Page 1

.75

'N

OUTDOOR POWER EQUIPMENT

for all seasons

LEAF

BLOWERS

Important:

Read Safety Rules and

Instructions Carefully

PRINTED IN U.S.A.

Model Numbers

245-692-000

245-693-000

245-694-000

24695S

Thank you for purchasing

an American-built product.

J

FORM NO. 770-3990

Page 2

INDEX

Safe Operation Practices.............................................. 3

Assembly Instructions................................................... 4

Operation..

Adjustments.................................................................. 6

...

................................................................ 5

Insti uctions given with this symbol are

▲

for I lersonal safety. Be sure you follow

them.

♦

LIMITEiD WARRANTY

♦

♦

♦

♦

♦

♦

♦

♦

For one year from the date of ori'

repair or replace, at its option, free

part or parts found to be defective

the movement of any power equipr

chaser. Transportation charges for

ty must be paid by the purchaser ui

This warranty will not apply to any part which has become inoperative due to misuse, ex

cessive use, accident, neglect, im jroper maintenance, alterations, or unless the unit has

been operated and maintained in accordance with the instructions furnished. This warran

ty does not apply to the engine, mo tor, battery, battery chargeror component parts thereof.

Please refer to the applicable marufacturer’s warranty on these items.

jinal retail purchase, MTD PRODUCTS INC will either

of charge, F.O.B. factory or authorized service firm, any

in material or workmanship. Transportation charges for

lent unit or attachment are the responsibility of the purany parts submitted for replacement under this warraniless such return is requested by MTD PRODUCTS INC.

Maintenance and Lubrication

Off-Season Storage.............................................................. f

Illustrated Parts

..................................................................

...............................................

8,b

♦

♦

♦

t

♦

♦

\

6:

♦

♦

♦

♦

♦

♦

This warranty will not apply where the unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. If

you do not know the dealer or distr butor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit wiN lot be accepted by the factory unless prior written per

mission has been extended by M'f D.

This warranty gives you specific I jgal rights. You may also have other rights which vary

from state to state.

♦

♦

♦

♦

♦

♦

i

WARNING

This unit is equipped with an internal combuition engine and should not be used on or near any unimproved

forest-covered, brush-covered or grass-covered and unless the engine's exhaust system is equipped with a spark

arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective

working order by the operator.

X

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other

states may have similar laws. Federal laws apply c n federal lands. A spark arrester muffler is available at your nearest

engine authorized service center.

2

Page 3

IMPORTANT

It is suggested that this manual be read in its entirety before attempting to assemble or operate. Keep this

manual in a safe place for future reference and for ordering replacement parts.

This unit is shipped WITHOUT GASOLINE or OIL. After assembly, see separate engine manual for proper

fuel and engine oil recommendations.

SAFE OPERATION PRACTICES FOR LEAF BLOWERS

1. Read this operating and service instructing manual

carefully. Be thoroughly familiar with the controls

and proper use of the power leaf blower.

2. Never allow children to operate this power

leaf blower.

3. Keep the area of operation clear of all persons,

particularly small children and pets.

4. Check fuel before starting engine. Do Not fill fuel

tank indoors, when engine is running, or while

engine is hot. Wipe off any spilled fuel before

starting engine.

5. Do Not change engine governor settings.

Do Not put hands near rotating parts for any

reason.

7. If the power leaf blower should start to vibrate

abnormally, stop the engine and check immediate

ly for the cause. Vibration is generally a warning

of trouble.

8. Before cleaning, repairing or inspecting make

certain ail moving parts have come to a complete

stop. Disconnect spark plug wire and keep wire

away from plug to prevent accidental starting.

Also keep throttle control lever in the stop

position.

9. If the power leaf blower should become blocked

with debris at any point, shut engine off and wait

until the impeller comes to a complete stop before

attempting to remove the.obstruction. Disconnect

spark plug wire to prevent accidental starting.

10. Check all bolts for tightness at frequent peroids.

11. Never store this power leaf blower with fuel in

the tank. Allow engine to cool before storing in

any enclosure.

12. Keep equipment free of debris when not in use.

13. Never operate this leaf blower unless impeller

guard and guard assembly are properly affixed in

their place.

14. Never change inlet nozzle or auxiliary hose

attachment when engine is running.

15. The manufacturer recommends that the operator

wear safety glasses or some other suitable eye

protection when operating this machine.

16. Exercise caution whenever operating leaf blower.

Do Not allow exhaust to be pointed in the

direction of persons.

17. No one should operate this unit while

intoxicated or while taking medication that impairs

the senses or reactions.

