Page 1

OLIVER’S

MANUAL

3 1/2 H.P.

LOG SPUTTERS

.75

Model Numbers

242-635A

24635A

Important:

Read Safety Rules and

Instructions Carefully

Thank you for purchasing an

American built product.

PRINTED IN U.S.A.

_____________________________________

FORM NO. 770-1814

Page 2

INDEX

Safe Operation Practices ..............................................3

Assembly Instructions ...................................................4

Operation

Adjustments

......................................................................

.....

............................................................

r

LIMITED WARRANTY

♦

♦

♦

♦

♦

♦

♦

♦

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repairer replace, at its option, free of charge, F.O.B. factory or authorized service firm, any

part or parts found to be defective in material or workmanship. Transportation charges for

the movement of any power equipment unit or attachment are the responsibility of the pur

chaser. Transportation charges for any parts submitted for replacement under this warran

ty must be paid by the purchaser Unless such return is requested by MTD PRODUCTS INC.

This warranty will not apply to any part which has becomejnoperative due to misuse, ex

cessive use, accident, neglect, improper maintenance, alterations, or unless the unit has

been operated and maintained in accordance with the instructions furnished. This warran

ty does not apply to the engine, motor, battery, battery chargeror component parts thereof.

Please refer to the applicable manufacturer’s warranty on these items.

Maintenance ..................................................................5

Off-Season Storage

4

5

Illustrated Parts

Repair Parts List

.............................

....................................................

.................................................

..........................

8

10, 12

11, 13

♦

♦

♦

♦

♦

♦

This warranty will not apply where the unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. If

you do not know the dealer or distributor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will not be accepted by the factory unless prior written per

mission has been extended by MTD.

This warranty gives you specific legal rights. You may also have other rights which vary

from state to state.

V

WARNING

TO PURCHASERS

OF INTERNAL COMBUSTION ENGINE EQUIPPED

MACHINERY OR DEVICES IN THE STATE OF CALIFORNIA

The equipment which you have just purchased does not have a spark arrester. If this equipment is used on

any forest covered land, brush covered land, or grass covered unimproved land in the State of California,

before using on such land, the California law requires that a spark arrester be provided. In addition, spark

arrester is required by law to be in effective working order. The spark arrester must be attached to the

exhaust system and comply with Section 4442 of the California Public Resources Code.

Page 3

IMPORTANT

It is suggested that this manual be read in its entirety before attempting to assemble or operate. Keep this

manual in a safe place for future reference and for ordering replacement parts.

This unit is shipped WITHOUT GASOLINE or OIL. After assembly, see operating section of this manual

for proper fuel-and engine oil recommendations.

Your log splitter is a precision piece of power equipment, not a plaything. Therefore exercise extreme caution

at all times.

SAFE OPERATION PRACTICES FOR LOG SPLITTERS

4.

TRAINING

1. Know the controls and how to stop quicklyREAD THE OWNER'S MANUAL

2. Do not allow children to operate. Do not allow

adults to operate it without proper instruction.

Only persons well acquainted with these rules of

safe operation should be allowed to use your log

splitter.

When cleaning, repairing or inspecting, make

certain all moving parts have stopped. Disconnect

the spark plug wire, and keep the wire away from

the plug to prevent accidental starting.

5.

Handle gasoline with care. It is highly flammable.

A. Use approved gasoline container.

B. Never remove cap or add gasoline to a running

or hot engine or fill fuel tank indoors. Wipe

up spilled gasoline.

C. Open doors if engine is run in garage-

exhaust fumes are dangerous. Do not run

engine indoors.

.^REPARATION

Do not wear loose fitting clothing that could get

1.

caught on the moving parts.

Do not operate equipment when barefoot or wear

2.

ing open Sandies. Always wear substantial foot

wear.

Check the fuel before starting the engine. Do not

3.

fill the gasoline tank indoors, when the engine is

running, or while the engine is still hot. Wipe off

any spilled gasoline before starting the engine.

