Page 1

OUTDOOR POWER EQUIPMENT

for all seasons

,75

2H.P.

EDGER

Important:

Read Safety Rules and Instructions Carefully

V

PRINTED IN U.S.A.

Model Numbers

245-596-000

24596S

Thank you for purchasing

an American-built product.

J

FORM NO 770-4058

Page 2

INDEX

Safe Operation Practices

Assembly Instructions . .

Operation

Adjustments

Lubrication

..........................

......................

........................

r

♦

♦

♦

♦

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm, any

part or parts found to be defective in material or workmanship. Transportation charges for

the movement of any power equipmsnt unit or attachment are the responsibility of the pur

chaser. Transportation charges for my parts submitted for replacement under this waranty must be paid by the purchaser un ess such return is requested by MTD PRODUCTS INC.

♦

♦

♦

This warranty will not apply to an^ part which has become inoperative due to misuse, ex

cessive use, accident, neglect, imp oper maintenance, alterations, or unless the unit has

been operated and maintained inaccordance with the instructions furnished. This warranty

does not apply to the engine, moto", battery, battery charger or component parts thereof.

Please refer to the applicable manufc cturer's warranty on these items.

♦

♦

♦

♦

♦

♦

♦

This warranty will not apply where the unit has been used commercially.

Warranty service is available througi your local authorized service dealer or distributor. If

you do not know the dealer or distri butor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will not be accepted by the factory unless prior written per

mission has been extended by MTD.

This warranty gives you specific lejal rights. You may also have other rights which vary

from state to state.

3 Maintenance .................................................................. 8

A

4 Off-Season Storage

7 Troube Shooting Chart

7 Illustrated Parts

8 Replacement Parts List...............................................11

Instr jctions given with this symbol are

for personal safety. Be sure to follow

then-.

.......................................................

.................................................... . 9

............................................................

LIMITED WARRANTY

9

10

♦

♦

♦

♦

♦

♦

♦

t

♦

♦

♦

♦

♦

♦

V

AC WARNING {

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved

forest-covered, brush-covered or grass-covere f land unless the engine's exhaust system is equipped with a

spark arrester meeting applicable local or state laws ( if any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code),

Other states may have similar laws. Federal la vs apply on federal lands. A spark arrester muffler is available at

your nearest engine authorized service center.

Page 3

WARNING

A

t

reduce the potential for any injury, comply with the following safety instructions. Failure to comply with the

structions may result in personal injury.

t

SAFE OPERATION PRACTICES FOR EDGERS

TRAINIMG

1. Read this owner's manual carefully in its en

tirety before attempting to assemble or operate

this machine. Be completely familiar with the

controls and the proper use of this machine be

fore operating it. Keep this manual in a safe place

for future and regular reference and for ordering

replacement parts.

2. Your edger is a precision piece of power equip

ment, not a plaything. Therefore, exercise extreme

caution at all times.

3. Never allow children to operate a power edger.

Only persons well acquainted with these rules of

safe operation should be allowed to use your

edger.

4. Keep the area of operation clear of all persons,

particularly small children and pets. Stop engine

when they are in the vicinity of your edger. Althoughtthe area of operation should be complete

ly cleared of foreign objects, an object may have

been overlooked and could be accidently thrown

by the edger in any direction and cause serious

■V personal injury to the operator or any others

allowed in the area.

d. No one should operate this unit while intoxicated

or while taking medication that impairs the senses

or reactions.

PREPARATION

1. Thoroughly inspect the area where the equip

ment is to be used. Remove all stones, sticks,

wire, bones and other foreign objects which

could Be picked up and thrown by th.e edger in

any direction and cause serious personal injury to

the operator or any others allowed in the area.

2. Do not operate equipment when barefoot or wear

ing open sandals. Always wear substantial foot

wear.

3. Checkthefuel before starting the engine. Gasoline

is an extremely flammable fuel. Do not fill the

gasoline tank indoors, while the engine is running,

or while the engine is still hot. Wipe off any

spilled gasoline before starting the engine as it

may cause a fire or explosion.

4. Disengage the blade clutch on units so equipped

before starting the engine.

Never attempt to make a wheel adjustment while

the engine is running.

