MTD 21AA404D299, 01721957-7 Owner’s Manual

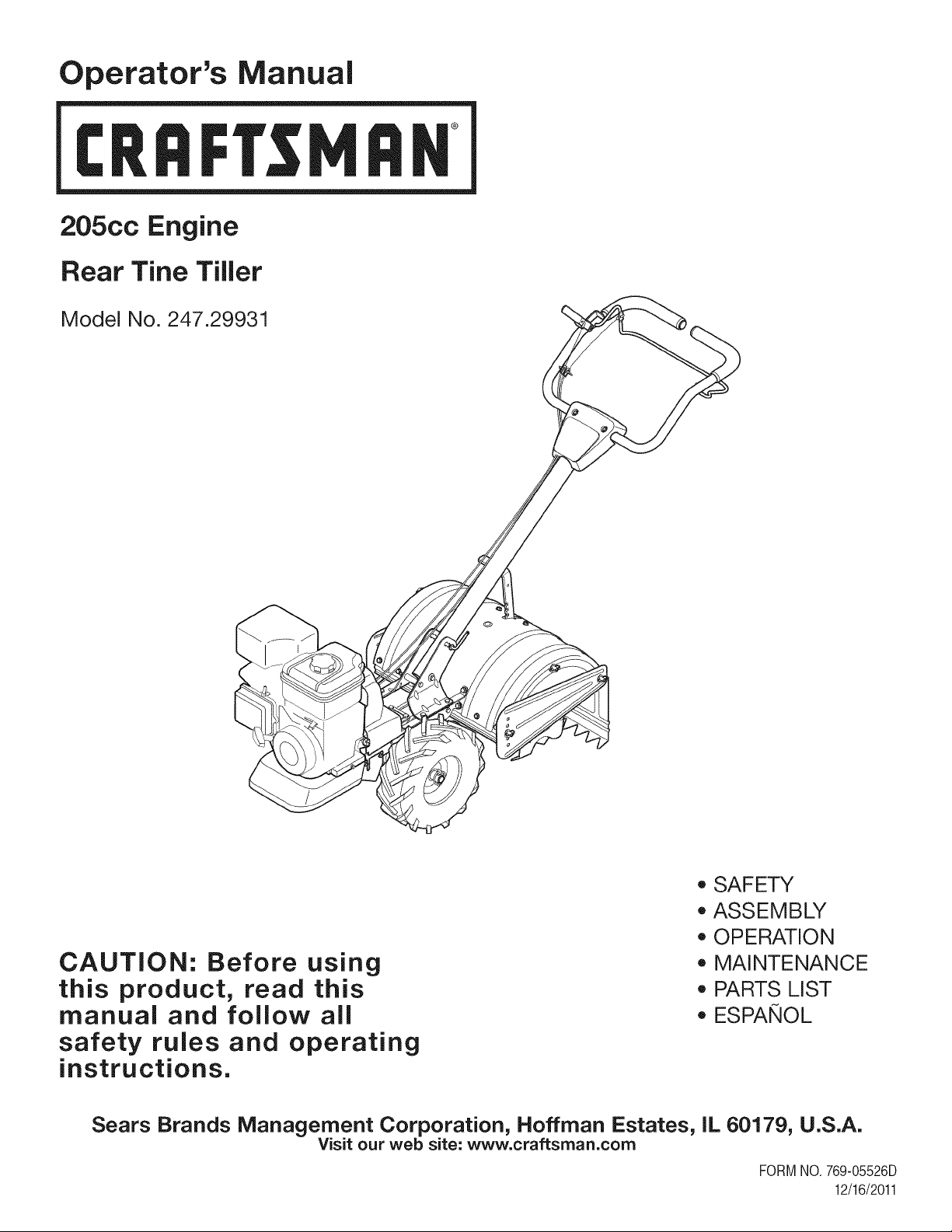

Operator's Manual

I:Rl FI'SlVl N

205cc Engine

Rear Tine Tiller

Model No. 247.29931

* SAFETY

* ASSEMBLY

* OPERATION

CAUTION: Before using

this product, read this

manual and follow aJl

* MAINTENANCE

* PARTS LIST

* ESPANOL

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our web site: www.craftsman.com

FORMNO.769-05526D

12/16/2011

WarrantyStatement..................................Pac

Safetyinstructions....................................Pac

Assembly..................................................Pac

Operation..................................................Pac

ServiceandMaintenance.........................Pac

Off-SeasonStorage..................................Pac

Troubleshooting........................................Pac

CRAFTSMAN TWO YEAR FULL WARRANTY

FORTWOYEARSfromthe dateof purchase,this productis warrantedagainstanydefectsinmaterialor workmanship,Adefectiveproductwill

receivefreerepairorreplacementif repairisunavailable,

Forwarranty coverage details to obtain free repairor replacement,visit theweb site: www.craftsman.com

This warranty covers ONLYdefects in materialandworkmanship. Warrantycoveragedoes NOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,suchastheblades,tines,orbelts.

• Productdamageresultingfromuserattemptsat productmodificationor repairorcausedby productaccessories.

• Repairsnecessarybecauseof accidentorfailuretooperateor maintainthe productaccordingtoallsuppliedinstructions.

• Preventivemaintenance,orrepairsnecessaryduetoimproperfuel mixture,contaminatedor stalefuel.

e2

es3-6

es7-8

es9-16

es17-22

e23

e24

PartsList...................................................Page26-40

LabelMap.................................................Page41

RepairProtectionAgreement...................Page44

Espa_ol.....................................................Page45

ServiceNumbers......................................BackCover

Thiswarrantyisvoidif thisproductiseverusedwhile providingcommercialservicesorif rentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

EngineSeries: 205cc

EngineOilType: SAE30

EngineOilCapacity: 20ounces

Fuel: UnleadedGasoline

SparkPlug: Champion®RC-12YC

SparkPlugGap: .030"

ModelNumber.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

©KCDIP,LLC 2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothe safeopera-

tionpracticesinthismanual.Aswithanytypeof powerequipment,

carelessnessorerroronthe partof theoperatorcan resultin

seriousinjury.Thismachineiscapableofamputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethefollowing

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm.Bat-

tery posts,terminals,andrelatedaccessoriescontainleadand lead

compounds,chemicalsknowntothe Stateof Californiatocause

cancerandreproductiveharm.Washhandsafterhandling.

TRAINING

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualina safeplaceforfutureand regularreference

andfororderingreplacementparts.

• ReadtheOperator'sManualandfollowallwarningsandsafety

instructions.Failuretodosocanresultin seriousinjurytothe

operatorand/or bystanders.Forquestions,call1-800-4MY-HOME.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsof agetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultstooperatethis machinewithoutproper

instruction.

• Keepbystanders,pets,andchildrenatleast75feetfromthe

machinewhileitisinoperation.Stopmachineifanyoneenters

thearea.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

Your Responsibility--Restrictthe useof thispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon the machine.

SAVETHESEINSTRUCTIONS!

PREPARATION

• Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall rocks,bottles,cans,or otherforeignobjectswhich

couldbepickedupor thrownandcausepersonalinjuryor

damageto themachine.

• Alwayswearsafetyglassesor safetygogglesduringoperation

andwhileperformingan adjustmentorrepair,to protectyour

eyes.Thrownobjectswhichricochetcancauseseriousinjuryto

theeyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesorjewelrycan becaughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.

• Beforestarting,checkallboltsandscrewsfor propertightnessto

besurethe machineisinsafeworkingcondition.Also,visually

inspectmachinefor anydamageatfrequentintervals.

• Disengageclutchleversandshift(if provided)intoneutral("N")

beforestartingtheengine.

• Neverleavethismachineunattendedwiththeenginerunning.

• Neverattempttomakeanyadjustmentswhiletheengineis

running,exceptwherespecificallyrecommendedinthe operator's

manual.

• Maintainorreplacesafetyandinstructionslabels,asnecessary.

3

SafeHandling of Gasoline:

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Neverfill containersinsidea vehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthe groundaway

fromyourvehiclebeforefilling.

• Whenpractical,removegas-poweredequipmentfromthetruck

ortrailerand refuelitonthe ground.Ifthisis notpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

• Keepthe nozzleincontactwiththerimofthe fueltankor

containeropeningatalltimesuntilfuelingiscomplete.Donot use

a nozzlelock-opendevice.

• Extinguishallcigarettes,cigars,pipesandother sourcesof

ignition.

• Neverfuel machineindoors.

• Neverremovegascapor addfuel whilethe engineishot or run-

ning.Allowenginetocool atleasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Fill tankto nomorethan1/2inchbelow

bottomoffillerneckto allowspacefor fuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipe itoff theengineandequipment.Move

unitto anotherarea.Wait5 minutesbeforestartingtheengine.

• To reducefirehazards,keepmachinefreeofgrass,leaves,or

otherdebrisbuild-up.Cleanupoil orfuelspillageand removeany

fuelsoakeddebris.

• Neverstorethe machineorfuelcontainerinsidewherethereis an

openflame,sparkor pilotlightas on awaterheater,spaceheater,

furnace,clothesdryerorothergasappliances.

OPERATION

• Do notputhandsorfeetnear rotatingparts.Contactwiththe

rotatingpartscanamputatehandsandfeet.

• Do notoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Neveroperatethismachinewithoutgoodvisibilityor light.Always

be sureof yourfootingandkeepa firmholdonthehandles.

• Keepbystandersawayfromthe machinewhileitisinoperation.

Stopthe machineif anyoneentersthearea.

• Becarefulwhentillinginhardground.Thetines maycatchinthe

groundandpropelthetillerforward.Ifthis occurs,let goofthe

handlebarsanddo not restrainthemachine.

• Exerciseextremecautionwhenoperatingonor crossinggravel

surfaces.Stayalertforhiddenhazardsortraffic. Donotcarry

passengers.

• Neveroperatethemachineat hightransportspeedsonhardor

slipperysurfaces.

• Exercisecautiontoavoidslippingorfalling.

• Lookdownand behindandusecarewhenin reverseor pulling

machinetowardsyou.

• Startthe engineaccordingtothe instructionsfoundinthismanual

and keepfeetwell awayfromthetinesat all times.

• Afterstrikingaforeignobjector ifyourmachineshouldstartmak-

inganunusualnoiseor vibration,immediatelyshutthe engineoff.

Disconnectthe sparkplugwire,grounditagainstthe engineand

performthefollowingsteps:

a. Inspectfordamage.

b. Repairorreplaceanydamagedparts.

c. Checkforanyloosepartsandtightento assurecontinued

safeoperation.

• Disengageall clutchlevers(iffitted)and stopenginebeforeyou

leavethe operatingposition(behindthe handles).Waituntil

thetinescometo a completestopbeforeuncloggingthe tines,

makinganyadjustments,or inspections.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,an odorlessanddeadlygas.

• Mufflerandenginebecomehotandcancausea burn.Do not

touch.

• Usecautionwhentillingnearfences,buildingsandunderground

utilities.Rotatingtinescan causepropertydamageorpersonal

injury.

• Donotoverloadmachinecapacitybyattemptingtotill soiltoo

deepattoo fastof a rate.

• Ifthe machineshouldstartmakinganunusualnoiseor vibration,

stoptheengine,disconnectthesparkplugwireandgroundit

againsttheengine.Inspectthoroughlyfor damage.Repairany

damagebeforestartingandoperating.

• Keepallshields,guards,and safetydevicesinplaceandoperat-

ing properly.

• Neverpickuporcarrymachinewhiletheengineis running.

• Useonly attachmentsandaccessoriesapprovedbythe manu-

factureras listedin thePartsListpagesofthisoperator'smanual.

Failuretodosocan resultin personalinjury.

• Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgement.ContactCustomerSupportat 1-800-4MY-

HOMEforassistanceandthenameofthenearestservicedealer

MAINTENANCE & STORAGE

• Keepthemachine,attachmentsandaccessoriesin safeworking

order.

• Allowthemachinetocoolat leastfiveminutesbeforestoring.

Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.

• Checkboltsandscrewsforpropertightnessat frequentintervals

to keepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

• Beforecleaning,repairing,or inspecting,stoptheengineand

makecertainthetinesandall movingpartshavestopped.

Disconnectthesparkplugwireandgrounditagainsttheengineto

preventunintendedstarting.

4

• Do notchangetheenginegovernorsettingsor over-speedthe

engine.Thegovernorcontrolsthemaximumsafeoperatingspeed

ofengine.

Maintainor replacesafetyandinstructionlabels,as necessary.

Followthis manualforsafeloading,unloading,transporting,and

storageof thismachine.

Alwaysreferto theoperator'smanualforimportantdetailsif the

machineisto bestoredforanextendedperiod.

If thefuel tankhasto be drained,do thisoutdoors.

Observeproperdisposallawsandregulationsforgas,oil,etc.to

protecttheenvironment.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 130hoursof

operation.Atthe endof theAverageUsefulLifehavethemachine

inspectedannuallybyanauthorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failuretodosocanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyenginein anyway.

Tamperingwiththegovernorsettingcanleadto a runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOff RoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(CO),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brushcoveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any)

Ifa sparkarrestorisused,it shouldbe maintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorforthemufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine

and muffler to cool before touching.

WARNING: YourResponsibility--Restricttheuseofthis powermachineto personswhoread,understandandfollowthe

warningsand instructionsinthis manualandonthe machine.

SAVETHESEINSTRUCTIONS!

6

IMPORTANT:Thisunit isshippedwithoutgasolineoroil intheengine.

Becertaintoserviceenginewithgasolineandoilas instructedinthe

Operationsectionofthismanualbeforeoperatingyourmachine.

NOTE:Referenceto rightandlefthandsideofthe Tilleris observed

fromtheoperatingposition.

OPENING CARTON

1. Removeall staplesfromaroundthe bottomof theperimeter.

2. Removethecartonfromthe skid.

3. Removeall looseparts.

4. Removeloosepackingmaterial.

REMOVING UNiT FROM SKiD

1. Thetiller isheavy,do notattemptto removeitfromtheskiduntil

instructedtodosointheseassemblysteps.