Use only in daylight or in good artificial light.

4.

Never operate the equipment in the rain. Always

5.

be sure of your footing.

OPERATION

1. Do not change the engine governor settings or

overspeed the engine. Excessive engine speeds are

dangerous.

Do not put hands or feet near rotating or moving

parts.

3. If the equipment should start to vibrate abnor

mally, stop the engine and check immediately for

the cause. Vibration is generally a warning of

trouble.

6.

Always stand beside the controls when operating

the log splitter.

7.

Be careful not to touch the muffler after the

engine has been running. It is HOT.

MAINTENANCE and STORAGE

1. Keep all nuts, bolts and screws tight to be sure

equipment is in safe working condition.

2. Never store the equipment with gasoline in the

tank inside of a building where fumes may reach

an open flame of spark. Allow the engine to cool

before storing in any enclosure.

3. To reduce fire hazard keep engine free of grass,

leaves, wood chips, excessive grease and oil.

4. Do not change the engine governor settings or

overspeed the engine. Excessive engine speeds

are dangerous.

5. Never store outside without a waterproof cover.

Rain will cause rust on the unit.

Page 4

ASSEMBLY

USING YOUR LOG SPLITTER

NOTE

This unit shipped WITHOUT GASSOLI NE or OIL. After assembly, see

separate engine manual for proper fuel

and engine oil recommendations.

1. Remove the log splitter, loose parts, and literature

from the carton. Make certain all parts and

literature have been removed before the carton is

discarded.

2. Thread the engagement handle into the engage

ment handle bracket as shown in figure 1.

t\GACf N'lF NT HANDLE

NOTE

Reference to right or left hand side of

the unit is determined when standing

behind the unit, at the engine.

Your log splitter is designed for safe, efficient

operation. CARE, OF COURSE, MUST BE EXER

CISED THAT HANDS ARE KEPT AWAY FROM

MOVING PARTS.

