Page 1

OWNERS

MANUAL

.75

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

Important:

3-1/2 H.P.

LOG SPLITTER

Model Number

244-638-000

24638L

Read Safety Rules and

Instructions Carefully

PRINTED IN U.S.A.

Thank you for purchasing an

American built product.

FORM NO. 770-3133

Page 2

INDEX

Operation Practices...................................................... 3

Assembly Instructions................................................... 5

Operation ..................................................................... 8

Maintenance ................................................................ 9

Off-Season Storage

r

...................................................

11

LIMITED WARRANTY

♦

♦

♦

♦

♦

♦

♦

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm, any

part or parts found to be defective in naterial or workmanship. Transportation charges for

the movement of any power equipment unit or attachment are the responsibility of the pur

chaser. Transportation charges for an/ parts submitted for replacement under this warran

ty must be paid by the purchaser unless such return is requested by MTD PRODUCTS INC.

This warranty will not apply to any p£ rt which has become inoperative due to misuse, ex

cessive use, accident, neglect, improper maintenance, alterations, or unless the unit has

been operated and maintained in accordance with the instructions furnished. This warran

ty does not apply to the engine, motor, battery, battery chargeror component parts thereof.

Please refer to the applicable manufacturer’s warranty on these items.

Trouble Shooting Chart

Illustrated Parts

Repair Parts List

Parts Information

.....................................................

............................................... 13, 15

..........................................

...............................................

13, 14

Back Cover

12

♦

♦

♦

♦

This warranty will not apply where the unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. If

you do not know the dealer or distributor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will not be accepted by the factory unless prior written per

mission has been extended by MTD.

♦

♦

This warranty gives you specific iegi:

from state to state.

rights. You may also have other rights which vary

V

I WARNING {

TC PURCHASERS

OF INTERNAL COMBUSTION ENGINE EQUIPPED

MACHINERY OR DEVICES IN THE STATE OF CALIFORNIA

The equipment which you have just purchaser does not have a spark arrester, if this equipment is used on

any forest covered land, brush covered land, c r grass covered unimproved land in the State of California,

before using on such land, the California law requires that a spark arrester be provided. In addition, spark

arrester is required by law to be in effectivî working order. The spark arrester must be attached to the

exhaust system and comply with Section 4442 of the California Public Resources Code.

Page 3

IMPORTANT

It is suggested that this manual be read in its entirety before attempting to assemble or operate. Keep this manual

^ in a safe place for future reference and for ordering replacement parts.

This unit is shipped WITHOUT GASOLINE or 01L. After assembly, see separate engine manual for proper fuel and

engine oil recommendations.

Your log splitter is a precision piece of power equipment, not a plaything. Therefore exercise extreme caution at

all times.

SAFE OPERATION PRACTICES FOR LOG SPLITTERS

TRAINING

1. Know the controls and how to stop quickly-READ THIS OWNER'S MANUAL.

2. Do not allow children to operate. Do not allow

adults to operate it without proper instruction.

Only persons well acquainted with these rules of

safe operation should be allowed to use your log

splitter.

3. Never use your splitter for any other purpose

than splitting wood. It is designed for this use

only and any other use may cause an injury.

4. Only the operator is to be near your log splitter

during use. Keep all others, including pets, a

minimum of 20 feet away from your work zone.

Flying wood can be hazardous.

*^5. Don't step over your splitter when engine is

running. You may trip or accidentally activate

ram if you step over. If you need to get to the

other side, walk around.

PREPARATION

1. Do not wear loose fitting clothing that could get

caught on the moving parts.

Do not operate equipment when barefoot or

2.

wearing open sandals. Always wear safety shoes or

heavy boots. A dropped log can seriously injure

your foot.

Check the fuel before starting the engine. Do not

3.

fill the gasoline tank indoors, when the engine is

running, or while the engine is still hot. Wipe off

any spilled gasoline before starting the engine.

Use only in daylight or in good artificial light.

4.

Never operate your splitter on slippery, wet,

5.

muddy, or icy surfaces. Safe footing is essential in

preventing accidents. Never operate your splitter

while attached to a towing vehicle.

Always wear safety glasses or goggles while oper

6.

ating your log splitter. A piece of splitting log

could fly off and hit your eyes.

Both ends of each log must be cut square. This

7.

will prevent the log from flying out of thesplitter

while under pressure.

OPERATION

1. Do not change the engine governor settings or

overspeed the engine. Excessive engine speeds are

dangerous.

2. Never place hands or feet between log and split

ting wedge or between log and ram during forward

or reverse stroke. To do so may result in crushed

or amputated fingers or toes, or worse, you may

lose an arm or foot.

