Page 1

■'x

$1.00

OWNHrS GUIDE

ASSEMBLY • OPERATION • MAINTENANCE • PARTS

Model Numbers

249-650-000

5 H.R

24650-9

SHREDDER

Important: Read Safety Rules and Instructions Carefully

PRINTED IN U.S.A.

FORM NO. 770-5902D

Page 2

INDEX

Rules for Safe Operation..............................................................................3

Assembly.............................................................................................. . . 4

Operation........................................................................................................6

Adjustments.................................................................................................. 8

Ins uructions given with this sym

bol are for personal safety. Be

A

suie to follow them.

Maintenance ..................................................................................................9

Off-Season Storage ......................................................................................9

Trouble Shooting Chart ............................................................................11

Repair Parts ......................................................................................12, 13

A

This unit is equipped with an internal combust on engine and should not be used on or near any unproved

forest-covered, brush-covered or grass-covered laid unless the enigne's exhaust system is equipped with a spark

arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained in

effective working order by the operator.

In the State of California the above is required bv law (Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal law at?ply on federal lands. A spark arrester for the muffler is available

through your nearest engine authorized service dealer.

{ warning {

i

2

Page 3

♦

■N

WARNING

At;

To reduce the potential for any injury, comply with the following safety instruc

♦

tions. Failure to comply with the instructions may result in personal injury.

RULES FOR SAFE OPERATION

TRAINING

1. Read this owner's manual carefully in its entirety

before attempting to assemble or operate this

machine. Be completely familiar with the controls

and the proper use of this machine before operating

it. Keep this manual in a safe place for future and

regular reference and for ordering replacement

parts.

2. Children must never be allowed to operate this

equipment.

3. No one should operate this unit while intoxicated or

while taking medication that impairs the senses or

reactions.

4. This equipment should never be operated in the

vicinity of children, pets or other persons.

5. Never run your machine in an enclosed area as the

exhaust from the engine contains carbon monox

ide, which is an odorless, tasteless and deadly

poisonous gas.

6. Never allow your hands or any part of your body or

clothing inside the feeding chamber, discharge

chute, or near any moving part while the machine

or engine is running.

7. If it is necessary for any reason to inspect or repair

the feeding chamber or any part of the machine

where a moving part can come in contact with your

body or clothing, stop the machine, allow it to cool,

and disconnect the spark plug wire from the spark

plug before attempting such inspection or repair.

PREPARATION

1. Wear safety glasses provided with your unit

while operating the chipper-shredder to prevent in

jury from any chips which may be ejected out of

the openings.

2. Wear proper apparel. Avoid wearing loose fitting

clothing. Wear gloves when handling material.

3. HANDLE FUEL WITH CARE as gasoline is an

extremely flammable fuel.

A. Check the fuel before starting the engine. Do

not fill the fuel tank indoors, while the engine

is running, or while the engine is still hot. Turn

the unit off and let the engine cool before

refueling.

B. Fuel your shredder in a clean area. Do not

smoke while refueling.

C. Fuel tank cap must be secure at all times

except during refueling.

D. Avoid spilling gasoline or oil. Wipe the unit

clean of any spilled fuel or oil.

E. Store fuel and oil in approved containers, away

from heat or open flame, and out of reach of

children.

4. This machine should be operated only upon an

level earthen surface.

5. Assure that all screws, nuts and bolts and other

fasteners are properly secured.

OPERATION

1. When feeding shreddable material into this equip

ment, be extemely careful that pieces of metal.

rocks, bottles, cans or other foreign objects are not

included.

2. If the cutting mechanism strikes any foreign object

or if your machine should start making an unusual

noise or vibration, immediately stop the engine and

disconnect the spark plug wire from the spark plug.

Allow the machine to stop and take the following

steps:

A. Inspect for damage.

B. Replace or repair any damaged parts.

C. Check for any loose parts and tighten to assure

continued safe operation.

3. The engine must be kept clean of debris and other

accumulations.

4. Do not allow an accumulation of processed material

to build up in the discharge area as this will pre

vent proper discharge and can result in kick-back

from feed opening.

5. Never allow your hands or any other part of your

body or clothing inside the feeding chamber,

discharge chute or near any moving part while the

engine is running.

