MTD 243-651B000 User Manual

OWNEirS GUIDE

• ASSEMBLY • OPERATION • MAINTENANCE • PARTS •

5 and 8 H.P.

SHREDDERS

$1.00

Important:

Read Safety Rules

and Instructions Carefully

WARNING: This unit is equipped with an internal combustion engine and should not be used

on or near any unimproved forest-covered, brush-covered or grass-covered land unless the

engine’s exhaust system is equipped with a spark arrester meeting applicable local or state

laws (if any). If a spark arrester is used, it should be maintained in effective working order by

the operator.

In the State of California the above is required by law (Section 4442 of the California Public

Made

in

AMERICA

Resources Code). Other states may have similar laws. Federal laws apply on federal lands.

A spark arrester for the muffler is available through your nearest engine authorized service

dealer or contact the service department, P.O. Box 360900, Cleveland, Ohio 44136.

Model Numbers

243-645B000

243-648B000

243-650B000

243-651BOOO

IMPORTANT!

Record the Model No. and Mfg. Code which

appear on your unit in the space below. You

must have these numbers, along with the date

of purchase, in order to receive warranty or ser

vice.

MEETS ANSI SAFETY STANDARDS

MODEL NO. MFG. CODE

FORM NO. 770-8162H

S/iFETY RULES

WARNING: TO REDUCE THE POTENTIAL FOR ANY INJURY, COMPLY WITH THE FOLLOWING

SAFETY INSTRUCTIONS. FAILURE TO COMPLY WITH THE INSTRUCTIONS MAY RESULT IN

A

PERSONAL INJURY.

TRAINING

• Read this owner’s manual carefully in its entire :y before

attempting to assemble or operate this machine. Be com

pletely familiar with the controls and the proprir use of

this machine before operating it. Keep this matual in a

safe place for future and regular reference and lor order

ing replacement parts.

• Children must never be allowed to operate th s equip

ment.

• No one should operate this unit while intoxicatec or while

taking medication that impairs the senses or reac tions.

• This equipment should never be operated in tha vicinity

of children, pets or other persons.

• Never run your machine in an enclosed area as the

exhaust from the engine contains carbon monoxide, which

is an odorless, tasteless and deadly poisonous gc s.

• Never place your hands or any part of your body or cloth

ing inside the feeding chamber, discharge chute, or near

any moving part while the machine or engine is r jnning.

• If it is necessary for any reason to inspect or repair the

feeding chamber or any part of the machine where a mov

ing part can come in contact with your body or clothing,

stop the machine, allow it to cool, disconnect tne spark

plug wire from the spark plug and move it away from the

spark plug before attempting such inspection or repair.

PREPARATION

• Wear safety glasses provided with your unit whit j operat

ing the shredder to prevent injury from any material which

may be ejected out of the openings.

• Wear proper apparel. Avoid wearing loose fitting clothing.

Wear gloves when handling material.

• HANDLE GASOLINE WITH CARE as it is an extremely

flammable fuel.

• Check the fuel before starting the engine. Do n 5t fili the

fuel tank indoors, while the engine is running, or /vhile the

engine is still hot. Turn the unit off and let the enqine cool

before refueling.

• Fuel your shredder in a clean area. Do not smoko while

refueling.

• Fuel tank cap must be secure at all times except during

refueling.

• Avoid spilling gasoline or oil. Wipe the unit clean of any

spilled fuel or oil.

• Store fuel and oil in approved containers, away from heat

or open flame, and out of reach of children.

• This machine should be operated only upon a level sur

face.

• Assure that all screws, nuts and bolts and other f isteners

are properly secured.

OPERATION

• When feeding shreddable material into this equipment,

be extremely careful that pieces of metal, rocks; bottles,

cans or other foreign objects are not included. Personal

injury or damage to the machine could result.

• If the cutting mechanism strikes any foreign object or if

your machine should start making an unusual noise or

vibration, immediately stop the engine, disconnect the

spark plug wire from the spark plug and move it away

from the spark plug. Allow the machine to stop and take

the following steps:

Inspect for damage.

Replace or repair any damaged parts.

Check for any loose parts and tighten to assure continued

safe operation.

• The engine must be kept clean of debris and other accu

mulations.