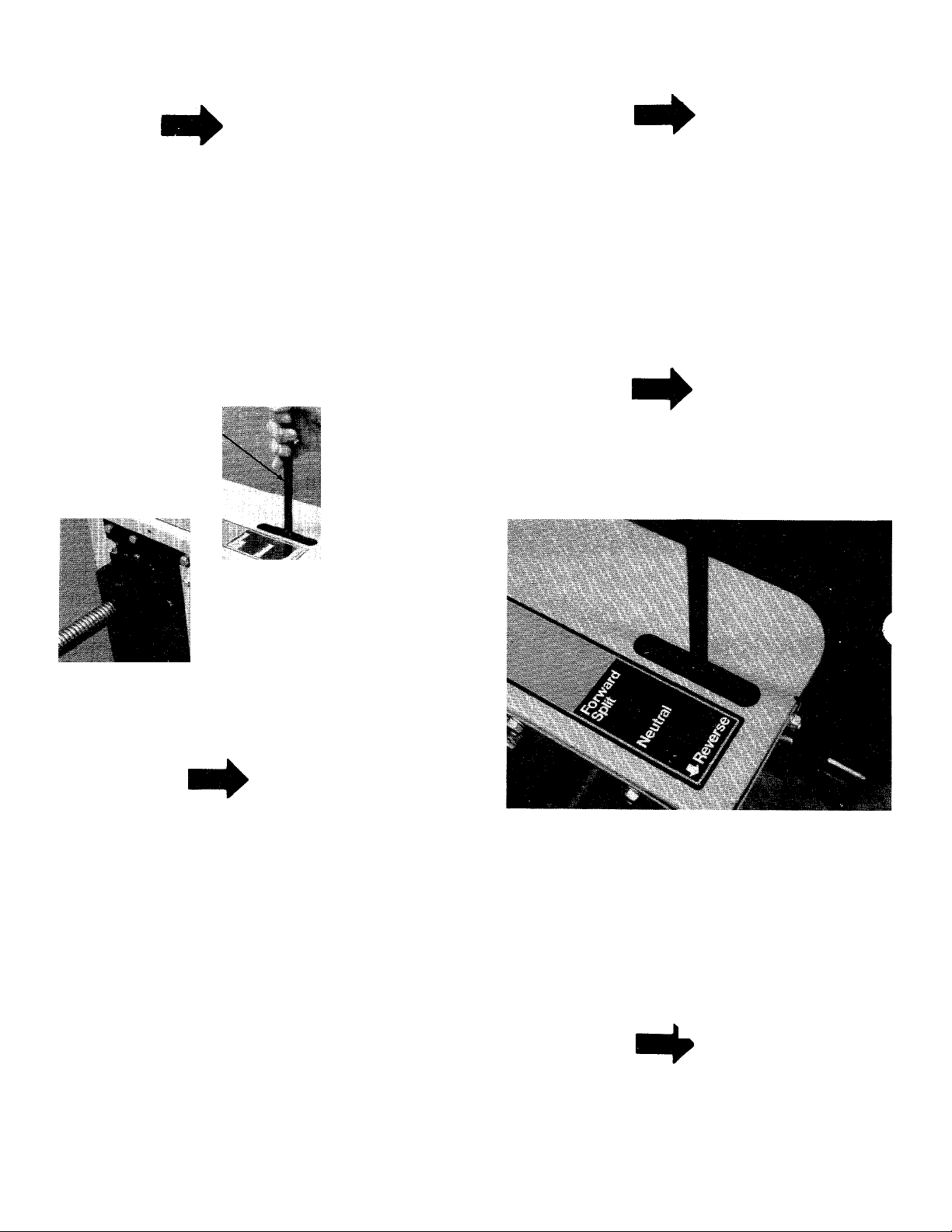

Engagement handle has three positions: (See figure 2)

Forward—Wedge moves toward engine.

Neutral—Wedge stops in place.

Reverse—Wedge returns.

NOTE

When the engagerrtent handle is

released, it will automatically return

to "NEUTRAL" position.

I

FIGURE 1

OPERATION

NOTE

Refer to engine manual packed with

log splitter for complete instructions

for the care and maintenance of

engine. READ DIRECTIONS CARE

FULLY.

Fill sump with oil as instructed in the separate

1.

engine manual.

Fill fuel tank, using clean, fresh, regular grade

2.

automotive gasoline. Fill tank completely.

Before operating log splitter for the first time,

lubricate the two large screws on the wedge and

screw assembly with engine oil. Screws must be

oiled at least every two operating hours or more

often if necessary.

Start engine as instructed in the separate engine

manual.

To stop engine, move throttle control lever to

5.

STOP position. Disconnect and ground the spark

plug wire to prevent accidental starting while

equipment is unattended.

FIGURE 2

Maximum length that can be split is 24".

1. Set throttle at maximum speed.

2. Place log on frame assembly.

3. Stand beside the engagement handle on the left

side of the unit.

4. Move engagement handle forward until log is split,

then release handle.

NOTE

After the log is split, do not keep the

engagement handle in the forward

position or the wedge assembly will be

jammed.

5. Move the engagement handle to the reverse

position to return ram.

