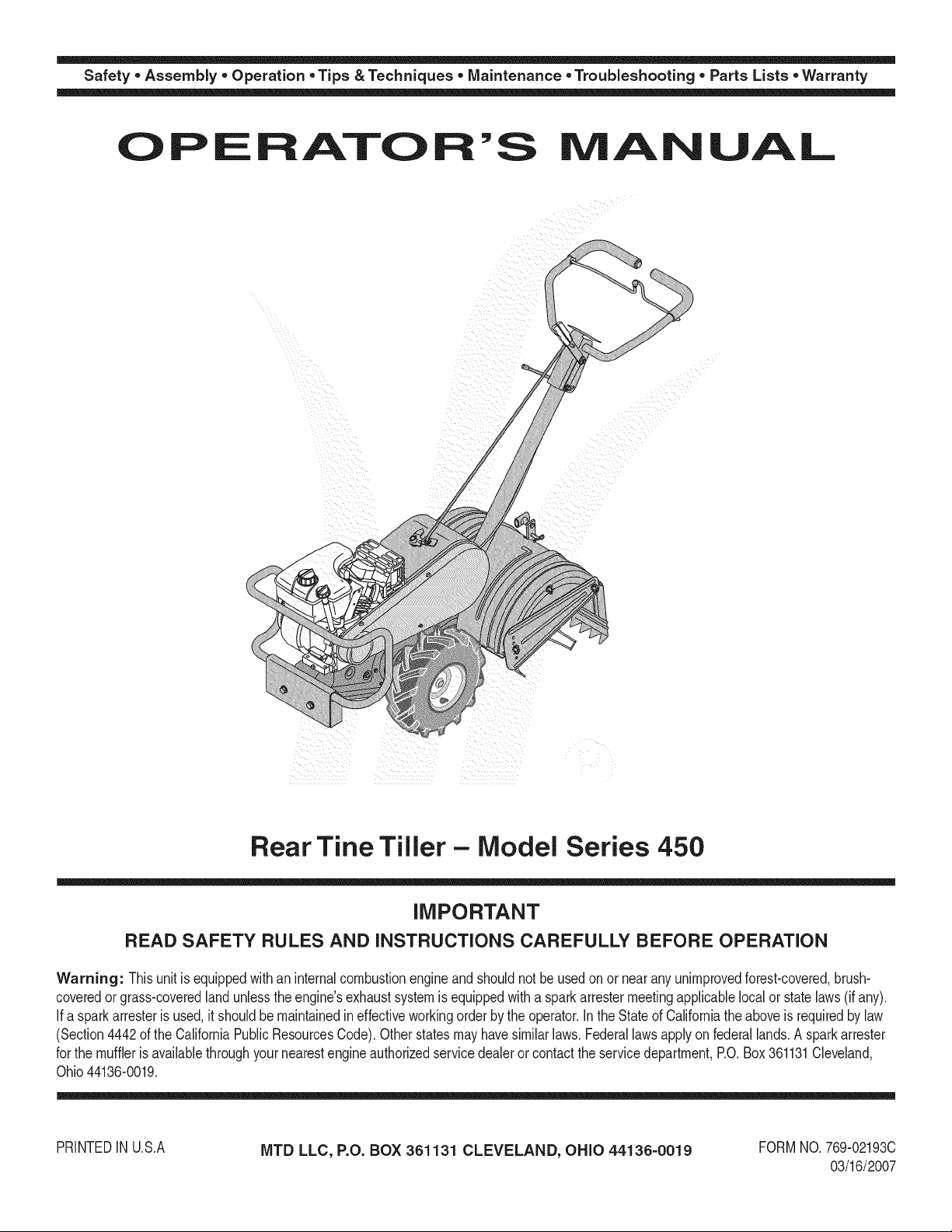

MTD 21AB455C730 Owner’s Manual

Safety • Assembly • Operation • Tips & Techniques • Maintenance • Troubleshooting • Parts Lists • Warranty

OF A O AL

Rear Tine Tiller - Model Series 450

iMPORTANT

READ SAFETY RULES AND iNSTRUCTiONS CAREFULLY BEFORE OPERATION

Warning: Thisunitisequippedwithan internalcombustionengineandshouldnotbeusedon or nearanyunimprovedforest-covered,brush-

coveredor grass-coveredlandunlesstheengine'sexhaustsystemisequippedwitha sparkarrestermeetingapplicablelocalor statelaws(if any).

If a sparkarresterisused,it shouldbemaintainedineffectiveworkingorderby theoperator.IntheStateofCaliforniatheaboveisrequiredbylaw

(Section4442oftheCaliforniaPublicResourcesCode).Otherstatesmayhavesimilarlaws.Federallawsapplyonfederallands.A sparkarrester

forthemufflerisavailablethroughyournearestengineauthorizedservicedealeror contactthe servicedepartment,RO.Box361131Cleveland,

Ohio44136-0019.

