Page 1

$1.00

K

owicirs GUIDE

• ASSEMBLY • OPERATION • MAINTENANCE • PARTS •

POWER

VACUUMS

Important:

Read Safety Rules

and Instructions Carefully

WARNING: This unit is equipped with an internal combustion engine and shouid not be used

on or near any unimproved forest-covered, brush-covered or grass-covered land unless the

engine’s exhaust system is equipped with a spark arrester meeting applicable local or state

laws (if any), if a spark arrester is used, it should be maintained in effective working order by

the operator.

in the State of California the above is required by law (Section 4442 of the California Public

Made ^

in

AMERICA

Resources Code). Other states may have simiiar iaws. Fédérai laws apply on federal lands.

A spark arrester for the muffler is available through your nearest engine authorized service

dealer or contact the service department, P.O. Box 360900, Cleveland, Ohio 44136.

Model Numbers

242-660-000

242-662-000

242665

IMPORTANT!

Record the Model No. and Mfg. Code which

appear on your unit in the space below. You

must have these numbers, along with the date

of purchase, in order to receive warranty or ser

vice.

MEETS ANSI SAFETY STANDARDS

MODEL NO. MFG. CODE

FORM NO. 770-5207G

Page 2

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFET' INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE

PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS

▲

MANUAL BEFORE ATTEMPTING TO OPERATE \OUR POWER VACUUM. FAILURE TO COMPLY WITH THESE INSTRUC

TIONS MAY RESULT IN PERSONAL INJURY. WHE N YOU SEE THIS SYMBOL- ^ HEED ITS WARNING.

Your power vacuum was juilt to be operated according to the rules for safe operation in this manu-

DANGER: al. As with any type of po ver equipment, carelessness or error on the part of the operator can result

A

in serious injury. If you vi( ilate any of these rules, you may cause serious injury to yourself or others.

RULES FOR SAFE OPERATION

A

1. Read this operating and service instruction manual carefull;'. Be thor

oughly familiar with the controls and proper use of the po /ver vacu

um.

2. Never allow children to operate this power vaccum.

3. Keep the area of operation clear of all persons, particul irly small

children and pets.

4. Check fuel before starting engine. Do not fill fuel tank indc ors, when

engine is running, or while engine is hot. Wipe off any s Dilled fuel

before starting engine.

5. Do not change engine governor settings.

6. Do not put hands near rotating parts for any reason.

7. If the power vacuum should start to vibrate abnormally stop the

engine and check immediately for the cause. Vibration is g snerally a

warning of trouble.

8. Before cleaning, repairing or inspecting, make certain £ll moving

parts have come to a complete stop. Disconnect spark plui i wire and

keep wire away from plug to prevent accidental starting. \lso keep

throttle control lever in the stop position.

9. If the power vacuum should become blocked with debris at any point,

shut engine off and wait until the impeller comes to a com alete stop

before attempting to remove the obstruction. Disconnect s park plug

wire to prevent accidental starting.

10. Check all bolts for tightness at frequent periods.

11. Never store this power vacuum with fuel in the tank. Allow engine to

cool before storing in any enclosure.

12. Keep bag and equipment free of debris when not in use.

Never operate this power vacuum unless air duct and vacuum bag

13,

are properly affixed in their places. Large zippered end of bag must

be closed when operating to prevent objects from being blown out.

14.

Never empty vacuum bag when engine is running.

Never change auxiliary hose attachment when engine is running.

15.

16. The manufacturer recommends that the operator wear safety glass

es or some other suitable eye protection when operating this

machine.

17.

Check the vacuum bag frequently for wear and replace when neces

sary.

18,

Never operate as a leaf blower unless deflector assembly (optional

equipment) is properly affixed in its place.

19.

Exercise caution whenever operating as a leaf blower. Do not allow

discharge to be pointed in the direction of persons.

20,

No one should operate this unit while intoxicated or while taking

medication that impairs the senses or reactions.

