Page 1

"'N

$1.00

3 HR

EDGER

IMPORTANT: Read Safety Rules and Instructions Carefully^

Thank you for purchasing an American-built product.

Model Numbers

247-604-000

24604B

OPTlOfJfIL CUPB tOH£EL /('¡T

f n0-Z\7-fiAS PT.

Alo-r fl\IAl2-/}BL£ -"Rt3SOl/!i£S h/ejL

^Xn?A SJ!/ J.jT~.

FORM NO. 770-5201B

JjJL

Page 2

INDEX

Safe Operation Practices

Assembly Instructions

Controls .......................................................................... 7

Operation ........................................................................ 8

Lubrication

......................................................................

................................................

.....................................................

lnsi ructions given with this symbol are

▲

for personal safety. Be sure to follow

them.

3

4

9

Maintenance .................................................................

Off-Season Storage ..................................................

Trouble Shooting Chart...................................................|1

Illustrated Parts

Replacement Parts List...................................................13

...............................................................

12

ikc WARNING \

This unit is equipped with an internal combustion engine and should not be used on or near any unim

proved forest-covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped

with a spark arrester meeting applicable local 5r state laws (if any). If a spark arrester is used, it should be

maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources

Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester muffler is

available at your nearest engine authorized serv ce center.

Page 3

WARNING

A

To reduce the potential for any injury, comply with the following safety instructions. Failure to comply with the

''^structions may result in personal injury.

t

SAFE OPERATION PRACTICES FOR EDGERS

TRAINING

1. Read this owner's manual carefully in its en

tirety before attempting to assemble or operate

this machine. Be completely familiar with the

controls and the proper use of this machine be

fore operating it. Keep this manual in a safe place

for future and regular reference and for ordering

replacement parts.

2. Your edger is a precision piece of power equip

ment, not a plaything. Therefore, exercise extreme

caution at all times.

3. Never allow children to operate a power edger.

Only persons well acquainted with these rules of

safe operation should be allowed to use your

edger.

4. Keep the area of operation clear of all persons,

particularly small children and pets. Stop engine

when they are in the vicinity of your edger. Al

though the area of operation should be complete

ly cleared of foreign objects, an object may have

been overlooked and could be accidently thrown

by the edger in any direction and cause serious

personal injury to the operator or any others

allowed in the area.

. No one should operate this unit while intoxicated

or while taking medication that impairs the senses

or reactions.

PREPARATION

1. Thoroughly inspect the area where the equip

ment is to be used. Remove all stones, sticks,

wire, bones and other foreign objects which

could be picked up and thrown by the edger in

any direction and cause serious personal injury to

the operator or any others allowed in the area.

2. Do not operate equipment when barefoot or wear

ing open sandals. Always wear substantial foot

wear.

3. Check the fuel before starting the engine. Gasoline

is an extremely flammable fuel. Do not fill the

gasoline tank indoors, while the engine is running,

or while the engine is still hot. Wipe off any

spilled gasoline before starting the engine as it

may cause a fire or explosion.

4. Disengage the blade clutch on units so equipped

before starting the engine.

Never attempt to make a wheel adjustment while

the engine is running.

d. Never operate the equipment in wet grass. Always

be sure of your footing. A slip and fall can cause

serious personal injury. Keep a firm hold on the

handle and walk, never run.

OPERATION

1. Never operate this edger unless wearing safety

glasses or some other suitable eye protection at

all times the engine is running.

2. Do not change the engine governor settings or

overspeed the engine.

3. Do not put hands or feet near or under rotating

parts. Keep clear of the discharge opening at all

times as the rotating blade can cause injury.

4. Stop the blade when crossing gravel drives, walks

or roads.

5. After striking a foreign object, stop the engine,

remove the wire from the spark plug, and thor

oughly inspect the edger for any damage. Repair

the damage before restarting and operating the

edger.

6. If the equipment should start to vibrate abnor

mally, stop the engine and check immediately

for the cause. Vibration is generally a warning

of trouble.

7. Stop the engine whenever you leave the equip

ment, before cleaning the guard assembly, and

when making any repairs or inspections.

8. Before cleaning, repairing or inspecting, make

certain the blade and all moving parts have stop

ped. Disconnect the spark plug wire, and keep

the wire away from the spark plug to prevent

accidental starting.

