Page 1

Owner's Operating

Service Instruction

lOcfc

Manual

• ASSEMBLY

• OPERATION

• REPAIR PARTS

POWER SHREDDER

yryrOTYTrrirrnrrrryTrrrYTrrOTrrirrSTrrrnrryYrOTYrrrrr^

Model-No. “

244-650A

WARRANTY

For one year from date of purchase, MTD Products Inc will replace for the original purchaser, free

of charge, F.O.B. factory or authorized service firm, any part or parts found to be defective in material

or workmanship. All transportation charges on parts submitted for replacement under this warranty

must be paid by the purchaser. This warranty does not include replacement of parts which become

inoperative through misuse, excessive use, accident, neglect, improper maintenance or alterations by

unauthorized persons. This warranty does not include the engine, motor, battery,, battery charger or any

component parts thereof. For service on these units, refer to the applicable manufacturer's warranty.

The above warranty will apply only to the original owner and will be effective only if the warranty

card has been properly processed. It will not apply where the unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. UNDER

NO CIRCUMSTANCES WILL THE RETURN OF A COMPLETE UNIT BE ACCEPTED BY THE

FACTORY UNLESS PRIOR WRITTEN PERMISSION HAS BEEN EXTENDED.

IX A ».BXO-g-gJLtJJLgJU A.^.«-MJUL^-UJLUXJJLtJLLtJUUl«t 9AX!UJULiiXXXXXtSJLSUtJlJtJULSLXJUL9JAJA I«I

MTD PRODUCTS INC

PRINTED IN U.S.A.

5389 WEST 130th STREET

P.O.BOX 2741 CLEVELAND OHIO 44111

FORM NO. 770-4889

Page 2

IMPORTANT

SAFE OPERATION PRACTICES

1. Read the Operating and Service Instruction Manual

carefully. Be thoroughly familiar with the controls

and proper use of equipment.

2. N'eVei" aii'S^children to operate a power shredder.

3. Keep the are^ operation clear of all persons,

particularly sn^;all children and pets.

4. Check fuel before starting engine. Do not fill gas

oline tank indoors, when engine is running, or

while engine is still hot. Wipe off any spilled gas

oline before si’arting engine.

5. Do not chs-fige engine governor settings or over

speed engine.

6. Do not put hands near rotating parts. Keep clear

of discharge opening at all times.

7. If the equipment should start to vibrate abnor

mally, stop the engine (motor) and check imme

diately for the cause. Vibration is generally a

warning of trouble.

^ '^'hen cleaning, repairing or inspecting, make cer

tain blade and all moving parts have stopped. Dis

con, ract spark plug wire and keep wire away from

plug no prevent accidental starting.

9. Shut engine (motor) off and wait until blade comes

to a complete stop before unclogging chute.

10. Check blade and engine mounting bolts at fre

quent intervals for proper tightness.

11. Keep all nuts, bolts, and screws tight to be sure

equipment is in safe working condition.

12. Never store equipment with gasoline in the tank

inside of a building where fumes may reach an

open flame or spark. Allow engine to cool before

storing in any enclosure.

13. To reduce fire hazard keep free of grass, leaves or

excessive grease.

USING YOUR SHREDDER

Your shredder is designed for safe, efficient, operation.

CARE, OF COURSE, MUST BE EXERCISED THAT HANDS

ARE KEPT AWAY FROM ALL OPENINGS.

