MTD 21AA45M5099 Owner’s Manual

Operator's Manual

I:Rl FI'SlVl N

208cc Engine

Rear Tine Tiller

Model No. 247.29932

* SAFETY

* ASSEMBLY

* OPERATION

CAUTION: Before using

this product, read this

manual and follow aJl

* MAINTENANCE

* PARTS LIST

* ESPANOL

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, iL 60179, U.S.A.

Visit our web site: www.craftsman.com

FORMNO.769-05425C

2/1/2011

WarrantyStatement..................................Pac

SafetyInstructions....................................Pac

SafetyLabels............................................Pac

Assembly..................................................Pac

Operation..................................................Pac

ServiceandMaintenance.........................Pac

Off-SeasonStorage..................................Pac

CRAFTSMAN TWO YEAR FULL WARRANTY

FORTWOYEARSfromthe dateof purchase,this productiswarrantedagainstanydefectsinmaterialorworkmanship.Defectiveproductwill

receivefreerepairorfree replacementif repairisunavailable.

For warranty coverage details to obtain repair or replacement, visit the web site: www.craftsman.com

This warranty covers ONLY defects in material and workmanship. Warranty coverage does NOT include:

• Expendableitemsthatcan wearoutfromnormalusewithinthewarrantyperiod,suchas

blades,tines,orbelts.

Productdamageresultingfromuserattemptsat productmodificationor repairorcausedbyproductaccessories.

Repairsnecessarybecauseof accidentorfailureto operateormaintaintheproductaccordingtoall suppliedinstructions.

Preventivemaintenance,or repairsnecessaryduetoimproperfuelmixture,contaminatedor stalefuel.

e2

es3-6

e7

es8-10

es11-17

es18-22

e23

Troubleshooting........................................Page24

PartsList...................................................Page26-39

LabelMap.................................................Page40

RepairProtectionAgreement...................Page43

Espa_ol.....................................................Page44

ServiceNumbers......................................BackCover

Thiswarrantyisvoidif thisproductisever usedwhileprovidingcommercialservicesorif rentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

EngineSeries: 208cc

EngineOilType: 10w30

EngineOilCapacity: 20ounces

Fuel: UnleadedGasoline

SparkPlug: F6RTC

SparkPlugGap: .030"

ModelNumber.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

©SearsBrands,LLC 2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingto thesafeopera-

tionpracticesinthismanual.Aswithanytypeof powerequipment,

carelessnessorerroronthe partof theoperatorcan resultin

seriousinjury.Thismachineiscapableofamputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethefollowing

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateof California

tocausecancerandbirthdefectsorotherreproductiveharm.Bat-

tery posts,terminals,andrelatedaccessoriescontainleadand lead

compounds,chemicalsknowntothe Stateof Californiatocause

cancerandreproductiveharm.Washhandsafterhandling.

TRAINING

• Read,understand,andfollowall instructionson the machineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualina safeplaceforfutureand regularreference

andfororderingreplacementparts.

• ReadtheOperator'sManualand followallwarningsand safety

instructions.Failuretodosocan resultin seriousinjuryto the

operatorand/or bystanders.Forquestions,call1-800-4MY-HOME.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsof agetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultstooperatethis machinewithoutproper

instruction.

• Keepbystanders,pets,andchildrenatleast75feetfromthe

machinewhileit isin operation.Stopmachineifanyoneenters

thearea.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

Your Responsibility=Restrict theuseofthispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon the machine.

SAVETHESEINSTRUCTIONS!

PREPARATION

• Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall rocks,bottles,cans,or otherforeignobjectswhich

couldbepickedupor thrownandcausepersonalinjuryor

damageto themachine.

• Alwayswearsafetyglassesor safetygogglesduringoperation

andwhileperformingan adjustmentorrepair,to protectyour

eyes.Thrownobjectswhichricochetcancauseseriousinjuryto

theeyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesorjewelrycan becaughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.

• Beforestarting,checkallboltsandscrewsfor propertightnessto

besurethe machineisinsafeworkingcondition.Also,visually

inspectmachinefor anydamageatfrequentintervals.

• Disengageclutchleversandshift(if provided)into neutral("N")

beforestartingtheengine.

• Neverleavethismachineunattendedwiththeenginerunning.

• Neverattempttomakeanyadjustmentswhilethe engineis

running,exceptwherespecificallyrecommendedinthe operator's

manual.

• Maintainorreplacesafetyandinstructionslabels,asnecessary.

3

SafeHandling of Gasoline:

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycan occurwhengasolineisspilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Neverfill containersinsideavehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthe groundaway

fromyourvehiclebeforefilling.

• Whenpractical,removegas-poweredequipmentfromthetruck

ortrailerand refuelitonthe ground.Ifthisis notpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

• Keepthe nozzleincontactwiththerimofthe fueltankor

containeropeningatalltimes untilfuelingiscomplete.Donotuse

a nozzlelock-opendevice.

• Extinguishallcigarettes,cigars,pipesandother sourcesof

ignition.

• Neverfuel machineindoors.

• Neverremovegascapor addfuel whilethe engineishot or run-

ning.Allowenginetocool atleasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Fill tankto nomorethan1/2inchbelow

bottomoffillerneckto allowspacefor fuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipe itoff theengineandequipment.Move

unitto anotherarea.Wait5 minutesbeforestartingtheengine.

• To reducefirehazards,keepmachinefreeof grass,leaves,or

otherdebrisbuild-up.Cleanupoil orfuelspillageand removeany

fuelsoakeddebris.

• Neverstorethe machineorfuelcontainerinsidewherethereis an

openflame,sparkor pilotlightas on awaterheater,spaceheater,

furnace,clothesdryerorothergasappliances.

OPERATION

• Do notputhandsorfeetnear rotatingparts.Contactwiththe

rotatingpartscanamputatehandsandfeet.

• Do notoperatemachinewhileunderthe influenceofalcoholor

drugs.

• Neveroperatethismachinewithoutgoodvisibilityor light.Always

be sureof yourfootingandkeepa firmholdonthehandles.

• Keepbystandersawayfromthe machinewhileit isinoperation.

Stopthe machineif anyoneentersthearea.

• Becarefulwhentillinginhardground.Thetines maycatchinthe

groundandpropelthetillerforward.Ifthis occurs,let goofthe

handlebarsanddo not restrainthemachine.

• Exerciseextremecautionwhenoperatingonor crossinggravel

surfaces.Stayalertforhiddenhazardsortraffic. Donotcarry

passengers.

• Neveroperatethemachineat hightransportspeedsonhardor

slipperysurfaces.

• Exercisecautiontoavoidslippingorfalling.

• Lookdownand behindandusecarewhenin reverseor pulling

machinetowardsyou.

• Startthe engineaccordingtothe instructionsfoundinthis manual

and keepfeetwell awayfromthetinesat all times.

• Afterstrikingaforeignobjector ifyourmachineshouldstartmak-

inganunusualnoiseor vibration,immediatelyshutthe engineoff.

Disconnectthe sparkplugwire,grounditagainstthe engineand

performthefollowingsteps:

a. Inspectfordamage.

b. Repairorreplaceanydamagedparts.

c. Checkforanyloosepartsandtightento assurecontinued

safeoperation.

• Disengageall clutchlevers(iffitted)and stopenginebeforeyou

leavethe operatingposition(behindthe handles).Waituntil

thetinescometo a completestopbeforeuncloggingthe tines,

makinganyadjustments,or inspections.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,an odorlessanddeadlygas.

• Mufflerandenginebecomehotandcancausea burn.Do not

touch.

• Usecautionwhentillingnearfences,buildingsandunderground

utilities.Rotatingtinescan causepropertydamageorpersonal

injury.

• Donotoverloadmachinecapacitybyattemptingtotillsoil too

deepattoo fastof a rate.

• Ifthe machineshouldstartmakinganunusualnoiseor vibration,

stoptheengine,disconnectthesparkplugwire andgroundit

againsttheengine.Inspectthoroughlyfordamage.Repairany

damagebeforestartingandoperating.

• Keepallshields,guards,and safetydevicesinplaceandoperat-

ing properly.

• Neverpickuporcarrymachinewhiletheengineis running.

• Useonly attachmentsandaccessoriesapprovedbythe manu-

factureras listedin thePartsListpagesofthisoperator'smanual.

Failuretodosocan resultin personalinjury.

• Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgement.ContactCustomerSupportat 1-800-4MY-

HOMEforassistanceandthenameof thenearestservicedealer

MAINTENANCE & STORAGE

• Keepthemachine,attachmentsandaccessoriesin safeworking

order.

• Allowthemachinetocoolat leastfiveminutesbeforestoring.

Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.

• Checkboltsandscrewsforpropertightnessat frequentintervals

to keepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

• Beforecleaning,repairing,or inspecting,stopthe engineand

makecertainthetinesandall movingpartshavestopped.

Disconnectthe sparkplugwireandgrounditagainsttheengineto

preventunintendedstarting.

4

• Do notchangetheenginegovernorsettingsor over-speedthe

engine.Thegovernorcontrolsthemaximumsafeoperatingspeed

ofengine.

Maintainor replacesafetyandinstructionlabels,as necessary.

Followthis manualfor safeloading,unloading,transporting,and

storageof thismachine.

Alwaysreferto theoperator'smanualforimportantdetailsifthe

machineisto bestoredforan extendedperiod.

If thefuel tankhasto be drained,do thisoutdoors.

Observeproperdisposallawsandregulationsforgas,oil, etc.to

protecttheenvironment.

Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 130hoursof

operation.Atthe endof theAverageUsefulLifehavethemachine

inspectedannuallybyanauthorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failureto do socan resultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyenginein anyway.

Tamperingwiththegovernorsettingcan leadto a runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOff RoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(CO),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brushcoveredor grass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any)

Ifa sparkarrestorisused,it shouldbe maintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorforthe muffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowallinstructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine

and muffler to cool before touching.

WARNING: YourResponsibility--Restricttheuse ofthispowermachinetopersonswho read,understandandfollowthe

warningsand instructionsinthis manualandonthemachine.

SAVETHESEINSTRUCTIONS!

6

7

IMPORTANT:Thisunit isshippedwithoutgasolineoroil intheengine.

Becertaintoserviceenginewithgasolineandoilas instructedinthe

Operationsectionofthis manualbeforeoperatingyourmachine.

f

Fiat Washer

NOTE:Referenceto rightand lefthandsideof theTillerisobserved

fromtheoperatingposition.

OPENING CARTON

1. Removethe staples,breaktheglueonthetop flaps,orcut the

tapeat theendof thecartonand peelit alongthetop flapto open.

2. Removealllooseparts.

3. Cutthecornersandlaythecartondown fiat.

4. Removeloosepackingmaterial.

REMOVING UNIT FROM CARTON

1. Usethehandlebartoliftand pullthetiller backwardstoa flat

area.Checkthecartonthoroughlyforlooseparts.

2. Extendthecontrolcableandlayit on thefloor.Becardul notto

bendor kinkthecontrolcable.

LOOSE PARTS IN CARTON

• HandlebarAssembly

• Tiller

• EngineOil

• Operator'sManual

• ShiftRod

• DepthStake

Bolt

Pin

DepthStake

J

Figure1

f

Bolts & Flange

Lock Nuts

Handle

Y

Bracket

Beforeassembly,disconnectthesparkplugwireandgroundit

againsttheengineto preventunintendedstarting.

