Page 1

OWNER’S

MANUAL

5 and 8 H.P.

LOG SPLITTERS

.75

Model Numbers

242-642A

242-645A

24642-A

24645-A

important:

Read Safety Rules and

Instructions Carefully

Thank you for purchasing an

American built product.

PRINTED IN U.S.A.

FORM NO. 770-1801

Page 2

INDEX

Safe Operation Practices

Assembly Instructions ....................................................4

Operation .......................................................................5

Adjustments ...................................................................8

r

...............................................

LIMITED WARRANTY

♦

♦

♦

♦

♦

♦

♦

♦

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm, any

part or parts found to be defective in material or workmanship. Transportation charges for

the movement of any power equipment unit or attachment are the responsibility of the pur

chaser. Transportation charges for any parts submitted for replacement under this warran

ty must be paid by the purchaser unless such return is requested by MTD PRODUCTS INC.

This warranty will not apply to any part which has become inoperative due to misuse, ex

cessive use, accident, neglect, improper maintenance, alterations, or unless the unit has

been operated and maintained in accordance with the instructions furnished. This warran

ty does not apply to the engine, motor, battery, battery chargeror component parts thereof.

Please refer to the applicable manufacturer’s warranty on these items.

3

Maintenance ................................................................. 8

Off-Season Storage

Illustrated Parts .....................................................10,

Repair Parts List

.......................................................

.....................................................

11,12

♦

♦

♦

♦

♦

♦

♦

t

♦

♦

♦

♦

This warranty will not apply where the unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. If

you do not know the dealer or distributor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will not be accepted by the factory unless prior written per

mission has been extended by MTD.

♦

♦

This warranty gives you specific legal rights. You may also have other rights which vary

from state to state.

V

^ WARNING I

TO PURCHASERS

OF INTERNAL COMBUSTION ENGINE EQUIPPED

MACHINERY OR DEVICES IN THE STATE OF CALIFORNIA

The equipment which you have just purchased does not have a spark arrester. If this equipment is used on

any forest covered land, brush covered land, or grass covered unimproved land in the State of California,

before using on such land, the California law requires that a spark arrester be provided. In addition, spark

arrester is required by lawn to be in effective working order. The spark arrester must be attached to the

exhaust system and comply with Section 4442 of the California Public Resources Code.

♦

♦

♦

♦

♦

♦

J

Page 3

IMPORTANT

It is suggestsd that this manual be read in its entirety before attempting to assemble or operate Keep

^ this manual in a safe place for future reference and for ordering replacement parts.

This unit is shipped WITHOUT GASOLINE or OIL. After assembly, see operating section of this manual

for proper fuel and engine oil recommendations.

Your log splitter is a precision piece of power equipment, not a plaything. Therefore exercise extreme

caution at all times.

SAFE OPERATION PRACTICES FOR LOG SPLITTERS

TRAINING

1. Know the controls and how to stop quickly-READ THE OWNER'S MANUAL.

2. Do not allow children to operate. Do not allow

adults to operate it without proper instruction.

Only persons well acquainted with these rules of

safe operation should be allowed to use your log

splitter.

PREPARATION

1. Do not wear loose fitting clothing that could get

caught on the moving parts.

2. Do not operate equipment when barefoot or wearing open Sandies. Always wear substantial foot

wear.

3. Check the fuel before starting the engine. Do not

fill the gasoline tank indoors, when the engine is

running, or while the engine is still hot. Wipe off

any spilled gasoline before starting the engine.

4. Use only in daylight or in good artificial light.

5. Never operate the equipment in the rain. Always

be sure of your footing.

OPERATION

C. Open doors if engine is run in garage-

exhaust fumes are dangerous. Do not run

engine indoors.