3. If the equipment should start to vibrate abnor

mally, stop the engine and check immediately for

the cause. Vibration is generally a warning of

trouble.

4. When cleaning, repairing or inspecting, make

certain ail moving parts have stopped. Disconnect

the spark plug wire, and keep the wire away from

the plug to prevent accidental starting.

5. Handle gasoline with care. It is highly flammable.

A. Use approved gasoline container.

B. Never remove cap or add gasoline to a running

or hot engine or fill fuel tank indoors. Wipe

up spilled gasoline.

C. Don't run engine in an enclosed area. Ex

haust gases contain carbon monoxide. This

odorless gas can be deadly when inhaled.

6. Stand behind the ram when operating. See draw

ings.

7. Be careful not to touch the muffler after the

engine has been running. It is HOT.

8. Never try to split two logs on top of each other.

One may fly out and injure you.

Page 4

9. Never attempt to split wood across the grain.

Some types of wood may burst or fly oit of

your splitter and result in injury to you or a

bystander.

10. Never leave your log splitter unattended wit ithe

engine running. Shut off the engine if you are

leaving your splitter, even for a short period of

of time. Someone could accidentally activate the

ram and be injured.

11. Only use your hand to operate the ram or co itrol

lever. Never use your foot or a rope or any other

extension device. This could result in your ir abil

ity to stop your splitter quickly enough and

cause an injury.

12. Only operate your splitter on the level ground and

not on the side of a hill. It could tip, or rolling

logs or poor footing could cause an accicent.

This also prevents the spillage of gas from the

tank.

MAINTENANCE and STORAGE

1. Don't operate your splitter in poor mechiinical

condition or when in need of repair.

2. Keep all nuts, bolts, screws, hose clamp;; and

hydraulic fittings tight to be sure equipment is

in safe working condition.

3. Replace all damaged or worn parts such cS hy

draulic hoses and fittings immediately with man

ufacturer approved replacement parts.

4.

Never store the equipment with gasoline in the

tank inside of a building where fumes may reach

an open flame or spark. Allow the engine to cool

before storing in any enclosure.

To reduce fire hazard keep engine free of grass,

5.

leaves, wood chips, excessive grease and oil.

The hydraulic system of your log splitter re

6.

quires the careful inspection along with the

mechanical parts. Be sure to replace frayed,

kinked, cracked or otherwise damaged hydraulic

components.

Fluid escaping from a very small hole can almost

be invisible. Do not check for leaks with your

hand. Escaping fluid under pressure can have

sufficient force to penetrate skin, causing serious

personal injury. Leaks can be located by passing

a piece of cardboard or wood over the suspected

leak and look for discoloration.

Should it become necessary to loosen or remove

8.

any hydraulic fitting or line, be sure to relieve

all pressure by shutting off the engine and moving

the control handle back and forth several times.

Don't remove the cap from the hydraulic tank or

9.

reservoir while your log splitter is running. Hot

oil under pressure could cause injury.

10. Never store outside without a waterproof cover.

Rain will cause rust on the inside of the cylinder.,

CAUTION

THIS UNIT SHOULD NOT BE TOWED ON ANY

STREET, HIGHWAY OR PUBLIC ROAD. ANY

LICENSING NI:EDED TO COMPLY WITH THE

EXISTING FEDERAL, LOCAL OR STATE VEH

ICLE REQUIRI MENTS IS THE SOLE RESPONSI

BILITY OF the; purchaser.

Page 5

>N, A-

FIGURE 1.

\

G

TOOLS REQUIRED

(1) Raw Hide or Plastic Hammer

(1) 3/4" Wrench or Adjustable Wrench

(1) Pipe Wrench

(1) Pair of Pliers

OTHERS MATERIALS NEEDED

One gallon of regular grade gasoline (for engine).

1-1/2 pints of SAE 30 or 10W30 oil (for engine)

Approximately 2 gallons of Dexron II automatic

transmission fluid (may be obtained at any local

service station or auto parts store)

Funnel

Pipe sealant

CONTENTS OF HARDWARE PACK (See figure 1):

A (1) Shoulder Bolt

B (1) Wave Washer

C (1) Ferrule

D (1) Hairpin Cotter

E (2) Flat Washers

F (1) Cotter Pin

G (2) Axle Push Caps

H (1) Spacer

ASSEMBLY INSTRUCTIONS

1

FIGURE 2.