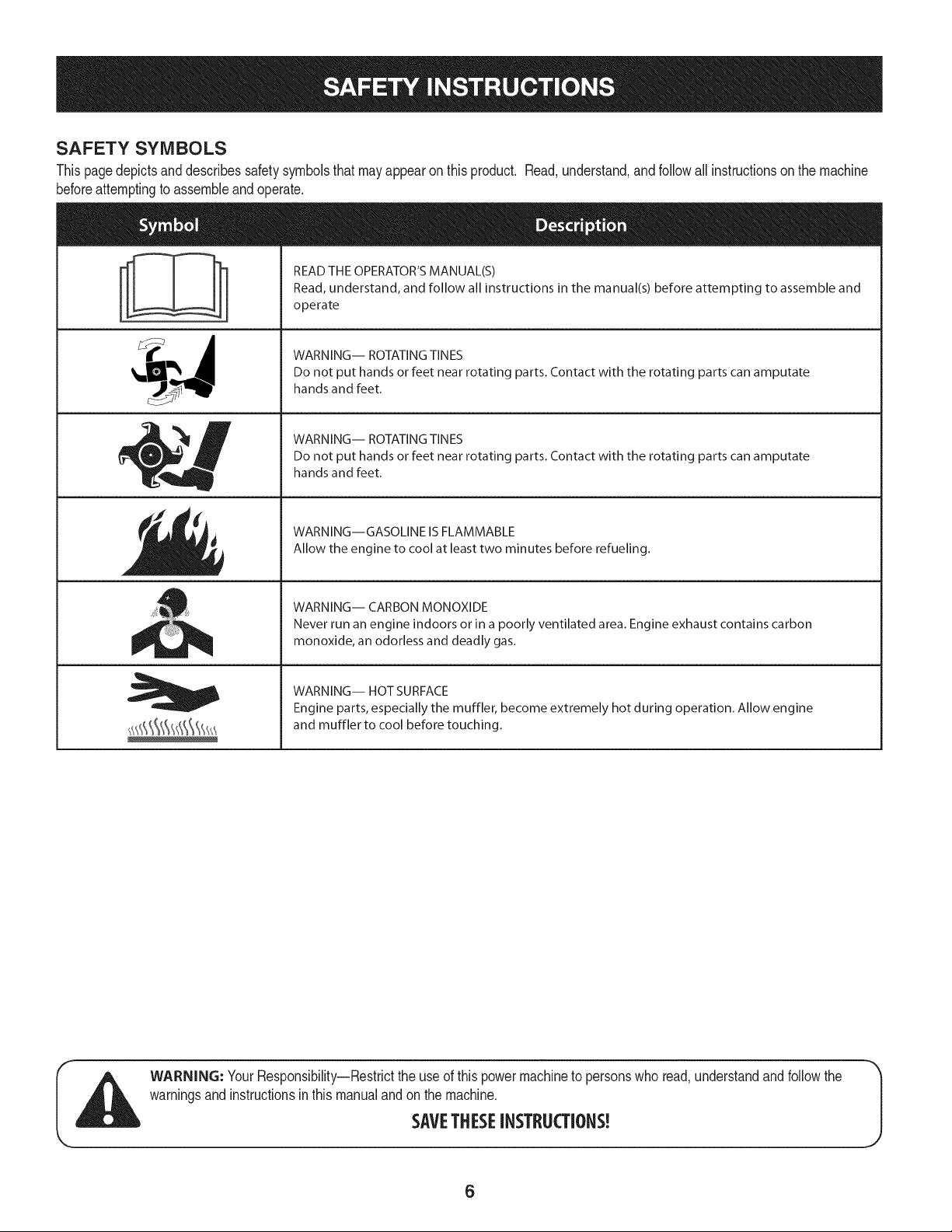

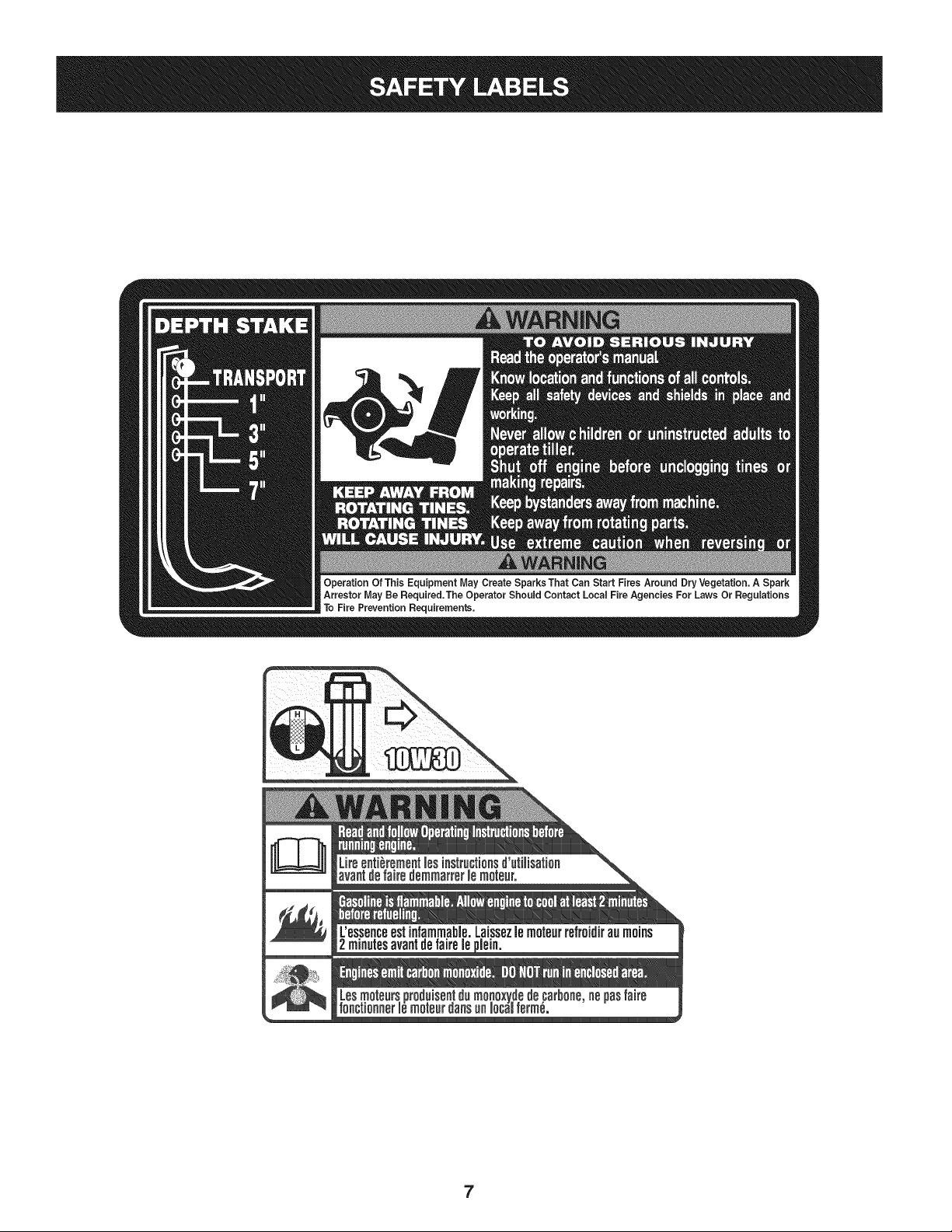

ATTACHING THE DEPTH STAKE

1. Tipthetillerforwardso thatitrestson thefrontcounterweight.

2. Unthreadthe"T"knobfromthetopofthedepthstakeand remove

theflat washerandhexbolt. Removethecotterpinfromtheclevis

pin.SeeFigure1.

3. Raisethefine shieldhingeflap assemblyandinsertthedepth

stakeassemblyinthe slot,underthe fineshieldandupthrough

thefine shieldassembly.

4. Insertthe clevispinthroughthetine shieldanddepthstake

assemblies.Secureit withthecotterpin.

5. Insertthe hexbolt intothe topholeof thedepthstakeassembly.

Placetheflat washeron thehexboltandthreadtheT-knobonto

thehexbolt.Tightensecurely.SeeFigure1.

6. Tipthetillerbackdownsothat it restsonthe tines.

Figure2

ATTACHING THE HANDLE ASSEMBLY

1. Removethetoptwoboltsand flangelocknutsfromthehandle

mountingbrackets,but do notremovethebottomboltandnut.

See Figure2.

2. Placethehandleassemblyin positionbetweenthe handle

mountingbrackets.

3. Lineup theholesinthehandlewiththe holesin the bracketand

securewiththehardwarepreviouslyremoved.

8

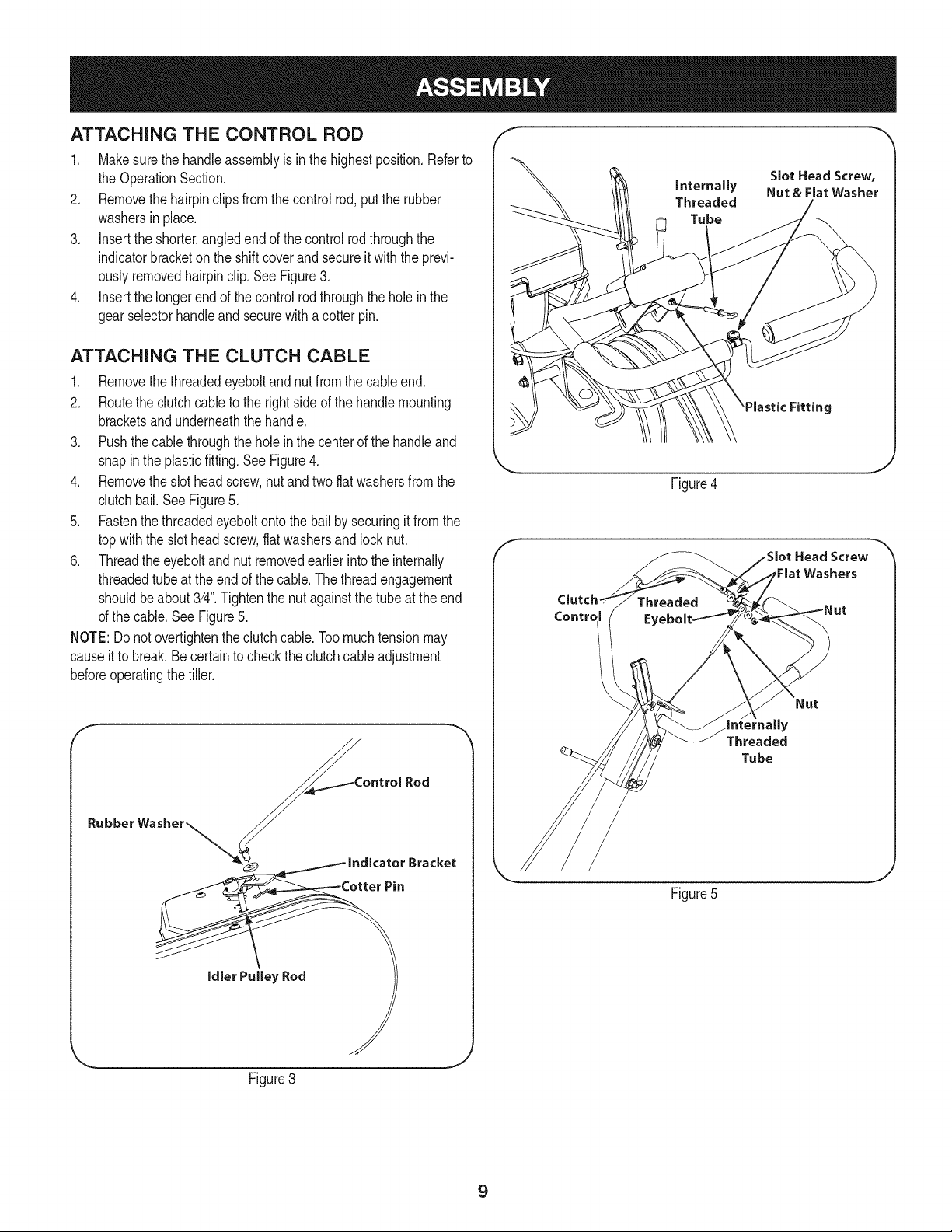

ATTACHING THE CONTROL ROD

1. Makesurethehandleassemblyis inthehighestposition.Referto

theOperationSection.

2. Removethehairpinclipsfromthecontrolrod,putthe rubber

washersinplace.

3. Insertthe shorter,angledendof thecontrolrodthroughthe

indicatorbracketonthe shiftcoverandsecureit withtheprevi-

ouslyremovedhairpinclip.SeeFigure3.

4. Insertthe longerendofthe controlrodthroughthe holeinthe

gearselectorhandleandsecurewitha cotterpin.

ATTACHING THE CLUTCH CABLE

1. Removethethreadedeyeboltandnutfromthe cableend.

2. Routetheclutchcableto therightsideof thehandlemounting

bracketsandunderneaththe handle.

3. Pushthecablethroughtheholeinthe centerofthe handleand

snapin the plasticfitting.SeeFigure4.

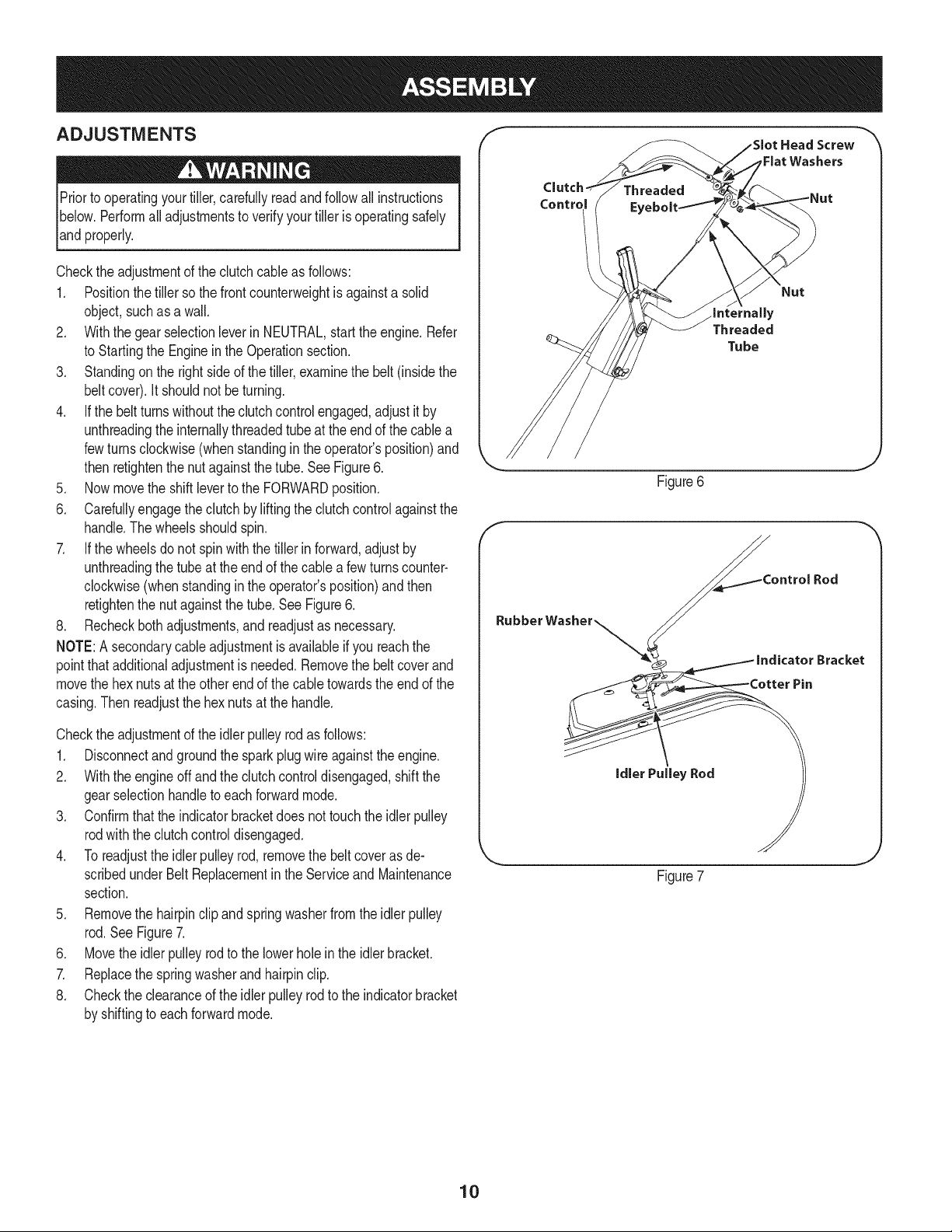

4. Removetheslot headscrew,nutandtwo fiatwashersfromthe

clutchbail.SeeFigure5.