9. Do not run the engine indoors.

10. Shut the engine off and wait until the blade

comes to a complete stop before unclogging

guard assembly.

11. Never operate edger without proper guards, plates

or other safety protective devices in place.

12. Always operate the edger so that the protective

guard guide is positioned between the walk and

the rotating blade. Never allow the rotating blade

to operate directly against concrete walk or drive.

MAINTENANCE AND STORAGE

1. Check the blade and engine mounting bolts at

frequent intervals for proper tightness.

2. Keep all nuts, bolts, and screws tight to be sure

the equipment is in safe working condition.

3. Never store the equipment with gasoline in the

tank inside of a building where fumes may reach

an open flame or spark. Allow the engine to

cool before storing in any enclosure.

4. To reduce fire hazard, keep the engine free of

grass, leaves, or excessive grease.

Page 4

NOTE

ASSEMBLY INSTRUCTIONS

This unit is shipped WITHOUT GAS

OLINE or OIL. After assembly, see

operating section of this manual for

proper fuel and engine oil recom-

A mendations.

r

.4

i.l iO

HOLE AND SLOT

IN FRAME

i j t ’ t

i

I' .7

NOTE

Any reference to right and left hand

will be determined from behind the

edger, in the operator's position.

TOOLS REQUIRED:

A

B

C

D

E

F

Adjustable Wrench.

(1)

7/16" Open End or Box Wrench.

(1)

9/16" Open End or Box Wrench.

(1)

Pair of Pliers.

(1)

Hammer

(1)

Block of Wood.

(1)

CONTENTS OF HARDWARE PACK:

(See Figure 1)

A (2)

B (1)

C (2)

D (1)

E (2)

F (2)

G (2)

H (2)

I (2)

J (4)

K (4)

L (4)

M (1)

N (1)

0 (1)

P (1)

Q (2)

R (4)

S (2)

T (3)

U (1)

Hair Pin Cotters

Rod Adjustment Link

Cotter Pins 1/8" Dia. x 1.00"

Spacer .50" I.D. x .62" O.D.

Push Caps

Shoulder Bolts (Rear Axles)

Lock Washers 3/8" I.D.

Hex Nuts 3/8-16 Thread

Cable Ties

Carriage Bolts 1/4-20 x 1.25"

Lock Washers 1/4" I.D.

Hex Nuts 1/4-20 Thread

Hex Bolt 5/16-18 X 1.75" Long

Compression Spring

Flat Washer

Hex Center Lock Nut 5/16-18 Thread

Hex Bolts 1/4-20 x 1.25" Long

Hex Center Lock Nuts 1/4-20 Thread

Hex Bolts 1/4-20 X 1.00" Long

Grips

Self-Tapping Screw

Long

X 1.62" Long

Long

FIGURE 2

_ ^SHOULDER

LOCK WASHER (G) BOLT (F)

1. Remove the edger and all parts from the carton.

Make certain that all loose parts and literature

are removed from carton before carton is dis

carded.

2. Line up holes in lower handle with holes in

frame. Secure rear wheels (larger) and lower

handle to frame with shoulder bolts (F), lock

washers (G) and hex nuts (H). See figure 2.

Using a hammer, tap one push cap (E) onto the

end of the front axle which has a hole closer to it.

See figure 3.

Page 5

HAIR‘D COTTERS (A)

