Page 1

OWNERS

MANUAL

.75

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

Important:

POWER

VACUUM

Model Number

244-660-000

24665L

Read Safety Rules and

Instructions Carefully

PRINTED IN U.S.A.

Thank you for purchasing an

American built product.

F0RI\ii iSIO. 770-3096

Page 2

INDEX

Safe Operation Practices

Assembly Instructions

Operation .................................................................... 7

Adjustments .................................................................. 8

.............................................

..................................................

3

f

LIMITED WARRANTY

♦

♦

♦

t

♦

♦

♦

For one year from the date of orig nal retail purchase, MTD PRODUCTS INC will either

repair or replace, at Its option, free c f charge, F.O.B. factory or authorized service firm, any

part or parts found to be defective in material or workmanship. Transportation charges for

the movement of any power equipm^mt unit or attachment are the responsibility of the pur

chaser. Transportation charges for г ny parts submitted for replacement under this warran

ty must be paid by the purchaser unless such return is requested by MTD PRODUCTS INC.

This warranty will not apply to any part which has become inoperative due to misuse, ex

cessive use, accident, neglect, imp oper maintenance, alterations, or unless the unit has

been operated and maintained in ac ;ordance with the instructions furnished. This warran

ty does not apply to the engine, motor, battery, battery chargeror component parts thereof.

Please refer to the applicable manifacturer’s warranty on these items.

4

Maintenance ......................................................... .. 8

Illustrated Parts.......................................................... ■*

Replacement Parts List

Parts Information ..........................................Back Cover

.............................................

1 .

♦

♦

♦

The equipment which you have just purchasid does not have a spark arrester. If this equipment is used on

any forest covered land, brush covered land, or grass covered unimproved land in the State of California, before^

using on such land, the California law required that a spark arrester be provided. In addition, spark arrester

required by law to be in effective working ordi;r. The spark arrester must be attached to the exhaust system a

comply with Section 4442 of the California Public Resources Code.

This warranty will not apply where he unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. If

you do not know the dealer or distrib utor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will not be accepted by the factory unless prior written per

mission has been extended by MTC .

This warranty gives you specific leijal rights. You may also have other rights which vary

from state to state.

f} I WARNING I

TO PURCHASERS

OF INTERNAL COMBUSTION ENGINE EQUIPPED

MACHINERY OR DEVICES IN THE STATE OF CALIFORNIA

Page 3

IMPORTANT

-H is suggested that this manual be read in its entirety before attempting to assemble or operate. Keep this manual

a safe place for future reference and for ordering replacement parts.

This unit is shipped WITHOUT GASOLINE or OIL. After assembly, see separate engine manual for proper fuel

and engine oil recommendations.

SAFE OPERATION PRACTICES FOR POWER VACUUMS

1. Read this operating and service instructing manual

carefully. Be thoroughly familiar with the controls

and proper use of the power vacuum.

2. Never allow children to operate this power

vacuum.

3. Keep the area of operation clear of all persons,

particularly small children and pets.

4. Check fuel before starting engine. Do not fill fuel

tank indoors, when engine is running, or while

engine is hot. Wipe off any spilled fuel before

starting engine.

5. Do not change engine governor settings.

6. Do not put hands near rotating parts for any

reason.

7. if the power vacuum should start to vibrate

abnormally, stop the engine and check immedi

ately for the cause. Vibration is generally a

warning of trouble.

9. If the power vacuum should become blocked with

debris at any point, shut engine off and wait

until the impeller comes to a complete stop

before attempting to remove the obstruction.

Disconnect spark plug wire to prevent accidental

starting.

10. Check ail bolts for tightness at frequent periods.

11. Never store this power vacuum with fuel in the

tank. Allow engine to cool before storing in any

enclosure.

12. Keep bag and equipment free of debris when not

in use.

13. Never operate this power vacuum unless air duct

and vacuum bag are properly affixed in their

place. Large zippered end of bag must be closed

when operating to prevent objects from being

blown out.

14. Never empty vacuum bag when engine is running.

15. Never change auxiliary hose attachment when

engine is running.

