MTD 243-685-000 User Manual

OWICirS GUIDE

G ASSEMBLY • OPERATION • MAINTENANCE • PARTS •

POWER

VACUUMS

Model Numbers

$1.00

Important:

Read Safety Rules

and Instructions Carefully

WARNING: This unit is equipped with an internal combustion engine and should not be used

on or near any unimproved forest-covered, brush-covered or grass-covered land unless the

engine’s exhaust system is equipped with a spark arrester meeting applicable local or state

laws (if any). If a spark arrester is used, it should be maintained in effective working order by

the operator.

In the State of California the above is required by law (Section 4442 of the California Public

Made ^

in

AMERICA

Resources Code). Other states may have similar laws. Federal laws apply on federal lands.

A spark arrester for the muffler is available through your nearest engine authorized service

dealer or contact the service department, P.O. Box 360900, Cieveland, Ohio 44136.

243-675-000

243-685-000

243-689-000

243677

243687

IMPORTANT!

Record the Model No. and Mfg. Code which

appear on your unit in the space below. You

must have these numbers, along with the date

of purchase, in order to receive warranty or ser

vice.

MEETS ANSI SAFETY STANDARDS

MODEL NO. MFG. CODE

FORM NO. 770-5208H

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER

THE PERSONAL SAFETY AND/OR PROPERTY (T YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS

A

IN THIS MANUAL BEFORE ATTEMPTING TO 0 DERATE YOUR POWER VACUUM. FAILURE TO COMPLY WITH THESE

INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL— HEED ITS WARNING.

Your power vacuum was I )uilt to be operated according to the rules for safe operation in this manual.

DANGER:

A

As with any type of powe^ equipment, carelessness or error on the part of the operator can result in

serious injury, if you viola e any of these rules, you may cause serious injury to yourseif or others.

RULES FOR SAFE OPERATION

£

1. Read this operating and service instruction manual

Be thoroughly familiar with the controls and proper

power vacuum.

2. Never allow children to operate this power vacuum.

3. Keep the area of operation clear of all persons, p;

small children and pets.

4. Check fuel before starting engine. Do not fill fuel tan

when engine is running, or while engine is hot. Wi|

spilled fuel before starting engine.

5. Do not change engine governor settings.

6. Do not put hands near rotating parts for any reason.

7. If the power vacuum should start to vibrate abnorrr

the engine and check immediately for the cause. Vi

generally a warning of trouble.

8. Before cleaning, repairing or inspecting, make certaii

ing parts have come to a complete stop. Disconnect:

wire and keep wire away from plug to prevent accide

ing. Also keep throttle control lever in the stop positio

9. If the power vacuum should become blocked with del

point, shut engine off and wait until the impeller c(

complete stop before attempting to remove the ob

Disconnect spark plug wire to prevent accidental start

carefully,

jse of the

irticularly

c indoors,

'6 off any

ally, stop

oration is

I all movpark plug

Jtal start-

.

1

|ris at any

mes to a

jtruction.

¡ng.

10. Check all bolts for tightness at frequent periods.

11. Never store this power vacuum with fuel in the tank. Allow

engine to cool before storing in any enclosure.

12. Keep bag and equipment free of debris when not in use.

13. Never operate this power vacuum unless air duct and vacuum

bag are properly affixed in their place. Large zippered end of

bag must be closed when operating to prevent objects from

being blown out.

14. Never empty vacuum bag when engine is running.

15. Never change inlet nozzle or auxiliary hose attachment when

engine is running.

16. The manufacturer recommends that the operator wear safety

glasses or some other suitable eye protection when operating

this machine.

17. Check the vacuum bag frequently for wear and replace when

necessary.

18. Never operate as a leaf blower unless impeller guard and guard

assembly are properly affixed in their place.

19. Exercise caution whenever operating as a leaf blower. Do not

allow discharge to be pointed in the direction of persons.

20. No one should operate this unit while intoxicated or while tak

ing medication that impairs the senses or reactions.