5. Fastenthethreadedeyeboltontothebailby securingitfromthe

topwiththe slotheadscrew,flatwashersandlocknut.

6. Threadtheeyeboltandnutremovedearlierintotheinternally

threadedtubeatthe endofthe cable.Thethreadengagement

shouldbeabout3/4".Tightenthenutagainstthetubeattheend

ofthe cable.SeeFigure5.

NOTE:Do notovertightentheclutchcable.Toomuchtensionmay

causeitto break.Becertaintochecktheclutchcableadjustment

beforeoperatingthetiller.

Internally

Threaded

Tube

Figure4

ff Head Screw _'_

Contro!

Slot Head Screw,

Nut & Fiat Washer

Washers

Nut

Rubber

Threaded

Tube

Figure5

idler PulleyRod )

J

J

Figure3

9

ADJUSTMENTS f "_

Fiat Washers

Priortooperatingyourtiller,carefullyreadand followall instructions

below.Performall adjustmentsto verifyyourtillerisoperatingsafely

_andpropery.

Checktheadjustmentofthe clutchcableasfollows:

1. Positionthetillersothefrontcounterweightisagainstasolid

object,suchas a wall.

2. Withthegearselectionleverin NEUTRAL,startthe engine.Refer

toStartingthe EngineintheOperationsection.

3. Standingonthe rightsideofthe tiller,examinethe belt(insidethe

beltcover).It shouldnotbe turning.

4. Ifthe beltturnswithouttheclutchcontrolengaged,adjustit by

unthreadingthe internallythreadedtubeatthe endofthe cablea

fewturnsclockwise(whenstandingin theoperator'sposition)and

thenretightenthenutagainstthe tube.SeeFigure6.

5. Nowmovetheshiftleverto theFORWARDposition.

6. Carefullyengagetheclutchby liftingtheclutchcontrolagainstthe

handle.Thewheelsshouldspin.

7. Ifthewheelsdo not spinwiththe tillerin forward,adjustby

unthreadingthetubeat theendof thecable afewturnscounter-

clockwise(whenstandingin theoperator'sposition)andthen

retightenthenut againstthetube.SeeFigure6.

8. Recheckbothadjustments,andreadjustas necessary.

NOTE:A secondarycableadjustmentisavailableifyoureachthe

pointthatadditionaladjustmentisneeded.Removethebeltcoverand

movethehexnutsatthe otherendof thecabletowardstheendofthe

casing.Thenreadjustthehexnutsatthe handle.

Control

Nut

Threaded

Tube

J

Figure6

f

Rod

RubberWasher,

,,_f_ Indicator Bracket

Checktheadjustmentofthe idlerpulleyrodas follows:

1. Disconnectandgroundthesparkplugwireagainsttheengine.

2. Withtheengineoffandthe clutchcontroldisengaged,shiftthe

gearselectionhandletoeachforwardmode.

3. Confirmthatthe indicatorbracketdoes nottouchthe idlerpulley

rodwiththeclutchcontroldisengaged.

4. Toreadjustthe idlerpulleyrod,removethebeltcoverasde-

scribedunderBeltReplacementinthe ServiceandMaintenance

section.

5. Removethe hairpinclipandspringwasherfromtheidlerpulley

rod.SeeFigure7.

6. Movetheidlerpulleyrodtothe lowerholeinthe idlerbracket.

7. Replacethespringwasherandhairpinclip.

8. Checktheclearanceofthe idlerpulleyrodto the indicatorbracket

byshiftingtoeach forwardmode.

idlerPulleyRod J

Figure7

10

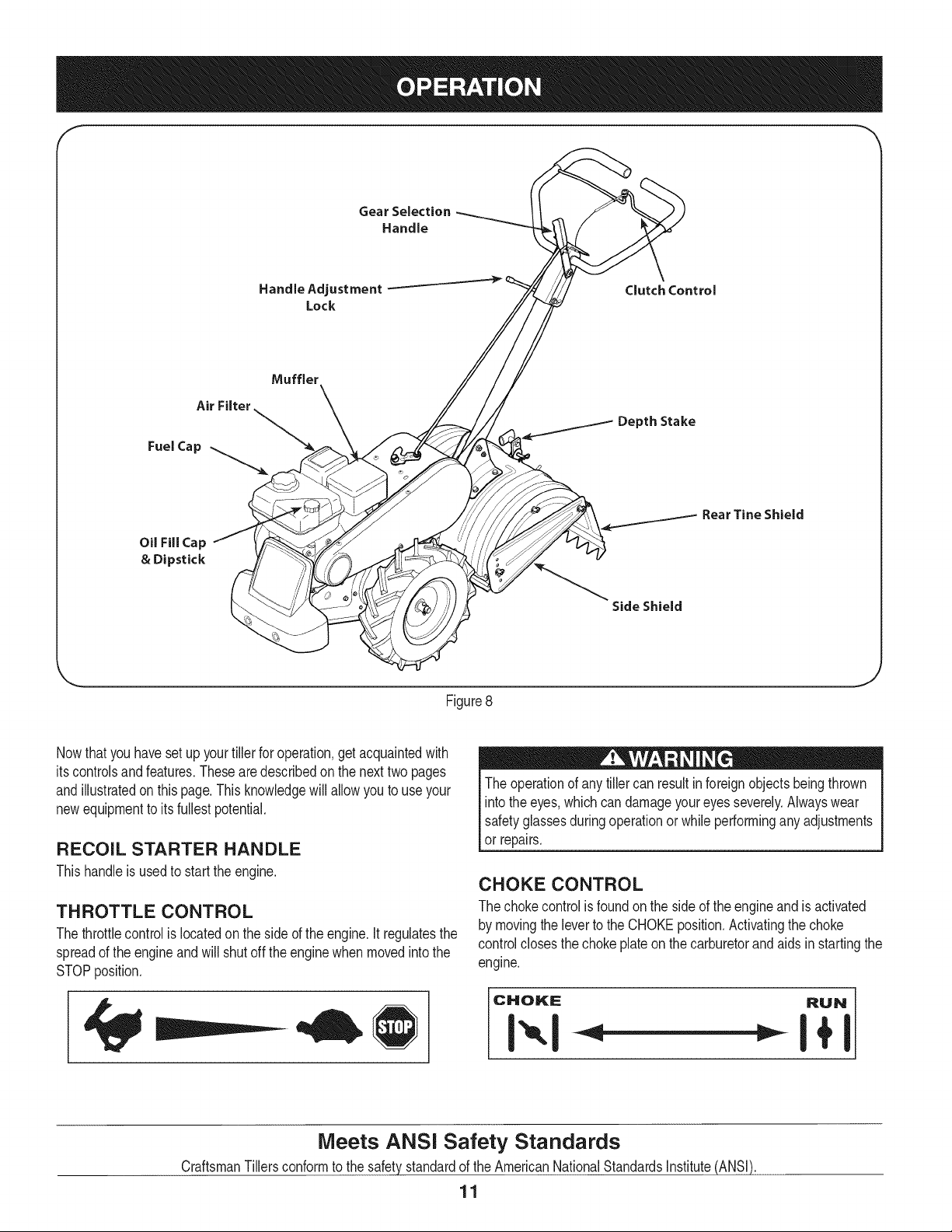

Gear Selection

Handle

Fuel Cap

OU Fill Cap

& Dipstick

Air Filter

Handle Adjustment

Lock

Muffler

Clutch Control

Depth Stake

Rear Tine Shield

Side Shield

J

Figure8

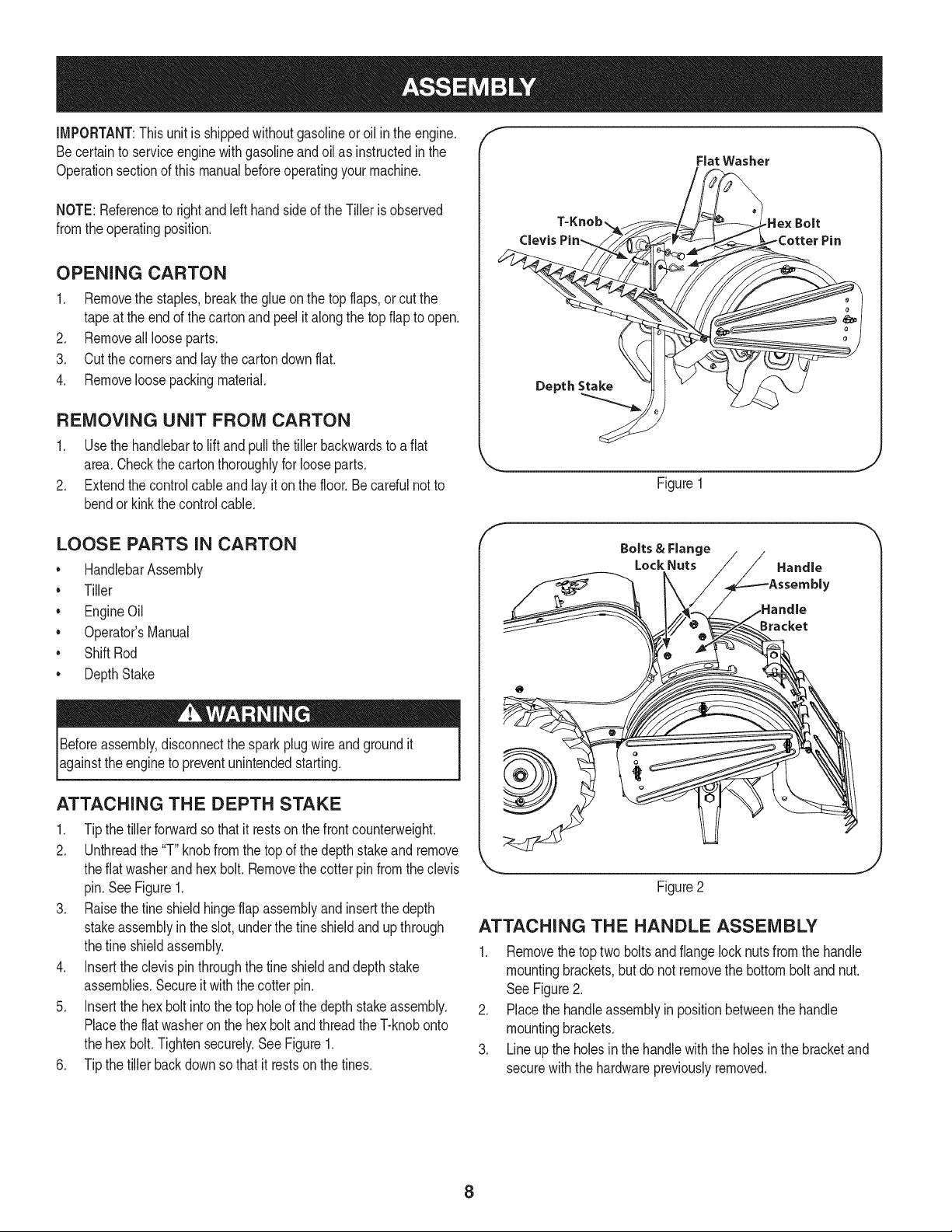

Nowthat youhavesetup yourtillerforoperation,getacquaintedwith

itscontrolsandfeatures.Thesearedescribedonthe nexttwopages

andillustratedon thispage.Thisknowledgewillallowyouto useyour

newequipmenttoits fullestpotential.

RECOIL STARTER HANDLE

Thishandleisusedto starttheengine.

THROTTLE CONTROL

Thethrottlecontrolis locatedonthe sideof theengine.Itregulatesthe

spreadoftheengineandwill shutoff theenginewhen movedintothe

STOPposition.

Meets ANSi Safety Standards

CraftsmanTillersconformtothe safetystandardofthe AmericanNationalStandardsInstitute(ANSI).

Theoperationofanytillercan resultinforeignobjectsbeingthrown

intothe eyes,whichcan damageyoureyesseverely.Alwayswear

safetyglassesduringoperationor whileperforminganyadjustments

or repairs.

CHOKE CONTROL

Thechokecontrolis foundon the sideof theengineandis activated

bymovingthe leverto theCHOKEposition.Activatingthechoke

controlclosesthe chokeplateon the carburetorandaidsin startingthe

engine.