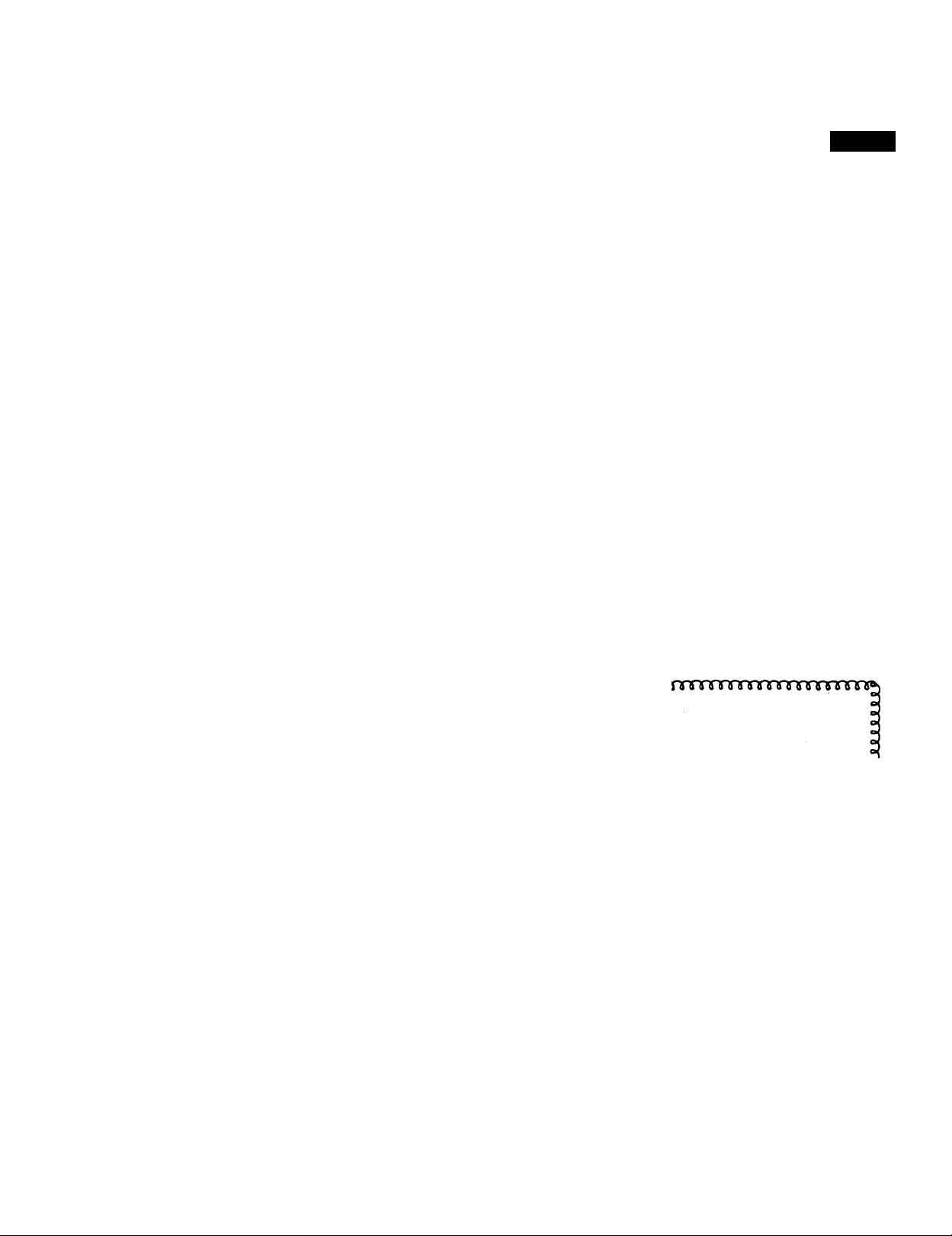

Your shredder guide extension is adjustable. It may be

adjusted to desired height by loosening the hand knob

as shown in figure 1.

