Page 1

OUTDOOR POWER EQUIPMENT

for all seasons

.75

5 AND 8 H.P.

LOG SPLITTERS

Important:

Read Safety Rules and

Instructions Carefully

V-

PRINTED IN U.S.A.

----------------------

Model Numbers

245-642-000

245-645-000

24642S

24645S

Thank you for purchasing

an American-built product.

-

FORM NO. 770-3966

Page 2

INDEX

Safe Operation Practices

Assembly Instructions

Operation

Maintenance

......................................

.................................

For one year from the date of orig

repair or replace, at its option, free c

part or parts found to be defective ii

the movement of any pow/er equipmi

chaser. Transportation charges for e

ty must be paid by the purchaser uni

This warranty will not apply to any (lart which has become inoperative due to misuse, ex

cessive use, accident, neglect, improper maintenance, alterations, or unless the unit has

been operated and maintained in ac ;ordance with the instructions furnished. This warran

ty does not apply tothe engine, mot( >r, battery, battery chargeror component parts thereof.

Please refer to the applicable manufacturer’s warranty on these items.

....................

............

............................... 3 Off-Season Storage ....................

............................... 5 Illustrated Parts

............................... 8 Repair Parts List..........................

............................... 10 Trouble Shooting Chart

Instructions given

are for personal

follow them.

with this symbol

safety. Be sure to

LIMITED WARRANTY

nal retail purchase, MTD PRODUCTS INC will either

f charge, F.O.B. factory or authorized service firm, any

I material or workmanship. Transportation charges for

mt unit or attachment are the responsibility of the pur-

ny parts submitted for replacement under this warraness such return is requested by MTD PRODUCTS INC.

...........................

...............

...............

...........

...........

..................15

11

12, 14

13, 14

This warranty will not apply where the unit has been used commercially.

Warranty service is available throug n your local authorized service dealer or distributor. If

you do not know the dealer or distributor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will not be accepted by the factory unless prior written per

mission has been extended by MTC.

This warranty gives you specific letial rights. You may aiso have other rights which vary

from state to state.

AC WARNING {

This unit is equipped with an internal combustion engine and should not be used on or near any unim

proved forest-covered, brush-covered or grass-i;overed land unless the engine's exhaust system is equipped

with a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be

maintained in effective working order by the o|>erator.

In the State of California the above is required by law (Section 4442 of the California Public Resources

Code). Other states may have similar laws. Fe feral laws apply on federal lands. A spark arrester muffler is

available at your nearest engine authorized service center.

Page 3

▲

IMPORTANT

It is suggested that this manual be read in its entirety before attemtping to assemble or operate. Keep this manual

a safe place for future reference and for ordering replacement parts.

nis unit is shipped WITHOUT GASOLINE or 01L. After assembly, see separate engine manual for proper fuel and

engine oil recommendations.

Your log splitter is a precision piece of power equipment, not a plaything. Therefore exercise extreme caution at all

times.

▲

TRAINING

1. Know the controls and how to stop quicklyREAD THIS OWNER'S MANUAL.

2. Do not allow children to operate. Do not allow

adults to operate it without proper instruction.

Only persons well acquainted with these rules of

safe operation should be allowed to use your log

splitter.

3. No one should operate this unit while intoxicated

or while taking medication that impairs the senses

or reactions.

4. Never use your splitter for any other purpose

than splitting wood. It is designed for this use

only and any other use may cause an injury.

5. Only the operator is to be near your log splitter

during use. Keep all others, including pets, a

minimum of 20 feet away from your work zone.

Flying wood can be hazardous.

6. Don't step over your splitter when engine is

running. You may trip or accidentally activate

ram if you step over. If you need to get to the

other side, walk around.

PREPARATION

1. Do not wear loose fitting clothing that could get

caught on the moving parts.

2. Do not operate equipment when barefoot or

wearing open sandals. Always wear safety shoes or

heavy boots. A dropped log can seriously injure

your foot.

3. Check the fuel before starting the engine. Do not

fill the gasoline tank indoors, when the engine is

running, or while the engine is still hot. Wipe off

any spilled gasoline before starting the engine.

4. Use only in daylight or in good artificial light.

5. Never operate your splitter on slippery, wet,

muddy, or icy surfaces. Safe footing is essential in

preventing accidents. Never operate your splitter

while attached to a towing vehicle.

6. Always wear safety glasses or goggles while operating your log splitter. A piece of splitting log

could fly off and hit your eyes.

7. Both ends of each log must be cut square. This

will prevent the log from flying out of the splitter

while under pressure.

SAFE OPERATION PRACTICES FOR LOG SPLITTERS

OPERATION

1. Do not change the engine governor settings or

overspeed the engine. Excessive engine speeds are

dangerous.

2. Never place hands or feet between log and split

ting wedge or between log and ram during forward

or reverse stroke. To do so may result in crushed

or amputated fingers or toes, or worse, you may

lose an arm or foot.

3. If the equipment should start to vibrate abnor

mally, stop the engine and check immediately for

the cause. Vibration is generally a warning of

trouble.

4. When cleaning, repairing or inspecting, make

certain all moving parts have stopped. Disconnect

the spark plug wire, and keep the wire away from

the plug to prevent accidental starting.

