Page 1

YaRD-MaN

OUTDOOR POWER EQUIPMENT

for all seasons

Owner’s

8H.P.

SHREDDER

Manual

ASSEMBLY

OPERATION

MAINTENANCE

IMPORTANT:

Read Safety Rules and

Thank you for purchasing an American-built product.

Model Number

Instructions Carefully

WARNING: This unit is equipped with an internai combustion engine and shouid not be used on or near any unimproved for

est-covered, brush-covered or grass-covered iand uniess the engine’s exhaust system is equipped with a spark arrester

meeting appiicable iocai or state iaws (if any). If a spark arrester is used, it should be mairitained in effective working order

by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states

may have similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest

engine authorized service dealer or contact sen/ice department, P.O. Box 368022, Cleveland, Ohio 44136-9722.

PRINTED IN U.S.A.

244-648D401

FORM NO. 770-8607J

Page 2

A

S>VFETY RULES

WARNING: TO REDUCE THE POTENTIAL FOR ANY INJURY, COMPLY WITH THE FOLLOWING

SAFETY INSTRUCTIONS. FAILURE TO COMPLY WITH THE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY.

TRAINING

• Read this owner’s manual carefully in its entir« ty before

attempting to assemble or operate this machine Be com

pletely familiar with the controls and the propsr use of

this machine before operating it. Keep this me nual in a

safe place for future and regular reference and for order

ing replacement parts.

• Children must never be allowed to operate tf is equip

ment.

• No one should operate this unit while intoxicated or while

taking medication that impairs the senses or rea Dtions.

• This equipment should never be operated in tt le vicinity

of children, pets or other persons.

• Never run your machine in an enclosed area as the

exhaust from the engine contains carbon monoxi de, which

is an odorless, tasteless and deadly poisonous g as.

• Never place your hands or any part of your bod;' or cloth

ing inside the feeding chamber, discharge chut i, or near

any moving part while the machine or engine is unning.

• If it is necessary for any reason to inspect or epair the

feeding chamber or any part of the machine whe re a mov

ing part can come in contact with your body oi clothing,

stop the machine, allow it to cool, disconnect :he spark

plug wire from the spark plug and move it awa^ from the

spark plug before attempting such inspection or repair.

PREPARATION

• Wear safety glasses provided with your unit whi e operat

ing the shredder to prevent injury from any mate rial which

may be ejected out of the openings.

• Wear proper apparel. Avoid wearing loose fittinc clothing.

Wear gloves when handling material.

• HANDLE GASOLINE WITH CARE as it is an extremely

flammable fuel.

• Check the fuel before starting the engine. Do t lot fill the

fuel tank indoors, while the engine is running, or while the

engine is still hot. Turn the unit off and let the er gine cool

before refueling.

• Fuel your shredder in a clean area. Do not smoh e while

refueling.

• Fuel tank cap must be secure at all times excepi during

refueling.

• Avoid spilling gasoline or oil. Wipe the unit clean of any

spilled fuel or oil.

• Store fuel and oil in approved containers, away 1 rom heat

or open flame, and out of reach of children.

• This machine should be operated only upon a le /el sur

face.

• Assure that all screws, nuts and bolts and other ;asteners

are properly secured.

OPERATION

• When feeding shreddable material into this e(|uipment,

be extremely careful that pieces of metal, rock;, bottles,

cans or other foreign objects are not included. Personal

injury or damage to the machine could result.

• If the cutting mechanism strikes any foreign object or if

your machine should start making an unusual noise or

vibration, immediately stop the engine, disconnect the

spark plug wire from the spark plug and move it away

from the spark plug. Allow the machine to stop and take

the following steps:

Inspect for damage.

Replace or repair any damaged parts.

Check for any loose parts and tighten to assure continued

safe operation.

• The engine must be kept clean of debris and other accu

mulations.

• Do not allow an accumulation of processed material to

build up in the discharge area as this will prevent proper

discharge and can result in kick-back from feed opening.