FIGURE 1. GUIDE EXTENSION ADJUSTMENT

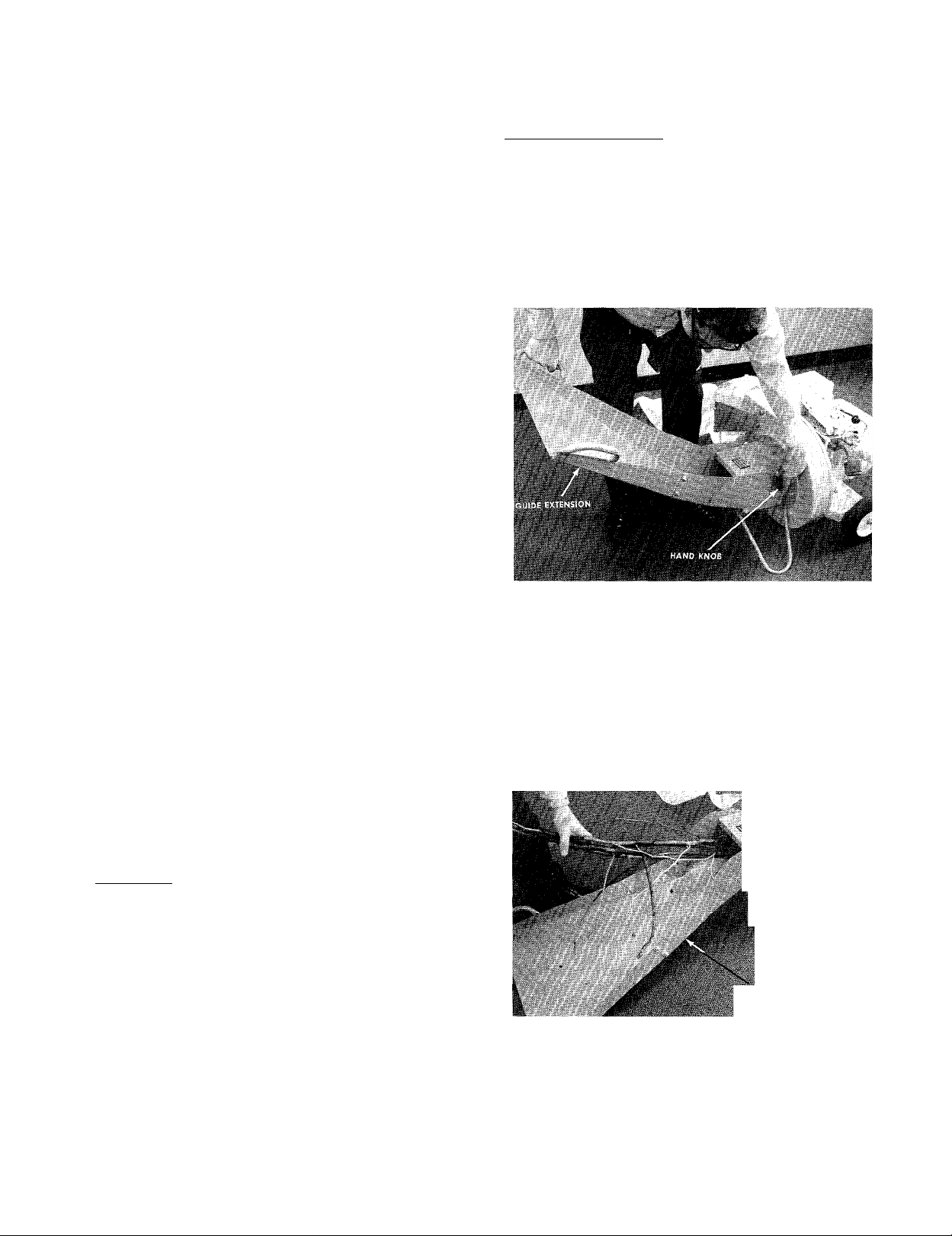

Feed the material so that it slides down the guide ex

tension. See figure 2.

OPERATION

1. Service engine with gas and oil. See engine man

ual packed with shredder for complete instruc

tions for the care and maintenance of engine.

READ DIRECTIONS CAREFULLY.

2. When ready to start engine, place throttle control

lever in START position and start engine in accord

ance with instructions in engine manual. After en

gine starts, move throttle control lever to desired

engine speed. The engine is stopped by placing

control lever in the STOP position.

CAUTION:

The manufacturer recommends that the operator'

I wear safety glasses or some other suitable eye protec- .

tion as it is possible for chips to be elected out of the

I inlet openings while feeding material.

GUIDE EXTENSION

HGURE 2. FEEDING MATERIAL INTO GUIDE

Page 3

EXTENSION

A steady flow of material provides the best results.