5. Handle gasoline with care. It is highly flammable.

A. Use approved gasoline container.

B. Never remove cap or add gasoline to a running

or hot engine or fill fuel tank indoors. Wipe

up spilled gasoline.

C. Don't run engine in an enclosed area. Ex

haust gases contain carbon monoxide. This

odorless gas can be deadly when inhaled.

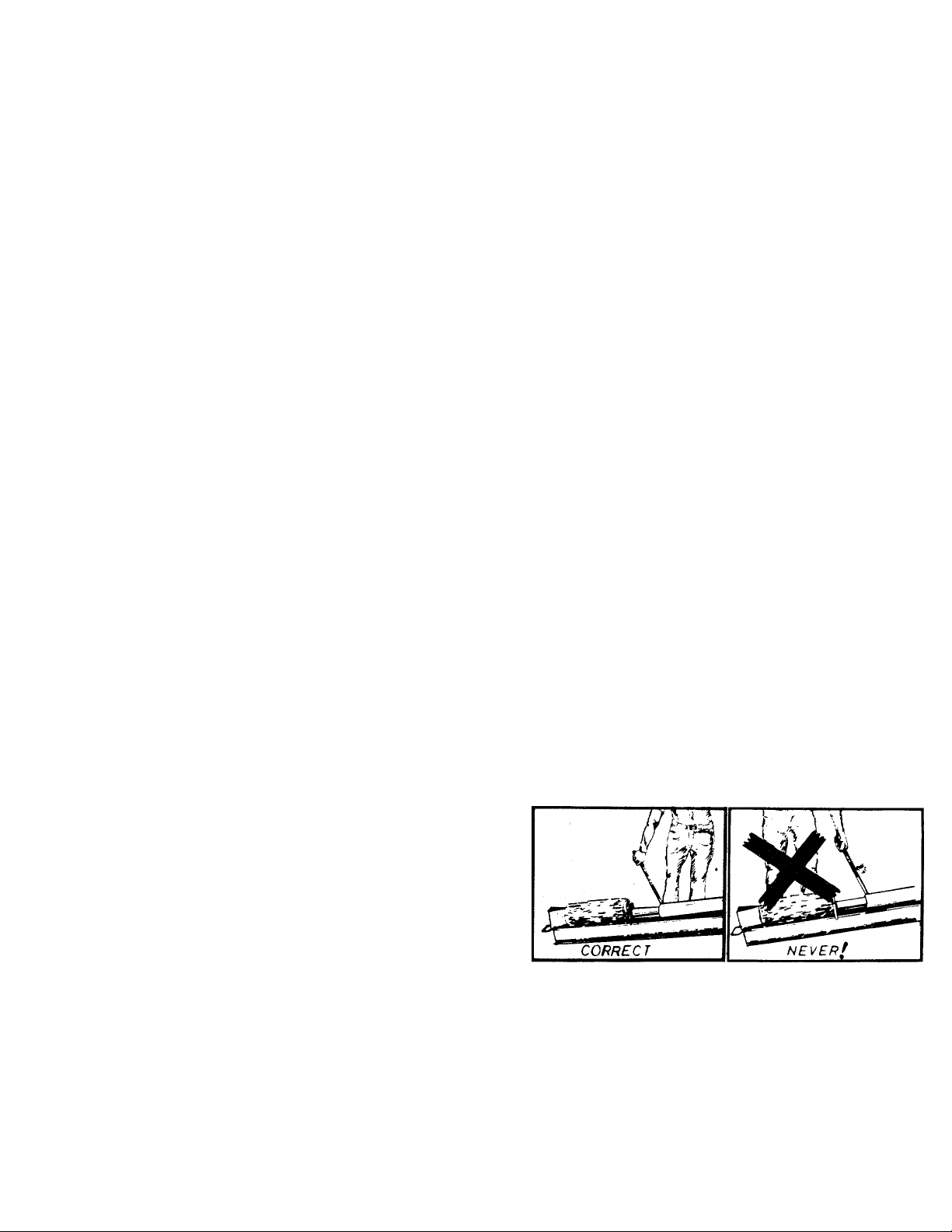

6. Stand behind the ram when operating. See draw

ings.

7.

Be careful not to touch the muffler after the

engine has been running. It is HOT.

8

Never try to split two logs on top of each other.

One may fly out and injure you.

When loading the log splitter, place your hands on

9.

the sides of the log, not at the ends.

10. For logs that are not cut square, the longest

portion of the log should be rotated down and

the most square end placed against the ram.

Page 4

11. Never attempt to split wood across the jrain.

Some types of wood may burst or fly ojt of

your splitter and result in injury to you or a

bystander.

12. Never leave your log splitter unattended wilh the

engine running. Shut off the engine if yoj are

leaving your splitter, even for a short period of

time. Someone could accidentally activât; the

ram and be injured.

13. Only use your hand to operate the ram or cc ntrol

lever. Never use your foot or a rope or any ather

extension device. This could result in your i labil

ity to stop your splitter quickly enough and

cause an injury.

14. Only operate your splitter on the level ground and

not on the side of a hill. It could tip, or railing

logs or poor footing could cause an acc dent.

This also prevents the spillage of gas from the

tank.