6. Keep all guards and deflectors in place and in

good working condition to assure continued safe

operation.

7. Always stand clear of the discharge area when

operating this machine.

8. Keep your face and body back from the feed

opening to avoid accidental bounce back of any

material.

9. Do not over-reach. Keep proper balance and

footing at all times.

10. The engine governor settings on your machine

must not be altered, changed, or tampered with.

The governor controls the maximum safe operating

speeds and protects the engine and all moving

parts from damage caused by overspeed.

11. Do not transport machine while engine is running.

12. Do not operate engine if air cleaner or cover

directly over carburetor air intake is removed,

except for adjustment. Removal of such parts

could create a fire hazard.

MAINTENANCE AND STORAGE

1. When this equipment is stopped for servicing,

inspection, storage or to change an accessory,

make sure the spark plug wire is disconnected from

the spark plug. The machine should be allowed to

cool down before making such inspection, ad

justments, service, eta Maintain your machine with

care and keep it clean for the best and continued

safe operation.

2. Do not use flammable solutions to clean the air

filter.

3. When not in use, your machine should be stored out

of the reach of children. Keep where gasoline fumes

will not reach an open flame or spark. For long

periods of storage, the gasoline should be drained

and disposed in a safe manner. Always allow the

machine to cool before storing in any enclosure.

Page 4

NOTE

This unit is shipped WITHOUT GASOLINE

or OIL. After assembly, see separate

engine manual for proper fuel and engine

oil recommendations.

ASSEMBLY INSTRUCTIONS

Tools Required for Assembly:

(2) 7/16" Open End or Box Wrenches*

(1) 1/2" Socket Wrench

* An Adjustable Wrench may be used in place of one

of the wrenches.

FIGURE 1.

NOTE

The right and left side of your shredder

is determined from behind the unit.

UNPACKING

Remove the shredder and loose parts from the

carton. Make certain ail parts and literature have been

removed before the carton is discarded.

Parts in Carton:

