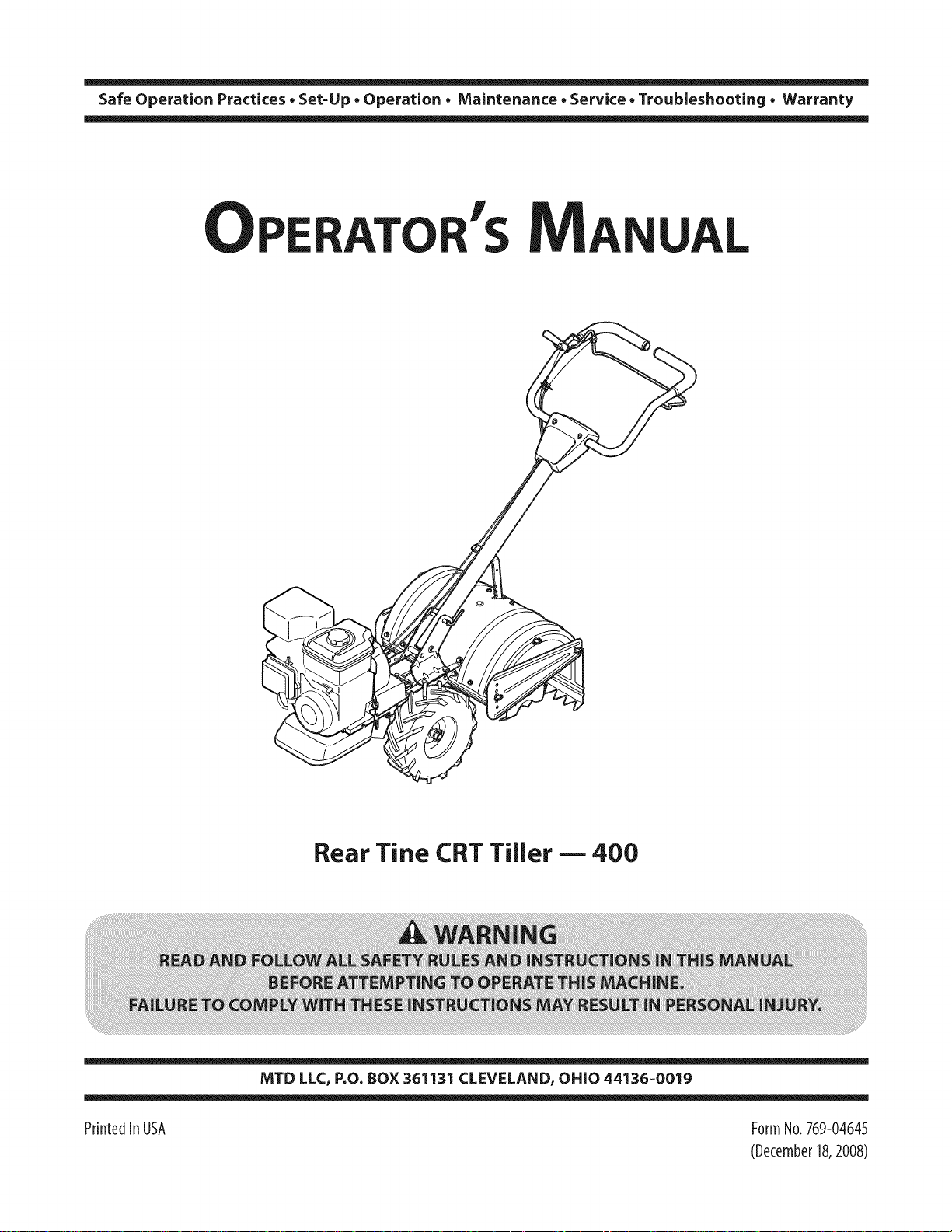

MTD 21AA404B031 Owner’s Manual

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

L

Rear Tine CRTTiller -- 400

MTD LLC, P.O. BOX 361131 CLEVELAND, OHiO 44136-0019

PrintedIn USA FormNo.769-04645

(December18,2008)

ToTheOwner

ThankYou

1

Thank you for purchasing a garden tiller manufactured by

MTD LLC. It was carefully engineered to provide excellent

performance when properly operated and maintained.

Please read this entire manual prior to operating the equipment.

It instructs you how to safely and easily set up, operate and

maintain your machine. Please be sure that you, and any other

persons who will operate the machine, carefully follow the

recommended safety practices at all times. Failure to do so could

result in personal injury or property damage.

All information in this manual is relative to the most recent

product information available at the time of printing. Review

this manual frequently to familiarize yourself with the machine,

its features and operation. Please be aware that this Operator's

Manual may cover a range of product specifications for various

models. Characteristics and features discussed and/or illustrated

in this manual may not be applicable to all models. MTD LLC

reserves the right to change product specifications, designs and

equipment without notice and without incurring obligation.

Tableof Contents

Safe Operation Practices ........................................ 3

Assembly & Set-Up .................................................. 7

Controls & Features ................................................ 10

Operation ................................................................ 12

Maintenance & Adjustments ................................. 17

If you have any problems or questions concerning the machine,

phone a authorized MTD service dealer or contact us directly.

MTD's Customer Support telephone numbers, website address

and mailing address can be found on this page. We want to

ensure your complete satisfaction at all times.

Throughout this manual, all references to right and left side of the

machine are observed from the operating position.

Service .................................................................... 20

Troubleshooting .................................................... 22

Replacement Parts ................................................ 23

Warranty ................................................................ 24

RecordProductInformation

Before setting up and operating your new equipment, please

locate the model plate on the equipment and record the

information in the provided area to the right. You can locate the

model plate by standing at the operator's position and looking

down at the rear of the tiller. This information will be necessary,

should you seek technical support via our web site, Customer

Support Department, or with a local authorized service dealer.

MODEL NUMBER

F1NF1NF1NF1NF1ND

SERIALNUMBER

DIqE]IqE]IqE]IqE]IqD

CustomerSupport

Please do NOT return the machine to the retailer or dealer without first contacting our Customer Support Department.

If you have difficulty assembling this product or have any questions regarding the controls, operation, or maintenance of

this machine, you can seek help from the experts. Choose from the options below:

0 Visit us on the web at www.mtdproducts.com

0 Call a Customer Support Representative at (800) 800-7:310 or (330) 220-468:3

0 Write us at MTD LLC • RO. Box :3611:31 • Cleveland, OH • 441:36-0019

ImportantSafeOperationPractices

WARNING! This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read and follow

all instructions in this manual before attempting to operate this machine. Failure to comply

with these instructions may result in personal injury.

When you see this symbol. HEED ITS WARNING!

CALIFORNIA PROPOSITION 65

WARNING! Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to State of California to cause cancer and birth defects

or other reproductive harm.

WARNING! Battery posts, terminals, and related accessories contain lead and lead

,A

compounds, chemicals known to the State of California to cause cancer and reproductive

harm. Wash hands after handling

DANGER! This machine was built to be operated according to the safe operation practices in

this manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. This machine is capable of amputating fingers, hands,

toes and feet. Failure to observe the following safety instructions could result in serious

injury or death.

2

Training 2.

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place for

future and regular reference and for ordering replacement

parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years of age to operate this

machine. Children 14 and over should read and understand

the instructions and safe operation practices in this manual

and on the machine and be trained and supervised by an

adult.

4_

Never allow adults to operate this machine without proper

instruction.

5.

Keep the area of operation clear of all persons, particularly

small children and pets. Stop machine if anyone enters the

area.

3. Disengage clutch levers and shift (if provided) into neutral

4. Never leave this machine unattended with the engine

5. Never attempt to make any adjustments while engine is

SafeHandlingofGasoline:

To avoid personal injury or property damage use extreme care

in handling gasoline. Gasoline is extremely flammable and the

vapors are explosive. Serious personal injury can occur when

gasoline is spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

Preparation

Thoroughly inspect the area where the equipment is to

be used. Remove all stones, sticks, wire, and other foreign

objects which could be tripped over and cause personal

injury.