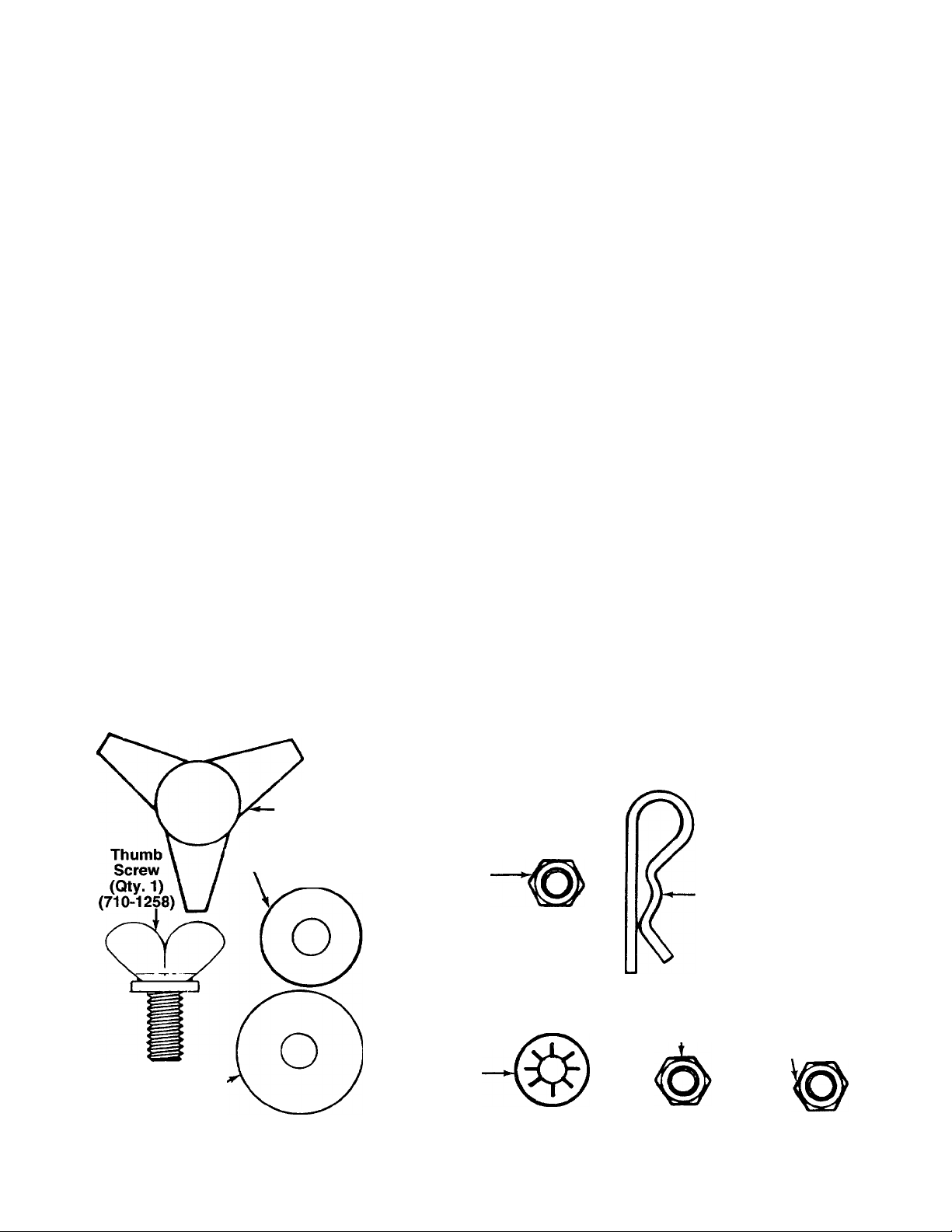

CONTENTS OF HARDWARE PACK

(Hardware pack may contain extra items which are not used on your unit. Quantities of parts and part

numbers are shown in parentheses.)