MAINTENANCE and STORAGE

1. Don't operate your splitter in poor mechmical

condition or when in need of repair.

2. Keep ail nuts, bolts, screws, hose clamp ; and

hydraulic fittings tight to be sure equipm;nt is

in safe working condition.

3. Replace all damaged or worn parts such cs hy

draulic hoses and fittings immediately with manu

facturer approved replacement parts.

4. Never store the equipment with gasoline in the

tank inside of a building where fumes may reach

an open flame or spark. Allow the engine to cool

before storing in any enclosure. _

5. To reduce fire hazard keep engine free of grai

leaves, wood chips, excessive grease and oil.

6. The hydraulic system of your log splitter re

quires the careful inspection along with the

mechanical parts. Be sure to replace frayed,

kinked, cracked or otherwise damaged hydraulic

components.

7. Fluid escaping from a very small hole can almost

be invisible. Do not check for leaks with your

hand. Escaping fluid under pressure can have

sufficient force to penetrate skin, causing serious

personal injury. Leaks can be located by passing

a piece of cardboard or wood over the suspected

leak and looking for discoloration.

8. Should it become necessary to loosen or remove

any hydraulic fitting or line, be sure to relieve

all pressure by shutting off the engine and moving

the control handle back and forth several times.

9. Don't remove the cap from the hydraulic tank or

reservoir while your log splitter is running. Hot

oil under pressure could cause injury.

10. Never store outside without a waterproof cover—

Rain will cause rust on the inside of the cylinder

A

CAUTION

THIS UNIT SHOULD NOT BE TOWED ON ANY

STREET, HIGHU/AY OR PUBLIC ROAD. ANY

LICENSING NELDED TO COMPLY WITH THE

EXISTING FEDLRAL, LOCAL OR STATE VEH

ICLE REQUIREMENTS IS THE SOLE RESPONSI

BILITY OF THE »URCHASER.

Page 5

TOOLS REQUIRED:

(1) Raw Hide or Plastic Hammer

(1) 1-1/8" Wrench or Adjustable Wrench

JJ) 3/4" Wrench

THER MATERIALS WEEDED:

One gallon of regular grade gasoline (for engine)

1-1/2 pints of SAE 30 or 10W-30 oil (for engine)

Approximately 2-1/2 gallons of Dexron II auto

matic transmission fluid (may be obtained at your

local service station or auto parts store.)