6. Never operate the equipment in wet grass. Always

be sure of your footing. A slip and fall can cause

serious personal injury. Keep a firm hold on the

handle and walk, never run.

OPERATION

1. Never operate this edger unless wearing safety

glasses or some other suitable eye protection at

all times the engine is running.

2. Do not change the engine governor settings or

overspeed the engine.

3. Do not put hands or feet near or under rotating

parts. Keep clear of the discharge opening at all

times as the rotating blade can cause injury.

4. Stop the blade when crossing gravel drives, walks

or roads.

5. After striking a foreign object, stop the engine,

remove the wire from the spark plug, and thor

oughly inspect the edger for any damage. Repair

the damage before restarting and operating the

edger.

6. If the equipment should start to vibrate abnor

mally, stop the engine and check immediately

for the cause. Vibration is generally a warning

of trouble.

7. Stop the engine whenever you leave the equip

ment, before cleaning the guard assembly, and

when making any repairs or inspections.

8. Before cleaning, repairing or inspecting, make

certain the blade and all moving parts have stop

ped. Disconnect the spark plug wire, and keep

the wire away from the spark plug to prevent

accidental starting.

9. Do not run the engine indoors.

10. Shut the engine off and wait until the blade

comes to a complete stop before unclogging

guard assembly.

11. Never operate edger without proper guards, plates

or other safety protective devices in place.

12. Always operate the edger so that the protective

guard guide is positioned between the walk and

the rotating blade. Never allow the rotating blade

to operate directly against concrete walk or drive.

MAINTENANCE AND STORAGE

1. Check the blade and engine mounting bolts at

frequent intervals for proper tightness.

2. Keep all nuts, bolts, and screws tight to be sure

the equipment is in safe working condition.

3. Never store the equipment with gasoline in the

tank inside of a building where fumes may reach

an open flame or spark. Allow the engine to

cool before storing in any enclosure.

4. To reduce fire hazard, keep the engine free of

grass, leaves, or excessive grease.

Page 4

NOTE

ASSEMBLY

This unit is shipped WITHOUT GAS

OLINE or OIL. After assembly, see

operating section of this manual for

proper fuel and engine oil recom

mendations.

