MTD 240-623-003 User Manual

|,Soo-45S-70//

DUSRR

MODEL NUMBERS

PRO/20

(240-622-003)

424/LCD/22

(240-623-003)

IMPORTANT:

•Read this Manual

Before Attempting

to Assemble and

LOG SPLITTERS

Use

•Read Safety

Rules and

Instructions

Carefully

•Protect Your

Warranty —

Read “Important

Information for

Log Splitter

Users” (Page 2)

Carefully

DUERR/MTD PRODUCTS INC • P. O. BOX 360900 • CLEVELAND, OHIO 44136

IMPORTANT INFORMATION

ALWAYS:

Use clean fluid and check fluid level regularly

Use Dexron II Automatic Transmission Fluid o

10W non-foaming hydraulic fluid.

Use a filter (clean or replace regularly)

Use a breather cap on fluid reservoir

Keep end of reservoir return tube below fluid lavel

Make certain pump is mounted and aligned prjperly

Use a flexible “spider” type coupling between 6 ngine

and pump driveshafts

Keep hoses clear and unblocked

Bleed air out of hoses before operating

Flush and clean hydraulic system before startup after

any malfunction or servicing

Use “pipe dope” on all hydraulic fittings

Allow time for warmup before splitting wood

Prime the pump before initial startup by turnimj over

the engine with spark plug disconnected

Split wood with the grain (lengthwise) only

FOR LOG SPLITTER USERS

NEVER:

Use fluid below 0° F., or above 150° F.

Use a solid engine/pump coupling

Force pump when mounting

Operate through relief valve for more than several

seconds

Attempt to adjust unloading or relief valve settings

without pressure gauges

Operate with air in hydraulic system

Use Teflon tape on hydraulic fittings

Warm up engine apart from pump in cold weather

Attempt to cut wood across the grain

CONDITIONS WHICH WILL VOID YOUR WARRANTY

1. Failure to maintain proper fluid level in Reservoir will void your warranty, causing permanent damage to

pump by allowing air to be drawn into pump. Fluid will become foamy. Refer to “Initial Preparation” in the

Operation Section of this manual.

2. Changing the relief valve setting or pres sure adjustment of control valve without proper knowledge and

instruction from the factory will void your warranty. A very minor adjustment could destroy the structural and

safety limits for which the unit was desigred. The system will produce more power than the structure will

withstand. Higher pressure could cause tfie hoses to burst, cylinder to rupture and intense fluid releases,

which could result in serious personal inji ry.

3. Disassembling the pump will void your wa'ranty. If replacment is necessary, merely disconnect and replace.

Do not attempt to adjust pump settings, as they are adjusted by the manufacturer at the factory.

4. Use of incorrect hydraulic fluid will void your warranty. Use only Dexron II automatic transmission fluid or

low non-foaming hydraulic fluid.

5. The flexible pump coupler must be insp acted regularly. Allowing the coupler to deteriorate will void your

warranty. Deterioration of spider insert and prolonged use after deterioration will destroy pump bearings and

engine bearings, along with total destructon of coupler hubs.

6. Improper beam lubrication will cause pr€ mature wear and looseness. Lubricate the beam regularly. Lack

of lubrication will void your warranty.

7. Improper adjustment of splitting wedge /vill void your warranty. Become familiar with the proper tolerance

required for adjustment of the splitting wedge as instructed in the adjustment section of this manual.

a. If wedge is too loose, cylinder beam a id wedge wear will result. Allowing the wedge to loosen and be

used under operating stress will cause damage which will not be covered under warranty.

b. If wedge is too tight, severe beam damage will result which will not be covered under warranty.

8. Warranty card must be mailed or delivered directly to factory. Proper information must be completed and

mailed as per instructions. No warranty records on file may result in delay.

9. Do not overheat the hydraulic system. Excessive heat will destroy the hydraulic system with hardened 0-rings

and excessive friction.

10. Do not attempt to start in temperatures under 20° F. without pre-heating fluid in reservoir. Excessively

cold fluid cannot circulate and draw into pump. Warranty will be void.

