MTD 21AA45M5031 Owner’s Manual

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

L

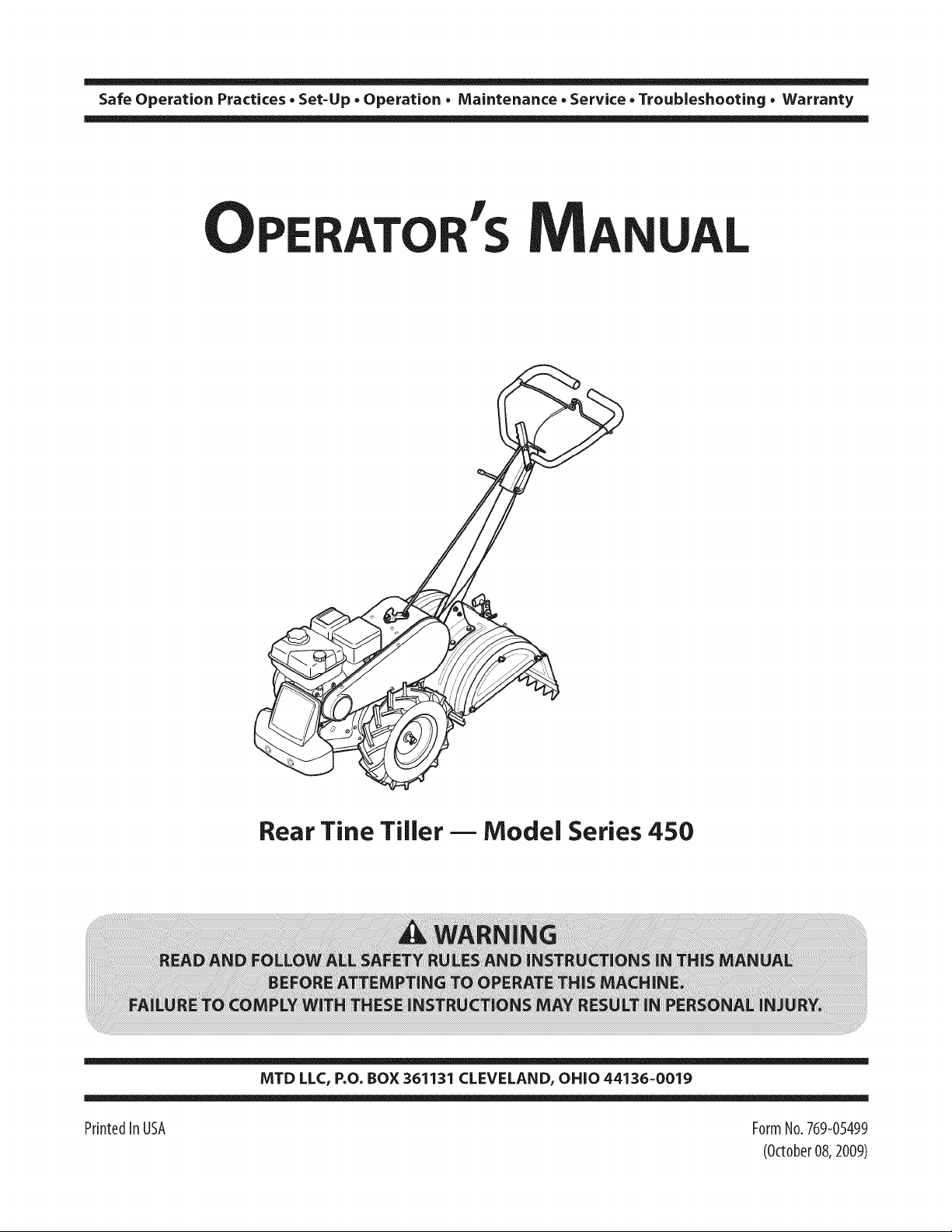

Rear Tine Tiller m Model Series 450

MTD LLC, P.O. BOX 361131 CLEVELAND, OHiO 44136-0019

PrintedIn USA FormNo.769-05499

(October08,2009)

ToTheOwner

ThankYou

1

Thank you for purchasing a Garden Tiller manufactured by

MTD LLC. It was carefully engineered to provide excellent

performance when properly operated and maintained.