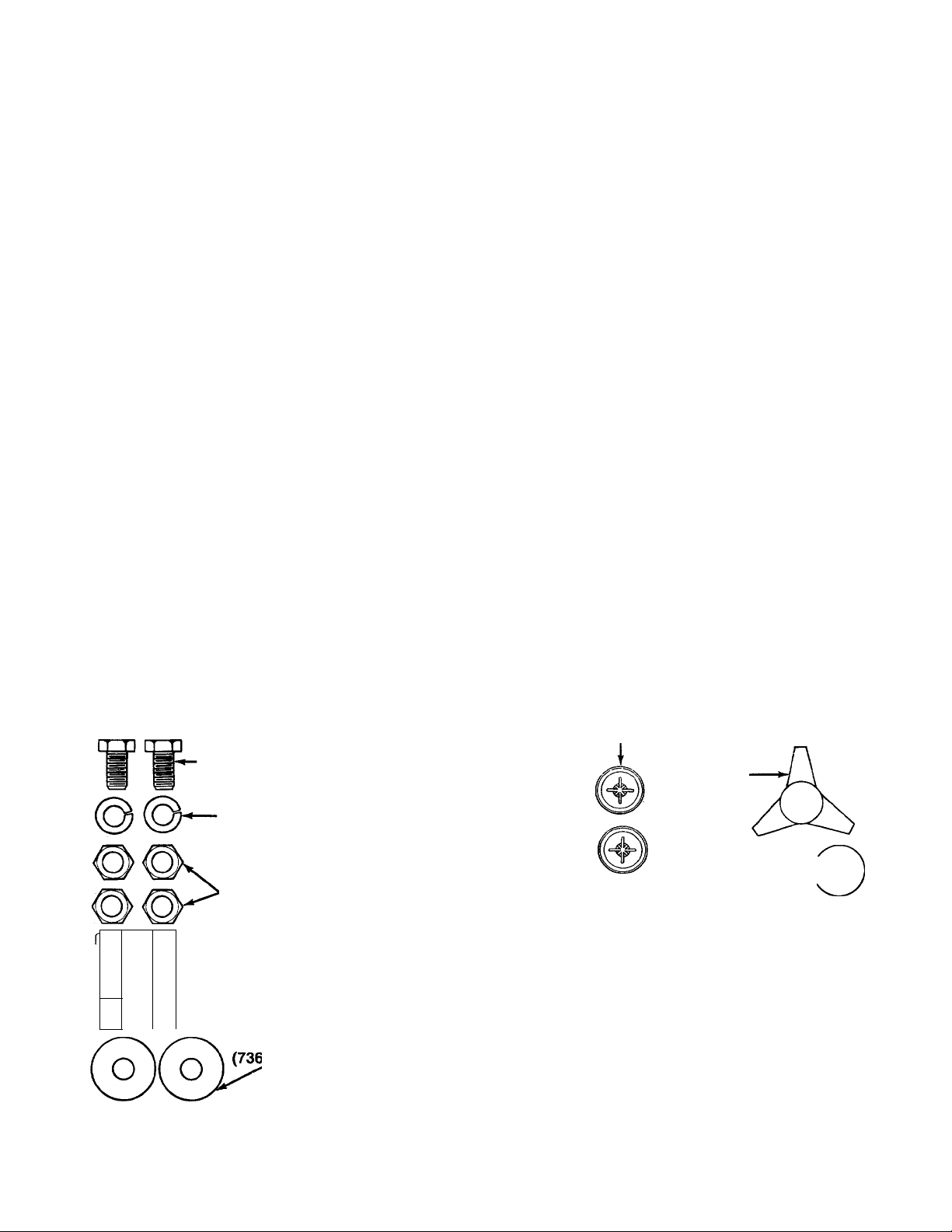

CONTENTS OF HARDWARE PACK

Hardware pack may contain extra ite ns which are not used on your unit. Hardware is shown

approximately one-half size. Quantiti }s of parts and part numbers are shown in parentheses.