Funnel

[3F1

t

2

|<0))))))))))))))^MPM

Y

0

ASSEMBLY INSTRUCTIONS

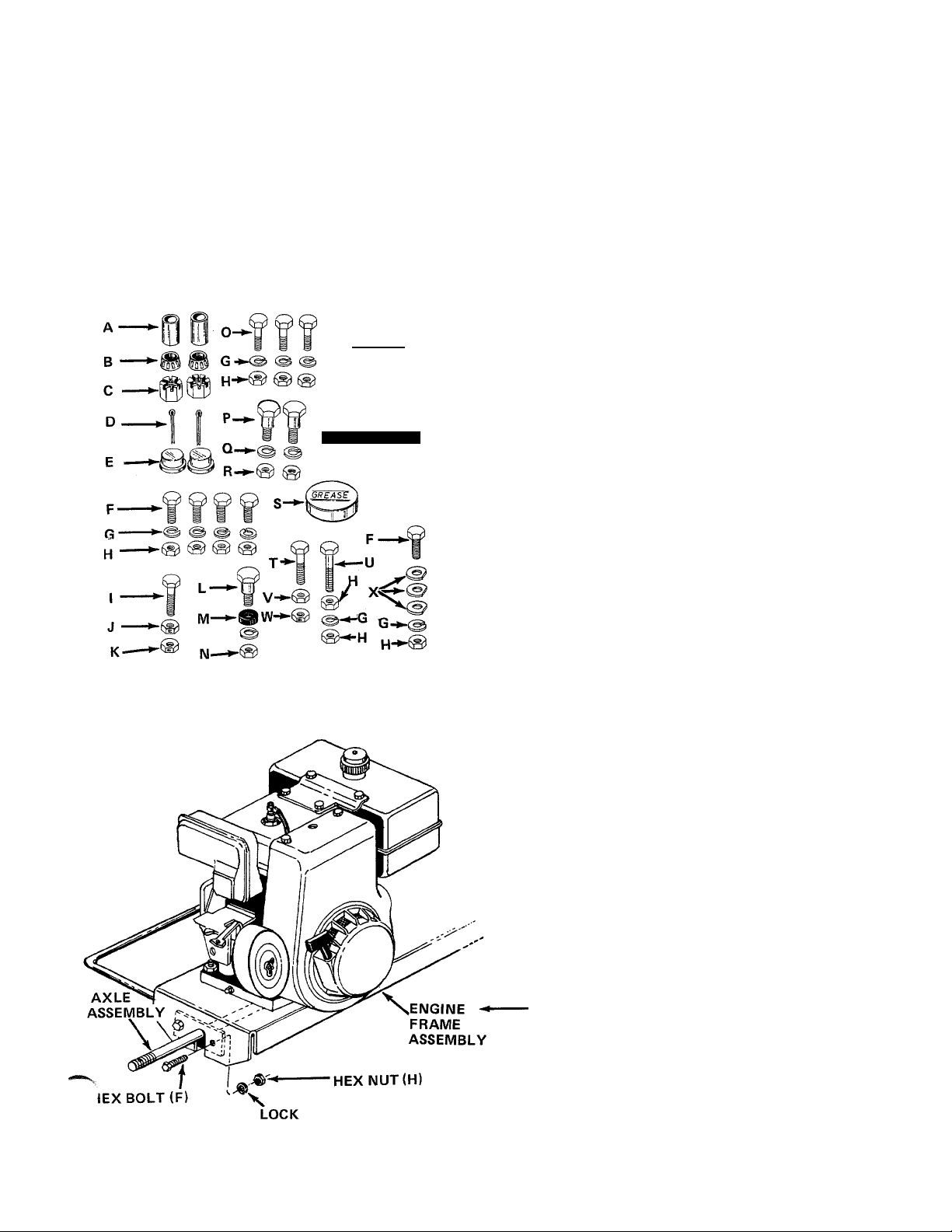

CONTENTS OF HARDWARE PACK (See Figure 1):

A (2) Spacers 1-1/2" Long

B (2) Tapered Roller Bearings

C (2) Castle Nuts 3/4-16 Thread

D (2) Cotter Pins

E (2) Hub Caps

F (5) Hex Bolts 3/8-24 X 1" Long

G (9) Lock Washers 3/8" I.D.

H (10) Hex Nuts 3/8-24 Thread

I (1) Hex Bolt 1/4-20 X 1-3/4" Long

J (1) Hex Lock Nut 1/4-20 Thread

K (1) Hex Lock Nut 5/16-18 Thread

L (1) Shoulder Bolt

M (1) Rubber Washer

N (1) Hex Nut 3/8-16 Thread

0 (3) Hex Bolts 3/8-16 x 3/4" Long

P (2) Shoulder Bolts

Q (2) Lock Washers 5/16" I.D.

R (2) Hex Nuts 5/16-18 Thread

S (1) Automotive Grease

T (1) Hex Bolt 1/4-28 X 1" Long

U (1) Hex Bolt 3/8-24 x 1-3/4" Long

V (1) Hex Nut 1/4-28 Thread

W (1) Hex Lock Nut 1/4-28 Thread

X (3) Flat Washers (Special)

Y (1) Spring

Z (2) Pivot Brackets

FIGURE 1

LOOSE PARTS IN CARTON:

(1) Axle Assembly

(2) Wheels

(2) Tow Hitch Brackets

(1) Tow Hitch Assembly

(1) Pivot Stand

(1) Hitch Chain

(1) Engagement Rod Assembly

(1) Engagement Handle

Remove log splitter and loose parts from carton. Make

certain all parts and literature have been removed

from the carton before the carton is discarded.

INSTALLATION OF WHEELS

1. Place the axle assembly in position inside the

the engine frame assembly as shown in figure 2.

Secure with hex bolts (F), lock washers (G) and

hex nuts (H).

FIGURE 2

WASHER (G)

Page 6

HUBCAP

TAPERED (A)

ROLLER _

BEARING (B)

HUB

CAP (E)

TAPERED

BEARING

(TAPER TO

INSIDE)

SPACER

2. Pack the tapered roller bearings (B) with auto

motive grease provided.

NOTE

Do not put any grease in the hub caps.

Place one spacer (A) on the axle, then one wheel

and a tapered roller bearing (B). See figure 3.

Thread hex castle nut (C) on axle. Tighten castle

nut until snug, then back off approximately 1/3

turn or until one of the slots on the castle nut

lines up with hole in axle. Secure castle nut to

axle with cotter pin (D). See figure 3.

NOTE

COTTER

FIGURE 3

FIGURE 4

FIGURE 5

HEX^

nut\

HEX CASTLE

NUT (C)

PIVOT

BRACKET (Z)

LOCK

3-1/2" LO MG

HEX BOLTS

PIVOT

BRACKET (Z)

TOW HITCH

BRACKETS

Make certain wheel bearings were

packed with grease.

5. Place hub cap (E) in position on wheel and tap

on with a plastic hammer.

6. Repeat steps 3 through 6 for the second wheel.

ASSEMBLY OF TOW HITCH AND STAND

The wedge is already assembled to the log splitter,

and is held in place with four 3-1/2" long hex bolts,

lock washers and hex nuts. The top two bolts and.,

nuts are tightened securely. The bottom two bolts a'

nuts have been assembled loosely.

1. Remove the two bottom bolts, lock washers and

—■ hex nuts from the beam and wedge. See figure 4.

2. Place one tow hitch bracket on each side of the

beam, lining up the large holes in the brackets

with the bottom holes in the beam. Secure the

tow hitch brackets with one hex bolt, lock washer

and hex nut just removed.

3. Place one pivot bracket (Z) on each side of the

two hitch brackets, lining up the holes in the

hitch bracket with the holes toward the end of the

beam. The pivot brackets must be assembled with

the bend to the outside as shown in figure 4.

Secure with the other hex bolt, iock washer and

hex nut removed in step 1.

Place the tow hitch assembly in position on the

tow hitch brackets. Secure the left side of tow

hitch assembly with two hex bolts (0), lock

washers (G) and hex nuts (H). See figure 5.