Bulky material, such as stalks or heavy branches, should

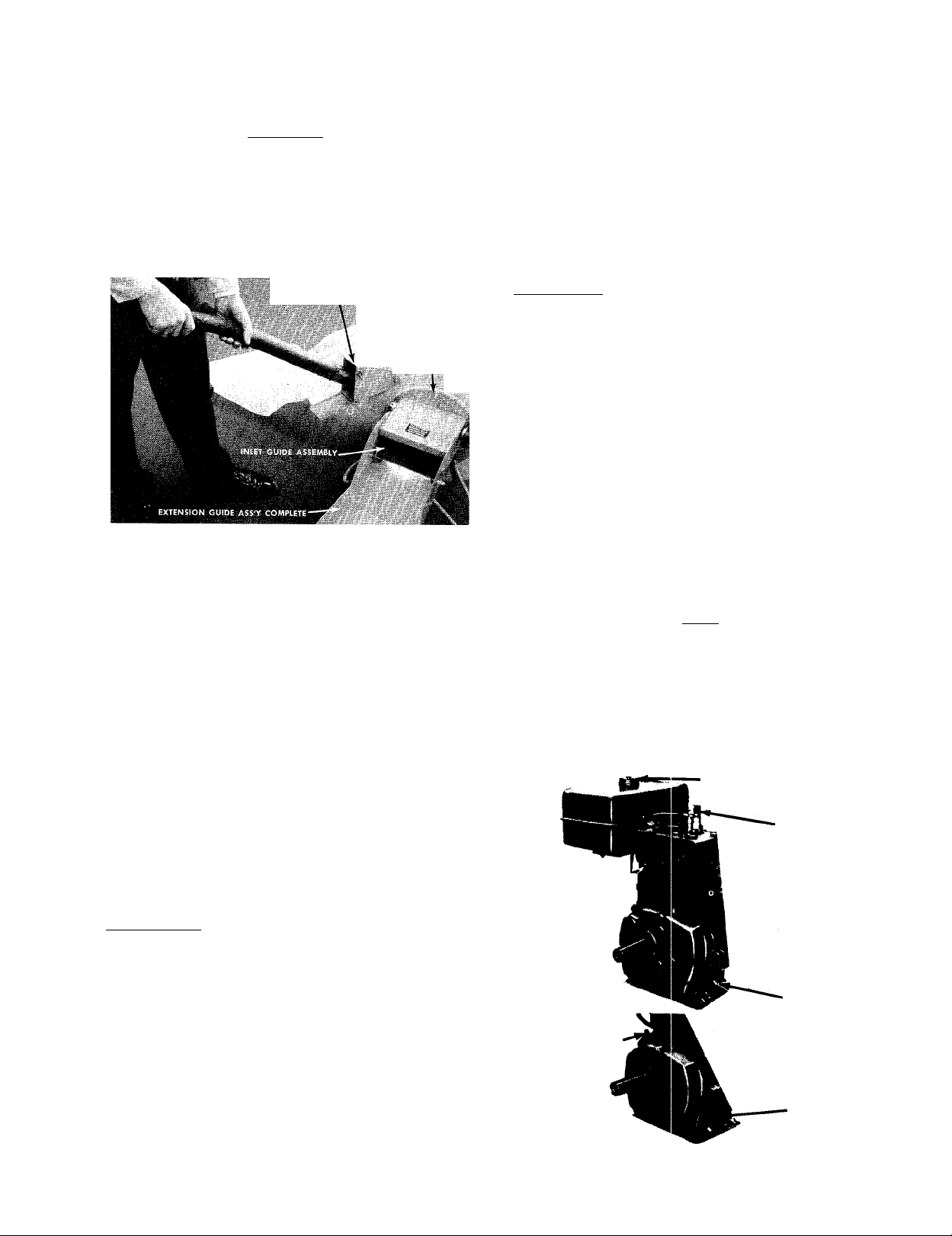

be fed into the upper guide extension. See figure 3.

When sharpening blade, follow the original angle of

grind as a guide. It is extremely important that each

cutting edge receives an equal amount of grinding to

prevent an unbalanced! blade. An unbalanced blade

will cause excessive vibration when rotating at high

speeds and may cause damage to the unit. Upon reas

sembly, make certain a I parts are assembled properly

and tightened securely.

UPPER GUIDE EXTENSION

ELASTIC LOCK NUT

FIGURE 3. FEEDING MATERIAL INTO UPPER GUIDE

EXTENSION

It is possible to feed too fast and you will find it will

take some experimenting with feeding rates to get

the most out of your shredder without stalling the en

gine.

Under certain conditions, it may be necessary to push

the materials into the inlet guide assembly. When this

becomes necessary, use a small diameter stick—NOT

YOUR HANDS. The stick should be of a size that will be

ground up if it gets into the impeller assembly.

The discharge chute will direct the shredded material

into a pile or a container. NOTE: Your shredder is

equipped with a nylon bag with drawstring lock. This

will accommodate a perforated disposable plastic bag.

CAUTION: Keep clear of the chute area since the

shredded material comes out with considerable velo

city. Always stop engine and disconnect spark plug

wire when changing bags.

LUBRICATION

WHEELS—Wheel bearings are of lifetime Fortiflex. They

require no lubrication.

ENGINE—Follow engine manual for lubrication instruc

tions.

«•

u

o

Do Not deposit material larger

O

o

than y?" diameter in hopper.

o

This may cause damage to the

0

< >

shredding mechanism.

CAUTION

1 I

BEFORE STARTING

NOTE

Do not mix oil with gasoline.

1. Fill fuel tank with fresh regular gasoline. (See fig

ure 4.)