Before cleaning, repairing or inspecting, make

certain all moving parts have come to a complete

stop. Disconnect spark plug wire and keep wire

away from plug to prevent accidental starting.

Also keep throttle control lever in the stop

position.

16. The manufacturer recommends that the operator

wear safety glasses or some other suitable eye

protection when operating this machine.

17. Check the vacuum bag frequently for wear and

replace when necessary.

Page 4

FIGURE 1

a*-'";

1

ASSEMBLY INSTRUCTIONS

TOOLS REQUIRED:

(2) 9/16" Wrenches

(2) 7/16" Wrenches

(1) Hammer or Rubber Mallet

LOOSE PARTS IN CARTON (See figure 1):

P"

i

•

—L

1 :

, H—'i- c

M

i !!“•'

Y

^ 0*^ " *' ‘i

--

-----

i i r

J.

f . 1 \ ^ ,,

K

A

-------

B

C

D

E

F

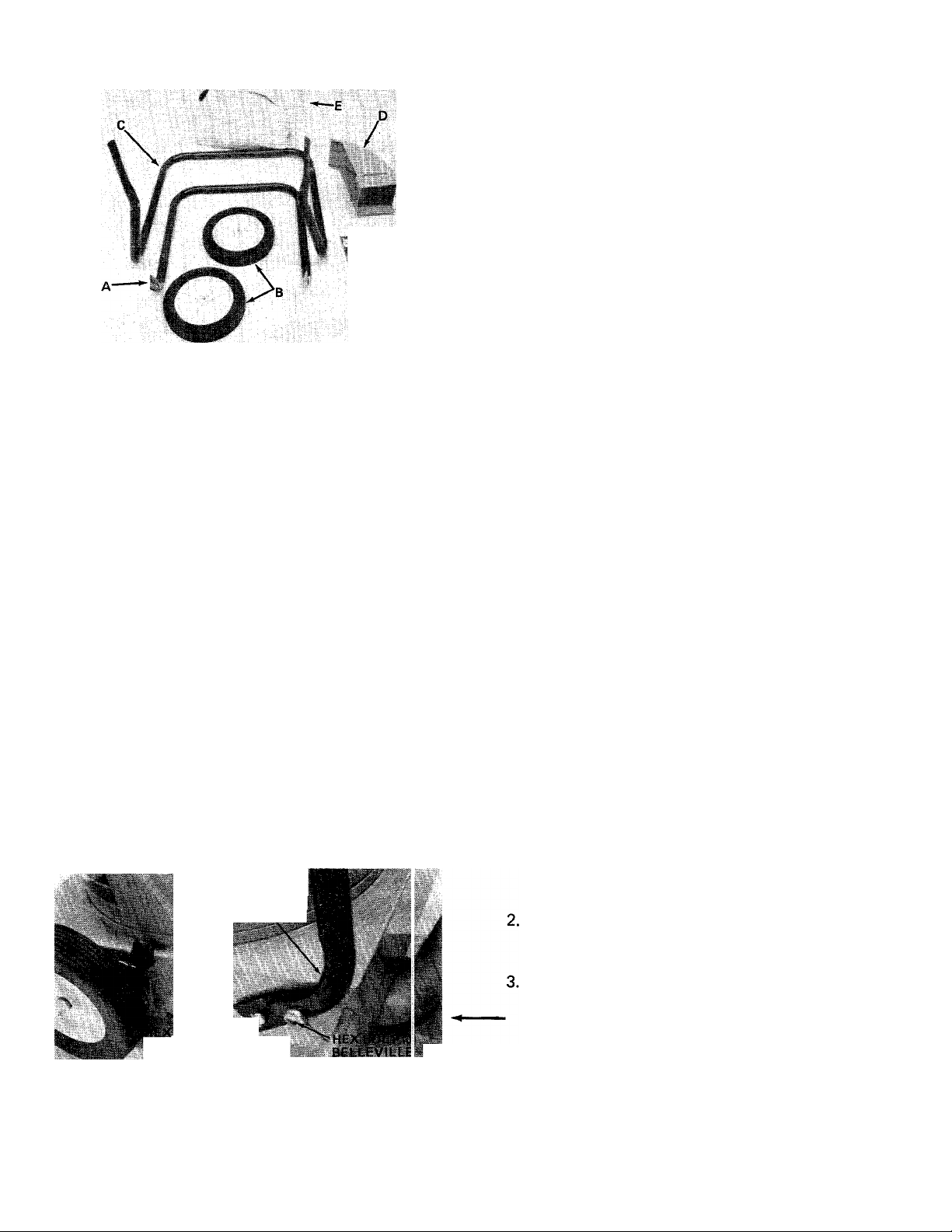

CONTENTS OF HARDWARE PACK (See figure 2):

