MTD 21a665b766-proline Parts Manuals

For Parts Call 606-678-9623 or 606-561-4983

For Parts Call 606-678-9623 or 606-561-4983

Operator’s Manual

Rear-tine Tiller Model

663B —Pony

663E —Pony

665B —ProLine

®

®

®

Engine styles vary by model

E663E —Pony® ES

IMPORTANT:READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any).

If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required by law

(Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester

for the muffler is available by contacting the service department at Troy-Bilt LLC, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC, P.O. BOX 361131, CLEVELAND, OH 44136-0019

PRINTED IN USA FROM NO. 770-10597E

10/20/2006

www.mymowerparts.com

www.mymowerparts.com

Copy Model Number Here

Copy Serial Number Here

www.troybilt.com

TROY-BILT LLC

P. O. BOX

361 1 3 1

CLEVELAND, OH 44136

866-840-6483

330-558-7220

For Parts Call 606-678-9623 or 606-561-4983

For Parts Call 606-678-9623 or 606-561-4983

2

TABLE OF CONTENTS

Content Page

Calling Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Features and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Tiller Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Warrany Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Back Cover

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new Rear-tine Tiller. It will help you assemble, prepare and maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and copy the information from it in the space provided below. This information is very important if you need help from our Customer

Support Department or an authorized dealer.

• You can locate the model number by looking at the rear surface of the tine shield. A sample model plate is

explained below. For future reference, please copy the model number and the serial number of the equipment in

the space below

ENGINE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating, specifications, warranty and service. Please refer to the engine manufacturer’s Owner’s/Operator’s Manual packed separately with your unit for more information.

CALLING CUSTOMER SUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance

of this unit, please call the Customer Support Department.

Call 1- (330) 558-7220 or 1- (866) 840-6483 to reach a Customer Support representative. Please have

your unit’s model number and serial number ready when you call. See previous section to locate this information. You will be asked to enter the serial number in order to process your call .

For more details about your unit, visit our website at www.troybilt.com

www.mymowerparts.com

www.mymowerparts.com

For Parts Call 606-678-9623 or 606-561-4983

For Parts Call 606-678-9623 or 606-561-4983

Section

3

1

Safety Alert Symbol

This is a safety alert symbol. It is used in this

manual and on the unit to alert you to potential

hazards. When you see this symbol, read and

obey the message that follows it. Failure to obey

safety messages could result in personal injury or property damage.

TRAINING

1. Carefully read this

Owner’s Manual, the

separate Engine Owner’s

Manual, and any other

literature you may receive. Be thoroughly

familiar with the controls and the proper

use of the tiller and its engine. Know how

to stop the unit and disengage the controls quickly.

2. Never allow children to operate the

tiller. Never allow adults to operate the

tiller without proper instruction.

3. Keep the area of operation clear of all

persons, particularly children and pets.

4. Keep in mind that the operator or user

is responsible for accidents or hazards

occurring to other people, their property

and themselves.

PREPARATION

1. Thoroughly inspect the area where the

tiller is to be used and remove all foreign

objects.

2. Be sure all controls are released and

the Wheel Gear Lever is in ENGAGE

before starting the engine.

3. Do not operate the tiller without

wearing adequate outer garments. Avoid

loose garments or jewelry that could get

caught in moving parts.

4. Do not operate the tiller when barefoot

or wearing sandals, sneakers, or light

footwear. Wear protective footwear that will

improve footing on slippery surfaces.

5. Do not till near underground electric

cables, telephone lines, pipes or hoses. If

in doubt, contact your telephone or utility

company.

6. Warning: Handle fuel with care; it is

highly flammable and its vapors are explosive. Take the following precautions:

a. Store fuel in containers specifically

designed for this purpose.

b. The gas cap shall never be removed

or fuel added while the engine is

running. Allow the engine to cool

for several minutes before adding

fuel.

c. Keep matches, cigarettes, cigars,

pipes, open flames, and sparks

away from the fuel tank and fuel

container.

d. Fill fuel tank outdoors with extreme

care. Never fill fuel tank indoors.

Use a funnel or spout to prevent

spillage.

e. Replace all fuel tank and container

caps securely.

f. If fuel is spilled, do not attempt

to start the engine, but move the

machine away from the area of

spillage and avoid creating any

source of ignition until fuel vapors

have dissipated.

7. Never make adjustments when engine

is running (unless recommended by

manufacturer).

Safety

This machine meets voluntary safety standard B71.8

– 1996, which is sponsored by the Outdoor Power

Equipment Institute, Inc., and is published by the

American National Standards Institute.

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

OPERATION

1. Do not put hands or feet near or under

rotating parts.

2. Exercise extreme caution when on or

crossing gravel drives, walks, or roads.

Stay alert for hidden hazards or traffic. Do

not carry passengers.

3. After striking a foreign object, stop

the engine (and remove the ignition key

on electric start models), disconnect

the spark plug wire and prevent it from

touching the spark plug, carefully inspect

the tiller for any damage, and repair the

damage before restarting and operating

the tiller.

4. Exercise caution to avoid slipping or

falling.

5. If the unit should start to vibrate abnormally, stop the engine (and remove the

ignition key on electric start models).