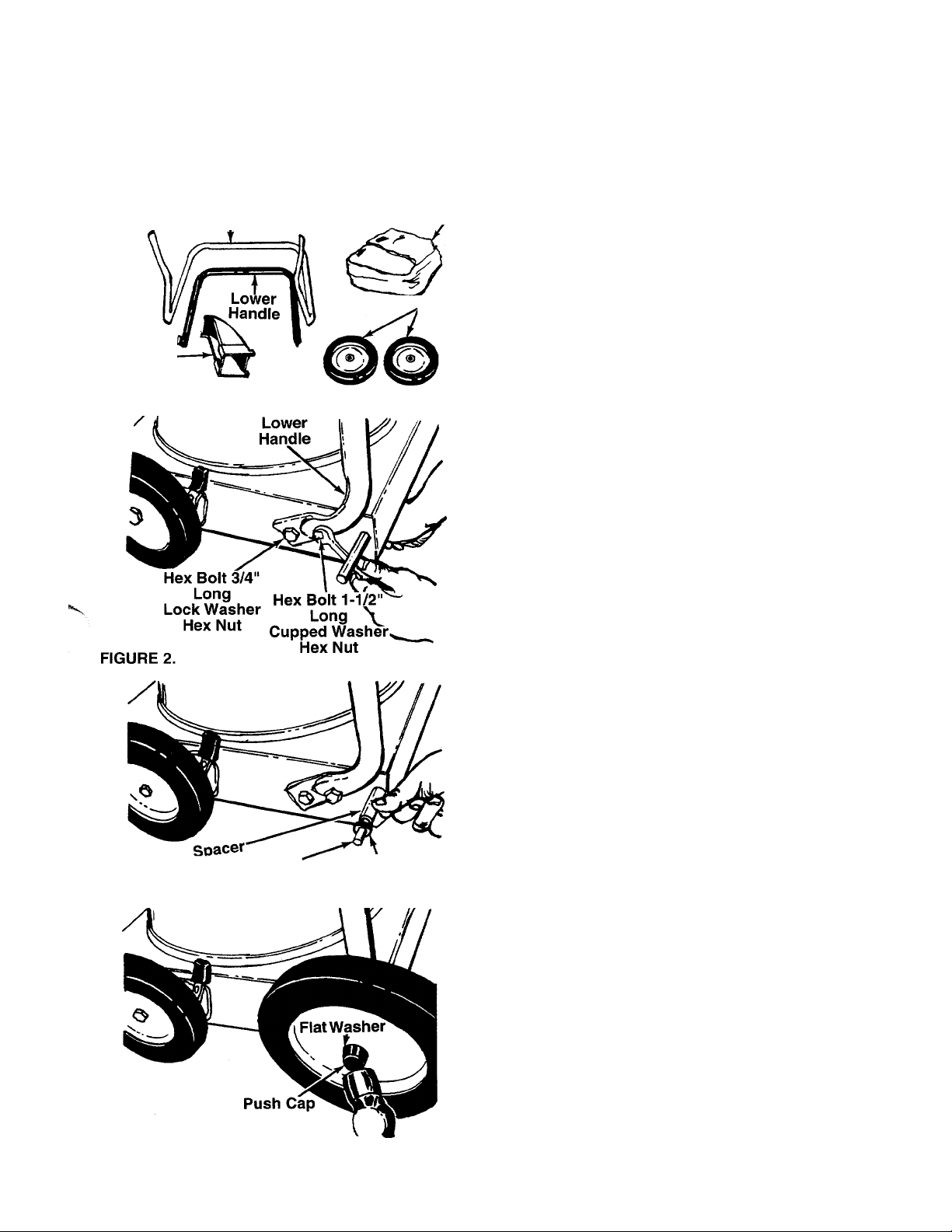

ATTACHING THE

LOWER HANDLE

J L

n

■

•===

Hex Bolts

-3/8-16 X 1-1/2"

Long

(710-0344)

-Lock Washers

3/8" I.D.

(736-0169)

Hex Nuts

3/8-16 Thread

(712-0798)

Hex Bolts

3/8-16 X 3/4"

Long

(710-0201)

Cupped Washers

3/8" I.D.

-0331)

ATTACHING THE

B

REAR WHEELS

Wheel Spacers

-f—1/2" I.D.

(750-0588)

I

____

I

Flat Washers

1/2" I.D. x1" O.D.

(736-0272)

@@@@

AT ACHING THE UPPER HANDLE

mp irri ozn azp

Hex Bolts 1/4-20 x

1-3/4" Long

-

-----

(710-0136)

Hex Lock Nuts

1/4-20 Thread

(712-0107)

Push Caps

(726-0128)

ATTACHING THE

AIR DUCT ASSEMBLY

Hand Knob

(720-0170)

Cupped

Washer 5/16" I.D.—W Q

(736-0242) ^

ATTACHING THE BAG

✓ —X Push-On

-Stud Pins

(711-0737)

—Speed Nuts

(1539-019)

I I

0

INCHES

I

I I I

I

I I I

I

I I I

I

I I I

I

I I I

I

I I

FIGURE 1.