2. Checkcartonthoroughlyforanyotherlooseparts.

LOOSE PARTS IN CARTON

• HandlebarAssembly

• Tiller

• EngineOil

• Operator'sManual

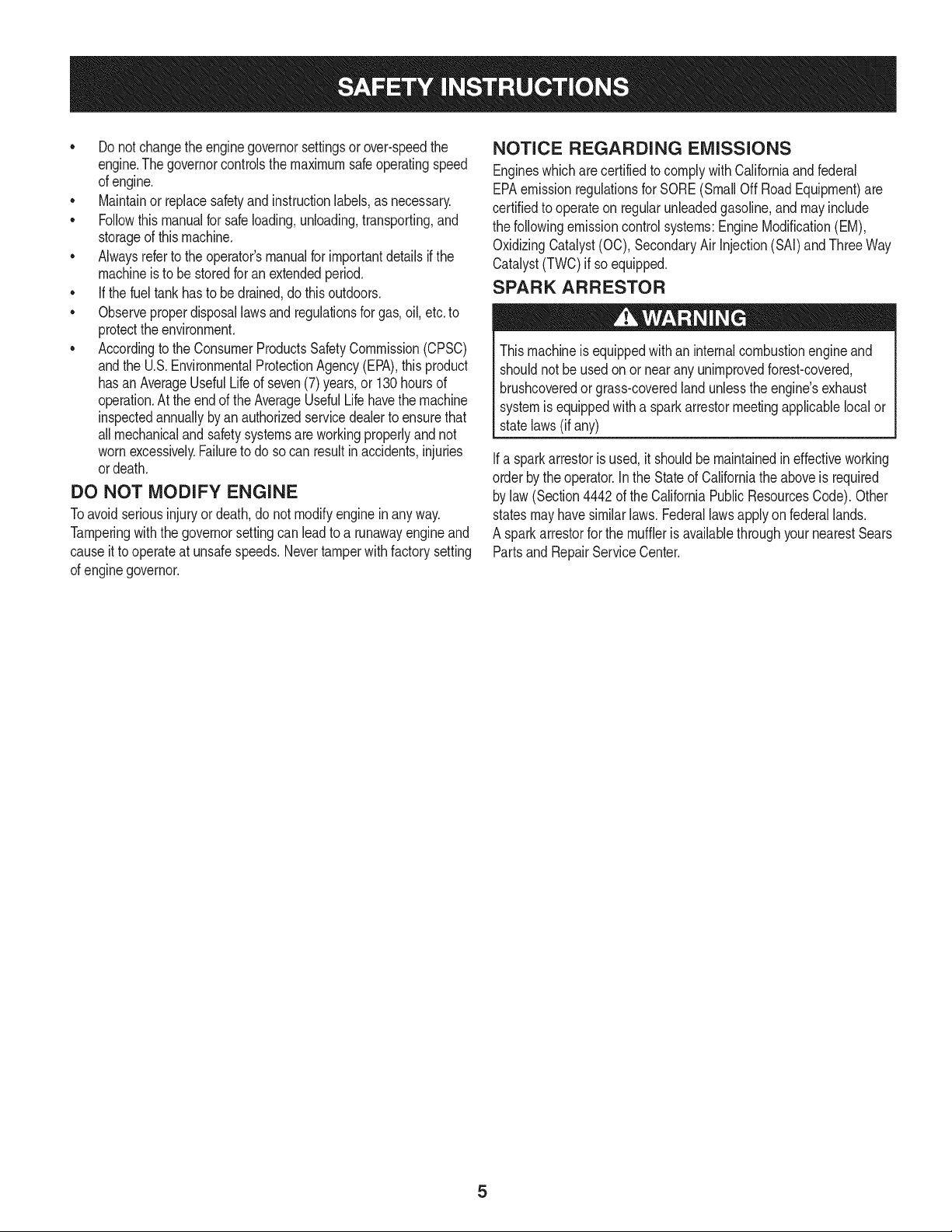

Figure1

ATTACHING THE HANDLE ASSEMBLY

1. Installthe handleontothetillerusingthehardwarepreinstalled

onthehandlemountingbrackets.Thisconsistsofa 5/16-18x

3.00"hexbolt,a handlecrankassembly,retainerbracketandtwo

5/16-18flangelocknuts.Removethishardwarefromthehandle

mountingbracketson thetiller.Referto Figure1inset.

2. Insertthe handleintothe handlemountingbrackets,liningupthe

pre-drilledholes.Insertthe5/16-18x3.00"hexboltinthe bottom

holefromtheleft handside throughtotheotherside.Placethe

roundholeendofthe hexretainerbracketoverthehexboltand

securelooselywitha bellwasherand5/16-18flangelocknut

removedearlier.Referto Figure1inset.

NOTE:Thebellwashershouldbepositionedwiththe topof thebell

shapetowardsthehexnutwhichwill createtensionandfurthersecure

theflange locknutonce tightened.Donottightenthishardwareatthis

time.

3. Installthe handle-crankadjustmentrodintothetop holeofthe

mountingbracketfromthelefthandsideofthe handleassembly,

securewiththeotherflangelocknut previouslyremoved.Fit

thehexendofthe retainerbracketovertheflangelocknut.See

Figure1.

4. TightenthehexboltinstalledinStep2 atthistime. Becarefulnot

toovertightenthishardware.

5. Withthe handleinthedesiredposition,tightenthehandlecrank

adjustmentrodatthistime.

/

J

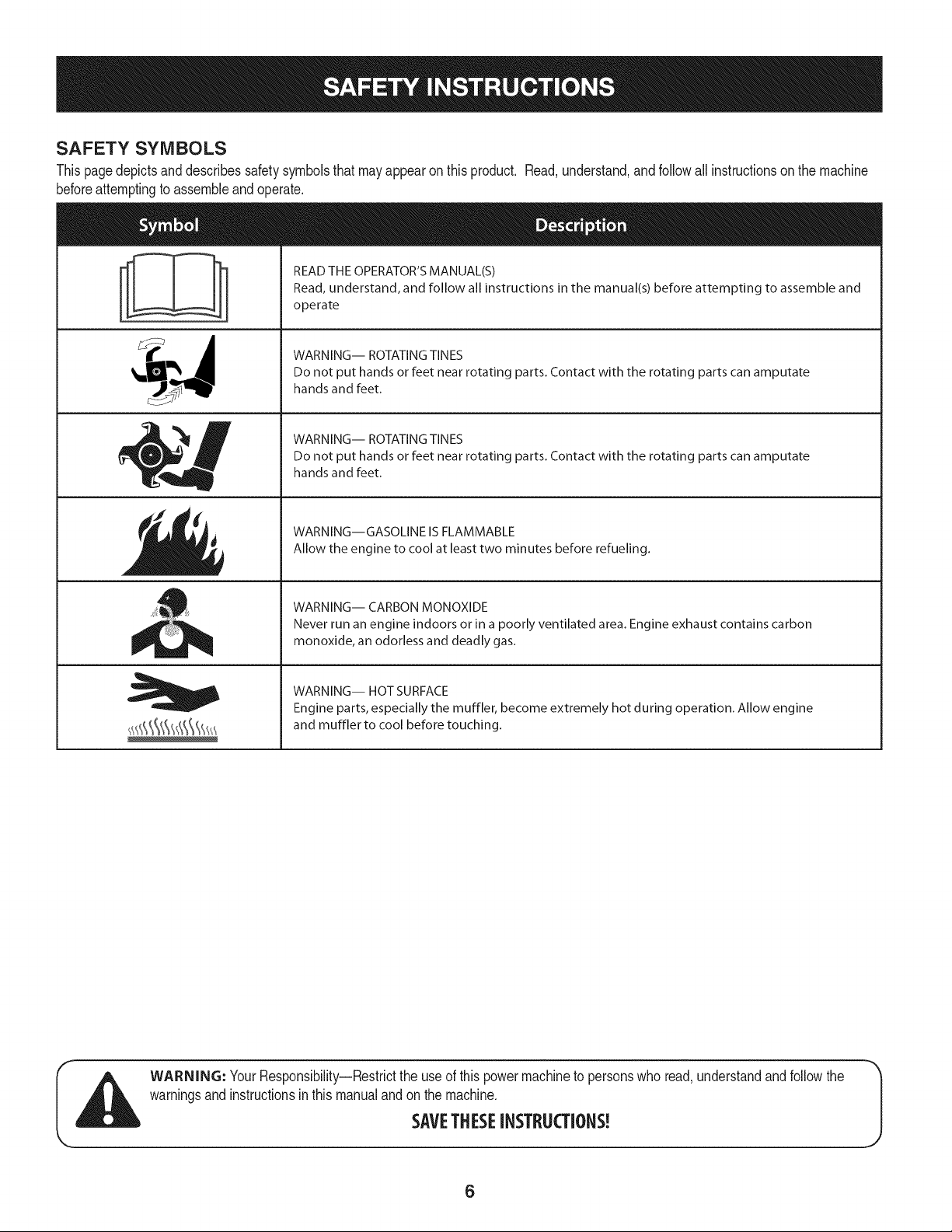

Figure2

ATTACHING THE CABLES

1. Routethe twocablesalongthehandleassemblyonthe righthand

side.

2. Connectthe reversecable(Red)to the reversecablecontrolby

feedingthez-hookthroughthe holeon thereversecablecontrol

fromtheinsidetowardstheoutside.SeeFigure2.

3. Connecttheforwarddrivecable(Black)tothe clutchbailby

feedingthez-hookthroughthe holeon theclutchbailfromthe

outsidetowardstheinside.SeeFigure2.

NOTE:Testthefunctionofthe reverseclutchby pullingthe reverse

handleand releasingit.The handleshouldreturntoits neutral

position.If it doesn't,contactCustomerSupportforassistanceorthe

nearestdealer.

Totest thefunctionofthe forwarddrivebail, liftthebailto thehandle

and releaseit.The bailshouldreturntoitsneutralposition.Ifit doesn't,

contactCustomerSupportforassistanceor thenearestdealer.

7

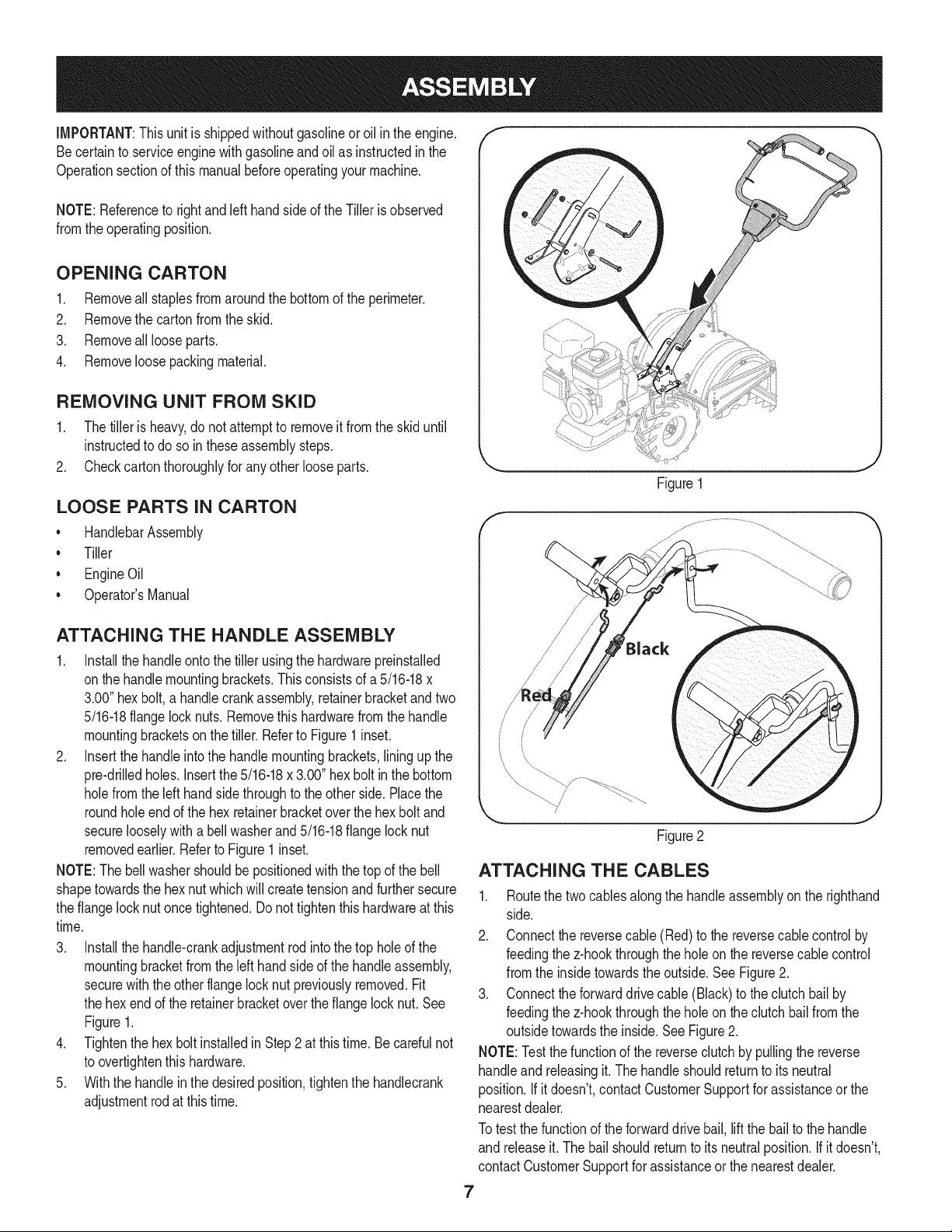

4. Snapthecablehousingclipsintothehandleassemblycable

mount.Theredclip(reversecable)fitsinto thetop positiononthe

handleassembly,whiletheblackclip (forward/clutchcable)feeds

intothe lowerpositiononthe handleassembly.See Figure3.

5. Clipthecablesintothe cableguideslocatedon the handle

assemblypanelas seenin Figure4.

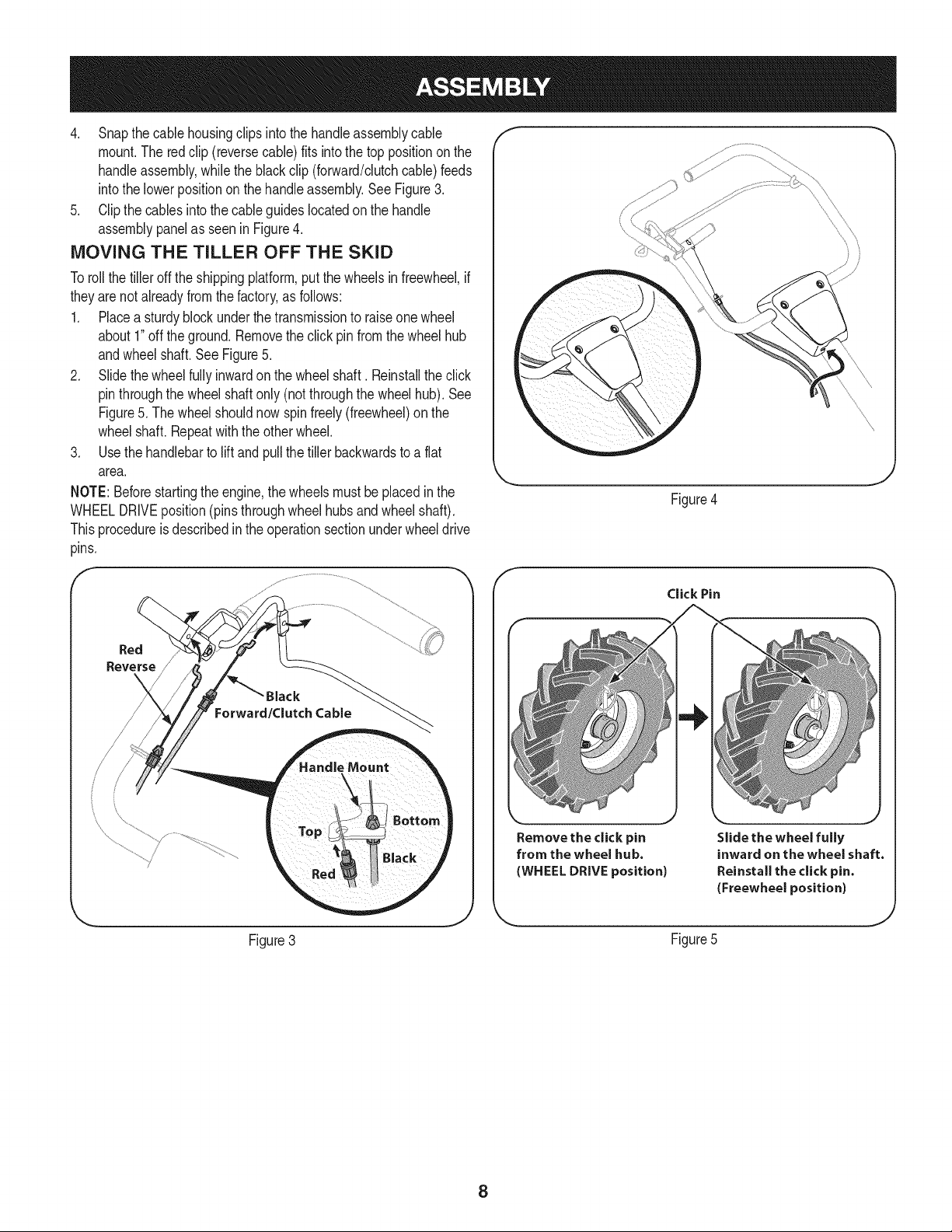

MOVING THE TILLER OFF THE SKID

Torollthe tilleroffthe shippingplatform,putthewheelsinfreewheel,if

theyarenotalreadyfromthefactory,asfollows:

1. Placea sturdyblockunderthe transmissionto raiseonewheel

about1"off theground.Removetheclickpinfromthewheelhub

andwheelshaft.SeeFigure5.