ATTACHiNG THE NOZZLE AND

AiR DUCT ASSEMBLY

i ATTACHING THE

B

UPPER HANDLE

ATTACHING THE CLUTCH ROD

(Self-Propelled Units Only)

Clutch Grip and Extension.

Spring are Not Shown Q

Flat

Washer (Qty. 1)'

(736-0231)

I

I I I I I I I

0

INCHES

I

I I I I I I I

Hand Knobs

(Qty. 2)

(720-0170)

Cupped

Washers (Qty. 3)

' (736-0242)

I

I I

Hex Bolts 1/4-20 x

1-3/4" Long (Qty. 4)

(710-0136)

Hex Lock Nuts

1/4:20 Thread

(Qty. 4)

(712-0107)

INSTALLING THE BAG

m

c

Stuti Pins (Qty. 2)

(711-0737)

Ifush-On

S| feed Nuts

(Qty. 2)

(1539-019)

I I

I

Clevis Pin

(Qty. 1)

(711-0679)-

Hairpin Clip

(Qty. 1)

(714-0145)

Hex Lock

Nut 1/4-20 Thread

(Qty. 1)

(712-0107)

Hex Jam Nut

1/4-20 Thread

(Qty.1)

(712-0298)

(Thinner Nut)

FIGURE 1.

ASSEMBLY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL. After assembly, service engine

with gasoline and oil as instructed in the separate

engine manual packed with your unit.

Upper

Nozzle

FIGURE 2.-Loose Parts in Carton

FIGURE 3.—Optional Tow Bar Kit

Handle^

(Self-Propelled

Models Only)

H

Air

Duct

Assembly

Directional

Discharge

Assembly

Impeller

Guard

Clutch

Rod

«5

NOTE: Reference to right or left hand side of the

vacuum is observed from behind the unit in the

operating position.

UNPACKING

Remove the vacuum, loose parts, hardware pack and

literature from the carton. Make certain all parts and

literature have been removed before the carton is dis

carded.

LOOSE PARTS IN CARTON

-(See Figure 2)

(1) Nozzle

(1) Upper Handle

(1) Air Duct Assembly

(1) Clutch Rod (Self-Propelled Models Only)

(1) Directional Discharge Assembly

(1) Impeller Guard

(1) Bag

TOW BAR KIT

Standard for push models, optional for self-pro

pelled models.

-(See Figure 3)

(2) Hex Bolts 5/16-18 x 1" Long

A

(2)

(4) Shoulder Spacers

B

(4)

C

D

E

F

G

H

I

Hex Nut 5/16-18 Thread

(2)

(1) Truss Machine Screw 1/4-20 x 3/4" Long

(1)

(1) Lock Washer 1/4" I.D.

(1)

Hex Nut 1/4-20 Thread

(1)

(1) Shouider Boit

(1)

(2) Cupped Washers 3/8" I.D.

(2)

Hex Jam Lock Nut 3/8-16 Thread

(1)

(2) Tow Bar Halves (Not Shown)

(2)

•N

FIGURE 4.

