Page 1

TEN CENTS

Page 2

IM PORTANT

It is suggested that this manual be read in its entirety before attempting to assemble or operate. Keep

this manual in a safe place for future reference and for ordering replacement parts.

This unit is shipped WITHOUT GASOLINE or OIL. After assembly, see operating section of this manual

for proper fuel and amount.

Your log splitter is a precision piece of power equipment, not a plaything. Therefore exercise extreme

caution at all times.

SAF E OP ER AT IO N PR AC TI CE S F OR L OG S PL IT TE RS

TRAINING

1. Know the controls and how to stop quickly—

READ THE OWNER’S MANUAL.

2. Do not allow children to operate. Do not allow

adults to operate it without proper instruction.

Only persons well acquainted with these rules of

safe operation should be allowed to use your

log splitter.

PREPARATION

1. Do not wear loose fitting clothing that could get

caught on the moving parts.

2. Do not operate equipment when barefoot or wear

ing open Sandies. Always wear substantial

footwear.

3. Check the fuel before starting the engine. Do not

fill the gasoline tank indoors, when the engine

is running, or while the engine is still hot. Wipe

off any spilled gasoline before starting the engine.

4. Use only in daylight or in good artifical light.

5. Never operate the equipment in the rain. Always

be sure of your footing.

OPERATION

0. Open doors if engine is run in garageexhaust fumes are dangerous. Do not run

engine indoors.

6. Always operate the log splitter from the engine

side of the beam.

Stand behind theramwhenoperating. See drawings.

¡J ^ 'K'"\

IV feo

\|ii]

^"^ORRECT

7. Be careful not to touch the muffler after the

the engine has been running, it is HOT.

1. Do not change the engine governor settings or

overspeed the engine. Excessive engine speeds

are dangerous.

2. Do not put hands or feet near rotating or moving

parts.

3. If the equipment should start to vibrate abnor

mally, stop the engine and check immediately

for the cause. Vibration is generally a warning

of trouble.

4. When cleaning, repairing or inspecting, make

certain all moving parts have stopped. Disconnect

the spark plug wire, and keep the wire away from

the plug to prevent accidental starting.

5. Handle gasol ine with care-it is highly flammable.

A. Use approved gasoline container.

B. Never remove cap or add gasoline to a running

or hot engine or fill fuel tank indoors. Wipe

up spilled gasoline.

MAINTENANCE and STORAGE

1. Keep all nuts, bolts, screws, hose clamps and

hydraulic fittings tight to be sure equipment is

in safe working condition.

2. Never store the equipment with gasoline in the tank

inside of a building where fumes may reach an open

flame of spark. Allow the engine to cool before

storing in any enclosure.

3. To reduce fire hazard keep engine free of grass,

leaves, wood chips, excessive grease and oil.

4. Do not change the engine governor setting

overspeed the engine. Excessive engine speeds

are dangerous.

5. Never store outside without a waterproof cover.

Rain will cause rust on the inside of the cylinder.

Page 3

ASSEMBLY INSTRUCTIONS

^^>*-^Remove the log splitter, parts pack all all literature

Tom the crate before discarding crate.

2. Block up rear end of log splitter so that the rear

wheels may be assembled.