Secure the right hand side of tow hitch assembly

with hex bolt (0), lock washer (G) and hex nut

(H) in the front hole only. _

Thread one hex nut (H) onto hex bolt (U). Secu

rear hole in tow hitch assembly with this bolt,

lock washer (G) and another hex nut (H).

NOTE: Spring (Y) will be attached to this bolt in step

9.

Page 7

PIVOT

BRACKET

SHOULDER

BOLT (P)

7. Thread hex nut (V) onto hex bolt (T). Secure tc

pivot stand with hex lock nut (W) as shown in

figure 6.

8. Assemble the pivot stand to the pivot brackets

with two shoulder bolts (P), lock washers (Q)

and hex nuts (R).

9. Attach extension spring (Y) to long hex bolts on

tow hitch and pivot stand. See figure 6.

EXTENSION

SPRING (Y)

HEX

BOLT (T)

FIGURE 6

CENTER LINK'

:ON CHAIN

> ^ \lock

' ^ \l PIVOT

HEX ■

NUT (V)

FLAT WASHER iX)

HEX

NUT(R)

WASHER (Q)

STAND

HEX

LOCK NUT

(W)

HEX

BOLT (F)

Find the center link of the tow hitch chain.

Place two special flat washers (X) on hex bolt (F),

then the center link on chain and another flat

washer (X). Insert bolt down through the hole in

the tow hitch assembly which is nearest the wedge.

Secure with lock washer (G) and hex nut (H).

See figure 7.

FIGURE 7

ENGAGEMENT

ASSEMBLY OF ENGAGEMENT ROD AND HANDLE

1. Attach the engagement rod assembly to the

control valve with hex bolt (I) and hex lock nut

(J) as shown in figure 8.

2.

Place the flattened end of the engagement handle

down through the slotted bracket beside the beam.

Insert the end of the ferrule on the engagement

rod into the second hole from the end of the

engagement handle. See figure 8.

3.

Place shoulder bolt (L) through bottom hole in

engagement handle. Place rubber washer (M) on

shoulder bolt. Secure to bracket with lock washer

(G) and hex nut (N).

Page 8

LOCK NUT (K)

Secure ferrule on engagement rod to engagement

handle with hex lock nut (K). See figure 9.

FIGURE 9

PLUNGER

^ ON PUMP

FIGURE 10

ENGAGEM!NT

HANDLE,

5.6.Place the engagement handle in reverse position,

locked in the notch in the slotted bracket. See

figure 10.

Adjust the engagement rod by tightening the hex

nut on the end of the rod until the plunger on thi

pump is pushed all the way in when the engagement

handle is locked in the reverse position. Insert a

screwdriver into the slot in the plunger to keep

the rod from turning as the hex nut is tightened.

See figure 10.

FUNNEL

OPERATION

BEFORE STARTING

1. Fill reservoir tank on log splitter with approxmately 2-1/2 to 3 gallons of Dexron II automatic

transmission fluid as follows. Check oil level befc re

each use.

A. Place log splitter in the operating position w th

the beam level, using the stand provided.

B. Remove the oil check plug.from the back of

the log splitter. See figure 11. If oil starts to

come out of the hole, oil level is correct, k it

does not, remove the cap from the breatier

tube and add oil until oil starts out of lhe

check hole.

C. Replace oil check plug. Replace cap on lhe

breather tube.

BREATHER

TUBE

OIL

CHECK

PLUG

FIGURE 11

Page 9

NOTE

DO NOT operate log splitter without

proper amount of oil in reservoir tank

(beam).

2. Fill sump with oil as instructed in the separate

engine manual packed with your unit.

3. Fill fuel tank, using clean, fresh, regular grade

automotive gasoline. Fill tank completely.

NOTE

Refer to engine manual packed with

log splitter for complete instructions

for the care and maintenance of en

gine. READ DIRECTIONS CARE

FULLY.

TO START ENGINE

1. Place throttle control lever in FAST or CHOKE

position. See figure 12.

2. Place choke control in CHOKE position (if unit

is so equipped).

NOTE

A warm engine may not require

choking.

3. Grasp starter handle, place one foot on wheel and

pull starter handle with a quick, full arm stroke.

Return rope slowly to the engine.

4. After engine starts, move choke control gradually

to OFF position (if unit is so equipped). Move

throttle control to desired engine speed.

TO STOP ENGINE

1. Move throttle control lever to STOP position.

2. Disconnect spark plug wire from spark plug to

prevent accidental starting while equipment is

unattended.

USING YOUR LOG SPLITTER

WARNING

áki

This unit should not be towed on any

street, highway or public road. Any

licensing needed to comply with the

existing federal, local or state vehicle

requirements is the sole responsibility

of the purchaser. Make certain the

stand is folded up against the beam

when transporting.

Your log splitter is designed for safe, efficient

operation. BE CAREFUL TO KEEP HANDS AND

FEET AWAY FROM MOVING PARTS.

Engagement handle has three positions: (See figure 13)

Forward - ram moves toward wedge.

Neutral - ram stops in place.

Reverse - ram returns.

t

FIGURE 12A - 5 H.P. Tecumseh engine shown

ENGAGEMENT HANDLE

IN NEUTRAL POSITION.