• Never place your hands or any other part of your body or

clothing inside the feeding chamber, discharge chute or

near any moving part while the engine is running.

• Keep all guards and deflectors in place and in good work

ing condition to assure continued safe operation.

• Always stand clear of the discharge area when operating

this machine.

• Keep your face and body back from the feed opening to

avoid accidental bounce back of any material.

• Do not over-reach. Keep proper balance and footing at all

times.

• The engine governor settings on your machine must not

be altered, changed, or tampered with. The governor

controls the maximum safe operating speeds and pro

tects the engine and all moving parts from damage

caused by overspeed.

• Do not transport machine while engine is running.

• Do not operate engine if air cleaner or cover directly over

carburetor air intake is removed, except for adjustment.

Removal of such parts could create a fire hazard.

MAINTENANCE AND STORAGE

• When this equipment is stopped for servicing, inspection,

storage or to change an accessory, make sure the spark

plug wire is disconnected from the spark plug and moved

away from the spark plug. The machine should be

allowed to cool down before making such inspection,

adjustments, service, etc. Maintain your machine with

care and keep it clean for the best and continued safe

operation.

• Do not use flammable solutions to clean the air filter.

• When not in use, your machine should be stored out of

the reach of children. Keep where gasoline fumes will not

reach an open flame or spark. For long periods of stor

age, refer to the “Off-Season Storage” section of this

manual.

Page 3

ASSEMBLY INSTRUCTIONS

N

IMPORTANT: This unit is shipped WITHOUT GASO

LINE or OIL. After assembly, see operation section of

this manual for proper fuel and engine oil recommen

dations.

NOTE: To determine right and left hand sides of your

chipper-shredder, stand behind and face the hopper

(engine is at the front of the unit).

Your chipper-shredder has been completely assem

bled at the factory, except for the chute deflector and

the catcher bag. A pair of safety glasses are also

included in the carton.

TO REMOVE CHIPPER-SHREDDER FROM CARTON

Cut the corners of the carton. Remove all packing

inserts. Roll chipper-shredder out of the carton. Make

certain all parts, literature and the safety glasses have

been removed before the carton is discarded.

TOOLS REQUIRED FOR ASSEMBLY

(2) 7/16" or Adjustable Wrenches

Spacers

(Inside^

Hinge)'

FIGURE 1.

Hex Bolt

Chute

Deflector

HOW TO SET-UP YOUR CHIPPER-SHREDDER

WARNING: Make certain the spark plug

wire is disconnected and moved away

A

from the spark plug before assembling

the chipper-shredder.

AHACHING THE CHUTE DEFLECTOR

1. Remove the hand knobs and cupped washers

from each side of the discharge opening on the

left side of the shredder.

2. Remove the hex lock nut, two spacers and hex

bolt from inside the hinge on top of the discharge

opening. Do not remove one spacer from the hex

bolt.

3. Place the chute deflector in position on the dis

charge opening. Insert bolt through hinge on chute

deflector and housing (spacer fits inside hinge).

4. Place second spacer over the hex bolt, inside the

other part of hinge. Secure with hex lock nut.

Tighten securely.

5. Secure both sides of the chute deflector to the

housing using hand knobs and cupped washers

(cupped side of washers go against chute deflec

tor).