Shredder

Chute Deflector

Hopper

Upper Leaf Ramp Section

Catcher Bag

Hardware Pack

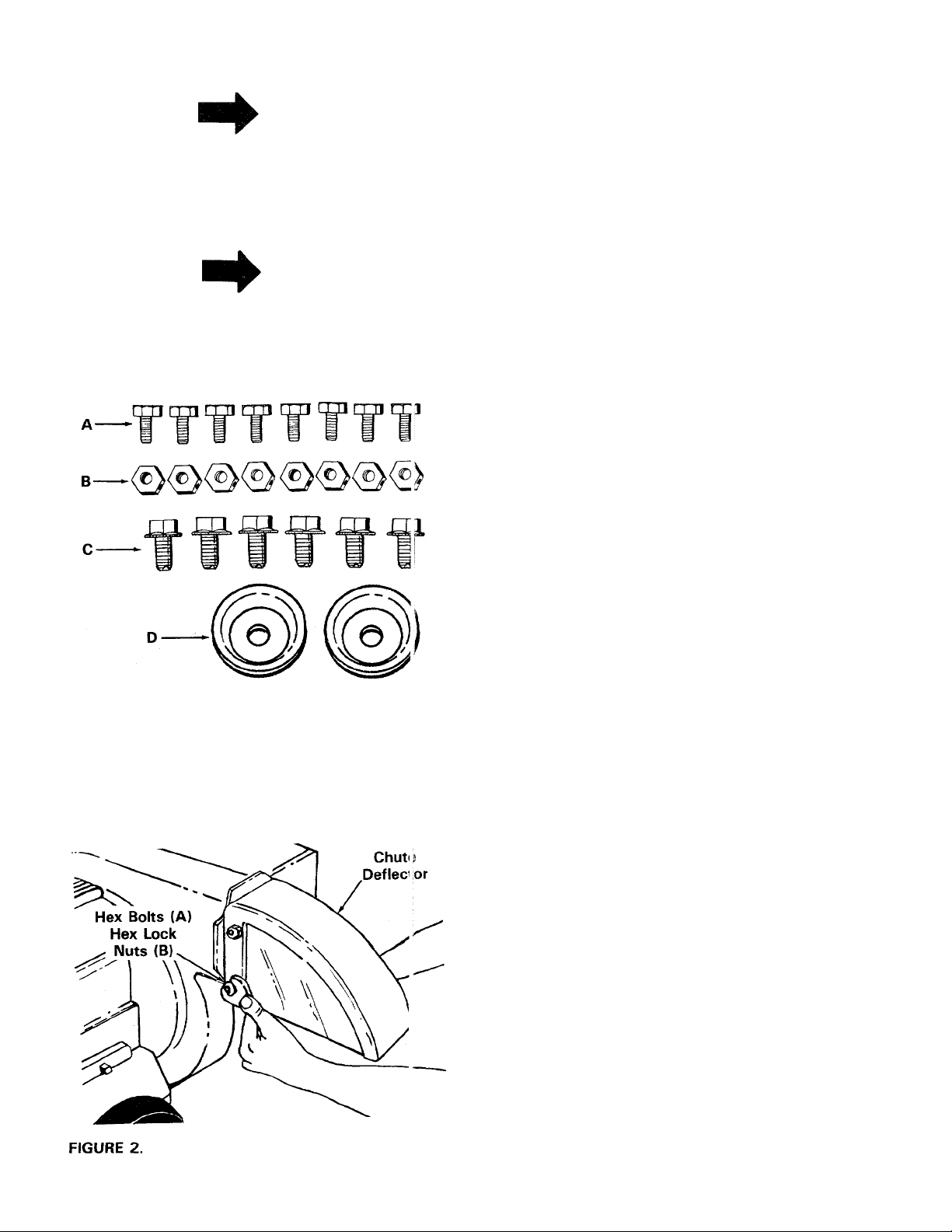

Contents of Hardware Pack (See Figure 1):

A

B (8)

C (6)

D (2)

Hex Bolts 1/4-20 x 1/2" Long

(8)

Hex Lock Nuts 1/4-20 Thread

Hex Washer Head Self-Tapping Screws

5/16-18 X 3/4" Long

Keepers

Safety Glasses (Not Shown)

(1) :

CHUTE DEFLECTOR INSTALLATION

1. Place the chute deflector in position on the

discharge opening (on the left side of the shred-

------

der). See figure 2.

2. Secure chute deflector to discharge opening with

hex bolts (A) and hex lock nuts (B). Heads of the

hex bolts are inside the discharge opening. Hex nuts

go on the outside.

3. Tighten all four nuts and bolts securely.

Page 5

Hopper’^

FIGURE 3.