Please read this entire manual prior to operating the equipment.

It instructs you how to safely and easily set up, operate and

maintain your machine. Please be sure that you, and any other

persons who will operate the machine, carefully follow the

recommended safety practices at all times. Failure to do so could

result in personal injury or property damage.

All information in this manual is relative to the most recent

product information available at the time of printing. Review

this manual frequently to familiarize yourself with the machine,

its features and operation. Please be aware that this Operator's

Manual may cover a range of product specifications for various

models. Characteristics and features discussed and/or illustrated

in this manual may not be applicable to all models. MTD LLC

reserves the right to change product specifications, designs and

equipment without notice and without incurring obligation.

Table of Contents

Safe Operation Practices ........................................ 3

Assembly & Set-Up .................................................. 7

Controls & Features ................................................ 11

Operation ................................................................ 12

Maintenance &Adjustment. ................................. 14

If you have any problems or questions concerning the machine,

phone your local authorized MTD service dealer or contact us

directly. MTD's Customer Support telephone numbers, website

address and mailing address can be found on this page. We want

to ensure your complete satisfaction at all times.

Throughout this manual, all references to right and left side of the

machine are observed from the operating position

Engine Maintenance .............................................. 16

Service .................................................................... 20

Troubleshooting ..................................................... 21

Replacement Parts ................................................ 22

Warranty .................................................. Back Cover

RecordProductinformation

Before setting up and operating your new equipment, please

locate the model plate on the equipment and record the

information in the provided area to the right. You can locate the

model plate by standing at the operator's position and looking

down at the front right corner of the tine shield. This information

will be necessary, should you seek technical support via our web

site, Customer Support Department, or with a local authorized

service dealer.

MODEL NUMBER

[3N[3N[3N[3N[3ND

SERIALNUMBER

FINFINFINFINFIND

CustomerSupport

Please do NOT return the machine to the retailer or dealer without first contacting our Customer Support Department.

If you have difficulty assembling this product or have any questions regarding the controls, operation, or maintenance of

this machine, you can seek help from the experts. Choose from the options below:

0 Visit us on the web at www.mtdproducts.com

0 Call a Customer Support Representative at (800) 800-7:310 or (330) 220-468:3

0 Write us at MTD LLC • RO. Box :3611:31 • Cleveland, OH • 441:36-0019

importantSafeOperationPractices

WARNING! This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read and follow

all instructions in this manual before attempting to operate this machine. Failure to comply

with these instructions may result in personal injury.

When you see this symbol. HEED ITS WARNING!

CALIFORNIA PROPOSITION 65

WARNING! Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to State of California to cause cancer and birth defects

or other reproductive harm.

WARNING! Battery posts, terminals, and related accessories contain lead and lead

,A

compounds, chemicals known to the State of California to cause cancer and reproductive

harm. Wash hands after handling

DANGER! This machine was built to be operated according to the safe operation practices in

this manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. This machine is capable of amputating fingers, hands,

toes and feet. Failure to observe the following safety instructions could result in serious

injury or death.

2

Training 2.

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place for

future and regular reference and for ordering replacement

parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years of age to operate this

machine. Children 14 and over should read and understand

the instructions and safe operation practices in this manual

and on the machine and be trained and supervised by an

adult.

4_

Never allow adults to operate this machine without proper

instruction.

5.

Keep the area of operation clear of all persons, particularly

small children and pets. Stop machine if anyone enters the

area.

3. Disengage clutch levers and shift (if provided) into neutral

4. Never leave this machine unattended with the engine

5. Never attempt to make any adjustments while engine is

SafeHandling 0f 6as01ine:

To avoid personal injury or property damage use extreme care

in handling gasoline. Gasoline is extremely flammable and the

vapors are explosive. Serious personal injury can occur when

gasoline is spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

Preparation

Thoroughly inspect the area where the equipment is to

be used. Remove all stones, sticks, wire, and other foreign

objects which could be tripped over and cause personal

injury.

Wear sturdy, rough-soled work shoes and close fitting

slacks and shirt. Loose fitting clothes or jewelry can be

caught in moving parts. Never operate this machine in bare

feet or sandals.