Wear sturdy, rough-soled work shoes and close fitting

slacks and shirt. Loose fitting clothes or jewelry can be

caught in moving parts. Never operate this machine in bare

feet or sandals.

('N") before starting the engine.

running.

running, except where specifically recommended in the

operator's manual.

a. Use only an approved gasoline container.

b. Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

containers on the ground away from your vehicle

before filling.

When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment on

a trailer with a portable container, rather than from a

gasoline dispenser nozzle.

d_

Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times until fueling is

complete. Do not use a nozzle lock-open device.

e_

Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

fl

Never fuel machine indoors.

g.

Never remove gas cap or add fuel while the engine

is hot or running. Allow engine to cool at least two

minutes before refueling.

h. Never over fill fuel tank. Fill tank to no more than 1/2

inch below bottom of filler neck to allow space for

fuel expansion.

i. Replace gasoline cap and tighten securely.

j. If gasoline is spilled, wipe it off the engine and

equipment. Move unit to another area. Wait 5

minutes before starting the engine.

k. To reduce fire hazards, keep machine free of grass,

leaves, or other debris build-up. Clean up oil or fuel

spillage and remove any fuel soaked debris.

I. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

as on a water heater, space heater, furnace, clothes

dryer or other gas appliances.

Operation

1. Do not put hands or feet near rotating parts. Contact with

the rotating parts can amputate hands and feet.

2. Do not operate machine while under the influence of

alcohol or drugs.

3. Never operate this machine without good visibility or light.

Always be sure of your footing and keep a firm hold on the

handles.

4. Keep bystanders away from the machine while it is in

operation. Stop the machine if anyone enters the area.

5. Be careful when tilling in hard ground. The tines may catch

in the ground and propel the tiller forward. If this occurs,

letgo of the handle bars and do not restrain the machine.

6. Exercise extreme caution when operating on or crossing

gravel surfaces. Stay alert for hidden hazards or traffic. Do

not carry passengers.

7. Never operate the machine at high transport speeds on

hard or slippery surfaces.

8. Exercise caution to avoid slipping or falling.

9. Look down and behind and use care when in reverse or

pulling machine towards you.

10. Start the engine according to the instructions found in this

manual and keep feet well away from the tines at all times.

11. After striking a foreign object, stop the engine, disconnect

the spark plug wire and ground against the engine.

Thoroughly inspect the machine for any damage. Repair

the damage before starting and operating.

12. Disengage all clutch levers (if fitted) and stop engine

before you leave the operating position (behind the

handles). Wait until the tines come to a complete stop

before unclogging the tines, making any adjustments, or

inspections.

13. Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless

and deadly gas.

14. Muffler and engine become hot and can cause a burn. Do

not touch.

15. Use caution when tilling near fences, buildings and

underground utilities. Rotating tines can cause property

damage or personal injury.

16. Do not overload machine capacity by attempting to till soil

too deep at too fast of a rate.

17. If the machine should start making an unusual noise or

vibration, stop the engine, disconnect the spark plug wire

and ground it against the engine. Inspect thoroughly for

damage. Repair any damage before starting and operating.

18. Keep all shields, guards, and safety devices in place and

operating properly.

19. Never pick up or carry machine while the engine is running.

20. Use only attachments and accessories approved by the

manufacturer. Failure to do so can result in personal injury.

21. If situations occur which are not covered in this manual, use

care and good judgement. Contact Customer Support for

assistance and the name of you nearest servicing dealer..

Maintenance & Storage

1. Keep machine, attachments and accessories in safe

working order.

2. Allow a machine to cool at least five minutes before

storing. Never tamper with safety devices. Check their

proper operation regularly.

3. Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4. Before cleaning, repairing, or inspecting, stop the engine

and make certain the tines and all moving parts have

stopped. Disconnect the spark plug wire and ground it

against the engine to prevent unintended starting.

5. Do not change the engine governor settings or over-speed

the engine. The governor controls the maximum safe

operating speed of engine.

6. Maintain or replace safety and instruction labels, as

necessary.

7. Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

8. Always refer to the operator's manual for important details

if the machine is to be stored for an extended period.

4 J SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES

9_

If the fuel tank has to be drained, do this outdoors.

10.

Observe proper disposal laws and regulations for gas, oil,

etc. to protect the environment.

11.

According to the Consumer Products Safety Commission

(CPSC) and the U.S. Environmental Protection Agency (EPA),

this product has an Average Useful Life of seven (7) years,

or 130 hours of operation. Atthe end of the Average Useful

Life have the machine inspected annually by an authorized

service dealer to ensure that all mechanical and safety

systems are working properly and not worn excessively.

Failure to do so can result in accidents, injuries or death.

Notice Regarding Emissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and

may include the following emission control systems: Engine

Modification (EM), Oxidizing Catalyst (OC), Secondary Air

Injection (SAI) and Three Way Catalyst (TWC) if so equipped.

SparkArrestor

internal combustion engine and should not be used

_ ARNING! This machine is equipped with an

Ira spark arrester is used, it should be maintained in effective

working order by the operator. In the State of California the

above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws

apply on federal lands.

A spark attester for the muffler is available through your

nearest engine authorized service dealer or contact the service

department, RO. Box 361131 Cleveland, Ohio 44136-0019.

on or near any unimproved forest-covered,

brushcovered or grass-covered land unless the

engine's exhaust system is equipped with a spark

arrester meeting applicable local or state laws (if

any).

SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES S

Safety Symbols

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the

machine before attempting to assemble and operate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to

assemble and operate

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

A

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine

and muffler to cool before touching.

WARNING! Your Responsibility--Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

6 I SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES

SAVETHESEINSTRUCTIONS!

Assembly& Set-Up

Contentsof Carton

OneTiller

WARNING! To prevent personal injury or property

damage, do not start the engine until all assembly

steps are complete and you have read and

understand the Safe Operation Practices Section

and the Operating Section in this manual.

Assembly

UnpackingInstructions

NOTE:While unpacking, do not severely bend any of the control

cables.

1. The tiller is heavy, do not attempt to remove it from

the shipping platform until instructed to do so in these

Assembly steps.

2. Remove all parts from the carton. Check that you have the

items listed in the Contents of Carton list (contact your

local dealer or the factory if items are missing or damaged).

3. Remove any packaging material from the carton. Remove

any staples from the bottom of the carton and remove the

carton from the shipping platform.

Handle

NOTE: All references to the right or left side of the tiller are from

the operator's position.

1. Install the handle onto the tiller using the hardware pre-

installed on the handle mounting brackets. This consists of

a 5/16-18 x 3.00" hex bolt, a handle crank assembly, retainer

bracket and two 5/16-18 flange lock nuts. Remove this

hardware from the handle mounting brackets on the tiller.

2. Insert the handle into the handle mounting brackets, lining

up the pre-drilled holes. Insert the 5/16-18 x 3.00" hex bolt

in the bottom hole from the left hand side through to the

other side. Place the round hole end of the hex retainer

bracket over the hex bolt and secure loosely with a bell

washer and 5/16-18 flange lock nut removed earlier.

Note:The bell washer should be positioned with the top

of the bell shape towards the hex nut which will create

tension and further secure the flange lock nut once

tightened. Do not tighten this hardware at this time.

