Page 1

(f

OUTDOOR POWER EQUIPMENT

for all seasons

.75

8 TON MANUAL

LOG SPLITTER

Important:

Read Safety Rules and

Instructions Carefully

PRINTED IN U.S.A.

Model Numbers

245-632-000

24632S

Thank you for purchasing

an American-built product.

FORM NO. 770-3956

Page 2

INDEX

Safe Operation Practices........................................... 3

Assembly Instructions............................................ ... 4

Operation .............................................................. ... 5

Maintenance

♦

♦

♦

♦

♦

♦

♦

.........................................................

LIMITED WARRANTY

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm, any

part or parts found to be defective in material or workmanship. Transportation charges for

the movement of any power equipment unit or attachment are the responsibility of the pur

chaser. Transportation charges for an / parts submitted for replacement under this warran

ty must be paid by the purchaser unk ss such return is requested by MTD PRODUCTS INC.

This warranty will not apply to any part which has become inoperative due to misuse, ex

cessive use, accident, neglect, improDer maintenance, alterations, or unless the unit has

been operated and maintained in accoi dance with the instructions furnished.

... 6

Illustrated Parts

Repair Parts List.............................................9

Seal-Kit...........................................................9

.............................................

8

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

V

This warranty will not apply where the unit has been used commercially.

Warranty service is available through /our local authorized service dealer or distributor. If

you do not know the dealer or distribi tor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will net be accepted by the factory unless prior written per

mission has been extended by MTD.

This warranty gives you specific lega rights. You may also have other rights which vary

from state to state.

£k

THIS UN T SHOULD NOT BE

TOWED OSI ANY STREET, HIGH

WAY OR PUBLIC ROAD. ANY

LICENSING NEEDED TO COMPLY

WITH THE EXISTING FEDERAL,

LOCAL OR STATE VEHICLE

REQUIREMENTS IS THE SOLE

RESPONSIBILITY OF THE PUR

CHASER.

CAUTION

t

♦

♦

♦

♦

♦

♦

Page 3

IMPORTANT

It is suggested that this manual be read in its entirety before attempting to assemble or operate. Keep this manual

'n a safe place for future reference and for ordering replacement parts.

Your log splitter is a precision piece of equipment, not a plaything. Therefore exercise extreme caution at all times.

A

TRAINING

1. Do not allow children to operate. Do not allow

adults to operate it without proper instruction.

Only persons well acquainted with these rules of

safe operation should be allowed to use your log

splitter.

2. Never use your splitter for any other purpose than

splitting wood. It is designed for this use only

and any other use may cause an injury.

3. Only the operator is to be near your log splitter

during use. Keep all others, including pets, a

minimum of 20 feet away from your work zone.

Flying wood can be hazardous.

-PREPARATION

1. Do not wear loose fitting clothing that could get

caught on the moving parts.

2. Do not operate equipment when barefoot or

wearing open sandals. Always wear safety shoes or

heavy boots. A dropped log can seriously injure

your foot.

SAFE OPERATION PRACTICES FOR LOG SPLITTERS

2. Never place hands or feet between log and splitting

wedge or between log and ram during forward or

reverse stroke. To do so may result in crushed or

amputated fingers or toes, or worse, you may lose

an arm or foot.

3. Never try to split two logs on top of each other.

One may fly out an injure you.

4. Never attempt to split wood across the grain.

Some types of wood may burst or fly out of your

splitter and result in injury to you or a bystander.

5. Only use your hand to operate the ram or control

lever. Never use your foot or a rope or any other

extension device. This could result in your inability

to stop your splitter quickly enough and cause an

injury.

6. Only operate your splitter on the level ground and

not on the side of a hill. It could tip, or rolling logs

or poor footing could cause an accident.

3. Use only in daylight or in good artificial light.

4. Never operate your splitter on slippery, wet,

muddy, or icy surfaces. Safe footing is essential

in preventing accidents.

5. Always wear safety glasses or goggles while

operating your log splitter. A piece of splitting

log could fly off and hit your eyes.

6. Both ends of each log must be cut square. This

will prevent the log from flying out of the splitter

while under pressure.

OPERATION

1. No one should operate this unit while intoxicated

or while taking medication that impairs the senses

or reactions.

7. When loading log splitter, place your hands on the

side of the log, not at the ends.

8. For logs that are not cut square, the longest

portion of the log should be rotated down and the

most square end placed against the ram.

MAINTENANCE and STORAGE

1. Don't operate your splitter in poor mechanical

condition or when in need or repair.

2. Keep all nuts, bolts and screws tight to be sure

equipment is in safe working condition.

3. Replace all damaged or worn parts with manu

facturer approved replacement parts.

4. Never store outside without a waterproof cover.

Rain will cause rust on the inside of the cylinder.