M

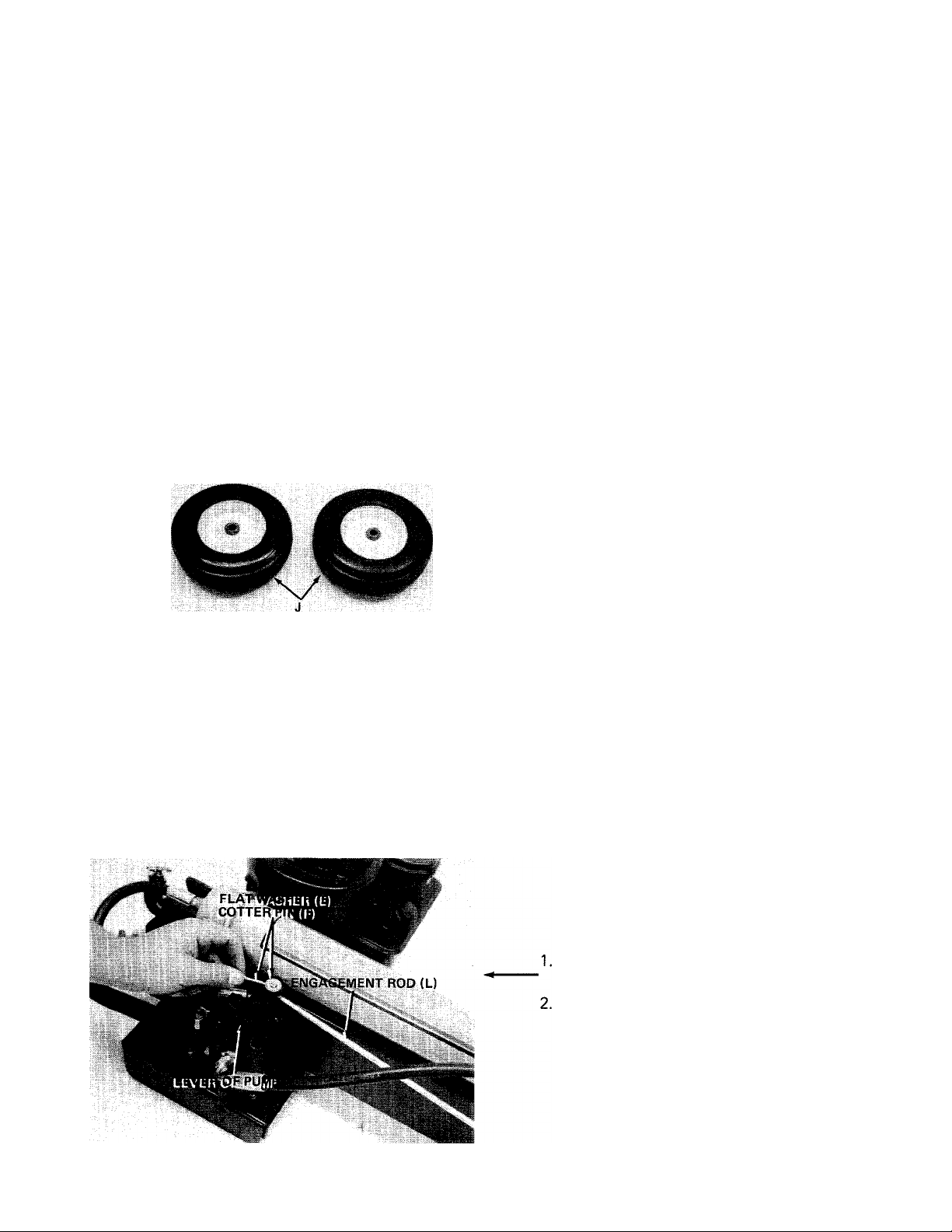

■LOOSE PARTS IN CARTON (See figure 2):

J (2) Wheels

K (1) Axle Shaft

L (1) Engagement Rod

M (1) Engagement Handle

Hook the bent end of the engagement rod (L)

into the lever on top of the pump. See figure 3.

Next, place flat washer (E) over the rod. Insert

the cotter pin (F) into the hole in the rod and

secure by bending the ends of the cotter pin in

opposite directions.

FIGURE 3.

Page 6

SHOULDER BOLT (A)

FIGURE 4.

— ENGAGEMENT HANDLE IM)

Place the flattened end of the engagement handle

(M) down through the slotted bracket beside the

beam. Secure the bottom hole in the handle to

the beam with shoulder bolt (A) and wave washer

(B) as shown in figure 4.

WAVE WASHER (B)

HAIR PIN COTTER (D)

FIGURE 5.

HAMMER

AXLE PUSH CAP (G)

Place the engagement handle in the notch in the

slotted bracket. See figure 5. Thread the ferrule

(C) onto the engagement rod until the ferrule

lines up with the hole on engagement handle.