Disconnect the spark plug wire and prevent

it from touching the spark plug, and check

immediately for the cause. Vibration is

generally a warning of trouble.

6. Stop the engine (and remove the ignition key on electric start models), disconnect the spark plug wire and prevent it

from touching the spark plug whenever

you leave the operating position, before

unclogging the tines, or when making any

repairs, adjustments or inspections.

www.mymowerparts.com

www.mymowerparts.com

For Parts Call 606-678-9623 or 606-561-4983

For Parts Call 606-678-9623 or 606-561-4983

4 Section 1: Safety

7. Take all possible precautions when

leaving the machine unattended. Stop the

engine. Remove ignition key on electric

start models. Disconnect spark plug wire

and move it away from the spark plug.

Move Wheel Gear Lever to ENGAGE.

8. Before cleaning, repairing, or inspecting, stop the engine, remove the ignition

key on electric start models, and make

certain all moving parts have stopped.

Disconnect the spark plug wire and

prevent it from touching the spark plug

to prevent accidental starting. On electric

start models, always remove the cable

from the negative side (–) of the battery.

9. Always keep the tiller tine hood flap

down, unless using the hiller/furrower

attachment.

10. Never use the tiller unless proper

guards, plates, or other safety protective

devices are in place.

11. Do not run engine in an enclosed

area. Engine exhaust contains carbon

monoxide gas, a deadly poison that is

odorless, colorless, and tasteless.

12. Keep children and pets away.

13. Never operate the tiller under

engine power if the Wheel Gear Lever

is in DISENGAGE (FREEWHEEL). In

this position, the wheels will not hold

the tiller back and the revolving tines

could propel the tiller rapidly, possibly

causing loss of control. Always move

the Wheel Gear Lever to ENGAGE before

starting the engine or engaging the tines/

wheels with the Forward Clutch Control or

the Reverse Clutch Control.

14. Be aware that the tiller may unexpectedly bounce upward or jump

forward if the tines should strike

extremely hard packed soil, frozen

ground, or buried obstacles like large

stones, roots, or stumps. If in doubt

about the tilling conditions, always use

the following operating precautions to

assist you in maintaining control of the

tiller:

a. Walk behind and to one side of

the tiller, using one hand on the

handlebars. Relax your arm, but

use a secure hand grip.

b. Use shallower depth regulator set-

tings, working gradually deeper

with each pass.

c. Use slower engine speeds.

d. Clear the tilling area of all large

stones, roots and other debris.

e. Avoid using downward pressure on

handlebars. If need be, use slight

upward pressure to keep the tines

from digging too deeply.

f. Before contacting hard packed soil

at the end of a row, reduce engine

speed and lift handlebars to raise

tines out of the soil.

g. In an emergency, stop tines and

wheels by releasing whichever

Clutch Lever is engaged. Do not

attempt to restrain the tiller.

15. Do not overload the tiller’s capacity

by attempting to till too deeply at too fast

a rate.

16. Never operate the tiller at high transport speeds on hard or slippery surfaces.

Look behind and use care when backing

up.

17. Do not operate the tiller on a slope

that is too steep for safety. When on

slopes, slow down and make sure you

have good footing. Never permit the tiller

to freewheel down slopes.

18. Never allow bystanders near the unit.

19. Only use attachments and accessories

that are approved by the tiller

manufacturer.

20. Use tiller attachments and accessories when recommended.

21. Never operate the tiller without good

visibility or light.

22. Never operate the tiller if you are

tired, or under the influence of alcohol,

drugs or medication.

23. Operators shall not tamper with the

engine-governor settings on the machine;

the governor controls the maximum safe

operating speed to protect the engine and

all moving parts from damage caused by

overspeed. Authorized service shall be

sought if a problem exists.

24. Do not touch engine parts which may

be hot from operation. Let parts cool

down sufficiently.

25. The battery on electric start model

tillers contains sulfuric acid. Avoid

contact with skin, eyes, or clothing. Keep

out of the reach of children.

Antidote–

diately with lots of water.

Antidote–

ties of water or milk. Follow with milk of

magnesia, beaten eggs or vegetable oil.

Call a doctor immediately.

Antidote–

for 15 minutes. Get prompt medical

attention.

26. Batteries produce explosive gases.

Keep sparks, flame, and smoking materials

away. Ventilate when charging batteries or

when using a battery in an enclosed space.

ALWAYS wear safety goggles when working

near batteries.

27. Please remember: You can always

stop the tines and wheels by releasing

the Forward Clutch Control Lever or the

Reverse Clutch Control knob (whichever

control you have engaged), or by moving

the Engine Throttle Control Lever (located

on engine) to STOP on recoil start models

or by turning the ignition key to OFF on

electric start models.

28. To load or unload the tiller, see the

instructions in Section 4 of this Manual.

29. Use extreme caution when reversing or

pulling the machine towards you.

30. Start the engine carefully according to

instructions and with feet well away from

the tines.

31. Never pick up or carry a machine while

the engine is running.

External Contact: Flush imme-

Internal: Drink large quanti-

Eye Contact: Flush with water

MAINTENANCE AND STORAGE

1. Keep the tiller, attachments and accessories in safe working condition.

2. Check all nuts, bolts, and screws at

frequent intervals for proper tightness to

be sure the equipment is in safe working

condition.