CHOKE RUN

I÷l

11

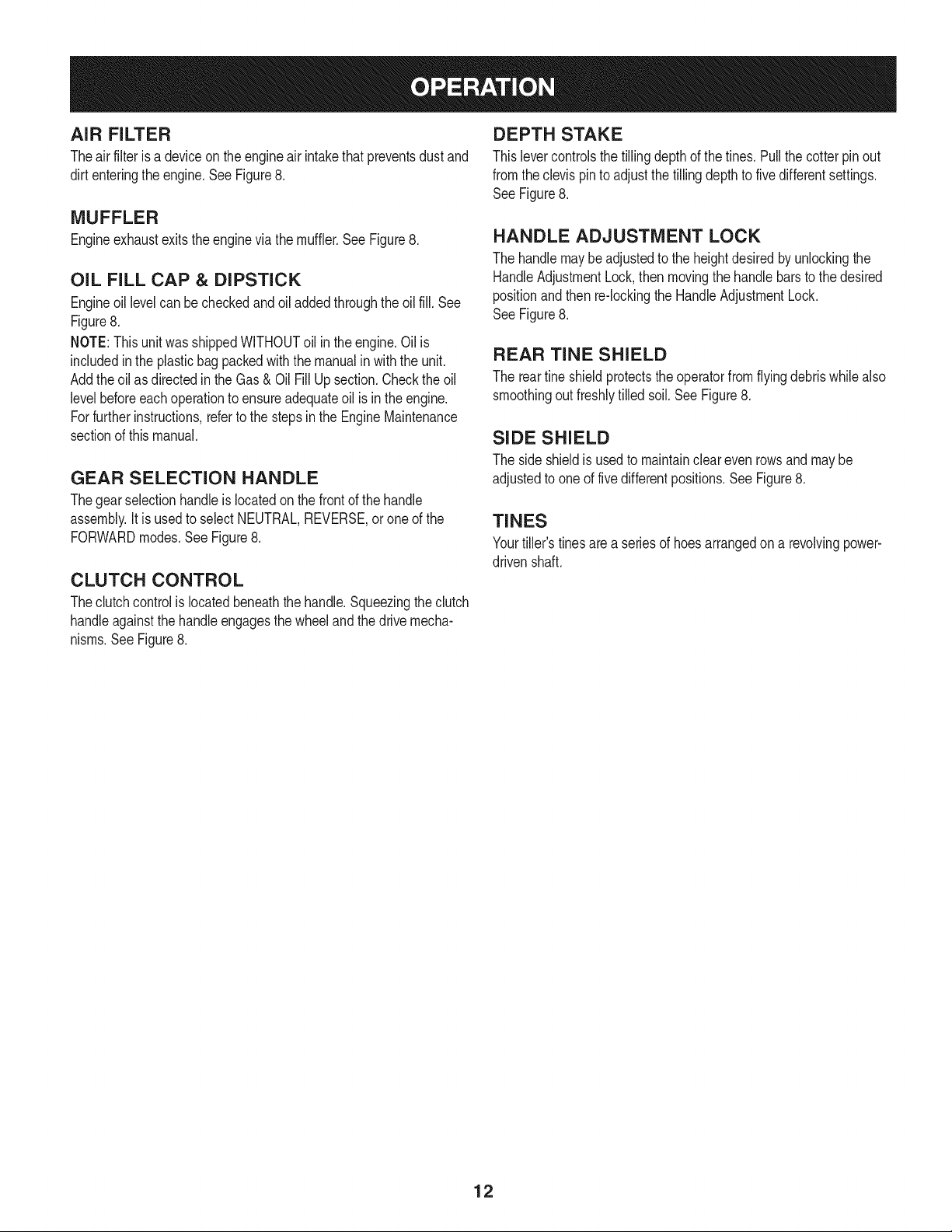

AiR FILTER

Theair filteris a deviceontheengineair intakethatpreventsdustand

dirtenteringtheengine.SeeFigure8.

MUFFLER

Engineexhaustexitstheenginevia themuffler.SeeFigure8.

OIL FILL CAP & DIPSTICK

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill. See

Figure8.

NOTE:ThisunitwasshippedWITHOUToil inthe engine.Oilis

includedintheplasticbagpackedwiththemanualinwiththeunit.

Addtheoil as directedin theGas & OilFillUp section.Checktheoil

levelbeforeeachoperationtoensureadequateoil is intheengine.

Forfurtherinstructions,refertothestepsintheEngineMaintenance

sectionof thismanual.

GEAR SELECTION HANDLE

Thegearselectionhandleislocatedonthe frontof thehandle

assembly.It isusedto selectNEUTRAL,REVERSE,oroneof the

FORWARDmodes.SeeFigure8.

CLUTCH CONTROL

Theclutchcontrolislocatedbeneaththehandle.Squeezingtheclutch

handleagainstthehandleengagesthewheelandthedrivemecha-

nisms.SeeFigure8.

DEPTH STAKE

Thislevercontrolsthetillingdepthof thetines. Pullthecotterpinout

fromtheclevispintoadjustthe tillingdepthto fivedifferentsettings.

SeeFigure8.

HANDLE ADJUSTMENT LOCK

Thehandlemaybeadjustedto theheightdesiredby unlockingthe

HandleAdjustmentLock,thenmovingthe handlebarsto thedesired

positionandthenre-lockingtheHandleAdjustmentLock.

SeeFigure8.

REAR TINE SHIELD

Therearfine shieldprotectstheoperatorfromflyingdebriswhilealso

smoothingoutfreshlytilled soil.See Figure8.

SIDE SHIELD

Theside shieldis usedto maintaincleareven rowsandmaybe

adjustedtooneof fivedifferentpositions.SeeFigure8.

TINES

Yourfiller'stinesarea seriesofhoesarrangedon a revolvingpower-

drivenshaft.

12

GAS AND OIL FILL-UP

Oil (one bottle shipped with unit)

FirstTimeUse

1. Removeoilfilldipstick.

2. Withthetilleron levelground,usea funneltoemptyentire

contentsofoil bottleprovidedintothe engine.

3. Replaceoilfilldipstickandtighten.

Subsequent Uses

Onlyusehighqualitydetergentoil ratedwithAPIserviceclassifica-

tionSF,or SG.Selecttheoil'sSAEviscositygradeaccordingtothe

expectedoperatingtemperature.Followthechartbelow.

Imlm _llm lOw

_ _ )Ow

mm m_O

_30

40 l_

20w40.20w50 _ _ _ _

I I

15w40, 15w50 =row =m_ mm,_ ,,,ml _w= 1link,.

® 10w40

10w30 mlm_ _m

(°C)-300 -200 -100 0° 100 200 300 400

(°F)-200 0° 20U 40U 60U 800 100U

Ambient Temperature

1. SingleViscosity

2. Multi Viscosity

Althoughmulti-viscosityoils (5W30,10W30,etc.)improvestarting

in coldweather,theywillresultinincreasedoilconsumptionwhen

usedabove32°F.Checkyourengineoil levelmorefrequentlytoavoid

possibleenginedamagefromrunninglowon oil.

1. Checktheoillevelmakingcertainnotto rubthedipstickalong

theinsidewallsofthe oil filltube.Thiswould resultina false

dipstickreading.Wipedipstickcleanwithcloth. Replacedipstick

intotheoil fillerneck, butdo not screwit in.Removeandcheck

oil level.Refillto FULLmarkon dipstick,ifnecessary.Capacityis

approximately20oz.Overfillingwillcausethe enginetosmoke

profuselyandwill resultin poorengineperformance.

2. Replaceoilfilldipstickandtighten.

3. KeepoillevelatFULL.Runningtheenginewithtoolittleoilcanresult

in permanentenginedamage.

Alcoholblendedfuels(calledgasoholorusingethanolormethanol)

canattractmoisturewhichleadsto separationandformationofacids

duringstorage.Acidicgascandamagethefuel systemofanengine

whileinstorage.

Toavoidengineproblems,the fuelsystemshouldbeemptiedbefore

storagefor30 daysor longer.Drainthe gastank, startthe engine

andletit rununtilthe fuellinesandcarburetorareempty.Usefresh

fuelnextseason.SeeSTORAGEInstructionsforadditionalinforma-

tion.

Neveruseengineor carburetorcleanerproductsinthe fueltankor

permanentdamagemayoccur.

3. Fillfuel tankwithclean,fresh,unleadedregulargasolineonly.Do

notusegasolinecontainingMETHANOL.Replacefuelcap.

NOTE:Checkthefuellevelperiodicallytoavoidrunningoutof

gasolinewhileoperatingthetiller.

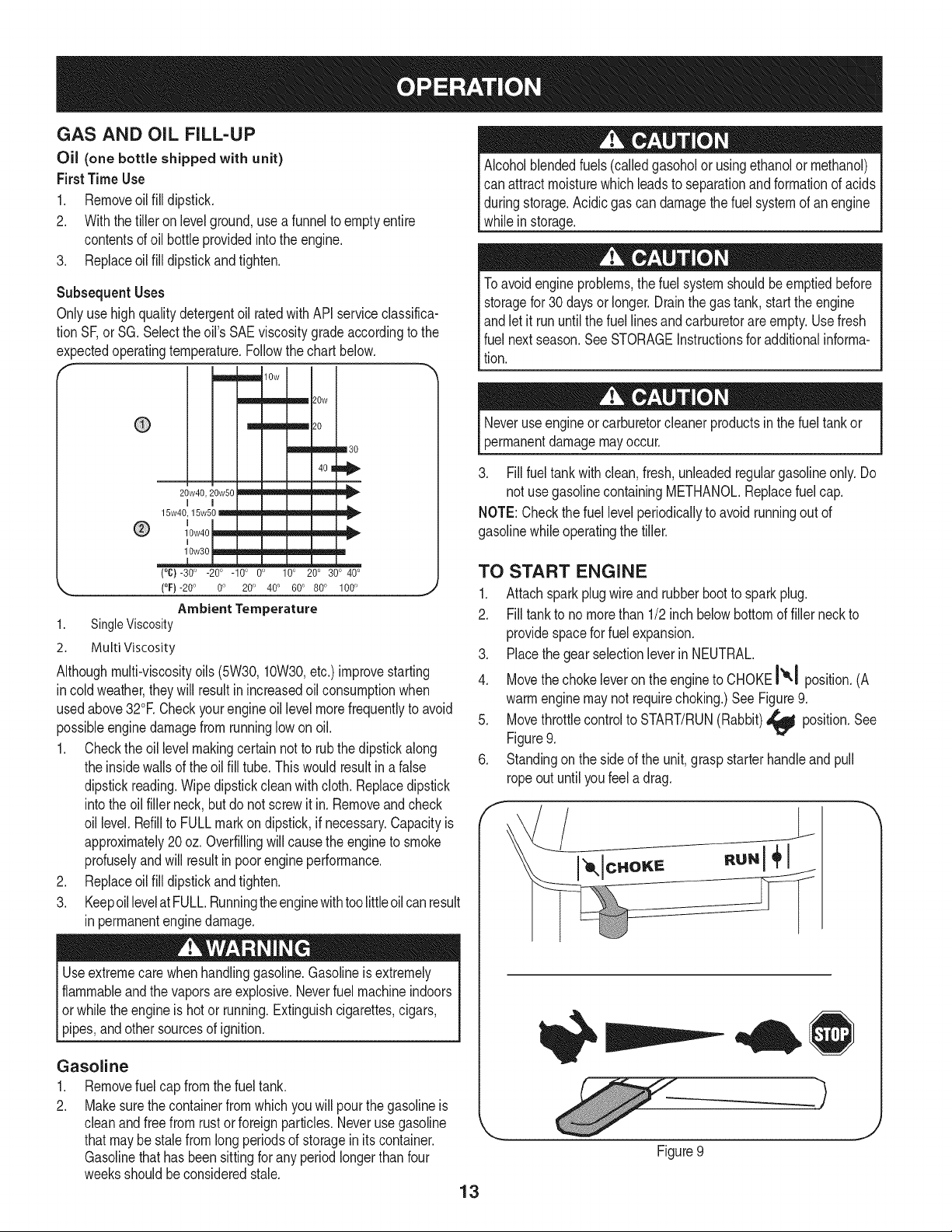

TO START ENGINE

1. Attachsparkplugwireandrubberbootto sparkplug.

2. Filltankto no morethan 1/2inchbelowbottomoffiller neckto

providespacefor fuelexpansion.

3. PlacethegearselectionleverinNEUTRAL.

4. Movethechokeleveron theengineto CHOKEI'=,1 position.(A

warmenginemaynotrequirechoking.)SeeFigure9.

5. Movethrottlecontrolto START/RUN(Rabbit)_ position.See

Figure9.

6. Standingonthe sideof theunit,graspstarterhandleandpull

ropeoutuntilyoufeela drag.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthe vaporsareexplosive.Neverfuelmachineindoors

orwhilethe engineis hotor running.Extinguishcigarettes,cigars,

pipes,andothersourcesof ignition.

Gasoline

1. Removefuelcap fromthefuel tank.

2. Makesurethecontainerfromwhichyouwill pourthegasolineis

cleanandfreefrom rustorforeignparticles.Neverusegasoline

thatmaybestalefromlongperiodsofstorageinitscontainer.

Gasolinethathas beensittingfor anyperiodlongerthan four

weeksshouldbeconsideredstale.

J

Figure9

13

7. Pulltheropewitha rapid,continuous,fullarm stroke.Keepafirm

griponthe starterhandle.Lettheroperewindslowly.

8. Repeat,if necessary,untilenginestarts.Whenenginestarts,

movechokecontrolgraduallytowardthe RUNI _'I position..

9. Ifenginefalters,movechokecontrolbacktowardtheCHOKE

I'_1 positionand repeatsteps5 though8.

10. ALWAYSkeepthethrottlecontrolintheSTART/RUN(Rabbit

positionwhenoperatingthetiller.

TO STOP ENGINE

1. Tostopthewheelsandtines,releasetheClutchControl.

2. Movethrottlecontrollevertoslow(turtle)_ position.Whenever

possible,graduallyreduceenginespeedbeforestoppingengine.

3. MovethrottlecontrollevertoSTOP_ orOFFposition.

4. Disconnectsparkplugwireandgrounditagainsttheengineto

preventaccidentalstartingwhilethe equipmentisunattended.

TO ENGAGE DRIVE & TINES

Donotpushdownon thehandlebarstotry to makethetillertill more

deeply.Thispreventsthewheelsfromholdingthetiller backandcan

allowthetinesto rapidlypropelthetiller,whichcould resultinlossof

control,propertydamage,orpersonalinjury.

1. Forforwardmotionofthewheelsusethegearselectionhandleand

forpowertothe tinespulltheClutchControlupagainstthe

handlebar.

2. Whentilling,letthewheelspullthe machinewhilethetinesdig.

Walkslowlybehindthetillerallowingitto moveat itsownpace

whilekeepinga securegripon thehandlebarwithyourelbows

flexed.

3. Releasethebailto stopthewheelsandtines.

To move in reverse: (Do not till in reverse)

a. ReleasetheClutchControl.Thenlift thehandlebaruntilthe

tinesareoff theground.

b. Pullbackonthegearselectionhandle,andwalkbackwards

withthe machine.

Note:In reversemode,thetineswill reverserotation.

TURNING THE TILLER

1. Practiceturningthetillerinalevel,openarea.Beverycarefultokeep

yourfeetandlegs awayfromthetines.

2. Tobeginaturn, liftthe handlebarsuntil thetinesareout ofthe

groundandtheengineandtinesarebalancedoverthewheels.

3. Withthetillerbalanced,pushsidewayson thehandlebartosteer

inthedirectionof theturn.Afterturning,slowlylowerthetinesinto

thesoil toresumetilling.

SETTING THE DEPTH

Becertainsparkplugwireisdisconnectedandgroundedagainstthe

enginewhenperforminganyadjustments.