• Do not allow an accumulation of processed material to

build up in the discharge area as this will prevent proper

discharge and can result in kick-back from feed opening.

• Never place your hands or any other part of your body or

clothing inside the feeding chamber, discharge chute or

near any moving part while the engine is running.

• Keep all guards and deflectors in place and in good work

ing condition to assure continued safe operation.

• Always stand clear of the discharge area when operating

this machine.

• Keep your face and body back from the feed opening to

avoid accidental bounce back of any material.

• Do not over-reach. Keep proper balance and footing at all

times.

• The engine governor settings on your machine must not

be altered, changed, or tampered with. The governor

controls the maximum safe operating speeds and pro

tects the engine and all moving parts from damage

caused by overspeed.

• Do not transport machine while engine is running.

• Do not operate engine if air cleaner or cover directly over

carburetor air intake is removed, except for adjustment.

Removal of such parts could create a fire hazard.

MAINTENANCE AND STORAGE

• When this equipment is stopped for servicing, inspection,

storage or to change an accessory, make sure the spark

plug wire is disconnected from the spark plug and moved

away from the spark plug. The machine should be

allowed to cool down before making such inspection,

adjustments, service, etc. Maintain your machine with

care and keep it clean for the best and continued safe

operation.

• Do not use flammable solutions to clean the air filter.

• When not in use, your machine should be stored out of

the reach of children. Keep where gasoline fumes will not

reach an open flame or spark. For long periods of stor

age, refer to the “Off-Season Storage” section of this

manual.

I I

ASSEMBLY INSTRUCTIONS

ATTACHING THE LOWER

LEAF RAMP SECTION

Hex Bolt

-5/16-18 X 8-3/8“ Long

Flat

Washer

5/16“ I.D

Hex Lock

Nut 5/16-18

Thread

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL. After assembly, see separate

engine manual for proper fuel and engine oil rec

ommendations.

NOTE: To determine right and left hand sides of your

shredder, stand behind and face the hopper (engine

is at the front of the unit).

Your shredder has been completely assembled at the

factory, except for the hopper, lower and upper leaf

ramp sections, chute deflector and the catcher bag.

The hardware pack and safety glasses are also

included in the carton.