Secure the ferrule (C) to engagement handle

with flat washer (E) and hairpin cotter (D).

See figure 5.

Using a raw hide or plastic hammer, tap one axle

push cap (G) on one end of axle shaft (K). See

figure 6.

AXLE

SHAFT (K)

FIGURE 6.

Page 7

AXLE PUSH CAP

(G)

FIGURE?.

LEFT .

HAND SIDE

OF

SPLITTER ' j ,

4

SPACER(H)

7. Slide one wheel onto the axle shaft, then the

spacer (H). See figure 7.

WHEEL

8. Slide the axle through the frame from the left

hand side of the splitter (as viewed from standing

behind it). Spacer should be on the engine side

of the splitter. See figure 8.

FIGURES.

N

AXLE PUSH CAP (H)

FIGURES.

9. Place the other wheel on the axle and secure with

push cap (H). See figure 9.

Page 8

OPERATION

BEFORE STARTING

NOTE

Refer to engine manual packed with

log splitter for complete instructions

for the care and maintenance of en

gine. READ DIRECTIONS CARE

FULLY.

1.

Fill sump with oil as instructed in the sepa ate

engine manual. Drain and fill the engine from

the same opening. See figure 10.

TO START ENGINE

1. Place throttle control lever (on engine) in RUN

position, towards the front of splitter. See figure

12.

THRO

FIGURE 12.

FIGURE 10.

2.

Fill fuel tank, using clean, fresh, regular g ade

automotive gasoline. Fill tank completely.

Fill reservoir tank on log splitter. Remove the

3.

breather plug from breather tube. See fijure

11. Pour approximately 2 gallons of De);ron

automatic transmission fluid ONLY into brea:her

tube.

A

DO NOT operate log splitter without

proper amount of oil in reservior tank

beam.

CAUTION

me

Open the breather valve. Valve must be open

2.

when running log splitter. Valve must be closed

when transporting log splitter. See figure 13.

Grasp starter handle, place one foot on wheel and

3.

pull starter handle with a quick, full arm stroke.

Return rope slowly to the engine.

VALVE IN CLOSED

POSITION

VALVE IN OPEN

POSITION

t

BREATHER PLUG AND VALVE

NOTE: Valve has left hand threads.

Turn clockwise to close.

FIGURE 11.

FIGURE 13.

TO STOP ENGINE

1. Move throttle control lever to STOP position.

2. Remove high tension wire from spark plug to

prevent accidental starting by children while

equipment is unattended.

Page 9

USING YOUR LOG SPLITTER

CAUTION

A

This unit should not be towed on any

street, highway or public road. Any

licensing needed to comply with the

existing federal, local or state vehicle

requirements is the sole responsibility

of the purchaser.

Your log splitter is designed for safe, effecient

operation. CARE, OF COURSE, MUST BE EXER

CISED THAT HANDS AND FEET ARE KEPT

AWAY FROM MOVING PARTS.

Engagement handle has three positions: (See figure 14)

Forward - ram moves toward wedge.

Neutral - ram stops in place.

Reverse - ram returns.

The ram should take approximately 22 seconds to

make a complete cycle. This speed may vary de

pending on throttle setting and temperature of oil.

NOTE

If you lock the engagement handle in the reverse slot,

the ram will return until it hits the return stroke stop

plunger, which will throw the engagement handle

into neutral automatically.

t WARNING j

Never attempt to cut a log in half

with the log splitter.

Never stand next to the ram when

operating. Always stand behind the

ram.

ENGAGEMENT HANDLE

IN NEUTRAL POSITION.

ENGAGEMENT HANDLE

HELD IN FORWARD

POSITION.

•n

ENGAGEMENT HANDLE

LOCKED IN REVERSE

POSITION.

STROKE RETURN STOP

PLUNGER.

FIGURE 14

Maximum length that can be split is 20".

1.

Set throttle at maximum speed.

Place log on beam and hold in place with right

2.

hand.

Slowly move engagement handle forward until

3.

ram rests against log. Release engagement handle

(Neutral).

'4.

Remove your hand from the log and step behind

the ram.

5.

Move engagement handle forward until log is split.

Move the engagement handle to the rear to return

6.

ram.

1

MAINTENANCE

\ WARNING {

Always stop engine and disconnect

spark plug wire before performing any

maintenance or adjustments.

ENGINE OIL

Change oil first two (2) hours of operation and check

oil level every five (5) operating hours or each time

equipment is used.

Change oil every twenty-five (25) operating hours or

sooner if equipment is operated in extremely dusty

or dirty conditions.

Refer to engine manual for quantity and type of oil.