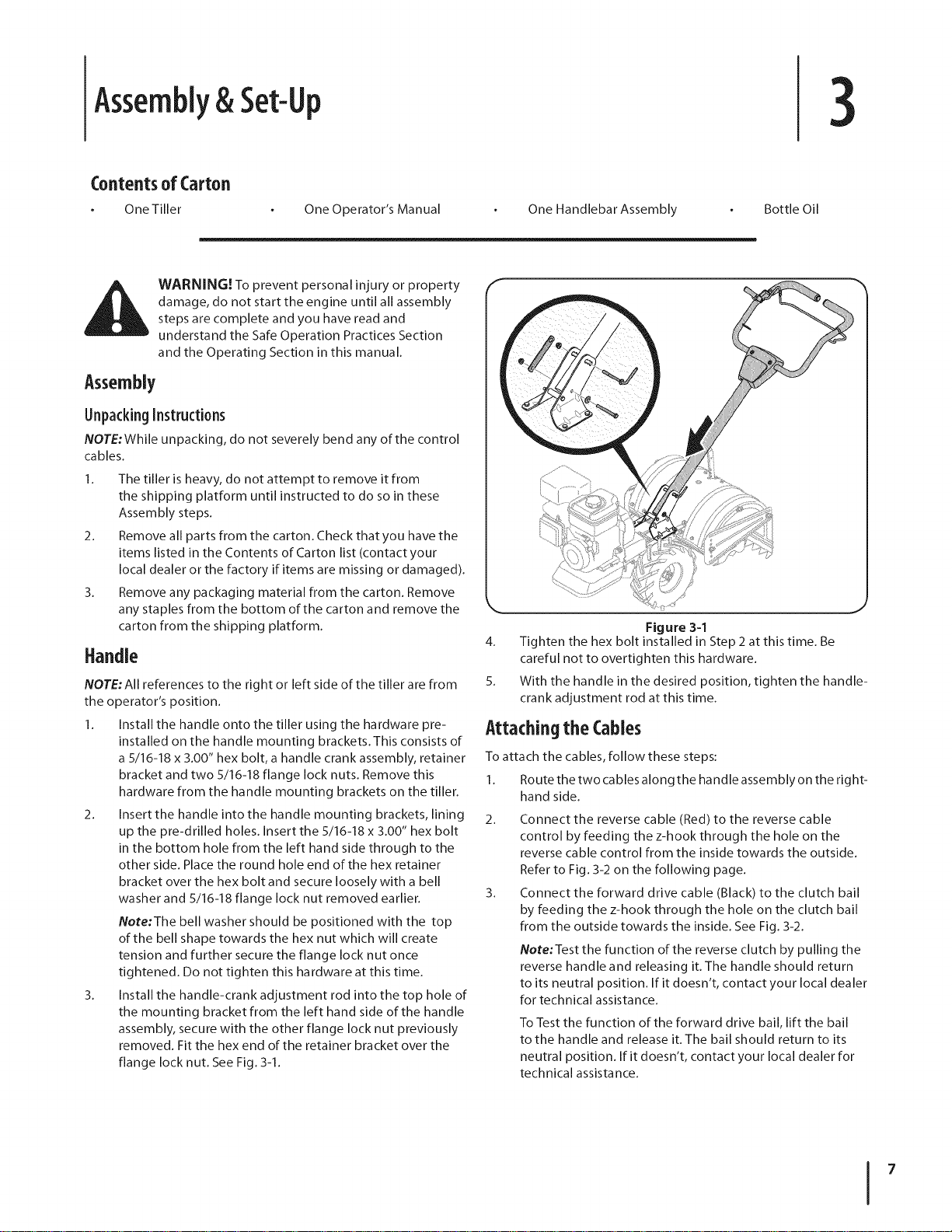

3. Install the handle-crank adjustment rod into the top hole of

the mounting bracket from the left hand side of the handle

assembly, secure with the other flange lock nut previously

removed. Fit the hex end of the retainer bracket over the

flange lock nut. See Fig. 3-1.

One Operator's Manual One Handlebar Assembly

Bottle Oil

Tighten the hex bolt installed in Step 2 at this time. Be

careful not to overtighten this hardware.

5.

With the handle in the desired position, tighten the handle-

crank adjustment rod at this time.

Figure 3=1

Attachingthe Cables

To attach the cables, follow these steps:

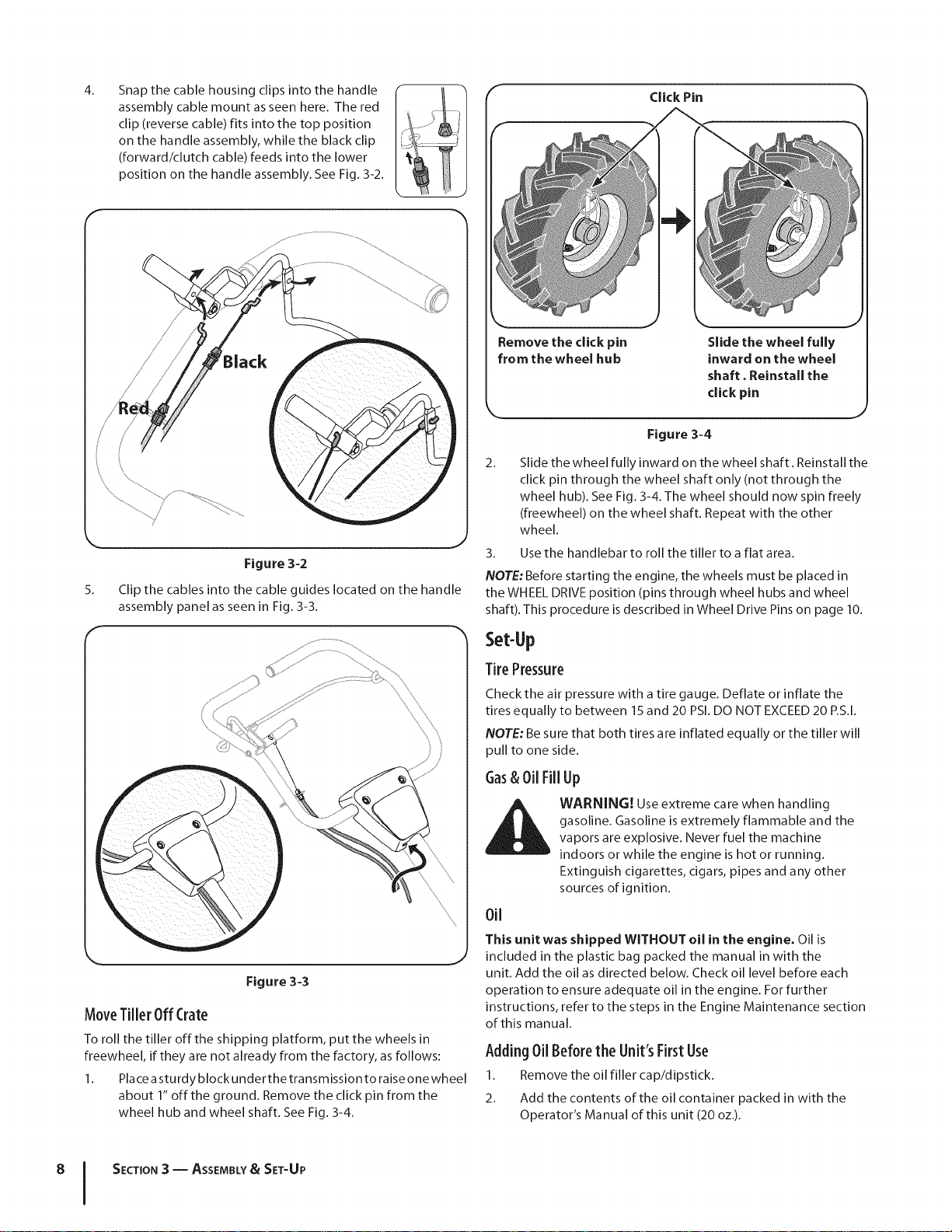

1.

Route the two cables along the handle assembly on the right-

hand side.