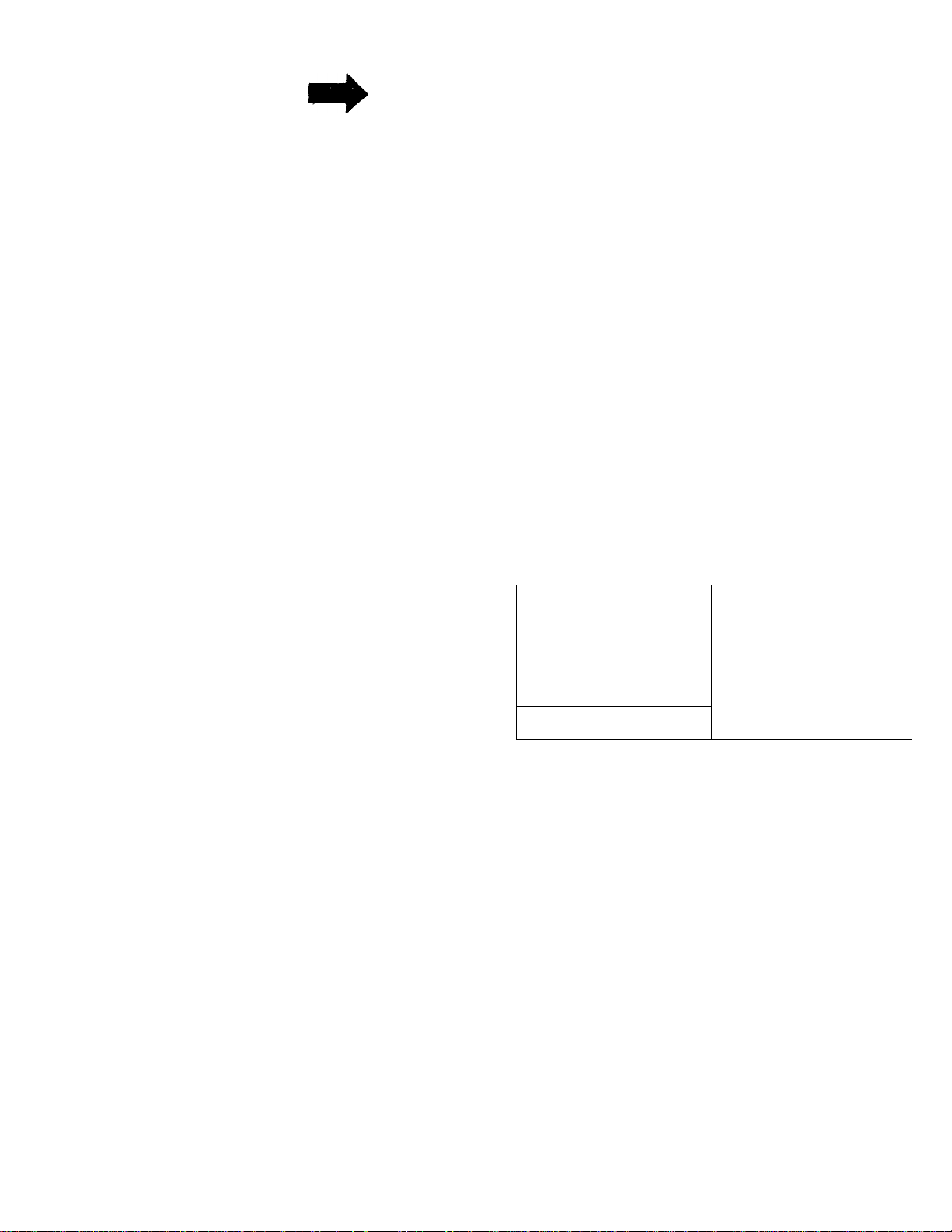

3. Place flat washers (A) on axle, then wheels and

secure with collars and set screws (B). See figures

1 and 2.

4. The engagement handle is partly assembled, pivot

handle upward into positionand secure with shoulder

bolt (C). See figure 3.

ENGAGEMENT HANDLE

SHOULDER BOLT (C)

SHOULDER BOLT

tEADY IN

FIGURE 3

5. Tighten both shoulder bolts securely.

OPERATION

1. Service engine with gas and oil. See engine manual

packed with log splitter for complete instructions

for the care and maintenance of engine. READ

DIRECTIONS CAREFULLY.