Page 3

ASSEMBLY INSTRUCTIONS

\ IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL. After assembly, service engine

with gasoline and oii as instructed in the separate

engine manual packed with your unit.

Upper Handle ,Bag

Rear

Wheels

Air Duct

Assembly

FIGURE 1.

NOTE: Reference to right or left hand side of the

vacuum is observed from behind the unit in the

operating position.

TOOLS REQUIREO FOR ASSEMBLY

(2) 9/16" Wrenches

(2) 7/16" Wrenches

(1) Hammer or Rubber Mallet

UNPACKING

Remove the vacuum, loose parts, hardware pack and

literature from the carton. Make certain all parts and

literature have been removed before the carton is dis

carded.

-LOOSE PARTS IN CARTON (See figure 1)

(1) Upper Handle

(1) Lower Handle

(1) Air Duct Assembly

(2) Rear Wheels

(1) Bag

ATTACHING THE LOWER HANOLE (Hardware A)

1. Raise the back of the unit off the floor approxi

mately 3 inches and block it so that the lower

handle and rear wheels may be assembled.

2. Place lower handle in position on the vacuum, lin

ing up the holes in the handle with the holes on

-------

the frame. See figure 2. Place hex bolts 3/4" long

through lower hole in handle and frame. Secure

with 3/8" lock washers and hex nuts on the inside

of frame, finger tight only.

3. Place hex bolts 1-1/2" long through upper hole in

handle and frame. Secure with 3/8" cupped

washers (cupped side against the frame) and hex

nuts.

4. Tighten all four nuts and bolts using two 9/16"

wrenches.

FIGURE 3.

FIGURE 4.

Axle''

Shaft

Flat

Washer

-ATTACHING THE REAR WHEELS (Hardware B)

1. Slide spacers onto the axle shafts. Place one flat

washer on each shaft next to the spacers. See

figure 3.

2. Place rear wheels in position on the shafts, then

another flat washer. Secure with black push cap

by placing the push cap in position and tapping

— on with hammer or rubber mallet. See figure 4.

Page 4

FIGURE 5.

Upper

—Handle

Hex Bolt s

Hex Loc i

Nuts

Low sr

Handle

Air Duct

Assembly

ATTACHING THE UPPER HANDLE (Hardware C)

Place the upper handle in position over lower handle.

Fasten with four hex bolts 1-3/4" long and hex lock

-nuts. See figure 5. Two 7/16" wrenches are required.

ATTACHING THE AIR DUCT ASSEMBLY

(Hardware D)

1. Place the tabs on the air duct assembly into the

--------

slots in the frame as shown in figure 6. Raise the

air duct into position.

FIGURE 7.

Secure air duct with hand knob and cupped

washer. Cupped side of washer must be against

■ the air duct. See figure 7.

ATTACHING THE BAG (Hardware E)

1. Place the stud pins in holes in upper handle

(head of pins go to the inside of handle). Secure

pins with push-on speed nuts by holding speed

nut with box wrench and tapping pin with ham-

------

mer. See figure 8.

Page 5

k Air Duct Assembly

FIGURE 10.

2. Attach the bag by slipping the top straps on the

bag over upper handle. Hook the two small straps

— over the stud pins on handle. See figure 9.

3. Slip the elastic opening of the bag over the air

duct assembly, making certain the elastic opening

is secured behind the flanges on all four sides of

— the air duct. See figure 10.

Flange On

OPERATION

BEFORE STARTING ENGINE

Service engine with gas and oil. See engine manuai

packed with vacuum for complete instructions for care

and maintenance of engine. Read directions carefully.

WARNING: Revolving blades — keep

A

TO START ENGINE

After the engine has been properly fueled and oiled

(refer to engine operating and maintenance instruc

tions), start engine as follows.

1. Move throttle control lever on engine to FAST or

2. Crank engine by puiiing recoil starter with a quick,

3. After two or three full firm pulls on recoil (or as

hands away from all openings.

START position.

firm stroke. Do not pull out so far the rope stops

with a jerk. Do not aliow rope and handie to snap

back into piace.

soon as engine fires), move throttle control to

RUN position.

TO STOP ENGINE

1. To stop engine, move throttle control lever to OFF

position.

2. Disconnect spark plug wire and ground to prevent

accidentai starting while equipment is un

attended.