('N") before starting the engine.

running.

running, except where specifically recommended in the

operator's manual.

a. Use only an approved gasoline container.

b. Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

containers on the ground away from your vehicle

before filling.

When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment on

a trailer with a portable container, rather than from a

gasoline dispenser nozzle.

d_

Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times until fueling is

complete. Do not use a nozzle lock-open device.

e_

Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

fl

Never fuel machine indoors.

g.

Never remove gas cap or add fuel while the engine

is hot or running. Allow engine to cool at least two

minutes before refueling.

h. Never over fill fuel tank. Fill tank to no more than 1/2

inch below bottom of filler neck to allow space for

fuel expansion.

i. Replace gasoline cap and tighten securely.

j. If gasoline is spilled, wipe it off the engine and

equipment. Move unit to another area. Wait 5

minutes before starting the engine.

k. To reduce fire hazards, keep machine free of grass,

leaves, or other debris build-up. Clean up oil or fuel

spillage and remove any fuel soaked debris.

I. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

as on a water heater, space heater, furnace, clothes

dryer or other gas appliances.

Operation

1. Do not put hands or feet near rotating parts. Contact with

the rotating parts can amputate hands and feet.

2. Do not operate machine while under the influence of

alcohol or drugs.

3. Never operate this machine without good visibility or light.

Always be sure of your footing and keep a firm hold on the

handles.

4. Keep bystanders away from the machine while it is in

operation. Stop the machine if anyone enters the area.

5. Be careful when tilling in hard ground. The tines may catch

in the ground and propel the tiller forward. If this occurs,

letgo of the handle bars and do not restrain the machine.

6. Exercise extreme caution when operating on or crossing

gravel surfaces. Stay alert for hidden hazards or traffic. Do

not carry passengers.

7. Never operate the machine at high transport speeds on

hard or slippery surfaces.

8. Exercise caution to avoid slipping or falling.

9. Look down and behind and use care when in reverse or

pulling machine towards you.

10. Start the engine according to the instructions found in this

manual and keep feet well away from the tines at all times.

11. After striking a foreign object, stop the engine, disconnect

the spark plug wire and ground against the engine.

Thoroughly inspect the machine for any damage. Repair

the damage before starting and operating.

12. Disengage all clutch levers (if fitted) and stop engine

before you leave the operating position (behind the

handles). Wait until the tines come to a complete stop

before unclogging the tines, making any adjustments, or

inspections.

13. Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless

and deadly gas.

14. Muffler and engine become hot and can cause a burn. Do

not touch.

15. Use caution when tilling near fences, buildings and

underground utilities. Rotating tines can cause property

damage or personal injury.

16. Do not overload machine capacity by attempting to till soil

too deep at too fast of a rate.

17. If the machine should start making an unusual noise or

vibration, stop the engine, disconnect the spark plug wire

and ground it against the engine. Inspect thoroughly for

damage. Repair any damage before starting and operating.

18. Keep all shields, guards, and safety devices in place and

operating properly.

19. Never pick up or carry machine while the engine is running.

20. Use only attachments and accessories approved by the

manufacturer. Failure to do so can result in personal injury.

21. If situations occur which are not covered in this manual, use

care and good judgement. Contact Customer Support for

assistance and the name of you nearest servicing dealer..

Maintenance & Storage

1. Keep machine, attachments and accessories in safe

working order.

2. Allow a machine to cool at least five minutes before

storing. Never tamper with safety devices. Check their

proper operation regularly.

3. Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4. Before cleaning, repairing, or inspecting, stop the engine

and make certain the tines and all moving parts have

stopped. Disconnect the spark plug wire and ground it

against the engine to prevent unintended starting.

5. Do not change the engine governor settings or over-speed

the engine. The governor controls the maximum safe

operating speed of engine.

6. Maintain or replace safety and instruction labels, as

necessary.

7. Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

8. Always refer to the operator's manual for important details

if the machine is to be stored for an extended period.

4 I SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES

9.

If the fuel tank has to be drained, do this outdoors.

10.

Observe proper disposal laws and regulations for gas, oil,

etc. to protect the environment.

11.