Page 4

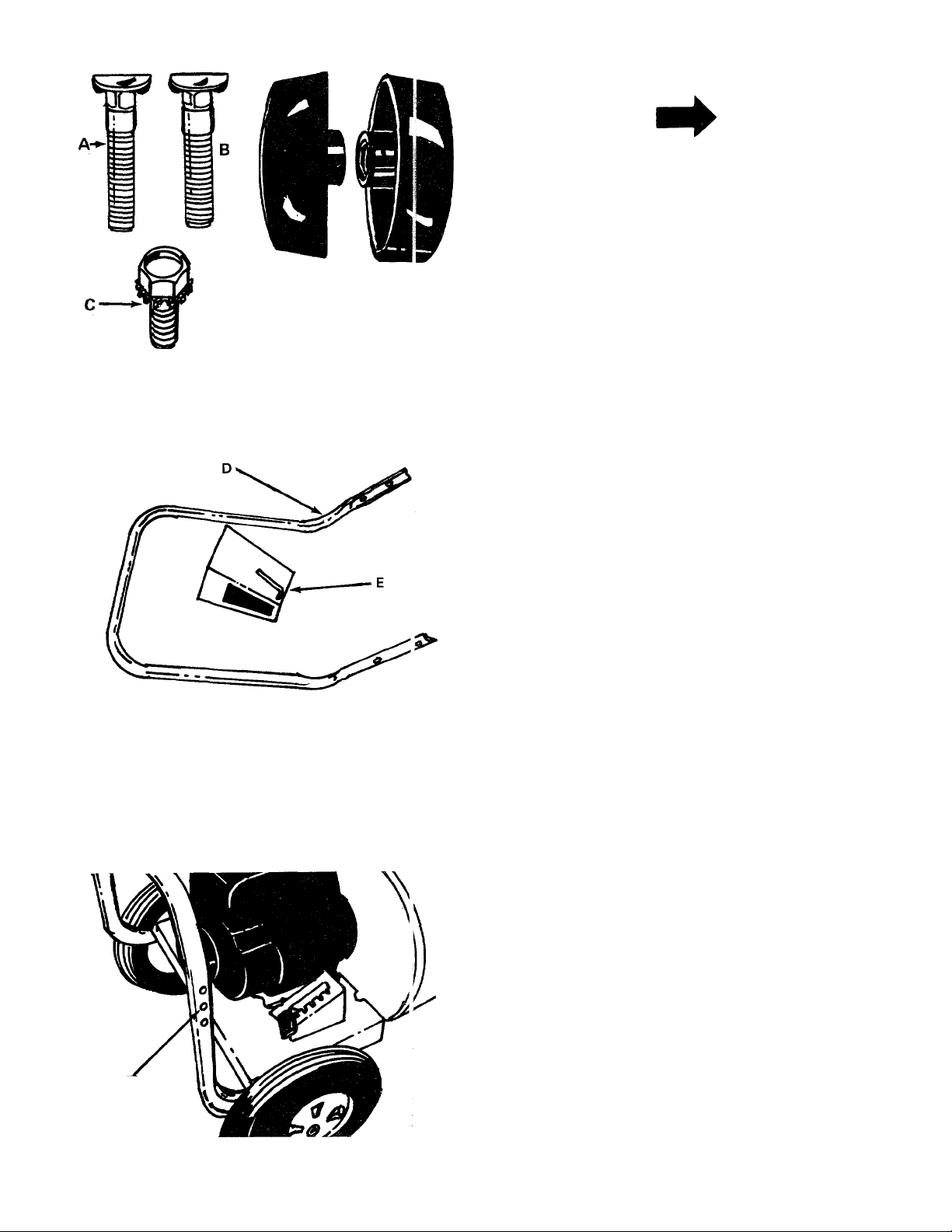

FIGURE 1.

ASSEMBLY INSTRUCTIONS

NOTE

Vacuum hose attachment 245-204-000

comes with model 694. It is optional

equipment on all other models.

CONTENTS OF HARDWARE PACK:

(See Figure 1)

A (2) Carriage Bolts

B (2) Hand Knobs

C (1) Hex Sems Bolt

FIGURE 2.

PARTS IN CARTON (See Figure 2):

D (1) Upper Handle

E (1) Directional Discharge

NOTE

The right and left side of your leaf

blower is determined from operator's

position.

1. Remove the leaf blower, hardware pack and all

literature from the carton before discarding

carton.

USE THIS

HOLE ONLY

FIGURE 3.

2. Figure 3 shows lower handle. Upper handle

mounts in center hole only.

Page 5

FIGURE 4.