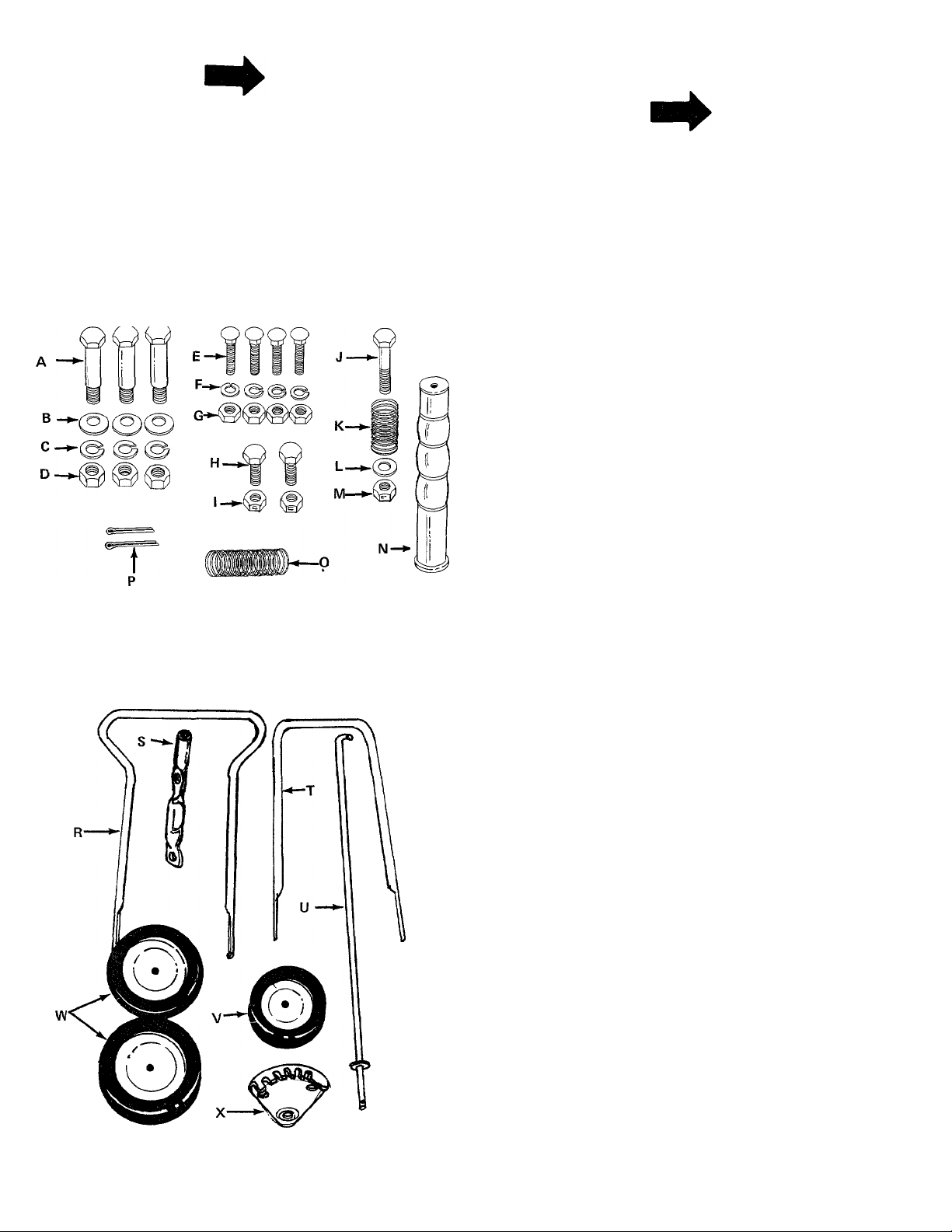

FIGURE 1

NOTE

Right and left hand side is determined

from behind the edger, in the opera

tor's position.

TOOLS REQUIRED

(1) Adjustable wrench or 3/4" open end or box

wrench

(2) 7/16" open end or box wrench

(1) 9/16" open end or box wrench

CONTENTS OF HARDWARE PACK

- (See figure 1)

A (3) Shoulder Bolts 3/8=16 Thread

B (3) Belleville Washers 3/8" I.D.

C (3) Lock Washers 3/8" I.D.

D (3) Hex Nuts 3/8-16 Thread

E (4) Carriage Bolts 1/4-20 x 1 1/4" Long

F (4) Lock Washers 1/4" I.D.

G (4) Hex Nuts 1/4-20 Thread

H (2) Hex Bolts 1/4-20 x 1 1/4" Long

I (2) Hex Lock Nuts 1/4-20 Thread

J (1) Hex Bolt 5/16-18 X 1 3/4" Long

K (1) Compression Spring 1 3/8" Long

L (1) Flat Washer 5/16" I.D.

M (1) Hex Lock Nut 5/16-18 Thread

N (1) Grip

0 (1) Compression Spring 2" Long

P (2) Cotter Pins

FIGURE 2

LOOSE PARTS IN CARTON (See figure 2)

R

S

T

U

V

w

X

Your new edger is shipped preassembled with the

exception of the handle, rear wheels and front wh^ “'

1. Remove the edger and all parts from the carte

carded.

Upper Handle

(1)

Clutch Handle

(1)

Lower Handle

(1)

Clutch Rod

(1)

Front Wheel 6"

(1)

(2) Rear Wheels 7"

Clutch Plate

(1)

Make certain that all loose parts and literature

are removed from carton before carton is dis

Dia.

Dia.

Page 5

HANDLE THROUGH

SLOT IN FRAME

SHOULDER

BOLT (A)

BELLEVILLE

WASHER (B)

FIGURES.

HEX NUT (D)

t

LOCK

WASHER (C)

BELLEVILLE

WASHER (B)

FRONT

WHEEL

2.

Place lower handle into the slots in the rear

frame. See figure 3.

3.

Line up holes in handle with holes in frame.

See figure 3.

4.

Secure rear wheels (P) and lower handle (M) to

frame with shoulder bolts (A), belleviile washers

(B) (cupped side of washer against the frame),

lock washers (C) and hex nuts (D). See figure 3.