2.

Connect the reverse cable (Red) to the reverse cable

control by feeding the z-hook through the hole on the

reverse cable control from the inside towards the outside.

Refer to Fig. 3-2 on the following page.

3.

Connect the forward drive cable (Black) to the clutch bail

by feeding the z-hook through the hole on the clutch bail

from the outside towards the inside. See Fig. 3-2.

Note:Test the function of the reverse clutch by pulling the

reverse handle and releasing it. The handle should return

to its neutral position. If it doesn't, contact your local dealer

for technical assistance.

To Test the function of the forward drive bail, lift the bail

to the handle and release it. The bail should return to its

neutral position. If it doesn't, contact your local dealer for

technical assistance.

3

4_

Snap the cable housing clips into the handle

assembly cable mount as seen here. The red

clip (reverse cable) fits into the top position

on the handle assembly, while the black clip

forward/clutch cable) feeds into the lower

)osition on the handle assembly. See Fig. 3-2.

Figure 3-2

5. Clip the cables into the cable guides located on the handle

assembly panel as seen in Fig. 3-3.

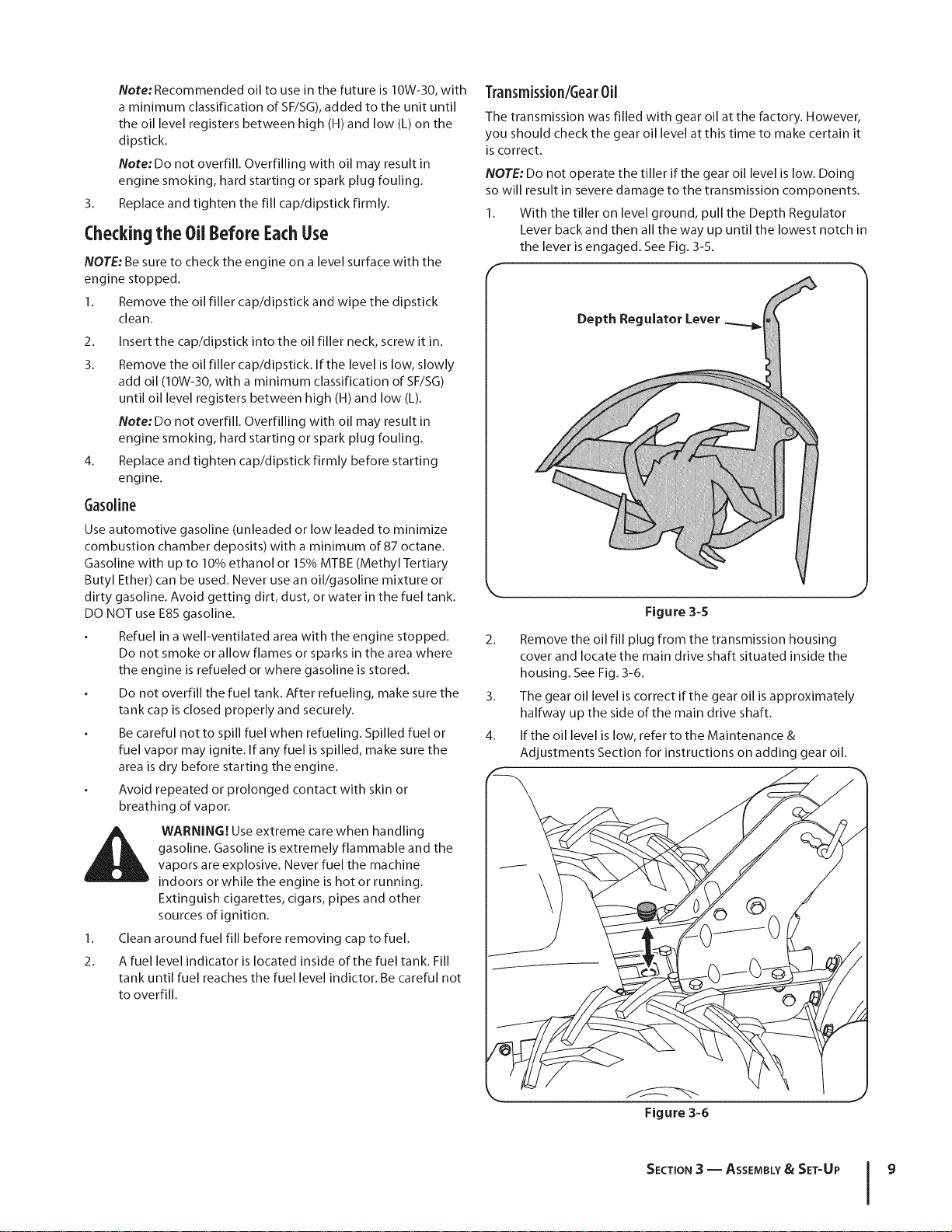

Click Pin

Remove the dick pin Slide the wheel fully

from the wheel hub inward on the wheel

shaft. Reinstall the

click pin

\ ,J

Figure 3-4

2_

Slide the wheel fully inward on the wheel shaft. Reinstall the

click pin through the wheel shaft only (not through the

wheel hub). See Fig. 3-4. The wheel should now spin freely

(freewheel) on the wheel shaft. Repeat with the other

wheel.

3. Use the handlebar to roll the tiller to a flat area.

NOTE: Before starting the engine, the wheels must be placed in

the WHEEL DRIVE position (pins through wheel hubs and wheel

shaft). This procedure is described in Wheel Drive Pins on page 10.

Figure 3-3

MoveTiller Off Crate

To roll the tiller off the shipping platform, put the wheels in

freewheel, if they are not already from the factory, as follows:

1. Place a sturdy block under the transmission to raise one wheel

about 1" off the ground. Remove the click pin from the

wheel hub and wheel shaft. See Fig. 3-4.

Set-Up

TirePressure

Check the air pressure with a tire gauge. Deflate or inflate the

tires equally to between 15 and 20 PSI. DO NOT EXCEED 20 P.S.I.

NOTE: Be sure that both tires are inflated equally or the tiller will

pull to one side.

Gas&OilFillUp

_ ARNING! Use extreme care when handling

0il

This unit was shipped WITHOUT oil in the engine. Oil is

included in the plastic bag packed the manual in with the

unit. Add the oil as directed below. Check oil level before each

operation to ensure adequate oil in the engine. For further

instructions, refer to the steps in the Engine Maintenance section

of this manual.

Adding Oil Beforethe Unit'sFirstUse

1. Remove the oil filler cap/dipstick.

2. Add the contents of the oil container packed in with the

gasoline. Gasoline is extremely flammable and the

vapors are explosive. Never fuel the machine

indoors or while the engine is hot or running.

Extinguish cigarettes, cigars, pipes and any other

sources of ignition.

Operator's Manual of this unit (20 oz.).

8 I SECTION3 -- ASSEMBLY& SET-UP

Note: Recommended oil to use in the future is 10W-30,with

a minimum classification of SF/SG),added to the unit until

the oil level registers between high (H) and low (L)on the

dipstick.

Note: Do not overfill. Overfilling with oil may result in

engine smoking, hard starting or spark plug fouling.

3.

Replaceand tighten the fill cap/dipstick firmly.

Checkingthe OilBefore EachUse

NOTE: Be sure to check the engine on a level surface with the

engine stopped.

1. Remove the oil filler cap/dipstick and wipe the dipstick

clean.

2. Insert the cap/dipstick into the oil filler neck, screw it in.

3. Remove the oil filler cap/dipstick. If the level is low, slowly

add oil (10W-30, with a minimum classification of SF/SG)

until oil level registers between high (H) and low (L).

Note: Do not overfill. Overfilling with oil may result in

engine smoking, hard starting or spark plug fouling.

4. Replace and tighten cap/dipstick firmly before starting

engine.