Lower Leaf

Ramp Section

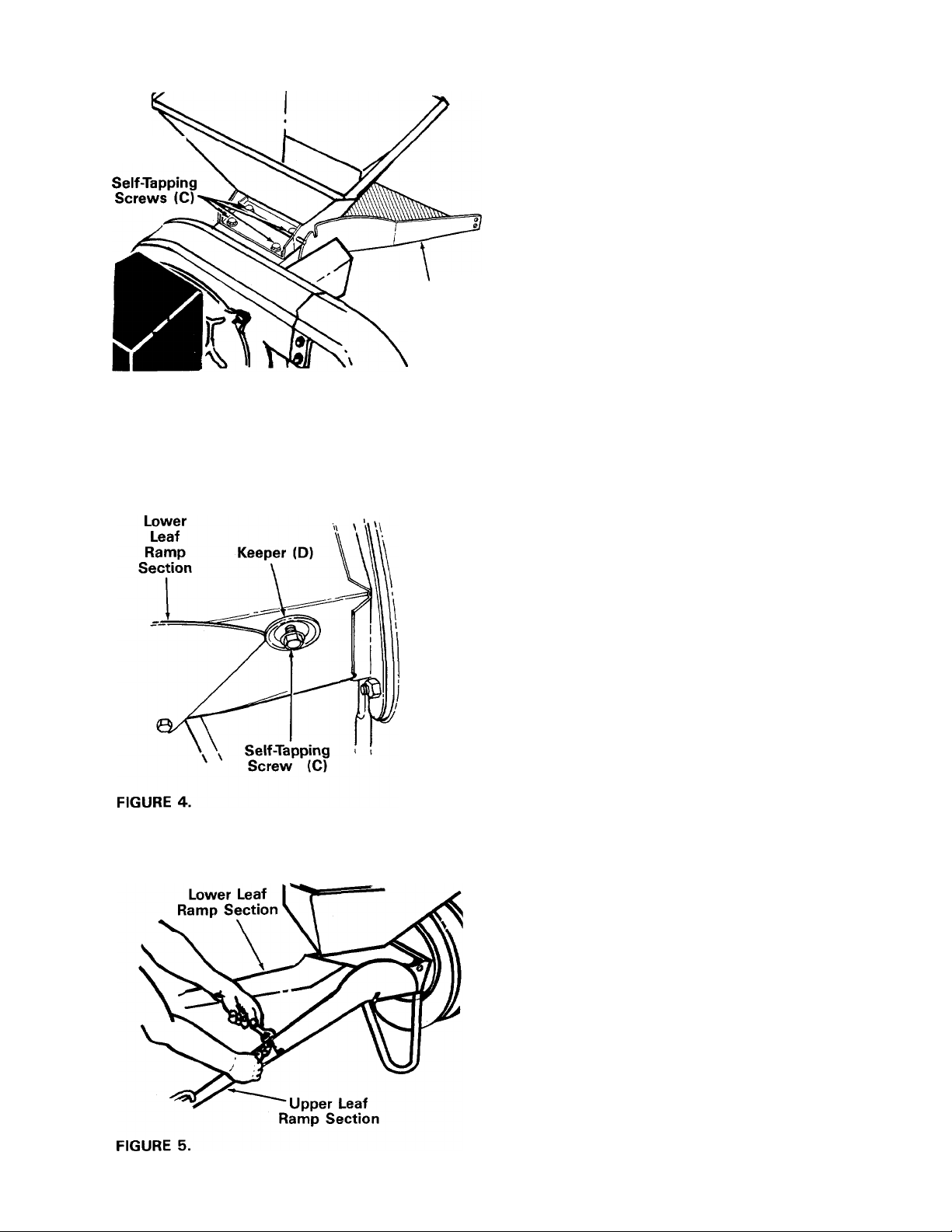

INSTALLATION OF HOPPER AND UPPER GUIIDE

EXTENSION

1. The lower leaf ramp section on the shredder is

placed in an upright position for shipping

purposes. Lower this section.

2.

Place the hopper in position on the shredder.

See figure 3. Start all four hex washer head self

tapping screws (C), then tighten securely using

a 1/2" socket wrench.

Assemble the keepers (D) to the sides of the unit

3.

with two hex washer head self-tapping screws (C),

using a 1/2" socket wrench. Tighten securely.

I I

4. Place upper leaf ramp section inside the lower leaf

ramp section. Secure with four hex bolts (A) and

hex lock nuts (B). Tighten securely. See figure 5.

Page 6

ATTACHING THE CATCHER BAG

Your unit is equipped with a nylon bag which attaches

to the discharge opening. If desired, place the end of

the bag over the chute deflector. Depress plunger, pull

on the drawstring, and release plunger to lock it in

• position. See figure 6.

OPERATION

GAS AND OIL FILL UP

NOTE

ENGINE IS SHIPPED WITHOUT OIL. FILL

CRANKCASE WITH OIL BEFORE STAR

TING.

Service engine with gasoline and oil as instruc ed in

the separate engine manual packed with your shred

der. Read instructions carefully.

TO START ENGINE

1. Attach spark plug wire to spark plug.

2. Place choke lever on engine in CHOKE pos tion.

See figure 7 or 7A.

NOTE

A warm engine may not require

choking.

3. Place the throttle control lever on engine in 7\ST

position.

Throttle Control

Lever in Start

Position

Choke

Lever

Tecumseh Engine

Grasp starter handle (see figure 8) and pull rope

out slowly until engine reaches start of compres

sion cycle (rope will pull slightly harder at this

point). Let the rope rewind slowly.

NOTE

FIGURE 7. - Briggs and Stratton Engine

A noise will be heard when finding

the start of the compression cycle. This

noise is caused by the flails and fingers

which are part of the shredding

mechanism falling into place, and

should be expected.

Pull rope with a rapid, continuous, full arm stroke.

5.

Keep a firm grip on start handle. Let rope rewind

slowly. Do not let starter handle snap back

against starter.

Repeat preceding instructions 4 and 5 until

6.

engine fires.