FIGURE 4

HOLES IN

AXLE

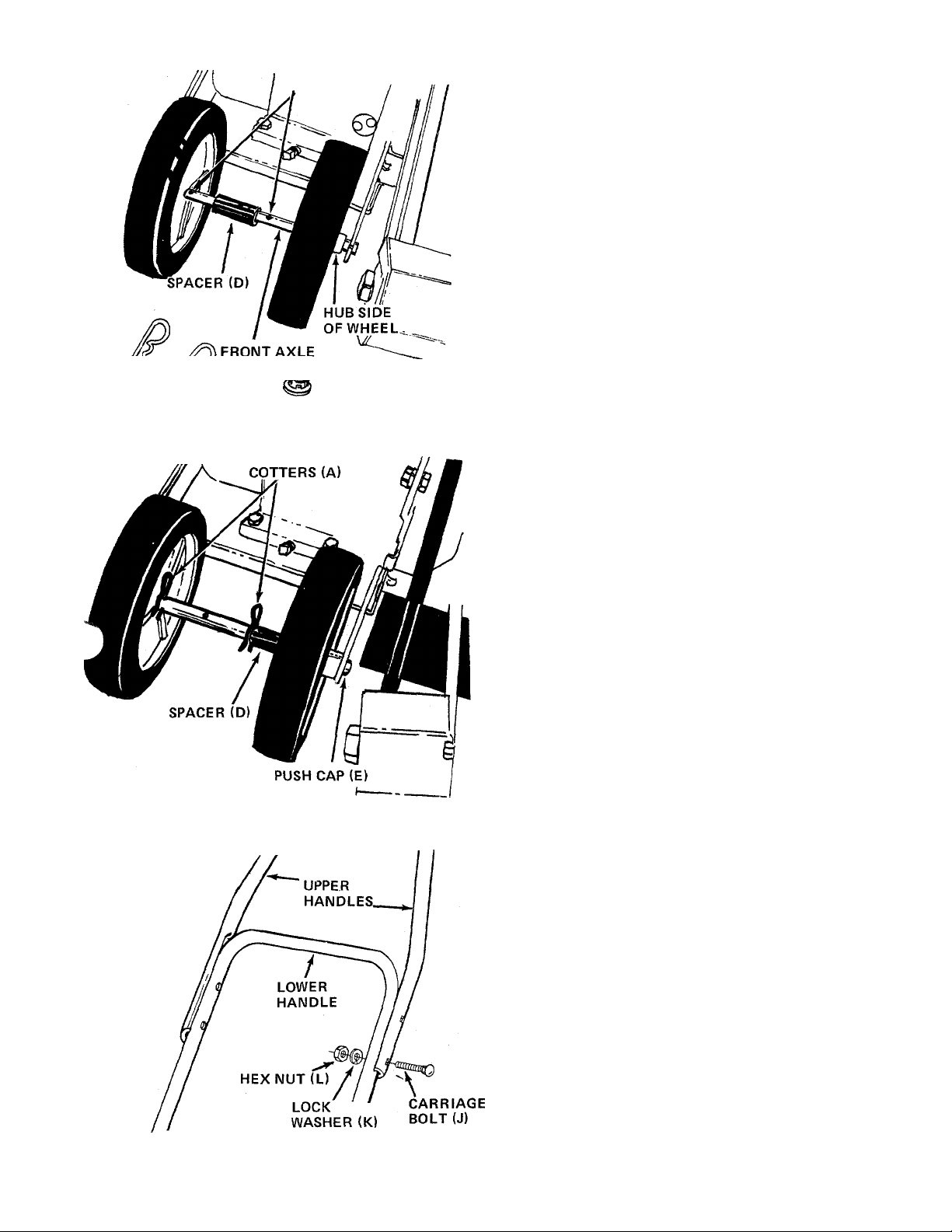

4. Starting on the right side of the edger, place the

axle through the support arm on the frame. Then

place axle through one wheel so the hub of the

wheel is to the outside of the unit. Next place

axle through spacer (D), the other wheel (hub to

the outside of the unit) and through second

— support arm. See figure 4. Secure with push cap

(E) by tapping it on with a hammer. See figure 5.

It is necessary to hold a block of wood or a

second hammer against the push cap on the other

side of the axle.

FRONT AXLE

HAIR PIN

FIGURE 5

Secure the front wheels and axle in position

using two hairpin cotters (A). See figure 5.

6. Slip the three handle grips (T) on the upper

handles and the engagement handle. They will slip

on more easily if you first soak them in warm,

soapy water.

7. Assemble the two upper handles to the lower

handle with four carriage bolts (J), lock washers

(K) and hex nuts (L). Tighten only finger tight at

this time. See figure 6.

FIG U RE 6

Page 6

FIGURE 7

HEX LOCK NUT (R)

8. Assemble the throttle control to the handle panel

as follows.

A. Hold the throttle control assembly beneath

the handle panel. Turn the control sideways

and insert the lever up through the wide

portion of the slot on the handle panel. See

figure 7A.