LOG SPLITTER RESERVOIR OIL

Check oil in log splitter reservoir before every use.

See figure 15.

1. Block up front of log splitter so beam is level.

2. Remove check pipe plug in rear of beam. See

figure 5. If oil starts to come out of check pipe

plug hole, oil level is correct. IF IT DOES NOT,

add oil to breather tube (see figure 11) until oil

starts out.

NOTE

Use hydraulic sealant tape or pipe

sealant on pipe plug threads.

Page 10

3. Replace check pipe plug. Remove block from

under front of beam.

OIL CHECK PIPE PLUG

STRAINER TUBE ASSEMBLY

If the ram does not move back and forth smoothly,

the strainer tube assembly may be clogged.

To clean, follow instructions for changing the reservoir

oil, step number 1 through 3. Clean the strainer tube

assembly and reassemble using a hydraulic pipe sealant

on the threads.

HOSE CLAMPS

Check the hose clamps on the bottom of the pump

for proper tightness before each use.

Hose clamps on the return hose should be checked

once a season.

STROKE RETURN STOP PLUNGER

If the engagement handle does not return to neutral

(from reverse) before the pressure relief bypass opens,

loosen the hex lock nut, and back out the hex bolt

one or two turns. See figure 17.

FIGURE 15

Change oil in the reservoir every (100) hou s of

operation.

1. Remove the hose clamp at inlet hose (bottom

hose on rear of beam). See figure 16.

NOTE

Be prepared to catch oil in a suitable

container.

2. Pull off inlet hose from strainer tube assembly^ and

catch oil in a suitable container. See figure 1£.

3. With an adjustable wrench remove the strainer

tube assembly. See figure 16.

NOTE

The strainer tube assembly is 42" long.

4. Drain oil, clean strainer tube and reassemble

using a hydraulic pipe sealant on the threads.

5. Remove the breather plug from breather :ube.

See figure 7. Pour approximately 2 galloris of

Dextron II transmission fluid ONLY into breither

tube.

NOTE

When the pressure relief valve opens,

a loud high pitohed sound is heard and

engine labors.

Tighten hex lock nut and operate log splitter. Repeat

if necessary.

HEX BOLT

/if I

STROKE RETURN

STOP PLUNGER

FIGURE 17

RAM OPERATION

If the ram does not move smoothly, run the ram its

full stroke several times to clear out air in the system.

Be sure the breather valve is open.

If this does not correct the problem, see Strainer Tube

Assembly paragraph.

HEX NUT

CARBURETOR ADJUSTMENTS

I WARNING {

If any adjustments are made to the

engine while the engine is running

(e.g. carburetor), keep clear of all

moving parts. Be careful of heated

surfaces and muffler.

Refer to engine manual packed with your unit for

carburetor adjustment information.

10

Page 11

BELT REPLACEMENT

1. Disconnect the spark plug wire from the spark

plug and ground against the engine block.

''-2. Drain the gasoline from the fuel tank or place a

piece of plastic under the cap to prevent leakage.

3. Tip the splitter on one side.

4. Remove four self-tapping screws from the bottom

belt cover and frame. See figure 18.

8. Slide the engine outward to tighten the new belt

until there is approximately 1/2.'/-. deflection.

Tighten engine mounting bolts securely.

FIGURE 20

FIGURE 18

^5. Using a 9/16" wrench, remove the engine pulley

by removing the hex bolt and lock washer. See

figure 19. Slip the pulley and belt off.

NOTE

Be careful not to lose the square key

on the crankshaft.

OFF-SEASON STORAGE

In event engine is to be stored for any length of time

(30 days or more), prepare as follows:

1. Drain gasoline by tipping or by siphon hose, then

run engine until remainder is used and tank and

carburetor are empty.

A

Drain gasoline into container outdoors

from fire or flame.

2.

Drain carburetor by running engine until it stops

from lack of fuel.

3.

Protect the inside of engine for storage by

removing spark plug and pouring one ounce of

SAE 30 oil through spark plug hole into cylinder.

Crank engine, without starting, several times to

spread oil over cylinder walls.

4.

Never store outside without a waterproof cover.

CAUTION

»kFIGURE 19

6.

Loosen the three engine mounting bolts using a

1/2" wrench. See figure 20.

7. Install the new belt.

11

A

When storing any type of power equip

ment in an unventilated or metal

storage shed, care should be taken to

rust proof the equipment. Using a

light oil or silicone, coat the equip

ment, especially springs and bearings.

CAUTION

Page 12

TROUBLE SHOOTING CHART

SYMPTOM

1. Engine fails to start

2. Hard starting or loss of

power.