5. Assemble the front wheel (O) as shown in figure

4. Place shoulder bolt (A) through wheel, then

belleviile washer (B) (between wheel and frame,

cupped side against the frame). Secure with lock

washer (C) and hex nut (D). See figure 4.

FIGURE 4.

HEX NUT,

(D)

6. Assemble the upper handle (R) to lower handle.

Place the head of carriage bolts (E)to the outside

of handle. Secure with lock washers (F) and

and hex nuts (G). See figure 5.

Page 6

HEX LOCK-T

NUT (M) 1

FIGURE 7

7. Place clutch plate (X) on the left hand side of the

upper handle as shown in figure 6. Secure in

place with hex bolts (H) and hex lock nuts (I).

CLUTCH

RCID (U)

8. Place hex bolt (J) through bottom hole in clutch

handle as shown in figure 7, then through hole in

adjustment bracket.

9. Secure hex bolt with compression spring (K).

fiat washer (L) and hex lock nut (M) on the inside

of the adjijstment bracket.

HEX BOLT (J)

COMPRESSION

SPRING (K)

10. Place compression spring (O) over straight end

of clutch rod (U). Place end of rod in spindle

bracket assembly and secure with cotter pin (P).

See figure 8.

11. Secure bent end of clutch rod to clutch handle

with cotter pin (P). See figure 7.

12. Slip the handle grip (N) on the end of the elute’

handle. It will slip on more easily if it is firs,

soaked in warm, soapy water.

Page 7

OPERATION

1. Fill the crankcase with oil using a high quality

detergent oil classified "For Service MS". Use

SAE 30 oil. Nothing should be added to the

recommended oil.

Place the engine level. Remove oil fill cap. FILL

THE OIL SUMP TO POINT OF OVERFLOW. Pour

slowly. See figure 9.

_____

A

Rotating cutting blade may throw

objects causing personal injury. Always

wear safety glasses or some other

suitable eye protection at all times the

engine is running. Keep area clear of

bystanders and do not operate without

guards in place.

To stop the edger engine, push the grounding clip

against the spark plug. See figure 11.

SPARK

PLUG

CAUTION

, Fill the fuel tank with clean, fresh, lead-free,

low-lead or regular grade leaded gasoline. DO

NOT MIX OIL WITH GASOLINE.

3. Pull the choke control out to "choke" position

if necessary. See figure 10.

PULLOUT

TO CHOKE

FIGURE 10

■i. Grasp the starter handle and pull out the cord

rapidly. Return it slowly to the engine.

5. After engine starts, push choke control in grad

ually.

FIGURE 11

Depth Control Adjustment - The clutch handle

controls the clutching and declutching of the belt. To

declutch, the handle is pulled back toward the

operator. To move the clutch handle, first move it to

the left so the handle is out of the notch.

ADJUSTMENTS

AC WARNING \

Disconnect the spark plug wire and

ground against the engine before per

forming any adjustments, repairs or

maintenance.

Front Wheel Adjustment

The front wheel may be raised or lowered to give

added cutting depth.

Loosen the second bolt on the front wheel support

bracket. Pivot the bracket up or down to desired

height. Retighten bolt. See figure 12.

Page 8

SECOND

BOLT

WHEEL

SUPPORT

BRACKET

FIGURE 12

LUBRICATION

Engine - Refer to separate engine manual for lubr ca

tion instructions.

Wheels - The wheels require no lubrication.

Spindle Bearing - The ball bearing in the spindh is

lubricated and sealed at the factory and requires no

lubrication. Lubricate all other moving parts vith

engine oil.

MAINTENANCE

A I*WARNING

FIGURE 13

Belt Removal - Remove the spark plug wire and

ground. Remove the gasoline.

1. Tip the edger back so that it rests on the handle.

2. Remove the cotter pin securing the castle nut

on the bottom of belt cover. See figure 14.

Disconnect the spark plug wire and

ground against the engine before per

forming any adjustments, repairs or

maintenance.

Blade Removal - Hold head of spindle bolt \/ith

a 3/4" or adjustable wrench and remove spindle lut.

See figure 13.

Engine Oil - Check oil level before starting en pne

and after every 5 hours of operation. Add oi as

necessary to keep level full to point of overflowing.