ENGAGEMENT HANDLE

LOCKED IN REVERSE

POSITION.

FIGURE 13

ENGAGEMENT HANDLE

HELD IN FORWARD

POSITION.

-r'-X'i

Maximum length that can be split is 26".

Page 10

TO OPERATE LOG SPLITTER:

1. Set throttle at maximum speed.

2. Place log on beam and hold in place with right

hand. See figure 14.

3. Slowly move engagement handle forward until

ram rests against log. Release engagement bundle

(Neutral).

4. Remove your hand from the log and step b( hind

the ram. See figure 15.

5. Move engagement handle forward until log is split.

6. Move the engagement handle to the rear to ruturn

ram.

AC warnIng^}

Never attempt to cut a log in half with the

log splitter. See figure 16.

Never stand next to the ram when

operating. Always stand behind the ram.

See figure 17.

FIGURE 16

FIGURE 15

The ram should take approximately 12 seconds to

make a complete cycle. This speed may varv de

pending on throttle setting and temperature of oi .

NOTE

If you lock the engagement handle in

the reverse slot, the ram will return until

it hits the engagement bracket, which will

throw the engagement handle into neutral

automatically.

FIGURE 17

MAINTENANCE

J* waVning^I

Always stop engine and disconnect spark

plug wire before performing any mainte

nance or adjustments.

ENGINE OIL

Change oil first two (2) hours of operation. Check

oil level every five (5) operating hours or each tinr«’equipment is used.

Change oil every twenty-five (25) operating hours or

sooner if equipment is operated in extremely dusty

or dirty conditions.

Refer to engine manual for quantity and type of oil.

10

A

Page 11

LOG SPLITTER RESERVOIR OIL

Check oil in log splitter reservoir before every use.

Refer to "Before Starting" under OPERATION

^ection.

hange the oil in the reservoir every 100 hours of

operation. Remove the six hex bolts, lock washers

and hex nuts which hold the end plate to the beam.

Remove the plate and drain the oil. Be prepared to

catch oil in a suitable container.

NOTE

Drain the oil and flush the reservoir

tank assembly and hoses each time

repair work is performed on the tank,

hydraulic pump or valve. Contaminants

in the oil will damage the hydraulic

components.

END

PLATE

CARBURETOR ADJUSTMENTS

A

If any adjustments are made to the

engine while the engine is running

(e.g. carburetor), keep clear of all

moving parts. Be careful of heated

surfaces and muffler.

Refer to engine manual packed with your unit for

carburetor adjustment information.

TIRE PRESSURE

Check sidewall of tire for manufacturer's max

imum tire pressure. If this information does not

appear on your tire, maximum tire pressure under

any circumstances is 30 p.s.i. Equal tire pressure

should be maintained on all tires.

INSTALLATION OF TIRE TO RIM

^ yVARNING (

HEX BOLTS

LOCK WASHERS

HEX NUTS

FIGURE 18

When the oil is drained from the reservoir, clean the

strainer tube assembly as shown.

1. Remove the hose clamp at the inlet hose (bottom

hose). See figure 18.

2. Pull the inlet hose off the fitting at the beam.

Using an adjustable wrench, remove the fitting

from the beam.

3. Reach inside the end of the beam and pull out the

strainer tube assembly.

4. Clean the strainer tube assembly and reassemble in

reverse order.

Reassemble the end plate. Refill oil reservoir with

approximately 2-1/2 to 3 gallons of Dexron II

automatic tarnsmission fluid as instructed in "Before

Starting" under OPERATION section.

*^SE CLAMPS

..,neck the hose clamps on the bottom of the pump

for proper tightness before each use.

Hose clamps on the return hose should be checked

once a season.

A

The following procedure must be

followed when removing or install

ing a tire to the rim.

1. Be sure rim is clean and rust free.

2. Lubricate both the tire and rim generously.

3. Never inflate to over 30 p.s.i. to seat beads.

Excessive inflation pressure when seating beads

may cause tire/rim assembly to burst with force

sufficient to cause serious injury.

{ WARNING {

OFF-SEASON STORAGE

If the machine is to be inoperative for a period

longer than 30 days, prepare for storage as follows.

1. Clean the engine and the entire unit thoroughly.

2. Wipe the entire machine with an oiled rag to

protect the surfaces.

3. Refer to the engine manual for correct engine

storage instructions. The engine must be

completely drained of fuel to prevent gum

deposits from forming on essential carburetor

parts, fuel lines and fuel tanks.

4. Store unit in a clean, dry area.

NOTE

When storing any type of power

equipment in an unventilated or

metal storage shed, care should be

taken to rust proof the equipment.

Using a light oil or silicone, coat the

equipment, especially all moving parts.

11

Page 12

Models 642 and 645

If YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

64 77

NOTE: The engine is not under warranty by

the log splitter manufacturer ... If repairs or

service is needed on the engine, please contact

your nearest authorized engine service outlet.

Check the "Yellow Pages" of your telephone

book under " Engines — Gasoline".

*The hydraulic pump is one of two tvpes. As complete units, the two pumps are interchangeable

(refer to parts list for part number). If it is necessary to determine the specific type of pump

on your unit, refer to the illustrations below.