Page 4

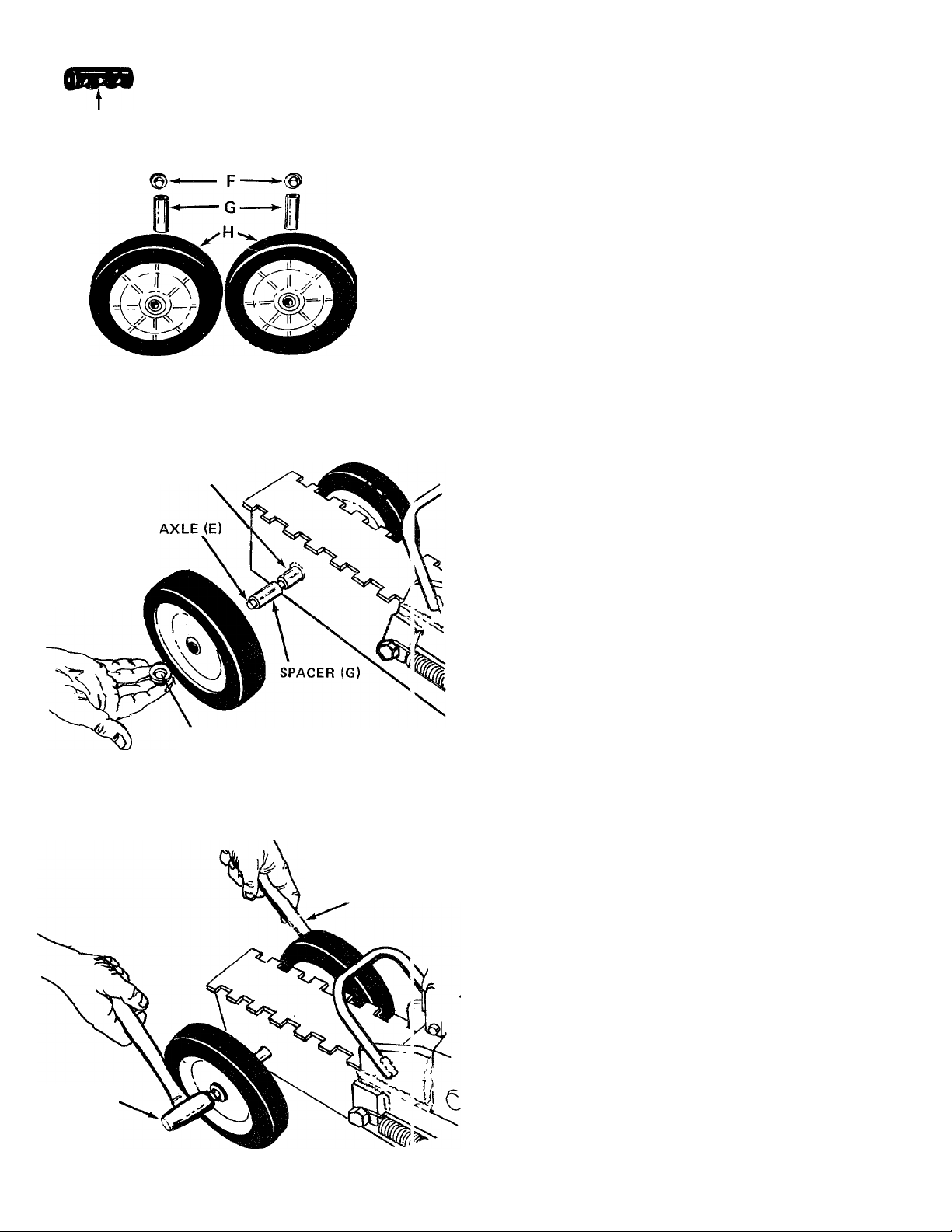

FIGURE 1

I—D

WELDED TUBE

ASSEMBLY INSTRUCTIONS

I

B

CONTENTS OF HARDWARE PACK AND LOOSE

- PARTS: (See Figure 1)

A (1) Handle Grip

B (1) Handle

C (1) Hairpin Cotter (may be rings)

D (1) Clevis Pin (may be pin)

E (1) Axle

F (2) Push on caps 1/2" Dia.

G (2) Spacers

H (2) Wheels

WHEEL (H)

FIGURE 2

\

PUSH ON CAP (F)

USE A SECOND

HAMMER, OR E LOCK

OF WOOD

1. Remove the log splitter, loose parts and literature

from carton. Check to be sure all parts are removed

from carton before discarding the carton.

2. Place the axle (E) through the welded tube on

splitter. See figure 2.

3. Next, place spacers (G) on each side of splitter,

over axle. See figure 2.

Next, place wheels (H) over each end of axle.

4.

See figure 3.