B. After the end of the lever is through the slot,

turn and then tip the control forward as shown

in figure 7B to slide it through the slot.

NOTE

The lever must be all the way to the

back of the control housing as shown

in figure 7B.

C. Push the control back into the slot in the

handle panel and press in place. Be certain the

control is locked securely into the slot. See

figure 7C.

D. Secure the throttle control to the handle panel

using self-tapping screw (U). See figure 7D.

HANDLE PANEL

ADJUSTMENT

BRACKET

HEX BOLT (3)

9. Place the handle panel over the upper handles and

line up the holes. See figure 8.

,10. Secure the right hand side of handle panel with

two one-inch long hex bolts (S) and hex lock nuts

(R). Do not tighten.

11. Secure the adjustment bracket to the left hand

side of handle panel with 1-1/4 inch long he

bolts (Q) and hex lock nuts (R). See figures.

12. Now tighten securely all four bolts and nuts at

handle panel and four bolts and nuts at lower

handle.

13. Place hex bolt (M) through bottom hole in

engagement handle as shown in figure 9, then

through hole in adjustment bracket.

14. Secure hex bolt with compression spring (N), fiat

washer (0) and hex lock nut (P) on the inside of

of the adjustment bracket.

15. Secure bent end of clutch rod half to engagement "

handle with cotter pin (C). See figure 9.

Page 7

16.

Thread rod adjustment link (B) onto the upper

clutch rod half, using about half of the threads.

See figure 10.

17.

Thread the lower clutch rod half into the bottom

of the rod adjustment link. See figure 10.

COTTER PIN (C)

SLACK IN BELT

CLUTCH ROD

FIGURE 11

CONTROLS

THROTTLE CONTROL

The throttle control lever is located on the handle

panel. It regulates the engine speed and stops the

engine. See figure 12.

18.

Pull the blade and guard assembly all the way back

by hand until there is slack in the belt. See figure

11.

Secure the end of the lower clutch rod half to the

19.

arm extension on the pivot bracket with cotter pin

(C). See figure 11.

20.

Secure the throttle control cable to handles with

two cable ties (I).

DEPTH CONTROL ADJUSTMENT

The engagement handle controls the clutching and

declutching of the belt. To declutch, the handle is

pulled back toward the operator. The farther forward

the handle is pushed, the deeper the cut. To move the

engagement handle, first move it to the left so the

the handle is out of the notch. See figure 12.

NOTE

If belt slips when engagement handle

is in the engaged position, lengthen the

clutch rod by turning the rod adjust

ment link. Refer to figure 10.

FIG U RE 1 2

Page 8

BLADE PLANE ADJUSTMENT

The cutting blade can be adjusted to eight positic>ns

from vertical to horizontal. To adjust, release tie

adjustment lever on the pivot bracket and rotate lhe

spindle housing. Place adjustment lever in notch

desired. See figure 13.

When the blade is adjusted toward the horizontal

position, the front wheels must also be adjusted.

Remove the two hairpin cotters and slide the spacer

and wheel to the right as shown in figure 14. Reinse.'rt

the hairpin cotters.

NOTE

If the wheels are not adjusted, the

blade will hit the left front wheel,

causing the belt to slip.

Become familiar with all the controls and adjustments

before operating the edger so you can adjust it easily

to a variety of cutting and trimming conditions. While

the engine is running, DO NOT ATTEMPT TO MAKE

ANY ADJUSTMENTS except with the throttle

control.

OPERATION

1. Fill the crankcase with oil using a high quality

detergent oil classified " For Service MS." Nothing

should be added to the recommended oil. SUM

MER- Use SAE 30. WINTER - (Below 400 p j Use

SAE 5W-20orSAE low.

Place the engine level. Remove filler plug. FILL

THE OIL SUMP TO POINT OF OVERFLOW.

Pour slowly. See figure 15.

2. Fill the fuel tank with clean, fresh, lead-free, lowlead, or regular grade leaded gasoline. DO NOT

MIXOILWITH GASOLINE.

FIGURE 13

SPACER

FIG U RE 1 4

HAIR PIN COTTERS

ADJUSTMENT

LEVER

Move the engagement handle (depth control) back

3.

as far as it will go and place in the last notch. See

figure 12.