PRINTEDIN U.S.A

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

FORMNO.769-02193C

03/16/2007

This Operator's Manual is an important part of your new tiller, it will help you assemble,

prepare, and maintain the unit for best performance. Please read and understand what it says.

Table of

Safety Labels ...................................................... 3

Safe Operation Practices ................................... 4

Assembling Your Tiller ........................................ 6

Know Your Tiller .................................................. 8

Operating Your Tiller ......................................... 10

Making Adjustments ........................................ 11

Finding and Recording Model Number

BEFOREYOUBEGINASSEMBLINGYOURNEW

EQUIPMENT,pleaselocatethe model plate on the equipment

and copy the informationto the samplemodel plate provided

to the right.You can locatethe modelplate by looking at

the rearof the tine shield. This informationis importantfor

usewhenvisiting the manufacturer'sweb site,obtaining

assistancefrom the CustomerSupport Department, or when

communicatingwith anauthorizedservice dealer.

Contents

Maintaining Your Tiller ...................................... 12

Off Season Storage .......................................... 13

Parts List ........................................................... 14

Troubleshooting ................................................ 20

Notes .................................................................. 21

Warranty ............................................. Back Cover

Model Number

www.mtdproducts.com

Serial Number

MTD LLC

P.O= BOX 361131

CLEVELAND, OH 44136

330=220=4683

800-800-731 0

Customer Support

Please do NOTreturn the unit to the retailer from which it was

purchased, without first contacting Customer Support.

Ifyou have difficulty assemblingthis product or have any questions regardingthe controls, operation,or maintenanceof this

unit,youcanseek helpfromthe experts.Choosefrom the options below:

1. Visit mtdproducts.com. Click on the Service & Support menu option.

2. Phonea Customer Support Representative at 1 (800) 800-7310.

3. The engine manufacturer is responsiblefor all engine-relatedissueswith regardsto performance,power-rating,specifica-

tions,warranty and service. Pleasereferto the engine manufacturer'sOwner's/Operator'sManual,packedseparatelywith

your unit, for more information.

2

WARNING

Thissymbolpoints

out importantsafety

instructionswhich,if

notfollowed,could

endangerthepersonal

safetyand/or property

of yourselfandothers.

Readandfollowall

instructionsinthis

manualbeforeat-

temptingto operate

this machine.Failure

to complywiththese

instructionsmayresult

in personalinjury.When

youseethis symbol.

HEED ITS WARNING!

Your Responsibility

Restrictthe use

ofthis power machine

to persons who read,

understand

and follow thewarnings

and instructions

in this manual

and onthe machine.

3

WARNING: Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to State of California to cause

cancer and birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation

in this manual. As with any type of power equipment, carelessness or error on the part of

the operator can result in serious injury.This machine iscapable of amputating hands and

feet and throwing objects. Failure to observethe following safety instructionscould result in

serious injuryordeath.

WARNING

Thissyrnbolpointsout

importantsafety in-

structionswhich, ff not

followed,could endanger

ithe personalsafetyand/or

i property ofyourself and

others_Readand follow all

Iinstructionsinthisrnanual

i beforeattempting tooper-

iatethis machine.Failure

fITS WARNING!

Training

• Read,understand,andfollowall instructionson the

machineandinthemanual(s)beforeattemptingto

assemNeand operate.Keepthis manualina safe

placefor futureandregularreferenceandforordering

replacementparts.

• Befamiliarwithallcontrolsandtheirproperoperation.

Knowhowtostopthemachine.

• Neverallowchildrenunder14yearsoldtooperate

thismachine.Children14yearsoldandover should

readand understandtheoperationinstructionsand

safetyrulesinthismanualandshouldbetrainedand

supervisedbya parent.

• Neverallowadultstooperatethismachinewithout

properinstruction.

• Keepbystanders,helpers,pets,andchildrenat least

75feetfromthemachinewhileit isin operation.Stop

machineif anyoneentersthearea.

Preparation

• Thoroughlyinspecttheareawheretheequipmentis

tobeused.Removeall stones,sticks,wire,andother

foreignobjectswhichcouldbetrippedoverandcause

personalinjury.

• Wearsturdy,rough-soledworkshoesandclose

fittingslacksand shirt.Loosefittingclothesor jewelry

canbe caughtin movaNeparts.Neveroperatethis

machinein barefeetorsandals.

• Disengagedutchleversandshift (ifprovided)into

neutral("N') beforestartingtheengine.

• Neverleavethis machineunattendedwiththeengine

running.

• Neverattempttomakeanyadjustmentswhileengine

isrunning,exceptwherespedficallyrecommendedin

theoperator'smanual.

• Toavoidpersonalinjuryor propertydamageuse

extremecarein handlinggasoline.Gasolineis

extremelyflammableandthevaporsareexplosive.

Seriouspersonalinjurycan occurwhengasolineis

spilledonyourselforyourclotheswhichcanignite.

Washyourskinandchangeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Extinguishall cigarettes,cigars,pipesandother

sourcesofignition.

• Neverfuelmachineindoors.

• Neverremovegascaporaddfuelwhiletheengine

ishot or running.

• Allowenginetocoolat leasttwominutesbefore

refueling

• Neveroverfillfueltank.FilltanktonomorethanY2

inchbelowbottomoffillernecktoprovidespacefor

fuelexpansion.

• Replacegasolinecapandtightensecurely.

• If gasolineisspilled,wipeit off theengineand

equipment.Movemachineto anotherarea.Waitfive

minutesbeforestartingtheengine.

• Neverstorethemachineorfuelcontainerinside

nearanopenflame,sparkor pilotlight(e.g.furnace,

wateror spaceheater,clothesdryer,etc.).

• Allowmachinetocoolfiveminutesbeforestoring.

Operation

• Donotputhandsor feetnearrotatingparts.Contact

withtherotatingpartscanamputatehandsandfeet.

• Donotoperatemachinewhileundertheinfluenceof

alcoholordrugs.

• Neveroperatethismachinewithoutgoodvisibilityor

light.Nwaysbesureof yourfootingandkeepa firm

holdonthehandles.

• Keepbystanders,helpers,pets,andchildrenat least

75feetfromthemachinewhileit isin operation.

Stopthe machineifanyoneentersthearea.

• Becarefulwhentillinginhardground.Thetinesmay

catchin thegroundandpropelthetillerforward.

If thisoccurs,letgod the handlebarsanddo not

restrainthemachine.

• Exerciseextremecautionwhenoperatingonor

crossinggravelsurfaces.Stayalertforhidden

hazardsortraffic.

• Neveroperatethemachineat hightransportspeeds

onhardorslipperysurfaces.

• Exercisecautiontoavoidslippingor falling.

• Lookdownandbehindandusecarewhenin reverse

orpullingmachinetowardsyou.

• Starttheengineaccordingtotheinstructionsfound

in thismanualandkeepfeetwellawayfromthetines

atalltimes.

4

• Afterstrikingaforeignobject,stoptheengine,

disconnectthesparkplugwireandgroundagainst

theengineThoroughlyinspectthe machineforany

damage.Repairthedamagebeforestartingand

operating.

• Disengageallclutchlevers(iffitted)andstopengine

beforeyouleavetheoperatingposition(behindthe

handles).Waituntilthetinescometoa complete

stopbeforeuncloggingthetines,makinganyadjust-

ments,or inspections.

• Neverrunanengineindoorsorina poorlyventilated

area.Engineexhaustcontainscarbonmonoxide,an

odorlessanddeadlygas.

• Mufflerandenginebecomehotandcancausea

burn.Donottouch.

• Usecautionwhentillingnearfences,buildingsand

undergroundutilities.Rotatingtinescancause

propertydamageorpersonalinjury.

• Donotoverloadmachinecapacitybyattemptingto

till soiltoodeepattoo fastofarate.

• Ifthemachineshouldstartmakinganunusualnoise

or vibration,stoptheengine,disconnectthespark

plugwireand grounditagainsttheengine.Inspect

thoroughlyfordamage.Repairanydamagebefore

startingandoperating.

• Keepallshields,guards,andsafetydevicesinplace

andoperatingproperly.

• Neverpickuporcarrymachinewhiletheengineis

running.

Useonlyattachmentsandaccessoriesapproved

bythemanufacturer.Failuretodo socanresultin

personalinjury.

• Ifsituationsoccurwhichare notcoveredinthis

manual,usecare andgoodjudgment.Contactyour

dealerorcallthecustomerservicenumberfoundon

pagetwo.

Maintenance & Storage

• Nevertamperwithsafetydevices.Checktheir

properoperationregularly.

• Checkboltsandscrewsforpropertightnessat

frequentintervalstokeepthemachineinsafe

workingcondition.Also,visuallyinspectmachine

foranydamage.

• Beforecleaning,repairing,or inspecting,stopthe

engineandmakecertainthetinesandallmoving

partshavestopped.Disconnectthesparkplug

wireandgroundit againsttheenginetoprevent

unintendedstarting.

• Donotchangetheenginegovernorsettingsor

over-speedtheengine.Thegovernorcontrolsthe

maximumsafeoperatingspeedoftheengine.

• Maintainorreplacesafetyandinstructionlabels,

asnecessary.

• Followthismanualforsafeloading,unloading,

transporting,and storageofthis machine.

• Neverstorethemachineorfuelcontainerinside

wherethereisanopenflame,sparkor pilotlight

suchasa waterheater,furnace,clothesdryer,etc.

• Alwaysrefertotheoperator'smanualforproper

instructionson off-seasonstorage.

• If thefueltankhastobedrained,do thisoutdoors.

• Observeproperdisposallawsand regulationsfor

gas,oil,etc.toprotecttheenvironment.