Page 5

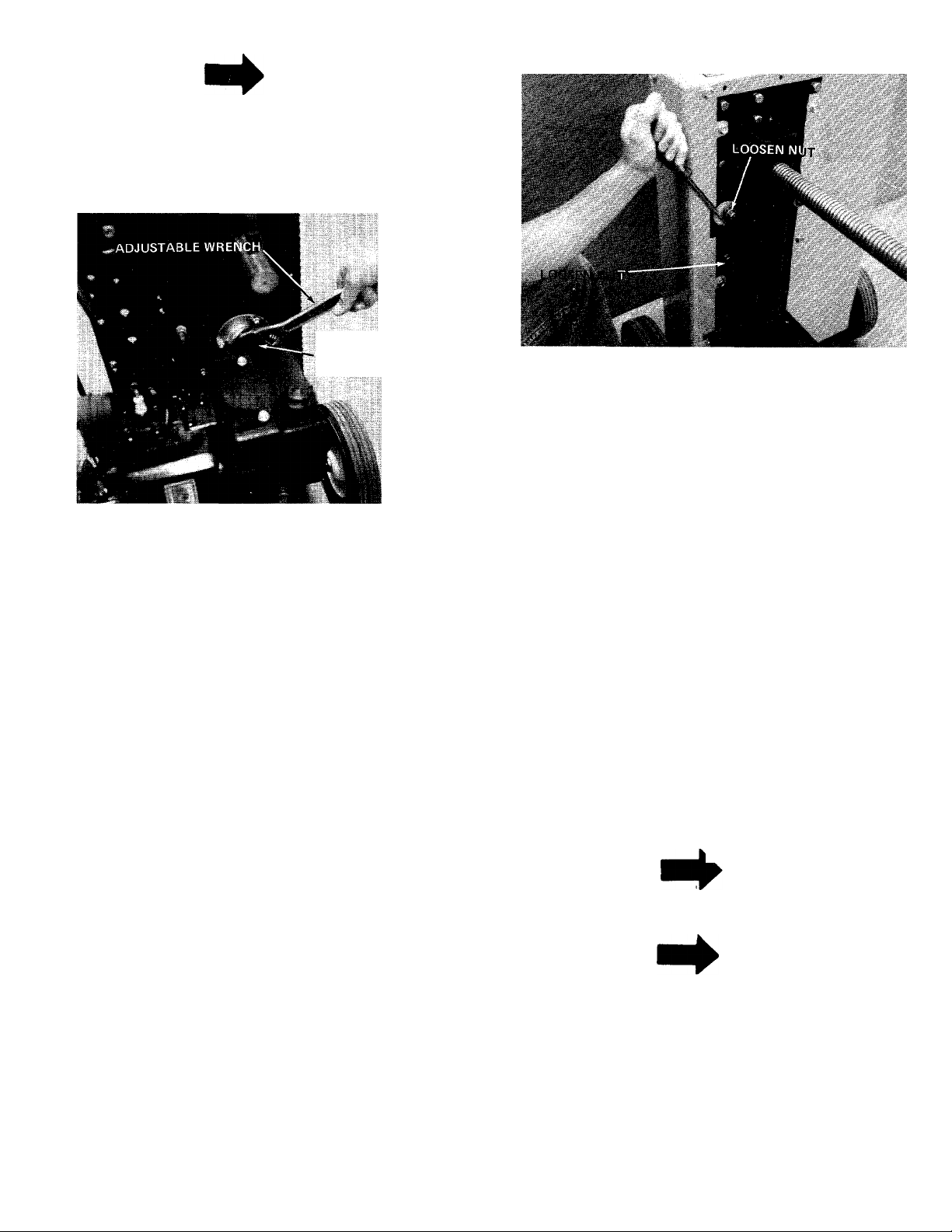

NOTE

If the wedge assembly becomes

jammed, turn the jack shaft spindle

assembly counterclockwise until the

wedge can be returned. See figure 3.

A large adjustable wrench is required.

JACK SHAFT SPINDLE

ASSEMBLY

FIGURE 4

MAINTENANCE

\ WARNING \

FIGURE 3

WARNING

Never attempt to cut a log in half

against the grain (cross ways). Never

stand next to the log when operating

the splitter.

ADJUSTMENTS

CARBURETOR ADJUSTMENTS

t warning!

If any adjustments are made to the

engine while the engine is running

(e.g. carburetor), disengage all clutches.

Keep clear of all moving parts. Be

careful of heated suVfaces and muffler.

Refer to engine manual packed with your unit for

carburetor adjustment information.