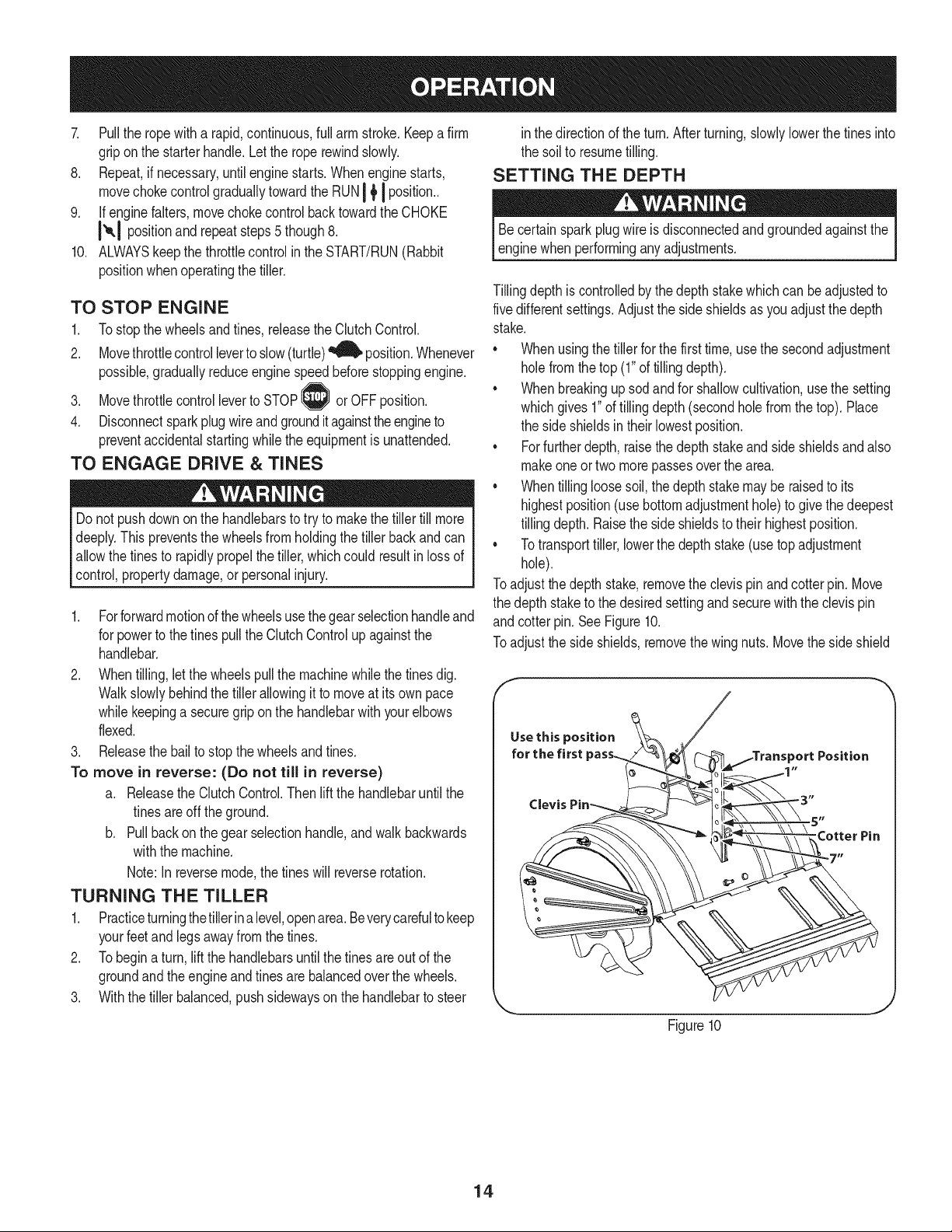

Tillingdepthiscontrolledbythedepth stakewhichcan beadjustedto

fivedifferentsettings.Adjusttheside shieldsasyou adjustthedepth

stake.

• Whenusingthetillerforthefirst time,usethe secondadjustment

holefromthetop (1"oftillingdepth).

• Whenbreakingupsodandfor shallowcultivation,usethe setting

whichgives1"oftillingdepth(secondholefromthetop).Place

theside shieldsintheirlowestposition.

• Forfurtherdepth,raisethe depthstakeandsideshieldsandalso

makeoneortwo morepassesoverthe area.

• Whentillingloosesoil,thedepth stakemaybe raisedtoits

highestposition(usebottomadjustmenthole)togivethedeepest

tillingdepth.Raisethe sideshieldsto theirhighestposition.

• Totransporttiller,lowerthedepthstake(usetopadjustment

hole).

Toadjustthe depthstake,removetheclevispinandcotter pin.Move

thedepth staketothedesiredsettingandsecurewiththeclevispin

andcotterpin. SeeFigure10.

Toadjustthe sideshields,removethewingnuts.Movethe sideshield

E

Use this position

for the first }ort Position

14

Figure10

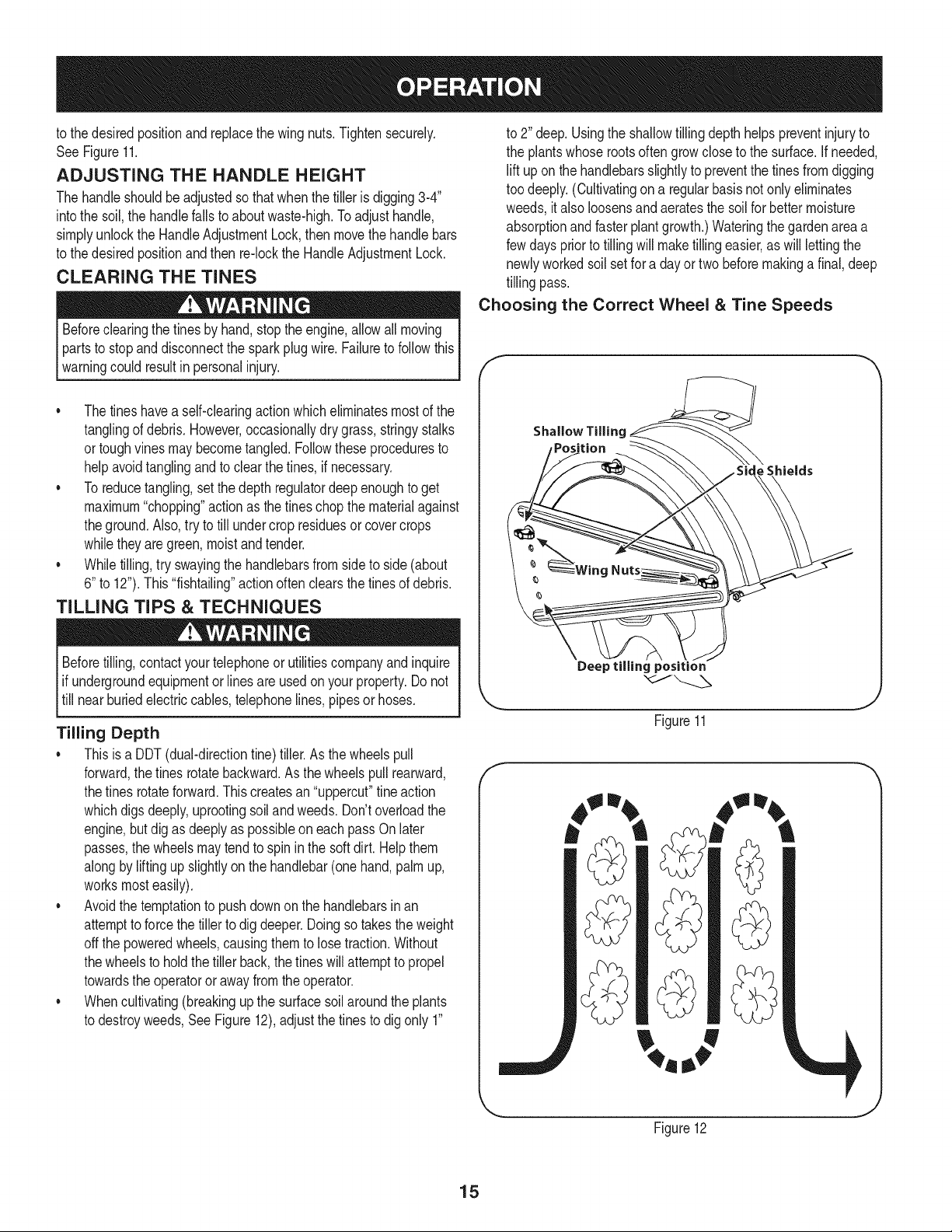

tothe desiredpositionandreplacethewing nuts.Tightensecurely.

SeeFigure11.

ADJUSTING THE HANDLE HEIGHT

Thehandleshouldbe adjustedsothatwhenthetilleris digging3-4"

intothe soil,thehandlefallsto aboutwaste-high.To adjusthandle,

simplyunlockthe HandleAdjustmentLock,thenmovethehandlebars

tothe desiredpositionandthen re-locktheHandleAdjustmentLock.

CLEARING THE TINES

Beforeclearingthetinesby hand,stoptheengine,allowall moving

partsto stopanddisconnectthe sparkplugwire.Failureto followthis

warningcouldresultin personalinjury.

• Thetineshavea self-clearingactionwhicheliminatesmostofthe

tanglingofdebris.However,occasionallydrygrass,stringystalks

ortoughvinesmaybecometangled.Followtheseproceduresto

helpavoidtanglingandtoclearthetines,ifnecessary.

• To reducetangling,setthe depthregulatordeepenoughtoget

maximum"chopping"actionasthe tineschopthe materialagainst

theground.Also,try totill undercropresiduesorcovercrops

whiletheyaregreen,moistandtender.

• Whiletilling,try swayingthehandlebarsfromsidetoside (about

6"to12").This"fishtailing"actionoftenclearsthetinesofdebris.

TILLING TIPS & TECHNIQUES

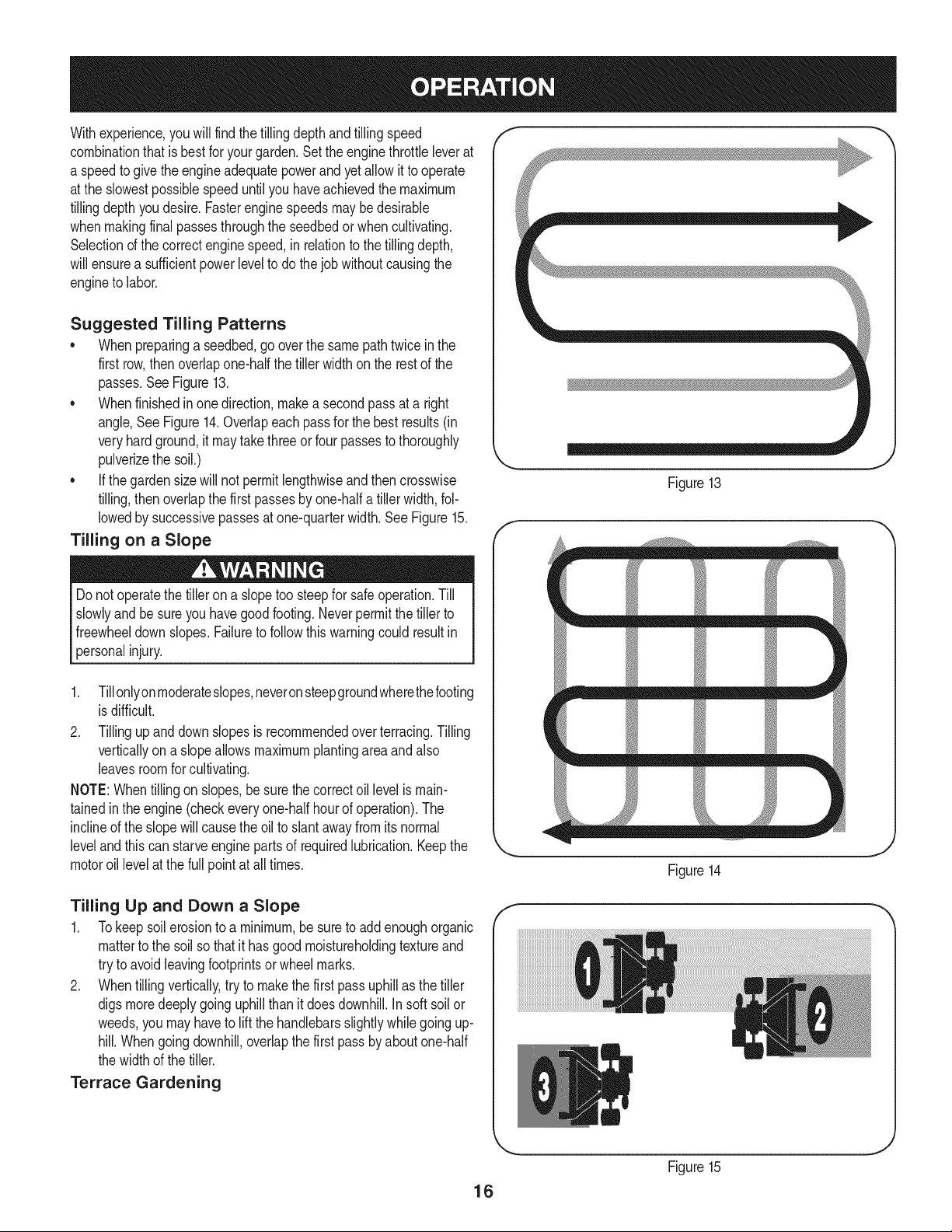

to2" deep.Usingtheshallowtillingdepthhelpspreventinjuryto

theplantswhoserootsoftengrowclosetothe surface.Ifneeded,

lift up onthehandlebarsslightlyto preventthetinesfromdigging

toodeeply.(Cultivatingon a regularbasisnot onlyeliminates

weeds,it alsoloosensandaeratesthe soilfor bettermoisture

absorptionandfasterplantgrowth.)Wateringthe gardenareaa

fewdayspriorto tillingwillmaketillingeasier,as willlettingthe

newlyworkedsoilsetfor a dayor twobeforemakinga final,deep

tillingpass.