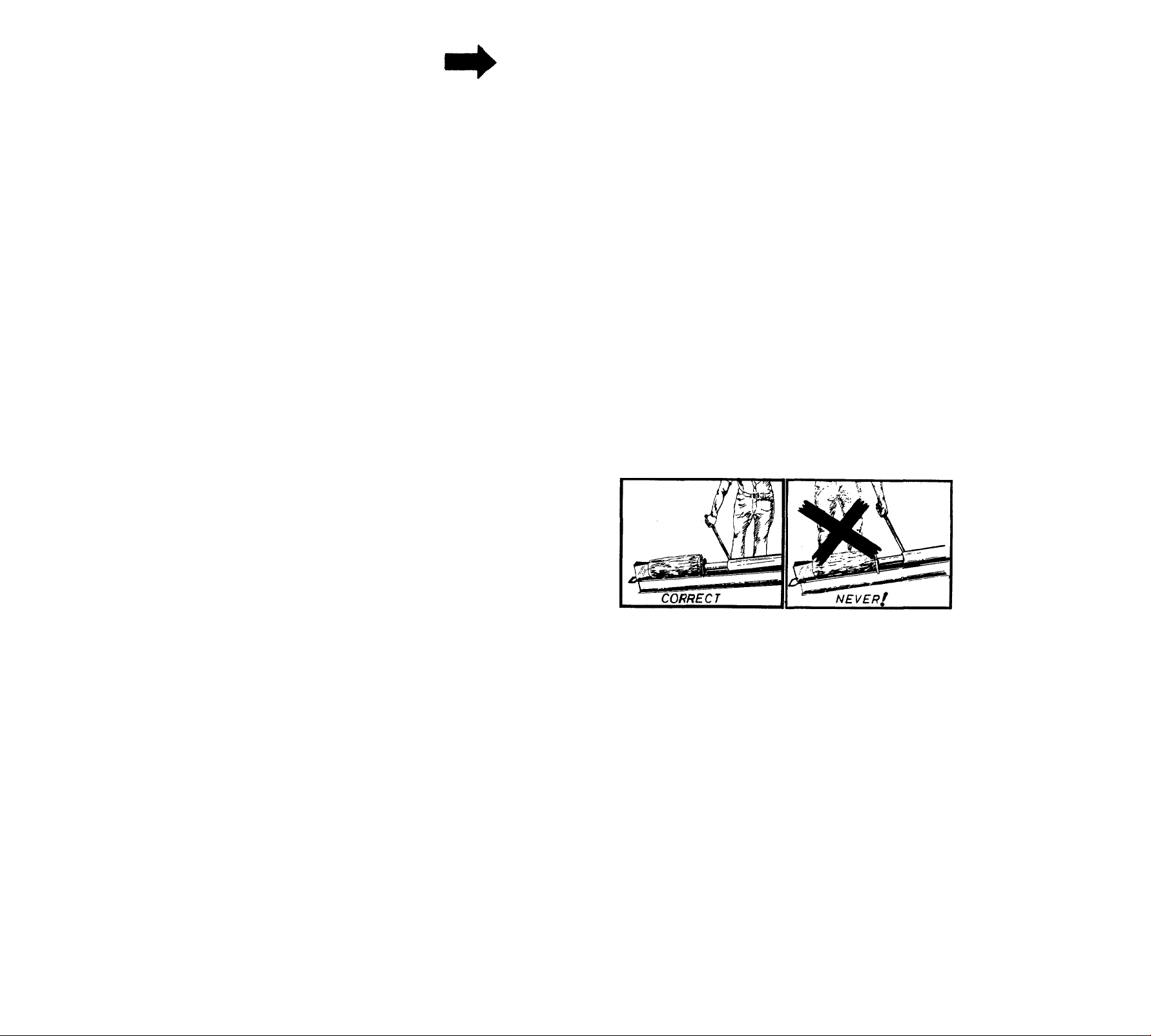

6. Always operate the log splitter from the engine

side of the beam.

Stand behind the ram when operating. See drawings.

Be careful not to touch the muffler after the

engine has been running. It is HOT.

1. Do not change the engine governor settings or

overspeed the engine. Excessive engine speeds are

dangerous.

2. Do not put hands or feet near rotating or moving

parts.

3. If the equipment should start to vibrate abnor

mally, stop the engine and check immediately for

the cause. Vibration is generally a warning of

trouble.

4. When cleaning, repairing or inspecting, make

certain all moving parts have stopped. Disconnect

the spark plug wire, and keep the wire away from

the plug to prevent accidental starting.

Handle gasoline with care--it is highly flammable.

A. Use approved gasoline container.

B. Never remove cap or add gasoline to a running

or hot engine or fill guel tank indoors. Wipe

up spilled gasoline.

MAINTENANCE and STORAGE

1. Keep all nuts, bolts, screws, hose clamps and

hydraulic fittings tight to be sure equipment is

in safe working condition.