Your Responsibility

• Restricttheuseof thispowermachinetopersons

whoread,understand,andfollowthewarningsand

instructionsin thismanualandonthemachine.

• Thesafetylabelsonthetillerare showninthe

"SafetyLabels"section.Toensuresafeoperation

ofthetiller,followtheinstructionsonalllabels

closely.

Practices

WARNING

Thissymbolpointsout

importantsafetyin-

structions which,if not

followed, couldendanger

the personalsafetyand/or

propertyof yourself and

others.Readandfollow all

instructionsinthis manual

beforeattempting to oper-

atethis machine. Failure

to comply with these

instructions may result in

personal injury. Whenyou

seethis symbol, HEEDITS

WARNING!

5

WARNING

Disconnectthe spark

plugwire and ground

itagainst the engine

to preventunintended

starting.

Becertain to check

the clutchcable

adjustmentbefore

operatingthe tiller.

NOTE:specificationsare

subjecttochangewithout

notification or obligation

imagesmynotreflectyour

exact modelandarefor

refeiencepurposeson!y

NOTE:Referencesto rightorleft sideofthetillerare ff

determinedfrombehindtheunitintheoperatingposition.

To Remove Unit From Carton

• Removestaples,breakglueon topflaps,orcuttape

atcartonend andpeelalongtopflaptoopencarton.

• Removeloosepartsincludedwithunit (i.e.,

operator'smanual,etc.).

• Cutcornersandlaycartondownflat.

• Removepackingmaterial.

• Rollorslideunitoutof carton.Checkcarton

thoroughlyforlooseparts.

• Extendcontrolcableand layonthefloor.Becareful

nottobendorkinkcontrolcable.

IMPORTANT:Thisunitisshippedwithoutgasoline

oroilintheengine.Becertainto serviceenginewith

gasolineandoil as instructedinthe separateengine

manualbeforeoperatingyourmachine.

Loose Parts In Carton

• DepthStake

• HandleAssembly

• ShiftRod

NOTE: Allhardwareneededforassemblyisattached

totheloosepartsorthetiller.

Before Assembly

_ ARNING:Disconnectthe spark plug

wire and ground it against theengineto

preventunintended starting.