Upper

Handle

FIGURE 5

Nozzle-1

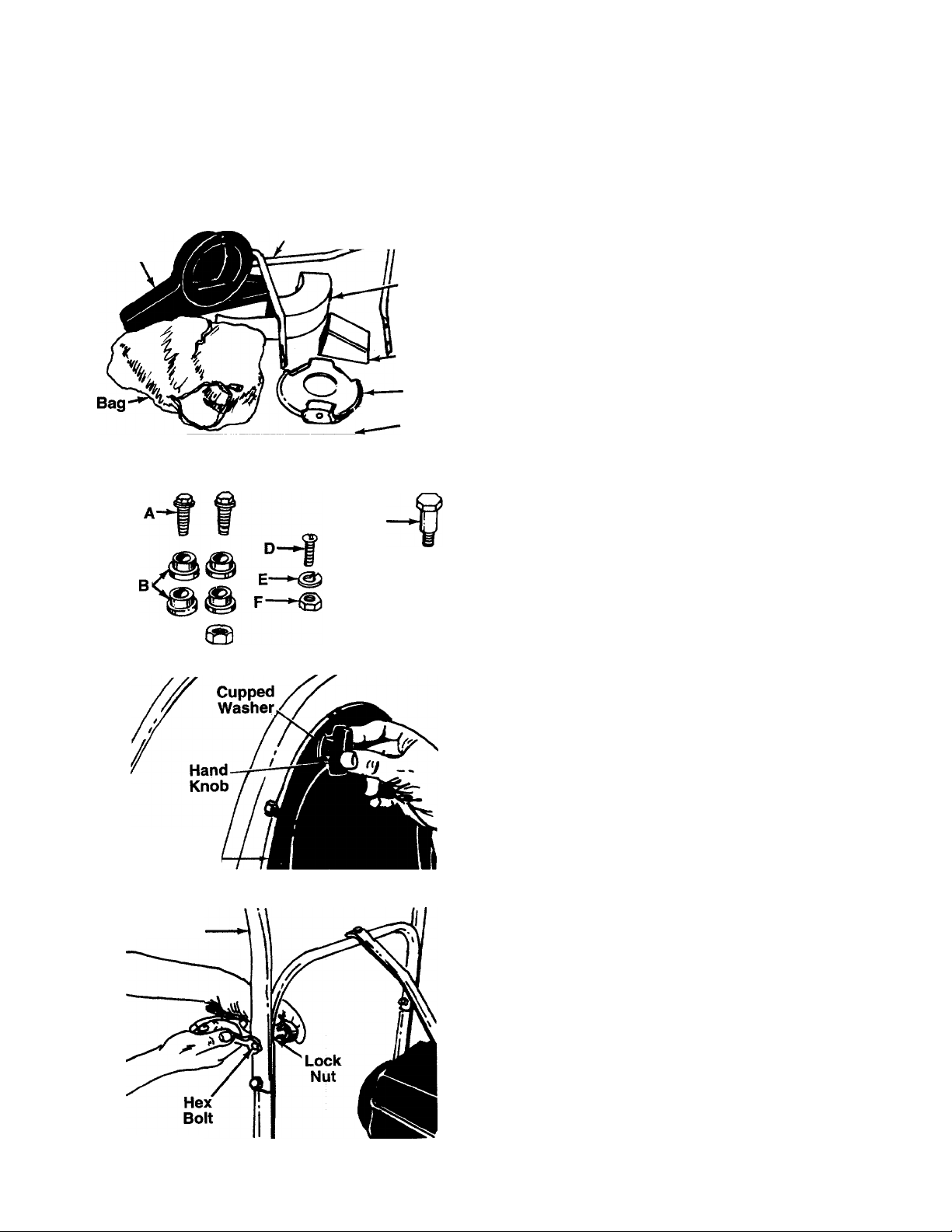

AHACHING THE NOZZLE (Hardware A)

Place nozzle in position on front of housing so that it

rests in flanges. Secure with one hand knob and

cupped washer (cupped side of washer against the

-nozzie). See figure 4.

AHACHING THE UPPER HANDLE (Hardware B)

Place the upper handle in position over iower handle.

Fasten with four hex boits and lock nuts provided.

-See figure 5. Two 7/16" wrenches are required.

Hand

Knob

Cupped

.Washer

Cupped

Was her

FIGURE 6.

Thumb

Screw

ATTACHING THE AIR DUCT ASSEMBLY

(Hardware A)

Place air duct assembly over opening on top of hous

ing. Secure front of air duct assembly with one flat

washer, cupped washer (cupped side of washer

against flat washer) and a hand knob. Secure back

(close to engine) with one cupped washer (cupped

side against air duct assembly) and thumb screw. See

-figure 6.