Set the throttle control in "START" position.

4.

Pull the choke knob out.

5.

NOTE

A warm engine may not require

choking.

Grasp the starter handle and pull out the cord

6.

rapidly. Return it slowly to the engine. If the

engine does not start after two pulls, move the

throttle control to the "FAST" position.

7. After engine starts, push choke knob in gradually.

To stop engine, move throttle control to "STOP"

position. Disconnect spark plug wire and ground to

prevent accidental starting while equipment is un

attended.

Page 9

A

Rotating cutting blade may throw

objects causing personal injury. Always

wear safety glasses or some other

suitable eye protection at all times the

engine is running. Keep area clear of

bystanders and do not operate without

guards in place.

OPERATING THE EDGER

1. Set the adjustment lever (refer to figure 12) in the

second notch at the top to edge vertically. See

figure 16.

CAUTION

3. Move the front wheels all the way to the left when

using the edger on a curb. See figure 18.

FOR USE ON CURBS

FIGURE 18

4. To operate the unit as a trimmer, move the adjust

ment lever and rotate the cutting blade 90°. See

figure 19. Move the front wheels all the way to the

right, as described in the Control section.

FLAT DRIVE

FIGURE 16

2. Set the adjustment lever (refer to figure 13) in the

first notch at the top for trenching. See figure 17.

TRENCHING

FIG U RE 1 7

A

Do not adjust the blade guard with

the engine running.

UP TO FENCE, FOUNDATIONS, ETC.

FIGURE 19

CAUTION

LUBRICATION

Wheels - The wheels are plastic and require no lubric-

cation.

Engine - Refer to engine manual for lubrication

instructions.

Cutting Head Bearings - The two ball bearings in the

cutting head are lubricated and sealed at the factory

and require no lubrication. Lubricate all other moving

parts with engine oil.

Shaft - Lubricate the two bearings and under the

compression spring on the shaft with light oil at least

once a season. See figure 20.

Page 10

MAINTENANCE

Ac

WARNING {

Disconnect the spark plug wire and

ground against the engine before per

forming any adjustment, repairs or

maintenance.

BLADE REMOVAL

Use a wrench on both sides of the blade when removing

it for replacement.

BELT REMOVAL

1. To remove the V-belt, remove the belt guard

assembly at the engine pulley. Remove the hex

nuts and lock washers. See figure 20.

2.

Remove the belt guard at the spindle assembly by

removing two hex bolts, lock washers and hex nuts.

See figure 21.

3.

Remove the old belt, and reassemble with a new

belt, part number 754-0142.

ENGINE OIL

Check oil level before starting engine and after every

5 hours of operation. Add oil as necessary to keep

level full to point of overflowing. Before removing

plug, clean area around plug to prevent dirt from

entering oil fill opening. Refer to figure 15.

Change oil after first 5 hours of operation. There

after, change every 25 hours. Change oil while engine

is warm. Oil may be drained thru oil drain plug.

Crankcase capacity - 1-1/4 pints.

Refer to engine manual for complete instructions

for care and maintenance of engine.

FIGURE 20

HEX NUTS

OFF-SEASON STORAGE

The following steps should be taken to prepare unit

for storage.

1. Clean and lubricate unit thoroughly.

2. Refer to engine manual for correct engine storage

instructions.

3. Coat unit's cutting blade with chassis grease to

prevent rusting.

4. Store unit in a dry, clean area.

NOTE

When storing any type of power

equipment in an unventilated or metal

storage shed, care should be taken to

rustproof the equipment. Using a light

oil or silicone, coat the equipment,

especially springs and bearings.

10

Page 11

^

-------------------------------------PROBLEM

TROUBLE SHOOTING CHART

CAUSE (S)

CORRECTIVE ACTION(S)

1. Engine fails

to start.

2. Hard starting

or loss of power.

3. Engine over

heats.

4. Excessive

vibration at

blade.

5. Belt slips. A. Belt worn or stretched.

6. Blade guard

pivots forward,

throwing dirt on

operator.

A. Check fuel tank for gas.

B. Spark plug lead wire

disconnected.

C. Faulty spark plug.

A. Spark plug wire loose.

B. Dirty air cleaner.

A. Carburetor not adjusted

properly.