7.

After engine starts, move throttle control lever on

engine to slow position for a few minutes warm

up. Move choke lever gradually to RUN position.

Then move throttle control lever to FAST posi

tion for shredding operations.

Page 7

TO STOP ENGINE

1. Move throttle control lever to OFF position.

Air

Screen

If it becomes necessary to push materials into the

shredder, use a small diameter stick, NOT YOUR

HANDS. The stick should be small enough that it will

be ground up if it gets into the impeller assembly.

WARNING

Ac

Do not deposit material larger then 1/2"

diameter in the hopper or upper guide

extension. Any material heavier then 1/2”

should be fed into the chip-it guide.

2. Disconnect spark plug wire from spark plug and

ground against the engine to prevent accidental

starting while equipment is unattended.

HOW TO USE YOUR SHREDDER

Your shredder is designed for safe, efficient operation.

KEEP HANDS AND FEET AWAY FROM ALL OPENINGS.

AC WARNING \

Wear the safety glasses provided with

your unit while operating the shredder to

prevent injury from any chips which may

be ejected out of the openings. Make

certain chip-it guide is closed when not

in use.

Wear gloves when handling material. Feed material in

to the shredder at a steady rate. It is possible to feed

too fast. Experiment with feeding rates to determine

what rate provides the best results without stalling the

engine or plugging the discharge chute.

The discharge chute will direct the shredded material

into a pile, a container or the bag provided with your

shredder.

Leaves and smaller branches can be fed into the

hopper with the leaf ramp raised as shown in figures

9 and 10.

No larger than

1/2 inch diameter

^^Hopper

Chip-it

Guide

Ac WARNING \

The shredder discharges material with

considerable velocity. Keep away from the

area around the discharge chute. Always

stop the engine and disconnect the spark

plug wire when removing or attaching the

bag, when changing containers or when

removing the shredded material.

Leaf

Ramp

FIGURE 10.

Page 8

Lower the leaf ramp by holding the handle and pulling

up on the release bar. See figure 11. Leaves and snail

twigs can be raked into the shredder with the leaf ra mp

in this position. See figure 12.

NOTE

Bulky material, such as stalks or heavy

branches (anything up to 2" diameter),

should be fed into the chip-it guide. See

figure 14. Do not force or jam material in

to the chip-it guide. Make certain leaf

ramp is raised as shown in figure 14 when

using the chip-it guide.

t WARNING i

Make certain chip-it guide door is closed

A

when not in use.

Keep Leaf Ramp Raised

When Using Chip-lt Guide

FIGURE 12.

Small branches can also be fed into the leaf ramp. See

figure 13.

No larger than

1/2 inch diameter

Leaf Ramp

FIGURE 13.

/iW/lLi.IKU

FIGURE 14

ADJUSTMENTS

CARBURETOR ADJUSTMENT

▲

If any adjustments are made to the engine

while the engine is running (e.g. car

buretor), keep clear of all moving parts.

Be careful of heated surfaces and muffler.

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude

or load. If adjustment is needed, refer to the separate

engine manual packed with your shredder.

A DIRTY AIR CLEANER WILL CAUSE

•ENGINE TO RUN ROUGH. BE CERTAIN

AIR CLEANER IS CLEAN AND ATTACH

ED TO THE CARBURETOR BEFORE

ADJUSTING CARBURETOR. DO NOT

MAKE UNNECESSARY ADJUSTMENTS.

FACTORY SETTINGS ARE SATISFAC

TORY FOR MOST APPLICATIONS AND

CONDITIONS.

\ WARNING j

NOTE

Page 9

MAINTENANCE

N

'■’V

Disconnect spark plug wire and ground

it against the engine before performing

any repairs or maintenance.

ENGINE

Refer to the separate engine manual packed with your

unit for all engine maintenance procedures. Read

instructions carefully.

AIR CLEANER

The air cleaner prevents damaging dirt, dust, etc., from

entering the carburetor and being forced into the engine

and is important to engine life and performance.

Never run your engine without air cleaner completely

assembled.

To service air cleaner; refer to the separate engine

manual packed with your unit.

"N

LUBRICATION

Wheels - The wheels require no lubrication.