3. Never store the tiller with fuel in the

fuel tank inside a building where ignition

sources are present such as hot water and

space heaters, furnaces, clothes dryers,

stoves, electric motors, etc. Allow engine to

cool before storing in any enclosure.

www.mymowerparts.com

www.mymowerparts.com

STOP

STOP

For Parts Call 606-678-9623 or 606-561-4983

For Parts Call 606-678-9623 or 606-561-4983

Section 1: Safety 5

4. To reduce the chances of a fire

hazard, keep the engine free of grass,

leaves, or excessive grease.

5. Store gasoline in a cool, well-ventilated area, safely away from any sparkor flame-producing equipment. Store

gasoline in an approved container,

safely away from the reach of children.

6. Refer to the Maintenance section of

this Manual and in the separate Engine

Owner’s Manual for instructions if the

tiller is to be stored for an extended

period.

7. Never perform maintenance while

the engine is running or the spark plug

wire is connected, except when specifically instructed to do so.

8. If the fuel tank has to be drained, do

this outdoors.

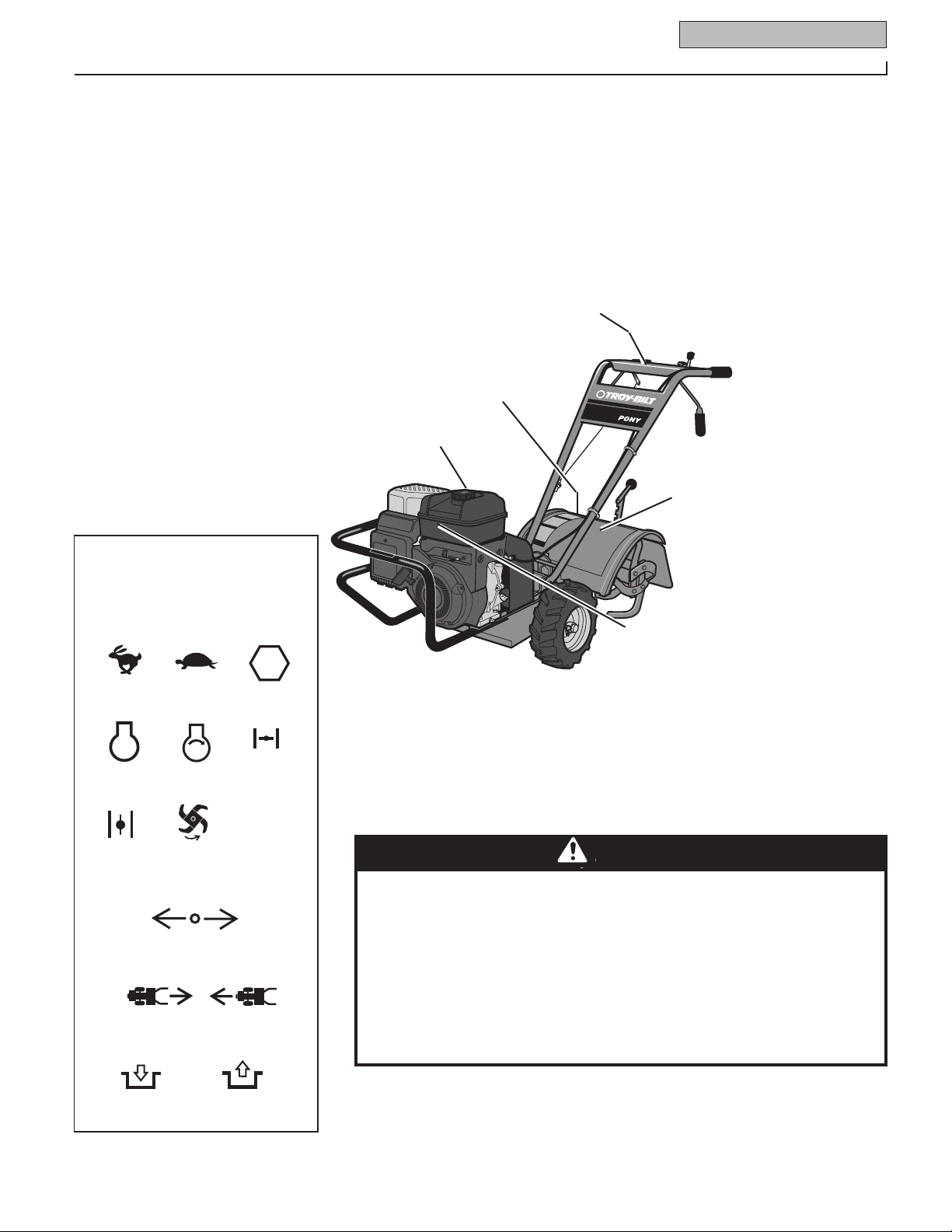

Operating Symbols

Various symbols (shown here, with

word descriptions) may be used on the

tiller and engine.

DECALS

For your safety and the safety of others,

various safety message decals are on your

unit (see Figure below). Keep the decals

clean and legible at all times. Contact your

local service dealer or the factory for

Control Descriptions

Tine Warning (on right

side of hood flap)

Starting Stabilization (on

top of engine or fuel tank)

replacements if any decals are damaged or

missing.