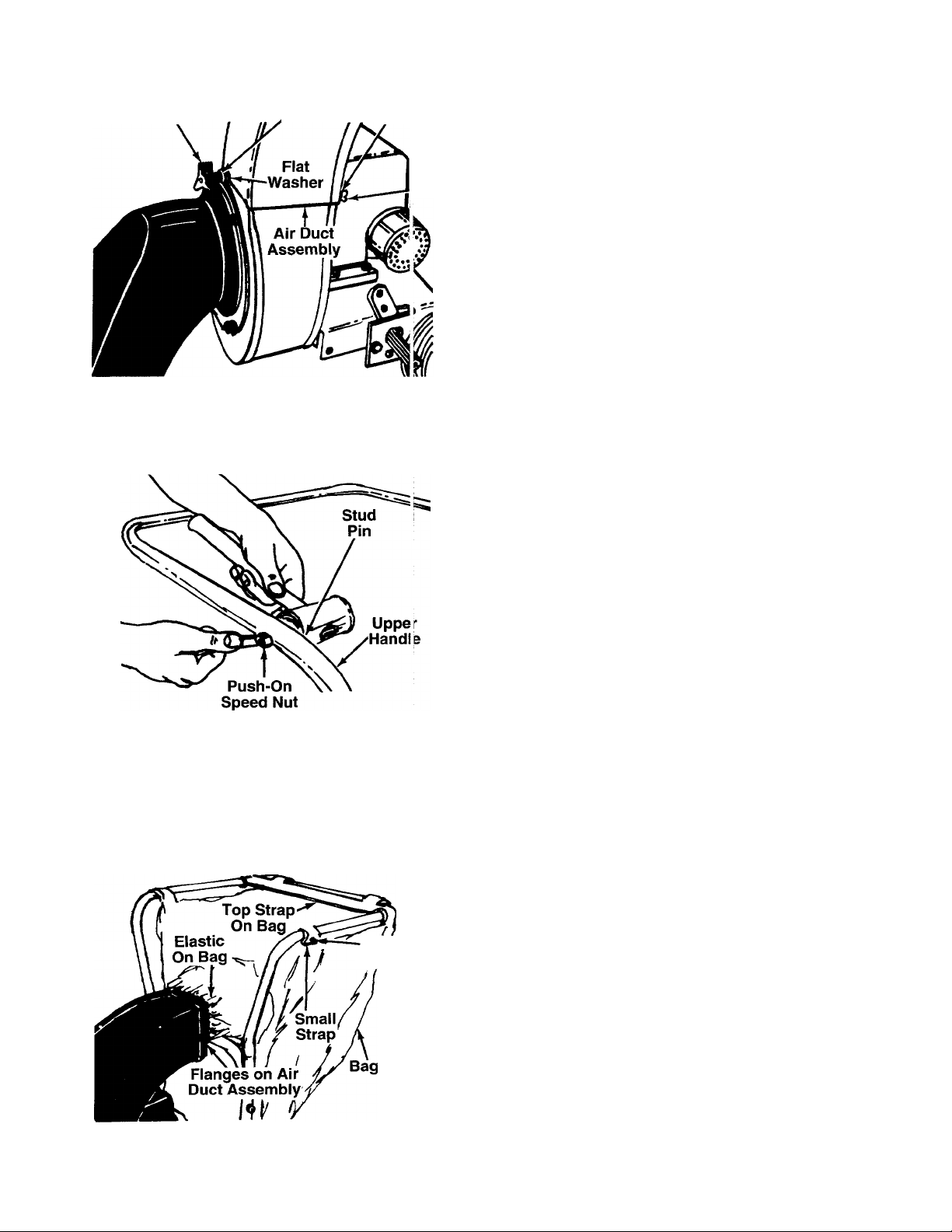

INSTALLING THE BAG (Hardware C)

1.

----

Place the stud pins in holes in upper handle

(head of pins go to the inside of handle). Secure

pins with push-on speed nuts by holding speed

nut with box wrench and tapping pin with ham-

-----

mer. See figure 7.

FIGURE 7.

FIGURE 8.

Stud Pin

On Handle

2. Assemble the bag by slipping the top straps on

bag over upper handle. Hook two small straps

over stud pins on handle. Slip elastic opening of

bag over air duct assembly. Be certain elastic on

bag is placed over the flanges on air duct assem-

— bly. See figure 8.

Loading...

Loading...