2. Never store the equipment with gasoline in the

tank inside of a building where fumes may reach

an open flame of spark. Allow the engine to cool

before storing in any enclosure.

3. To reduce fire hazard keep engine free of grass,

leaves, wood chips, excessive grease and oil.

4. Do not change the engine governor settings or

overspeed the engine. Excessive engine speeds

are dangerous.

5. Never store outside without a waterproof cover.

Rain will cause rust on the inside of the cylinder.

Page 4

FIGURE 1

C-

D-

-ii

-F

-G

ASSEMBLY INSTRUCTIONS

TOOLS REQUIRED:

(1) Raw Hide or Plastic Hammer

(1) 1-1/8" Wrench or Adjustable Wrench

(1) 3/4" Wrench

OTHER MATERIALS NEEDED:

(A) One gallon of regular grade gasoline (for engine)

(B) 1-1/2 pints of SAE 30 or 10W-30 oil (for engine)

(C) Approximately 3 gallons of Dexron II automatic

transmission fluid. (May be obtained at your

local service station or auto parts store).

(E)

Automotive Grease

(F)

Funnel

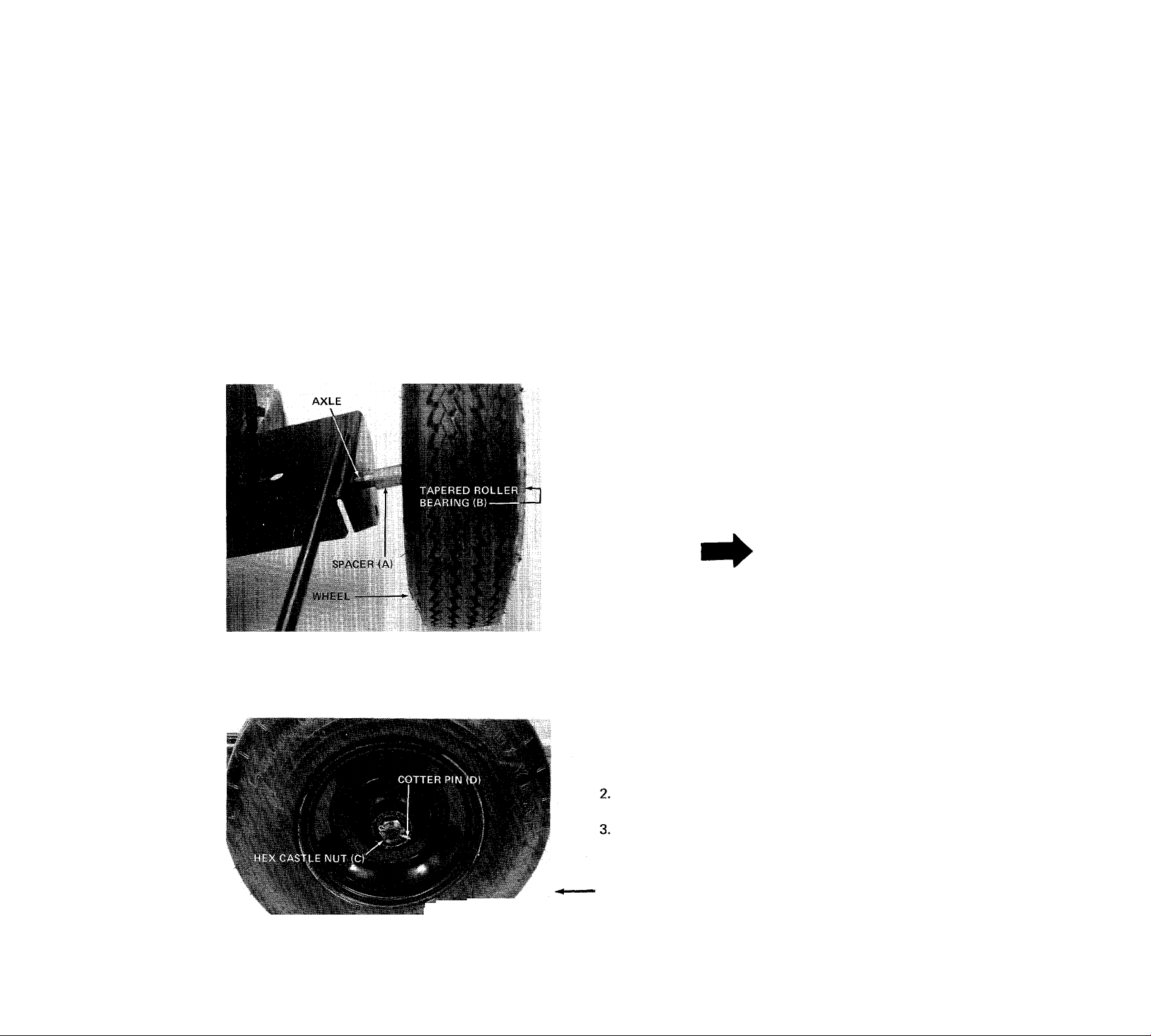

CONTENTS OF HARDWARE PACK (See Figure 1):

(A) (2) Spacers

(B) (2) Tapered Roller Bearings

(C) (2) Hex Castle Nuts 3/4-16 Thread

(D) (2) Cotter Pins

(E) (2) Hub Caps

(F) (1) Shoulder Bolt

(G) (1) FlatWasher

FIGURE 2

1. Pack the tapered roller bearings with automotive

grease.

NOTE

Do not put any grease in the hub caps.

Place one spacer (A) on axle, then one wheel and

tapered roller bearing (B). See figure 2.

Thread hex castle nut (C) on axle. Tighten castle

nut until snug, then back off approximately 1/3

turn or until one of the slots on the castle nut lines

up with hole in axle. Secure castle nut to axle

with cotter pin (D). See figure 3.

FIGURES

Page 5

HAI'/iMER

FIGURE 4

4. Place hub cap (E) in position on wheel and tap on

with a plastic hammer. See figure 4.

5. Repeat steps 1 through 4 for the second wheel.

ENGAGEMENT ROD

FIGURES

OPERATION

BEFORE STARTING

ENGAGEMENT HANDLE

HAIR PIN COTTER

FERRULE

6. Secure engagement handle to beam with shoulder