CHAIN ADJUSTMENT

The chain must be adjusted after the first hour of

/•^“^ial operation and every ten hours thereafter.

adjust the chain, loosen the two nuts shown in

figure 4. Place a screwdriver on the chain adjuster as

shown in figure 4. Pivot the chain adjuster by pulling

downward on the screwdriver to take the slack out of

the chain. Tighten the two nuts.

®

Always stop engine and disconnect

spark plug wire before performing any

maintenance or adjustments.

ENGINE OIL

Change oil first two (2) hours of operation and check

oil level every five (5) operating hours or each time

equipment is used.

Change oil every twenty-five (25) operating hours or

sooner if equipment is operated in extremely dusty or

dirty conditions.

Refer to engine manual for quantity and type of oil.

WEDGE AND SCREW ASSEMBLY

Lubricate the two screws on the wedge and screw

assembly with engine oil every two operating hours or

more often if necessary.

BELT REPLACEMENT

NOTE

If belt replacement is required, it is

advisable to replace both belts at the

same time,

NOTE

Reference to right or left hand side of

the unit is determined when standing

behind the unit, at the engine.

It is suggested that all instructions be read through

before beginning belt replacement.

1. Disconnect and ground the spark plug wire against

the engine block.

2. Using a 1/2" wrench, remove the top cover by

removing the five self tapping screws which secure

it to the side covers.

Page 6

.1 I'l •' ‘ .* ’•’ ■' ■,■'■ ■'

FIGURE 5

3. Block the frame of the unit on the left hand side.

Remove the left wheel by removing the cotter pin

and flat washer. Slide wheel off. See figure 6.

5. Remove the 5-1/2" bolt and spacer, located on the

left hand side of unit, which act as a belt keeper.

Two 9/16" wrenches are required. See. figure 8.

FIGURE 8

COTTER PIN

FIGURE 6

4. Using a 1/2" wrench, remove the right and left

hand side covers. See figure 7.

LEFTSIDE COVER^

^-------\—

6. Remove the two idler pulleys as shown in figure

9. Two 9/16" wrenches are required.

FIGURE 9

RIGHT SIDECOVER

FIGURE 7

,V- -

7. Hold the engagement lever in the forward positio.

(spark plug wire must be disconnected). Pull the

recoil starter rope to rotate the chain until the

master link can be located. Remove the master

link and chain. See figure 10.

Page 7

MASTER LINK

FIGURE 10

8. Remove the two belt keepers on the right hand

side of frame using two 7/16" wrenches. See

figure 11.

10. Block up the front of the frame as shown in figure

13. Remove the three bottom bolts, lock washers

and nuts. See figure 13.

FIGURE 13

FIGURE 11

9. Remove the top three bolts, lock washers and nuts

as shown in figure 12. Two 9/16" wrenches are

required.

THREE TOP BOL

11. Lift up on the rear frame so it will clear the

large sprocket. Pull back to separate front and

rear frames. See figure 14.

REAR FRAME

LARGE

SPROCKET

FRONT FRAME

FIGURE 14

FIGURE 12

12. Slip belts between jack shaft bearing and front

frame. See figure 15.

Page 8

UUihiiiiMmtíM

FIGURE 15

13. Reassemble with new belts, following instructions

in reverse order.

NOTE

When reassembling the frame halves, be

certain that the jackshaft bearing is

properly seated into the hole in the

front frame. Secure frame halves with

one top and bottom bolt, finger tight

only. Check position of bearing. Then

reassemble rest of bolts, tightening

securely.

‘NOTE

Belts and chain must be reassembled as

shown in illustration on page 10. If

assembled incorrectly, log splitter will

operate in reverse.

OFF-SEASON STORAGE

In event engine is to be stored for any length of time

(30 days or more), prepare as follows:

1. Drain gasoline by tipping or by siphon hose, then

run engine until remainder is used and tank and

carburetor are empty.

CAUTION

A

Drain into container outdoors away

from fire or flame.

Drain carburetor by running engine until it stops

from lack of fuel.

3.