Flails and Fingers - If the unit is disassembled for any

reason, lubricate the flails and fingers with a light oil

(engine oil may be used).

AC

WARNING {

Hold the blade retainer on the impeller assembly

5.

with an adjustable wrench to keep the blade from

turning as shown in figure 15.

Remove the blade by removing the center bolt, lock

6.

washer and flat washer.

NOTE

Use caution when removing the blade to

avoid contacting the weld bolts

protruding from the housing.

WARNING

AC

The blade is reversible and can be

assembled to the crankshaft with either

side showing.

CUTTING BLADE

The cutting blade may be removed for grinding or

replacement as follows.

1. Lower the upper guide extension.

2. Block up the housing. See figure 15.

3. Remove the four elastic lock nuts from the back

of the housing using a 1/2" wrench. Refer to figure

13. Separate the shredder into two halves.

4. Remove the back-up plate. See figure 15.

NOTE

When reassembling, make certain the

opening on the back-up plate is toward

the bottom of the unit. The back-up plate

may be reversed to provide a new cutting

edge.

When sharpening the blade, follow the original angle

of grind as a guide. It is extremely important that each

cutting edge receives an equal amount of grinding tp

prevent an unbalanced blade. An unbalanced blade will

cause excessive vibration whèn rotating at high speeds

and may cause damage to the unit.

The blade can be tested by balancing it on a round shaft

screwdriver or nail. Remove metal from the heavy side

until it balances evenly. See figure 16.

Page 10

When reassembling the blade, tighten to betweer. 375

and 450 inch pounds, or lacking torque wrench, tighten

securely.

FLAILS AND FINGERS

The ^lailsjand fingers may be reversed when they

become dull. It is suggested that this procedu e be

performed by your nearest authorized service d taler.

OFF-SEASON STORAGE

If the shredder is to be inoperative for a period longer

than 30 days, the following precautions are

recommended.

1. Working outdoors, drain all fuel from the fuel tank.

Run the engine until it stops from lack of fuel.

WARNING

DO NOT DRAIN FUEL WHILE SMOKING,

OR IF NEAR AN OPEN FIRE.

2.

Drain all the oil from the crankcase (this shoi Id be

done after the engine has been operated and s still

warm) and refill crankcase with fresh oil.

3.

Protect the inside of the engine for stora(|e as

follows.

Remove spark plug, pour approximately 1/2 c unce

(approximately one tablespoon) of engine o I into

cylinder and crank slowly to distribute oil. ReDlace

spark plug.

Clean the engine and the entire unit thoroughly.

iJcrr '}?£M£.RSIBL£.

NOTE

When storing any type of power

equipment in an unventilated or metal

storage shed, care should be taken to

rustproof the equipment. Using a light oil

or silicone, coat the equipment, especially

all moving parts.

5. Store in a clean, dry area.

10

Page 11

TROUBLE SHOOTING CHART

N

SYMPTOM

POSSIBLE CAUSE(S)

SOLUTION

Engine fails to start

Hard starting or loss of

power

Engine overheats

Material not shredding

Engine bogs down or

stalls

' JOTE: For repairs beyond the minor adjustments listed above, please contact your nearest authorized service dealer.

1. Check fuel tank for gas.

2. Spark plug lead wire

disconnected.

3. Faulty spark plug.

1. Spark plug wire loose.

2. Dirty air cleaner.

1. Carburetor not adjusted

properly

2. Air flow restricted.

3. Engine oil level low.

Blade and/or flails not sharp.

1. No fuel in fuel tank.

2. Feeding material into the

machine too quickly.

1. Fill tank if empty.

2. Connect lead wire.

3. Clean, adjust gap or replace.

1. Connect and tighten spark plug

wire.

2. Clean air cleaner as described in

separate engine manual.

1. Adjust carburetor as instructed in the

separate engine manual.

2. Remove blower housing and clean

as described in the separate engine

manual.

3. Fill crankcase with the proper oil.

Sharpen or reverse blade and flails.

1. Fill tank if empty.

2. Do not force material into the opening.

Feed gradually.

11

Page 12

Model 650

5^

Page 13

Model 650

PARTS LIST FOR MODEL 650 SHREDDER

Part

'>ef.

.tio.