CAUTION

A

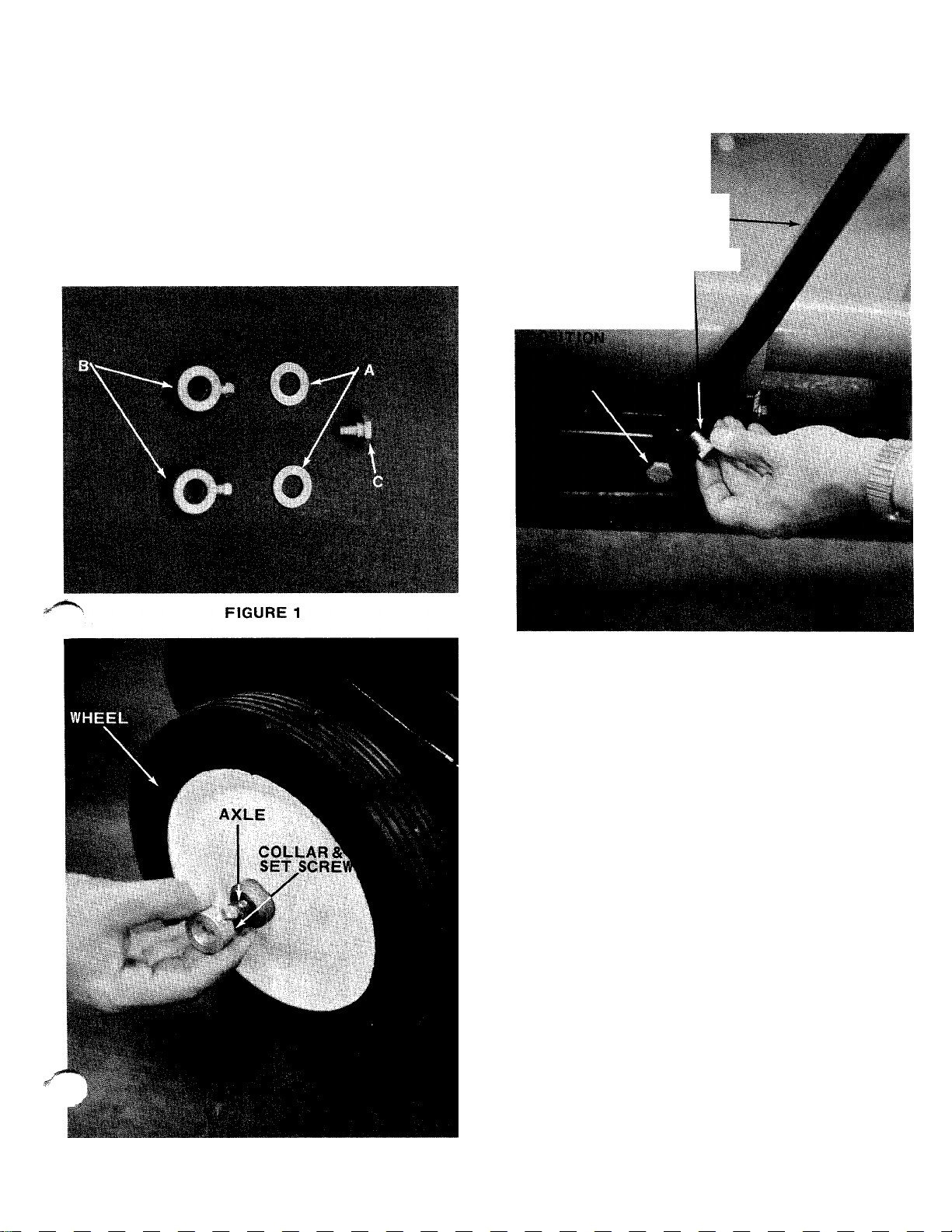

You must not operate log splitter

without proper amount of oil in reser

voir tank.

FIGURE 2

2. Remove the breather cap from reservoir tank.

See figure 4.

Page 4

NOTE

Carburetors are preset at the factory.

DO NOT attempt to make adjustments

at this time. See carburetor instructions

outlined under CARBURETOR AD

JUSTMENT.