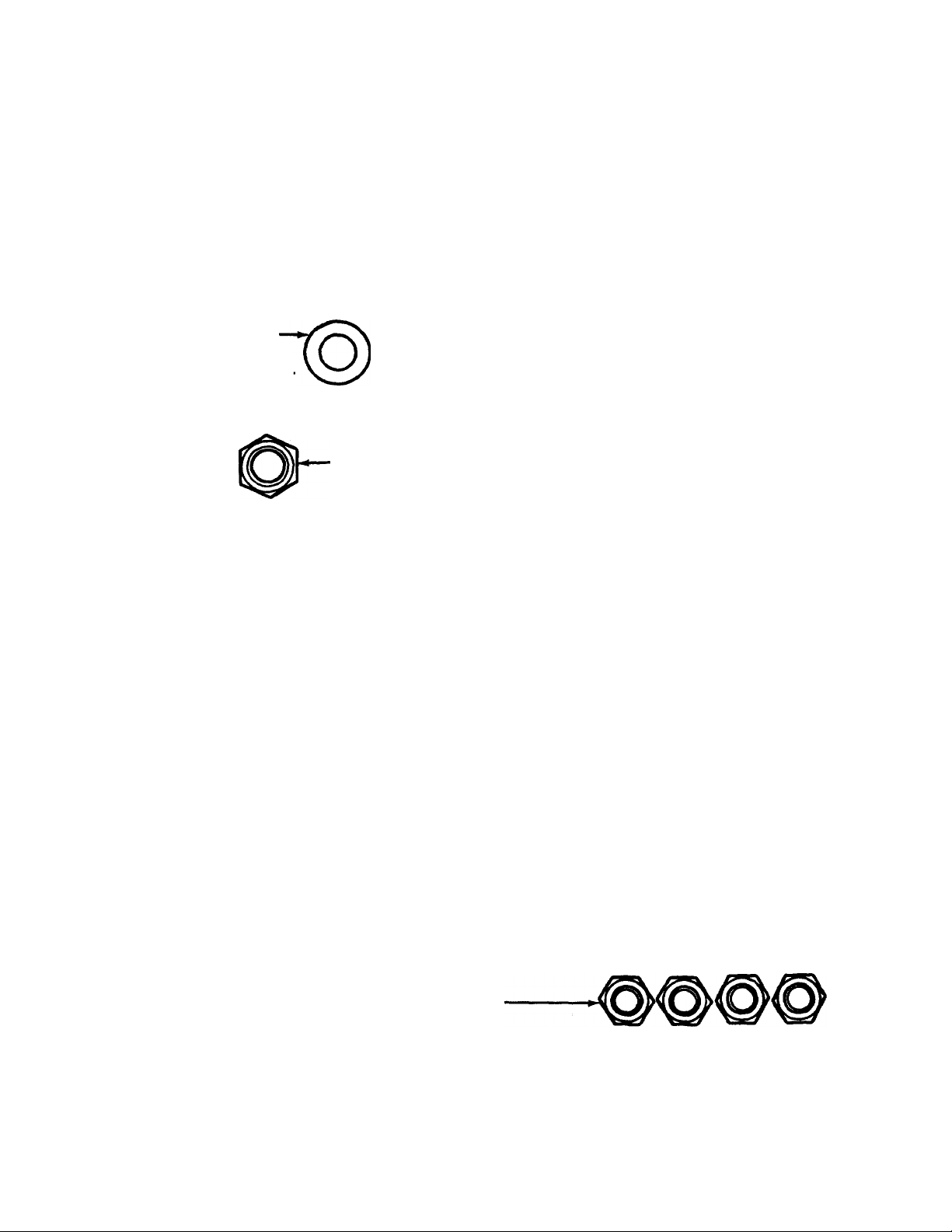

The hardware pack contains the parts shown in figure

1 (shown full size).

TO REMOVE SHREDDER FROM CARTON

Cut the corners of the carton. Remove all packing

inserts. Roll shredder out of carton. Make certain all

parts and literature have been removed before the

carton is discarded.

B

AHACHING THE UPPER LEAF RAMP SECTION

Truss Machine

Screws 1/4-20 x 1/2“-

Long

Hex Lock Nuts

1/4-20 Thread

TOOLS REQUIRED FOR ASSEMBLY

(1) Phillips Screwdriver

(2) 1/2" Wrenches (one must be a socket wrench)

(2) 7/16" Wrenches or Adjustable Wrenches

FIGURE 1.

FIGURE 2.

Spacers

(Inside

Hinge)

Housing

Assembly

Hex Bolt

Chute

[)ef lector

WARNING; Make certain the spark plug

wire is disconnected and moved away

A

from the spark plug before assembling

the shredder.