Choosing the Correct Wheel & Tine Speeds

f

Beforetilling,contactyourtelephoneor utilitiescompanyandinquire

l ifundergroundequipmentorlinesareusedonyour property.Donot

_tillnearburiedelectriccables,telephonelines,pipesor hoses.

Tilling Depth

• Thisis a DDT(dual-directionfine) tiller.Asthewheelspull

forward,thetinesrotatebackward.Asthewheelspullrearward,

thetines rotateforward.Thiscreatesan"uppercut"fineaction

whichdigsdeeply,uprootingsoilandweeds.Don'toverloadthe

engine,butdigasdeeplyaspossibleoneachpassOnlater

passes,thewheelsmaytendto spinin thesoftdirt. Helpthem

alongbyliftingup slightlyon thehandlebar(onehand,palmup,

worksmosteasily).

• Avoidthetemptationtopushdownon thehandlebarsinan

attempttoforcethe tillerto digdeeper.Doingsotakestheweight

offthepoweredwheels,causingthemto losetraction.Without

thewheelsto holdthetiller back,the tineswillattemptto propel

towardstheoperatororawayfromthe operator.

• Whencultivating(breakingupthe surfacesoilaroundtheplants

todestroyweeds,SeeFigure12),adjustthetinestodig only 1"

Deep tilling position

Figure11

f

J

Figure12

15

Withexperience,you willfindthetillingdepthandtilling speed

combinationthatis bestforyourgarden.Settheenginethrottleleverat

a speedtogivethe engineadequatepowerandyetallowit tooperate

atthe slowestpossiblespeeduntilyouhaveachievedthemaximum

tillingdepthyoudesire.Fasterenginespeedsmaybedesirable

whenmakingfinalpassesthroughtheseedbedorwhencultivating.

Selectiond thecorrectenginespeed,in relationtothetillingdepth,

willensurea sufficientpowerlevelto dothejob withoutcausingthe

enginetolabor.

Suggested Tilling Patterns

• Whenpreparinga seedbed,go overthesamepathtwice inthe

firstrow,thenoverlapone-halfthetillerwidthontherestof the

passes.SeeFigure13.

• Whenfinishedinonedirection,makeasecondpassat a right

angle,SeeFigure14.Overlapeachpassfor thebestresults(in

veryhardground,itmaytakethreeorfour passestothoroughly

pulverizethesoil.)

• if thegardensizewill notpermitlengthwiseandthencrosswise

tilling,thenoverlapthefirstpassesby one-halfatillerwidth,fol-

lowedby successivepassesat one-quarterwidth.SeeFigure15.

Tilling on a Slope

Figure13

Donot operatethetilleron a slopetoosteepfor safeoperation.Till

slowlyandbesureyouhavegoodfooting.Neverpermitthetillerto

freewheeldownslopes.Failureto followthiswarningcouldresultin

personalinjury.

1. Tillonlyonmoderateslopes,neveronsteepgroundwherethefooting

isdifficult.

2. Tillingupanddownslopesisrecommendedoverterracing.Tilling

verticallyon a slopeallowsmaximumplantingareaandalso

leavesroomforcultivating.

NOTE:Whentillingonslopes,besurethe correctoil levelismain-

tainedinthe engine(checkeveryone-halfhourofoperation).The

inclineof theslopewillcausethe oiltoslantawayfromits normal

levelandthiscan starveenginepartsof requiredlubrication.Keepthe

motoroil levelat thefull pointat all times.

Tilling Up and Down a Slope

1. Tokeepsoil erosiontoa minimum,be sureto addenoughorganic

mattertothe soilsothatit hasgoodmoistureholdingtextureand

tryto avoidleavingfootprintsor wheelmarks.

2. Whentillingvertically,trytomakethefirstpassuphillasthetiller

digsmoredeeplygoinguphillthan itdoesdownhill,in softsoilor

weeds,youmayhavetolift thehandlebarsslightlywhilegoingup-

hill.Whengoingdownhill,overlapthefirstpassbyaboutone-half

thewidthof thetiller.

Terrace Gardening

iim_mlm Imlmlml_i

/ i

Figure14

16

Figure15

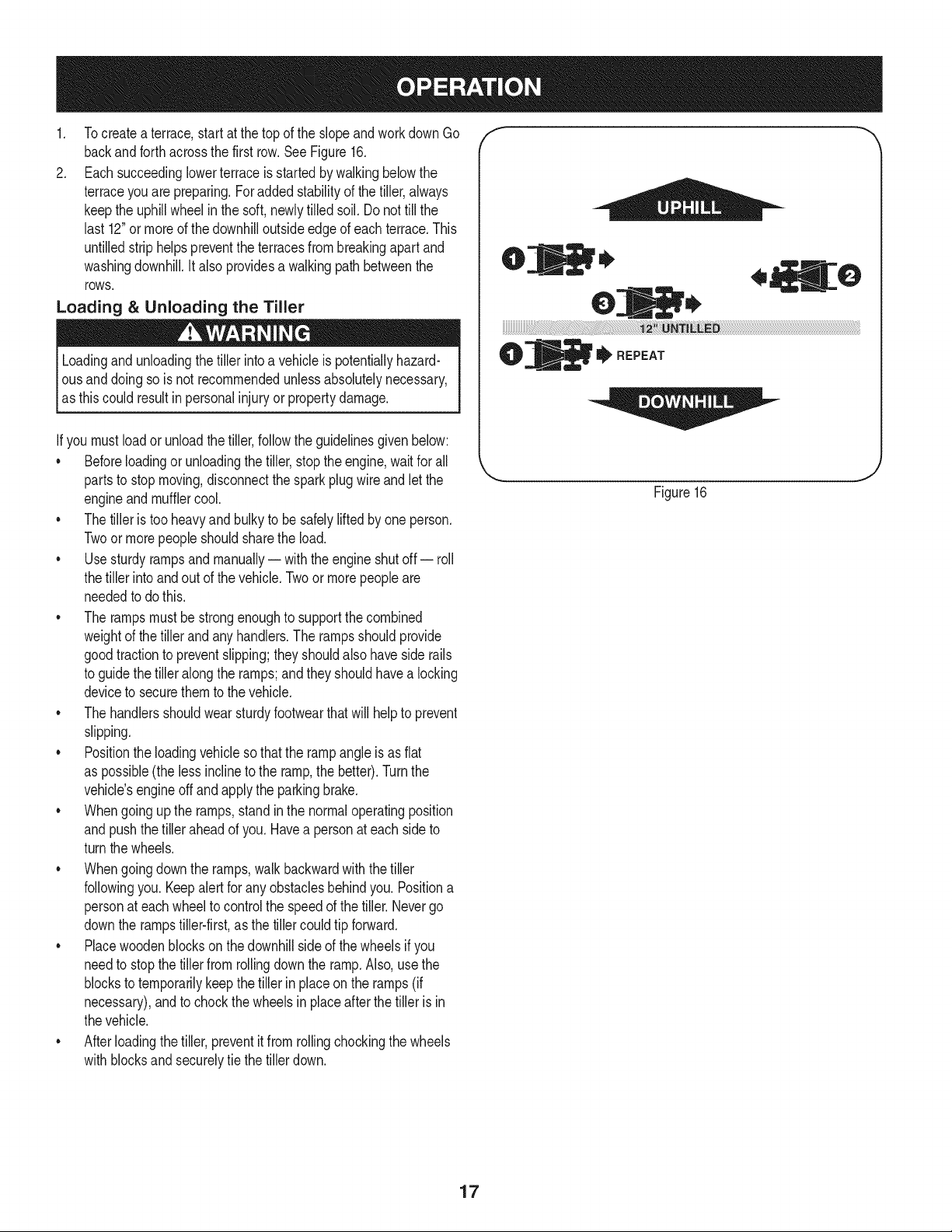

1. Tocreateaterrace,startatthetopoftheslopeandworkdownGo

backandforthacrossthefirstrow.SeeFigure16.

2. Eachsucceedinglowerterraceisstartedbywalkingbelowthe

terraceyouarepreparing.Foraddedstabilityofthetiller,always

keeptheuphillwheelinthesoft,newlytilledsoil.Donottillthe

last12"ormoreofthedownhilloutsideedgeofeachterrace.This

untilledstriphelpspreventtheterracesfrombreakingapartand

washingdownhill.Italsoprovidesawalkingpathbetweenthe

rows,

Loading & Unloading the Tiller

f

Loadingandunloadingthetiller intoa vehicleis potentiallyhazard-

ousanddoingso isnot recommendedunlessabsolutelynecessary,

asthis couldresultin personalinjuryor propertydamage.

ifyou mustloador unloadthetiller,followtheguidelinesgivenbelow:

• Beforeloadingor unloadingthetiller,stopthe engine,waitfor all

partstostopmoving,disconnectthesparkplugwireand letthe

engineandmufflercool.

• Thetilleris tooheavyandbulkyto be safelyliftedby oneperson.

Twoor morepeopleshouldsharetheload.

Usesturdyrampsandmanually-- withtheengineshutoff -- roll

thetiller intoandout ofthe vehicle.Twoormorepeopleare

neededtodothis.

• The rampsmustbestrongenoughto supportthecombined

weightofthe tillerandany handlers.Therampsshouldprovide

goodtractiontopreventslipping;theyshouldalsohavesiderails

toguidethe tilleralongthe ramps;andtheyshouldhavea locking

devicetosecurethemto thevehicle.

Thehandlersshouldwearsturdyfootwearthatwillhelpto prevent

slipping.

• Positiontheloadingvehiclesothatthe rampangleis asflat

aspossible(theless inclinetotheramp,the better).Turnthe

vehicle'sengineoffandapplytheparkingbrake.

• Whengoingup theramps,standinthenormaloperatingposition

andpushthe tilleraheadof you.Havea personateachside to

turnthe wheels.

• Whengoingdownthe ramps,walkbackwardwiththetiller

followingyou.Keepalertforanyobstaclesbehindyou.Positiona

personateachwheelto controlthe speedofthetiller.Nevergo

downthe rampstiller-first,as thetillercouldtip forward.

• Placewoodenblocksonthedownhillsideof thewheelsif you

needto stopthe tillerfrom rollingdowntheramp.Also,use the

blocksto temporarilykeepthetillerin placeonthe ramps(if

necessary),andto chockthewheelsinplaceafterthe tilleris in

thevehicle.

• Afterloadingthetiller,preventitfrom rollingchockingthewheels

withblocksandsecurelytiethe tillerdown.

I' REPEAT

J

Figure16

17

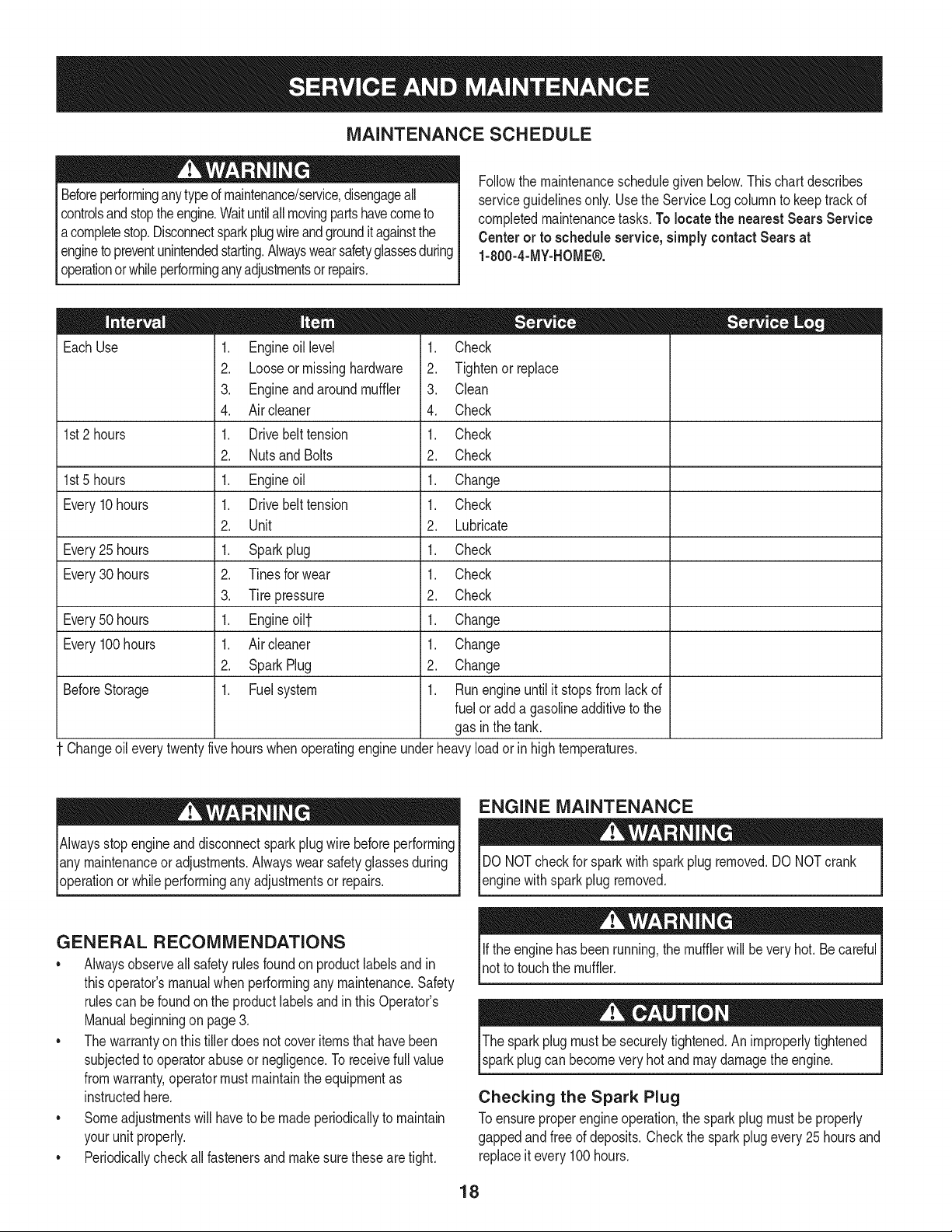

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.To locate the nearest Sears Service

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

operationorwhileperforminganyadjustmentsorrepairs.