2. Slidethewheelfullyinwardon the wheelshaft. Reinstallthe click

pinthroughthewheelshaftonly(notthroughthewheelhub).See

Figure5.Thewheelshouldnowspinfreely(freewheel)on the

wheelshaft.Repeatwiththe otherwheel.

3. Usethehandlebarto liftand pullthetillerbackwardstoa flat

area.

NOTE:Beforestartingthe engine,thewheelsmustbe placedinthe

WHEELDRIVEposition(pins throughwheelhubsandwheelshaft).

Thisprocedureis describedintheoperationsectionunderwheeldrive

pins.

f

Figure4

f

Click Pin

Figure3

Remove the click pin

from the wheel hub.

(WHEEL DRIVE position)

8

Slide the wheel fully

inward on the wheel shaft.

Reinstall the click pin.

(Freewheel position)

J

Figure5

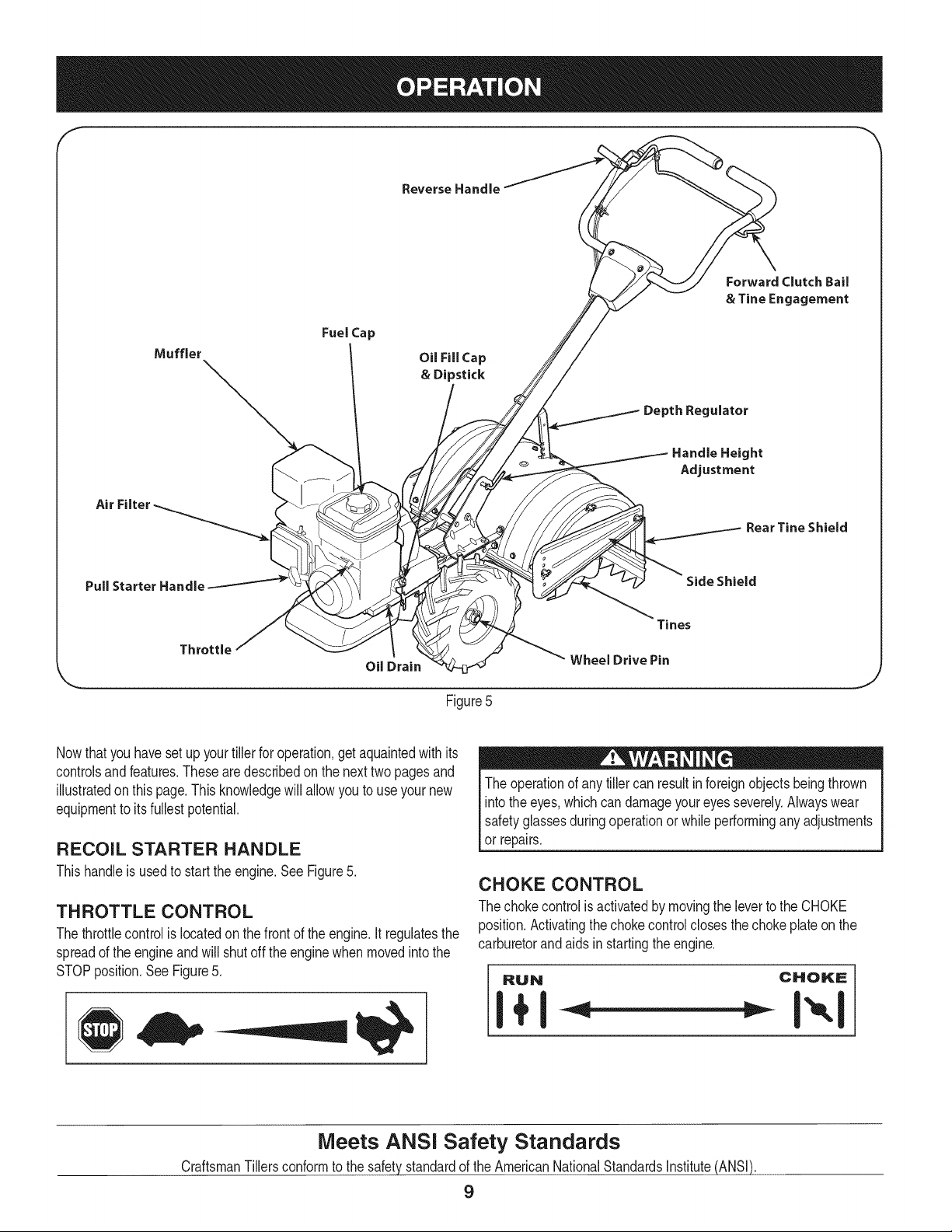

f

Reverse Handle

Forward Clutch Bail

& Tine Engagement

Fuel Cap

OU Fill Cap

& Dipstick

Depth Regulator

Handle Height

Adjustment

Air

RearTine Shield

Pull Starter Handle

Throttle

Oil Drain

Figure5

Nowthat youhavesetup yourtillerforoperation,getaquaintedwithits

controlsandfeatures.Thesearedescribedonthe nexttwopagesand

illustratedonthispage.Thisknowledgewillallowyouto useyour new

equipmenttoitsfullestpotential.

RECOIL STARTER HANDLE

Thishandleisusedto starttheengine.See Figure5.

THROTTLE CONTROL

Thethrottlecontrolislocatedon thefrontof theengine.It regulatesthe

spreadoftheengineandwill shutoff theenginewhen movedintothe

STOPposition.SeeFigure5.

Side Shield

Tines

Wheel Drive Pin

Theoperationofanytillercan resultinforeignobjectsbeingthrown

intothe eyes,whichcan damageyoureyesseverely.Alwayswear

safetyglassesduringoperationor whileperforminganyadjustments

or repairs.

CHOKE CONTROL

Thechokecontrolis activatedbymovingtheleverto theCHOKE

position.Activatingthe chokecontrolclosesthechokeplateonthe

carburetorandaidsinstartingtheengine.

RUN CHOKE

Meets ANSi Safety Standards

CraftsmanTillersconformtothesafetystandardof theAmericanNationalStandardsInstitute(ANSI).

9

AiR FILTER REAR TJNE SHIELD

Theair filterisa deviceontheengineair intakethatpreventsdustand Therearfine shieldprotectstheoperatorfromflyingdebriswhilealso

dirtenteringtheengine.SeeFigure5. smoothingoutfreshlytilled soil.See Figure5.

MUFFLER

Engineexhaustexitstheenginevia themuffler.SeeFigure5.

OIL FILL CAP & DIPSTICK

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill. See

Figure5.

NOTE:ThisunitwasshippedWITHOUToil inthe engine.Oilis

includedintheplasticbag packedwiththemanualinwiththeunit.

Addtheoil as directedin theGas & OilFillUp section.Checktheoil

levelbeforeeachoperationtoensureadequateoil is intheengine.

Forfurtherinstructions,refertothestepsintheEngineMaintenance

sectionof thismanual.

REVERSE HANDLE

TheReverseHandlecontrolsthereversedriveof thewheelsandthe

tines.SeeFigure5.

FORWARD CLUTCH BAiL & TINE ENGAGE-

MENT

Theforwardclutchbailcontrolstheengagementof theforwarddriveof

thewheelsandtines.SeeFigure5.

DEPTH REGULATOR LEVER

Thislevercontrolsthetillingdepthof thetines.Pulltheleverbackand

slideit upor downto engagethenotchedheight.SeeFigure5.

SIDE SHIELD

Theside shieldis usedto maintainclearevenrowsandmaybe

adjustedtooneof fivedifferentpositions.SeeFigure5.

TINES

Yourfiller'stinesarea seriesofhoesarrangedon a revolvingpower-

drivenshaft.SeeFigure5.

WHEEL DRIVE PiNS

Eachwheelis equippedwitha wheeldriveclickpinthat securesthe

wheelto thewheelshaft.Thewheelscan bepositionedineithera

WHEELDRIVEora FREEWHEELmode.SeeFigure5.

OiL DRAIN

Removingtheoil drainplugwilldrainthe oilfromtheengine.See

Figure5.

HANDLEBAR HEIGHT ADJUSTMENT

Thehandlebarheightisadjustableto threedifferentsettings.In

general,adjustthehandlebarsso theyareatwaistlevelwhenthetines

are3-4"intheground.SeeFigure5.

10

GAS AND OiL FILL-UP f "_

Oil (one bottle shipped with unit)

FirstTimeUse

1. Removeoilfilldipstick.

2. Withthetilleron levelground,usea funnelto emptyentire

contentsofoil bottleprovidedintothe engine.

3. Replaceoilfilldipstickandtighten.

Subsequent Uses

Onlyusehighqualitydetergentoil ratedwithAPIserviceclassification

SF,SG,SH,SJor higher.Selecttheoil'sSAEviscositygradeaccord-

ingtothe expectedoperatingtemperature.Followthe chartbelow.

oc

Althoughmulti-viscosityoils(5W30,10W30,etc.)improvestarting

in coldweather,theywillresultinincreasedoilconsumptionwhen

usedabove32°RCheckyourengineoillevelmorefrequentlytoavoid

possibleenginedamagefromrunninglowon oil.

1. Checktheoillevelmakingcertainnotto rubthedipstickalong

theinsidewallsofthe oil filltube.Thiswould resultina false

dipstickreading.Wipedipstickcleanwithcloth. Replacedipstick

intotheoil fillerneck, butdo not screwit in.Removeandcheck

oil level.Refillto FULLmarkon dipstick,ifnecessary.Capacityis

approximately20oz.Overfillingwillcausetheenginetosmoke

profuselyandwill resultin poorengineperformance.

2. Replaceoilfilldipstickandtighten.

3. Keepoil levelatFULL.Runningtheenginewithtoo littleoilcan

resultinpermanentenginedamage.

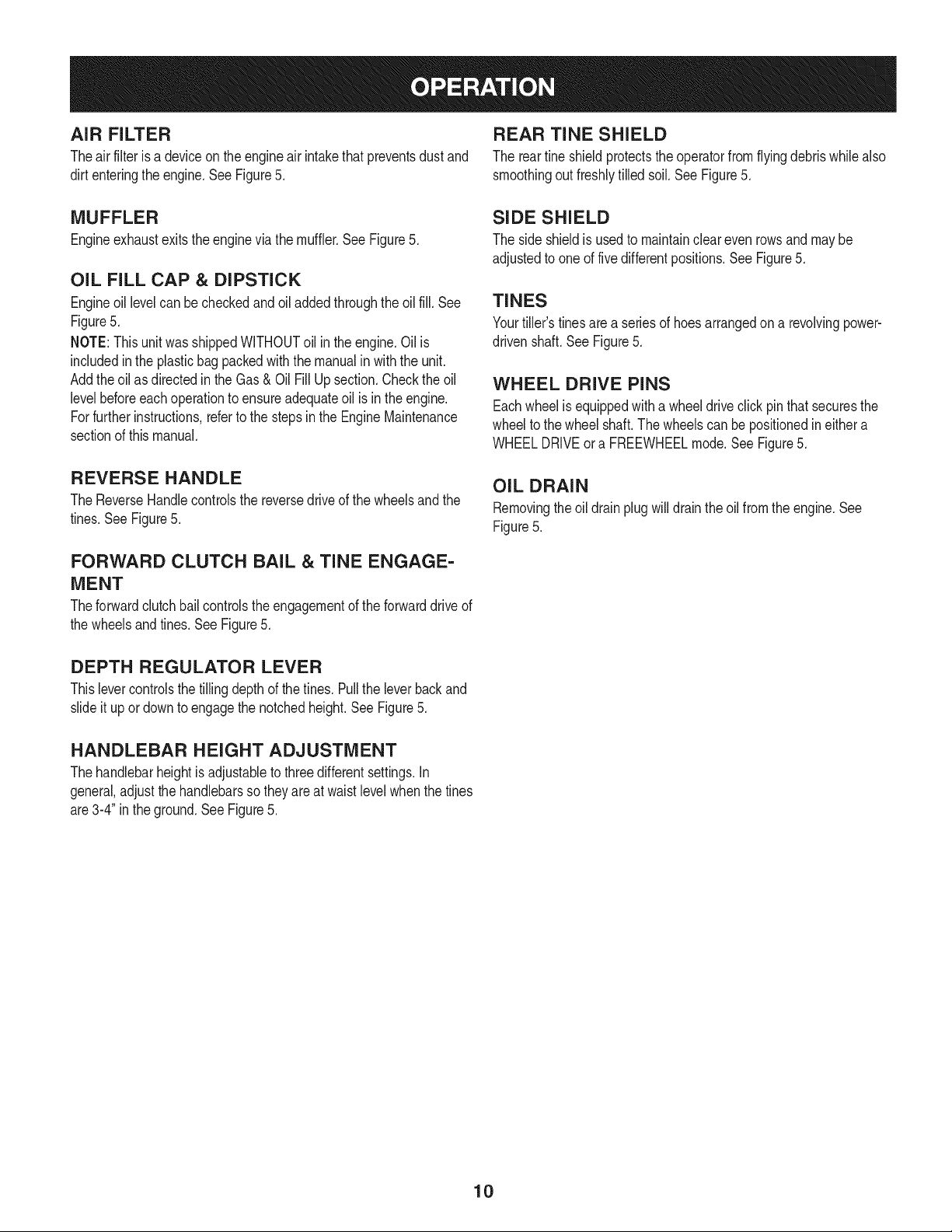

Transmission/Gear Oil

FirstTimeUse

1. Withthe tilleron levelground,pullthe DepthRegulatorLever

backandthenall thewayup untilthe lowestnotchin the leveris

engaged.SeeFigure6.