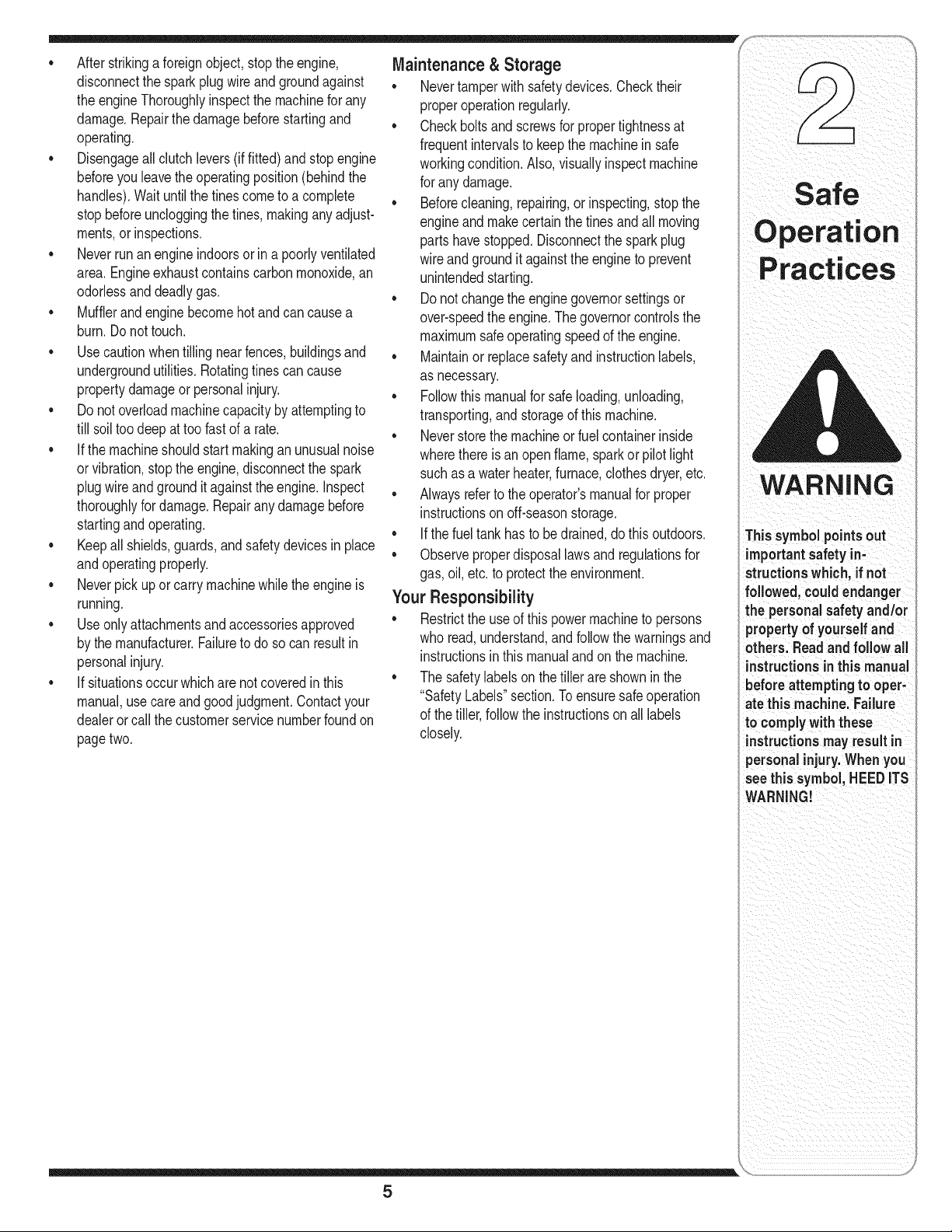

Attaching Depth Stake

• Tipthetillerforwardsoit restsonfrontcounterweight.

• Unthreadthe"T"knobfromthetopofthedepthstake

andremovetheflatwasherandhexbolt.Removethe

hairpinclipfromtheclevispin.SeeFigure3-1.

• Raisethefine shieldhingeflap assemblyandinsert

thedepthstakeassemblyintheslot (underthe tine

shield)andupthroughthefineshieldassembly.

• Insertclevispinthroughthefineshieldanddepth

stakeassemblies.Securewithhairpinclip.

• Insertahexboltintotopholeofthedepthstake

assembly.Placeflatwasheronthehexboltandthread

"T"knobontothehexbolt.Tightensecurely.

SeeFigure3-1.

• Tipthetillerbackdownso itrestson thetines.