2. Fill crankcase with oil. (See figure 4.)

Fili with regular gasoline

Shorting Clip

Oil Dip Stick

MAINTENANCE

CAUTION: Always stop engine and disconnect spark

plug wire before doing any maintenance.

Cutting Blade—The blade may easily be removed for

grinding or replacement as follows:

1. Remove guide extension assembly by removing

four elastic locknuts (Ref. No. 11). See figure 8.

2. Remove bolt (Ref. No. 38), lockwasher (Ref. No.

37) and flat washer (Ref. No. 36) holding blade

(Ref. No. 45) to engine crankshaft. See figure 9.

3. NOTE: Blade is reversible and can be assembled

to crankshaft with either side showing.

Drain Plug

Oil Filler Plug

Drain Plug

FIGURE 4.

Page 4

Position equipment so that engine is setting level.

Remove dip stick or oil filler plug (Figure 1). Pour

oil into oil filler tube from which dip stick was re

moved and fill to FULL mark on dip stick. Do not over

fill. After initial filling follow instructions on dip stick.

Be sure dip stick is screwed into filler opening as far

as it will go when measuring oil level.

During initial break-in period, oil level should be

watched closely See ENGINE MAINTENANCE.

Use MS classification oil. Do not use oils marked only

MM or ML or unmarked.

Above 32° use SAE 30; below 32° use SAE lOW These

recommendations must be followed for best perform

ance and long life.

Change oil first two (2) hours of operation and check

oil level every five (5) operating hours or each time

equipment is used.

Change oil every twenty-five (25) operating hours or

sooner if equipment is operated in extremely dusty or

dirty conditions.

TO STOP ENGINE

1. Press shorting clip against end of spark plug (fig

ure 4) and hold until engine stops running. If short

ing clip is not present move carburetor control to

STOP position. If key starting is used, turn key to

OFF position.

2. Turn off gasoline shutoff valve at underside of tank,

if engine is so equipped. Some engines may have

two valves, one at each end of tank.

3. Remove high tension wire from spark plug to pre

vent accidental stVting by children while equip

ment is unattended.

ENGINE MAINTENANCE

To obtain long life and trouble-free service from

your engine, certain normal maintenance must be per

formed as outlined below:

NOTE: Carburetors are preset at the factory. DO NOT

attempt to make adjustments at this time. See carbu

retor instructions outlined under CARBURETOR AD

JUSTMENT.

NOTE: If engine is equipped wth 6:1 gear reduction

use the following recommended oil weights in the

gear box.

Above 32°F use EP 90 in gear box; below 32°F use

SAE lOW in gear box.

TO START ENGINE

CAUTION

If engine is used on lawnmower, be

sure to keep clear of mower blade at

all times.

1. Be sure shorting clip (figure 4) is away from spark

plug if engine is so equipped.

2. Be sure that fuel valve, if present, under fuel tank

is turned on or opened and that the spark plug

wire is properly attached.

1. Change oil in crankcase after first two (2) hours of

operation. Then, follow instructions outlined at left.

CAUTION

Disconnect high tension wire at spark

plug to prevent accidental starting of

engine. Unscrew oil drain plug located

on side at bottom of engine (figure 4).

NOTE: Always tip engine toward oil drain hole. Be

sure oil drains completely.

Replace oil drain plug and refill with oil as directed

on page 5 or engine nameplate.

2. Check oil every five (5) operating hours or each

time equipment is used.

If engine has dip stick, keep oil level at mark indicated

by adding if necessary.

3. Cleaning engine—This is an aircooled engine which

operates most efficiently when the cooling fins ate

clean.

Clean cylinder fins and underside of tanjc oi housing

thoroughly of all accumulated grass and debris.

3. if equipment is equipped with remote engine and

speed controls, set control in CHOKE or START po

sition.

Some equipment may have the controls on the engine.

Set control on CHOKE or START.

4. Rewind starters—Use quick full arm stroke. Keep

firm grip on handle and return rope slowly.

Be sure equipment controls are in NEUTRAL and that

engine controls are set for starting. Stand clear of

mower and move release lever to START position.

After engine has started, move carburetor control off

CHOKE or STARTING position and on to RUN position.

4. Air Cleaners

a. Paper Type Element. Remove every 10 hours or

oftener if under dusty conditions. Tap to remove

loose dirt and/or blow from inside out with low

pressure air. Replace if torn or perforated or when

plugged to maintain proper carburetor setting (50

hours). DO NOT WASH IN ANY LIQUID AND DO

NOT OIL.

b. Oil Bath. Remove element. Clean element and bowl.