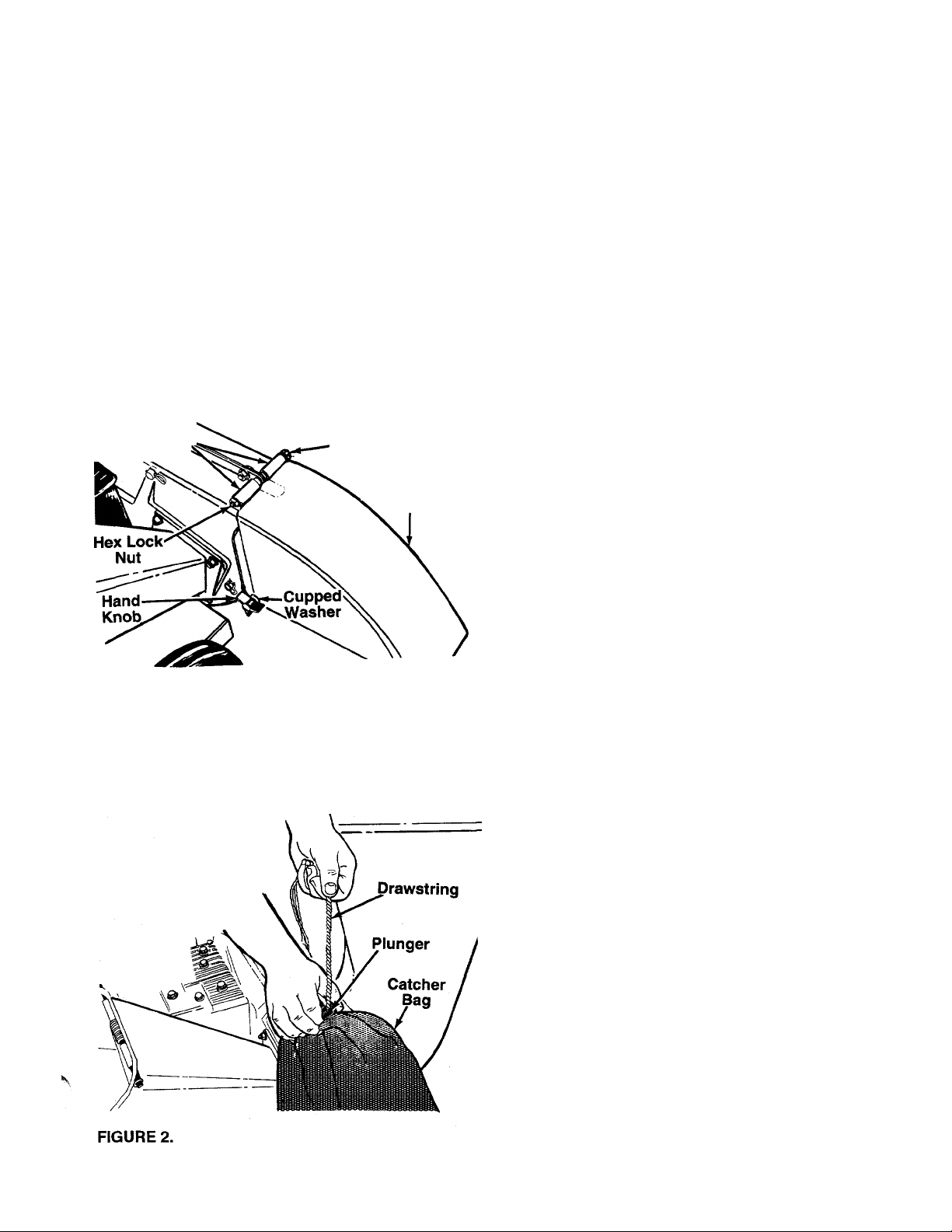

AHACHING THE CATCHER BAG

Your chipper-shredder is equipped with a catcher bag

to catch the shredded material.

To attach bag, place bag opening over the chute

deflector so it completely covers chute opening.

Depress plunger on drawstring, pull on drawstring

until bag is tight around chute opening. Release

plunger to lock it into position. See figure 2.