Followthemaintenanceschedulegivenbelow.Thischartdescribes

= =

EachUse

1st2 hours

1st5 hours

Every10hours

Every25 hours

Every30 hours

Every50 hours

Every100hours

BeforeStorage

.

Engineoillevel

2.

Looseormissinghardware

3.

Engineandaroundmuffler

4.

Aircleaner

1.

Drivebelttension

2.

Nutsand Bolts

1.

Engineoil

1.

Drivebelttension

2.

Unit

1.

Sparkplug

2.

Tinesforwear

3.

Tirepressure

1.

Engineoill-

1.

Aircleaner

2.

SparkPlug

1.

Fuelsystem

1. Check

2. Tightenor_place

3. Clean

4. Check

1. Check

2. Check

1. Change

1. Check

2. Lubricate

1. Check

1. Check

2. Check

1. Change

1. Change

2. Change

1. Runengineuntilit stopsfromlackof

fueloradda gasolineadditivetothe

gasin thetank.

Changeoileverytwentyfivehourswhenoperatingengineunderheavyloadorinhightemperatures.

Alwaysstopengineanddisconnectsparkplugwirebeforeperforming

lanymaintenanceor adjustments.Alwayswearsafetyglassesduring

[operationorwhileperformingany adjustmentsor repairs.

GENERAL RECOMMENDATIONS

• Alwaysobserveallsafetyrulesfoundonproductlabelsandin

thisoperator'smanualwhenperforminganymaintenance.Safety

rulescan befoundonthe productlabelsandin thisOperator's

Manualbeginningon page3.

• Thewarrantyonthistillerdoesnotcoveritemsthathavebeen

subjectedto operatorabuseor negligence.Toreceivefullvalue

fromwarranty,operatormustmaintaintheequipmentas

instructedhere.

• Someadjustmentswillhaveto be madeperiodicallytomaintain

yourunit properly.

• Periodicallycheckall fastenersand makesurethesearetight.

ENGINE MAINTENANCE

DONOTcheckforsparkwithsparkplugremoved.DONOTcrank

enginewithsparkplug removed.

Iftheenginehas beenrunning,themufflerwillbeveryhot. Becareful

notto touchthemuffler.

Thesparkplugmustbesecurelytightened.Animproperlytightened

sparkplugcanbecomeveryhot andmaydamagetheengine.

Checking the Spark Plug

Toensureproperengineoperation,thesparkplugmustbeproperly

gappedandfreeof deposits.Checkthe sparkplugevery25hoursand

replaceitevery100hours.

18

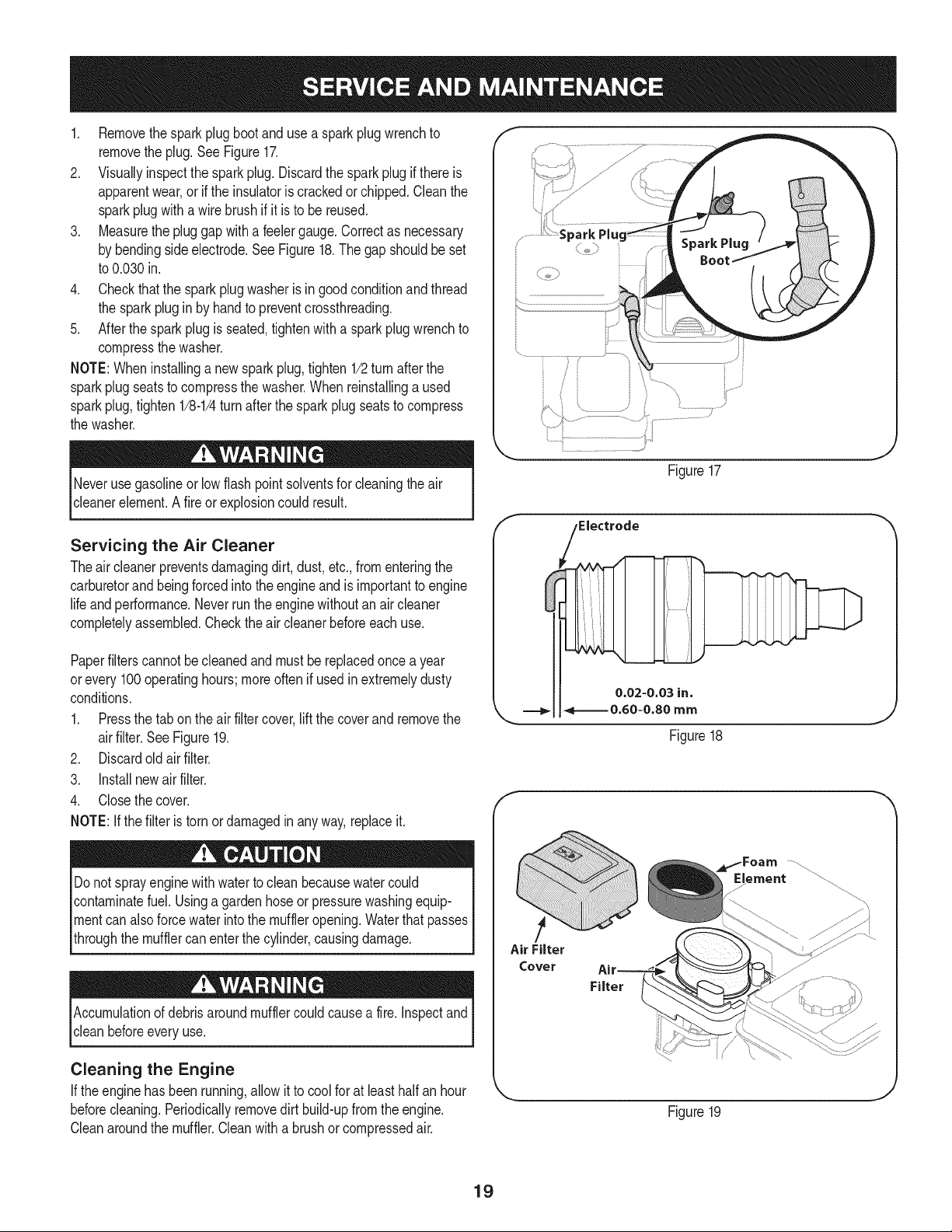

1. Removethesparkplugbootandusea sparkplugwrenchto

removetheplug.See Figure17.

2. Visuallyinspectthesparkplug.Discardthesparkplugif thereis

apparentwear,orif the insulatoriscrackedorchipped.Cleanthe

sparkplugwitha wirebrush ifit isto be reused.

3. Measurethepluggapwithafeelergauge.Correctas necessary

bybendingsideelectrode.SeeFigure18.Thegapshouldbeset

to0.030in.

4. Checkthatthe sparkplugwasherisingoodconditionandthread

thesparkplugin by handtopreventcrossthreading.

5. Afterthesparkplugis seated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2turnafterthe

sparkplugseatsto compressthewasher.Whenreinstallinga used

sparkplug,tighten1/8-1/4turnafterthesparkplugseatsto compress

thewasher.

Neverusegasolineorlowflashpointsolventsforcleaningtheair

ceanereement. A fre orexpos oncou d resut.

Servicing the Air Cleaner

Theair cleanerpreventsdamagingdirt, dust,etc.,fromenteringthe

carburetorand beingforcedintothe engineandisimportanttoengine

lifeandperformance.Neverrunthe enginewithoutanaircleaner

completelyassembled.Checktheaircleanerbeforeeachuse.

Paperfilterscannotbecleanedandmustbe replacedoncea year

orevery 100operatinghours;moreoftenifusedin extremelydusty

conditions.

1. Pressthe tabonthe airfiltercover,liftthe coverandremovethe

airfilter.SeeFigure19.

2. Discardoldairfilter.

3. Installnewairfilter.

4. Closethecover.

NOTE:Ifthe filteristorn ordamagedinanyway,replaceit.

Donot sprayenginewithwatertoclean becausewatercould

contaminatefuel. Usinga gardenhoseorpressurewashingequip-

mentcanalso forcewaterintothe muffleropening.Waterthat passes

throughthemufflercanenterthe cylinder,causingdamage.

,Electrode

0.02-0.03 in.

===_1_====0.60-0.80 rnrn

Air Filter

Cover

Filter

Figure17

J

Figure18

Accumulationofdebrisaroundmufflercouldcausea fire.Inspectand

cleanbeforeeveryuse.

Cleaning the Engine

If theenginehasbeenrunning,allowitto coolfor atleasthalfan hour

beforecleaning.Periodicallyremovedirtbuild-upfromtheengine.

Cleanaroundthe muffler.Cleanwitha brushor compressedair.

J

Figure19

19

Check Engine Oil

1. Checkoilbeforeeachuse.Stopengineandwaitseveralminutes

beforecheckingoil level.Withengineon levelground,theoilmust

beto FULLmarkon dipstick.

2. Removeoilfilldipstickandwipecleanwithcloth.

3. Replacedipstickintotheoilfillerneck,butdonot screwitin.

Removeandcheckoil level.Levelshouldbeat FULLmark.

4. If needed,addoil slowly- recheck.Donotoverfill.

5. Wipedipstickclean,replacebutdonot tighten.Removeand

checkoil level.Oillevelshouldbeat FULLlineondipstick.

6. Replaceandtightendipstickfirmlybeforestartingengine.

DONOTuse non-detergentoilor 2-strokeengineoil.Itcouldshorten

theengine'sservicelife.

Change Engine Oil

• SAE10W-30is recommendedforgeneral,all temperatureuse.

Whenaddingoilto theengine,referto viscositychart inthe

operationsection.Usea4-stroke,oranequivalenthighdeter-

gent,premiumqualitymotoroil certifiedto meetor exceedU.S.

automobilemanufacturer'srequirementsforserviceclassification

SG,SR MotoroilsclassifiedSG,SFwill showthisdesignationon

thecontainer.

• Changeengineoil afterthefirst fivetoeight hoursofoperation,

andeveryfifty hoursoreveryseasonthereafter.Changeoil every

twentyfivehourswhenoperatingengineunderheavyloadorin

hightemperatures.

Beforetippingengineor equipmenttodrainoil, drainfuelfromtank by

runningengineuntilfuel tankisempty.

Usedmotoroil maycauseskincancerifrepeatedlyleftin contactwith

theskinfor prolongedperiods.Althoughthis isunlikelyunlessyou

handleusedoil ona daily basis,itisstilladvisableto thoroughlywash

yourhandswithsoapandwateras soonas possibleafter handling

usedoil.

Drain

Figure 20

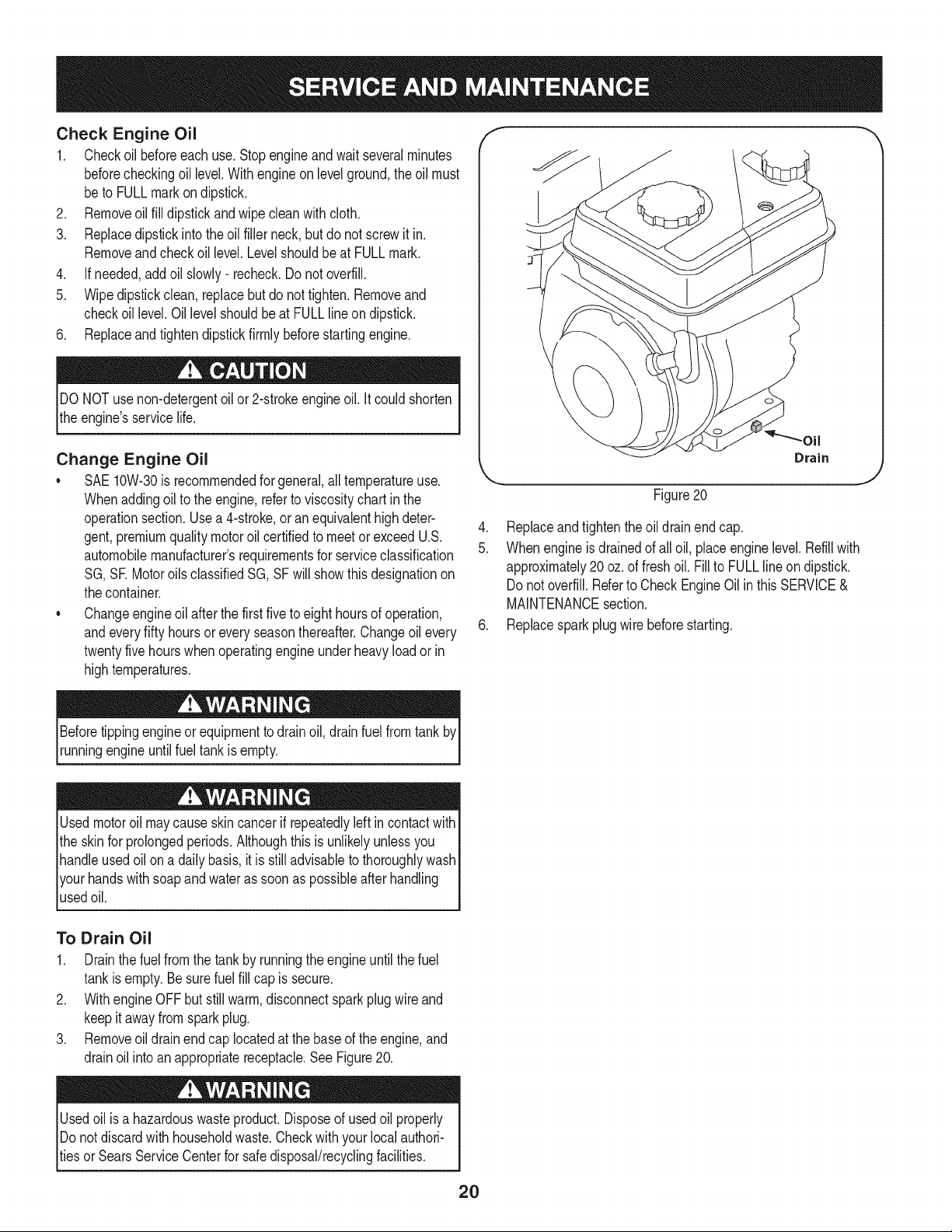

4. Replaceandtightentheoildrainendcap.

5. Whenengineisdrainedofall oil, placeenginelevel.Refillwith

approximately20oz.offreshoil. Fillto FULLlineondipstick.