Using same oil used for engine, fill bowl to line.

Replace element.

CAUTION: Do not pour oil down center of bowl (fig

ure 6).

4

Page 5

'Attaching Screw

Paper Element

Element

4. Open one and one-half 1 Vi turns (counter-clock

wise).

5. Start engine. Follow starting instructions page 5.

6. With throttle open (carburetor control at RUN or

FAST position) adjust power adjusting needle oneeighth (’/s) turn at ei time forward or backward un

til engine runs smoothly. If engine tends to stall

under load enrich mixture slightly (counterclock

wise).

7. Hold throttle lever closed or move carburetor con

trol to IDLE or SLOW position and adjust idle ad

justing needle until engine runs smoothly proceed

ing as in step six (6) above.

8. Allow several seconds between each adjustment

when performing either step six (6) or seven (7) to

allow engine to reeict to new setting.

FIGURE 5.

FIGURE 6

CARBURETOR ADJUSTMENTS

Do not make unnecessary adjustments. Factory settings

are correct for most application. If adjustments are

needed, proceed as follows:

1. Close power adjusting needle (figure 7) by turning

to right (clockwise). Close finger tight only. Forcing

will cause damage.

FEED CARBURETOR

FIGURE 7.

STORAGE INSTRUCTIONS

In event engine is to be stored for any length of time

(30 days or more) or at the end of mowing season,

prepare as follows:

1. Drain gasoline by tipping or by syphon hose, then

run engine until remainder is used and tank and

carburetor are empty.

CAUTION: Drain into container outdoors away from

fire or flame.

2. Drain carburetor by pressing upward on bowl

drain (figure 7).

2. Open one turn (counterclockwise).

3. Close idle adjusting needle (figure 7) by turning to

right (clockwise). Close finger tight only. Forciitg

will cause damage.

3. Inside protection of engine for storage is performed

by removing spark plug and pouring one ounce of

SAE 30 oil through spark plug hole into cylinder.

Crank engine, without starting, several times to

spread oil over cylinder walls.

Page 6

244-650A

IF YOU WRITE TO US ABOUT THIS AliTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

FIGURE 8

Page 7

PARTS LIST FOR FIGURE 8 MODEL 244-650A

REF.

NO.

1

2

3

736-264

4 712-429

5

6 710-621 Hex Scr. 5/16-18 X .50" Lg.*

7 736-119

8 11479—463

9

10 11467—463

712-429

11

12

736-264

13

14

712-429

15

736-264

16

17 711-566

712-107 Hex Center L-Nut 14-20 Thd.

18

710-289 Hex Scr. ’/4-20 x .50" Lg.*

19

COLOR

PART

CODE

NO.

11460—463

11472—463

—463 Hopper Assembly

11481

11454—463

9966 Knob Ass'y.

11480 Stop Washer

Guide Extension Assembly

Guide Extension

Spring L-Wash. 5/16" Scr.*

Clamp Rod Assembly

Back-up Plate

Inlet Guide AssembI y

FI. Wash. .50" Dia.*

Chute Pivot Rod

DESCRIPTION

Flat Washer 5/16" Scr.*

Elastic Stopnut 5/16-18 Thd.

Elastic Stopnut 5/16-18 Thd.

FI-Wash. .50" Dia.*

Elastic Stopnut 5/16-18 Thd.

NEW

PART

*For faster service obtain standard nuts, bolts and washers locally. If these items cannot be obtained locally, order

by part number and size as shown on parts list.

(463—Top Flite Red)

• When ordering parts, if color or finish is important, use the appropriate color code

shown at left. (e.g. Top Flite Red—11464 (463).)

Find us fast in the

The engine is not under warranty by the mower manufacturer. If repairs or service is needed on the

engine, please contact your nearest authorized engine service outlet. Check the "Yellow Pages" of

your telephone book under "Engines—Gasoline."

Page 8

244-650A

keep this door

closed except

when feeding

material

If YOU WRITt TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

FtGURE 9

CAUTION

REVOLVING BLADE

keep hands away

from all openings

Page 9

PARTS LIST FOR FIGURE 9 MODEL 244-650A

PART

REF.

NO.

1

710-465 Hex Scr. '/2-20 X 4.50" Lg.*

2

3 711-580 Clevis Pin

711-579 Flail Spacer 7/32" Lg.

4

5

736-921

6

7

726-111 Palnut 3/ 16" Dia.