FIGURE 4

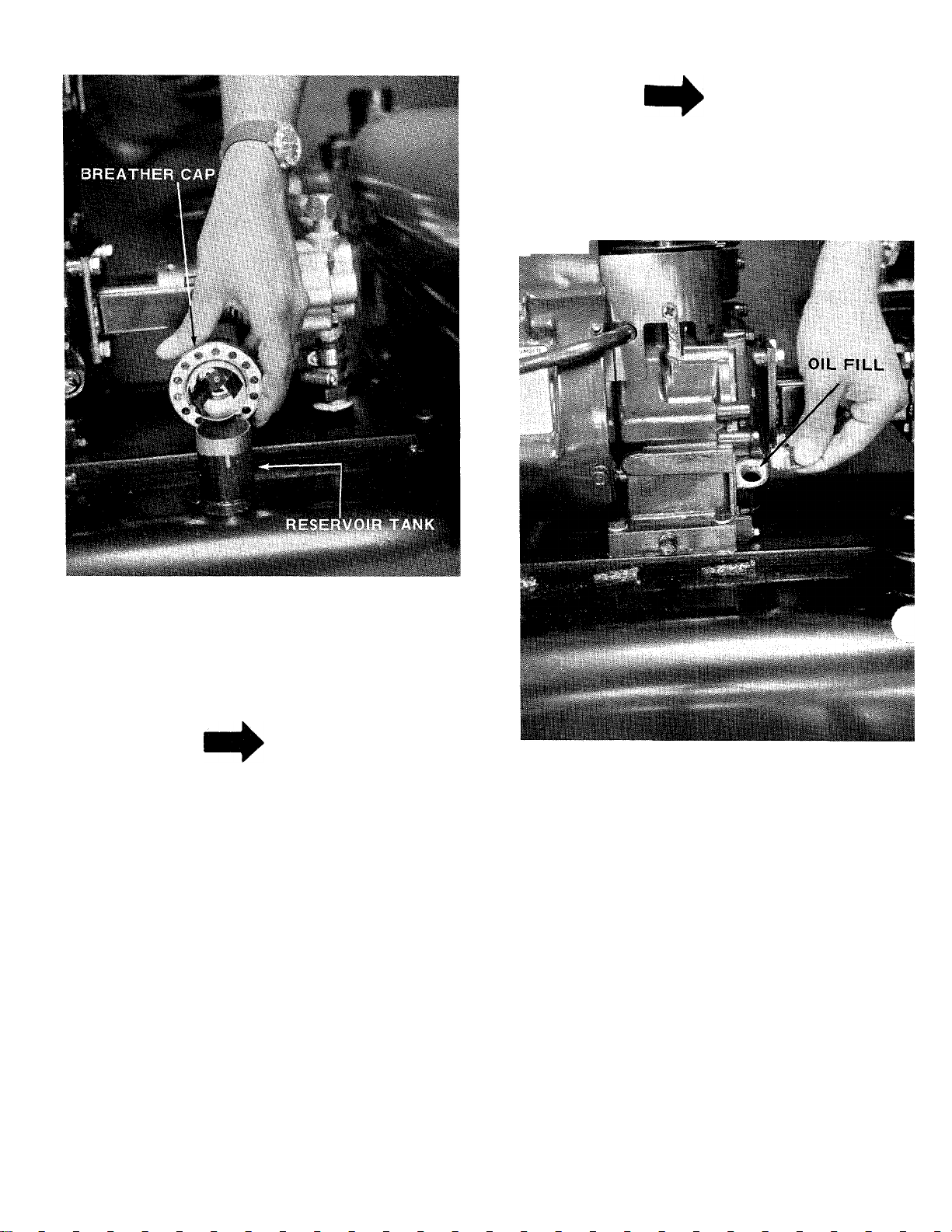

3. The hydraulic system takes 4-1/2 gallons of

low 30 HD only detergent oil. Fill the reservoir

tank to the bottom of the fill tube.

NOTE

You can not get all the oil in the

system until after the engine is run.

Replace the breather cap.

BEFORE STARTING

During initial break-in period, oil level should be

watched closely. See ENGINE MAINTENANCE.

Use MS classification oil. Do not use oils marked

only MM or ML or unmarked.

Above 32° use SAE 30; below 32° use SAE 10W.

These recommendations must be followed for best

performance and long life.

Change oil first two (2) hours of operation and

check oil level every five (5) operating hours or

each time equipment is used.

Change oil every twenty-five (25) operating hours

or sooner if equipment is operated in extremely

dusty of dirty conditions. 4

FIGURE 5

TO START ENGINE

1. Place control lever (on engine) in run position.

See figure 6.

2. Move choke lever to CHOKE position. See

figure 7.

3. Rewind starter-use quick full arm stroke. Keep

firm grip on handle and return rope slowly.

TO STOP ENGINE

1. Move control levertoSTOP position. See figure 6.

2. Remove high tension wire from spark plug to

prevent accidental starting by children while

equipment is unattended.