bolt (F) and flat washer (G). See figure 5.

7. Remove the hair pin cotter from ferrule.

8. Secure engagement rod to engagement handle

with hair pin cotter. See figure 5.

TIRE PRESSURE

FOR SHIPPING PURPOSES, THE TIRES ON YOUR

UNIT MAY BE OVER-INFLATED. TIRE PRESSURE

SHOULD BE REDUCED BEFORE UNIT IS PUT

INTO OPERATION. RECOMMENDED PRESSURE

SHOULD BE APPROXIMATELY 15 P.S.I. EQUAL

TIRE PRESSURE SHOULD BE MAINTAINED ON

ALL TIRES. MAXIMUM TIRE PRESSURE IS 30

P.S.I.

NOTE

Refer to engine manual packed with

log splitter for complete instructions

for the care and maintenance of engine.

READ DIRECTIONS CAREFULLY.

1. Fill oil sump with approximately 1-1/2 pints of

SAE 30 oil, or to full mark on dipstick. See Figure

6. Use MS classification oil. Do not use oils

marked only MM or ML or unmarked. Above

32°, use SAE 30; below 32° use SAE 10W-30.

These recommendations must be followed for

\ best performance and long life.

During initial break-in period, oil level should be

watched closely. Refer to the engine manual.

2. Fill fuel tank, using clean, fresh, regular grade

automotive gasoline. Fill tank completely.

FIGURE 6

Page 6

3. Fill reservoir tank on log splitter. Remove the

the breather plug from breather tube. See figure

7. Pour approximately 3 gallons of Dexron

automatic transmission fluid ONLY into breather

tube.

VALVE IN OPEN

VALVE IN CLOSED

POSITION POSITION

1

■

DEXRON

TRANSMI

FLUID

FUNNEL

A

CAUTION

DO NOT operate log splitter without

proper amount of oil in reservoir tank

(beam).

• U- ■

BREATHER PLUG AND VALVE.

NOTE: Valve has left hand threads.

Clockwise to close.

TO STOP ENGINE

1. Move throttle control lever to STOP position.

2. Remove high tension wire from spark plug to

prevent accidental starting by children while

equipment is unattended.

USING YOUR LOG SPLITTER

Your log splitter is designed for safe, efficient

operation. CARE, OF COURSE, MUST BE EXER

CISED THAT HANDS ARE KEPT AWAY FROM

MOVING PARTS.