712-922

8

9 714-507

10 11465—463

11 712-107 L-Nut '/4-20 Thd.

12 710-289

714-114

13

14

15 710-157

16 736-119

17

18

19 11464—463

20 712-123

21

736-119 L-Wash. 5/16" Scr.*

22

736-119

23 712-123

24

726-221

25 7006

26

8306-522

27

736-100

28 710-237

29

712-429

30

710-237

31

714-115

32

736-192

33

34

711-564

35

711-578

36

736-247

37

736-21 7

38

710-151

39

40 712-107

41

42

43

726-111

44

712-109

45 1 1458—463

46

COLOR

CODE

NO.

1 1476—403 Door—Upper Guide Extension

11455—463 Cuffing Finger

Lockwasher '/2" Scr.*

Hex Jam Nuf '/2-20 Thd.*

Cotter Pin 3/32" Dia. x %" Lg.*

Chute Deflector

Hex Scr. '/4-20 X .50" Lg.*

Sq. Key ’/4" X 2.00" Lg.*

11473—463

11452—463

11459—463

11474—463

1 1477—463

11478

1 1475—463

Impeller Assembly

L-Wash. 5/16" Scr.*

Hopper to Engine Mtg. Plate

Engine

Engine Mounting Plate

Hex Nuf 5/16-24 Thd.*

L-Wash. 5/16" Scr.*

Hex Nuf 5/16-24 Thd.*

Push Cap

Fortiflex Bearing

Wheel Ass'y.—Comp.

FI. Wash. .50" I.D.*

Hex Scr. 5/16-24 X.62" Lg.*

Elastic Stopaut 5/16-18 Thd.

Hex Scr. 5/16-24 x .62" Lg.*

Cotter Pin Vs" Dia. x 1.00" Lg.*

FI. Wash. .531" I.D. x .937 O.D.

Flail

Flail Spacer 23/32" Lg

Clevs Pin .50" Dia. x 3.0" Lg.

FI. Wash. .406" I.D. x 1.25"

Hex Scr. %-24x2.00" Lg. H.T.

Flail Housing Ass'y.—Comp.

Upper Guide Extension Ass'y.

Hinge Pin

Palnut 3/16" Dia.

Wing Nut Elastic 'A-20 Thd

Blade

Axle

DESCRIPTION

Hex Scr. 5/16-24x%" Lg.*

X .09

O.D. Hdn.

L-Wash. %" Scr. Heavy Duty

Hex Center L-Nut 'A-20 Thd.

NEW

PART

*For faster service obtain standard nuts, bolts and washers locally. If these items canno" be obtained locally, order

by part number and size as shown on parts list.

(463—Top Flife Red) — When ordering parts, if color or finish is important, use the appropriate color code

shown at left. (e.g. Top Flife Red—1 1464 (463).)

Find us fast In the

The engine is not under warranty by the mower manufacturer. If repairs or service is needed on the

engine, please contact your nearest authorized engine service outlet. Check the "Yellow Pages" of

your telephone book under "Engines—Gasoline."

Page 10

PARTS INFORMATION

DEFECTIVE OR MISSING PARTS must be reported

to the factory immediately. Such claims must include

your model number and date of purchase.

POWER EQUIPMENT PARTS AND SERVICE

Parts and service for all MTD manufactured power

equipment are available through the authorized serv

ice firms listed below. All orders should specify the

model number of your unit, parts numbers, descrip

tion of parts and the quantity of each part required.

A 1 Engine A Mower Co.

327 East 9th Street

Salt Lake City, Utah 84102

American Eiecirie ignition Co.

124 N. W. 8th Street

Okiahoma City, Oklahoma 73102

Auto Electric & Carburetor Co.

2S25 4th Avenue, S.

P. O. Box 1948

Birmingham, Alabama 35233

Automotive Equipment Service Co.

3117 Holmes Street

Kansas City, Missouri 64109

Bailey's Rebuild Inc.

1325 E. Madison Street

Seattle Washington 98102

Bleckrie, Inc.

7900 Lorain Avenue

Cleveland, Ohio 44102

Brown Equipment Distributor Inc.

110 Beech Street

Corydon, Indiana 47112

Bullard Supply

2409 Commerce Street

Houston, Texas 77003

Carl A. Anderson Co.

623 S. I6th Street

Omaha, Nebraska 68102

Catto A Putty, Inc.