Page 4

I I

OPERATION

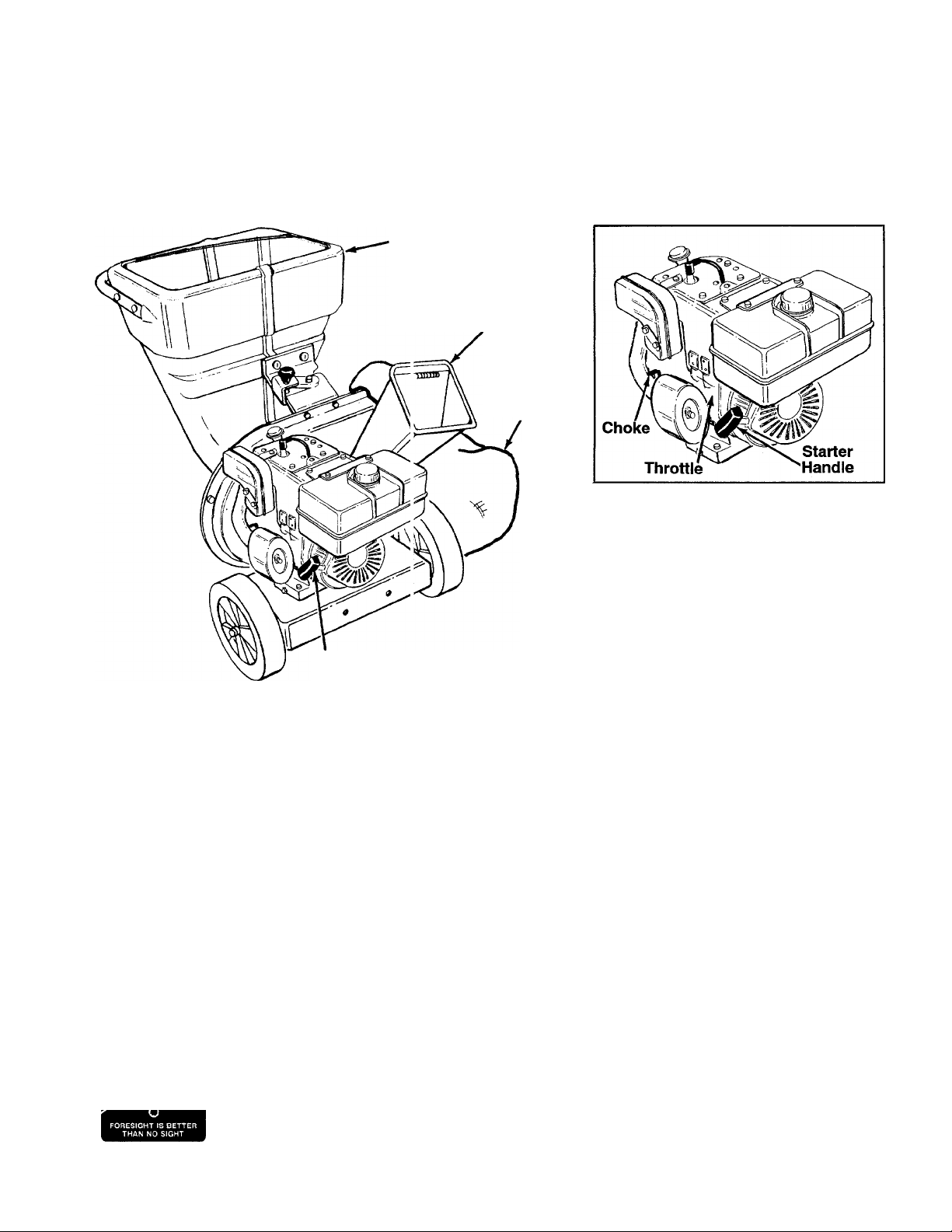

KNOW YOUR SHREODER

READ THIS OWNER’S MANUAL AND SAFliTY RULES BEFORE OPERATING YOUR SHREDDER. Compare

the illustrations with your shredder to familiarize yourself with the location of various controls and adjustments.

Save this manual for future reference.

Ho pper

Chipper

Chute

Catcher

Bag

Starter

Handle

FIGURE 3.

OPERATING CONTROLS (See figure 3 and 1)

RELEASE HANDLE—Used to release the hopper

when lowering to the ground.

CHOKE LEVER—Used to enrich the fuel n ixture in

the carburetor when starting a cold engine.

STARTER HANDLE—Used to manually start the

engine.

THROTTLE CONTROL—Controls engine sp eed and

stops the engine.

The operation of any shredder can result in for

eign objects being thrown into the eyeri, which

can result in severe eye damage.