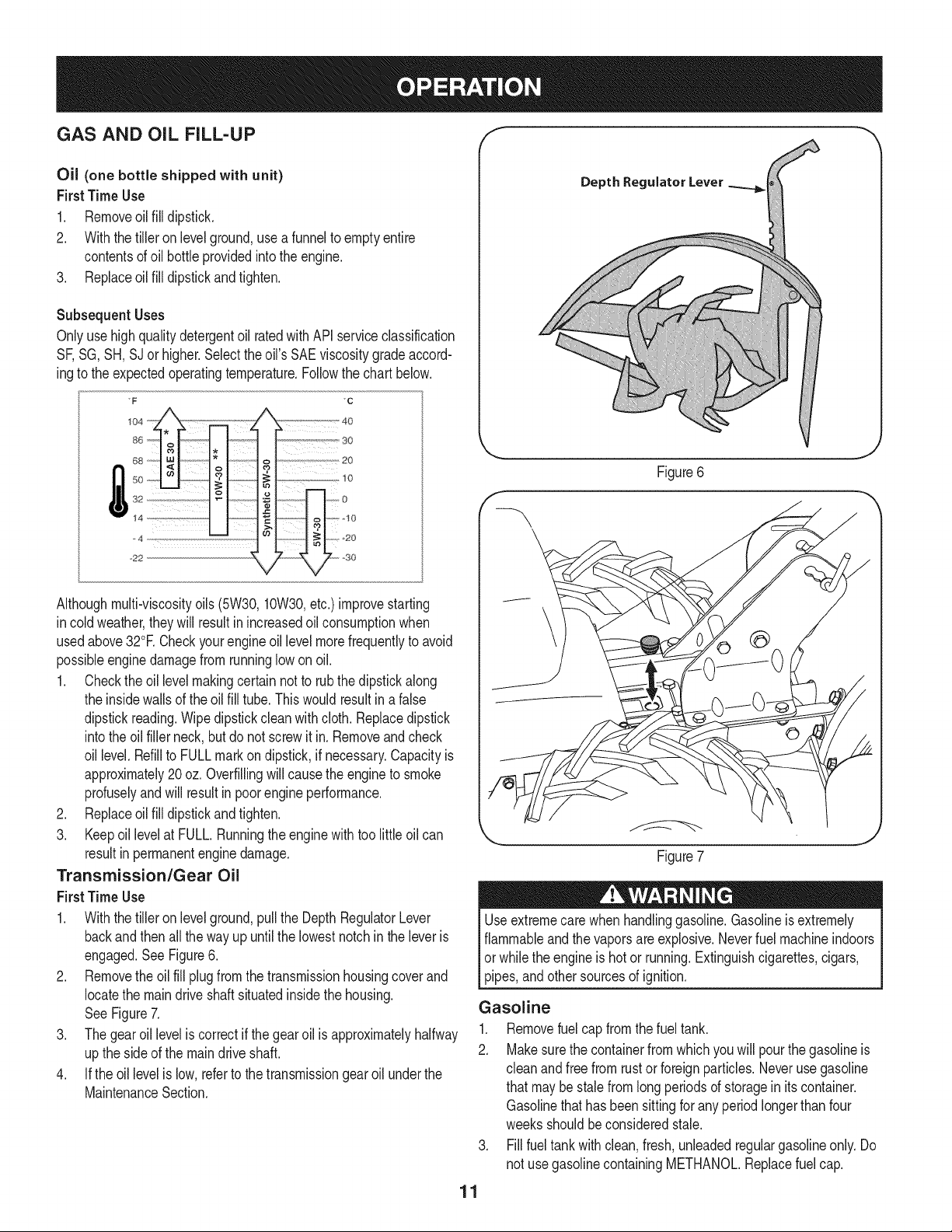

2. Removetheoilfillplugfromthe transmissionhousingcoverand

locatethemaindriveshaftsituatedinsidethehousing.

See Figure7.

3. Thegearoil leveliscorrectifthegearoilis approximatelyhalfway

up theside ofthe maindriveshaft.

4. If theoillevelis low,refertothetransmissiongearoilunderthe

MaintenanceSection.

Depth Regulater Lever

Figure6

\

J

Figure7

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsare explosive.Neverfuel machineindoors

or whiletheengineishot or running.Extinguishcigarettes,cigars,

pipes,andothersourcesofignition.

Gasoline

1. Removefuelcapfromthefueltank.

2. Makesurethe containerfromwhichyouwillpourthegasolineis

cleanandfree fromrustorforeignparticles.Neverusegasoline

that maybe stalefromlongperiodsof storageinits container.

Gasolinethathas beensittingforanyperiodlongerthan four

weeksshouldbeconsideredstale.

3. Fillfuel tankwithclean,fresh,unleadedregulargasolineonly.Do

notusegasolinecontainingMETHANOL.Replacefuelcap.

11

Alcoholblendedfuels(calledgasoholorusingethanolormethanol)

canattractmoisturewhichleadstoseparationandformationofacids

duringstorage.Acidicgascandamagethefuelsystemofanengine

whileinstorage.

Toavoidengineproblems,thefuelsystemshouldbeemptiedbefore

storagefor30daysorlonger.Drainthegastank,starttheengine

andletitrununtilthefuellinesandcarburetorareempty.Usefresh

fuelnextseason.SeeSTORAGEInstructionsforadditionalinforma-

tion.

Neveruseengineorcarburetorcleanerproductsinthefueltankor

permanentdamagemayoccur.

NOTE:Checkthefuellevelperiodicallytoavoidrunningoutof

gasolinewhileoperatingthetiller.

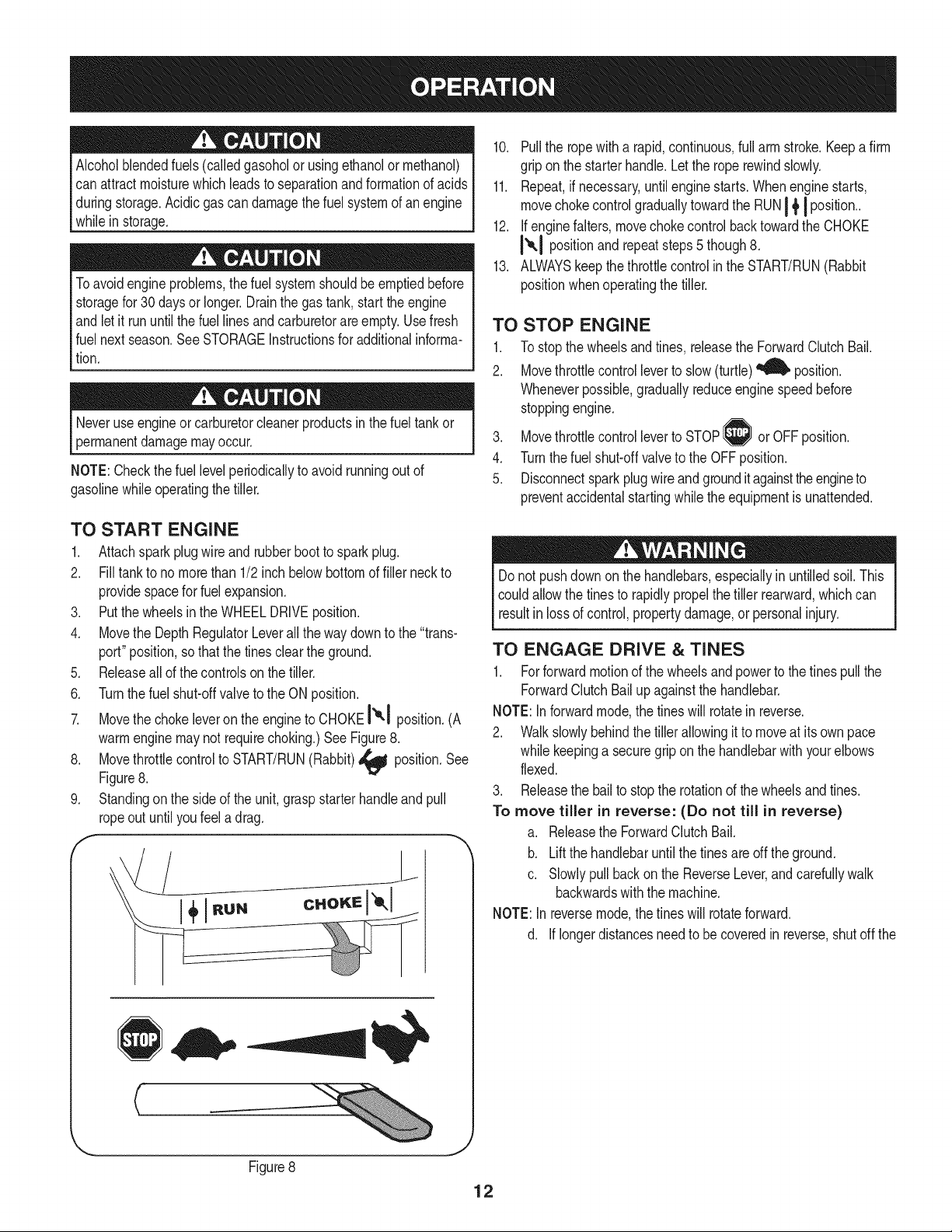

TO START ENGINE

1. Attachsparkplugwireandrubberboottosparkplug.

2. Filltankto nomorethan 1/2inch belowbottomoffiller neckto

providespacefor fuelexpansion.

3. PutthewheelsintheWHEELDRIVEposition.

4. Movethe DepthRegulatorLeverallthewaydowntothe"trans-

port"position,sothatthetinescleartheground.

5. Releaseallofthecontrolsonthetiller.

6. Turnthefuelshut-offvalveto theON position.

7. Movethechokeleveron theenginetoCHOKEI'_1 position.(A

warmenginemaynotrequirechoking.)SeeFigure8.

8. Movethrottlecontrolto START/RUN(Rabbit)_ position.See

Figure8.

9. Standingonthe sideoftheunit,graspstarterhandleandpull

ropeoutuntilyoufeel a drag.

f

__jL

10.Pulltheropewitharapid,continuous,fullarmstroke.Keepafirm

griponthestarterhandle.Lettheroperewindslowly.

11.Repeat,ifnecessary,untilenginestarts.Whenenginestarts,

movechokecontrolgraduallytowardtheRUNI_'Iposition..

12.Ifenginefalters,movechokecontrolbacktowardtheCHOKE

I_,1positionandrepeatsteps5though8.

13.ALWAYSkeepthethrottlecontrolintheSTART/RUN(Rabbit

positionwhenoperatingthetiller.

TO STOP ENGINE

1. To stopthewheelsandtines, releasetheForwardClutchBail.

2. Movethrottlecontrolleverto slow(turtle)'_ position.

Wheneverpossible,graduallyreduceenginespeedbefore

stoppingengine.

3. Movethrottlecontrolleverto STOP or OFFposition.

4. Turnthefuelshut-offvalveto theOFFposition.

5. Disconnectsparkplugwireandgrounditagainsttheengineto

preventaccidentalstartingwhiletheequipmentisunattended.

Donot pushdownonthehandlebars,especiallyin untilledsoil.This

couldallowthetinesto rapidlypropelthetillerrearward,whichcan

resut n ossofcontro, propertydamage,or persona njury.

TO ENGAGE DRIVE & TINES

1. Forforwardmotionofthewheelsandpowertothe tinespullthe

ForwardClutchBailupagainstthehandlebar.

NOTE:Inforwardmode,thetineswill rotatein reverse.

2. Walkslowlybehindthetillerallowingitto moveat itsown pace

whilekeepinga securegriponthe handlebarwithyourelbows

flexed.

3. Releasethebailtostoptherotationofthe wheelsandtines.

To move tiller in reverse: (Do not till in reverse)

a. Releasethe ForwardClutchBail.

b. Liftthehandlebaruntilthetinesareoffthe ground.

c. Slowlypullbackon the ReverseLever,andcarefullywalk

backwardswiththemachine.

NOTE:In reversemode,thetineswillrotateforward.

d. Iflongerdistancesneedto becoveredinreverse,shutoff the

Figure8

J

12

engine,thenplacethe twowheelsin FREEWHEEL.

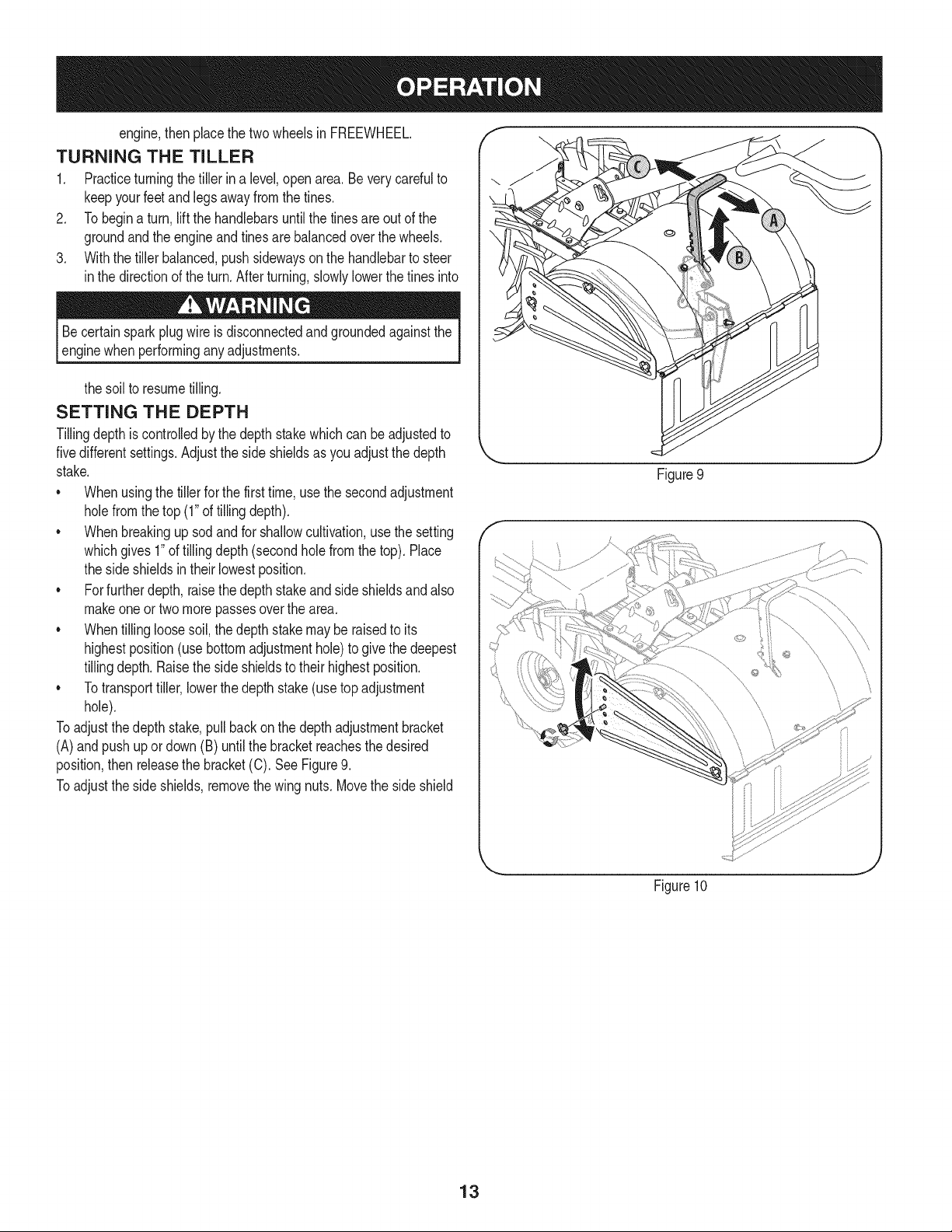

TURNING THE TILLER

1. Practiceturningthetiller ina level,openarea.Beverycarefulto

keepyourfeetandlegsawayfromthe tines.