Lower Handle

(1)

(2)

Rear Wheels

Upper Handle

(1)

Air Duct Assembly

(1)

Bag

(1)

Hardware Pack

(1)

G (2) Hex Bolts 3/8-16x3/4" Long

H (2) Lock Washers 3/8" I.D.

I (4) Hex Nuts 3/8-16 Thread

J (2) Hex Bolts 3/8-16 x 1-1/2" Long

-K (2) Belleville Washers 3/8" I.D. X 1-1/8" O.D.

L (2) Spacers 1/2" I.D. x 15/16" Long

M (4) Flat Washers 1/2" I.D. x 1" O.D.

N (2) Black Push Caps

0 (4) Hex Bolts 1/4-20 x 1-3/4" Long

P (4) Hex Lock Nuts 1/4-20 Thread

Q (1) Thumb Screw 5/16-18 Thread

R (1) Belleville Washer 5/16" I.D. X 7/8" O.D.

S (2) Stud Pins (Not Shown)

T (2) Push-On Speed Nuts (Not Shown)

FIGURE 2

FIGURE 3

LOWER

HANDLE lA)

BOLTCfe)-^'

LOCK WASHER (H)

HEX NU1 (II

WASHER (i )

HEX WUT (I)

1.

Remove the vacuum, loose parts, hardware pack

and literature from the carton. Make certain all

parts and literature have been removed before

the carton is discarded.

Raise the back of the unit off the floor approxi

mately 3 inches and block it so that the lower

handle and rear wheels may be assembled.

Place lower handle (A) in position on the vacuum,

lining up the holes in the handle with the holes

on the frame. See figure 3. Place hex bolts (G)

(3/4" long) through lower hole in handle and

frame. Secure with lock washers (H) and hex

1

nuts (I) on the inside of frame, finger tight only.

Place hex bolts (J) through upper hole in hand/

4.

and frame. Secure with belleville washers (k

(cupped side against the frame) and hex nuts (I).

5.

Tighten all four nuts and bolts using two 9/16"

wrenches.

Page 5

FIGURE 4

.-s'

Slide spacers (L) onto the axle shafts. Place one

flat washer (M) on each shaft next to the spacers.

See figure 4.

SPACER (L)

AXLE

SHAFT FLAT

WASHER (M)

Place rear wheels in position on the shafts, then

another flat washer (M). Secure with black push

cap (N) by placing the push cap in position and

tapping on with hammer or rubber mallet. See

figure 5.

FIGURE 5

PUSH CAP (N)

UPPER HANDLE

HEX BOLTS (O)

HEX LOCK

NUTS(P)

LOWER HAND

Place the upper handle (C) in position over lower

8.

handle. Fasten with four hex bolts (O) and hex

lock nuts (P) provided. See figure 6. Two

7/16" wrenches are required.

FIGURE 6

Page 6

. i i.-SH-ON

-. ..'NUTIT)

I

t<M

STUD PIN (S)

9. Place the stud pins (S) in holes in upper handle

(head of pins go to the inside of handle). Secure

pins with push-on speed nuts (T) by holding

speed nut with box wrench and tapping pin with

hammer. See figure 7.

¿i'-

■

FIGURE?

%

UH

SLOT

DUC"

VelSSEMBLY

10. Place the tabs on the air duct assembly (D) into

the slots in the frame as shown in figure 8. Raise

the air duct into position.

FIGURE 8

FIGURE 9

^ *

THUMB

'SCREW (Q)

*' ..-BELLEVILLE

' VASHER(RI

11. Secure air duct with thumb screw (Q) and belle-

*

ville washers (R). Cupped side of washer must be

against the air duct. See figure 9.