Place the upper handle (D) over the lower handle,

lining up the holes. Secure with carriage bolts (A)

and hand knobs (B). See figure 4.

4. Slip end of directional discharge (E) over chute

opening. Secure in position with hex sems bolt

(C). See figure 5.

DIRECTIONAL

DISCHARGE (E)

FIGURE 5.

OPERATION

BEFORE STARTING ENGINE

Service engine with gas and oil. See engine manual

packed with leaf blower for complete instructions

'''or care and maintenance of engine. READ DIREC

TIONS CAREFULLY.

TO START ENGINE

2. Pull starter rope once with quick, full stroke.

Move hand throttle to "FAST" position and pull

starter rope again.

3. When engine starts, move throttle to "RUN"

position until engine warms up.

TO STOP ENGINE

1. Move throttle to "START" position.

Move throttle control lever to "OFF" position.

Page 6

ADJUSTMENTS

\C WARNING I

Do Not make this adjustment or any

adjustment with the engine running.

Stop the engine, disconnect the spark

plug wire and ground plug wire to

engine block.

TWO-WAY AIR DISCHARGE

Your leaf blower is equipped with an adjustable

chute deflector. Simply push down on handle provid

ed and swing door towards the front or side as dei ired.

See figure 6.

MAINTENANCE AND LUBRICATION

Your leaf blower, like all machines with moving parts

must receive care and maintenance. The following

tips, if used, will contribute many troublefree hours

to your blower.

1. Check oil level frequently. When changing oil,

make sure dirt and debris is cleaned off oil sump

before removing oil plug.

2. Keep blower clean, especially the engine and

engine air filter.

3. Check all nuts, bolts and screws occasionally to be

sure blower is in good operating condition.

4. The wheel bearings are pre-lubricated at the

factory and should require no further attention

until blower is serviced. However, it is advisable

to remove the wheels and apply a small amount

of light oil to each axle at least once a season.

DIRECTIONAL

DISCHARGE

FIGURE 6.

HEIGHT ADJUSTMENT

To adjust the height of the discharge, stand oi the

right hand side of the leaf blower and move the index

handle towards the engine. Move handle to\\/ards

rear of unit to lower height. Move the handle forward

to raise the height. See figure 7.

OFF-SEASON STORAGE

If you are going to store your blower for any length

of time (30 days or longer), it is important that the

following steps be taken:

1. Drain the gas tank. Start the engine. Allow it to

run out of gas. Gasoline left in the engine will

leave gum deposits in the carburetor and gas tank.

2. Clean engine of all foreign matter.

3. Lubricate cylinder by removing the spark plug

and pour in one ounce of clean lubricating oil

through the spark plug hole into the cylinder.

Crank engine slowly to spread oil and replace

spark plug. To start after storage, remove spark

plug and rotate engine with starter to remove

excess oil.

NOTE

FIGURE 7.

When storing any type of power

equipment in an unventilated or metal

storage shed, care should be taken to

rust proof the equipment. Using a

light oil or silicone, coat the equip

ment, especially springs and bearings.

Page 7

TROUBLE SHOOTING CHART

PROBLEM

1. Excessive

vibration.

2. Height adjust

ment slips out

of lockout

position.

3. Engine fails A. Check fuel tank for gas.

to start.

4. Hard starting A. Spark plug wire loose.

or loss of power.

5. Engine over

heats.

.OTE: For repairs beyond the minor adjustments listed above, please contact your local service dealer.

A. Bent crankshaft.

B. Vane plate out of balance.

B. Spark plug lead wire

C. Faulty spark plug.

B. Dirty air cleaner.

A. Carburetor not adjusted

B. Air flow restricted.

C. Engine oil level low.

CAUSE

Handle bent.

disconnected.

properly.

A. Replace crankshaft (should be done by an authorized service

dealer).

B. Replace vane plate.

Replace index handle and index plate.

A. Fill tank if empty.

B. Connect lead wire.

C. Spark should jump gap between control electrode and side

electrode. If spark does not jump, replace the spark plug.

A. Connect and tighten spark plug wire.

B. Clean air cleaner as described in engine manual.

A. Adjust carburetor. See engine manual.

B. Remove blower housing on engine and clean as described in the

engine manual.

C. Fill crankcase with the proper oil.

REMEDY

Page 8

Models 692, 693, 694 and 24695

34

L

35

\ ?

29

27

f

(%

If YOU WRITE TO US ABOUT THIS ARTI

OR IF YOU ORDER REPLACEMENT PART

WAYS MENTION THIS MODEL & SERIAL

REF.

PART NO.

NO.