According to the Consumer Products Safety Commission

(CPSC) and the U.S. Environmental Protection Agency (EPA),

this product has an Average Useful Life of seven (7) years,

or 130 hours of operation. Atthe end of the Average Useful

Life have the machine inspected annually by an authorized

service dealer to ensure that all mechanical and safety

systems are working properly and not worn excessively.

Failure to do so can result in accidents, injuries or death.

Notice Regarding Emissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and

may include the following emission control systems: Engine

Modification (EM), Oxidizing Catalyst (OC), Secondary Air

Injection (SAI) and Three Way Catalyst (TWC) if so equipped.

SparkArrester

internal combustion engine and should not be used

_ ARNING! This machine is equipped with an

Ira spark arrester is used, it should be maintained in effective

working order by the operator. In the State of California the

above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws

apply on federal lands.

A spark attester for the muffler is available through your

nearest engine authorized service dealer or contact the service

department, RO. Box 361131 Cleveland, Ohio 44136-0019.

on or near any unimproved forest-covered,

brushcovered or grass-covered land unless the

engine's exhaust system is equipped with a spark

arrester meeting applicable local or state laws (if

any).

SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES S

Safety Symbols

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the

machine before attempting to assemble and operate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to

assemble and operate

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

A

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine

and muffler to cool before touching.

WARNING! Your Responsibility--Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

6 I SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES

SAVETHESEINSTRUCTIONS!

Assembly& Set-Up

Contents of Carton

OneTiller

One Depth Stake

One Handlebar Assembly

One Operator's Manual

3

One Shift Rod

One Engine Operator's Manual

NOTE:This operator's manual covers various models of tillers.

The tiller illustrated may vary slightly from your machine. Follow

only those instructions which pertain to your model number.

Assembly

UnpackingInstructions

NOTE: References to the right or left side of the tiller are

determined from behind the machine in the operating position.

I. Remove the staples, break the glue on the top flaps, or cut

the tape at the end of the carton and peel it along the top

flap to open.

2. Remove any loose parts included with the tiller (i.e., the

Operator's Manual, etc.).

3. Cut the corners and lay the carton down flat.

4. Remove the packing material.

5. Roll or slide the tiller out of the carton. Check the carton

thoroughly for loose parts.

6. Extend the control cable and lay it on the floor. Be careful

not to bend or kink the control cable.

NOTE:This machine is shipped without gasoline or oil in the

engine. Be certain to service the engine with gasoline and oil

as instructed in the separate Engine Operator's Manual before

operating.