11. Repair any leaks in hydraulic system immediately. Unattended leaks will cause air to enter system and/or

decrease fluid level in reservoir, causing damage to the hydraulic system which will not be covered by warranty.

▲

A

IMPORTANT

RULES FOR SAFE OPERATION

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL

SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE AT

TEMPTING TO OPERATE YOUR LOG SPLIHER. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL IN

JURY. WHEN YOU SEE THIS SYMBOL-^HEED ITS WARNING.

AC PyOER ^

Your log splitter was built to be operated according to the rules for safe operation in this manuai. As

with any type of power equipment, carelessness or error on the part of the operator can result in serious

injury, if you violate any of these rules, you may cause serious injury to yourseif or others.

TRAINING

Before operating this splitter, read and understand this manual

completely. Become familiar with it for your own safety. To fail

to do so may cause serious injury. Do not allow anyone to operate

your splitter who has not read this manual. Keep this manual in

a safe place for future and regular reference and for ordering

replacement parts.

2. Never use your splitter for any other purpose than splitting wood.

It is designed for this use and any other use may cause an injury.

Your log splitter is a precision piece of power equipment, not a

playtoy. Therefore, excercise extreme caution at all times.

3. Never allow children to operate your log splitter. Do not allow adults

to operate it without proper instruction. Only persons well ac

quainted with these rules of safe operation should be allowed to

use your log splitter.

4. Only the operator is to be near your log splitter during use. Keep

all others, including pets and children, a minimum of 20 feet away

from your work zone. Flying wood can be hazardous. If a helper

is assisting in loading logs, never activate the control until the helper

is clear of the area. More accidents occur when more than one

person operates the log splitter than at any other time.

5. No one should operate this unit while intoxicated or while taking

medication that impairs the senses or reactions. A clear mind is

essential for safety. Never allow a person who is tired or other

wise not alert to use your splitter.

8. Only operate your splitter on level ground and not on the side of

a hill. It could tip, or rolling logs or poor footing could cause an

accident. Operating the splitter on level ground also prevents the

spillage of gasoline from the fuel tank.

9. Never attempt to move the log splitter over hilly or uneven terrain

without a tow vehicle or adequate help.

10. Always block the wheels to prevent movement of log splitter while

in operation.

11. Check the fuel before starting the engine. Gasoline is an extreme

ly flammable fuel. Do not fill the gasoline tank indoors, when the

engine is running, or while the engine is still hot. Replace gasoline

cap securely and wipe off any spilled gasoline before starting the

engine as it may cause a fire or explosion.

12. Both ends of each log must be cut as square as possible to help

prevent the log from riding out of the splitter during operation.

A

OPERATION

1. Stand behind the reservoir tank when operating. See illustrations.

A

A

PREPARATION

1

Never wear loose clothing or jewelry that can be caught by mov

ing parts of your log splitter and pull you into it. Keep clothing

away from all moving parts of your log splitter.

2.

Wear proper head gear to keep hair away from moving parts.

Always wear protective hearing devices as needed.

3. Always wear safety shoes. A dropped log can seriously injure your

foot.

4. Always wear safety glasses or goggles while operating your split

ter. A piece of splitting log could fly off and hit your eyes.

5. If you wear gloves, be sure they are tight fitting without loose cuffs

or draw strings.

6. Use your log splitter in daylight, or under good artificial light.

7. Never operate your splitter on slippery, wet, muddy or icy sur

faces. Safe footing is essential in preventing accidents. Never

operate your splitter while attached to a towing vehicle.

▲

2. Know how to stop the unit and disengage the controls.

3. Never place hands or feet between log and splitting we dge or be

tween log and end plate during forward or reverse str ike. To do

so may result in crushed or amputated fingers or toes, or worse,

you may lose an arm or foot.

4. Do not straddle the splitter when using it. A slip in ai ly position

could result in a serious injury.

5. Do not step over your log splitter when the engine is ru ining. You

may trip or accidentally activate the splitting wedge if you step

over. If you need to get to the other side, walk aroi nd.

6. Never try to split two logs on top of each other. One r lay fly out

and injure you.

7. When loading the log splitter, place your hands on the side of the

log, not at the ends. Never attempt to load your splitte r while the

splitting wedge is in motion. You may get caught by the wedge

and injured.