2. Tobeginaturn,lift the handlebarsuntilthetinesareout ofthe

groundandtheengineandtinesare balancedoverthewheels.

3. Withthetiller balanced,pushsidewayson thehandlebartosteer

inthedirectionof theturn.Afterturning,slowlylowerthetines into

Becertainsparkplugwireis disconnectedandgroundedagainstthe

enginewhenperforminganyadjustments.

thesoilto resumetilling.

SETTING THE DEPTH

Tillingdepthiscontrolledbythedepthstakewhichcan beadjustedto

fivedifferentsettings.Adjustthesideshieldsasyouadjustthedepth

stake.

• Whenusingthe tillerfor thefirst time,use thesecondadjustment

holefromthetop (1"oftillingdepth).

• Whenbreakingupsod andforshallowcultivation,usethesetting

whichgives1"oftillingdepth(secondholefromthe top).Place

thesideshieldsintheirlowestposition.

• Forfurtherdepth,raisethe depthstakeandsideshieldsandalso

makeoneor twomorepassesoverthe area.

• Whentillingloosesoil,thedepth stakemaybe raisedto its

highestposition(usebottomadjustmenthole)togivethedeepest

tillingdepth.Raisethe sideshieldsto theirhighestposition.

• Totransporttiller,lowerthedepthstake(usetopadjustment

hole).

Toadjustthe depthstake,pullbackonthe depthadjustmentbracket

(A)andpushupordown (B)untilthe bracketreachesthe desired

position,thenreleasethebracket(C).SeeFigure9.

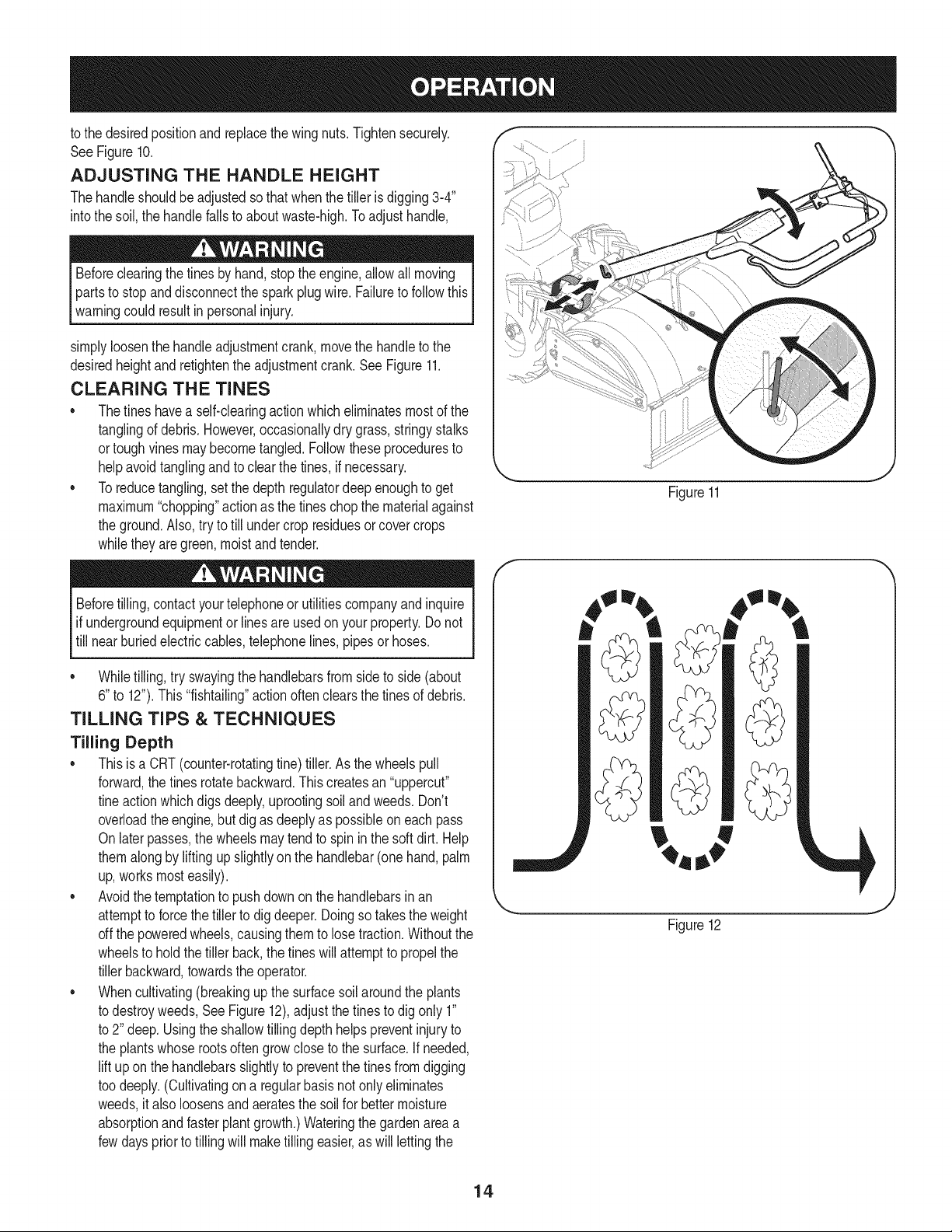

Toadjustthe sideshields,removethewingnuts.Movethesideshield

Figure9

13

J

Figure10

tothe desiredpositionandreplacethewing nuts.Tightensecurely.

SeeFigure10.

ADJUSTING THE HANDLE HEIGHT

Thehandleshouldbeadjustedsothatwhenthetillerisdigging3-4"

intothe soil,thehandlefallsto aboutwaste-high.Toadjusthandle,

Beforeclearingthetinesbyhand,stoptheengine,allowall moving

partstostopanddisconnectthesparkplugwire.Failuretofollowthis

warningcouldresultin personalinjury.

simplyloosenthehandleadjustmentcrank,movethehandletothe

desiredheightandretightentheadjustmentcrank.SeeFigure11.

CLEARING THE TINES

* Thetineshavea self-clearingactionwhicheliminatesmostofthe

tanglingofdebris.However,occasionallydrygrass,stringystalks

ortoughvinesmaybecometangled.Followtheseproceduresto

helpavoidtanglingandtoclearthetines,if necessary.

* Toreducetangling,setthe depthregulatordeepenoughto get

maximum"chopping"actionasthetineschopthematerialagainst

theground.Also,try totill undercropresiduesorcovercrops

whiletheyaregreen,moistandtender.

Figure11

f

Beforetilling,contactyourtelephoneorutilitiescompanyandinquire

ifundergroundequipmentorlinesareusedon yourproperty.Donot

till nearburiedelectriccables,telephonelines,pipesor hoses.

* Whiletilling,tryswayingthe handlebarsfromsidetoside (about

6"to 12").This"fishtailing"actionoftenclearsthetinesofdebris.

TILLING TIPS & TECHNIQUES

Tilling Depth

* ThisisaCRT(counter-rotatingtine)tiller.Asthe wheelspull

forward,thetinesrotatebackward.Thiscreatesan"uppercut"

tineactionwhichdigs deeply,uprootingsoilandweeds.Don't

overloadthe engine,butdig asdeeplyas possibleoneachpass

Onlaterpasses,thewheelsmaytendto spininthe softdirt.Help

themalongbyliftingupslightlyonthehandlebar(onehand,palm

up,worksmosteasily).

* Avoidthetemptationto pushdownon thehandlebarsin an

attempttoforcethe tillerto digdeeper.Doingsotakestheweight

offthepoweredwheels,causingthemto losetraction.Withoutthe

wheelstoholdthe tillerback,thetineswillattemptto propelthe

tillerbackward,towardstheoperator.

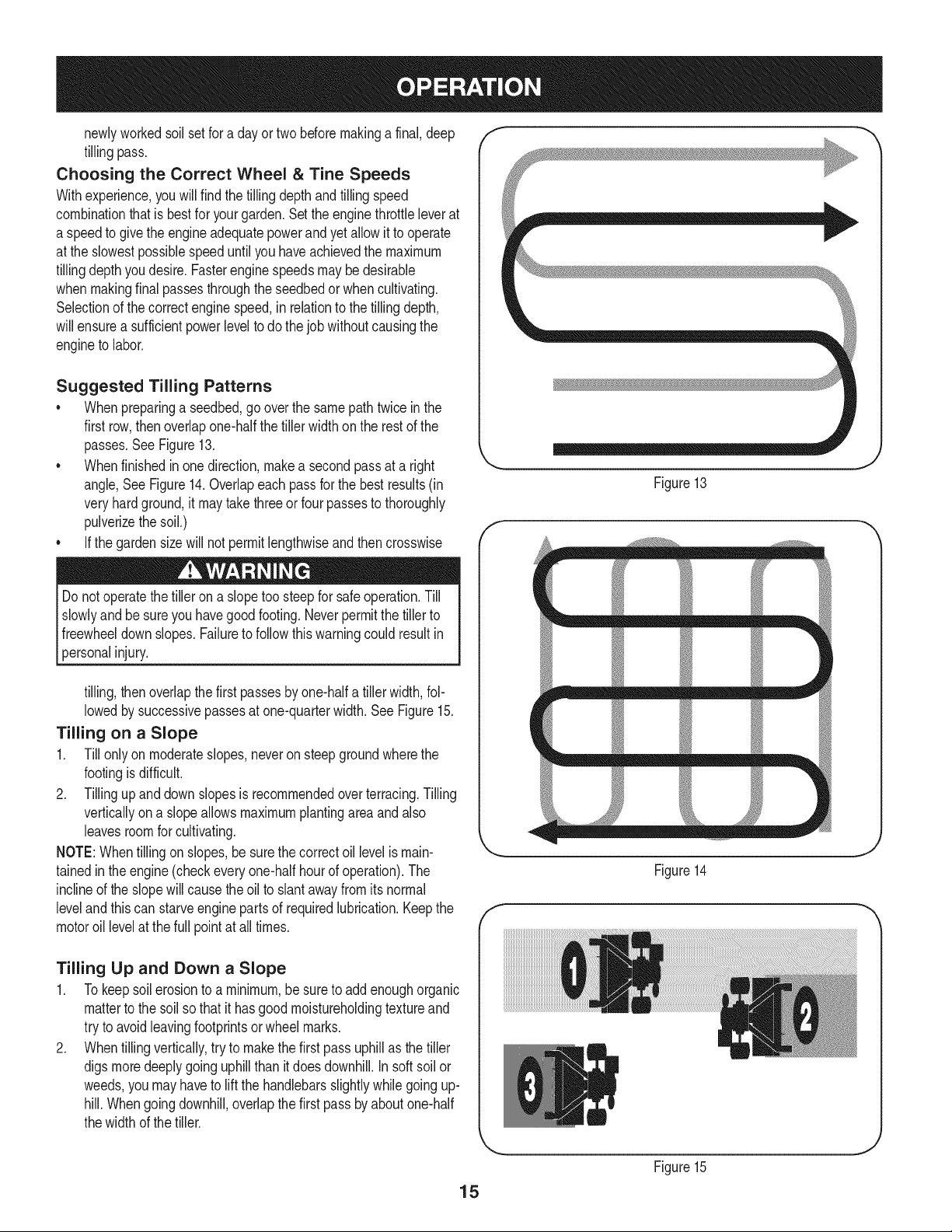

* Whencultivating(breakingupthe surfacesoilaroundtheplants

todestroyweeds,SeeFigure12),adjustthe tinestodig only 1"

to2" deep.Usingtheshallowtillingdepthhelpspreventinjuryto

theplantswhoserootsoftengrowclosetothe surface.If needed,

lift uponthehandlebarsslightlyto preventthetinesfromdigging

toodeeply.(Cultivatingona regularbasisnotonlyeliminates

weeds,it alsoloosensandaeratesthesoilfor bettermoisture

absorptionandfasterplantgrowth.)Wateringthegardenareaa

fewdayspriortotillingwillmaketilling easier,aswilllettingthe

Figure12

14

newlyworkedsoilsetfora dayortwo beforemakinga final,deep

tillingpass.

Choosing the Correct Wheel & Tine Speeds

Withexperience,youwillfindthetillingdepthandtilling speed

combinationthatis bestforyourgarden.Settheenginethrottleleverat

a speedto givethe engineadequatepowerandyetallowitto operate

atthe slowestpossiblespeeduntilyouhaveachievedthe maximum

tillingdepthyoudesire.Fasterenginespeedsmaybedesirable

whenmakingfinalpassesthroughtheseedbedorwhencultivating.

Selectionofthecorrectenginespeed,inrelationto thetillingdepth,

willensurea sufficientpowerlevelto dothejobwithoutcausingthe

enginetolabor.