Page 5

FIGURE 6

USING YOUR LOG SPLITTER

Your log splitter is designed for safe, efficient,

operation. CARE, OF COURSE, MUST BE EXER

CISED THAT HANDS ARE KEPT AWAY FROM ALL

MOVING PARTS.

A. Set throttle at maximum speed.

B. Engagement handle has three positions: Forward-

moves ram towards wedge. Neutral - ram stops

in place. Reverse - ram returns. See figure 8.

FIGURE 7

NOTE

After engine has been serviced,

finish filling oil reservoir. Start

engine and operate engagement handle

so the ram makes two complete strokes.

CAUTION

A

This is to purge the hydraulic system

of air.Continued operation will cause

permanent damage to pump and cyl

inder. Stop engine and finish filling

reservoir tank. It will take about 3

quarts of oil. See figure 4.

FIGURE 8

C. Maximum length that can be split is 23”

D. Place log on beam and hold in place with right

hand. See figure 9.

FIGURE 9

Page 6

E. Slowly move engagement handle forward until

ram rests against log. Release engagement

handle (Neutral).

F. Remove your hand from the log and step behind

the ram. See figure 10.

FIGURE 12

MAINTENANCE

FIGURE 10

G. Move engagement handle forward until log is

split.

NOTE

If you attempt to run the ram beyond

its normal stroke it will automatically

return the engagement handle to neutral.

H. Move the engagement handle to the rear to return

ram.

DANGER ^

Never attempt to cut a log in half

with the log splitter. See figure 11.

Never stand next to the ram when

operating. See figure 12. Always

stand behind the ram.

^^1^ ^ WARNING I

If ram takes longer than 30 seconds

to complete full forward cycle, check

strainer tube assembly.

A

Always stop engine and disconnect

spark plug wire before doing any

maintenance.

RAM OPERATION

If the ram does not move smoothly, run the ram its

full stroke several times to clear out air in the

system. If this does not correct the problem see

strainer tube assembly paragraph. (Page 7).

RETURN COLLAR

Adjust the return collar so it is 2 inches from the

front edge of the wedge.. See figure 13.

CAUTION

FIGURE 11 FIGURE 13

Page 7

HOSE CLAMPS

Check the hose clamps on the bottom of the pump

for proper tightness before each use. See figure 14.

lose clamps on the return hose should be checked

once a season. See figure 15.

BREATHER CAP

Clean breather cap when dirty. See figure 4.

A. Wash breather in detergent and water.

B. Air dry.

C. Lubricate with one tablespoon of 10W 30 oil.

STRAINER TUBE ASSEMBLY

If the ram does not move back and forth smoothly

the strainer tube assembly may be clogged.

To clean follow these steps.

A. Remove your engine bolts and lockwashers.

See figure 16.

HOSE

CLAMP

OIL RESERVOIR

FIGURE 14

FIGURE 15

FIGURE 16

B. Loosen hose clamps (either one) on the bottom

of the pump.

C. Lift engine and pump assembly and rotate to

one side. See figure 16.

D. With a wrench, remove strainer tube assembly.

See figure 17.

It is important to keep the oil clean in the reservoir

tank. Replace with 4-1/2 gallons of 10W 30 HD only

detergent oil if contaminated (e.g. water in tank).

FIGURE 17

Page 8

E. Clean and reassemble using a hydraulic sealant

on the threads.

ENGINE MAINTENANCE

To obtain long life and trouble-free service from

your engine, certain normal maintenance must be

performed as outlined below:

1. Change oil in crankcase after first two (2) hours

of operation. Then, follow instructions outlined

on page 4.

3. Cleaning engine-This is an aircooled engine

which operates most efficiently when the cooling

fins are clean.

Clean cylinder fins and underside of tank or housing_

thoroughly of all accumulated grass and debris

4. Air Cleaner. (See figure 19).

a.

Paper Type Element. Remove every 10 hours or

oftener if under dusty conditions. Tap to remove

loose dirt and/or blow from inside out with low

pressure air. Replace if torn or perforated or

when plugged to maintain proper carburetor setting

(50 hours). DO NOT WASH IN ANY LIQUID AND

DO NOT OIL.