Protect the inside of engine for storage by

removing spark plug and pouring one ounce of

SAE 30 oil through spark plug hole into cylinder.

Crank engine, without starting, several times to

spread oil over cylinder walls.

4.

Never store outside without a waterproof cover.

Page 9

Notes

Page 10

Model 635

IF YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

10

Page 11

Model 635

PARTS LIST FOR MODEL 635 LOG SPLITTER

Ref.

•No.

1

2

PART

No.

____

710-0649

__

COLOR

CODE

DESCRIPTION

Engine

Hex. Wash. SF Tapp Scr. 36

3/8" X 7/8" Lg.

710-0693 Hex Bolt 3/8-16 X 4.5" Lg.

3

4

750-0537

Spacer 3/8 I.D. x 5/8 O.D. x 38

X 2-5/8 Lg.

5 14822

Spring Retainer Bracket

6 712-0798 Hex Nut 3/8-16 Thd.*

736-0169

7

732-0121

8

9 738-0147

747-0389 Engagement Handle

10

11 14823

12 14809

714-0105

13

14

756-0381

714-0104 Internal Cotter Pin 1/8" Dia. 48

15

738-0322 ShId. Bolt

16

14716 Engagement Handle Brkt.

17

L-Wash. 3/8 I.D.^

Spring

Shid. Bolt

Lever Return Bracket

Motor Mounting Plate Ass'ySq. Key 3/16 x 1.0 Lg.

Step Pulley

Ass'y-

710-0830

18

736-0169

19

756-0225

712-0798

756-0225

710-0344 Hex Bolt 3/8-16 X 1.5" Lg.* 55

23

714-0474

24

Hex Bolt 3/8-24 x 3.0 Lg.* 51

L-Wash. 3/8 I.D.*

Idler Pulley 2-3/4

Hex Nut 3/8-16 Thd.*

Idler Pulley 2-3/4

Cotter Pin 1/8" Dia. x 3/4"

Lg-*

25 14811

712-0798

26

736-0169

27

756-0382

28

738-0525

29

714-0139

30

713-0298

31

710-0600

32

Engagement Bracket Ass'y.

Hex Nut 3/8-16 Thd.*

L-Wash. 3/8" I.D.*

Engine Pulley

Jack Shaft Spindle

Sq. Key 3/16 x 2.0 Lg.*

Sprocket 12T #20 Chain

Hex. Wash. TT Tapp Scr.

3/8 X 1/2" Lg.

33 14721

34 710-0118

Belt Cover R.H.

Hex Bolt 5/16-18 X.75" Lg.

NEW

PARI

Ref.

PART

No.

35 08253

741-0919

No.

COLOR

CODE

DESCRIPTION

Small Bearing Housing

Ball Bearing .787 I.D. x

1.85 O.D.

738-0147 Shid. Bolt

37

750-0531 Spacer .38 I.D. x 62 O.D.

4.5 Lg.

N

39 736-0119

L-Wash. 5/16 I.D.*

40 736-0133 FI.-Wash. 3/8 I.D. x 1.25

O.D. x.10 Thd.

41 712-0798

42 711-0735

Hex Nut 3/8-16 Thd.*

Stud 1/4" X 2-7/8" Lg.

N 44 712-0267 Hex Nut 5/16-18 Thd.*

N

712-0287 Hex Nut 1/4-20 Thd.*

45

N 46 719-0258 Flywheel

47 750-0528 Spacer 3/8 I.D. x .50 O.D.

N

710-0649

X 18

Hex Wash. SF Tapp Scr.

3/8 X 7/8

N

749-0493

49

712-0267 Hex Nut 5/16-18 Thd.*

50

Engine Brace

736-0119 L-Wash. 5/16 I.D.*

52 736-0329

L-Wash. 1/4" I.D.*

53 710-0428 Hex Bolt 1/4-24X 1-1/4"

Lg.*

54

710-0237 Hex Bolt 5/16-24 X 5/8" Lg.