Refer to the Parts List pages for decal

locations and part numbers.

Operating Instructions and

Warning Messages

Hot Surfaces/Moving Belts

(on top of belt cover)

FAST

STOP

CHOKE

OFF

LEVER DIRECTION

ENGAGED

SLOW

START

ROTATING

TINES

TILLER DIRECTION

REVERSE

DISENGAGED

STOP

CHOKE

ON

R

Figure 1: Location of Safety and Operating Decals

WARNING

TO AVOID SERIOUS INJURY:

• READ THE OWNER’S MANUAL.

• KNOW LOCATIONS AND FUNCTIONS OF ALL CONTROLS.

• KEEP ALL SAFETY DEVICES AND SHIELDS IN PLACE AND WORKING.

• NEVER ALLOW CHILDREN OR UNINSTRUCTED ADULTS TO OPERATE TILLER.

• SHUT OFF ENGINE AND DISCONNECT SPARK PLUG WIRE BEFORE MANUALLY UNCLOG

GING TINES OR MAKING REPAIRS.

• KEEP BYSTANDERS AWAY FROM MACHINE.

• KEEP AWAY FROM ROTATING PARTS.

• USE EXTREME CAUTION WHEN REVERSING OR PULLING THE MACHINE TOWARDS YOU.

-

www.mymowerparts.com

www.mymowerparts.com

WARNING

For Parts Call 606-678-9623 or 606-561-4983

For Parts Call 606-678-9623 or 606-561-4983

6

Section

To prevent personal injury or property

damage, do not start the engine until all

assembly steps are complete and you

have read and understand the safety and

operating instructions in this Manual.

INTRODUCTION

Carefully follow these assembly steps to

correctly prepare your tiller for use. It is

recommended that you read this Section

in its entirety before beginning assembly.

INSPECT UNIT

Inspect the unit and carton for damage

immediately after delivery. Contact the

carrier (trucking company) if you find

or suspect damage. Inform them of the

damage and request instructions for filing

a claim. To protect your rights, put your

claim in writing and mail a copy to the

carrier within 15 days after the unit has

been delivered. Contact us at the factory if

you need assistance in this matter.