Paper Element

FIGURE 18

A

Disconnect high tension wire at spark

plug to prevent accidental starting

of engine. Unscrew oil drain plug

located on side at bottom of engine

See figure 18.

Always tip engine towards oil drain

hole. Be sure oil drains completely.

Replace oil drain plug and refill with oil as directed

on page 4 or engine nameplate.

2. Check oil every five (5) operating hours or each

time equipment is used.

CAUTION

NOTE

Element

'Attaching Screw

FIGURE 19

CARBURETOR ADJUSTMENTS (See figure 20)

Do not make unnecessary adjustment. Factory settings

are correct for most application. If adjustments are

needed, proceed as follows:

1. Close power adjusting needle (figure 20) by

turning to right (clockwise). Close finger tight

only. Forcing will cause damage.

2. Open one turn (counterclockwise).

3. Close idle adjusting needle (figure 20) by turning

to right (clockwise). Close finger tight only.

Forcing will cause damage.

4. Open one and one-half (1 1/2) turns (counter

clockwise).

5. Start engine. Follow starting instructions page 4—

6. With throttle open (carburetor control at RUN

FAST position) adjust power adjusting needle

one-eighth (1/8) turn at a time forward or back

ward until engine runs smoothly. If engine tends

to stall under load enrich mixture slightly (counter

clockwise).

Page 9

Hold throttle lever closed or move carburetor

control to IDLE or SLOW position and adjust

idle adjusting needle until engine runs smoothly

proceeding in step six (6) above.

Allow several seconds between each adjust

ment when performing either step six (6) or

seven (7) to allow engine to react to new setting.

STORAGE

INSTRUCTIONS

In event engine is to be stored for any length of

time (30 days or more), prepare as foliows;

1. Drain gasoline by tipping or by syphon hose,

then run engine until remainder is used and tank

and carburetor are empty.

CAUTION

A

Drain into container outdoors away

from fire or flame.

Drain carburetor by running engine until it stops.

2.

Inside protection of engine for storage is per

3.

formed by removing spark plug and pouring one

ounce of SAE 30 oil through spark plug hole

into cylinder. Crank engine, without starting,

several times to spread oil over cylinder walls.

4. Never store outside without a waterproof cover.

FIGURE 20

Page 10

047-640^

24640'^

10

Page 11

LIST FOR LOG SPLITTER MODELS 247-640A and 24640-7

..ef.

No.

Part

No.

710-0331 HexScr. 3/8-24x2.25” Lg.* 25

1

13275

2

3 727-0203

4 737-0155

5

717-0364

6

736-0119

Color

Code

Description

New

Part

Cam Piate

High Pressure Hose Ass'y.

11.0” Lg.

Reducing Bushing N

Valve N

L.-Wash. 3/8” Scr.*

N

N

7 712-0241 Hex Nut 3/8-24 Thd.* 32

8

08118

9

737-0153

10 737-0154

732-0342

11

12

732-0341

13304

13

14

721-0159

15 13302

13314

7

726-0173

749-0251

18

19 13310

736-0119

20

Grip

Return Elbow N

Cylinder nipple .75”x4.5” Lg . N

Spring Clip N

Cylinder Return Spring

Cylinder Ass’y.

‘‘0”-Ring

Push Cylinder Ass’y.

Spring Hook Ass’y. N

Hose Clamp

Engagement Handle

Cylinder Holding Plate

L-Wash. 5/16” Scr.*

N

N

N

N

N

N

N

21 710-0528 Hex Scr. 5/16-18x1.25” Lg.

22

23

24

13305

13312

710-0494

”I”-Beam Ass’y. Comp.

Return Collar Ass’y.

Sq.Hd.SetScr.5/16-18x .38”

_________________________________________________________________________

N

N

Lg.

LL_

Ref.

No.

Part

No.

Color

Code

Description

13291 Engagement Lever Ass’y.

26 738-0258 Shoulder Scr. 3/8-16 Thd.

27

13280

Strainer Tube Ass’y.

28 727-0204 Return Hose

29

711-0169

30 734-0584

31 736-0237

13276

751-0224

33

34

727-0205

35

737-0151

717-0363

36

Coilar

Wheel Ass’y. Comp.