Page 7

12. Assemble the bag (E) by slipping the top straps

on the bag over upper handle. Hook the two

small straps over the stud pins on handle. See

figure 10.

13. Slip the elastic opening of the bag over the arr

duct assembly, making certain the elastic opening

is secured behind the flanges on all four sides of

on the air duct. See figure 11.

FIGURE 11

OPERATION

BEFORE STARTING

Service engine with gas and oil. See engine manual

packed with vacuum for complete instructions for

care and maintenance of engine. READ DIREC

TIONS CAREFULLY.

CAUTION

A'

Revolving Blades - Keep hands and

feet away from all openings.

) START ENGINE

After the engine has been properly fueled and oiled

(refer to engine operating and maintenance instruc

tions), start engine as follows.

1. Move throttle control lever on engine to START

position.

2. Crank engine. Pull recoil with quick firm pull.

Do not pull out so far the rope stops with a jerk

as this will cause rope failure. Do not allow rope

and handle to snap back into place.

3. After two or three full firm pulls on recoil (or as

soon as engine fires), move speed control to RUN

position.

TO STOP ENGINE

1. To stop engine, move throttle control lever to

STOP position.

2. Disconnect spark plug wire and ground to prevent

accidental starting while equipment is unattended.

Operate a new engine at intermediate speeds and light

load for the first few hours as you would a new

automotive engine.

Page 8

The bag may be emptied using the large zipper as

shown in figure 12. Be certain the zipper is closed

when operating the unit.

FIGURE 12.

CARBURETOR ADJUSTMENT

\ WARNING \

If any adjustments are made to the

engine while the engine is running

(e.g. carburetor), disengage all clutch

es. Keep clear of all moving parts. Be

careful of heated surfaces and muffler.

If carburetor needs adjustment to start or for operatidn, see "Carburetor Adjustment" section of engine

manual.

MAINTENANCE

ADJUSTMENTS

CAUTION

A

Do not at any time make any adjust

ment to the unit without first stopping

engine and disconnecting spark plug

wire.

HEIGHT ADJUSTMENT

An adjusting plate and thumb lever at both front

wheels provide height adjustment for the vacuum.

See figure 13. Each adjusting plate has nine positions.

Height will be changed when the thumb lover is

moved from one position to another. Simply repress

thumb lever towards wheel and move wheel an«i lever

assembly to desired position. Both wheels mjst be

placed in the same relative position. Lower tho front

of the unit to obtain more suction.

I WARNING \

Disconnect spark plug wire and ground

it against the engine before performing

any repairs or maintenance.

BAG

Under normal usage the bag is subject to wear,

should be checked periodically. Be sure any re

placement complies with the manufacturer's recom

mendation. Wash bag periodically with water.

Allow to dry thoroughly in the shade. Do not use

heat.

ENGINE

Refer to engine manual for proper maintenance

procedures. Follow instructions carefully.

OFF-SEASON STORAGE

The following steps should be taken to prepare the

vacuum for storage.

1. Clean the engine and the entire unit thoroughly.

2. Refer to engine manual for correct engine storage

instructions.

3. Store in a clean, dry area.

FIGURE 13

CAUTION

A

When storing any type of power

equipment in an unventilated or metal

storage shed, care should be taken to

rust proof the equipment. Using a

light oil or silicone, coat the equip

ment especially all moving parts.

Page 9

TROUBLE SHOOTING CHART

1 PROBLEM

1. Engine fails to

to start.

2. Hard starting or

loss of power.

3. Engine over

heats.

4. Excessive

vibration.

NOTE: For repairs beyond the minor adjustments listed above, please contact your local authorized service dealer.

A. Check fuel tank for gas.

B. Spark plug lead wire

C. Faulty spark plug.

A. Spark plug wire loose.

B. Dirty air cleaner.

A. Carburetor not adjusted

B. Air flow restricted.

C. Engine oil level low.

A. Bent crankshaft.

B. Impeller assembly out

CAUSE

disconnected.

properly.

of balance.

REMEDY

A. Fill tank if empty.

B. Connect lead wire.

C. Spark should jump gap between control electrode and side

electrode. If spark does not jump, replace the spark plug.