Before removing plug, clean area around plug to Dre-

vent dirt from entering oil fill opening.

Change oil after first 5 hours of operation. There

after, change every 25 hours. Change oil while engine

is warm. Oil may be drained thru oil drain plug.

See figure 9. Crankcase capacity - 1 1/4 pints.

FIGURE 14

3. Lift off the hex castle nut, belleville washer and

belt cover. See figure 15.

4. Remove the old belt and replace with new belt.

NOTE

While the belt cover is removed, it is

a good idea to apply a little grease to

the pivot point on belt cover. See

figure 15.

5. Reassemble the belt cover, making sure the new^

belt is over the engine pulley.

6. When tightening the castle nut, only tighten

enough to line up hole in bolt for cotter pin. DO

NOT OVER TIGHTEN. Belt cover must pivot

freely. See figure 15.

Page 9

ENGINE

PULLEY

7. Set edger back on its wheels. Replace spark plug

wire.

MOUNTING/^

BOLT

BELLEVILLE

WASHER

FIGURE 15

OFF-SEASON STORAGE

The following steps should be taken to prepare unit

for storage.

1. Clean and lubricate unit thoroughly.

2. Refer to engine manual for correct engine storage

instructions.

3. Coat unit's cutting blade with chassis grease to

prevent rusting.

4. Store unit in a dry, clean area.

BELT

NOTE

When storing any type of power

equipment in an unventilated or metal

storage shed, care should be taken to

rustproof the equipment. Using a

light oil or silicone, coat the equip

ment, especially springs and bearings.

TROUBLE SHOOTING CHART

PROBLEM CAUSE

1. Engine fails A. Check fuel tank for gas.

to start.

2. Hard starting'

or loss of power.

3. Engine over

heats.

4. Excessive

vibration at

blade.

5. Belt slips. A. Belt worn or stretched. A. Replace bolt.

______________________

NOTE; For repairs beyond the minor adjustments listed above, please contact your local service dealer.

B. Spark plug lead wire,

disconnected.

C. Faulty spark plug.

A. Spark plug wire loose.

B. Dirty air cleaner.

A. Carburetor not adjusted

properly.

B. Air flow restricted.

C. Engine oil level low.

A. Spindle bolt bent.

B. Ball bearing worn out.

B. Clutch handle will not

remain in clutch plate.

A. Fill tank if empty.

B. Connect lead wire.

C. Spark should jump gap between control electrode and side

electrode. If spark does not jump, replace the spark plug.

A. Connect and tighten spark plug wire.

B. Clean air cleaner as described in engine manual.

A. Adjust carburetor. See engine manual.

B. Remove blower housing on engine and clean as described in the

engine manual.

C. Fill crankcase with the proper oil.

A. Replace spindle belt.

B. Replace ball bearing.

B. Readjust spring tension at clutch handle.

REMEDY

Page 10

Models 596 and 24596

IF YOU WRITE TO US ABOUT THIS ARTICIE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

10

4/ 46

Page 11

Models 596 and 24596

—

PARTS LIST FOR MODEL 596 EDGER

PART

ÌF,

.JO.

1

712-0107

NO.

COLOR

CODE

DESCRIPTION

Hex Cent. L.-Nut 1/4-20 Thd.

2 781-0081 Clutch Plate N

3

710-0106 Hex Bolt 1/4-20 x 1.25" Lg.*

4

714-0115

Cotter Pin 1/8" Dia. x 1.0"

Lg.*

5 720-0120 Grip

6

7

8

749-0666

747-0358

732-0369

Clutch Handle

Clutch Rod

Compression Spring .50"

O.D. X 1.38" Lg.

9 736-0264

Fl.-Wash. .34" I.D. x .62"

O.D. X .063

10

712-0158

11

12

714-0105 Sq.Key 3/16 x 1.0" Lg.*

13

710-0938

14

710-0442

15 711-0421

Hex Cent. L.-Nut 5/16-18 Thd.

Engine

SetScr. 1/4-28X 1/4" Lg. 3/8-16 X. 75" Lg.