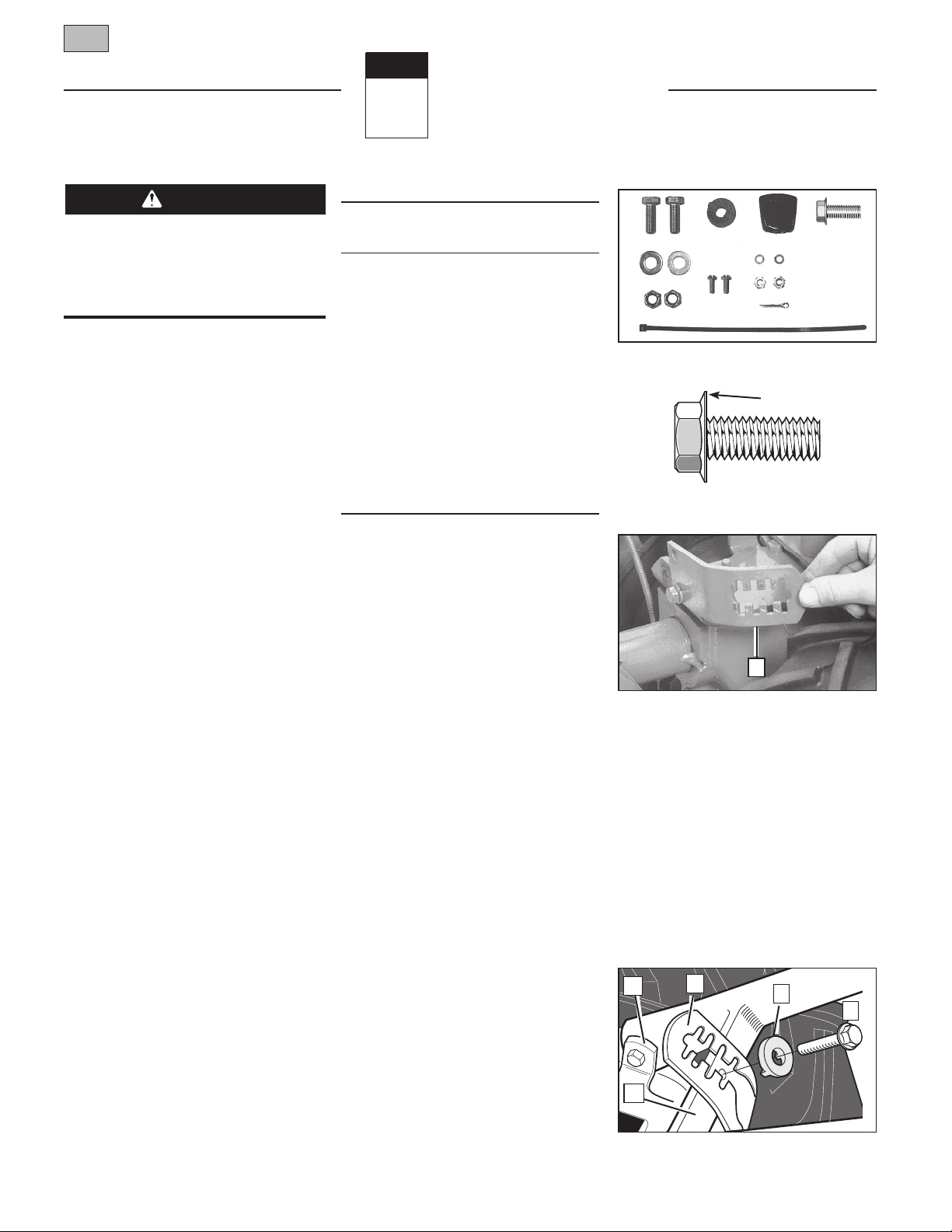

UNPACKING AND ASSEMBLY

INSTRUCTIONS

STEP 1: UNPACKING INSTRUCTIONS

1. Remove any card board inserts and

packaging material from the carton.

Remove any staples from the bottom of

the carton and remove the carton.

2. Cut the large, plastic tie strap that

secures the transmission tube to the shipping pallet. Leave the handlebars on top

of the tiller to avoid damaging any cables.

3. A bag with loose hardware is inside

the literature envelope. Check the contents against the following list and Figure

2-1.

NOTE: For electric start units, a second

hardware bag is located near the battery.

4. The tiller is heavy. You should not

attempt to remove it from the shipping

platform until instructed to do so in these

“Assembly” steps.

2

Assembly

HARDWARE BAG PARTS LIST

Fig.

Ref. Qty. Description

1 2 3/8-16 x 1" Hex Hd. Screw

2 1 Keyed Washer

3 1 Wheel Gear Lever Knob

4 1 Height Adjustment Flange

Screw (See Figure 2-1A)

5 2 3/8" Flat Washer

6 2 #10 Lockwasher

7 2 3/8"-16 Nylock Lock Nut

8 2 #10-32 x 1/2" Round Hd.

Screw

9 2 #10-32 Nut

10 1 Cotter Pin (not used)

11 4 Plastic Tie Strap (2 not used)

Tools/Materials Needed

for Assembly

(1) 3/8" open-end wrench*

(1) 7/16" open-end wrench* (electric

start unit only)

(2) 9/16" open-end wrench*

(1) 7/8" open-end wrench or 8" long

adjustable wrench

(1) Scissors (to trim plastic ties)

(1) Ruler

(1) Small board (to tap plastic knob on

lever)

(1) Tire pressure gauge

(1) Clean oil funnel

(1) Clean, high-quality motor oil. Refer

to the separate Engine Owner’s

Manual for motor oil specifications

and quantity required.

* Adjustable wrenches may be used.

IMPORTANT: Motor oil must be added to

the engine crankcase before the engine

is started. Follow the instructions in this

“Assembly” Section and in the separate

Engine Owner’s Manual.

NOTE: LEFT and RIGHT sides of the tiller

are as viewed from the operator’s position

behind the handlebars.

STEP 2: ATTACH HANDLEBARS

1. On electric start units, remove one

screw and lockwasher from the curved

2

5

7

Figure 2-1: Loose hardware (shown in

reduced size).

Figure 2-1A Handlebar height adjustment

uses the flange head screw.

8

11

31

6

10

Flange

4

9

A

Figure 2-2: On electric start units, move

height adjustment bracket aside.

height adjustment bracket (A, Figure 2-2),

loosen the second screw, and swing the

bracket to one side.

2. Cut the large, plastic cable ties that

secure the handlebar ends to the handlebar mounting tabs on the transmission

top cover.

3. Gently lift handlebar (do not overstretch attached cable) and place handlebar cross-brace (B, Figure 2-3) in front of

curved height adjustment bracket (C).

M

C

E

F

B

Figure 2-3: Forward clutch control cable not

shown for clarity.

www.mymowerparts.com

www.mymowerparts.com

For Parts Call 606-678-9623 or 606-561-4983

For Parts Call 606-678-9623 or 606-561-4983

Section 2: Assembly 7

4. With the forward clutch cable (N,

Figure 2-4) on the inside of handlebar, position the handlebar ends on the

outside of the two mounting tabs (M,

Figure 2-3) on the transmission top cover.

NOTE: The curved handlebar height

adjustment bracket appears as shown in

C, Figure 2-3 for non-electric start units.

For electric start units, the bracket is loosened and moved to one side.

5. Loosely attach the handlebars to

the mounting tabs with two 3/8-16 x 1"

screws (heads of screws go to inside of

tabs), 3/8" flat washers and 3/8"-16 lock

nuts (O, Figure 2-4).

6. On electric start units, reattach the

C

N

Figure 2-4: Attach handlebars.

height adjustment bracket (A, Figure 2-2).

Tighten both screws securely. Make sure

the handlebar cross-brace (B, Figure 2-3)

is under the bracket.

7. Move the handlebars up or down

to align the threaded hole in the crossbrace with one of the four slots in the

curved height adjustment bracket. Place

the keyed washer (E, Figure 2-3) on the

flange head height adjustment screw (F)

with the raised keys (edges) of the washer

facing down.