FI.-Wash. .656 I.D.x I.OOTh

Tank Ass’y. Complete

Breather Cap

Inlet Hose

Inlet Nipple

Pump - Complete(bJ£R.ST£i^)

37 737-0152 High Pressure Elbow

38

710-0376

39 712-0267

13295 Coupl ing Support Brkt. Ass’y

40

41

714-0114

42

710-0237

43 710-0528

44

717-0374 Flexible Coupling Comp.

45

46 714-0507

47 736-0142

48 711-0660

HexScr.5/16-18x 1.00” Lg

HexNut5/16-18 Thd.*

Sq. Key 1/4”x2.00” Lg.*

HexScr. 5/16-24X .62” Lg.*

Hex Scr. 5/16-18x1.25”Lg.

Engine

Cotter Pin 3/32” Dia.X .75”

Fl.-Wash. .28I.D.x.50”O.C

Clevis Pin

New

Part

N

N

N

d.

N

N

N

N

N

N

*

^ N

*

N

Lg.*

).

N

‘For faster service obtain standard nuts, bolts and washers locally. If these Items cannot be obtained locally, order by part

number and size as shown on parts list.

The engine is not under warranty by the log splitter manufacturer. If repairs or service is needed

on the engine, please contact your neorest authorized engine service outlet. Check the "Yellow

Pages” of your telephone book under "Engines — Gasoline.”

Find It Fast

InThs

Yellow Pages

11

Page 12

PARTS INFORMATION

POWER EQUIPMENT PARTS AND SERVICE

Parts and service for all MTD manufactured power

equipment are available through the authorized service

firms listed below. All orders should specify the model

number of your unit, ports numbers, description of parts

and the quantity of each part required.

ALABAMA BIRMINGHAM

Auto E lactric & Carburetor Co.. .2625 4th Ave. S.. 35233

ARKANSAS NORTH LITTLE ROCK

Sutton's Lawn Mower Shop .Rt. 4, Box 368

Mity Mite Motors, Inc;

CALIFORNIA SAN BERNARDINO

Lawn Mower Supply Co

J.W. Jewett Co

Luttig & Severson .................. 2030 28th St............... 95818

COLORADO DENVER

South Denver Lown Equip

CONNECTICUT SUFFIELD

The Jones & Ramsey Co

FLORIDA JACKSONVILLE

Rodeo Distributors

Moz-AII of Florida, Inc............ 365 Greco Ave

GEORGIA EAST POINT

East Point Cycle & Key

ILLINOIS LYONS

Keen Edge Co

INDIANA ELKHART

Ports & Soles Inc..................... 2101 Industrial Pkwy. ..46514

IOWA DUBUQUE

Power Lawn & Garden Equip. .2551 J.F. Kennedy —52001

KANSAS WICHITA

Hixon, Inc

LOUISIANA NEW ORLEANS

Suhren Engine Co.................... 8330 Eorhort Blvd

MARYLAND TAKOMA PARK

Center Supply Co

MASSACHUSETTS SPRINGFIELD

Morton B. Collins Co............... 300 Birnie Ave............01107

MICHIGAN MOUNT CLEMENS

Power Equipment Dist

Lorenz Service Co

MINNESOTA MINNETONKA

Hance Distributing Inc

MISSISSIPPI BILOXI

Biloxi Soles & Service, Inc. ....506 Caillovot St

MISSOURI KANSAS CITY

Automotive Equip. Service ..3117 Holmes St

Henzler, Inc

NEW YORK CARTHAGE

Gamble Dist., Inc...................... West End Ave

Kimber's, Inc

...................................

FORT SMITH

............

.........

SAN FRANCISCO

.........................

SACRAMENTO

....

.......

.................

CORAL GABLES

.......

..........................

.................

...........

LANSING

...................

............

ST. LOUIS

...............................

SYRACUSE

.............................

2515 Towson Ave

25608 E. Baseline .... 92410

981 Folsom St

527 West Evans

850 Thompsonvi He Rd. 06078

2403 Morket St

2834 Church St

8615 Ogden Ave

3030 Mascot

6867 NewHompshireAve. 20012

36463 South Uratiot... 48043

2500 S. Pennsylvonio .. 48900

11212 Woyzato Blvd. ..55343

2015 Lemoy Ferry Rd. 63125

115 N. Geddes St

..........