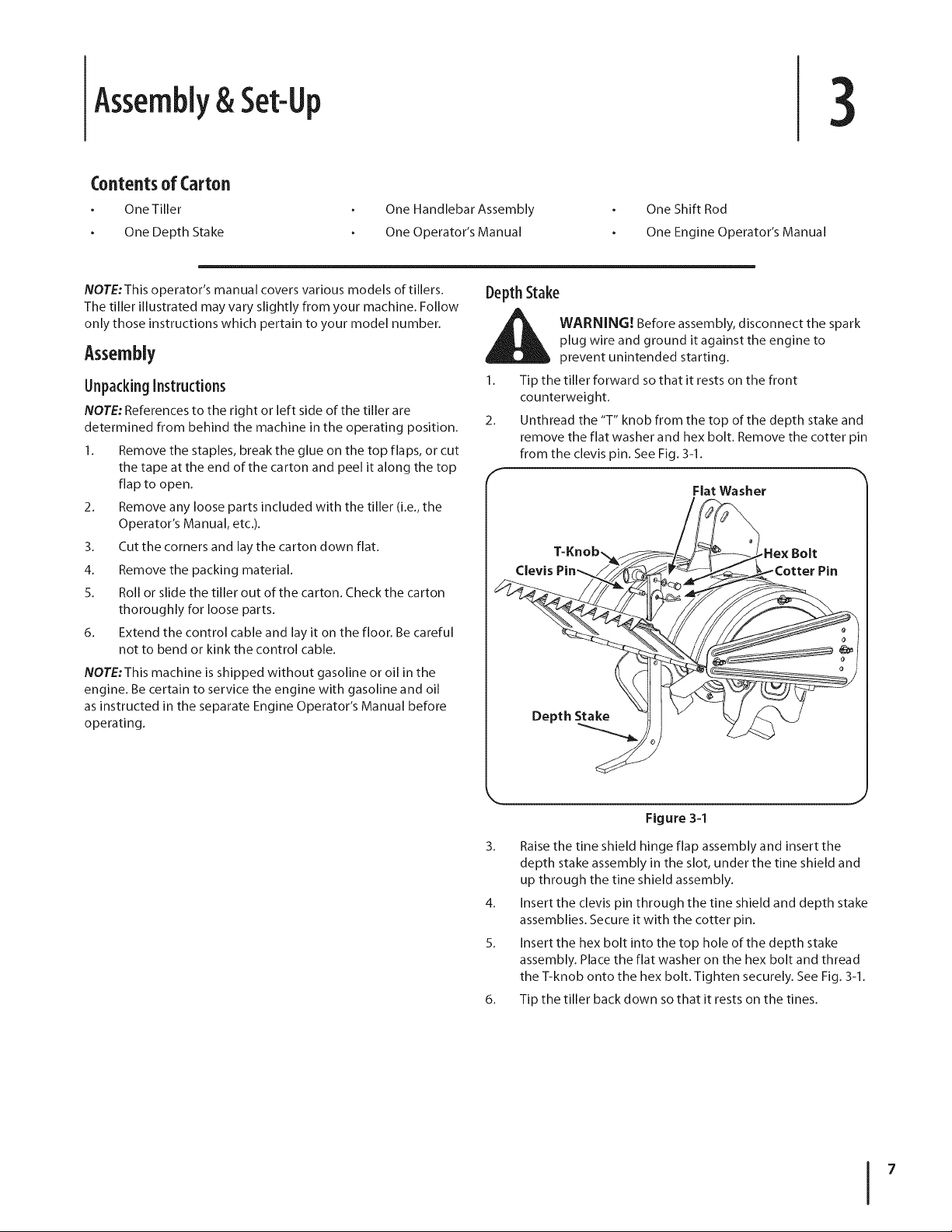

Depth Stake

_ ARNING! Before assembly, disconnect the spark

I. Tip the tiller forward so that it rests on the front

2. Unthread the "T" knob from the top of the depth stake and

plug wire and ground it against the engine to

prevent unintended starting.

counterweight.

remove the flat washer and hex bolt. Remove the cotter pin

from the clevis pin. See Fig. 3-I.

Flat Washer

Depth Stake

Figure 3-1

3. Raise the tine shield hinge flap assembly and insert the

depth stake assembly in the slot, under the fine shield and

up through the tine shield assembly.

4. Insert the clevis pin through the tine shield and depth stake

assemblies. Secure it with the cotter pin.

5. Insert the hex bolt into the top hole of the depth stake

assembly. Place the flat washer on the hex bolt and thread

the T-knob onto the hex bolt. Tighten securely. See Fig. 3-I.