Always wear safety glasses or eye

shields. We recommend wide

^ ' vision safety mask for ovei specta

cles or standard safety glasses.

FIGURE 4.

BEFORE STARTING

1. Place the shredder on a firm, level surface.

2. Attach spark plug wire to spark plug.

3. Service engine with gasoline and oil as instructed

in the separate engine manual packed with your

shredder.

4. Open fuel shut-off valve (if so equipped).

NOTE: Check the fuel level periodically to avoid run

ning out of gasoline while operating the chippershredder. If the unit runs out of gas as it is shredding

or chipping, it may be necessary to unclog the unit

before it can be restarted. Refer to “Removing the

Flail Screen” on page 7.

TO START ENGINE

WARNING: Be sure no one other than the

operator is standing near the shredder

A

while starting or operating.

Page 5

Place the throttle control lever in FAST position.

1.

See figure 4.

N

Move choke lever to CHOKE position (a warm

2.

engine may not require choking).

Grasp starter handle (see figure 4) and pull rope

out slowly until engine reaches start of compres

sion cycle (rope will pull slightly harder at this

point). Let the rope rewind slowly.

Pull rope with a rapid, continuous, full arm stroke.

4.

Keep a firm grip on starter handle. Let rope

rewind slowly. Do not let starter handle snap back

against starter.

Repeat preceding instructions 3 and 4 until

5.

engine fires. When engine starts, move choke

lever on engine halfway between CHOKE and

RUN.

Move throttle control to IDLE position for a few

6.

minutes warm-up. Move choke lever to RUN posi

tion as engine warms up.

NOTE: In order to idle smoothly, a new engine may

require 3 to 5 minutes running above slow idle speed.

Idle speed has been adjusted to be correct after this

break-in period.

A

WARNING: Do not put material larger than

1/2" in diameter into the hopper. Material

up to a maximum of 3" in diameter materi

al may be fed into the chipper chute. Do

not attempt to shred or chip any material

larger than 3" in diameter. Personal injury

or damage to the machine could result.

TO STOP ENGINE

1. Move throttle control lever to STOP position.

2. Disconnect spark plug wire and move away from

spark plug to prevent accidental starting while

equipment is unattended.

3. Close fuel shut-off valve (if so equipped) when

unit is not in use to prevent fuel leakage.

HOW TO USE YOUR SHREOOER

Do not attempt to shred or chip any material other

than vegetation found in a normal yard (i.e., branches,

leaves, twigs, etc.).

WARNING: The shredder discharges

material with considerable velocity. Keep

A

The shredder is designed for three different methods

of operation.

1. Leaves and small branches up to 1/2" diameter

away from the area around the chute

deflector. Always stop the engine and dis

connect the spark plug wire when remov

ing or attaching the bag, when changing

containers or when removing the shred

ded materiai, wear safety giasses and

gioves whenever using your shredder.

can be fed into the hopper when it is in the raised

position. See figure 5. If it becomes necessary to

push material into the shredder, use a small diam

eter stick—NOT YOUR HANDS. The stick cannot

exceed 1/2“ in diameter so it will be ground up if it

gets into the impeller assembly.

FIGURE 5.

2. Leaves and small twigs can be raked into the

shredder when the hopper assembly is lowered to

the ground. See figure 6.

To lower the hopper assembly to the ground, use

one hand to grasp the top of the hopper assem

bly. Push down on the release handle, and pivot

the hopper assembly to the right. See figure 7.

FIGURE 6.

Page 6

3. Bulky material, such as stalks or heavy branches,

up to 3" in diameter should be fed into tie chip

per chute. See figure 8.

WARNING: Make certain the chipper

▲

chute door is closed when not in i se.

I i

FIGURE 8.

IMPORTANT: There is a flail screen located inside

the housing in the discharge area. If the flail screen

becomes clogged, remove and clean as instructed in

the Maintenance section below.