P. O. Box 2408

510 Soledad Street

San Antonio, Texas 78205

Center Supply Company

6867 Now Hampshire Avenue

Takoma Park, Maryland 20012

Dixie Sales Company

P. O. Box 1408

327 Battleground Avenue

Greensboro, North Carolina 27402

East Point Cycle A Key Shop

1617 Whiteway

East Point, Georgia 30044

Gamble Distributors

West End Avenue

Carthage, New York 13619

Garden Equipment Co., Inc.

6600 Cherry Avenue

Long Beach, California 90805

Gardenville Supply, Inc.

Pipersville, Pennsylvania 18947

Henry W. O'Neil & Assoc., Inc.

410 North Goodman Street

Rochester, New York 14609

Henzier, Inc.

2015 Lemay Ferry Road

St. Louis, Missouri 63125

Kenton Supply

8216 North Denver Avenue

Portland, Oregon 97217

Kimber't Inc.

115 W. Geddes St.

Syracuse, New York 13204

The Lawnmower Shop

1340 El Camino Real

San Carlos, California 94070

Marr Brothers

423 E. Jefferson

Dallas, Texas 75203

Mathews Auto Electric Co.

420 East 2nd Street

Tulsa Oklahoma 74120

McClure Lawn A Garden Supply

1114 Lexington Avenue

Mansfield, Ohio 44907

Memphis Cycle A Supply Co.

421 Monroe Avenue

Memphis Tennessee 38103

Morton B. Collins Co.

300 Birnie Avenue

Springfield, Massachusetts 01107

Moz-AII of Florida, Inc.

365 Greco Avenue

Coral Gables, Florida 33146

BRIGGS & STRATTON, TECUMSEH AND PEERLESS PARTS AND SERVICE

Briggs & Stratton, Tecumseh and Peerless parts and

service should be handled by your nearest authorized

engine service firm. Check the yellow pages of your

telephone directory under the listing Engines —

Gasoline, Briggs & Stratton or Tecumseh Lauson —

Power Products.

National Central, Div. of

Joe Sterling, Inc.

Drawer "D" 687 Seville Rd.

Wadsworth, Ohio 44281

Parts A Sales Inc.

2101 Industrial Pkwy.

Elkhart, Indiana 46514

Power Equipment Distributor

36463 So. Gratiot Avenue

Mt. Clemens, Michigan 48043

Power Lawn A Garden Equip. Co.

2551-2571 J. F. Kennedy Road

Dubuque, Iowa 52001

Radco Distributors

2403 Market Street

P. O. Box 3216

Jacksonville, Florida 32206

Raub Supply Company

James A Mulberry Sts.

Lancaster, Pennsylvania 17604

Richmond Battery A Ignition

P. O. Box 25369 - 957 Myers St.

Richmond, Virginia 23260

Smith Hardware Company

515 N. George Street

Goldsboro, North Carolina 27530

South Denver Lawn Equip. Co.

527 West Evans

Denver, Colorado 80223

Suhren Engine

8330 Earhart Blvd.

New Orleans, Louisiana 70118

Sutton's lawn Mower Shop

Route 4, Box 343

North Little Rock, Arkansas 72117

Warner Equipment

7520 Lyndale Avenue, So.

Minneapolis, Minnesota S5423

Woodson Salas A Service

1702 North Sylvania

Ft. Worth, Texas 76111

♦

♦

♦

♦

t

♦

♦

♦

♦

♦

♦

♦

♦

FORM NO. 770-4-889

The purpose of warranty is to protect the customer from defects in workmanship and materials,

defects which are NOT detected at the time of manufacture. It does not provide for the unlimited

and unrestricted replacement of parts. Use and maintenance are the responsibility of the cus

tomer. The manufacturer cannot assume responsibility for conditions over which it has no

control. Simply put, if it's the manufacturer's fault, it's the manufacturer's responsibility; if

it's the customer's fault, it's the customer's responsibility.

CLAIMS AGAINST THE MANUFACTURER'S WARRANTY INCLUDES

1. Replacement of Missing Parts on new equip- 1. Model Number of unit involved,

ment.

2. Replacement of Defective Parts within the

warranty period.

3. Repair of Defects within the warranty , i c

", A. Nature of failure,

period.

WARRANTY PARTS AND SERVICE POLICY

All clairtis MUST be substantiated with the

following information:

2. Date unit was purchased or first put into

service.

3. Date of failure.

10 PRINTED IN U.S.A.

I

\

I

t

t

t

♦

♦

♦

♦

Loading...

Loading...