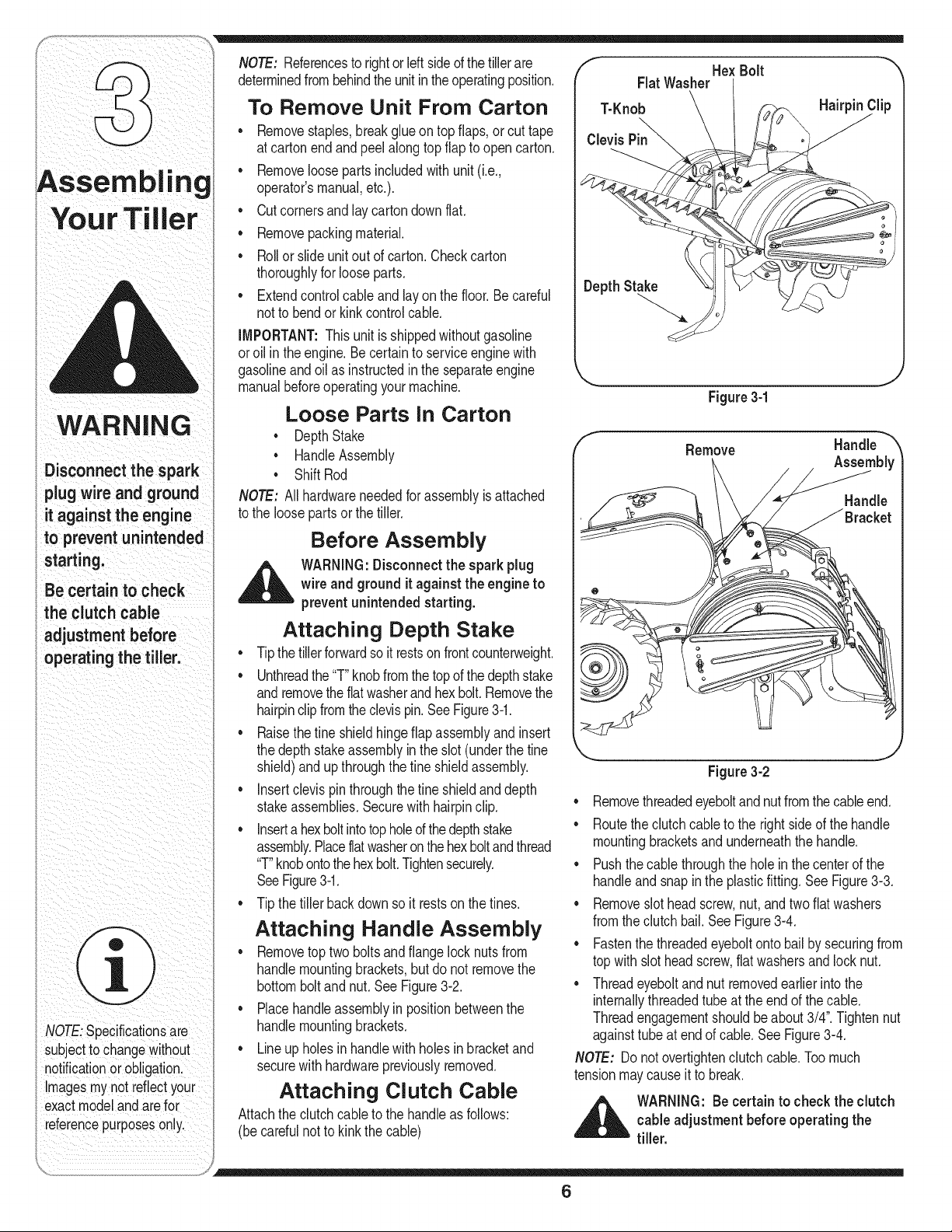

Attaching Handle Assembly

• Removetoptwo boltsandflangelocknutsfrom

handlemountingbrackets,butdonotremovethe

bottomboltandnut.SeeFigure3-2.

• Placehandleassemblyinpositionbetweenthe

handlemountingbrackets.

• Lineupholesin handlewithholesinbracketand

securewithhardwarepreviouslyremoved.

Attaching Clutch Cable

Attachtheclutchcabletothehandleas follows:

(becarefulnottokinkthe cable)

FlatWasher

T-Knob

DepthStake

HexBolt

o Hairpin Clip

J

Figure3-1

f

• Removethreadedeyeboltandnutfromthecableend.

• Routethe clutchcabletotheright sideof thehandle

mountingbracketsand underneaththe handle.

• Pushthecablethroughtheholeinthecenterof the

handleandsnapin theplasticfitting.See Figure3-3.

• Removeslotheadscrew,nut,andtwoflatwashers

fromtheclutchbail.SeeFigure3-4.

• Fastenthethreadedeyeboltontobailbysecuringfrom

topwithslotheadscrew,flatwashersandlock nut.

• Threadeyeboltandnut removedearlierintothe

internallythreadedtubeat theendofthecable.

Threadengagementshouldbeabout3/4".Tightennut

againsttubeat endofcable.SeeFigure3-4.

NOTE: Do notovertightenclutchcable.Toomuch

tensionmaycauseitto break.

_ ARNING: Becertain to checkthe clutch

cable adjustment before operating the

tiller.