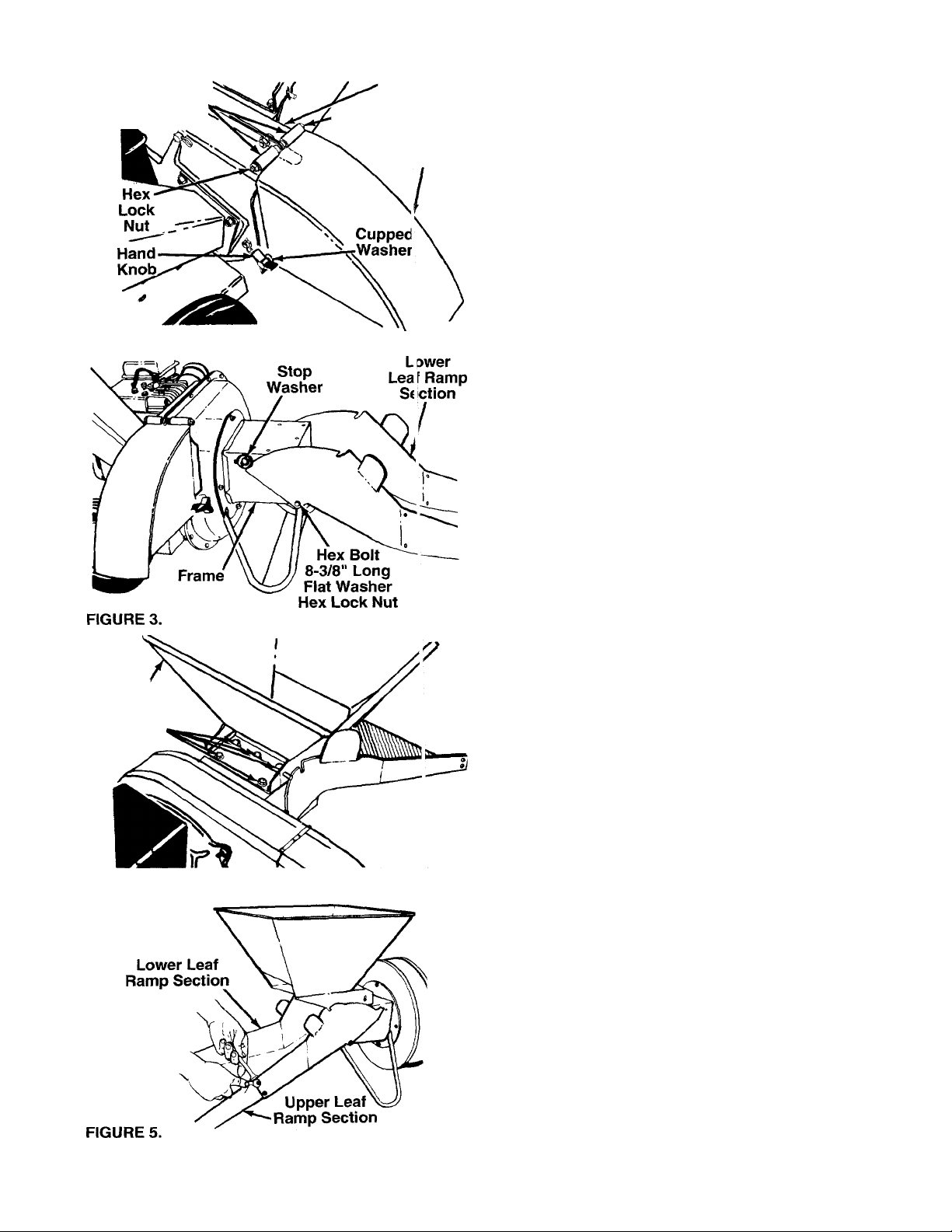

AHACHING THE CHUTE DEFLECTOR

(See Figure 2)

1.

Remove the hand knobs and cupped washers

from each side of the discharge opening on the

left side of the shredder.

2.

Remove the hex lock nut, two spacers and hex

bolt from inside the hinge on the housing assem

bly. Do not remove one spacer from the hex bolt.

Place the chute deflector in position on the dis

charge opening on the left side of the shredder.

Insert hex bolt and spacer through hinge on chute

deflector and housing (spacer fits inside of hinge).

4.

Place the second spacer over the hex bolt, inside

the other part of the hinge. Secure with hex lock

nut. Tighten securely.

Secure both sides of the chute deflector to the

5.

housing using the hand knobs and cupped wash

ers (cupped side of washers go against the chute

deflector).

WARNING: Do not operate this chippershredder unless the chute deflector has

A

been properly installed and is secured

with the hand knobs.

Hopper

Self-Tapping

Screws

FIGURE 4.

-ATTACHING THE LOWER LEAF RAMP SECTION

(Hardware A)

Insert hex bolt 8-3/8" long through lower leaf ramp

section and frame. Secure with flat washer 5/16" I.D.

and hex lock nut. Make certain the edges of the lower

leaf ramp section are underneath the stop washers.

See figure 3. Plastic insert in hex nut should face

away from lower leaf ramp section. Tighten hex nut

until parts are snug, but so lower leaf ramp section

can still be rotated on the frame.

ATTACHING THE HOPPER

When attaching the hopper, first remove the five self

tapping screws from the frame of the unit. Place the

-hopper In position on the shredder. See figure 4. Start

all five self-tapping screws, then tighten securely

using a 1/2" socket wrench.

AHACHING THE UPPER LEAF RAMP SECTION (Hardware B)

Place the edge of upper leaf ramp section inside the

lower leaf ramp section. Secure with four truss

machine screws and hex lock nuts. The heads of the

truss machine screws should be to the inside of the

upper leaf ramp section. Start all screws and nuts,

-then tighten securely. See figure 5.

Loading...

Loading...