For best performance, it is important to keep the

shredding blade and the chipper blades sharp. Refer

to Maintenance section, page 7. If the composition of

the material being discharged changes (becomes

stringy, etc.) or if the rate at which the material is dis

charged slows down considerably, it is likely that the

shredding blade and/or chipper blades are dull and

need to be sharpened or replaced.

Mi\INTENANCE

WARNING: Always stop engine end dis

connect spark plug wire before cleaning,

A

LUBRICATION

Lubricate the pivot points on the release hanc le, hop

per assembly, chute deflector and chipper chute once

a season using a light oil.

ENGINE

Refer to the separate engine manual for engir e main

tenance instructions.

Maintain engine oil as instructed in the ssparate

engine manual packed with your unit. Read ard follow

instructions carefully.

Service air cleaner every 25 hours under nornal con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and Hooding

usually indicates that the air cleaner should be ser

viced. To service the air cleaner, refer to the separate

engine manual packed with your unit.

lubricating or performing any repairs or

maintenance.

The spark plug should be cleaned and the gap reset

once a season. Spark plug replacement is recom

mended at the start of each season; check engine

manual for correct plug type and gap specifications.

Clean the engine regularly with a cloth or brush.

Keep the cooling system (blower housing area) clean

to permit proper air circulation which is essential to

engine performance and life. Be certain to remove all

dirt and combustible debris from muffler area.

CLEANING

The shredder may be cleaned by running water from

a hose through the hopper assembly and chipper

chute with the engine running. Allow the shredder to

dry thoroughly.

Wash the bag periodically with water. Allow to dry

thoroughly in the shade. Do not use heat.

REMOVING THE FLAIL SCREEN

If the discharge area becomes clogged, remove the

flail screen and clean area as follows.

Page 7

1. Stop the engine, make certain the shredder has

come to a complete stop and disconnect spark

plug wire from the spark plug before unclogging

the chute.

2. Loosen the two hand knobs on each side of the

chute deflector. Lift the chute deflector up, and tie

it out of the way.

3. Remove two hairpin clips from the clevis pins

which extend through the housing. Remove the

clevis pins. Lift the flail screen from inside the

housing. See figure 9.

4. Clean the screen by scraping or washing with

water. Reinstall the screen.

NOTE: Be certain to reassemble the flail screen with

the curved side down as shown in figure 9.

Chute Deflector

4. Rotate the impeller assembly by hand until you

locate one of the chipper blades in the chipper

chute opening. Remove the blade, using a 3/16"

alien wrench on the outside of the blade and 1/2"

wrench on the impeller assembly (inside the

housing). See figure 10.

5. Remove the other blade in the same manner.

Hand Knobs

FIGURE 9.

SHARPENING OR REPLACING CHIPPER BLADES

1. Disconnect spark plug wire and move it away

from spark plug.

2. Remove the flail screen as instructed in previous

section.

3. Remove the chipper chute by removing three hex

nuts and washers. A 1/2" wrench is required. See

N

figure 9.

NOTE: When reassembling, the cupped washer goes

on the bottom of the chipper chute with the cupped

side against the chute.

FIGURE 10.

Replace or sharpen blades, if sharpening, make cer

tain to remove an equal amount from each blade.

Reassemble in reverse order.

Make certain blades are reassembled with the sharp

edge facing the direction shown in figure 10 (sharp

edge is assembled toward the slotted opening in the

impeller assembly).

SHARPENING OR REPLACING SHREDDING BLADE

The shredding blade may be removed for sharpening

or replacement as follows.

1. Disconnect spark plug wire and move it away

from spark plug.

2. Lower the hopper assembly. Block up the hopper.

See figure 11.

3. Remove the six hex lock nuts and flat washers

from the housing weld bolts using a 1/2" wrench.

Remove the hopper assembly.

4. Remove the back-up plate.

NOTE: When reassembling the back-up plate, make

certain the single tab is at the top of the back-up

plate, and the two tabs are at the bottom. Also, make

certain the tabs go toward the blade.

Page 8

FIGURE 11.

Torque

Wrench

Allen

= crews

r

Blade

I i

When reassembling the blade, tighten to between 550

and 650 inch pounds, or lacking torque wrench, tight

en securely.