Remove

Figure 3-2

Handle

Assembly

Handle

6

B

f SlotHeadScrew,Nut_,

& FiatWashers

PlasticFitting

\ t

Figure3-3

f

ClutchControl

SlotHeadScrew

FiatWashers

ut

J

Figure3-4

//

RubberWasher /Control Rod

idlerPulleyRod

\ J

Figure3-5

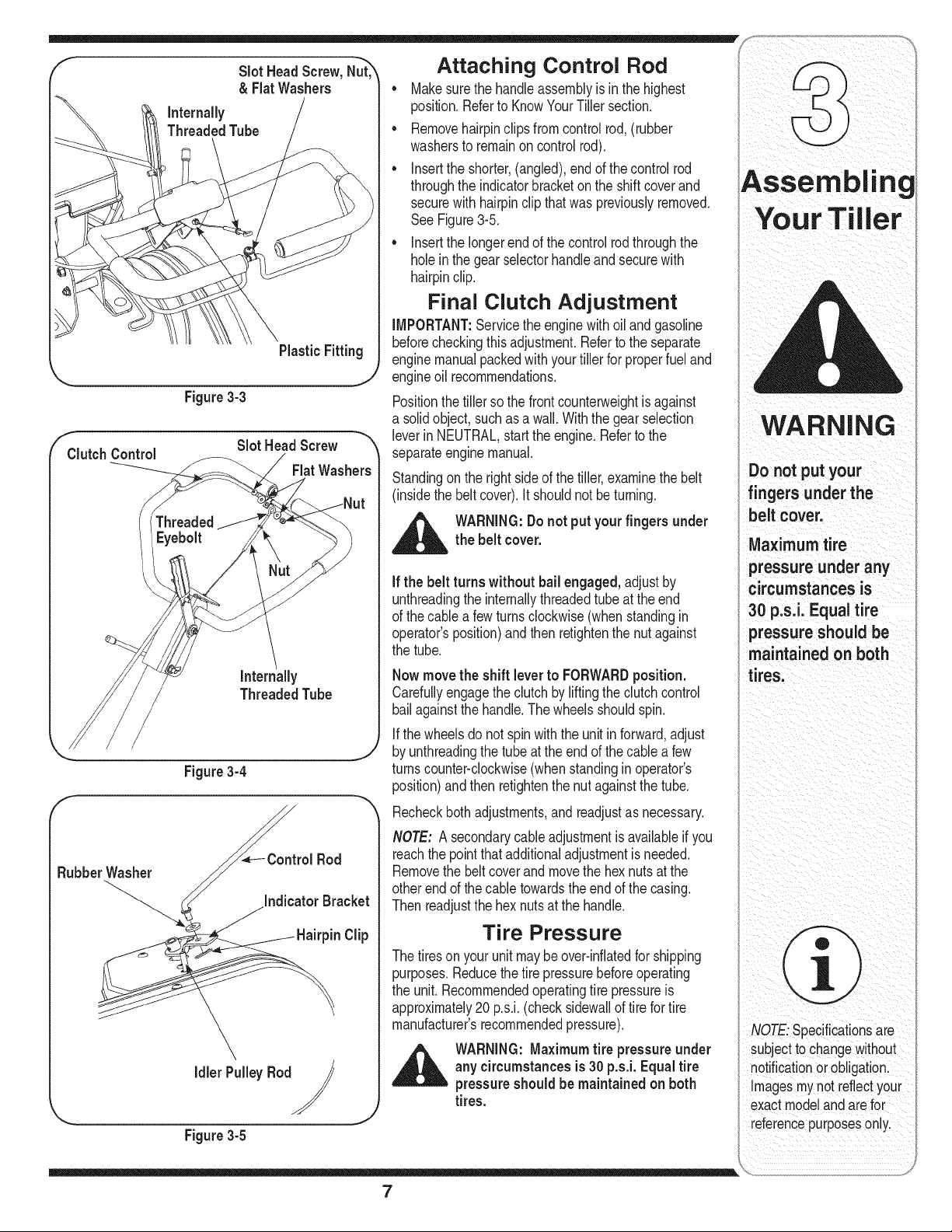

Attaching Control Rod

• Makesurethehandleassemblyisinthehighest

position.Referto KnowYourTillersection.

• Removehairpinclipsfromcontrolrod,(rubber

washerstoremainoncontrolrod).

• Inserttheshorter,(angled),endofthecontrolrod

throughtheindicatorbracketontheshift coverand

securewithhairpinclipthatwaspreviouslyremoved.

SeeFigure3-5.

• Insertthelongerendofthecontrolrodthroughthe

holeinthegearselectorhandleandsecurewith

hairpinclip.

Final Clutch Adjustment

IMPORTANT:Servicethe enginewithoilandgasoline

beforecheckingthis adjustment.Referto theseparate

enginemanualpackedwithyourtillerforproperfueland

engineoil recommendations.

Positionthetillersothefrontcounterweightis against

a solidobject,suchasawall.Withthegearselection

leverinNEUTRAL,starttheengine.Refertothe

separateenginemanual.

Standingonthe rightsideofthetiller,examinethebelt

(insidethe beltcover).Itshouldnotbeturning.

_ ARNING:Donotputyourfingers under

Ifthe belt turns without bail engaged,adjustby

unthreadingthe internallythreadedtubeattheend

ofthecablea fewturnsclockwise(whenstandingin

operator'sposition)and thenretightenthe nutagainst

thetube.

Now movethe shift leverto FORWARDposition.

Carefullyengagethe clutchby liftingtheclutchcontrol

bailagainstthehandle.Thewheelsshouldspin.

If thewheelsdo not spinwiththeunit inforward,adjust

byunthreadingthetubeat theendofthecablea few

turnscounter-clockwise(whenstandinginoperator's

position)andthenretightenthenut againstthetube.

Recheckbothadjustments,and readjustasnecessary.

NOTE: A secondarycableadjustmentisavailableifyou

reachthe pointthatadditionaladjustmentisneeded.

Removethe beltcoverand movethe hexnutsat the

otherendofthecabletowardstheendofthe casing.

Thenreadjustthehexnutsatthehandle.

the belt cover.

Tire Pressure

Thetireson yourunitmaybeover-inflatedfor shipping

purposes.Reducethe tirepressurebeforeoperating

theunit.Recommendedoperatingtirepressureis

approximately20 p.s.i.(checksidewallof tirefortire

manufacturer'srecommendedpressure).

_ ARNING: Maximumtire pressureunder

any circumstancesis 30 p.s.i.Equaltire

pressureshouldbemaintainedon both

tires.

Do not putyour

fingers underthe

belt cover.

Maximumtire

pressure under any

circumstancesis

30 p.s.i. Equal tire

pressureshould be

maintained on both

tires.

NOTE:Specificationsa[e

subjectto changewithout

notificationor obligationl

Imagesmy not reflect your

exactmodelandarefor

referencepurposeson!y.

7

/++_..-- .........,...............................,=

ii LI):i;¸ A "k

i GearSelectionHandle......

KnoWYour

/i

HandleAdjustment

Tiller

Depth Stake

!

i

WARNING

Make certain unit is

in NEUTRALwhen

starting the engine.

