. Pump setting incorrect.

A. Broken seals.

B. Scored cylinder.

A. Fill tank if empty.

B. Connect lead wire.

C. Clean, adjust gap or replace.

A. Connect and tighten spark plug wire.

engine manual.

A. Adjust carburetor. See engine

manual.

B. Remove blower housing and clean as

described in the engine manual.

C. Fill crankcase with the proper oil.

A. Check and fill reservoir tank as

instructed in Operation Section.

B. Adjust pump setting to between

3,000 and 3,100 p.s.i.*

A. Replace seals.*

B. Replace cylinder.*

NOTE: For repairs beyond minor adjustments, please contact your local service dealer.

•Should be performed by an authorized service dealer only.

13

Page 14

PRO/20 (Model 622)7 C

PRO/22 (Model 623) $

o rAj fO (JOT p£)iRo(jJ3:

5onrt£ -TAms

NOTE: The engine is not under warranty by the log

splitter manufacturer ... If repairs or service is

needed on the engine, please contact your nearest

authorized engine service outlet. Check the "Yellow

pages" of your telephone book under " Engines —

Gasoline".

Find It Fa 3t

In The

Yellow Ps ges

14

NOTE

Specifications subject to change without notice or

obligation.

Page 15

PRO/20 (Model 622) PRO/22 (Model 623)

PARTS LIST FOR MODELS 622 and 623 LOG SPLITTERS

PART

EF.

NO.

1

NO.

710-1010

2 710-1018

710-3029

3

712-0240

4

712-0333

5

714-0470

6

736-0921

7

738-0736

8

781-0127

9

781-0129

10

781-0130

11

781-0132

12

781-0140

13

781-0142

14

710-0672

15

711-3104

16

712-3057

17

V,2

736-0119

781-0273

23

781-0148

24

710-0409

25

712-0123

26

736-0119

27

737-0236

28

717-0885

29

717-0886

30

727-0307

31

737-0235

32

737-0238

33

737-0192

34

710-0117

35

710-0237

36

710-0363

37

710-0968

712-0123

38

714-0122

39

717-0887

40

717-0891

41

719-0278

42

719-0281

COLOR

CODE

DESCRIPTION

NEW

PART

Hex Bolt 1/2-20 x 3" Lg.

(Grade 8)

N

Hex Bolt 1/2-20 x 2.75"

Lg. (Grade 8)

N

Hex Bolt 7/16-20 x 1.25"

Lg.

N 48

Hex Jam Nut 7/16-20 Thd.

Hex Nut 1/2-20 Thd.

(Grade 8)

N

Cotter Pin 1/8 Dia.

L-Wash. 1/2" I.D.*

Hinge Pin 1/2" Dia.

Fixed Side Gib

Adjustable Gib

Adjustable Gib Shim

Beam (Kss'y. AiSE /Si-013!

Wedge Ass'y.

Wedge Back Plate

N

N

N

N

N

N

N

Hex Bolt 5/16-24 x 1.25"

Lg.*

Clevis Pin

Hex Nut 5/16-24 Thd.

(Grade 5)

L-Wash. 5/16" I.D.*

Pivot Latch Brkt.

N

Engine

Tank Ass'y. Complete

N

Hex Bolt 5/16-24 x 1.75"

Lg.*

Hex Nut 5/16-24 Thd.*

L.-Wash. 5/16" I.D.*

Vent Plug

Hydraulic Cylinder**

Control Valve-

Metal Pressure Tube

3/4" Hose Barb

Pipe Nipple

Elbow

Hex Bolt 5/16-24 x 1.0"

Lg.*

Hex Bolt 5/16-24 x .62"

Lg.*

Hex Bolt 5/16-24 x 4" Lg.

(622)

Hex Bolt 5/16-24 x 5" Lg.

(623)

Hex Nut 5/16-24 Thd.*

Sq. Key 3/16" x .75"

Pump J-ET SOPl. ¿a/i£AJ XO. wHG

Flexible Coupling

Coupling Shield (622)

Coupling Shield (623)

PART

REF.

NO

43

44 727-0308

45 727-0310

46

47

NO.