Find It Fast

In Tl le

Yellow I’ages

NOTE

This instruction manual covers various models and all

specifications shown do not necessarily apply to your

model. Specifications subject to change without notice

or obligation.

12

Page 13

Models 642 and 645

PARTS LIST FOR MODELS 642 AND 645 LOG SPLITTERS

Sef.

Л10.

1

PART

NO.

710-0118

2 710-0168

712-0267

3

717-0407

4

726-0132 Hose Clamp 5/8"

5

727-0297

6

727-0299 Return Hose - Valve to Tank

7

736-0119 L.-Wash. 5/16" I.D.*

8

736-0169 L.-Wash. 3/8" I.D.*

9

10

11

12

13

737-0153 Return Elbow

737-0171 90° Solid Male Adapter Lg.*

737-0192

781-0035

14

15 14806

710-0117

16

710-0157 Hex Bolt 5/16-24 x .75"

17

18

710-0653

19 712-0123

20 714-0172

21

22 735-0205

23

24 717-0479 Coupling Half 1.00" I.D.

25 717-0498

26

27

28

29 737-0192

30 710-0920

31 712-0203

32 717-0818

33

34

35

36 719-0269

37

Ì39

40

41

42 781-0020

43

COLOR

CODE

DESCRIPTION

Hex Bolt 5/16-18 X .75"

Lg.*

Hex Bolt 3/8-16 X.60" Lg.*

Hex Nut 5/16-18 Thd.*

Control Valve 400

High Pressure Hose Ass'y-

.38" I.D.

3/4" I.D.

90° Solid Male Adapter

Valve Mtg. Plate

13295

Coupling Support Brkt.

Ass'y.

Coupling Shield

Hex Bolt 5/16-24 X 1.00"

Lg.*

Lg.*

Hex Wash. Hd. Tap Scr. 58

1/4-20 X .38" Lg.

Hex Nut 5/16-24 Thd.*

Sq. Key 1/4" x 1/4" x 2.25

Lg.

717-0460 Pump with Woodruff Key

(642)

717-0461

Pump with Woodruff Key (645)

Spider L-0-90

710-0419 Set Scr. 1/4-20 X .25" Cup

Coupling Half .50" I.D.

726-0132 Hose Clamp 5/8" 66

727-0298 Suction Hose 1.0" Dia.

736-0119 L.-Wash. 5/16" I.D.*

90° Solid Male Adapter N

Hex Bolt 3/4" X 4.0" Lg. 70

Hex Nut 3/4" Thd.*

Hydraulic Cylinder 3-1/2"

Dia. (642)

717-0817

Hydraulic Cylinder 4"

Dia. (645)

736-0364 L.-Wash. 3/4" I.D.*

737-ea>52<52^

High Pressure 90° Elbow X 1.56" Lg.

737-0194 45° Male Adapter 3/4-16 MJ

3/8-18 NP

Pusher Plate (642) N

719-0268

738-0601

Pusher Plate (645)

Shoulder Bolt .62" Dia. x

4.75" Lg. (1/2-13 Thd.)

15850

713-0338

Flip Stand Bracket

Chain-Tow Hitch

727-0289 Tow Hitch Ass'y. Comp. N

Stand Pivot Bracket N

781-0037

Tow Hitch Brk't. 2 x 3/16 x 81

10.25" Lg.

NEW

PART

N 49

N

N

1

N 67

-

N

N 76

N 78

N

REF.

PART

NO.

NO.

44 13115

712-0214 Hex Cent. L.-Nut 3/8-24

45

COLOR

CODE

DESCRIPTION

Ferrule Ass'y.

Thd.

720-0157

46

732-0324 Compression Spring

47

48 736-0206

Grip-Black Vinyl

Special Washer .378 x 1.00"

X .125 Thd.*

747-0484 Engagement Rod 3/8' Dia. x

9.0" Lg.

749-0622 Engagement Handle N

50

51 710-0106

Hex Bolt 1/4-20X 1.75"

Lg.*

710-0152 Hex Bolt 3/8-24 X 1.00"

52

53 710-0180

Hex Bolt 3/8-24 x .75" Lg.*

54 710-0299 Hex Bolt 1/4-28 X 1.00"

Lg.*

710-0539 Hex Bolt 3/8-24 X 1.75" Lg.

55

(Grade 5)

712-0107 Hex Patch L.-Nut 1/4-20

.56

Lg.*

57 712-0117 Hex Cent. L.-Nut 1/4-28

Thd.

712-0138 Hex Nut 1/4-28 Thd.

59 712-0158 Hex Cent L.-Nut 5/16-18

Thd.

712-0241 Hex Nut 3/8-24 Thd.*

60

712-0267 Hex Nut 5/16-19 Thd.*

61

62 712-0299 Hex Castle Nut 3/4-16

Thd.

63 712-0798 Hex Nut 3/8-16 Thd.*

64 714-0162 Cotter Pin 5/32" Dia. x 1.25

Lg.* I

732-0429 Extension Spring .50" O.D. x

65

3.97." Lg.

734-0873

Hub Cap

735-0144 Rubber Washer

736-0119

68

L.-Wash. 5/16" I.D.*

69 736-0169 L.-Wash. 3/8" I.D.*

736-0262 Fl.-Wash. .375" I.D. x .870"

O.D. X .090

71 738-0143

Shoulder Bolt .498" Dia. x

X .340" Lg.