Secure wheels to axle with push on caps (F). A

5.

hammer and block of wood will be required to

hammer on the caps. See figures 2 and 3.

HAMMER'

FIGURE 3

Page 5

FIGURE 4

HANDLE ON

CYLINDER MOUNTING

ASSEMBLY

5. Lift the handle socket up so that the hole lines up

with the hole in plunger shaft. See figure 4.

6. Secure handle socket to plunger shaft with hair pin

(C) and clevis pin (D). See figure 4.

7. Place the handle grip (A) over one end of handle

(B). Warm soapy water will aid in assembly. Tap

grip on.

8. Place handle over handle socket.

OPERATION

This 8 ton capacity hydraulic unit is a special design,

manufactured for use one log splitter only.

1. This splitter can be adjusted manually for logs 8"

to 24" long. There are twelve different settings.

Settings are approximately 1-1/2" apart. See

figure 5.

2. Simply lift up on handle of cylinder mounting

assembly and slide the unit forward or backward

for the correct log length. See figure 5.

FIGURE 5

FIGURE 6

3. Pull the release valve up and back to lock. Then

-- handle can be pumped to split logs. See figure 6.

Page 6

Push the release valve down and forward to release

pressure. Cylinder will return, with the aid of two

return springs. See figure 7 and copy of label below.

FIGURE 7

FIGURES

CYLINDER RESEIIVOIR

SCREW AND WASHER

SCREWDRIVER HiVNDLE

HANDLE

DOWN TO .

RELEASE /

PRESSURE ^

/^A UP TO LOCK

/ 1 PUMP AND

------

y SPLIT

—5052

MAINTENANCE

RESERVOIR OIL

1. Lift the handle on the cylinder mounting assembly

and pull cylinder assembly all the way back to the

last notch. See figure 8.

2. Remove the pump handle.

3. Release the pressure in the cylinder.

4. Tip the log splitter up so it rests on the wheels and

handle on cylinder assembly. See figure 8.

5. With a standard screwdriver, remove screw anc

washer from cylinder reservoir. See figure 8. If oil

is up to hole, do not add any oil. If not, add oil to

bring level up to hole. Oil capacity is 10 fluid

ounces. Nuto H grade 32, or Exxon L.P.

conventional #150 Hydraulic oil.

6

Page 7

Notes

Page 8

Model 632

IF YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

Specifications subject to change without notice

or obligation.

MODEL

NOTE

Page 9

Model 632

J.

PART NO.

QUAN.

PARTS LIST FOR MODEL 632 LOG SPLITTER

NEW

DESCRIPTION

PART

REF.

NO.

PART NO. QUAN.

DESCRIPTION

NEW

PART

1

01166

2 747-0488 1

3 HW-66713

4 711-0599 1 Clevis Pin (Service

HW-66727 2

5

HW-66722

6

7 717-0614 1

781-0050 1

8

9 710-0925 2

10 781-0057 1 Cylinder Mounting

11

736-0169 2

1 Handle Grip

Handle 3/8" Dia. Rod N

1 Handle Socket

Only)

Pin & Ring Assembly N

2

Link N 17

Hydraulic Pump &

Cylinder

Push Plate Ass'y-

Socket Hd. Bolt 1/2-

13x .75" Lg. 21 712-0384 2

L.-Wash. 3/8" I.D.* 22 714-0149

13 732-0466

N 14 710-0820 2

734-1079 2

15

726-0221 2 1/2" Push Cap

16

750-0151

738-0584 1

18

N 19

20

781-0066

726-0221 2 1/2" Push Cap

2

Extension Spring .75"

O.D. X 10.75" Lg. N

Hex L.-Bolt 3/8-16 x

.75" Lg.*

Wheel 7.0" x 1.75"

2

Spacer

Axle 1/2" Dia. x 12"

Lg.

1

Tube and Rail Ass y. N

Hex Cent. L.-Nut 1/2-

13Thd.

1

Hair Pin Cotter (Service

12 710-0926 Socket Hd. Bolt 3/8- Only)

16 X .75" Lg.

*For faster service order standard nuts, bolts, and washers locally. If these items cannot be obtained locally, order by part number and size as shown on

parts list.

X

....

753-0389 1

Kit-Seal (See Below) N

N

PARTS IN SEAL-KIT 753-0389

REF.

NO.

1

Quad Ring

DESCRIPTION

2 Cup

Hair Pin Clip

Pin Ring

Back-Up Washer

5

"0"-Ring

6

REF.

NO.

Ball Retainer

7

Ball

8

9 Spring

Packing

10

Ball

11

Ball Retainer

12

Spring

13

DESCRIPTION

Page 10

Page 11

Page 12

MTD PRODUCTS INC

.................

P.O. BOX 36900 • CLEVELAND OHIO 44136

.................................

YaRD-MaN COMPANY

Loading...

Loading...