FLAILS

The flails, located inside the housing, may be

reversed when they become dull. It is suggested that

this procedure be performed by your nearest author

ized dealer.

CARBURETOR ADJUSTMENT

WARNING: If any adjustments are made

to the engine while the engine is running

A

(e.g. carburetor), keep clear of all moving

parts. Be careful of heated surfaces and

muffler.

5. Loosen the two hand knobs and cupped v /ashers

which secure the chute deflector, and riiise the

chute deflector.

6. Insert a 1/2" or 3/4“ diameter pipe through the flail

screen into the impeller assembly to keef it from

turning, or remove the flail screen, and nsert a

piece of wood (2 x 4) into the chute openir g.

7. Remove the two outside screws on the blade,

using a 3/16" alien wrench and a 1/2" wrench.

8. Remove the blade by removing the cen er bolt,

lock washer and flat washer.

NOTE: Use caution when removing the blade to avoid

contacting the weld bolts on the housing.

When sharpening the blade, follow the original angle

of grind as a guide. It is extremely important tf at each

cutting edge receives an equal amount of grinding to

prevent an unbalanced blade. An unbalanced blade

will cause excessive vibration when rotating at high

speeds and may cause damage to the unit.

The blade can be tested for balance by bak ncing it

on a round shaft screwdriver or nail. Remove metal

from the heavy side until it is balanced evenly. See

figure 12.

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude

or load.

NOTE: A DIRTY AIR CLEANER WILL CAUSE

ENGINE TO RUN ROUGH. BE CERTAIN AIR

CLEANER IS CLEAN AND ATTACHED TO THE

CARBURETOR BEFORE ADJUSTING CARBURE

TOR.

Do not make unnecessary adjustments. Factory set

tings are satisfactory for most applications and condi

tions. If adjustment is needed, refer to the separate

engine manual packed with your shredder.

OFF-SEASON STORAGE

The following steps should be taken to prepare your

shredder for storage.

1. Clean and lubricate the shredder thoroughly as

described in the lubrication instructions.

2. Refer to engine manual for correct engine storage

instructions.

3. If storing in an unventilated or metal storage

shed, coat metal parts with a light oil or silicone to

prevent rust.

4. Store in a dry, clean area. Do not store next to

corrosive materials, such as fertilizer.

Page 9

OPTIONAL EQUIPMENT

A vacuum hose kit (model 290-002-000) and a tow

hitch kit (model 290-003-000) are available as option

al equipment for the shredder shown in this owner’s

guide.

TROUBLE SHOOTING

PROBLEM

Engine fails to start 1. Spark plug wire disconnected.

Loss of power;

operation erratic

Engine overheats

Too much vibration Loose parts or damaged

Unit does not

discharge

POSSIBLE CAUSE(S)

2. Fuel tank empty, or stale fuel.

3. Fuel shut-off valve closed

(if so equipped).

4. Faulty spark plug.

1. Spark plug wire loose.

2. Unit running on CHOKE.

3. Blocked fuel line or stale fuel.

4. Water or dirt in fuel system.

5. Carburetor out of adjustment.

6. Dirty air cleaner.

1. Carburetor not adjusted

properly.

2. Engine oil level low.

impeller.

1. Discharge chute clogged.

2. Foreign object lodged in impeller.

CORRECTIVE ACTION

1. Connect wire to spark plug.

2. Fill tank with clean, fresh fuel.

3. Open fuel shut-off valve.

4. Clean, adjust gap or replace.

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF position.

3. Clean fuel line; fill tank with clean

fresh gasoline.

4. Disconnect fuel line at carburetor to drain fuel

tank. Refill with fresh fuel.

5. Adjust carburetor.f

6. Service air cleaner.f

1

. Adjust carburetor.f

2. Fill crankcase with proper oil.

Stop engine immediately and disconnect

spark plug wire. Tighten all bolts and nuts.

Make all necessary repairs. If vibration continues,

have unit serviced by an authorized sen/ice

dealer.