6as01ine

Use automotive gasoline (unleaded or low leaded to minimize

combustion chamber deposits) with a minimum of 87 octane.

Gasoline with up to 10% ethanol or 15% MTBE (Methyl Tertiary

Butyl Ether) can be used. Never use an oil/gasoline mixture or

dirty gasoline. Avoid getting dirt, dust, or water in the fuel tank.

DO NOT use E85 gasoline.

Refuel in a well-ventilated area with the engine stopped.

Do not smoke or allow flames or sparks in the area where

the engine is refueled or where gasoline is stored.

Do not overfill the fuel tank. After refueling, make sure the

tank cap is closed properly and securely.

Be careful not to spill fuel when refueling. Spilled fuel or

fuel vapor may ignite. If any fuel is spilled, make sure the

area is dry before starting the engine.

Avoid repeated or prolonged contact with skin or

breathing of vapor.

WARNING! Useextreme care when handling

gasoline. Gasoline isextremely flammable and the

vapors are explosive. Never fuel the machine

indoors or while the engine is hot or running.

Extinguish cigarettes, cigars, pipes and other

sources of ignition.

1.

Clean around fuel fill before removing cap to fuel.

2.

Afuel level indicator is located inside of the fuel tank. Fill

tank until fuel reaches the fuel level indictor. Becareful not

to overfill.

Transmissi0n/GearOil

The transmission was filled with gear oil at the factory. However,

you should check the gear oil level at this time to make certain it

is correct,

NOTE: Do not operate the tiller if the gear oil level is low. Doing

so will result in severe damage to the transmission components.

1. With the tiller on level ground, pull the Depth Regulator

Lever back and then all the way up until the lowest notch in

the lever is engaged. See Fig. 3-5.

F

Depth Regulator Lever

Figure 3-5

2. Remove the oil fill plug from the transmission housing

cover and locate the main drive shaft situated inside the

housing. See Fig. 3-6.

3. The gear oil level is correct if the gear oil is approximately

halfway up the side of the main drive shaft.

4. If the oil level is low, refer to the Maintenance &

Adjustments Section for instructions on adding gear oil.

Figure 3-6

SECTION 3 -- ASSEMBLY& SET-UP 9

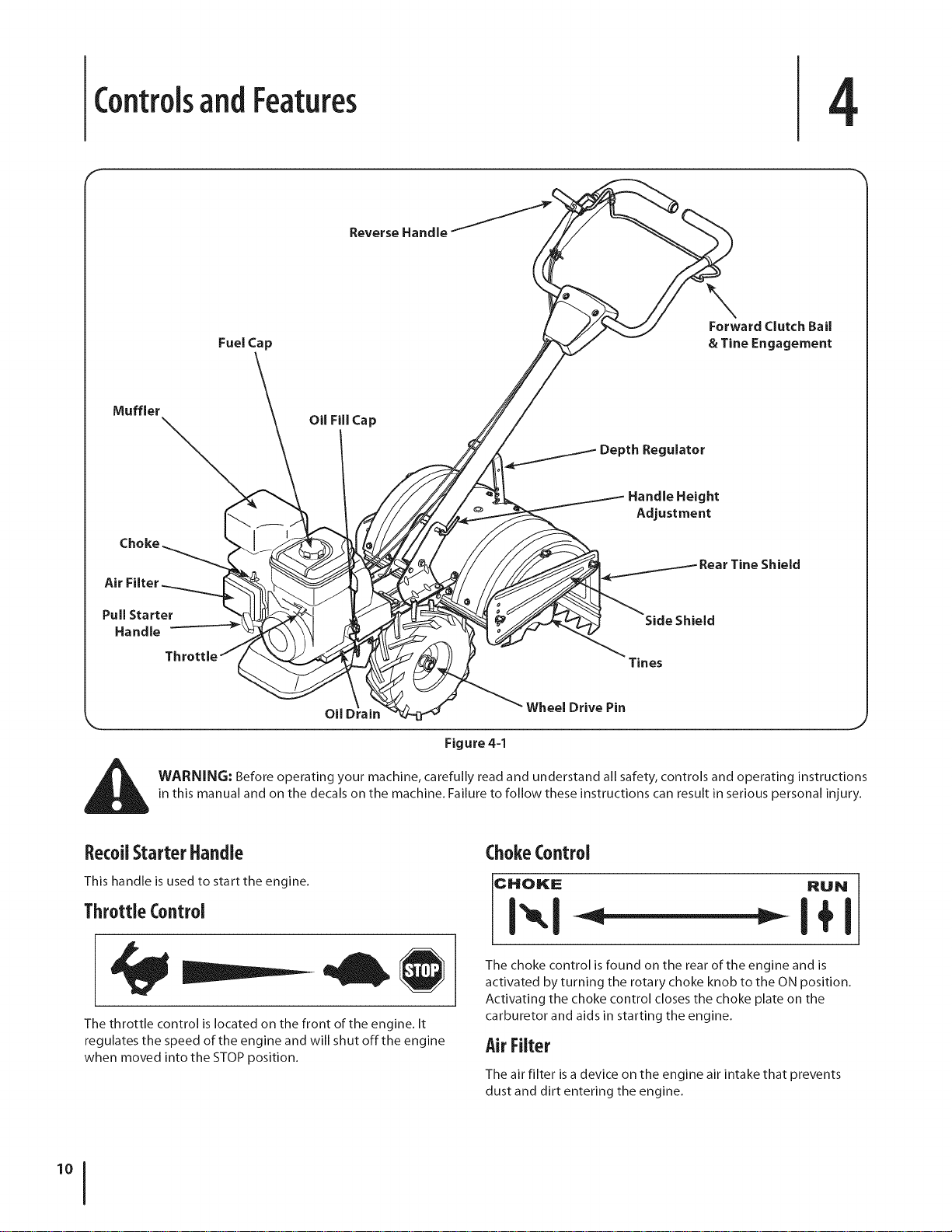

ControlsandFeatures

f

Reverse Handle

Fuel Cap

Oil Fill Cap

4

\

Forward Clutch Bail

& Tine Engagement

Depth Regulator

Handle Height

Adjustment

Air Filter

Pull Starter

Handle

WARNING: Before operating your machine, carefully read and understand all safety, controls and operating instructions

in this manual and on the decals on the machine. Failure to follow these instructions can result in serious personal injury.

RecoilStarter Handle

This handle is used to start the engine.

Throttle Control

The throttle control is located on the front of the engine. It

regulates the speed of the engine and will shut off the engine

when moved into the STOP position.

Shield

Side Shield

Tines

Wheel Drive Pin

Figure 4-1

ChokeControl

CHOKE RUN

The choke control is found on the rear of the engine and is

activated by turning the rotary choke knob to the ON position.

Activating the choke control closes the choke plate on the

carburetor and aids in starting the engine.

AirFilter

The air filter is a device on the engine air intake that prevents

dust and dirt entering the engine.

Muffler

RearTineShield

Engine exhaust exits the engine via the muffler.

FuelCap

Unscrew the fuel cap to add gasoline to the fuel tank. This unit

runs on regular gas.

Oil Fill Cap& Dipstick

Engine oil level can be checked and oil added through the oil fill.

NOTE: This unit was shipped WITHOUT oil in the engine. Oil

is included in the plastic bag packed the manual in with the unit.

Add the oil as directed in the Setup section. Check the oil level

before each operation to ensure adequate oil is in the engine. For

further instructions, refer to the steps in the Engine Maintenance

section of this manual.

ReverseHandle

The Reverse Handle controls the reverse drive of the wheels and

tines.

ForwardClutchBail& TineEngagement

The forward clutch bail controls the engagement of the forward

drive of the wheels and tines.