COLOR

CODE

DESCRIPTION

726-0146 Adjustable Hose Clamp

Suction Hose -20"

Pressure Hose

736-0119

L-Wash. 5/16" I.D.*

737-0234 90° Swivel N

781-0097

Rear Coupling Support

Brkt.

49

781-0098

Front Coupling Support

Brkt.

50

712-0299

Hex Slotted Nut 3/4-16

Thd.

51

714-0162

Cotter Pin 5/32" Dia.

52 734-0873 Hub Cap

53

734-1016

Wheel Ass'y. Comp.

734-0872 Tire Only

734-1017 Rim Only

734-0255

54 741-0107

736-0351 Fl.-Wash. .76" I.D. x 1.5"

56

Air Valve

Roller Bearing A. PEft. IdHREl

O.D.

750-0442 Spacer 1.56" Lg.

57

723-0405 Filter Element N

58

723-0406

59

60 727-0309

710-3144 Hex Bolt 3/8-16 X 2"

61

Filter Head N

Return Hose — 30" N

Lg. (Grade 5)

62 712-0430 Hex L-Nut 3/8-16 Thd.

63 781-0168

Stripper Half » N

64 710-0521 Hex Bolt 3/8-16x 3" Lg.

(Grade 8)

710-3130 Hex Bolt 3/8-16 X 3.25"

66

N

67 711-0813 Clevis Pin 5/16" Dia.

N

712-0375 Hex L-Nut 3/8-16 Thd.

69

N

70 712-0798 Hex Nut 3/8-16 Thd.*

N

71 713-0338

N

72 732-0194 Spring Pin

N

73 727-0311

74 736-0169

736-0185

75

Lg. (Grade 8)

Tow Hitch Chain

Hitch Coupler

L-Wash. 3/8" I.D.*

Fl.-Wash. .406" I.D. x .75"

O.D.

781-0160

80

781-0162 Jack Stand

81

750-0507 Spacer 3/8" I.D. x .27" Lg.

82

710-0157

83

Tongue

Hex Bolt 5/16-24 x 3/4"

Lg, (Grade 5) t

84 781-0271

-

85

781-0272 Fender Support t

Fender t N

86 736-3014 Fl.-Wash. .78" I.D. x 2.0"

N

87

736-0159 Fl.-Wash. .344" I.D. x .88"

O.D.

O.D.

NEW

PART

N

N

•

N

N

N

N

N

N

For faster service order standard nuts, bolts, and washers locally. If these items cannot be obtained locally, order by part

number and size as shown on parts list.

**Hydraulic cylinder "0" ring kit available - order part number 753-0458. h i

t PRO/22 (Model 623) Only.^ lil-OX/D ¿} U. ^TAhlt J

15

Page 16

R WARRANTY

NON-COMMERCIAL

Limitechtp Models P,10/20 and 424/LCD/20 Log Splitters

For three years from the date of original retail purch|3%«MiERR INC will either

repair or replace, at its option, fiee of charge, F.Ojg?^f^X£M*^r authorized service

firm, any part or parts fbund to be defedd^ in'material or workmanship.

Transportation charges forNthe movemem of any power equipment unit or

attacnment are tne responsiDJi ty or me

any parts submitted for replace tmem ur

purchaser unless such return iVmques

/ \

nurcnaser. iransnnrTaTinn

PART NUMBER

7/<2 07f/

12L-QIC=9

7/0-053J0

criRrp&a.

QUAN. t

^ '

the

to

or

;he

m-

on

-rVE OPiC>a}AL 5PM£R^ M£ Ab

i^LDEla- aU THe. (jQd

rHE2L. Amts (Uil Also Used oaJ

fkirr^ 4/?£ Fa^ Op J

7K/-0/3I 2eA«i Ussi. \

7/V- OHIO /

70K-D73L

' W- 0373

72/^OJ7S

72/-0377

\

DENI^IS^UERR

PRESIOmW^^

or

/ r

ite

/

ior

/ ^

/ .

1

ich

FORM NO. 770-6254C (R870909)

'We stand behind our products'

DUERR INC. • MEAD, WASHINGTON 99021

(509) 238-6124

Loading...

Loading...