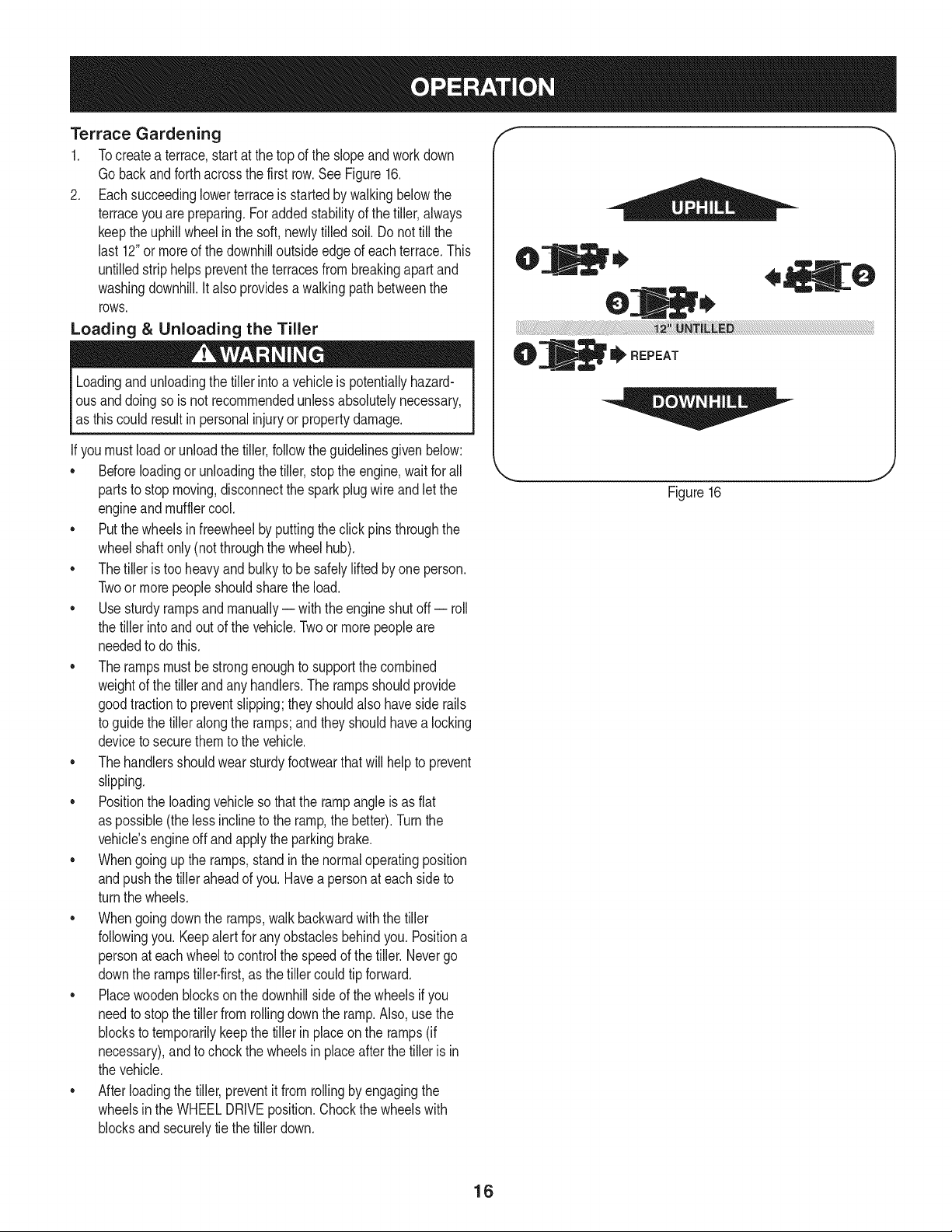

Suggested Tilling Patterns

• Whenpreparinga seedbed,gooverthe samepathtwiceinthe

firstrow,thenoverlapone-halfthetiller widthontherestof the

passes.SeeFigure13.

• Whenfinishedinonedirection,makeasecondpassat a right

angle,SeeFigure14.Overlapeachpassforthebestresults(in

veryhardground,itmaytakethreeorfour passestothoroughly

pulverizethesoil.)

• Ifthe gardensizewillnot permitlengthwiseandthen crosswise

f

J

Figure13

f

T

Donotoperatethetilleron a slopetoosteepfor safeoperation.Till

slowlyandbe sureyouhavegoodfooting.Neverpermitthetillerto

freewheeldownslopes.Failuretofollowthis warningcouldresultin

[persona njury.

tilling,thenoverlapthefirst passesbyone-halfa tillerwidth,fol-

lowedby successivepassesat one-quarterwidth.See Figure15.

Tilling on a Slope

1. Tillonlyon moderateslopes,neveronsteepgroundwherethe

footingisdifficult.

2. Tillingupanddownslopesisrecommendedoverterracing.Tilling

verticallyona slopeallowsmaximumplantingareaandalso

leavesroomfor cultivating.

NOTE:Whentillingonslopes,besurethe correctoil levelismain-

tainedinthe engine(checkeveryone-halfhourofoperation).The

inclineoftheslopewillcausetheoil toslantawayfromitsnormal

levelandthiscan starveenginepartsof requiredlubrication.Keepthe

motoroil levelat thefull pointat alltimes.

Tilling Up and Down a Slope

1. Tokeepsoilerosiontoa minimum,besuretoaddenoughorganic

matterto thesol sothatit hasgoodmoistureholdingtextureand

try toavoidleavingfootprintsorwheel marks.

2. Whentillingvertically,try tomakethe firstpassuphillas thetiller

digsmoredeeplygoinguphillthan itdoesdownhill.Insoft soilor

weeds,youmayhaveto lift thehandlebarsslightlywhilegoingup-

hill.Whengoingdownhill,overlapthefirstpassbyaboutone-half

thewidthof thetiller.

mm _

J

Figure14

f

15

Figure15

Terrace Gardening

1. Tocreatea terrace,startatthetopof theslopeandworkdown

Gobackandforthacrossthefirstrow.See Figure16.

2. Eachsucceedinglowerterraceisstartedbywalkingbelowthe

terraceyouarepreparing.Foraddedstabilityof thetiller,always

keepthe uphillwheelin the soft,newlytilledsoil.Donottill the

last 12"ormoreof thedownhilloutsideedgeof eachterrace.This

untilledstriphelps preventtheterracesfrombreakingapartand

washingdownhill.Italsoprovidesa walkingpathbetweenthe

rows.

Loading & Unloading the Tiller

Loadingandunloadingthe tillerintoa vehicleispotentiallyhazard-

ousanddoingso isnot recommendedunlessabsolutelynecessary,

as thiscouldresultinpersonalinjuryor propertydamage.

If youmustloador unloadthetiller,followthe guidelinesgiven below:

• Beforeloadingor unloadingthetiller,stoptheengine,waitforall

partstostopmoving,disconnectthesparkplugwireandletthe

engineandmufflercool.

• Putthewheelsin freewheelbyputtingtheclickpinsthroughthe

wheelshaftonly(notthroughthewheelhub).

• Thetilleris tooheavyandbulkyto be safelyliftedby oneperson.

Twoor morepeopleshouldsharethe load.

• Usesturdyrampsandmanually-- withtheengineshutoff -- roll

thetillerintoand outofthe vehicle.Twoormorepeopleare

neededtodothis.

• The rampsmustbestrongenoughto supportthe combined

weightofthe tillerandany handlers.Therampsshouldprovide

goodtractiontopreventslipping;theyshouldalsohavesiderails

toguidethe tilleralongthe ramps;andtheyshouldhavealocking

devicetosecurethemto thevehicle.

• Thehandlersshouldwearsturdyfootwearthatwill helpto prevent

slipping.

• Positiontheloadingvehiclesothatthe rampangleis asflat

aspossible(thelessinclineto theramp,the better).Turnthe

vehicle'sengineoff andapplythe parkingbrake.

• Whengoingup theramps,standinthenormaloperatingposition

andpushthe tilleraheadof you. Haveapersonat eachside to

turnthe wheels.

• Whengoingdownthe ramps,walkbackwardwiththetiller

followingyou.Keepalertforanyobstaclesbehindyou. Positiona

personateachwheeltocontrolthe speedof thetiller.Nevergo

downthe rampstiller-first,as thetiller couldtip forward.

• Placewoodenblocksonthedownhillsideof thewheelsif you

needtostopthe tillerfromrollingdowntheramp.Also,use the

blocksto temporarilykeepthetillerin placeonthe ramps(if

necessary),andto chockthe wheelsin placeafterthe tilleris in

thevehicle.

• Afterloadingthetiller,preventitfromrollingbyengagingthe

wheelsintheWHEELDRIVEposition.Chockthewheelswith

blocksandsecurelytiethetillerdown.

,O

O

_ REPEAT

Figure16

16

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationor whileperforminganyadjustmentsor repairs.

EachUse

1st2 hours

1st5 hours

Every10hours

Every25 hours

Every30 hours

AnnuallyorEvery50 hours

AnnuallyorEvery100hours

BeforeStorage

Changeoileverytwentyfivehourswhenoperatingengineunderheavyloadorinhightemperatures

1. Engineoil level

2. Looseormissinghardware

3. Engineandaroundmuffler

4. Air cleaner

1. Drivebelttension

2. NutsandBolts

1. Engineoil

1. Drivebelttension

2. Unit

1. Sparkplug

1. Transmissionoil level

2. Tinesforwear

3. Tirepressure

1. Engineoi11-

1. Air cleaner

2. SparkPlug

1. Fuelsystem

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.Tolocate the nearest SearsService

Centeror toscheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

1. Check

2. Tightenorreplace

3. Clean

4. Check

1. Check

2. Check

1. Change

1. Check

2. Lubricae

1. Check

1. Check

2. Check

3. Check

1. Change

1. Change

2. Change

1. Runengineuntilit stopsf_m lackd

fueloradda gasolineadditivetothe

gasinthe tank.

Alwaysstopengineanddisconnectsparkplugwirebeforeperforming

lanymaintenanceor adjustments.Alwayswearsafetyglassesduring

[operationorwhileperforminganyadjustmentsor repairs.

GENERAL RECOMMENDATIONS

• Alwaysobserveallsafetyrulesfoundonproductlabelsandin

thisoperator'smanualwhenperforminganymaintenance.Safety

rulescan befoundonthe productlabelsandin thisOperator's

Manualbeginningon page3.

• Thewarrantyonthistillerdoesnotcoveritemsthathavebeen

subjectedto operatorabuseor negligence.Toreceivefullvalue

fromwarranty,operatormustmaintainthe equipmentas

instructedhere.

• Someadjustmentswillhaveto be madeperiodicallytomaintain

yourunit properly.

• Periodicallycheckall fastenersand makesurethesearetight.

ENGINE MAINTENANCE

DONOTcheckforsparkwithsparkplugremoved.DONOTcrank

enginewithsparkplug removed.

Iftheenginehas beenrunning,themufflerwillbeveryhot. Becareful

notto touchthemuffler.

Thesparkplugmustbesecurelytightened.Animproperlytightened

sparkplugcanbecomeveryhot andmaydamagetheengine.

Checking the Spark Plug

Toensureproperengineoperation,thesparkplugmustbeproperly

gappedandfreeof deposits.Checkthe sparkplugevery25hoursand

replaceitevery100hours.

17

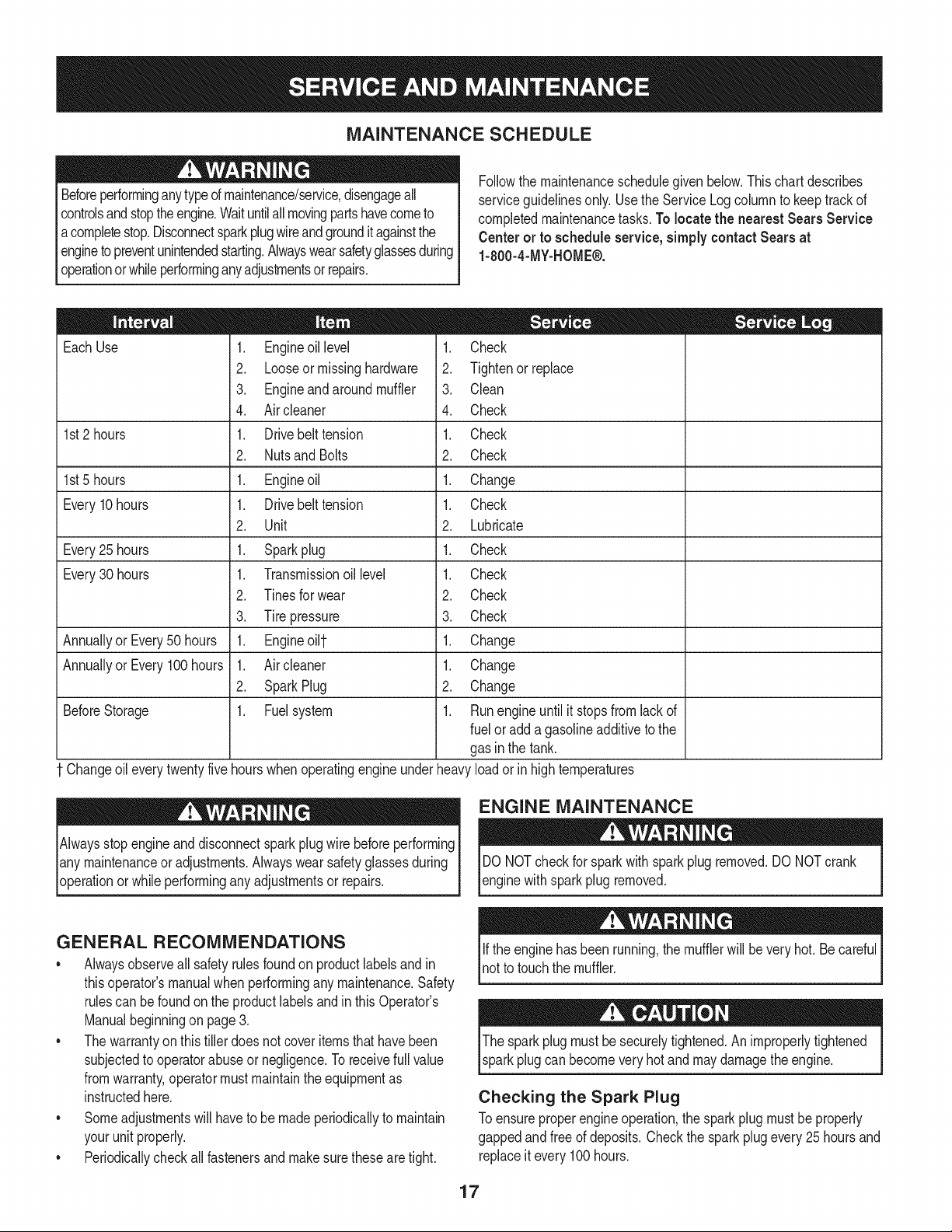

1. Removethesparkplugbootandusea sparkplugwrenchto

removetheplug.See Figure17.

2. Visuallyinspectthesparkplug.Discardthesparkplugif thereis

apparentwear,orif the insulatoriscrackedorchipped.Cleanthe

sparkplugwitha wirebrush ifit isto be reused.