Engagement handle has three positions: (See figure 9)

Forward-Ram moves toward wedge.

Neutral—ram stops in place.

Reverse—ram returns.

BREATHER

TUBE- “

FIGURE?

TO START ENGINE

1. Place throttle control lever (on beam) in run

position.

2. Move choke lever to CHOKE position.

3. Open the breather valve. Valve must be open when

running log splitter. Valve must be closed when

transporting log splitter. See figure 8.

4. Grasp starter handle, place one foot on wheel and

pull starter handle with a quick, full arm stroke.

Return rope slowly to the engine.

ENGAGEMENT HANDLE

IN NEUTRAL POSITION.

ENGAGEMENT HANDLE

LOCKED IN REVERSE

POSITION.

FIGURE 8

ENGAGEMENT HANDLE

HELD IN FORWARD

POSITION.

STROKE RETURN STOP

PLUNGER.

Page 7

Maximum length that can be split is 24".

1. Set throttle at maximum speed.

2. Place log on beam and hold in place with right

hand. See figure 10.

FIGURE 10

NOTE

If you lock the engagement handle in the reverse slot,

the ram will return until it hits the return stroke stop

plunger, which will throw the engagement handle

into neutral automatically.

DANGER

Never attempt to cut a log in half

with the log splitter. See figure 12.

Never stand next to the ram when

operating. See figure 13. Always stand

behind the ram.

3. Slowly move engagement handle forward until

ram rests against log. Release engagement handle

(Neutral).

4. Remove your hand from the log and step behind

the ram. See figure 11.

■1 V --

FIGURE 11

FIGURE 12

5. Move engagement handle forward until log is split.

6. Move the engagement handle to the rear to return

ram.

The ram should take approximately 30 seconds to

make a complete cycle. This speed may vary

depending on throttle setting and temperature of oil.

FIGURE 13

Page 8

ADJUSTMENTS

1. Block up front of log splitter so beam is level.

CARBURETOR ADJUSTMENTS

Refer to engine manual packed with your unit for

carburetor adjustment information.

PRESSURE RELIEF VALVE SETTING

If the pressure relief valve is set too low, it will open

up before enough pressure is built up to properly

operate the ram. See figure 14.

To set the pressure relief valve:

1. Have someone place a log crossways in the splitter

and allow the ram to push against it with the

engine at full throttle.

2. If the engine begins to labor, the relief valve

setting is correct.

3. If adjustment is necessary, tighten the screw until

the engine begins to labor.

2. Remove check pipe plug in rear of beam. See

figure 15. If oil starts to come out of check pipe

plug hole, oil level is correct. IF IT DOES NC'^

add oil to breather tube (see figure 7) until o

starts out.

NOTE

Use hydraulic sealant tape or pipe

sealant on pipe plug threads.

3. Replace check pipe plug. Remove block from

under front of beam.

FIGURE 14

MAINTENANCE

t WARNING i

Always stop engine and disconnect

spark plug wire before performing any

maintenance or adjustments.

ENGINE OIL

Change oil first two (2) hours of operation and

check oil level every five (5) operating hours or each

time equipment is used.

Change oil every twenty-five (25) operating hours

or sooner if equipment is operated in extremely

dusty or dirty conditions.

Refer to engine manual for quantity and type of oil.

LOG SPLITTER RESERVOIR OIL

Check oil in log splitter reservoir before every use.

See figure 15.

^ ^ ^ ^ ^ ^ ^ ^

FIGURE 15

Change oil in the reservoir every (100) hours of

operation.

1. Remove the hose clamp at inlet hose (bottom

hose on rear of beam). See figure 16.

NOTE

Be prepared to catch oil in a suitable

container.

Pull off inlet hose from strainer tube assembly and

2.

catch oil in a suitable container. See figure 16.

With an adjustable wrench remove the strainer

3.

tube assembly. See figure 16.

NOTE

The strainer tube assembly is 53" long.

Drain oil, clean strainer tube and reassemble-

4.

using a hydraulic pipe sealant on the threads.

Remove the breather plug from breather tube.

5.

See figure 7. Pour approximately 3 gallons of

Dexron transmission fluid ONLY into breather

tube.