....

............

........

........

...........

.........

........

............

.......

..........

...........

.....

72117

72901

94107

80223

32206

33146

30344

60534

67204

....

70118

39533

64109

13619

13204

BRIGGS & STRATTON, TECUMSEH AND PEERLESS

PARTS AND SERVICE

Briggs & Stratton, Tecumseh and Peerless parts ;

service should be handled by your nearest authoriz

engine service firm. Check the yellow pages of your

telephone directory under the listing Engines ______________

Gasoline, Briggs & Stratton or Tecumseh Lauson

NORTH CAROLINA GREENSBORO

Dixie Sales Company

Smith Hardware Co

OHIO WADSWORTH

National Central ........................687 Seville Rd

Bleckrie, Inc

Stebe's Mid-State Mower Supply Box 366

Sunshine Wholesola Tire Outlet Route 224

McClure Lawn 8i Garden Supply...1 11 ^ Lexington Ave. , 44903

OKLAHOMA MUSKOGEE

Victory Motors, Inc...................605 S. Cherokee

Ado Auto Supply

OREGON PORTLAND

Kenton Supply Co

PENNSYLVANIA LANCASTER

Roub Supply Co

Bluomont Co

TENNESSEE KNOXVILLE

Master Repair Service

Memphis Cycle & Supply Co. 421 Monroe Ave

American Solos & Service, Inc. . 1922 Lynnbrook .381 lo

TEXAS DALLAS

Morr Brothers, Inc. ................ 423 E. Jefferson

Bullard Supply Co

Cotto 8. Putty, (nc

Woodson Solos Corp.............. 1702 N. Sylvanio

UTAH SALT LAKE CITY

A-1 Engine & Mower Co......... 437 E. 9th St..............84111

VERMONT BURLINGTON

Vermont Appliance Co

VIRGINIA RICHMOND

RBI Corp..................................... 963 Myers St

WASHINGTON SEATTLE

Bailey's Rebuild, Inc

WEST VIRGINIA CHARLESTON

Young's, Inc

WISCONSIN APPLETON

Automotive Supply Co............123 S. Linwood Ave. ..54911

..............................

............................

...............................

.............

GOLDSBORO

...................

CLEVELAND

CARROLL

WILLARD

MANSFIELD

ADA

.....................

.....................

......................

PITTSBURGH

..........

MEMPHIS

HOUSTON

..................

SAN ANTONIO

...................

FORT WORTH

...........

..............

327 Battleground Ave.. 27402

515 N. George St

7900 Lorain Ave

301 E. 12th St

8216 N. Denver Ave. . 97217

James & Mulberry Sts...17604

11 125 Frankstown Rd.. 15235

2423 Broodwoy, N.E...379’"“

2409 Commerce St

P.O. Box 2408

44 Lakeside Avo

1325 E. Madison St. ...98102

233 Virginia St., E. ...25301

__________

.......

.........

.......

................

.............

....

...........

.......

.....

...

..........

....

..........

............

27530

44281

44102

43112

44890

74401

74820

38 i

75203

77003

78206

76111

05401

23260

WARRANTY PARTS AND SERVICE POLICY

The purpose of worronty is to protect the customer from defects in workmonship ond materials, defects which ore NOT detected

at the time of moriufocture. It does not provide for the unlimited ond unrestricted replocement of parts. Use and mointonance ore

the responsibility of the customer. The manufacturer cannot assume responsibility for conditions over which it has no control.

Simply put, if it's the manufacturer's foult, it's the manufacturer's responsibility; if it's the customer's fault, it’s the customer’s

responsibility.

CLAIMS AGAINST THE MANUFACTURER S

WARRANTY INCLUDES

Replacement of Missing Ports on new equipment. 1. Model Number of unit involved.

Replacement of Defective Ports within the worronty period. 2. Dote unit was purchased or first pot into service,

nair of Defects within the warranty period. 3- Dote of failure.

PRODUCTS INC

5389 WEST 130th STREET • P. 0. BOX 2741 CLEVELAND OHIO 44111

Ait claims MUST be substantiated with the following

information:

4. Nature of failure.

Loading...

Loading...