3. Engine overheats

4 Will not split logs

POSSIBLE CAUSE(S)

A. Check iuel tank for gas.

B. Spark plug lead wire

disconnected.

C. Faulty ipark plug.

A. Spark p lug wire loose.

B. Dirty a r cleaner.

A. Carbun tor not adjusted

prope riy.

B. Airflov/ restricted.

C. Engine oil level low.

A. Relief valve setting

incor ect.

B. Pump setting incorrect.

SOLUTION

A. Fill tank if empty.

B. Connect lead wire.

C. Spark should jump gap between

control electrode and side electrode.

If spark does not jump, replace the

spark plug.

A. Connect and tighten spark plug wire.

B. Clean air cleaner as described in

engine manual.

A. Adjust carburetor. See engine manual.

B. Remove blower housing and clean as

described in the engine manual.

C. Fill crankcase with the proper oil.

A. Shim valve with .010 flat washer.

B. Adjust pump setting.

5. Leaking cylinder

NOTE: For repairs beyond the minor adjustments isted above,please contact your local service dealer.

A. Broken seals.

B. Scored cylinder.

A. Replace seals.

B. Replace cylinder.

12

Page 13

Model 638

STAMPED PART NUMBER AND DATE CODE

No Letters - HEiL - Will Require Cylinder “0"-Ring Kit 753-0369

U2

'‘^U2 ’‘■2

STAMPED PART NUMBER AND DATE CODE

Letters "AF" - AGRI-FAB - Will Require Cylinder “0"-Ring Kit 753-0368

2-1/2" DIA. CYLINDER

PARTS LIST FOR MODEL 638

REF.

NO.

1

2

PART NO. DESCRIPTION

717-0804

753-0368

753-0369 2-1/2" Cyl. Kit "0"-Ring Set

Cylinder Ass'y- Comp.

2-1/2" Cyl. Kit "0"-Ring Set

(Agri-Fab)

(Heil)

13

Page 14

Model 638

NOTE

This instruction manual covers various models, and

all specifications shown do not necessarily apply to

your model. Specifications subject to change without

notice or obligation.

14

Page 15

Model 638

PARTS LIST FOR MODEL 638 LOG SPLITTER

REF.

NO..

2

PART

08118

1

710-0152

NO.

COLOR

CODE

DESCRIPTION

Grip

Hex Bolt 3/8-24 X 1.00"

Lg.*

3 710-0376

Hex Bolt 5/16-18 X 1.00"

Lg.*

710-0599 Hex Wash. Hd. TT Tap Scr. 33

4

1/4-20 X .50" Lg.

710-0624 Hex Bolt 5/16-24 X 1.5

5

Lg.*

6

710-0649

Hex Wash. Hd. TT Tap 35

Scr. 3/8-16 X .87" Lg. 3/4-16 M-Boss

7 710-0938

Set Scr. 1/4-28 X .25"

Cup

711-0628 Adjustment Ferrule 5/16-1

8

Thd.

g 712-0123

712-0267 Hex Nut 5/16-18 Thd.*

10

712-0798 Hex Nut 3/8-16 Thd.*

11

717-0803 Valve in Head Pump Ass'y-

12

717-0804

13

14

714-0133

Hex Nut 5/16-24 Thd.*

Cylinder Ass'ySq. Key 3/16 X 1-1/2"

Lg.

714-0104

15

726-0146

16

726-0173

17

726-0214 Push Cap .625" Dia.

18

Hair Pin Cotter

Hose Clamp 3/4" I.D.

Hose Clamp 1,0" I.D. 43

Black

736-0264 Fl.-Washer5/16" I.D. x

IS

5/8" O.D.

732-0252

20

Compression Spring .64

I.D. X .81 Lg. 46 Engine 3-1/2 H.P.

21

734-0736

22 741-0116

727-0291 Suction Hose 3/4" I.D.

23

Wheel Ass y. Comp. 10.x2.75 47 754-0278

Flange Bearing 48 756-0426 1/2" V-Pulley 5/8'^ I.D.

(Tank to Pump) N 49 756-0425

727-0292

24

Return Hose 1/2" I.D.

(Pump to Tank)

25

736-0232

Wave Wash. .53" I.D. x

.78" O.D. 51

727-0294 High Pressure Hose

26

(Forward & Return)

736-0105 Bell.-Wash. .400" I.D. x

27

.88" O.D. 54 714-0507

NEW

PART

REF.

NO.

PART

NO.

COLOR

CODE

28 736-0119

29 736-0159

30 736-0169 L.-Wash. 3/8" I.D.*

32 737-0104 Plug 1/4 NPTF Sq. Hd.