DepthRegulator Lever

This lever controls the tilling depth of the tines. Pull the lever

back and slide it up or down to engage the notched height

settings.

The rear tine shield protects the operator from flying debris

while also smoothing out freshly tilled soil.

SideShield

The side shield is used to maintain clear even rows and may be

adjusted to one of five different positions.

Tines

Your tiller's tines are a series of hoes arranged on a revolving

power-driven shaft.

WheelDrivePins

Each wheel isequipped with a wheel drive click pin that secures

the wheel to the wheel shaft. The wheels can be positioned in

either a WHEEL DRIVE or a FREEWHEEL mode.

Oil Drain

Removing the oil drain plug will drain the oil from the engine.

HandlebarHeightAdjustment

The handlebar height isadjustable to three different settings. In

general, adjust the handlebars sothey are at waist level when the

tines are 3-4" in the ground.

SECTION 4 -- CONTROLS AND FEATURES 11

Operation

WARNING: Before operating your machine,

carefully read and understand this manual and all of

its safety, operating and maintenance sections and

instructions, along with all of the decals on the

machine. Failure to follow these instructions can

result in serious personal injury.

introduction

Read this Operation Section and the Engine Maintenance section

of this manual before you start the engine. Then, take the time

to familiarize yourself with the basic operation of the tiller before

using it in the garden.

Find an open, level area and practice using the tiller controls

without the tines engaging the soil (put tines in "transport"

setting).

Only after you've become completely familiar with the tiller

should you begin using it in the garden.

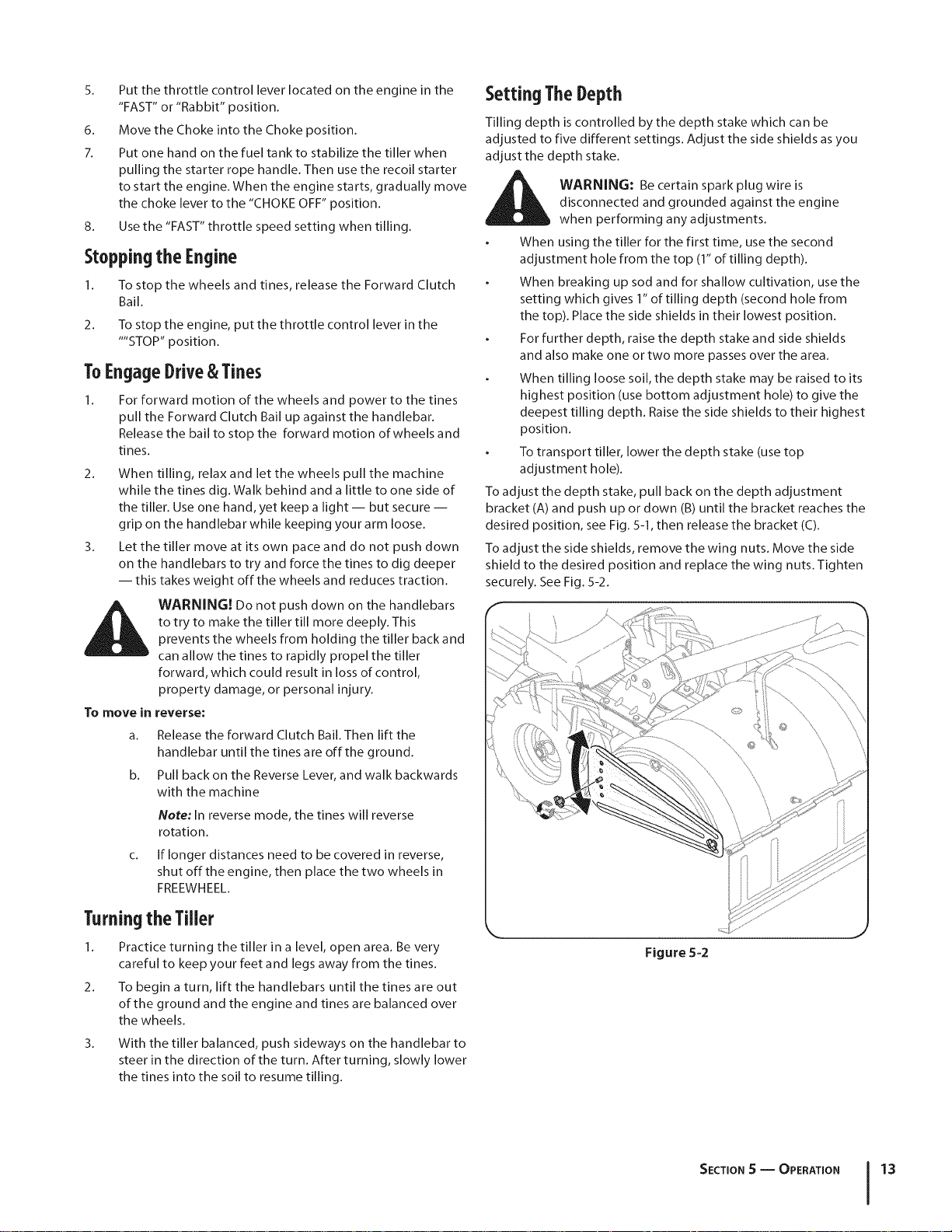

ToPutTheTinesinTransport:

Pull back on the depth adjustment bracket (A) and push down

(B) until the bracket reaches the highest notch. See Fig. 5-1. Then

release the bracket (C).

\J

Starting AndStopping

Pre-StartChecklist

With the spark plug wire disconnected from the spark plug,

perform the following checks and services before each use:

1. Read the Safety and Controls Sections in this manual. Read

the Engine Maintenance section in this manual.

2. Put the wheels in the WHEEL DRIVE position (wheel pins

must be through holes in wheel hubs and wheel shaft).

3. Check unit for loose or missing hardware. Service as

required.

4. Check engine oil level. See Engine Maintenance section.

5. Check that all safety guards and covers are in place.

6. Check air cleaner and engine cooling system. See the

Engine Maintenance section.

ITSVAPORS ARE EXPLOSIVE. Follow the gasoline

WARNING: GASOLINE IS HIGHLY FLAMMABLE AND

safety rules in the Important Safe Operations

Practices section of this manual. Failure to follow

gasoline safety instructions can result in serious

personal injury and property damage.

7. Fill the fuel tank with gasoline according to the directions

in the Assembly & Set-Up section of this Manual. Follow all

instructions and safety rules carefully.

8. Attach spark plug wire to spark plug.

Figure S-1

Break-inOperation

Perform the following maintenance after the first five (5) hours of

new operation (see Maintenance Sections in this manual).

1. Change engine oil.

2. Check for loose or missing hardware on unit. Tighten or

replace as needed.

3. Check transmission gear oil level.

Starting the Engine

or damage to equipment, put both wheels in the

WARNING! To help prevent serious personal injury

WHEEL DRIVE position. Never have wheels in

FREEWHEEL position when the engine is running.

When the wheels are in FREEWHEEL, they do not

hold back the tiller and the tines could propel the

tiller rapidly forward or backward. Put the Forward

Clutch Bail in neutral (disengaged) positions by

releasing the lever.

WARNING! Never run the engine indoors or in an

enclosed, poorly ventilated area. Engine exhaust

contains carbon monoxide, an odorless and deadly

gas. Avoid the engine muffler and nearby areas.

Temperatures in these areas may exceed 150° F.

1. Complete the Pre-Start Checklist above on this page.

2. Put the wheels in the WHEEL DRIVE position.

3. Move the Depth Regulator Lever all the way down to the

"transport" position, so that the tines clear the ground.

4. Release all of the controls on the tiller.

5. Putthethrottlecontrolleverlocatedontheengineinthe

"FAST"or"Rabbit"position.