736-0119 L-Wash. 5/16 I.D.* 1

56 712-0375 Hex Cent. L.-Nut 3/8-16 Thd.

712-0267 Hex Nut 5/16-18 Thd.*

57

N

58 14700

59

710-0237 Hex Bolt 5/16-24 X 5/8"

Motor Mount Cup N

Lg.*

N

60

61

734-0736

736-0116

Wheel Ass'y. 10.0 x 2.75

Fl.-Wash. 5/8 I.D. x 93 O.D.

X .06

N

62

63

64 736-0119

N

65

66 736-0119

67

714-0115

720-0143 Control Grip

712-0267

712-0318

Cotter Pin 1/8" X 1.0" Lg.*

L-Wash. 5/16 I.D.*

Hex Nut 5/16-18 Thd.*

L-Wash. 5/16 I.D.*

Hex Jam Nut 5/8-18 Thd.

NEW

PART

N

N

N

N

*

*For faster service obtain standard nuts and bolts locally. If

these items cannot be obtained locally, order by part

number and size as shown on parts list.

11

Page 12

Model 635

/ /

12

Page 13

Model 635

PARTS LIST FOR MODEL 635 LOG SPLITTER

NEW

PART

No.

No.

754-0244 V-Belt 1/2x40" Lg.

1

COLOR

CODE

DESCRIPTION

Ref.

PART

No.

20 710-0649

(Reverse)

2 754-0235

V-Belt 1/2x35 Lg.

21

(Forward)

3 14719

4

14720

14722

5

711-0628

6

747-0388 Lever Rod

7

710-0118 Hex Bolt 5/16-18 X. 75" Lg.* 25 736-0169

8

9 14714

10

14707

736-0119 L-Wash. 5/16" I.D.*

11

End Cover

L.H. Belt Cover

Comp. Wedge & Screw Ass'yAdjustment Ferrule 24 736-0133 Fl.-Wash. 3/8 I.D. x 1.25

Sprocket Hub Ass'y-

Frame Weldment Ass'y.

N

22

N 3/8 X 1/2" Lg.

N

23 14715

N

N

26

N

27

28

12 712-0267 Hex Nut 5/16-18 Thd.*

13 710-0831 Hex Bolt 3/8-16x5.5" Lg.*

14 712-0798

736-0105

15

16

736-0258

17 06605

736-0105

18

Hex Nut 3/8-16 Thd.* 30

Bell Wash. 3/8" I.D.

FI. Wash. 3/8 I.D. x 1.0 O.D.

X 13 32

Chain Adjuster

Bell Wash. 3/8" I.D.

19 712-0798 Hex Nut 3/8-16 Thd.*

N

29 14709 Idler Bracket Ass'y. N

31 710-0412 Hex Bolt 1/4-24x3/4" Lg.

33 710-0650 Hex Wash. SF Tapp Scr.

34

PART

No.

COLOR

CODE

DESCRIPTION

Hex Wash. SF Tapp Scr.

3/8 X 7/8" Lg.

713-0302

131 Link Chain #.420

713-0154 Master Link #.420

710-0773 Hex Wash. TT Tapp Scr.

10 Tooth Sprocket Ass'y. N

O.D. X 10 Thd.

L-Wash. 3/8" I.D.*

710-0152 Hex Bolt 3/8-24 X 1.0" Lg.*

710-0344

Hex Bolt 3/8-16 X 1.5" Lg.*

741-0133 Ball Bearing .50 I.D. x 1.38

O.D. X .437

736-0463

Fl.-Wash. 1/4 I.D. x 5/8

O.D. X .06

741-0355

Ball Bearing N

5/16x7/8

710-0600

Hex Wash. SF Tapp Scr.

5/16 X-1/2

NEW

PART

N

13

Page 14

MTD PRODUCTS INC

P.O.BOX 36900 • CLEVELAND, OHIO 44136

.....................................................

YaRD-МЭН COMPANY

Loading...

Loading...