8. Only use your hand to operate the splitting wedge or co itrol lever.

Never use your foot or a rope or any other extension d 3vice. This

could result in your ability to stop your splitter quid :ly enough

and cause injury.

9. Always keep fingers away from any cracks that open in the log

during splitting operation. They can quickly close and pinch or

amputate your fingers.

10. Never attempt to split woods across the grain. Some tyf es of wood

may burst or fly out of your splitter and result in injury to you

or a bystander.

11. For logs that are not cut square, the longest portion of the log

should be rotated down and the most square end placed against

the splitting wedge.

12. Keep your work area clean. Immediately remove split w 3od around

your splitter so that you do not stumble over it. Clean chips and

dirt off end plate (wood platform) after each log is split, (r whenever

necessary to maintain flat contact between wood an i end plate

(platform).

13. Never move the log splitter while the engine is runt ing.

14. Never leave your log splitter unattended with the engi le running.

Shut off the engine if you are leaving your splitter, ever for a short

period of time. Someone could accidentally activate the splitting

wedge and be injured.

15. Do not run engine in an enclosed area. Exhaust gases iontain car

bon monoxide. This odorless gas can be deadly when inhaled.

16. Be careful not to touch the muffler after the engine ha s been run

ning as it is HOT.

17. If the equipment should start to vibrate abnormally, sto) the engine

and check immediately for the cause. Vibration is gene ally a warn

ing of trouble.

18. When cleaning, repairing or inspecting, make certair ail moving

parts have stopped. Disconnect the spark plug wire aid keep the

wire away from the plug to prevent accidental starling.

MAINTENANCE

Do not operate your splitter in poor mechanical condit on or when

in need of repair.

Periodically check that all nuts, bolts, screws, hose tiamps and

hydraulic fittings are tight to be sure equipment is in s afe working

condition. Where appropriate, check all safety guards and shields

to be sure they are in the proper position. Never operal e your split

ter with safety guards, shields or other protective featur js removed.

These safety devices are for your protection.

3. Replace all damaged or worn parts such as hydraulic hoses and

fittings immediately with manufacturer approved replacement parts.

4. Do not change the engine governor settings or overspeed the

engine. This increases the hazard of personal injury. The max

imum engine speed is preset by the manufacturer and is within

safety limits.

5. Do not alter your splitter in any manner such as attaching a rope

or extension to the control lever or adding to the width or height

of the wedge. Such alterations may cause your splitter to be unsafe.

6. Perform all recommended maintenance procedures before you use

your splitter.

7. Do not service or repair your log splitter without disconnecting

the spark plug wire.

8. Never store the equipment with gasoline in the tank inside of a

building where ignition sources are present, such as hot water

and space heaters, clothes dryers and the like. Allow the engine

to cool before storing in any enclosure.

9. Always store gasoline in an approved, tightly sealed container.

Store the container in a cool, dry place. Do not store in a building

where ignition sources are present.

10.

To reduce fire hazard, keep engine free of grass, leaves, wood

chips, and excessive grease and oil.

11.

The hydraulic system of your log splitter requires careful inspec

tion, along with the mechanical parts. Be sure to replace frayed,

kinked, or otherwise damaged hydraulic components.

12.

Fluid escaping from a very small hole can be almost invisible. Do

not check for leaks with your hand. Escaping fluid under pressure

can have sufficient force to penetrate skin, causing serious per

sonal injury. Leaks can be located by passing a piece of card

board or wood over the suspected leak and looking for

discoloration.

1314Should it become necessary to loosen or remove any hydraulic

fitting or line, be sure to relieve all pressure by shutting off the

engine and moving the control handle back and forth several times.

Do not remove the cap from the hydraulic tank or reservoir while

your log splitter is running. Hot oil under pressure could cause

injury.

15. The pressure relief valve on your splitter is preset at the factory.

Do not adjust the valve. Only a qualified service technician should

perform this adjustment.

16. Completely drain fuel tank prior to storage. This guards against

accumulation of fuel fumes which could result in a fire hazard.

17. Never store log splitter outside without a waterproof cover. Rain

will cause rust on the inside of the cylinder.