TO EMPTY BAG

The bag may be emptied using the iarge zipper as

shown in figure 11. Be certain the zipper is closed

when operating the unit.

FIGURE 11.

Page 6

ADJUSTMENTS

WARNING: Do not at any time m ike any

adjustment to the unit without fir st stop-

A

HEIGHT ADJUSTMENT

An adjusting plate and thumb lever at both front

wheels provide height adjustment for the vacuum.

See figure 12. Each adjusting plate has nine posi

tions. Height will be changed when the thumb lever Is

moved from one position to another. Simply depress

thumb lever towards wheel and move wheel aid lever

assembly to desired position. Both wheels must be

placed in the same relative position. Lower th€ front of

the unit to obtain more suction.

ping engine and disconnectin<| spark

plug wire.

CARBURETOR ADJUSTMENT

WARNING: If any adjustments are made

to the engine while the engine is running

A

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude

or load.

NOTE: A dirty air cleaner will cause engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor.

Do not make unnecessary adjustments. Factory set

tings are satisfactory for most applications and condi

tions. If adjustment is needed, refer to the separate

engine manual packed with your vacuum.

(e.g. carburetor), keep clear of all moving

parts. Be careful of heated surfaces and

muffler.

MiMNTENANCE

WARNING: Always stop engine arid dis

connect spark plug wire before cl waning,

A

LUBRICATION

Wheels—The wheels require no lubrication. How

ever, if the wheels are removed for any reason, lubri

cate the surface of the axle bolt and the inner surface

of the wheel with light oil. A 4 oz. plastic bottle of light

oil lubricant is available. Order part number 737-0170.

Engine oil may also be used.

ENGINE

Refer to the separate engine manual for engine

maintenance instructions.

Maintain engine oil as Instructed in the S(}parate

engine manual packed with your unit. Read and follow

instructions carefully.

lubricating or performing any repairs or

maintenance.

OFF-SIEASON STORAGE

The following steps should be taken to preps re your

vacuum for storage.

1. Clean and lubricate the vacuum thcrcughly as

described in the lubrication instructions.

2. Refer to engine manual for correct engine storage

instructions.

Service air cleaner every 25 hours under normal con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding

usually indicates that the air cleaner should be ser

viced. Tc service the air cleaner, refer tc the separate

engine manual packed with ycur unit.

The spark plug should be cleaned and the gap reset

once a seascn. Spark plug replacement is recom

mended at the start of each season; check engine

manual for correct plug type and gap specifications.

Clean the engine regularly with a cloth or brush. Keep

the cooling system (blower housing area) clean to

permit proper air circulation which is essential to

engine performance and life. Be certain to remove all

dirt and combustible debris from muffler area.

3. If storing in an unventilated or metal storage

shed, coat metal parts with a light oil or silicone to

prevent rust.

4. Store in a dry, clean area. Do not store next to

corrosive materials, such as fertilizer.

Page 7

Models 660, 662 and

OPTIONAL EQUtPMENT

242665

Hose Attachment Kit Model 290-210-000 and

Blower Conversion Kit Model 290-211-000 are

available as optional equipment.

Blower

Aiiacnmeni mi

Model 290-210-000

Conversion Kit

Model 290-211-000

Page 8

PARTS LIST FOR MODE LS 660, 662 AND 242665 POWER VACUUMS

REF.

NO.

10 15780 638 Vacuum Deck Ass’y.

11

12

13 15790 Wiper Retaining Strip 42 764-0208A

14

15 735-0222 Nozzle Wiper Rear 44

16

17

18 738-0102

19 734-1139 Front Wheel Ass’y. Conp.

20

21 15262B

22 15261A Index Plate

24

25

PART

NO.

1 749-0664

2

—

3 710-0260

4

15784

710-0654A

5

6 15786A

7 736-0217

8

710-0591 Hex Bolt 3/8-24 X 1.0" l.g.

CODE

638

DESCRIPTION

Upper Handle

Engine 27

Carriage Bolt 5/16-18 x .62" Lg.*

Blower Housing Ass’y. X .06"

Hex Tap Scr. 3/8-16 x ' .0" Lg.

Impeller Ass’yL-Wash. 3/8" I.D.* 34

w/Patch

9 722-0137

P.V.C. Foam Strip-12"

15796 Front Baffle Ass’y. 40 712-0113

15788 Lower Baffle Ass’y. 41

REF.