Hex Bolt 5/16-18 X 1.50'^' Lg.*

Engine Pulley

16 08253 Bearing Housing

17

736-0242

Bell.-Wash. .34" I.D. x 88"

O.D. x .060

18 710-0528

Hex Bolt 5/16-18 X 1.25" Lg.*

19 09954 Blade

20 736-0112 Bell.-Wash. .535" I.D. x 1.50"

O.D. X .052

712-0239

.2

736-0112 Bell.-Wash. .535" I.D. x 1.50"

Hex Cent. L.-Nut 1/2-20 Thd.

O.D. X .052

23

24

711-0564

732-0330

Spacer

Compression Spring .57"

O.D. X 1.92" Lg.

25

736-0112

Bell.-Wash. .535" I.D. x

1.50" O.D. X .052

712-0114

26

711-0716

27

726-0111

28

09952

29

30 748-0298

Hex Castle Nut 1/2-20 Thd.

Shoulder Spacer

Push Cap

Guide

Spacer .354" I.D. x .635"

O.D. X .510" Lg.

14341 - 497

31

741-0919

32

13333 - 497 Spindle Bracket Ass'y.

33

34 736-0119

712-0267

35

756-0361

36

Blade Guard Ass'yBall Bearing .787" I.D.

X 1.85" O.D. X .551

L-Wash. 5/16" I.D.* O.D. X .060

Hex Nut 5/16-18 Thd. 70 710-0116

Pulley

NEW

>AR1

N

REF.

NO.

COLOR

CODE

DESCRIPTION

Bell.-Wash. .535" I.D. x 1.50"

NO.

37

PART

736-0112

O.D. X .052

38

39

710-0515

738-0108

Hex Bolt 1/2-20x3.50" Lg.*

Shoulder Bolt .498" Dia. x

1.450

40

734-1175

41

736-0169

42

712-0267

43

736-0119 L-Wash. 5/16" I.D.*

44

712-0798

45 13332

46

736-0105

Wheel Ass'y. Comp. 6" Dia.

X 1.50

L-Wash. 3/8" I.D.*

Hex Nut 5/16-18 Thd.*

Hex Nut 3/8-16 Thd.*

Front Wheel Support

Bell.-Wash. .400" I.D. x 88"

O.D. X .060

47 710-0623

48

738-0108

Hex Wash. Hd. Self Tap Scr.

Shoulder Bolt .498" Dia. x

1.450

49

734-1176 Wheel Ass'y. Comp. 7" Dia.

X 1.50

50

736-0105

Bell.-Wash. .400" I.D. x 88"

O.D.

749-0453

51

52 710-0111

Lower Handle

Carriage Bolt 1/4-20 x 1.25"

Lg.*

53

749-0452

54

736-0329

712-0287

55

56 736-0169

57 712-0798

13330 — 615

58

59

714-0115

Upper Handle

L-Wash. 1/4" I.D. *

Hex Nut 1/4-20 Thd.*

L-Wash. 3/8" I.D.*

Hex Nut 3/8-16 Thd.*

Base Ass'y.

Cotter Pin 1/8" Dia. x 1.0"

Lg.*

60 754-0142

712-0267

61

62 736-0119

63 718-0144

64 14427

65 711-0720

66 731-0532

67 710-0380

3V-Belt31.2" Lg.

Hex Nut 5/16-18 Thd.*

L-Wash. 5/16" I.D.*

Grip (Optional)

Flap Bracket

Hinge Pin

Debris Deflector

Hex Bolt 5/16-18 X 1.75"

Lg.*

736-0272

69

Fl.-Wash. .51 I.D. x 1.00

Hex Bolt 5/16-18x2.00"

Lg.*

NEW

PARI

*For faster service obtain standard nuts,

size as shown or parts list.

The engine is not under warranty by the edger manufacturer. If repairs or service is needed on the

engine, please contactyour nearest authorized engine service outlet. Check the "Yellow Pages" of

your telephone book under "Engines — Gasoline."

bolts and washers locally. If these items cannot be obtained locally, order by part number and

Find It Fast

In The

Yellow Pages

11

Page 12

MTD PRODUCTS INC

.......

...........

P.O. BOX 36900 • CLEVELAND OHIO 44136

*.......................... YaRD-MaN COMPANY

Loading...

Loading...