A

TOWING

This unit should not be towed on any street, highway or public

1.

road without checking the existing federal, local or state vehicle

requirements. Any licensing or modifications such as taillights,

etc., needed to comply with the existing federal, local or state

vehicle requirements is the sole responsibility of the purchaser.

2. Before towing, be certain the log splitter is correctly and securely

attached to the towing vehicle, and the safety chains are in place.

Leave slack in chains for turning allowance.

3. Do not allow anyone to sit or ride on your splitter. They can easily

fall off and be seriously injured.

NOTE: This unit is equipped with an internal combustion eng ne and should not be used on or near any unimproved forest-covered, brush-covered

or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any). If

a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have similar

laws. Federal laws apply on federal lands. A spark arreste' for the muffler is available through your nearest engine authorized service dealer

or through DUERR/MTD PRODUCTS INC.

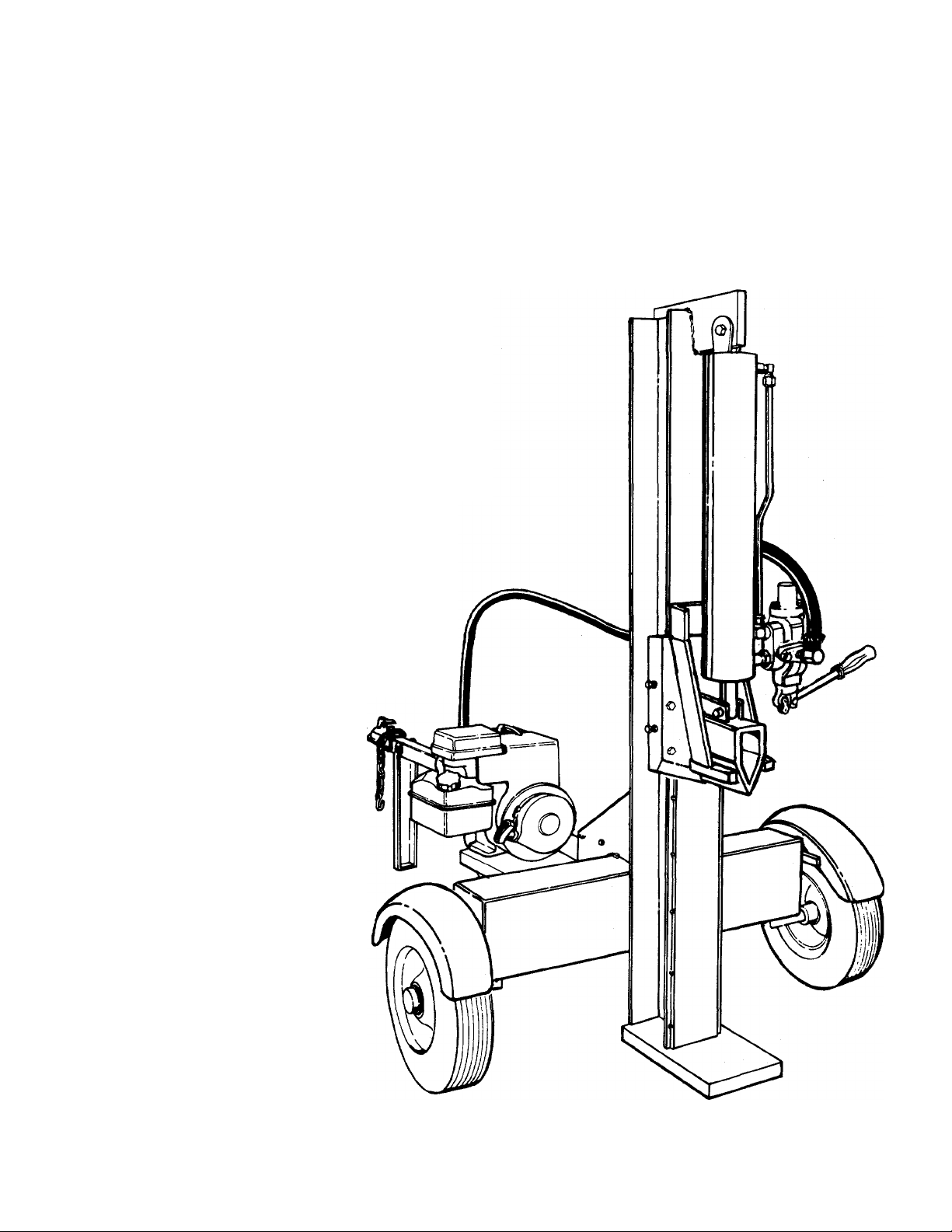

This unit has been shipped without

gasoline or oil in the engine. After

assembly, refer to separate engine

manual for proper fuel and engine oil

information.

Engine and

Pump Assembly

-Hitch

Assembly Tongue Assembly

FIGURE 1.

IMPORTANT

Reservoir

Tank Assembly Beam Support/

I Latch Bracket

ASSEMBLY

UNPACKING

Remove the log splitter parts from the carton by cut

ting the corners of the carton. Make certain all parts

and literature have been removed from the carton

before the carton is discarded.