A. Connect and tighten spark plug wire.

B. Clean air cleaner as described in engine manual.

A. Adjust carburetor. See engine manual.

B. Remove blower housing on engine and clean as described in the

engine manual.

C. Fill crankcase with the proper oil.

A. Replace crankshaft (should be done by an authorized service

dealer).

B. Replace impeller assembly

Hose Attachment Kit Model 294-210-000 and Blower Conversion Kit Model 294-211-000

are available as optional equipment.

Page 10

Model 660 and 24665

IF YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

10

Page 11

Model 660 and 24665

PARTS LIST FOR MODEL 660 POWER VACUUM

ef.

Part

i\lo.

No.

Color

Code

Description

New

Part

Ref.

No.

Part

No.

Color

Code

Description

New

Part

1 749-0480 Upper Handle

28 736-0272

2 Engine

710-0260 Carriage Bolt 5/16-18 x .62" Lg.

3

4 15784 - 488

5 710-0654

15786

6

Blower Housing Ass'yHex Tap Scr. 3/8-16 x 1.00" Lg. 30 736-0272

Impeller Ass'y.

7 736-0217 L-Wash. 3/8" I.D.*

*

29 734-1140

N

31 750-0588

8 710-0591 Hex Bolt 3/8-24 X 1.0" Lg.

w/Patch

32

736-0331 Bell.-Wash. .39" I.D. x 1.12"

9 723-0137 P.V.C. Foam Strip (4-Pcs. 12"

Lg.)

15780 - 488 Vacuum Deck Ass'y.

10

11 15796

Front Baffle Ass'y. N

12 15788 Lower Baffle Ass'y. N

13

14

15790

728-0123

Wiper Retaining Strip

Pop Rivet .188" Dia. 38 720-0170

33 712-0798 Hex Nut 3/8-16 Thd.*

N 34 15779 Air Duct Ass'y.

35 710-0201

710-0344

36

37

N

736-0242

15 735-0222 Nozzle Wiper Rear N 39 712-0107

712-0267 Hex Nut 5/16-18 Thd.* 40

16

736-0242 Bell.-Wash..34" I.D. X.87" O.D.

17

738-0102

18

Shid. Bolt 1/2" Dia. x 1.45" 42 764-0208

712-0113 Wing Nut 1/4-20 (Plastic)

41

710-0136 Hex Bolt 1/4-20 X 1.75" Lg.*

Lg. (3/8-16) 43 749-0592 Lower Handle

19 734-1139 Wheel Ass'y. Comp. 8 x 1.75" 44

- Front

N

;o 736-0331 Bell.-Wash. .39" I.D. x 1.12"

14578

14579

O.D.

21 15262

22

15261 Index Plate 46

736-0331

23

Wheel Pivot Bar

45 1539-019

Bell.-Wash. .39" I.D. x 1.12" 47

711-0737

714-0105

O.D. 48 735-0221

24 712-0798 Hex Nut 3/8-16 Thd.* 49 15789

25 14832 Spring Lever Ass'y. w/Knob

738-0507 Shoudler Bolt .500" x 7/16"

26

Lg. (3/8-16)

50 710-0302

51 736-0169

27 726-0128 Push Cap .50" Rod (Black)

Fl.-Wash. 1/2" I.D. x 1.0" O.D.

X .06

Wheel Ass'y. Comp. 10 x 1.75"

- Rear

Fl.-Wash. 1/2" I.D. x 1.0" O.D.

X .06

Wheel Spacer 1/2" I.D. x 15/16

Lg.

O.D.

Hex Bolt 3/8-16 X .75" Lg.*

Hex Bolt 3/8-16 X 1.50" Lg.*

Bell.-Wash. .34" I.D. x.87" O.D.

Thumb Scr. 5/16-18 x .75" Lg.

Hex Cent. L.-Nut 1/4-20 Thd.

Vacuum Bag (6.6 Bushel)

Height Adjuster Ass'y. Comp. -

R.H.

Height Adjuster Ass'y. Comp -

L.H. (Not Shown)

Push Speed Nut .25" Dia.

Stud Pin .250" Dia. X 1.75" Lg.