8. Thread the height adjustment screw (F,

Figure 2-3) into the hole in the handlebar

cross-brace, making sure that the raised

keys on the washer fit into the slot on the

height adjustment bracket. Tighten the

height adjustment screw securely. Next,

securely tighten the two screws and nuts

in the ends of the handlebar (M, Figure

2-3).

9. To remove the tiller from its shipping

platform, first carefully unwrap the wheel

gear cable (with attached lever - see

Figure 2-5) from around the chassis.

Move the Wheel Gear Lever (G) to the

DISENGAGE position--this allows the

wheels to rotate freely. Use the handlebars to roll the tiller off the platform.

O

G

Figure 2-5: Carefully unwrap Wheel Gear

Lever and move lever to DISENGAGE.

NOTE: The Wheel Gear Lever will be

installed later in this procedure.

IMPORTANT:

tion only when the engine is not running.

Before starting the engine, the Wheel

Gear Lever must be placed in the ENGAGE

position (see Section 3 for details).

Use the DISENGAGE posi-

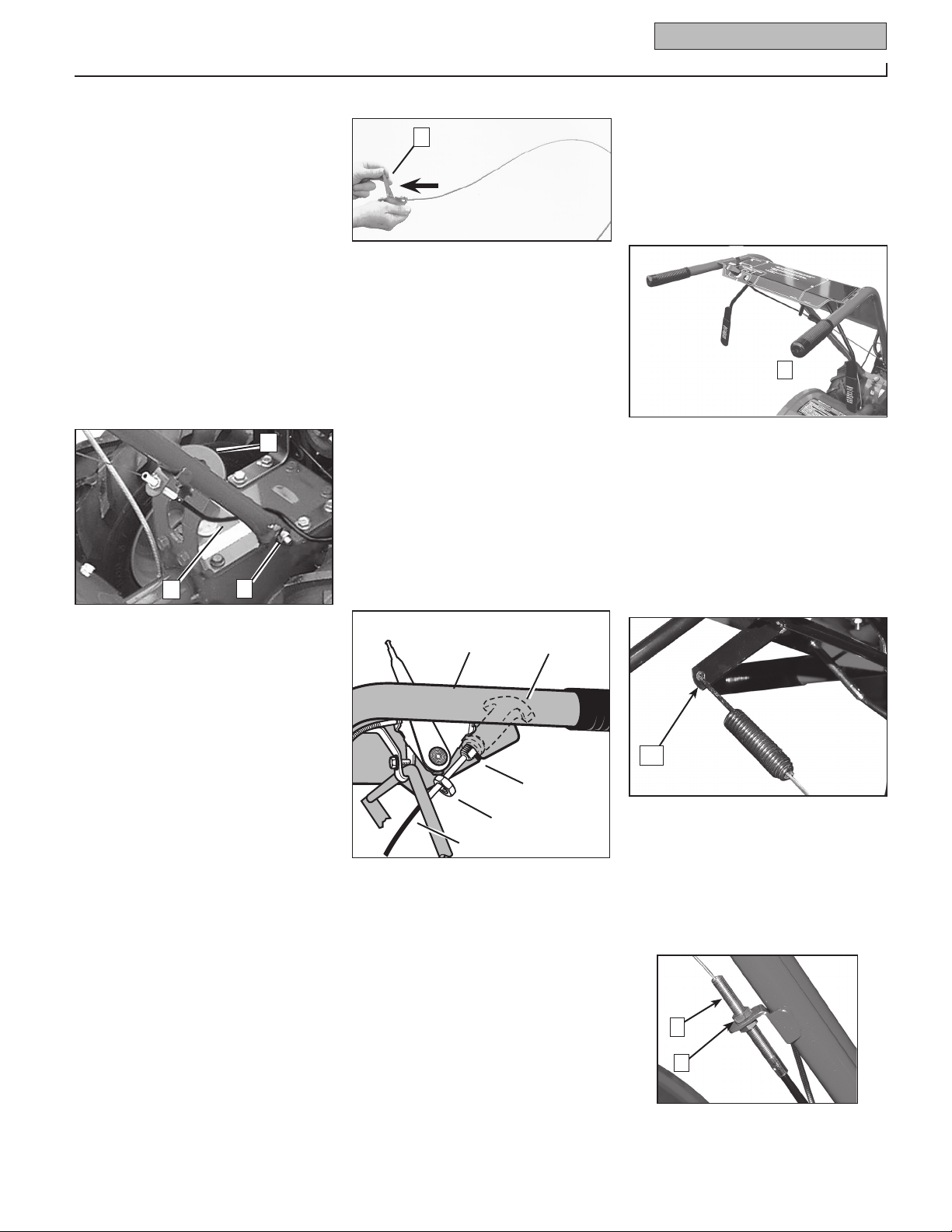

STEP 3: ATTACH REVERSE

CLUTCH CONTROL CABLE

1. Carefully unwrap the reverse clutch

control cable (H, Figure 2-6) from its

shipping position and route it up along

the inside edge of the left side handlebar.

A knob and large hex nut (I) is installed

on the cable.