1

NOTE:Specificationsare

i subjecttochangewith0ut

notification or obligation

ImageSmynotreflectyour

exact modelandarefo[

[eference purposeson!y,

Figure4-1

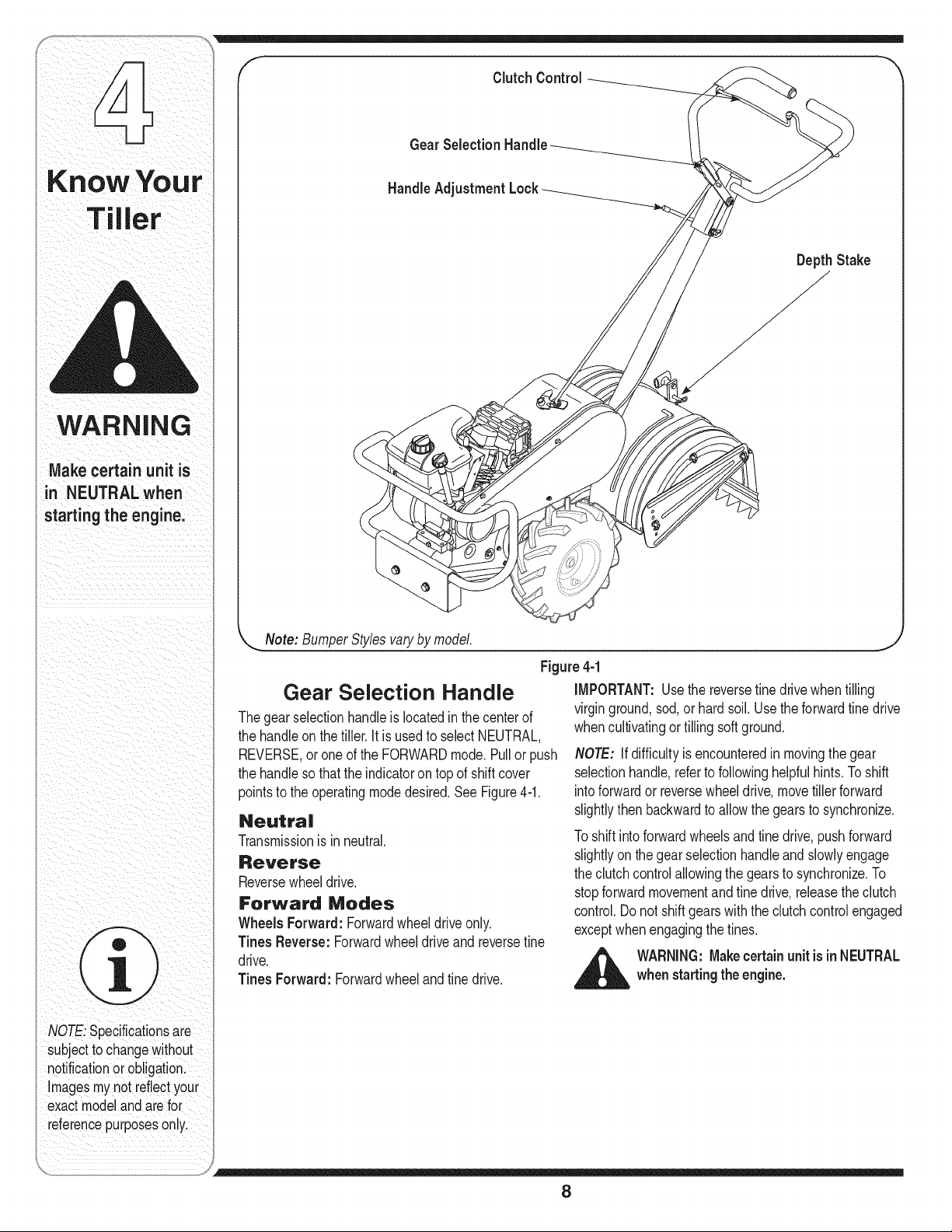

Gear Selection Handle

Thegearselectionhandleislocatedinthecenterof

thehandleonthetiller.It is usedtoselectNEUTRAL,

REVERSE,oroneofthe FORWARDmode.Pullorpush

thehandlesothattheindicatoron topof shiftcover

pointstotheoperatingmodedesired.SeeFigure4-1.

Neutra|

Transmissionisinneutral.

Reverse

Reversewheeldrive.

Forward Modes

Wheels Forward: Forwardwheeldriveonly.

Tines Reverse: Forwardwheeldriveandreversefine

drive.

Tines Forward: Forwardwheeland tinedrive.

iMPORTANT:Usethereversefinedrivewhentilling

virginground,sod,orhardsoil.Usetheforwardtinedrive

whencultivatingortilling softground.

NOTE: If difficultyis encounteredin movingthegear

selectionhandle,referto followinghelpfulhints.Toshift

intoforwardor reversewheeldrive,movetillerforward

slightlythenbackwardtoallowthegearstosynchronize.

Toshift intoforwardwheelsandtinedrive,pushforward

slightlyonthegearselectionhandleandslowlyengage

theclutchcontrolallowingthegearstosynchronize.To

stopforwardmovementandfinedrive,releasetheclutch

control.Donotshiftgearswiththeclutchcontrolengaged

exceptwhenengagingthetines.

_ ARNING:MakecertainunitisinNEUTRALwhenstartingtheengine.

8

Loading...

Loading...