Sq. Key 3/16 X 3/16 X 1.00" Lg.

Nozzle Wiper Side

Wiper Retaining Strip

Hex Wash. Hd. "F" Tap Scr.

#10

L-Wash. 3/8" I.D.*

N

i

N

N

N

N

N

N

*For faster service obtain standard nuts, bolts and washers

locally. If these items cannot be obtained locally, order by

part number and size as shown on parts list.

(488 - Mack Truck Yellow)

(615- Red)

When ordering parts, if color or finish is important use the

appropriate color code shown above, (e.g. Mack Truck

Finish - 14542 (488).)

•*c

ЮТЕ: The engine is not under warranty by the vacuum manufacturer ... If repairs or service is needed

on the engine, please contact your nearest authorized engine service outlet. Check the "Yellow Pages" of

your telephone book under "Engines - Gasoline."

This instruction manual covers various models and

all specifications shown do not necessarily apply

to your model. Specifications subject to change

without notice or obligation.

11

NOTE

Find II Fast

In The

Yellow Pages

Page 12

PARTS INFORMATION

POWER EQUIPMENT PARTS AND SERVICE

Parts and service are available through the authorized seivice

firms listed below. All orders should specify the model numb sr of

your unit, part numbers, description of parts and the quanti y of

each part required.

NOTE: If any parts are found to be missing or defective upon assembly of this unit, write to advise the factory so

that immediate replacement can be made.

ALABAMA BIRMINGHAM

Auto Electric & Carburetor Co. . .. 2625 4th Ave. S

ARKANSAS NORTH LITTLE ROCK

Sutton’s Lawn Mower Shop............... 5301 Roundtop Drive

CALIFORNIA PORTERVILLE

Billious...............................................75 North D Street

COLORADO DENVER

Spitzer Industrial Products Co. ... 6601 N.

FLORIDA JACKSONVILLE

Radco Distributors............................. 4909 Victor St.

Small Eng. Dist

GEORGIA EAST POINT

East Point Cycle & Key

ILLINOIS LYONS

Keen Edge Co.....................................8615 Ogden Ave

INDIANA ELKHART

Parts & Sales Inc...............................2101 Industrial Pkwy.. .^5516

IOWA DUBUQUE

Power Lawn & Garden Equip

LOUISIANA MONROE

Mid-South Power

Suhren Engine Co

MARYLAND ТАКОМА PARK

Center Supply Co

MASSACHUSETTS SPRINGFIELD

Morton B. Collins Co.......................... 300 Birnie Ave...............C1107

MICHIGAN LANSING

Lorenz Service Co

Power Equipment Dist

MINNESOTA HOPKINS

Hance Distributing Inc

MISSISSIPPI BILOXI

Biloxi Sales & Service, Inc

MISSOURI KANSAS CITY

Automotive Equip. Service

Ross-Frazier Supply Co

Henzier, Inc.........................................2015 Lemay Ferry Rd. .6 3125

NEW JERSEY BELLMAWR

Lawnmower Parts Inc........................717 Creek Rd

NEW MEXICO ALBUQUERQUE

Spitzer Eng. & Parts

NEW YORK CARTHAGE

Gamble Dist., Inc

Red Fox Parts Dist

..................................

......................

............

...............................

.............................

...............................

................. ...........

.......................

.......................

.................

...............

....................

..........................

...............................

............................

Box 368, Rt. 4

Washington St

Box 5459

OPA LOCKA

2351 N.W. 147th St. . . .3 3054

2834 Church St

2551 J.F. Kennedy . .. .f 2001

1500 Arkansas St

NEW ORLEANS

8330 Earhart Blvd

6867 New Hampshire

Ave

2500 S. Pennsylvania .. ^ 8910

MOUNT CLEMENS

340 Hubbard

420 Excelsior Ave. W. . E 5343

506 Caillavet St

3117 Holmes St

ST. JOSEPH

8th and Monterey...........6 4503

ST. LOUIS

1023 Third Ave. N.W. . .6 7103

West End Ave

SCHOHARIE

Rt. 30 P.O. Box 527.... 12157

....................

................

.............

..............

.......................

............

...........

..........