B. Air flow restricted.

C. Engine oil level low.

A. Spindle bent.

B. Ball bearings worn out.

B. Clutch handle will not

remain in clutch plate.

Cam lever and carriage

bolt at guard are loose.

A. Fill tank if empty.

B. Connect lead wire.

C. Clean, adjust gap or replace.

A. Connect and tighten spark plug wire.

B. Clean air cleaner as described in engine manual.

A. Adjust carburetor. See engine manual.

B. Remove blower housing on engine and clean as described in the

engine manual.

C. Fill crankcase with the proper oil.

A. Replace spindle.

B. Replace ball bearings.

A. Adjust clutch rod or replace belt.

B. Readjust spring tension at clutch handle.

Readjust guard, tighten cam lever and carriage bolt.

NOTE: For repairs beyond the minor adjustments listed above, please contact your local authorized service dealer.

11

Page 12

Model 604

i>£2T AucJdmEfOT

0f^f5£T mo^ £At&.

ro Slade: app^ov. VH\

^p- — — ^

SPACERS REVEASEti "^^^8

CAUSES BELT TO CO/r>£ OPP

'tJHEiU JStJMiE ts TMusD itmz.

12

Page 13

Model 604

PARTS LIST FOR MODEL 604 EDGER

REF.

>EF.0.PART

1

2

3 714-0115

NO.

720-0120

COLOR

CODE

Black Grip 45

DESCRIPTION

712-0107 Hex L.-Nut 1/4-20 Thd. 46

Cotter Pin 1/8” Dia. x 1.00" Lg.* 47 712-0287 Hex Nut 1/4-20 Thd.*

4 710-0106 Hex Bolt 1/4-20 x 1.25" Lg.*

710-0380 Hex Bolt 5/16-18 X 1.75" Lg.* 49 712-0287 Hex Nut 1/4-20 Thd.*

5

749-0666 Engagement Handle

6

7 781-0081

732-0369

8

736-0264

9

712-0158 Hex Cent. L.-Nut 5/16-18 Thd.

10

Adjustment Bracket

Compression Spring .50" O.D.

X 1.38" Lg.

FI.-Wash. .344" I.D. x .62" O.D. 54

X .063

11 747-0498 Clutch Rod Half 3/8" Dia. x

18.25" Lg.

12 710-0111 Carriage Bolt 1/4-20 x 1.25" Lg.*

1314750-0628

712-0287

736-0329 L.-Wash. 1/4" I.D.*

15

16 09955

714-0122

17

18 712-0798

Rod Adjustment Link

Hex Nut 1/4-20 Thd.*

Lower Handle 62

Sq. Key 3/16" x 3/16" x .75" Lg.

Hex Nut 3/8-16 Thd.*

19 736-0169 L.-Wash, 3/8" I.D.*

756-0327

21

20

750-0212

Engine Pulley

Spacer .75" I.D. 66

22 736-0258 Fl.-Wash. .385" I.D. x 1.0" O.D.

710-0152

23

24 734-0841

738-0108 Shoulder Bolt .498" Dia. x 1.45" Lg.

25

■^6 13960-463

Hex Bolt 3/8-24 X 1.0" Lg.* 68 732-0188

Rear Wheel Ass'y. 8 x 1.75

Belt Guard Ass'y.

NEW

PART

PART

NO.

NO.

781-0076 Guard Ass'y.

781-0080

48

736-0329

50 736-0329

51 781-0078 Spindle Plate Ass'y.

52 15319 Bearing Housing 1-3/8" I.D.

53 741-0155 Ball Bearing .62" I.D. x 1.38" O.D.

710-0258 Hex Bolt 1/4-20 x.62" Lg.*

55

56

756-0449

754-0142

57 710-0929 Hex Bolt 5/8-18x4.50" Lg.*

58 710-0289 Hex Bolt 1/4-20 x .50" Lg.*

59 781-0086

60

750-

61 712-0267 Hex Nut 5/16-18 Thd.*

736-0242 Bell.-Wash. .345" I.D. x .88" O.D.

63 714-0121 Spring Pin Spir. 1/4" Dia. x 2.00"

64

781-0090 Pivot Bracket Ass'y.