2. Insert the cable into the slot in the

Left Side

Handlebar

Reverse Clutch

Control Knob

Slot in

Control

Panel

I

H

Figure 2-6: Attach reverse clutch control

assembly to slotted hole in handlebar panel.

control panel and fit the threaded assembly into the hole in the slot (see Figure

2-6). Be sure that the flat side of the

threaded assembly is aligned with the flat

side of the hole. Slide the hex nut (I) up

the cable and tighten it securely.

3. Test the function of the reverse clutch

control cable by pulling the knob out and

releasing it. The knob should return to

its neutral position against the tapered

bushing. If it doesn’t, contact your local

dealer or the factory for technical

assistance.

STEP 4: ATTACH FORWARD

CLUTCH CONTROL CABLE

1. Remove any fasteners (rubber bands,

tape, etc.) that may secure the Forward

Clutch Control levers (J, Figure 2-7) to the

handlebar.

J

Figure 2-7: Forward Clutch Control levers

(J). Forward clutch control linkage (K).

2. The forward clutch control cable (with

attached spring) is hanging loosely near

the right-side wheel. Being careful not to

kink or stretch the cable, insert the z-connector (L, Figure 2-8 – end of the spring)

into the hole at the end of the forward

clutch control linkage (K, Figure 2-7).

L

Figure 2-8

3. Attach the cable adjuster (A, Figure

2-9) to the bracket on the right-side handlebar. Use two 1/2" wrenches to loosen

the two jam nuts (B) just enough to slide

the cable adjuster onto the bracket. Then

hand tighten the jam nuts.

A

B

Figure 2-9

www.mymowerparts.com

www.mymowerparts.com

CAUTION

For Parts Call 606-678-9623 or 606-561-4983

For Parts Call 606-678-9623 or 606-561-4983

8 Section 2: Assembly

Incorrect cable adjustment could cause

the wheels and tines to rotate unexpectedly. Follow adjustment procedures

carefully. Failure to do so could result

in personal injury or property damage.

4. Check for correct spring/cable tension

as instructed in Section 5, Checking and

Adjusting Forward Clutch Belt Tension.

5. When tension is correct, tighten the

two jam nuts (B) securely.

STEP 5: CHECK TRANSMISSION

GEAR OIL LEVEL

The transmission was filled with gear oil

at the factory. However, be sure to check

the oil level at this time to make certain it

is correct.

IMPORTANT: Do not operate the tiller

if the gear oil level is low. Doing so will

result in severe damage to the transmission components.

1. With the tiller on level ground, pull the

Depth Regulator Lever (R, Figure 2-13)

back and then slide it to the second notch

from the top. NOTE: If the lever does not

move, lift the tine hood flap and look for a

plastic tie securing the lever in place. Cut

and remove the tie.

2. Remove the oil level check plug (M,

Figure 2-10) on the left-side of the transmission. (Due to dried paint on the plug

threads, it may require some force to

remove the plug the first time.) The gear

oil level is correct if oil starts to flow out

of the hole as the plug is removed. If so,

securely reinstall the plug.

M

Figure 2-10: Gear oil level check plug.

3. If oil does not flow from the check

hole, add oil as follows:

NOTE: Do not use automatic transmission

fluid or motor oil in the transmission.

(a) Clean area around the fill hole (N,

Figure 2-11) and unscrew gear oil fill

plug.

N

Figure 2-11: Adding gear oil.

(b) If adding only a few ounces of gear

oil, use API rated GL-4 or GL-5 gear

oil having a viscosity of SAE 140, SAE

85W-140 or SAE 80W-90. If refilling an

empty transmission, use only GL-4 gear

oil having a viscosity of SAE 85W-140 or

SAE 140.

(c) Using a clean funnel, slowly add gear

oil until it flows from the gear oil level

check hole (N, Figure 2-11).

(d) Reinstall and tighten securely the gear

oil fill plug (M, Figure 2-10).