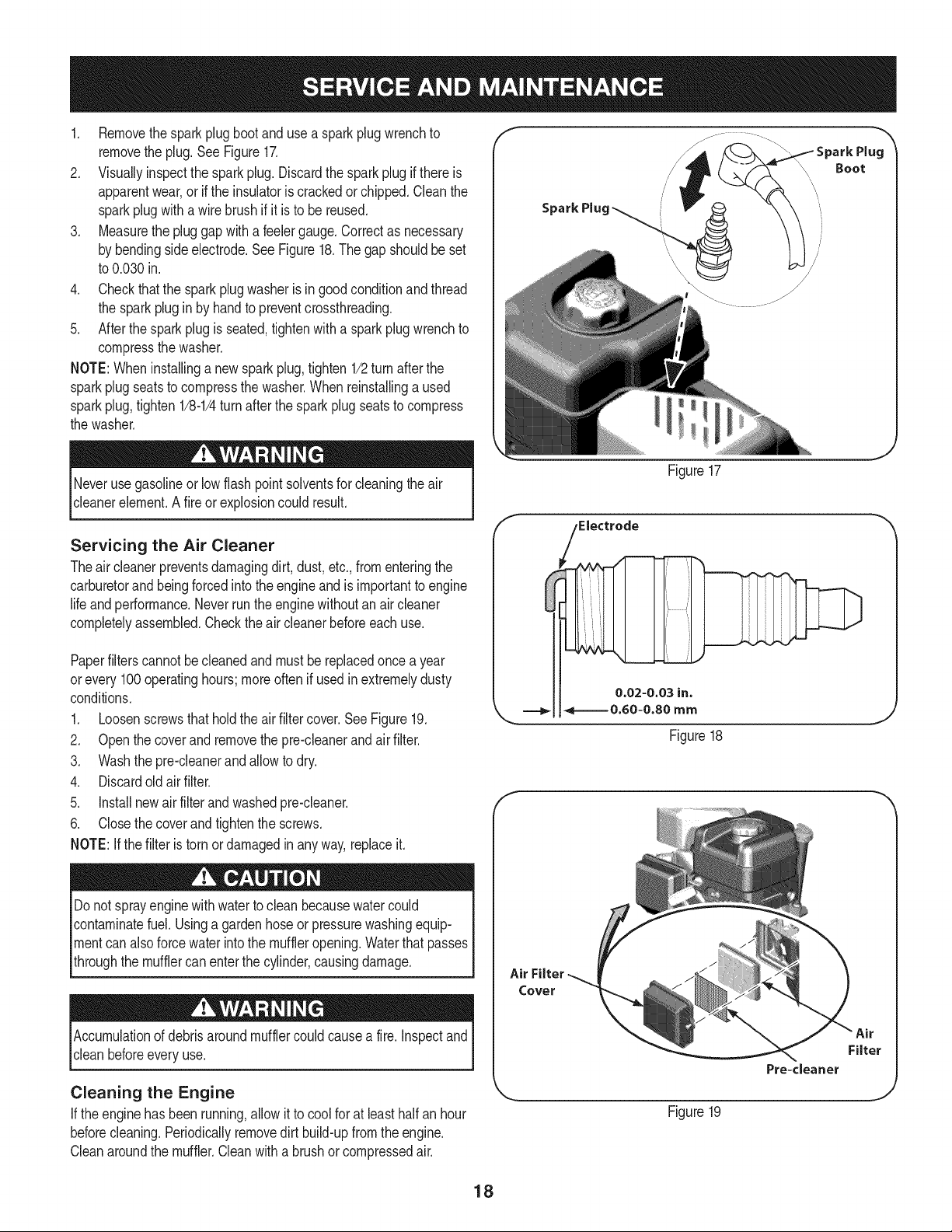

3. Measurethe pluggapwitha feelergauge.Correctas necessary

bybendingsideelectrode.SeeFigure18.Thegapshouldbeset

to0.030in.

4. Checkthatthe sparkplugwasherisingoodconditionandthread

thesparkplugin by handtopreventcrossthreading.

5. Afterthesparkplugis seated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2turnafterthe

sparkplugseatsto compressthewasher.Whenreinstallinga used

sparkplug,tighten1/8-1/4turnafterthesparkplugseatsto compress

thewasher.

Boot

Neverusegasolineorlowflashpointsolventsforcleaningthe air

ceanereement. A fre orexposoncou d resut.

Servicing the Air Cleaner

Theair cleanerpreventsdamagingdirt, dust,etc.,fromenteringthe

carburetorand beingforcedintothe engineandisimportanttoengine

lifeandperformance.Neverrunthe enginewithoutanaircleaner

completelyassembled.Checktheaircleanerbeforeeachuse.

Paperfilterscannotbecleanedandmustbe replacedonceayear

orevery 100operatinghours;moreoftenifusedin extremelydusty

conditions.

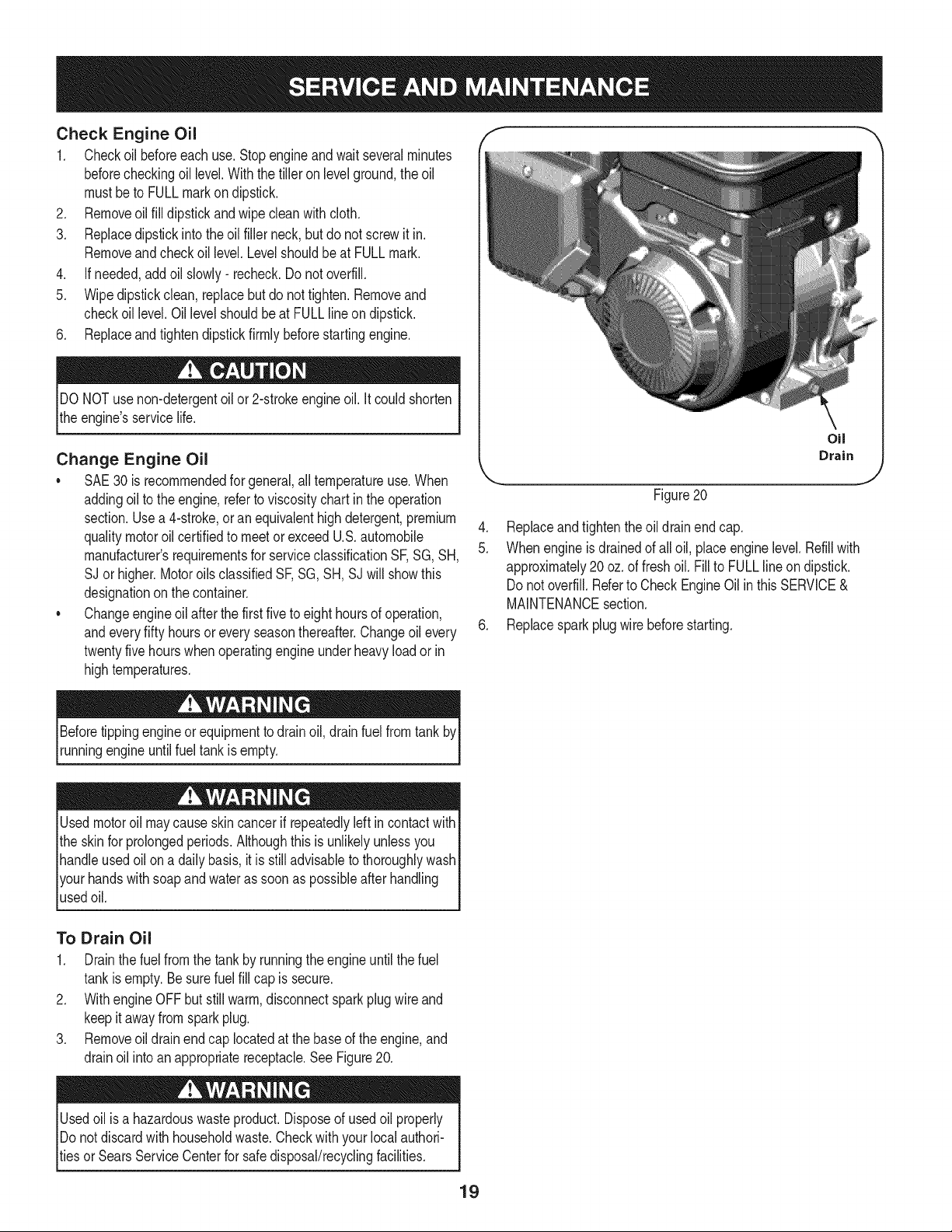

1. Loosenscrewsthatholdtheairfiltercover.SeeFigure19.

2. Openthecoverand removethepre-cleanerandairfilter.

3. Washthepre-cleanerandallowto dry.

4. Discardoldairfilter.

5. Installnewairfilterandwashedpre-cleaner.

6. Closethecoverandtightenthe screws.

NOTE:Ifthe filteristorn ordamagedinanyway,replaceit.

Donot sprayenginewithwatertoclean becausewatercould

contaminatefuel. Usinga gardenhoseorpressurewashingequip-

mentcanalso forcewaterintothe muffleropening.Waterthat passes

throughthemufflercanenterthe cylinder,causingdamage.

0.02-0.03 in.

===_1 _=====0.60=0.80 mm

E

Air Filter

Cover

Figure17

J

Figure18

Accumulationofdebrisaroundmufflercouldcausea fire.Inspectand

cleanbeforeeveryuse.

Cleaning the Engine

If theenginehasbeenrunning,allowitto coolfor atleasthalfan hour

beforecleaning.Periodicallyremovedirtbuild-upfromtheengine.

Cleanaroundthe muffler.Cleanwithabrushor compressedair.

Pre<leaner

J

Figure19

18

Check Engine Oil

1. Checkoilbeforeeachuse.Stopengineandwaitseveralminutes

beforecheckingoil level.Withthetilleron levelground,theoil

mustbeto FULLmarkon dipstick.

2. Removeoil filldipstickandwipe cleanwithcloth.

3. Replacedipstickintotheoilfiller neck,but donotscrewitin.

Removeandcheckoil level.Levelshouldbeat FULLmark.

4. If needed,addoil slowly- recheck.Donotoverfill.

5. Wipedipstickclean,replacebutdonot tighten.Removeand

checkoil level.Oillevelshouldbeat FULLlineondipstick.

6. Replaceandtightendipstickfirmlybeforestartingengine.

DONOTuse non-detergentoilor 2-strokeengineoil.Itcouldshorten

theengine'sservicelife.

Change Engine Oil

• SAE30 is recommendedforgeneral,all temperatureuse.When

addingoilto theengine,refertoviscositychartinthe operation

section.Usea4-stroke,oran equivalenthighdetergent,premium

qualitymotoroil certifiedto meetor exceedU.S.automobile

manufacturer'srequirementsfor serviceclassificationSF,SG, SH,

SJor higher.MotoroilsclassifiedSF,SG, SH,SJwill showthis

designationon thecontainer.

• Changeengineoil afterthefirst fivetoeight hoursofoperation,

andeveryfifty hoursoreveryseasonthereafter.Changeoil every

twentyfivehourswhenoperatingengineunderheavyloadorin

hightemperatures.

Figure20

4. Replaceandtightentheoildrainendcap.

5. Whenengineisdrainedofall oil, placeenginelevel.Refillwith

approximately20oz.offreshoil. Fillto FULLlineondipstick.

Donot overfill.Referto CheckEngineOilinthis SERVICE&

MAINTENANCEsection.

6. Replacesparkplugwirebeforestarting.

Beforetippingengineor equipmenttodrainoil,drainfuelfromtankby

runningengineuntilfuel tankisempty.

Usedmotoroil maycauseskincancerifrepeatedlyleftincontactwith

theskinfor prolongedperiods.Althoughthis isunlikelyunlessyou

handleusedoil ona daily basis,itisstilladvisableto thoroughlywash

yourhandswithsoapandwateras soonas possibleafter handling

usedoil.

To Drain Oil

1. Drainthefuelfromthe tankbyrunningtheengineuntilthefuel

tankisempty.Besurefuelfill capissecure.

2. WithengineOFFbutstillwarm,disconnectsparkplugwire and

keepitawayfromsparkplug.

3. Removeoil drainendcaplocatedatthebaseofthe engine,and

drainoil intoanappropriatereceptacle.SeeFigure20.

Usedoilisa hazardouswasteproduct.Disposeofusedoil properly

IDonotdiscardwithhouseholdwaste.Checkwithyourlocalauthori-

_tiesor SearsServiceCenterfor safedisposal/recyclingfacilities.

19

Check Transmission Gear Oil

Checkthetransmissiongearoilafterevery30 hoursofoperation

orwheneveryounoticeanyoil leak.Operatingthetiller whenthe

transmissionis lowon oilcan resultin severedamage.

ToChecktheTransmissionGearOil Level:

1. Checkthegearoil levelwhenthetransmissionis cool.Gearoil

willexpandinwarmoperatingtemperaturesandthis expansion

willprovidean incorrectoil levelreading.

2. Withthetiller on levelground,pulltheDepthRegulatorLeverall

thewayup.

3. Removetheoil fillplugfromthetransmissionhousingandlook

insidethe oilfillholeto locatethemaindriveshaftsituatedbelow

thehole.SeeFigure21.

4. Thegearoil leveliscorrectifthegearoilisapproximatelyhalfway

uptheside ofthe maindriveshaft.

5. If thegearoil levelislow,addgearoilasdescribednext.Ifthe

gearoillevelis okay,securelyreplacetheoil fillplug.

6. If addingonlya fewouncesofgearoil,useAPIratedGb4 or

Gb5 gearoil havingaviscosityof SAE 140,SAE85W-140or SAE

80W-90.Ifrefillinganemptytransmission,useonly Gb4 gearoil

havingaviscosityd SAE85W-140or SAE140.

7. Whilecheckingfrequentlytoavoidoverfilling,slowlyaddgearoil

intothe oilfill holeuntilit reachesthehalfwaypointon thedrive

shaft.

8. Securelyreplacetheoil fillplug.

\

Figure21

Handlebar

Hardware Depth Reg_

Change Transmission Gear Oil

Thetransmissiongearoildoesnotneedtobechangedunlessit has

beencontaminatedwithdirt, sandormetalparticles.Seeanautho-

rizedSearsServiceCentertohavethetransmissiongearoil changed

orto scheduleservice,simplycontactSearsat 1-800-4-MY-HOME®.