1 11476 Door Chip It 31 714-0144

2

3 711-0580 Clevis Pin

4 711-0579

5 11455 Cutting Finger 33 11459A

6

7

8 712-0922

9 714-0507 Cotter Pin 3/32" Dia. x 3/4"

10 16568 Chute Deflector

11 712-0107

12 710-0289 Hex Bolt 1/4-20 x .50" Lg.*

13

14 13430 Impeller Assembly 41

15 710-0157 Hex Bolt 5/16-24 x 3/4" Lg. 42

16 736-0119

17

18 Engine 45

19

20

21

22 738-0521

23 736-0170

^24 726-0221 Push Cap

25 711-0494 Spacer

26

28 710-0624

29

30 710-0237

Color

No.

Code

710-0465

736-0921 L-Wash. 1/2" I.D.* 34

726-0111 Palnut 3/16" Dia. 35

714-0114

14573 Hopper to Engine Mtg. Plate 44

11464A

712-0123

736-0119

734-1056 Wheel Ass'y.-Comp. (White) 53 16522

734-1173 Wheel Ass'y-Comp. (Silver)

712-0429

Hex Bolt 1/2-20 x 4.50" Lg.*

Flail Spacer 7/32" Lg.

Hex Jam Nut 1/2-20 Thd.* 36 736-0247

Lg-

L.-Nut 1/4-20 Thd. 39 14575-638

Sq. Key 1/4" x 2.00" Lg.

L.-Wash. 5/16" I.D.*

Engine Mounting Plate N

Hex Nut 5/16-24 Thd.* 47

L.-Wash. 5/16" I.D.*

Shaft

Special L-Wash. 5/16" I.D. 50 710-0601

Hex Bolt 5/16-24 x 1.50" Lg.*

Elastic Lock Nut 5/16-18 Thd.

Hex Bolt 5/16-24 x .62" Lg.*

Description

New

Ref.

Part

No.

32

37

38 710-0151 Hex Bolt 3/8-\24 x 2.0" Lg. H.T.

40 732-0546

43 747-0531

46

48 736-0264

49

52 11454

55 11480

56 710-0542

57

—

—

Part

Color

No.

'Code

Lg.* (Special)

736-0192

711-0564

711-0578 Clevis Pin .50" Dia. x 3.0" Lg.

736-0217

11477

11478

712-0109

13431 Blade

11460-638

16524-638 Lower Leaf Ramp Section

11481A-638 Hopper Assembly N

735-0639

764-0199 Bag (Not Shown)

723-0400

Fl.-Wash. .531" I.D. x 937

O.D. X .09

Flail

Flail Spacer 23/32" Lg.

O.D. Hdn.x

L.-Wash. 3/m: I.D. H.D.

Flail Housing Ass'y-Comp.

Torsion Spring .062 Dia. x 1.06

Lg.

Chip-lt Guide Ass'y.

Hinge Pin

Release Bar

Upper Leaf Ramp Section

Fl.-Wash. 5/16" I.D.

Hex Wash. Hd. Self-Tap Scr.

5/16-18 X .75" Lg.

Back-Up Plate

Inlet Guide Assembly

Stop Washer

Safety Glasses (Not Shown)

Description

Cotter Pin 1/8" Dia. x 1.00"

Fl.-Wash. .406" I.D. x 1.25"

Wing Nut Elastic 1/4-20 Thd.

Hex Bolt 5/16-18 X 8.38" Lg.

Spark Plug Boot (Optional)

New

Part

N

*For faster service obtain standard nuts, bolts and washers locally. If these items cannot be obtained locally, order part

number and size as shown on parts list.

638-Red

621 —Brilliant Fire Mist

483—Charcoal Gray

The engine is not under warranty by the shredder manufacturer. If repairs or service is needed on the engine,

please contact your nearest authorized engine service outlet. Check the "Yellow Pages" of your telephone

book under "Engines —Gasoline."

Specifications Subject to change without

notice or obligation.

yyhen ordering parts if color or finish is important, use color code shown at left,

[i.e. (part no.) —638 for Red Finish]

NOTE

13

Find If Fast

In The

Yellow Pages

Page 14

Page 15

N

X

Page 16

REPLACEMENT PARTS • P.O. BOX 360900 • CLEVELAND, OHIO 44136

Loading...

Loading...