749-0479 . Upper Handle

1

5

6

714-0114

710-0442

7 14526-488

8

9

10

11

736-0119 L.-Wash. 5/16" I.D.*

712-0267

736-0187

1544-009

12 712-0206

13

736-0921

14 734-1036

15

16

14571-488

710-0726

PARTS LIST FOR LEAF BLOWER MODELS 692, 693, 694 and 24695

COLOR

CODE

DESCRIPTION

PARI

REF.

NO.

PART NO.

COLOR

CODE

NEW

19 734-1035

Sq. Key 1/4" x 2.00"

Lg.*

Hex Bolt 5/16-18 X

734-1184 Wheel Ass.'y. Comp. 10.5"

1.50" Lg.*

Engine Mounting

Frame Ass'y.

Hex Nut 5/16-18 Thd.*

741-0313

736-0159

20

21 710-0170

Fl.-Wash. .63" I.D. x

1.25" O.D.

Cotter Pin 5/32" Dia. 27

X 1.25" Lg.*

Hex Nut 1/2-13 Thd.*

L.-Wash. 1/2" I.D.*

Swivel Caster Wheel 5'

Dia. X 1.25"

Caster Arm Ass'y.

Hex Wash. Hd. "AB"

22 736-0162

710-0118

28 14561

29

09966

31

720-0142

32 14552

34 749-0481

35

710-0487

Tap Scr. 5/16" X .7£ "

Lg.

**Tire Only - 734-1185, Rim Only - 734-1183.

DESCRIPTION

Wheel Ass'y. Comp. 12"

X 3.5" (Plastic-692 only)

(Incl. Bearings)

x4" (Steel)**

Bearings (For Steel Wheel)

Fl.-Wash. 34" I.D. x .87"

O.D.

Hex Locking Bolt 5/16-24

X .62" Lg.

Fl.-Wash.(692 only)

Hex Bolt 5/16-18 X .75"

Lg.*

Index Plate

Hand Knob

FI.-Grip Vinyl

Height Adj. Handle

Lower Handle

Carriage Bolt 5/16-18 x

2.0" Lg.

NEW

PART

Page 9

Models 692, 693, 694 and 24695

PARTS LIST FOR LEAF BLOWER MODELS 692, 693, 694 and 24695

REF.

NO.

1 14539

2

710-0600 Hex Self Tap Scr. 5/16" x .50" 15 14563 - 488

PART

NO,

COLOR

CODE

DESCRIPTION

Engine Housing Brace Ass'y-

Lg.

NEW

PART

REF.

NO.

14

16

PART

NO.

711-0758

710-0191

3 710-0118 Hex Bolt 5/16-18 X .75" Lg.* 17 736-0217

4 736-0119

5 14541

710-0627

6

7

710-0260

8 14479

- 488

L.-Wash. 5/16" I.D.* 18 14536 - 488

Right Angle Bracket

Hex Locking Bolt 5/16-24 x.75‘

\

22 710-0259

19

14496 -488

Carriage Bolt 5/16-18 x .62"

Lg.*

23 736-0242

Directional Discharge Ass'y. O.D.

11 736-0119 L.-Wash. 5/16" I.D.* 24 720-0170

12

712-0267 Hex Nut 5/16-18 Thd.*

13

731-0608

The engine is not under warranty by the leaf blower manufacturer. If repairs or service is needed on the

engine, please contact your nearest authorized engine service outlet. Check the "Yellow Pages" of your

telephone book under "Engines - Gasoline".

Blower Guard

*For faster service obtain standard nuts, bolts and washers locally. If these items cannot be

obtained locally, order part number and size as shown on parts list.

(488 - Mack Truck Yellow) When ordering parts if color or finish is important, use color code

(615 - Red) shown at left (e.g. Mack Truck Yellow Finish - 14542 (488).)

COLOR

CODE

DESCRIPTION

Hex Shoulder Nut .50" I.D.

Nozzle Plate Ass'y.

Hex Bolt 3/8-24 X 1.25" Lg.*

L.-Wash. 3/8" I.D. HD.

Air Vane Plate Ass'y.

Blower Housing Ass'y. - Comp.

Hex Sems Bolt 5/16-18 x .62"

Lg.*

Belleville Wash. 34" I.D. x .87"

3-Arm Thumb Scr. 5/16-18 x

.75" Lg.

Find It Fast

InTha

Yellow Pages

NEW

PART

Page 10

Page 11

Page 12

MTD PRODUCTS INC

.....................

..

..........

YaRD-MSN COMPANY

P.O. BOX 36900

CLEVELAND OHIO 44136

Loading...

Loading...