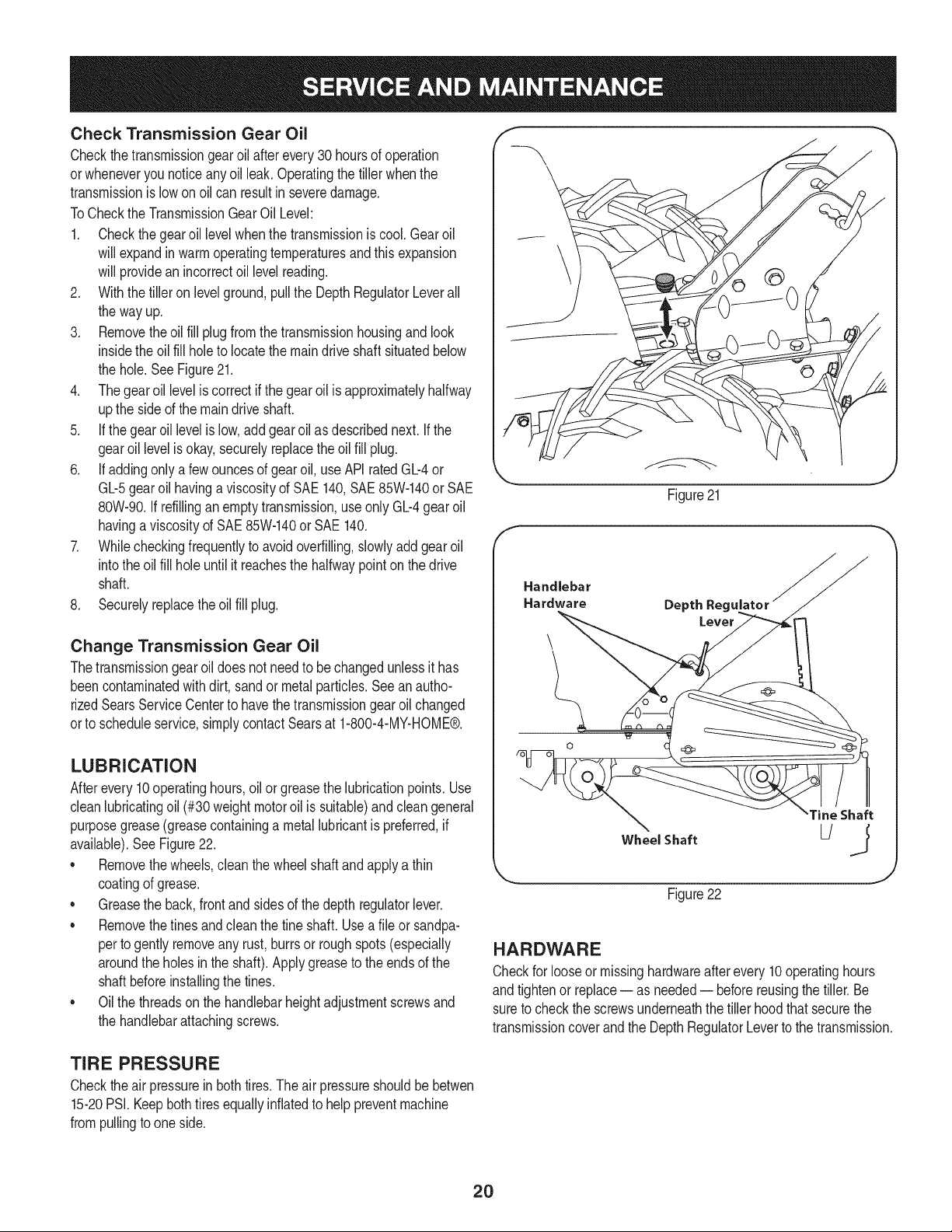

LUBRICATION

Afterevery10operatinghours,oilor greasethelubricationpoints.Use

cleanlubricatingoil(#30weightmotoroil is suitable)andcleangeneral

purposegrease(greasecontaininga metallubricantis preferred,if

available).SeeFigure22.

• Removethewheels,cleanthewheelshaft andapplya thin

coatingofgrease.

• Greasetheback,frontandsidesofthe depthregulatorlever.

• Removethetinesandcleanthefine shaft.Usea fileor sandpa-

pertogentlyremoveanyrust,burrsor roughspots(especially

aroundtheholesintheshaft).Applygreasetotheendsofthe

shaftbeforeinstallingthetines.

• Oilthe threadsonthehandlebarheightadjustmentscrewsand

thehandlebarattachingscrews.

TIRE PRESSURE

Checktheair pressurein bothtires.Theairpressureshouldbe betwen

15-20PSI.Keepbothtiresequallyinflatedto helppreventmachine

frompullingtooneside.

TineShaft

Wheel Shaft

J

Figure22

HARDWARE

Checkforlooseor missinghardwareafterevery10operatinghours

andtightenor replace-- as needed-- beforereusingthetiller.Be

sureto checkthe screwsunderneaththetillerhoodthat securethe

transmissioncoverandthe DepthRegulatorLevertothe transmission.

2O

Beforeperformingany typeofmaintenanceonthemachine,waitfor

all partsto stopmovinganddisconnectthesparkplugwire. Failure

tofollowthis instructioncouldresultinpersonalinjuryor property

damage.

BELT REPLACEMENT

Ifthedrive beltor augerbeltsneedto bereplaced,itis besttoreplace

bothbeltsat thesametime. Useonlyafactoryauthorizedbeltasan

"over-the-counter"beltmaynot performsatisfactorily.Theprocedure

requiresaveragemechanicalabilityandcommonlyavailabletools.

Toreplacethe DriveandAugerbelts,followthesesteps:

1. Makesurethe tillerisona flat surface,withthe engineturned

offandthe sparkplugwireunpluggedandgroundedto prevent

unintendedfiringofthe engine.

2. Removethe beltcoverbyfirst removingthetwo1/4-20self-

tappinghexscrews.SeeFigure23. Liftthe beltcoverupand

awayfromthetiller andsetin a safelocationuntilreinstallation.

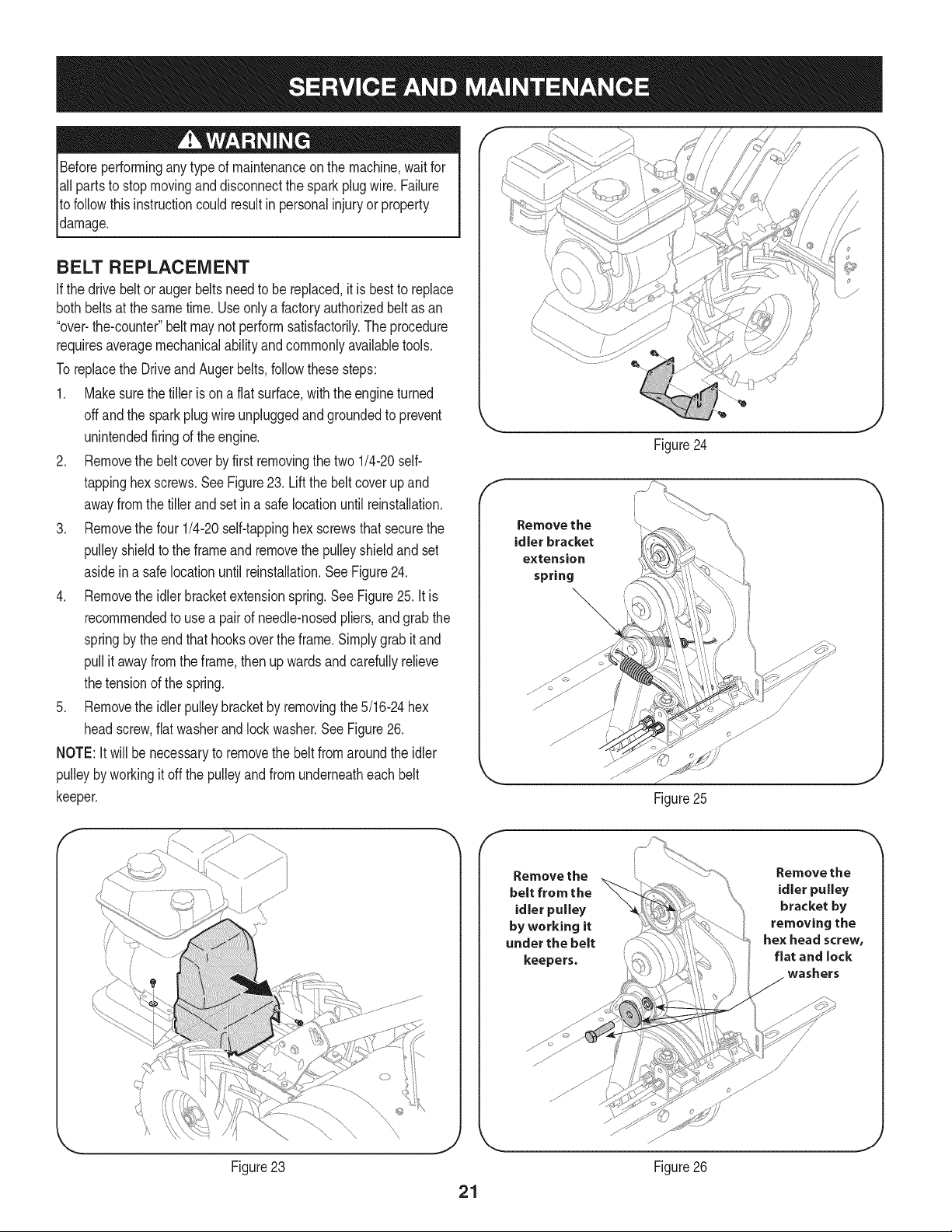

3. Removethefour 1/4-20self-tappinghexscrewsthatsecurethe

pulleyshieldtothe frameandremovethepulleyshieldandset

asideina safelocationuntilreinstallation.SeeFigure24.

4. Removethe idlerbracketextensionspring.SeeFigure25.It is

recommendedtousea pairof needle-nosedpliers,andgrabthe

springby theendthat hooksovertheframe.Simplygrabitand

pullitawayfromthe frame,thenupwardsandcarefullyrelieve

thetensionof thespring.

5. Removethe idlerpulleybracketbyremovingthe5/16-24hex

headscrew,flatwasherandlockwasher.SeeFigure26.

NOTE:It willbe necessarytoremovethe beltfromaroundtheidler

pulleybyworkingit offthe pulleyandfromunderneatheachbelt

keeper.

Figure24

Figure25

f

J

Figure23

f

Remove the

idler pulley

bracket by

removing the

he× head screw,

flat and lock

washers

Figure26

21

6. Removethehexboltssecuringthetransmissiondrivepulley,then

removethepulleyalongwiththetwobelts.SeeFigure27.

7. Replacetheold beltswiththe newbeltsin the sameorderthey

wereremoved.Thelongerbelt(1916658)belongscloserto the

engine,withthe shorterbelt(1916657)positionedcloserto the

tines.

8. Reinstallthetransmissiondrivepulleywiththe newbelts.

9. Reassemblethetillerinthereverseorderin whichitwasdisas-

sembled.

IMPORTANT:Whenreinstallingthebeltcover,besuretoengage

thebailandholdit sothatthe drivebelt istightbeforeattemptingto

reinstallthebeltcover.Thiswill enablethebelttofall underthebelt

keepingmechanismbuiltintothe beltcover.Failuretodo socould

damagethebeltand/or beltcover.

TINES

Thetineswill wearwithuseand shouldbeinspectedatthebeginning

ofeachtillingseasonandafterevery30 operatinghours.Thetines

canbereplaced.Refertothe PartsListsectionofthismanualforpart

numbers.

Tine inspection

Withuse,thetineswill becomeshorter,narrowerandpointed.Badly

worntineswill resultina lossoftilling depth,and reducedeffective-

nesswhenchoppingupandturningunderorganicmatter.

f

x

Figure27

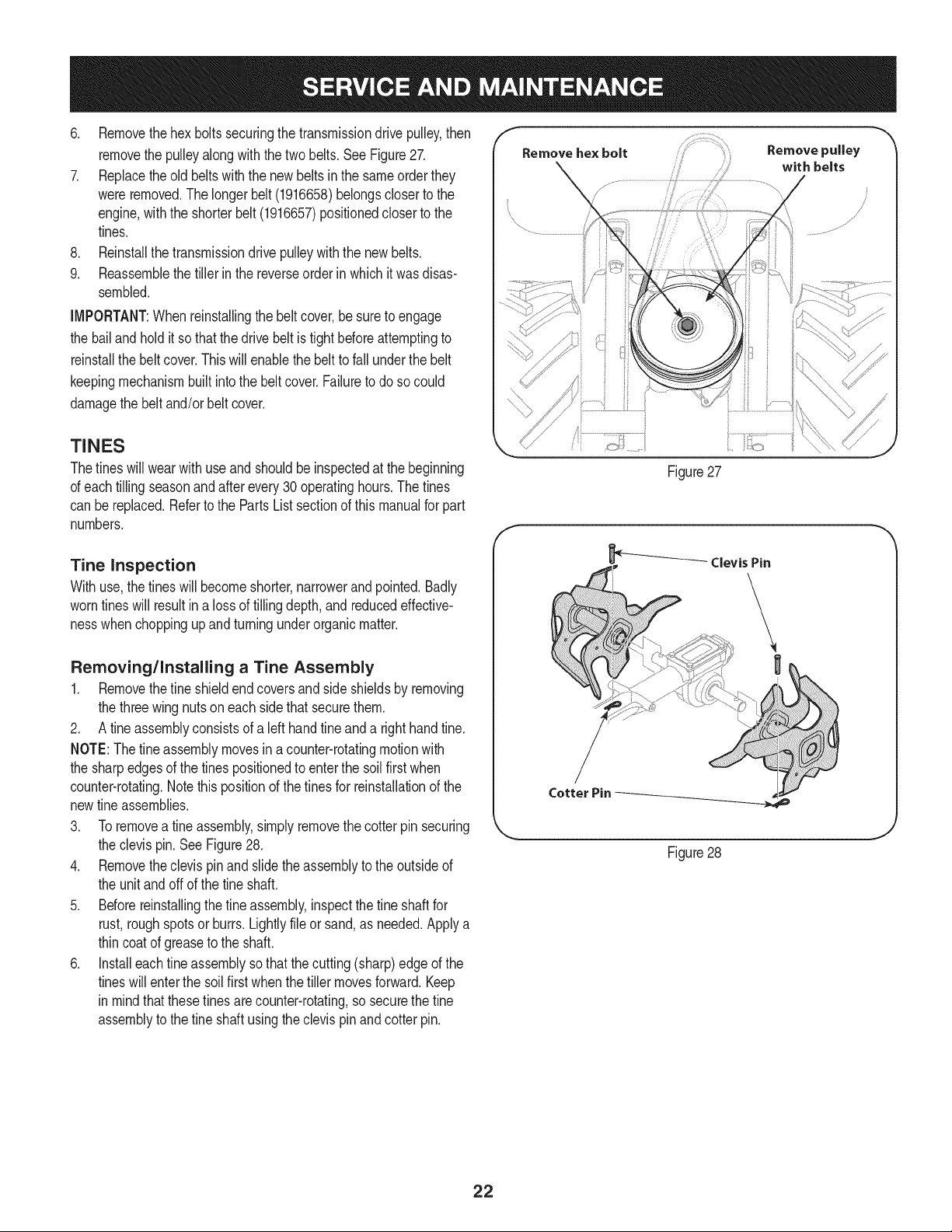

Removing/Installing a Tine Assembly

1. Removethefine shieldendcoversand sideshieldsby removing

thethreewingnutsoneach sidethatsecurethem.

2. A fineassemblyconsistsof a lefthandfineanda righthandtine.

NOTE:Thefineassemblymovesina counter-rotatingmotionwith

thesharpedgesofthetinespositionedtoenterthesoilfirstwhen

counter-rotating.Notethis positionof thetinesfor reinstallationofthe

newtine assemblies.

3. Toremovea tineassembly,simplyremovethecotterpin securing

theclevispin.SeeFigure28.

4. Removetheclevispinand slidetheassemblytotheoutsideof

theunitandoff ofthe tineshaft.

5. Beforereinstallingthe fineassembly,inspectthe fineshaftfor

rust,roughspotsor burrs.Lightlyfileor sand,as needed.Applya

thincoatof greaseto theshaft.

6. Installeachfineassemblyso thatthecutting (sharp)edgeof the

tineswillenterthesoil firstwhenthetiller movesforward.Keep

in mindthatthesetinesarecounter-rotating,sosecurethefine

assemblytothefineshaftusingtheclevispinandcotterpin.

J

Figure28

22

Loading...

Loading...