6. Tip the tiller back down so that it rests on the tines.

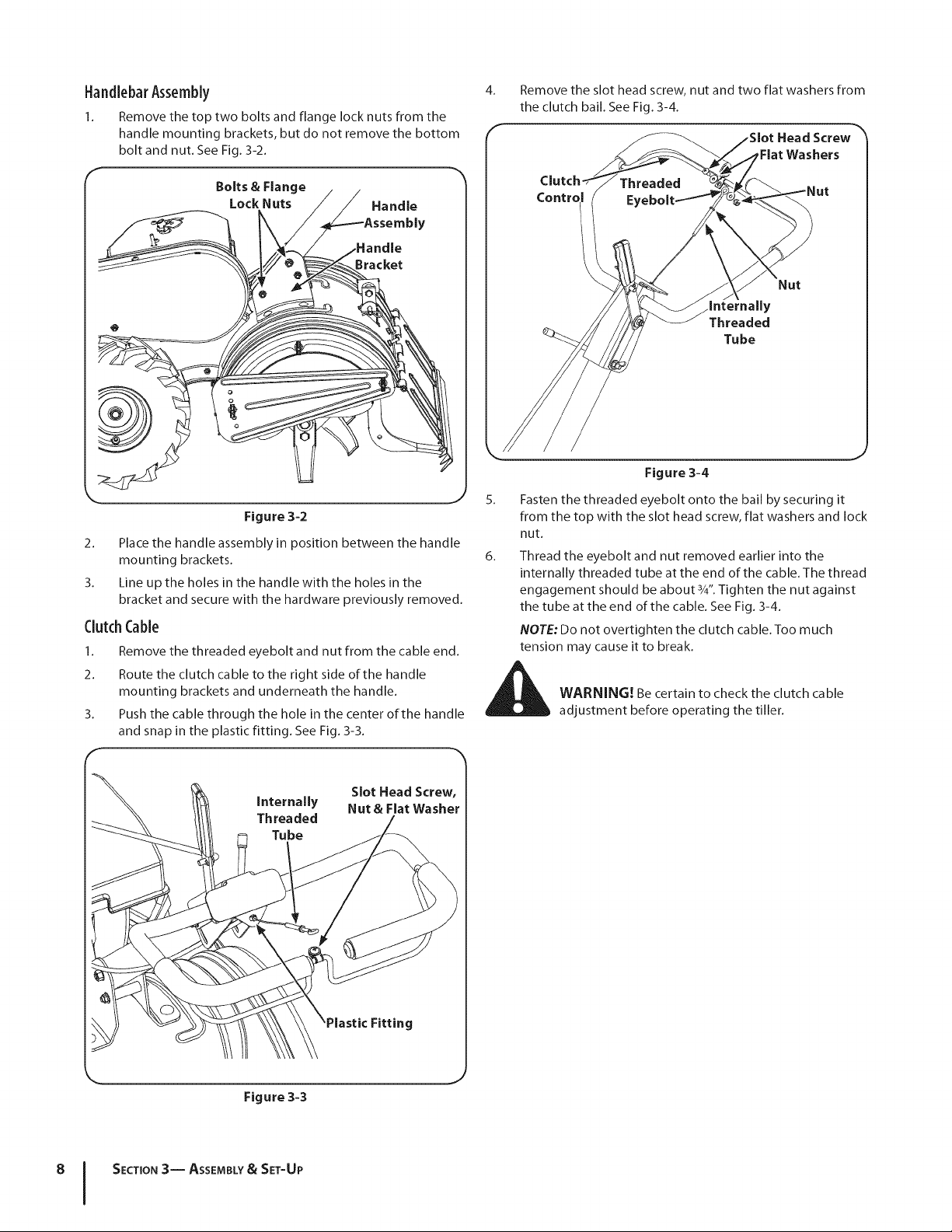

HandlebarAssembly

1. Remove the top two bolts and flange lock nuts from the

handle mounting brackets, but do not remove the bottom

bolt and nut. See Fig. 3-2.

4. Remove the slot head screw, nut and two flat washers from

the clutch bail. See Fig. 3-4.

Head Screw

Washers

Bolts&Flange / /

Lock Nuts / / Handle

!l_ /Handle

%_Bracket

Figure 3-2

2. Place the handle assembly in position between the handle

mounting brackets.

3. Line up the holes in the handle with the holes in the

bracket and secure with the hardware previously removed.

ClutchCable

1. Remove the threaded eyebolt and nut from the cable end.

2. Route the clutch cable to the right side of the handle

mounting brackets and underneath the handle.

3. Push the cable through the hole in the center of the handle

and snap in the plastic fitting. See Fig. 3-3.

Contro

Nut

Threaded

Tube

Figure 3=4

5.

Fasten the threaded eyebolt onto the bail by securing it

from the top with the slot head screw, flat washers and lock

nut.

6. Thread the eyebolt and nut removed earlier into the

internally threaded tube at the end of the cable. The thread

engagement should be about 3/4".Tighten the nut against

the tube at the end of the cable. See Fig. 3-4.

NOTE: Do not overtighten the clutch cable. Too much

tension may cause it to break.

WARNING! Be certain to check the clutch cable

adjustment before operating the tiller.

Internally

Threaded

Tube

Figure 3=3

8 I SECTION3-- ASSEMBLY& SET-UP

Loading...

Loading...