Page 9

INLET HOSE

HOSE CLAMP

STRAINER TUBE ASSEMBLY

INSTALLATION OF TIRE TO RIM

1. Lubricate tire beads and rim flanges.

HEX LOCKNUT

FIGURE 16

STRAINER TUBE ASSEMBLY

If the ram does not move back and forth smoothly,

the strainer tube assembly may be clogged.

To clean, follow instructions for changing the reservoir

oil, step number 1 through 3. Clean the strainer tube

assembly and reassemble using a hydraulic pipe sealant

the threads.

nOSE CLAMPS

Check the hose clamps on the bottom of the pump

for proper tightness before each use.

Hose clamps on the return hose should be checked

once a season.

lili

e

STROKE RETURN STOP PLUNGER

FIGURE 17

2. Do not exceed 30 P.S.I. when seating beads.

3. Adjust to recommended pressure after beads are

sealed.

OFF-SEASON STORAGE

In event engine is to be stored for any length of time

(30 days or more), prepare as follows:

1. Drain gasoline by tipping or by siphon hose,

then run engine until remainder is used and tank

and carburetor and empty.

HEX BOLT

STROKE RETURN STOP PLUNGER

If the engagement handle does not return to neutral

(from reverse) before the pressure relief bypass opens,

loosen the hex lock nut, and back out the hex bolt

one or two turns. See figure 17.

NOTE

When the pressure relief valve opens,

a loud high pitched sound is heard and

engine labors.

Tighten hex lock nut and operate log splitter. Repeat

if necessary.

RAM OPERATION

the ram does not move smoothly, run the ram its

.u(l stroke several times to clear out air in the system.

Be sure the breather valve is open.

If this does not correct the problem, see Strainer Tube

Assembly paragraph.

CAUTION

A

Drain into container outdoors away

from fire or flame.

Drain carburetor by running engine until it stops

2.

from lack of fuel.

Protect the inside of engine for storage by

removing spark plug and pouring one ounce of

SAE 30 oil through spark plug hole into cylinder.

Crank engine, without starting, several times to

spread oil over cylinder walls.

4.

Never store outside without a waterproof cover.

Page 10

Models 642 and 645

NOTE

This instruction manual covers various models, and

all specifications shown do not necessarily apply to

your model. Specifications subject to change without

notice or obligation.

10

Page 11

Models 642 and 645

PARTS LIST FOR LOG SPLITTER MODELS 642 and 645

Part

1

No.

717-0407

.vO.

2 727-0231

Color

Code

DESCRIPTION

Control Valve

Return Stroke High Pressure

New

Part

Hose

3 727-0211

Forward Stroke High Pressure

Hose 35

4

5

737-0161

737-0173

Breather Valve O.D. X 1.56" Lg.

Female Adapter 3/4-14 x

1/4-18 N.P.T.F.

737-0153 Return Elbow

6

726-0173 Hose Clamp 3/4" I.D.

7

8

727-0210

Return Hose 3/4" I.D. x

2.62" Lg.

9

737-0172

Nipple 1/2-14 N.P.T.F. x

1.5" Lg.

10 710-0117

Hex Bolt 5/16-24 x 1.00"

Lg. (Grade 5)

11 738-0406

12 750-0428

13 08118

14

747-0355 Cylinder Support Rod 42 736-0119 L-Wash. 5/16" I.D.*

Return Stroke Stop Plunger

Engagement Handle

Grip 41

(for 3-1/2" Dia.) (642) 43

747-0354

Cylinder Support Rod

(for 4" Dia.) (645) 44

737-0152 High Pressure 90° Elbow

5

3/8 N.P.T. X 9/16-18

16

Cylinder Assy* (See Page 12

for Breakdown)

17 736-0169

L-Wash. 3/8" I.D.*

18 712-0798 Hex Nut 3/8-16 Thd.*

15234

19

20

15235

710-0624 Hex Bolt 5/16-24 X 1.50"

21

Strainer Tube Ass'y- 48

Complete Oil Tank & Beam

Lg-

22 712-0123 Hex Nut 5/16-24 Thd.*

23 736-0159 Fl.-Wash. .34 I.D. x .88" O.D. 50

24 732-0252

Compression Spring .64 O.D.

X .81 Lg.

25

26

27

28

736-0160

738-0234

711-0198

747-0297

Fl.-Wash. .53" I.D. x .94" O.D.