737-0187

34 737-0161

737-0182

737-0183 Adapter - or Boss to MJtC

36

8 37

737-0184 Adapter 1/2 Tube 9/16-18

737-0185 90° Elbow Adapter 1/2"

38

39 737-0186

N Nipple

N

738-0147 Shld. Scr. .498 Dia. x

40

41 738-0406

42 747-0455 Cylinder Support Rod

747-0458 Axle Shaft 5/8" Dia. x

749-0625 Engagement Lever .88''

44

750-0118 Spacer 5/8" I.D. x 7/8"

45

N 50

781-0001

747-0457

52 781-0008

N

15234

53

DESCRIPTION

L.-Wash. 5/16" I.D.*

Fl.-Wash. .341" |.D. x

.88" O.D.

Female Adapter 1/4

NPTF N

Breather Valve 1/4

NPTF-M

Adapter 3/4 Tubing to

9/16-18 to 7/16-20

O.R. M-Boss

Tube 1/2 NPTF

90° Elbow - 1/2 NPTF

.170" Lg.

Return Stroke Stop

Plunger

X 25.25" Lg. N

O.D. x17"Lg. - N

O.D. x.90"Lg.

(4L) Belt 1/2" V X 30" Lg. N

X 3-1/4" O.D.

1/2" V-Pulley 7/8" I.D. x

3-1/4" O.D.

Oil Tank & Frame Ass'y.

Comp. N

Engagement Rod 5/16-2^

Thd.

Belt Cover

Strainer Tube Ass'y.

Cotter Pin 3/32" Dia. x

.75" Lg.*

NEW

PART

N

N

N

N

N

N

N

N

N

‘For faster service obtain standard nuts, bolts and washers locally. If these items cannot be obtained locally, order ly part-

number and size as shown on parts list.

The engine is not under warranty by the log splitter manufacturer. If repairs or service is needed on the

engine, please Contact your nearest authorized engine service outlet. Check the "Yellow Pages" of your

telephone book under "Engines - Gasoline.”

Find It Fast

In The

Yellow Pages

15

Page 16

PARTS INFORMATION

POWER EQUIPMENT PARTS AND SERVICE

Parts and service are available through the authorized ser vice

firms listed below. All orders should specify the model number of

your unit, part numbers, description of parts and the quantlly of

each part required.

NOTE: If any parts are found to be missing or defective upon assembly of this unit, write to advise the factory so

that immediate replacement can be made.

ALABAMA BIRMINGHAM

Auto Electric & Carburetor Co. ... 2625 4th Ave. S

............

ARKANSAS NORTH LITTLE ROCK

Sutton’s Lawn Mower Shop........... 5301 Roundtop Drive

Box 368, Rt. 4

............

CALIFORNIA PORTERVILLE

Billious

...........................................

75 North D Street ....

COLORADO DENVER

Spitzer Industrial Products Co.... 6601 N.

Washington St

...........

FLORIDA JACKSONVILLE

Radco Distributors

......................

4909 Victor St.

Box 5459

..................

OPA LOCKA

Small Eng. Dist

..............................

2351 N.W. 147th St. ..

GEORGIA EAST POINT

East Point Cycle & Key

.................

2834 Church St

..........

ILLINOIS LYONS

Keen Edge Co.............................8615 Ogden Ave.........

INDIANA ELKHART

Parts & Sales Inc

........................

2101 Industrial Pkwy..

IOWA DUBUQUE

Power Lawn & Garden Equip

........

2551 J.F. Kennedy ...

LOUISIANA MONROE

Mid-South Power

..........................

1500 Arkansas St. ...

NEW ORLEANS

Suhren Engine Co

MARYLAND TAKOMA PARK

Center Supply Co........................ 6867 New Hampshire

..........................

8330 Earhart Blvd. ...

^y0

...........................

MASSACHUSETTS SPRINGFIELD

Morton B. Collins Co

...................

300 Birnie Ave

............

MICHIGAN LANSING

Lorqnz Service Co

.........................

2500 S. Pennsylvania .

MOUNT CLEMENS

Power Equipment Dist

................

340 Hubbard...............

MINNESOTA HOPKINS

Hance Distributing Inc................. 420 Excelsior Ave. W.

MISSISSIPPI BILOXI

Biloxi Sales & Service, Inc

............

506 Caillavet St

..........

MISSOURI KANSAS CITY

Automotive Equip. Service .............3117 Holmes St

..........

ST. JOSEPH

Ross-Frazier Supply Co..............8th and Monterey ....

ST. LOUIS

Henzier, Inc.................................2015 Lemay Ferry Rd.