72 738-0296 Shoulder Bolt .437" Dia. x

.268" Lg.

750-0442

73

74

734-1016

Spacer .75" I.D. x 1.12" O.D.

Wheel Ass'y. Comp. 16.0 x

4.0"

75 734-0255 Air Valve-Tubeless

734-0872

734-1017 Wheel Rim Ass'y Only

77

Tire Only 16.0 X 4.0 -2 Ply

741-0107 Roller Rearing 3/4" I.D.

79 781-0018

Axle Ass'y. .75" Dia. x

35.25" Lg.

710-0117

80

Hex Bolt 5/16-24 X 1.00

Lg.*

710-0298

Hex Bolt 5/8-18 X 3.50"

Lg.*

NEW

PART

N

II

N

N

13

Page 14

PARTS LIST FOR MODELS 642 AND 645 LOG SPLITTERS (Continued)

REF.

PART

NO.

NO.

82

83 710-0442 Hex Bolt 5/16-18 X 1.50'

84

85 712-0267 Hex Nut 5/16-18 Thd.*

86

87 712-0338

88 721-0203

89

90 736-0119

91

92

COLOR

CODE

DESCRIPTION

710-0409 Hex Bolt 5/16-24 X 1.75

PART

NEW

REF.

NO.

94 738-0140 Shoulder Bolt .437" Dia. x

Lg.*

95 745-0174 Oil Fill Cap

96

97

712-0123

Lg.*

Hex Nut 5/16-24 Thd.*

98

712-0337

732-0352

Hex Nut 5/1-18 Thd.*

Hex Nut 11/16-12 Thd

Gasket 2.62 x 5.12

Extension Spring .50" 0, D.

x4.25" Lg.

N

N

N

99

100

101

102

L.-Wash. 5/16" I.D.*

736-0158 L.-Wash. 5/8" I.D.* 103

736-0275 Fl.-Wash. 34" I.D. x .68"

104

PART

NO.

COLOR

CODE

DESCRIPTION

.180" Lg.

781-0021

781-0023

781-0024

Strainer Tube Ass'y.

End Plate

Engagement Brk't. 1.39 x

11.75" Lg.

781-0025

Complete Oil Tank Ass'y.

781-0033 Engine Frame Ass'y.

781-0036

Filler Tube Ass'y.

721-0204 "0"-Ring 92" I.D. x 1.16"

O.D. X .116 Dia.

781-0038

Wedge Ass'y.

5 H.P. Engine (642)

NEW

PART

N

N

N

N

N

O.D. X .062 Thk. S8H.P. Engine (645)

93

*For faster service order standard nuts, bolts, and washers locally. If these items cannot be obtained locally, order by part number and

size as shown on parts list.

737-0191 Adapter 1.0" Tube 11/1(!-12 105 721-0168 Bearing Seal

"0"-Ring N 106

107

_____

_

710-0604 Hex Hd. Tap Scr. 5/16"

721-0205

Gasket

JL.

Models 642 and 645

REF.

NO.

PART NO.

12717-0818

753-0272

3-1/2" DIA. CYLINDER

PARTS LIST FOR MODEL 642

DESCRIPTION

Cylinder Ass'y. Comp.

3-1/2" Cyl. Kit "0"-Ring Snt

NEW

PARI

N

REF.

NO.

12717-0817

14

PART NO.

753-0273

4" DIA. CYLINDER

PARTS LIST FOR MODEL 645

DESCRIPTION

Cylinder Ass'y. Comp

4" Cyl. Kit "0"-Ring Set

new'

PART^

N

Page 15

TROUBLE SHOOTING CHART

SYMPTOM POSSIBLE CAUSE (S) SOLUTION

Engine fails to start A. Check fuel tank for gas.

B. Spark plug lead wire

disconnected.

C. Faulty spark plug.

2. Hard starting or loss of

power

3. Engine overheats

4. Will not split logs

5. Leaking cylinder

NOTE: For repairs beyond minor adjustments, please contact your local service dealer.

^Should be performed by an authorized service dealer only.

A. Spark plug wire loose.

B. Dirty air cleaner.

A. Carburetor not adjusted

properly.

B. Air flow restricted.

C. Engine oil level low.

A. Reservoir oil level low.

B. Pump setting incorrect.

A. Broken seals.

B. Scored cylinder.

A. Fill tank if empty.

B. Connect lead wire.

C. Spark should jump gap between

control electrode and side electrode.

If spark does not jump, replace the

spark plug.

A. Connect and tighten spark plug wire.

B. Clean air cleaner as described in

engine manual.

A. Adjust carburetor. See engine manual.

B. Remove blower housing and clean as

described in the engine manual.

C. Fill crankcase with the proper oil.

A. Check and fill oil reservoir tank as

instructed in Operation Section.

B. Adjust pump setting to 3,000 p.s.i.*

A. Replace seals.*

B. Replace cylinder.*

15

Page 16

MTD PRODUCTS INC

P.O. BOX 3690C • CLEVELAND OHIO 44136

..........................................................

YaRD-MaN CONIPANY

Loading...

Loading...