Donot overfill.Referto CheckEngineOilinthis SERVICE&

MAINTENANCEsection.

6. Replacesparkplugwirebeforestarting.

To Drain Oil

1. Drainthefuelfromthe tankbyrunningtheengineuntilthefuel

tankisempty.Besurefuelfill capissecure.

2. WithengineOFFbutstillwarm,disconnectsparkplugwireand

keepitawayfromsparkplug.

3. Removeoildrainendcaplocatedatthebaseoftheengine,and

drainoil intoanappropriatereceptacle.SeeFigure20.

Usedoilisa hazardouswasteproduct.Disposeofusedoil properly

IDonotdiscardwithhouseholdwaste.Checkwithyourlocalauthori-

_tiesor SearsServiceCenterfor safedisposal/recyclingfacilities.

2O

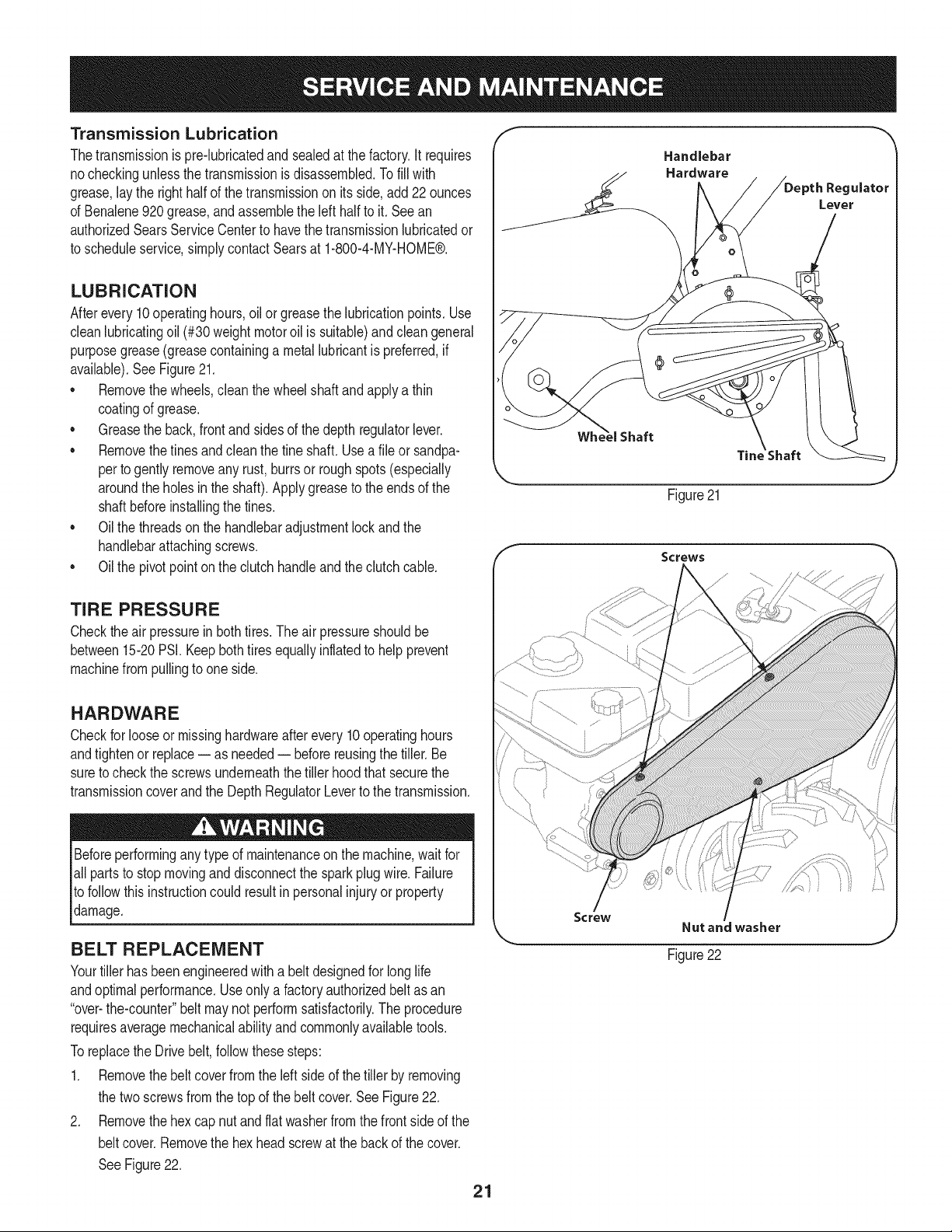

Transmission Lubrication

Thetransmissionispre-lubricatedand sealedatthe factory,itrequires

nocheckingunlessthetransmissionisdisassembled.Tofillwith

grease,laythe righthalfofthe transmissiononitsside,add22 ounces

ofBenalene920grease,andassembletheleft half toit. Seean

authorizedSearsServiceCenterto havethetransmissionlubricatedor

toscheduleservice,simplycontactSearsat 1-800-4-MY-HOME®.

LUBRICATION

Afterevery10operatinghours,oilor greasethelubricationpoints.Use

cleanlubricatingoil(#30weightmotoroil is suitable)andcleangeneral

purposegrease(greasecontaininga metallubricantis preferred,if

available).SeeFigure21.

• Removethewheels,cleanthewheelshaft andapplya thin

coatingofgrease.

• Greasetheback,frontandsidesofthe depthregulatorlever.

• Removethetinesandcleanthefine shaft.Usea fileor sandpa-

pertogentlyremoveanyrust,burrsor roughspots(especially

aroundtheholesintheshaft).Applygreasetotheendsofthe

shaftbeforeinstallingthetines.

• Oilthe threadsonthehandlebaradjustmentlockandthe

handlebarattachingscrews.

• Oilthe pivotpointonthe clutchhandleandthe clutchcable.

Handlebar

Hardware

Lever

Tin_

Figure21

Screws

TIRE PRESSURE

Checktheair pressurein bothtires.Theairpressureshouldbe

between15-20PSI.Keepbothtiresequallyinflatedtohelpprevent

machinefrompullingtoone side.

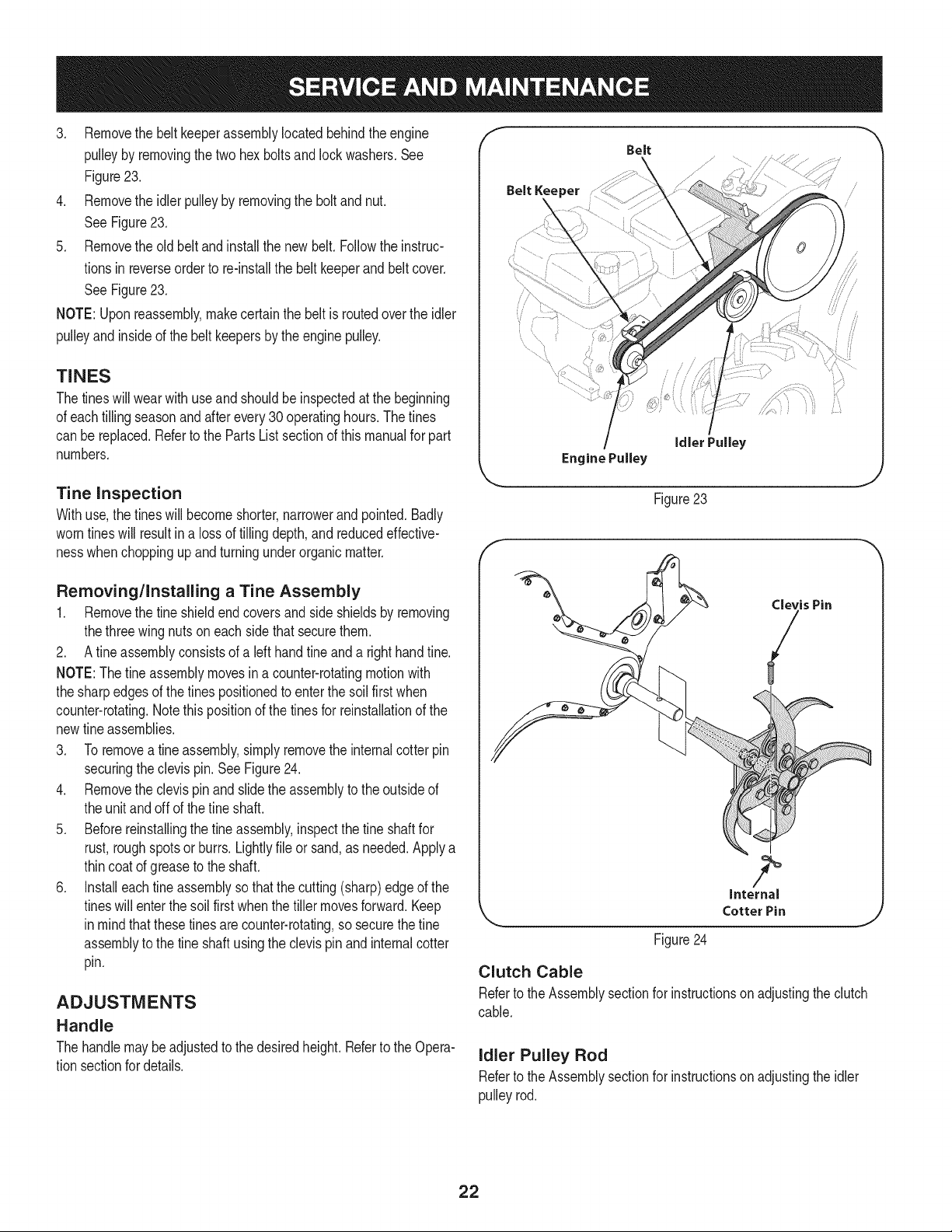

HARDWARE

Checkfor looseormissinghardwareafterevery10operatinghours

andtightenor replace-- asneeded-- beforereusingthetiller.Be

sureto checkthe screwsunderneaththe tillerhoodthatsecurethe

transmissioncoverandthe DepthRegulatorLeverto thetransmission.

Beforeperformingany typeofmaintenanceonthemachine,waitfor

all partsto stopmovinganddisconnectthesparkplugwire.Failure

tofollowthis instructioncouldresultinpersonalinjuryor property

damage.

BELT REPLACEMENT

Yourtillerhas beenengineeredwitha beltdesignedfor longlife

andoptimalperformance.Useonlya factoryauthorizedbeltasan

"over-the-counter"beltmaynotperformsatisfactorily.The procedure

requiresaveragemechanicalabilityandcommonlyavailabletools.

Toreplacethe Drivebelt,followthesesteps:

1. Removethebelt coverfromtheleftside ofthe tillerby removing

thetwoscrewsfromthe topof thebeltcover.SeeFigure22.

2. Removethehexcap nutandflatwasherfromthe frontsideof the

beltcover.Removethe hexheadscrewatthe backofthe cover.

SeeFigure22.

Nut andwasher

Figure22

21

3. Removethebeltkeeperassemblylocatedbehindtheengine

pulleybyremovingthetwohexboltsandlockwashers.See

Figure23.

4. Removetheidlerpulleybyremovingtheboltandnut.

SeeFigure23.

5. Removetheoldbeltandinstallthenewbelt.Followtheinstruc-

tionsinreverseordertore-installthebeltkeeperandbeltcover.

SeeFigure23.

NOTE:Uponreassembly,makecertainthebeltisroutedovertheidler

pulleyandinsideofthebeltkeepersbytheenginepulley.

TINES

Thetineswill wearwithuseand shouldbeinspectedatthe beginning

ofeachtillingseasonandafterevery30 operatinghours.Thetines

canbereplaced.Referto thePartsListsectionofthismanualforpart

numbers.

Tine inspection

Withuse,thetineswill becomeshorter,narrowerandpointed.Badly

worntineswill resultina lossof tillingdepth,andreducedeffective-

nesswhenchoppingupandturningunderorganicmatter.

Belt Kee

Engine Pulley

J

Figure23

f

Removing/Installing a Tine Assembly

1. Removethetineshieldendcoversandsideshieldsbyremoving

thethree wingnutsoneach sidethatsecurethem.

2. Afineassemblyconsistsofa lefthandfineanda righthandfine.

NOTE:Thefineassemblymovesina counter-rotatingmotionwith

thesharpedgesof thetinespositionedtoenterthesoilfirstwhen

counter-rotating.Notethispositionof thetinesfor reinstallationof the

newfine assemblies.

3. Toremoveafineassembly,simplyremovetheinternalcotterpin

securingtheclevispin.SeeFigure24.

4. Removetheclevispinandslidetheassemblytotheoutsideof

theunitandoff ofthe fineshaft.

5. Beforereinstallingthe fineassembly,inspectthetineshaftfor

rust,roughspotsorburrs.Lightlyfileor sand,as needed.Applya

thincoatof greaseto theshaft.

6. Installeachtineassemblysothatthecutting(sharp)edgeof the

tineswillenterthesoil firstwhenthetiller movesforward.Keep

in mindthatthesetinesarecounter-rotating,sosecurethe fine

assemblytothe tineshaftusingthe clevispinandinternalcotter

pin.

ADJUSTMENTS

Handle

Thehandlemaybeadjustedto thedesiredheight.RefertotheOpera-

tionsectionfordetails.

ClevisPin

/

.............

7

Internal

Cotter Pin

Figure24

Clutch Cable

RefertotheAssemblysectionforinstructionson adjustingtheclutch

cable.

idler Pulley Rod

RefertotheAssemblysectionforinstructionson adjustingtheidler

pulleyrod.

J

22

Loading...

Loading...