6. MovetheChokeintotheChokeposition.

7. Putonehandonthefueltanktostabilizethetillerwhen

pullingthestarterropehandle.Thenusetherecoilstarter

tostarttheengine.Whentheenginestarts,graduallymove

thechokelevertothe"CHOKEOFF"position.

8. Usethe"FAST"throttlespeedsettingwhentilling.

Stopping the Engine

1. To stop the wheels and tines, release the Forward Clutch

Bail.

2. To stop the engine, put the throttle control lever in the

....STOP" position.

ToEngageDrive&Tines

1.

For forward motion of the wheels and power to the tines

pull the Forward Clutch Bail up against the handlebar.

Release the bail to stop the forward motion of wheels and

tines.

2. When tilling, relax and let the wheels pull the machine

while the tines dig. Walk behind and a little to one side of

the tiller. Use one hand, yet keep a light -- but secure --

grip on the handlebar while keeping your arm loose.

3. Let the tiller move at its own pace and do not push down

on the handlebars to try and force the tines to dig deeper

-- this takes weight off the wheels and reduces traction.

WARNING! Do not push down on the handlebars

to try to make the tiller till more deeply. This

prevents the wheels from holding the tiller back and

can allow the tines to rapidly propel the tiller

forward, which could result in loss of control,

property damage, or personal injury.

To move in

reverse:

Release the forward Clutch Bail. Then lift the

a.

handlebar until the tines are off the ground.

b.

Pull back on the Reverse Lever, and walk backwards

with the machine

Note: In reverse mode, the tines will reverse

rotation.

If longer distances need to be covered in reverse,

shut offthe engine, then place the two wheels in

FREEWHEEL.

Setting TheDepth

Tilling depth is controlled by the depth stake which can be

adjusted to five different settings. Adjust the side shields as you

adjust the depth stake.

_ ARNING: Be certain spark plug wire is

To adjust the depth stake, pull back on the depth adjustment

bracket (A) and push up or down (B) until the bracket reaches the

desired position, see Fig. 5-1, then release the bracket (C).

To adjust the side shields, remove the wing nuts. Move the side

shield to the desired position and replace the wing nuts. Tighten

securely. See Fig. 5-2.

disconnected and grounded against the engine

when performing any adjustments.

When using the tiller for the first time, use the second

adjustment hole from the top (1" of tilling depth).

When breaking up sod and for shallow cultivation, use the

setting which gives 1" of tilling depth (second hole from

the top). Place the side shields in their lowest position.

For further depth, raise the depth stake and side shields

and also make one or two more passes over the area.

When tilling loose soil, the depth stake may be raised to its

highest position (use bottom adjustment hole) to give the

deepest tilling depth. Raise the side shields to their highest

position.

To transport tiller, lower the depth stake (use top

adjustment hole).

Turning the Tiller

1. Practice turning the tiller in a level, open area. Be very

careful to keep your feet and legs away from the tines.

2. To begin a turn, lift the handlebars until the tines are out

of the ground and the engine and tines are balanced over

the wheels.

3.

With the tiller balanced, push sideways on the handlebar to

steer in the direction of the turn. After turning, slowly lower

the tines into the soil to resume tilling.

Figure 5-2

SECTION S -- OPERATION 13

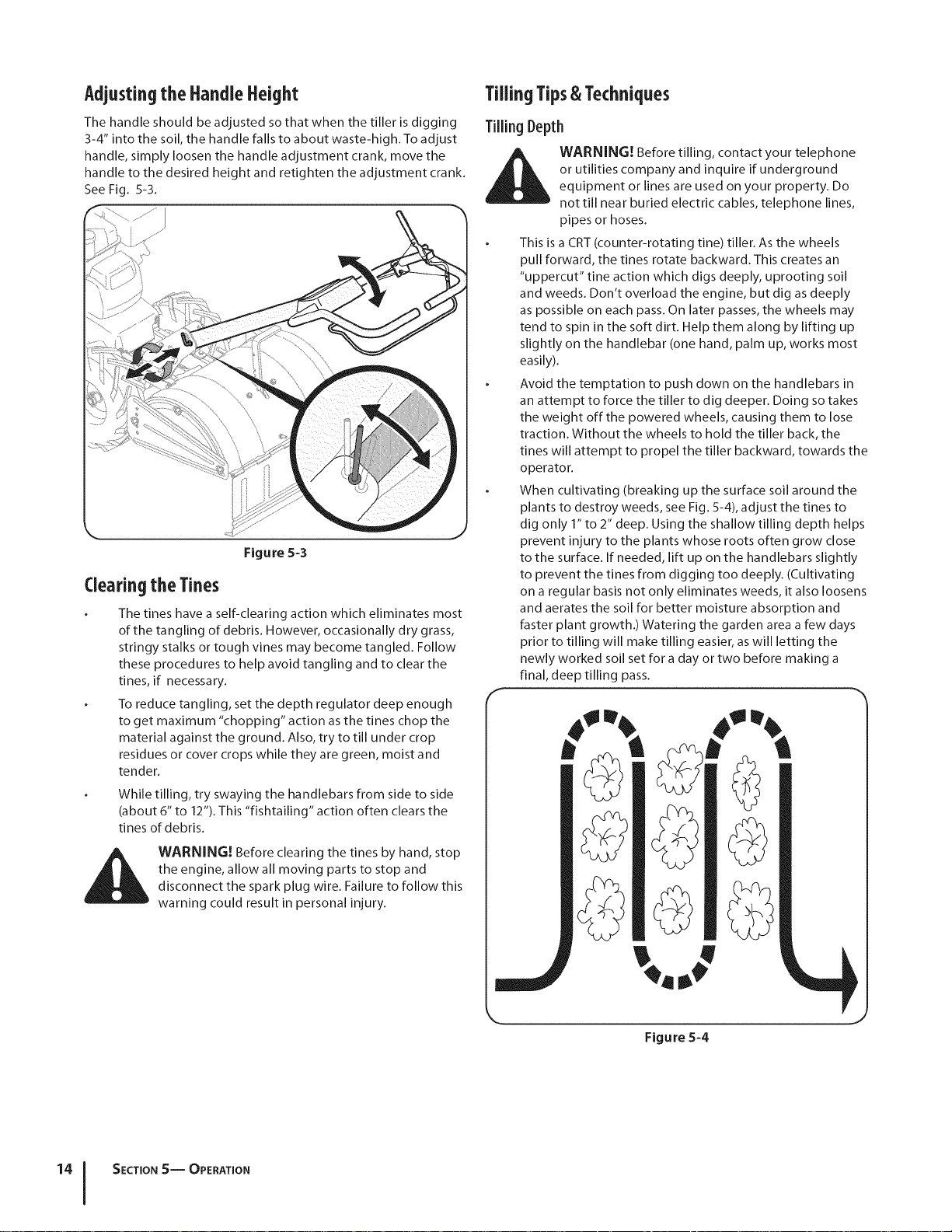

Adjustingthe HandleHeight

The handle should be adjusted so that when the tiller is digging

3-4" into the soil, the handle falls to about waste-high. To adjust

handle, simply loosen the handle adjustment crank, move the

handle to the desired height and retighten the adjustment crank.

See Fig. 5-3.

/

jJ"

Figure 5-3

Clearingthe Tines

The tines have a self-clearing action which eliminates most

of the tangling of debris. However, occasionally dry grass,

stringy stalks or tough vines may become tangled. Follow

these procedures to help avoid tangling and to clear the

tines, if necessary.

To reduce tangling, set the depth regulator deep enough

to get maximum "chopping" action as the tines chop the

material against the ground. Also, try to till under crop

residues or cover crops while they are green, moist and

tender.

While tilling, try swaying the handlebars from side to side

(about 6" to 12"). This "fishtailing" action often clears the

tines of debris.