65 710-0600 Hex Wash. Hd. Self Tap Scr.

781-0075 Arm Extension

67 781-0093 Adjustment Lever Ass'y.

69 712-0267 Hex Nut 5/16-18 Thd.*

70 736-0119

71

750-0622 Spacer .50" I.D. x .62" O.D. x

7 732-0187 Compression Spring

711-0379 Bushing

28

712-0267

29

736-0119 L.-Wash. 5/16" I.D.*

30

Hex Nut 5/16-18 Thd.*

31 715-0247 Spring Pin Spir. 3/16" Dia; X 1.00" 74

Lg.

712-0287

32

33 736-0112 Bell.-Wash. .535" I.D. x 1.50"O.D.

71/1 ^ni 1 K

34

35

712-0114

36

736-0329 L.-Wash. 1/4" I.D.*

781-0087

37

736-0342 Fl.-Wash. .25"!.D. x .75" O.D. x 81 781-0092 Handle Support Plate

38

Hex Nut 1/4-20 Thd.*

Cotter Pin 1/8" Dia. x 1.00" Lg. 77 Engine

Hex Slotted Nut 1/2-20 Thd. 78 726-0192 Cable Tie

Flap Bracket

72 738-0613 Axle .50" Dia. x 8.75" Lg.

73 781-0083 Base Ass'y.

714-0101

75 710-0442

76 734-0840 Front Wheel Ass'y. 7 x 1.50

79 749-0667 Upper Handle

80

710-0597

.030 82 831-0692

710-0289 Hex Bolt 1/4-20X .50" Lg.* 83 746-0421

39

40 731-0725 Flap 84 726-0221

41 710-0402 Hex Bolt 5/16-18 X 4.5" Lq.*

42

750 - 0118 4rLeHve . fc32" XO x,875 ÓD x. 9

43 736-0317 Bell.-Wash. .630" I.D. x 1.25" O.D. 87

44 712-0221

Hex Ins. L.-Nut 5/8-18 Thd. 88 711-0699 Stud 1/4-20 X 2.12" Lg.

85 711-0386 Spacer .386" I.D. x .510" O.D. x

86

781-0095

710-0118 Hex Bolt 5/16-18 X .75" Lg. Spec.

89

710-0779

COLOR

CODE

DESCRIPTION

NEW

PART

Edger Blade¿2..iTtu/Di: y 1 Laa& L 3Ó4. .

L.-Wash. 1/4" I.D.*

L.-Wash. 1/4" I.D.*

3/8" "V"-Pulley 2" X 5/8" I.D.

"V"-Belt •Vi'X 31-^0

Belt Guard

SPACER. .fcSS" ZD X, 9l"lD ?

Lg.

5/16-24 X .50" Lg.

Torsion Spring

L.-Wash. 5/16" I.D.*

1.62" Lg.

(Front)

Hair Pin Cotter 1/2" Dia.

Hex Bolt 5/16-18 X 1.50"

Lg.*

Hex Bolt 1/4-20X 1.00" Lg.*

Throttle Control Box Ass'y.

Throttle Control Wire 30" Lg.

Push Cap 1/2" Dia.

3.765" Lg.

Debris Deflector: .25" Lg.

Self-Tap Scr. #10 x .50" Lg.

ot

*For faster service order standard nuts, bolts, and washers locally. If these items cannot be obtained locally, order by

part number and size as shown on parts list.

463 — Topflite Red

621 — Brilliant Fire Mist (24604)

NOTE

This instruction manual covers various models

and all specifications shown do not necessari-

ly apply to your model. Specifications subject

to change without notice or obligation.

When ordering parts, if color or finish is important, use the appropriate color,

code shown at left. (e.g. Topflite Red 10112 (4631.)

NOTE; The engine is not under warranty by

the edger manufacturer . . If repairs or

service is needed on the engine, please

contact your nearest author-

ized engine service outlet.

Check the "Yellow Pages" of

your telephone book under

'‘Engines—Gasoline.”

13

Find It Fast

In The

Yellow Pages

Page 14

MTD PRODUCTS INC

P.O. BOX 36900 • CLEVELAND OHIO 44136

....................................................

YaRD-MaN COMPANY

Loading...

Loading...