Shid. Bolt .500" Dia. x .295

Pivot Bushing

Engagement Rod .38 Dia. x

31" Lg. 57 710-0106

714-0507 Cotter Pin 3/32" Dia. x .75"

29

Lg.*

30

31

13748

736-0119

Frame Ass'y.

L-Wash. 5/16" I.D.*

Ref.

No.

32

33 710-0409

Part

No.

712-0123

Color

Code

DESCRIPTION

Hex Nut 5/16-24 Thd.*

Hex Bolt 5/16-24 x 1.75"

Lg.*

34

750-0501

750-0442

36 734-1016

Filler Tube

Spacer .75" I.D. x 1.12"

Wheel Ass'y. Comp. 4.80/

4.00 X 8

734-1017 Wheel Rim Ass'y.

(Service Only)

734-0872

Tire Only 4.80/4.00 x 8

(Service Only)

741-0107

37

Tapered Roller Bearing

(Service Only)

38 714-0121 Cotter Pin 5/32" Dia. x 1.00

Lg.*

734-0873

39

40 712-0299

Hub Cap (Service Only)

Hex Castle Nut 3/4-16 Thd.

712-0123 Hex Nut 5/16-24 Thd.

714-0128 Sq. Key 1/4" x 1/4" x 1.00"

Lg.

736-0119 L-Wash. 5/16" I.D.*

45 710-0157

Hex Bolt 5/16-24 X.75"

Lg.*

46

727-0228 Suction Hose (642)

727-0229 Suction Hose (645)

47

Sq. Key (comes with Ref.

No. 48)

717-0460

Pump with Sq. Key 1/8" x

1/8" X 1.00" Lg. (642)

717-0461

Pump with Sq. Key 1/8" x

1/8" X 1.00" Lg. (645)

49 712-0123 Hex Nut 5/16-24 Thd.*

736-0119

51 717-0462

710-0117

52

53 13295

54

710-0216

55

736-0105 Belleville Wash. 3/8" I.D.

56 712-0107

L-Wash. 5/16" I.D.*

Flexible Coupling

Hex Bolt 5/16-24 X 1.00" Lg.*

Coupling Support Brkt. Ass'y.

Hex Bolt 3/8-16 X.75" Lg.*

Hex Cent. L.-Nut 1/4-20 Thd.

Hex Bolt 1/4-20 X 1.25" Lg.^

58 737-0171

59

770-0232 High Pressure Hose Ass'y.

60

61

726-0132

90° Solid Male Adapter

Engine

Hose Clamp 1" I.D.

New

Part

II

*For faster service obtain standard nuts, bolts and washers locally. If these items cannot be obtained locally, order by part

imber and size as shown on parts list.

The engine is not under warranty by the log splitter manufacturer. If repairs or service is needed on the

engine, please contact your nearest authorized engine service outlet. Check the "Yellow Pages" of your

telephone book under "Engines - Gasoline."

Find It Fast

Yellow Pages

11

In The

Page 12

Models 642 and 645

1&2

U2

PUSH PLATE WELDED TO

CYLINDER ROD

Ref.

No.

1 717-0459

2

3

4 717-0459

5

PART No.

;<753-027J_

753-02?®

753-0274

3-1/2" DIA. CYLINDER

PARTS LIST FOR MODEL 642

DESCRIPTION

Cylinder Ass'y- Comp. (Welded

Push Plate)

3-1/2" Cyl. Kit "0"-Ring Set

(Welded Push Plate)

3-1/2" Cyl. Kit "0"-Ring Set

(Removable Push Plate)

Cylinder Ass'y- Comp.

(Removable Push Plate)

3-1/2" Cyl. Push Plate Kit

PUSH PLATE REMOVABLE

Ref.

No.

1

3

4 717-0406

5

4&5

1^4*5

4" DIA. CYLINDER

PARTS LIST FOR MODEL 645

PART No.

717-0406 Cylinder Ass'y. Comp. (Welded

Push Plate)

753-0263 4" Cyl. Kit "0"-Ring Set

(Welded Push Plate)

753-0273

(Removable Push Plate)

Cylinder Ass'y. Comp.

(Removable Push Plate)

753-0275

4" Cyl. Push Plate Kit |

DESCRIPTION

4" Cyl. Kit "0"-Ring Set

MTD PRODUCTS INC ..........................

P.O. BOX 36900

............................... VaRD-MaN COMPANY

CLEVELAND OHIO 44136

Loading...

Loading...