NEW JERSEY BELLMAWR

Lawnmower Parts Inc

.................

717 Creek Rd

.............

NEW MEXICO ALBUQUERQUE

Spitzer Eng. & Parts.................... 1023 Third Ave. N.W. .

NEW YORK CARTHAGE

Gamble Dist., Inc.........................West End Ave..............

SCHOHARIE

Red Fox Parts Dist

........................

Rt. 30 P.O. Box 527

3 5233

72117

9 3257

8 3229

3 2207

3 3054

3 3344

6 0534

4 3516

Î2001

51201

.50118

5 0912

C1107

^8910

^8043

J5343

5 9533

(4109

(4503

(3125

(8030

i 7103

13619

12157

-----

BRIGGS AND STRATTON, TECUMSEH AND PEERLESS PARTS

AND SERVICE

Briggs & Stratton, Tecumseh and Peerless parts and service

should be handled by your nearest authorized engine service firm.

Check the yellow pages of your telephone directory under the

listing Engines—Gasoline, Briggs & Stratton or Tecumseh

Lauson.

NORTH CAROLINA GOLDSBORO

Smith Hardware Co

.......................

515 N. George St

GREENSBORO

Dixie Sales Company

....................

335 N. Green

..............

OHIO CARROLL

Stebe's Mid-State Mower Supply . Box 366, 71 High St... .43112

CLEVELAND

Bleckrie, Inc

...................................

7900 Lorain Ave

WADSWORTH

National Central

.............................

687 Seville Rd

...........

YOUNGSTOWN

Burton Supply Co

..........................

1301 Logan Ave.

Box 929

......................

OKLAHOMA MUSKOGEE

Victory Motors, Inc

.........................

605 S. Cherokee

OREGON PORTLAND

Kenton Supply Co

.........................

8216 N. Denver Ave. . . .97217

PENNSYLVANIA HARRISBURG

EECOInc........................................ 4021 N.6thSt

..............

PHILADELPHIA

Thompson Rubber Co.................... 5222-24 N. Fifth St

PITTSBURGH

Bluemont Co..................................11125 Frankstown Rd.. 15235

PUNXSUTAWNEY

Frank Roberts & Sons

..................

R.D. 2

..........................

SCRANTON

Scranton Auto Ignition Co

..............

1133-35 Wyoming Ave. 18509

TENNESSEE KNOXVILLE

Master Repair Service

...................

2000 Western Ave

MEMPHIS

American Sales & Service, Inc. ... 3035-43 Bellbrook ....38116

TEXAS DALLAS

Marr Brothers, Inc

..........................

423 E. Jefferson

FORT WORTH

Woodson Sales Corp..................... 1702 N. Sylvania

HOUSTON

Bullard Supply Co.......................... 2409 Commerce St. ...77003

SAN ANTONIO

Engine House Inc

..........................

8610 Botts Lane

P.O. Box 17867

UTAH SALT LAKE CITY

A-1 Engine & Mower Co

................

439 E. 900 So

............

VIRGINIA ASHLAND

RBI Corp........................................'101 Cedar Run Dr

WASHINGTON SEATTLE

Bailey’s Inc

....................................

1414 14th Ave

.............

WISCONSIN APPLETON

Automotive Supply Co

...................

123 S. Linwood Ave.

P.O. Box 798

..............

CHILTON

Horst. Dist...................................... 444 N. Madison

........

.........

........

.....

.....

.........

........

..........

......

..........

27530

27402

44102

44281

44501

74401

17110

19120

15767

37921

75203

76111

78217

84111

23005

98122

54911

53014

WARRANTY

The purpose of warranty is to protect the customer from

time of manufacture. It does not provide for the unlimite

sibility of the customer. The manufacturer cannot assun

the manufacturer’s fault, it’s the manufacturer’s responsi

CLAIMS AGAINST THE MANUFACTURER’S WARRANTY

INCLUDES:

1. Replacement of Missing Parts on new equipment.

2. Replacement of Defective Parts within the warranty p eriod.

3. Repairof Defects within the warranty period.

MTD PRODUCTS INC

P.O. BOX 36900

PARTS AND SERVICE POLICY (0483)

defects in workmanship and materials, defects which are NOT detected at the

J and unrestricted replacement of parts. Use and maintenance are the responle responsibility for conditions over which it has no control. Simply put, if it’s

bility; if it’s the customer’s fault, it’s the customers’s responsibility.

All claims MUST be substantiated with the following

information;

1. Modei Number of unit involved.

2. Date unit was purchased or first put into service.

3. Date of failure.

4. Nature of failure.

CLEVELAND, OHIO 44136

Loading...

Loading...