All hardware for assembly of the log splitter has been

placed in position on the various parts.

~Parts in Carton (See figure 1)

Reservoir Tank Assembly

Engine and Pump Assembly (Bolted to bottom of

carton)

Tongue Assembly

Wedge, Beam and Cylinder Assembly

Hitch Assembly

Wheels

Fenders (Not Shown—Model 424/LCD/22 Only)

Tools Required for Assembly

(1) Rubber Mallet or Plastic Hammer

(2) 9/16" Wrenches*

(2) 1/2" Wrenches*

(1) Adjustable Wrench

(1) Screwdriver

*Adjustable Wrenches may be used.

Other Materials Required for Assembiy:

Engine Oil

Unleaded Gasoline (regular grade gasoline is an

acceptable substitute)

Approximately 7.6 Gallons of Dexron II Automatic

Transmission Fluid or 10W Non-Foaming Hydraulic

Fluid

INSTALLATION OF WHEELS

Attach the wheels to the reservoir tank as follows. See

figure 2.

1. Pry off the hub caps which are attached to the

wheels. Remove one tapered roller bearing from

inside each wheel. See inset.

2. Remove the cotter pin, hex slotted nut and flat

washer from each axle.

3. Place one wheel on each axle, with the valve stem

facing outward.

4. Pack the tapered roller bearings with wheel bear

ing grease, and place one on each axle.

—5. Place one flat washer removed in step 2 on each

axle. Secure with hex slotted nut. Tighten sloted

nut until snug, then back off approximately 1/3 turn

or until one of the slots on the slotted nut lines up

with the hole in the axle.

6. Check the assembly of the wheels. There should

be no side to side play, and the wheel should spin

freely.

7. Place hub caps in position on wheels and tap on

with a rubber mallet or plastic hammer.