WARNING! Before clearing the tines by hand, stop

the engine, allow all moving parts to stop and

disconnect the spark plug wire. Failure to follow this

warning could result in personal injury.

Tilling Tips& Techniques

TillingDepth

or utilities company and inquire if underground

WARNING! Before tilling, contact your telephone

equipment or lines are used on your property. Do

not till near buried electric cables, telephone lines,

pipes or hoses.

This is a CRT (counter-rotating tine) tiller. As the wheels

pull forward, the tines rotate backward. This creates an

"uppercut" tine action which digs deeply, uprooting soil

and weeds. Don't overload the engine, but dig as deeply

as possible on each pass. On later passes, the wheels may

tend to spin in the soft dirt. Help them along by lifting up

slightly on the handlebar (one hand, palm up, works most

easily).

Avoid the temptation to push down on the handlebars in

an attempt to force the tiller to dig deeper. Doing so takes

the weight off the powered wheels, causing them to lose

traction. Without the wheels to hold the tiller back, the

tines will attempt to propel the tiller backward, towards the

operator.

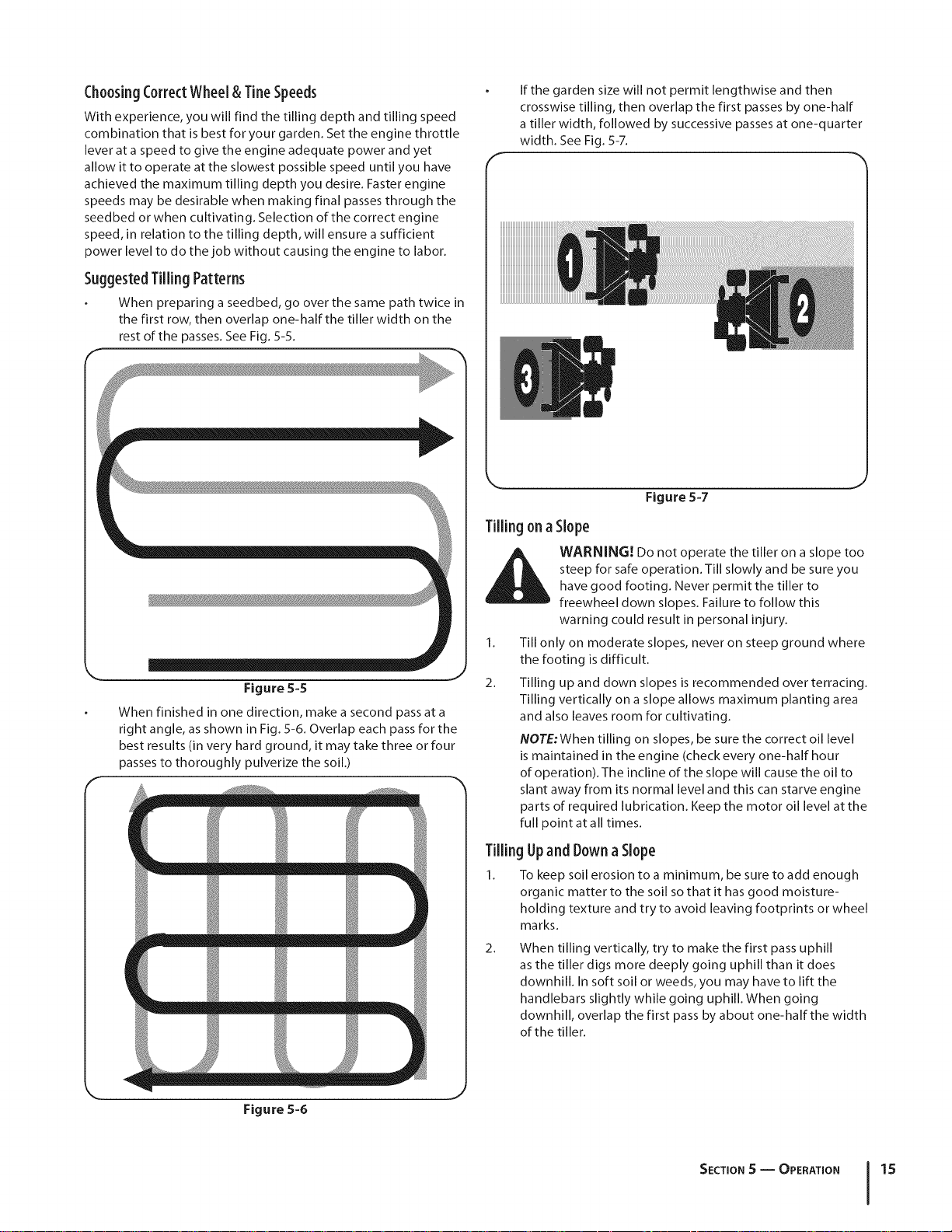

When cultivating (breaking up the surface soil around the

plants to destroy weeds, see Fig. 5-4), adjust the tines to

dig only 1" to 2" deep. Using the shallow tilling depth helps

prevent injury to the plants whose roots often grow close

to the surface. If needed, lift up on the handlebars slightly

to prevent the tines from digging too deeply. (Cultivating

on a regular basis not only eliminates weeds, it also loosens

and aerates the soil for better moisture absorption and

faster plant growth.) Watering the garden area a few days

prior to tilling will make tilling easier, as will letting the

newly worked soil set for a day or two before making a

final, deep tilling pass.

F

SECTION S-- OPERATION

J

Figure 5-4

ChoosingCorrectWheel& TineSpeeds

With experience, you will find the tilling depth and tilling speed

combination that is best for your garden. Set the engine throttle

lever at a speed to give the engine adequate power and yet

allow it to operate at the slowest possible speed until you have

achieved the maximum tilling depth you desire. Faster engine

speeds may be desirable when making final passes through the

seedbed or when cultivating. Selection of the correct engine

speed, in relation to the tilling depth, will ensure a sufficient

power level to do the job without causing the engine to labor.

SuggestedTilling Patterns

When preparing a seedbed, go over the same path twice in

the first row, then overlap one-half the tiller width on the

rest of the passes. See Fig. 5-5.

If the garden size will not permit lengthwise and then

crosswise tilling, then overlap the first passes by one-half

a tiller width, followed by successive passes at one-quarter

width. See Fig. 5-7.

F

Figure 5-7

Tilling ona Slope

Figure 5=5

When finished in one direction, make a second pass at a

right angle, as shown in Fig. 5-6. Overlap each pass for the

best results (in very hard ground, it may take three or four

passes to thoroughly pulverize the soil.)

/Imllll Iimmllml Ilmmlml

; i

illlmlm _ m_lmlil _

]

steep for safe operation. Till slowly and be sure you

WARNING! Do not operate the tiller on a slope too

have good footing. Never permit the tiller to

freewheel down slopes. Failure to follow this

warning could result in personal injury.

1. Till only on moderate slopes, never on steep ground where

the footing is difficult.

2. Tilling up and down slopes is recommended over terracing.

Tilling vertically on a slope allows maximum planting area

and also leaves room for cultivating.

NOTE:When tilling on slopes, be sure the correct oil level

is maintained in the engine (check every one-half hour

of operation). The incline of the slope will cause the oil to

slant away from its normal level and this can starve engine

parts of required lubrication. Keep the motor oil level at the

full point at all times.

TillingUpand Downa Slope

1. To keep soil erosion to a minimum, be sure to add enough

organic matter to the soil so that it has good moisture-

holding texture and try to avoid leaving footprints or wheel

marks.

2,

When tilling vertically, try to make the first pass uphill

as the tiller digs more deeply going uphill than it does

downhill. In soft soil or weeds, you may have to lift the

handlebars slightly while going uphill. When going

downhill, overlap the first pass by about one-half the width

of the tiller.

Figure 5-6

J

SECTION S -- OPERATION 15

Loading...

Loading...