NO.

26 738-0507B

28

PART

NO.

728-0128

736-0272

CODE

Shoulder Bolt .5" Dia. x 7/16" Lg.

Push Cap .5" Rod (Black)

FI-Wash. 1/2" I.D. X 1.0" O.D.

29 734-1140 Rear Wheel Ass’y. Comp.

31

750-0588 Wheel Spacer 1/2" I.D. x 15/16"

15779 Air Duct Ass’y.

35 710-0201 Hex Bolt3/8-16x.75"*

36 710-0344

Hex Bolt 3/8-16x1.5’’*

38 720-0170 Hand Knob

712-0107

39

Hex L-Nut 1/4-20 Thd.

Wing Nut 1/4-20 (Plastic)

710-0136 Hex Bolt 1/4-20 X 1.75"*

Vacuum Bag (6.6 Bushel)

728-0123

Pop Rivet .188" Dia. 43

749-0592

Lower Handle

14578 Height Adj. Ass’y. Comp.-R.H.

712-0267

Hex Nut 5/16-18 Thd.*

14579

Height Adj. Ass’y. Comp.-L.H.

736-0242 Bell-Wash. .34" I.D. x .fi7" O.D. (Not Shown)

Shid. Bolt .498" Dia. x 1.45" Lg. 45 1539-019 Push Speed Nut .25" Dia.

711-0737 Stud Pin .25" Dia. x 1.75" Lg.

736-0331

Bell-Wash. .39" I.D. x 1 12" O.D. 47

Wheel Pivot Bar 48

712-0798 Hex Nut 3/8-16 Thd.* 50

14832

Spring Lever Ass’y. w/H ,nob 51 736-0169 L-Wash. 3/8" I.D.*

46

714-0105

735-0221

49 15789

710-0302

Sq. Key 3/16" X 1" Lg.

Nozzle Wiper Side

Wiper Retaining Strip

Hex Self-Tap Scr. #10

DESCRIPTION

'For faster service obtain standard nuts, boits and washe s iocaliy.

If these items cannot be obtained locaiiy, order by par: number

and size as shown on parts list.

CODE; N notates a new part (not previousiy existing). A three digit

number is the color code. Specify coior code if coior or finish is

important when ordering parts, [i.e., (part no.)-638 for Red

Finish].

(638—Red) (498—Yeiiow)

TROUBLE SHOOTING

PROBLEM POSSIBLE CAUSE(ii) CORRECTIVE ACTION

Engine fails to start 1. Fuei tank empty, c r stale fuel.

2. Spark plug wire disconnected.

3. Faulty spark plug.

Loss of power;

operation erratic

1. Spark plug wire loi >se.

2. Blocked fuel line (i ’ so equipped)

or stale fuel.

3. Water or dirt in fue 1 system.

4. Carburetor out of < idjustment.

5. Dirty air cleaner.

Engine overheats

Too much vibration

1. Carburetor not adj jsted

properly.

2. Engine oil level lov/.

Loose parts or dar laged

crankshaft.

. — /

Unit does not X

discharge /

1. Directional dischaige clogged.

2. Foreign object lodijed in air vane

plate assembly.

1. Fill tank with clean, fresh fuel.

2. Connect wire to spark plug.

3. Clean, adjust gap or replace.

1. Connect and tighten spark plug wire.

2. Clean fuel line; fill tank with clean

fresh gasoline.

3. Disconnect fuel line at carburetor to drain fuel

tank. Refill with fresh fuel.

4. Adjust carburetor.t

5. Service air cleaner.f

1. Adjust carburetor.t

2. Fill crankcase with proper oil.

Stop engine immediately and disconnect

spark plug wire. Tighten all bolts and nuts.

Make all necessary repairs. If vibration continues,

have unit serviced by an authorized service

dealer.

1. Stop engine immediately and disconnect

spark plug wire. Clean directional discharge.

2. Stop engine immediately and disconnect

spark plug wire. Remove lodged object.

tRefer to the engine manual packed with your unit.

NOTE: Fo/repairs beyond the minor adjustments listed above, please contact your nearest authorized service dealer.

FOR REPLA CEMENT PARTS, CONTACT:

SERVICE DEPARTMENT • FlO. BOX 360900 • CLEVELAND, OHIO 44136

Loading...

Loading...