1. Stop engine immediately and disconnect

spark plug wire. Clean flail screen and inside

of housing. See Maintenance section of this

manual.

2. Stop engine immediately and disconnect

spark plug wire. Remove lodged object.

Rate of discharge

slows considerably or

composition of

discharged material

changes

s

tRefer to the engine manual packed with your unit.

NOTE: For repairs beyond the minor adjustments listed above, please contact your nearest authorized sen/ice dealer.

Shredding blade and/or chipper

blades dull.

Sharpen or replace shredding and chipper

blades.

Page 10

I I

Page 11

TWO YEAR LIMITED WARRANTY

For TWO YEARS from the date of retail purchase within the United States of America, its possessions

and territories, YSRO-MaN will, at its option, repair or replace, for the original purchaser, free of

charge, any part or parts found to be defective in material or workmanship. This warranty covers units

which have been operated and maintained in accordance with the owner’s instructions furnished with

the unit, and which have not been subject to misuse, abuse, commercial use, neglect, accident,

improper maintenance or alteration.

Normal wear parts or components thereof are subject to separate terms as noted below in the “No

Fault Ninety Day Consumer Warranty” clause.

Two year consumer warranty on normal wear parts with ninety day no fault protection. All normal wear

part failures will be covered on this product for a period of 90 days regardless of cause. After 90 days

but within the two year warranty period, normal wear parts failures will be covered if caused by defects

in material or workmanship or other component parts. Normal wear parts are defined as batteries,

belts, blades, blade adapters, grass bags, rider deck wheels, and seats.

How to obtain service: Warranty service is available, with proof of purchase, through your local

authorized service dealer. To locate the dealer in your area, please check the yellow pages or contact

the Customer Service Department of YRRD-MaN, P.O. Box 361131, Cleveland, Ohio 44136-0019.

Phone 1 (800) YaRD-MaN. The return of a complete unit will not be accepted by the factory unless

prior written permission has been extended by the service department of YaRD-MaN.

Transportation charges: Transportation charges for the movement of any power equipment unit or

attachment are the responsibility of the purchaser.

Units exported out of the United States: YaRD-MaN does not extend any warranty for products

sold or exported outside of the United States of America, its possessions and territories, except those

sold through YaRD-MaN’S authorized channels of export distribution.

OTHER WARRANTIES:

1. The engine or component parts thereof carry separate warranties from their manufacturers. Please

refer to the applicable manufacturer’s warranty on these items.

2. Log splitter pumps, valves and cylinders or component parts thereof are covered by a one year

warranty.

3. All other warranties, express or implied, including any implied warranty of merchantability or fitness

for a particular purpose, are hereby expressly disclaimed in their entirety.

4. The provisions as set forth in this warranty provide the sole and exclusive remedy of

YRRD-MaN’S obligations arising from the sales of its products. YaRD-MaN will not be liable for

incidental or consequential loss or damage.

How state law relates to this warranty: This limited warranty gives you specific legal rights, and you

may also have other rights which vary from state to state. Certain disclaimers are not allowed in some

states and therefore they may not apply to you under all circumstances.

NOTE: This warranty does not cover routine maintenance items such as lubricants, filters, blade sharp

ening and tune-ups, or adjustments such as brake adjustments, clutch adjustments or deck adjust

ments. Nor does this warranty cover normal deterioration of the exterior finish due to use or exposure.

"N

Page 12

I I

VISA

MC

DISC

For ParÉs» Accessories or Service liiformotiony

CAUL NOW!

1

(

800

9:00 AM to Midi night Monday through Friday

9:00 AIMi to 8:00 PM Saturday

Eastern Tim<^ (winter hours may vary)

The only way to ins

is to use original

which are designe<

cations. When yoi

quaiity, reliability, s

equipment parts—i

)

800-7310

ure the performance of your product

equipment parts and accessories,

I and engineered to exacting specifiI substitute, you take a chance on

afety and performance. Use original

»ee your local service dealer.

Loading...

Loading...