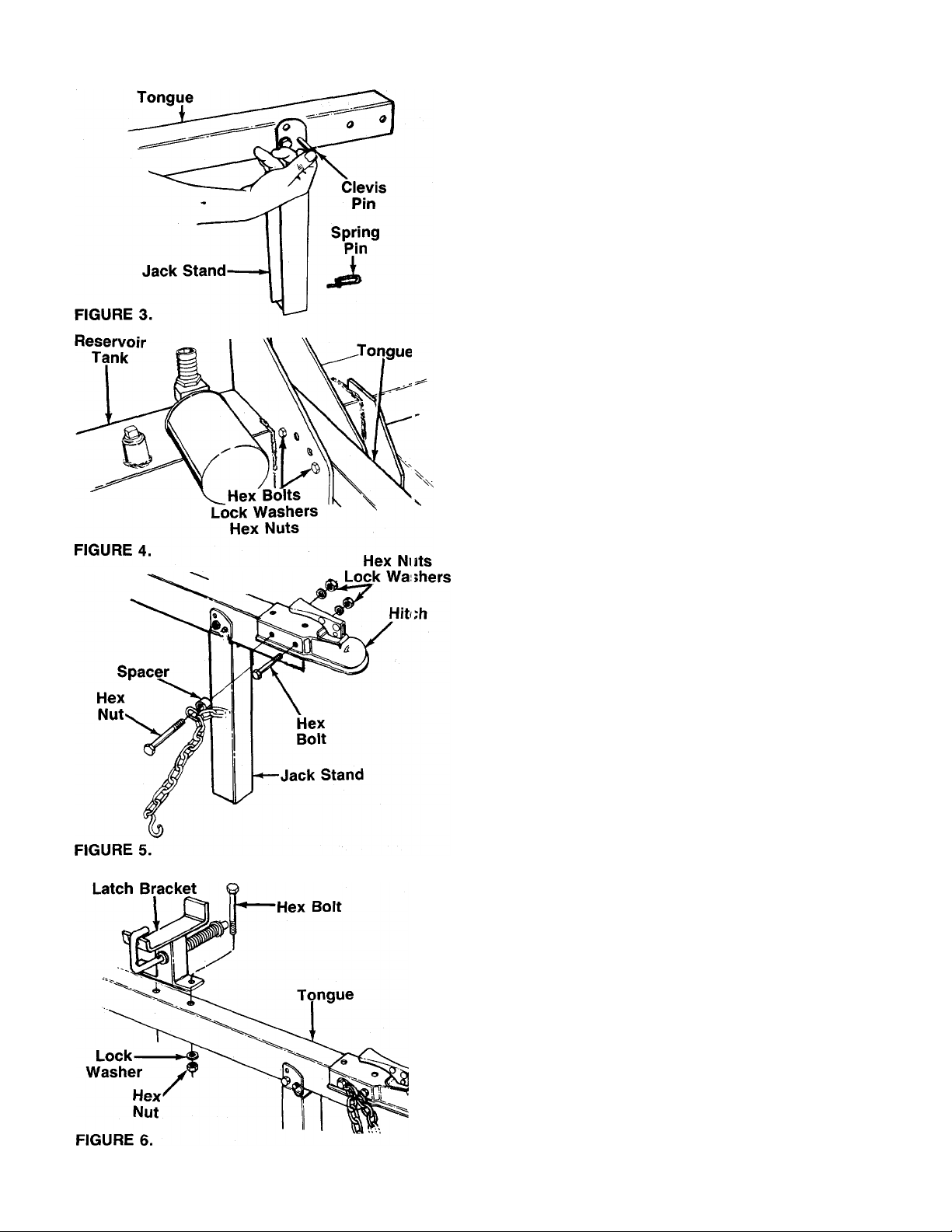

ATTACHING TONGUE TO RESERVOIR TANK

1. The tongue is shipped with the jack stand already

attached to the tongue. The jack stand is in the

transport position. Remove the spring pin and

clevis pin. Pivot the jack stand to the operating

position (90°), and secure with the clevis pin and

------

spring pin. See figure 3.

2.

Remove the two hex bolts, lock washers and hex

nuts on the front of the reservoir tank. Two 9/16"

wrenches are required. Place the tongue in posi

tion, and secure with hardware just removed. See

figure 4.

INSTALLING THE HITCH

1. Using two 9/16" wrenches, remove the two long

hex bolts, lock washers and hex nuts which are

assembled through the sides of the hitch. Do not

remove the chain and spacer from the one hex

bolt.

2.-Place the hitch in position on the end of the tongue

------

as shown in figure 5. Secure with hardware just

removed.

Beam Support/

ATTACHING THE WEDGE, BEAM AND CYLINDER

ASSEMBLY

1. Stand the wedge, beam and cylinder assembly

upright.

2. Remove the cotter pin from the hinge pin, located

on top of the reservoir tank assembly. Move the

reservoir tank assembly in position against the

beam.

3. Insert hinge pin just removed through welded

brackets on beam and reservoir tank assembly.

Secure with cotter pin, bending the ends of the pin

in opposite directions.

ATTACHING THE BEAM SUPPORT/LATCH

BRACKET

1. Remove the two hex bolts, lock washers and hex

nuts from the tongue, using two 9/16" wrenches.

Place the beam support/latch bracket on the

2.

-tongue as shown in figure 6. Secure with hex bolts,

lock washers and hex nuts just removed. Tighten

securely.

Loading...

Loading...