.........

.................................

.................

............

.............

................

................

3 3233

7 2117

9 3257

8D229

3 2207

3 0344

60534

Ï1201

7 0118

2 0912

^ 8043

2 9533

6 4109

6 8030

13619

BRIGGS AND STRATTON, TECUMSEH AND PEERLESS PARTS

AND SERVICE

Briggs & Stratton, Tecumseh and Peerless parts and service

should be handled by your nearest authorized engine service firm,

Check the yellow pages of your telephone directory under thr

listing Engines—Gasoline, Briggs & Stratton or Tecumse

Lauson.

NORTH CAROLINA GOLDSBORO

Smith Hardware Co

Dixie Sales Company

OHIO CARROLL

Stebe’s Mid-State Mower Supply . Box 366, 71 High St... .43112

Bleckrie, Inc....................................... 7900 Lorain Ave.............44102

National Central

Burton Supply Co

OKLAHOMA MUSKOGEE

Victory Motors, Inc............................. 605 S. Cherokee

OREGON PORTLAND

Kenton Supply Co

PENNSYLVANIA HARRISBURG

EECOInc

Thompson Rubber Co

Bluemont Co......................................11125 Frankstown Rd. .15235

Frank Roberts & Sons

Scranton Auto Ignition Co

TENNESSEE KNOXVILLE

Master Repair Service....................... 2000 Western Ave

American Sales & Service, Inc. ... 3035-43 Bellbrook . .. .3811

TEXAS DALLAS

Marr Brothers, Inc

Woodson Sales Corp

Bullard Supply Co

Engine House Inc

UTAH SALT LAKE CITY

A-1 Engine & Mower Co

VIRGINIA ASHLAND

RBI Corp............................................101 Cedar Run Dr...........23005

WASHINGTON SEATTLE

Bailey’sinc

WISCONSIN APPLETON

Automotive Supply Co

Horst Dist........................................... 444 N. Madison..............53014

...........................................

.........................................

...........................

........................

................................

..............................

.............................

.......................

......................

.............................

........................

.............................

..............................

....................

...............

....................

515 N. George St

GREENSBORO

335 N. Green

CLEVELAND

WADSWORTH

687 Seville Rd

YOUNGSTOWN

1301 Logan Ave.

Box 929

8216 N. Denver Ave. .. .97217

4021 N.6thSt

PHILADELPHIA

5222-24 N. Fifth St

PITTSBURGH

PUNXSUTAWNEY

R.D. 2..............................15767

SCRANTON

1133-35 Wyoming Ave. 18509

MEMPHIS

423 E. Jefferson

FORT WORTH

1702 N. Sylvania

HOUSTON

2409 Commerce St. . . .77003

SAN ANTONIO

8610 Botts Lane

P.O. Box 17867

439 E. 900 So

141414thAve

123 S. Linwood Ave.

P.O. Box 798

CHILTON

............

.................

...............

.........................

...........

..................

.........

.........

.............

...........

.............

................

..................

...............

27530

27402

44281

44501

74401

17110

19120

37921

75203

76111

78217

84111

98122

54911

WARRANTY

The purpose of warranty is to protect the customer from

time of manufacture. It does not provide for the unlimitei

sibility of the customer. The manufacturer cannot assun

the manufacturer’s fault, it’s the manufacturer’s responsi

CLAIMS AGAINST THE MANUFACTURER’S WARRANTY

INCLUDES;

1. Replacement of Missing Parts on new equipment.

2. Replacement of Defective Parts within the warranty p eriod.

3. Repair of Defects within the warranty period.

MTD PRODUCTS INC • P.O. BOX 36900 • CLEVELAND, OHIO 44136

PARTS AND SERVICE POLICY (0483)

defects in workmanship and materials, defects which are NOT detected at the

I and unrestricted replacement of parts. Use and maintenance are the respone responsibility for conditions over which it has no control. Simply put, if it’s

aility; if it’s the customer’s fault, it’s the customers’s responsibility.

All claims MUST be substantiated with the following

information:

1. Model Number of unit involved.

2. Date unit was purchased or first put into service.

3. Date of failure.

4. Nature of failure.

Loading...

Loading...