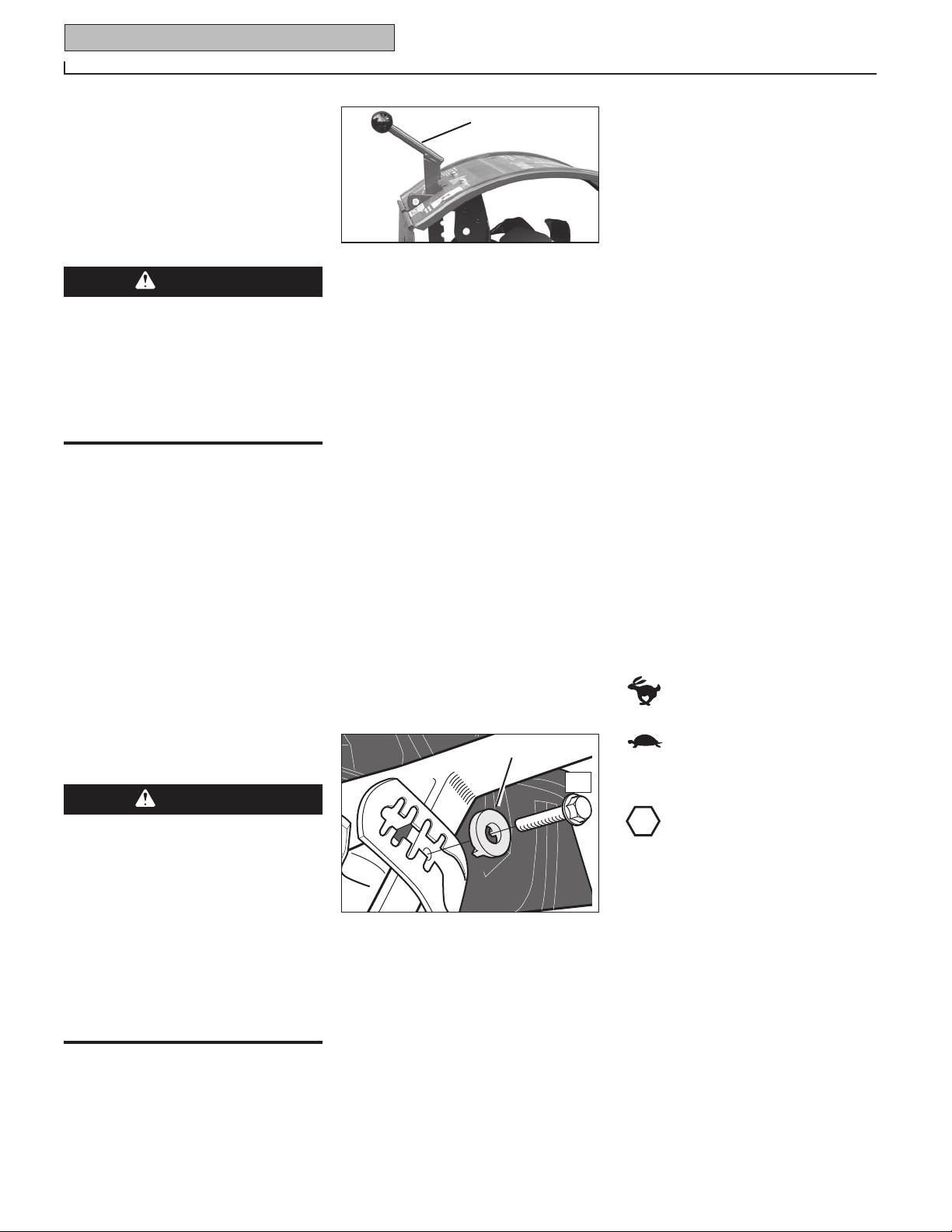

STEP 6: ATTACH WHEEL GEAR

LEVER

1. Insert the Wheel Gear Lever (P, Figure

2-12) up through the slot in the control

panel that is labeled “WHEEL GEAR.”

2. Insert two #10-32 x 1/2" round head

screws down through the “+” marks

on the control panel decal and securely

attach the wheel gear mounting bracket

using two #10 lockwashers and #10-32

nuts.

3. Use a small board to tap the Wheel

Gear Lever knob securely onto the lever.

4. Secure the wheel gear cable and the

reverse clutch control cable to the leftside handlebar with two plastic ties (S,

Figure 2-13) located about two feet apart.

Snip off any excess tie length with

scissors.

STEP 7 ATTACHING THE BATTERY

CABLES (MODEL E663E)

The positive battery terminal is marked

Pos. (+). The negative battery terminal is

marked Neg. (–).

1. Remove the hex bolt and hex nut from

the positive cable (heavy red wire).

2. Remove the plastic cover from the

positive battery terminal and attach the

positive cable to the positive battery terminal (+) with the bolt and hex nut. Make

certain that the rubber boot covers the

positive terminal to help protect it from

P

Figure 2-12: Attach Wheel Gear Lever.

S

Figure 2-13: Attach wheel gear cable and

reverse clutch cable with cable ties (S).

corrosion.

3. Remove the hex bolt and hex nut from

the negative cable (heavy black wire).

4. Remove the black plastic cover from

the negative battery terminal and attach

the negative cable to the negative battery

terminal (–) with the bolt and hex nut.

IMPORTANT:

If the battery is put into service after the

•

date shown on top of battery, charge the

battery as instructed in the Maintenence

section of this manual prior to operating

the tiller.

STEP 8: CHECK AIR

PRESSURE IN TIRES

Use a tire pressure gauge to check the air

pressure in both tires. Deflate or inflate

both tires equally to between 15 PSI

and 20 PSI). Be sure that both tires are

inflated equally or the unit will pull to one

side.

STEP 9: CHECK HARDWARE

FOR TIGHTNESS

Inspect the hardware on the unit and

tighten any loose screws, bolts and nuts.

www.mymowerparts.com

www.mymowerparts.com

WARNING

DANGER

WARNING

For Parts Call 606-678-9623 or 606-561-4983

For Parts Call 606-678-9623 or 606-561-4983

Section

9

3

Features and Controls

Before operating your machine, carefully read and understand all safety,

controls and operating instructions

in this Manual, the separate Engine

Owner’s Manual, and on the decals on

the machine.

Failure to follow these instructions can

result in serious personal injury.

INTRODUCTION

This Section describes the location and

function of the controls on your tiller.

Refer to the following section “Operation”

for detailed operating instructions.

Practice using these controls, with the

engine shut off, until you understand the

operation of the controls and feel confident with them.

IMPORTANT: Refer to the separate engine

manufacturer’s Engine Owner’s Manual

for information about the controls on the

engine.

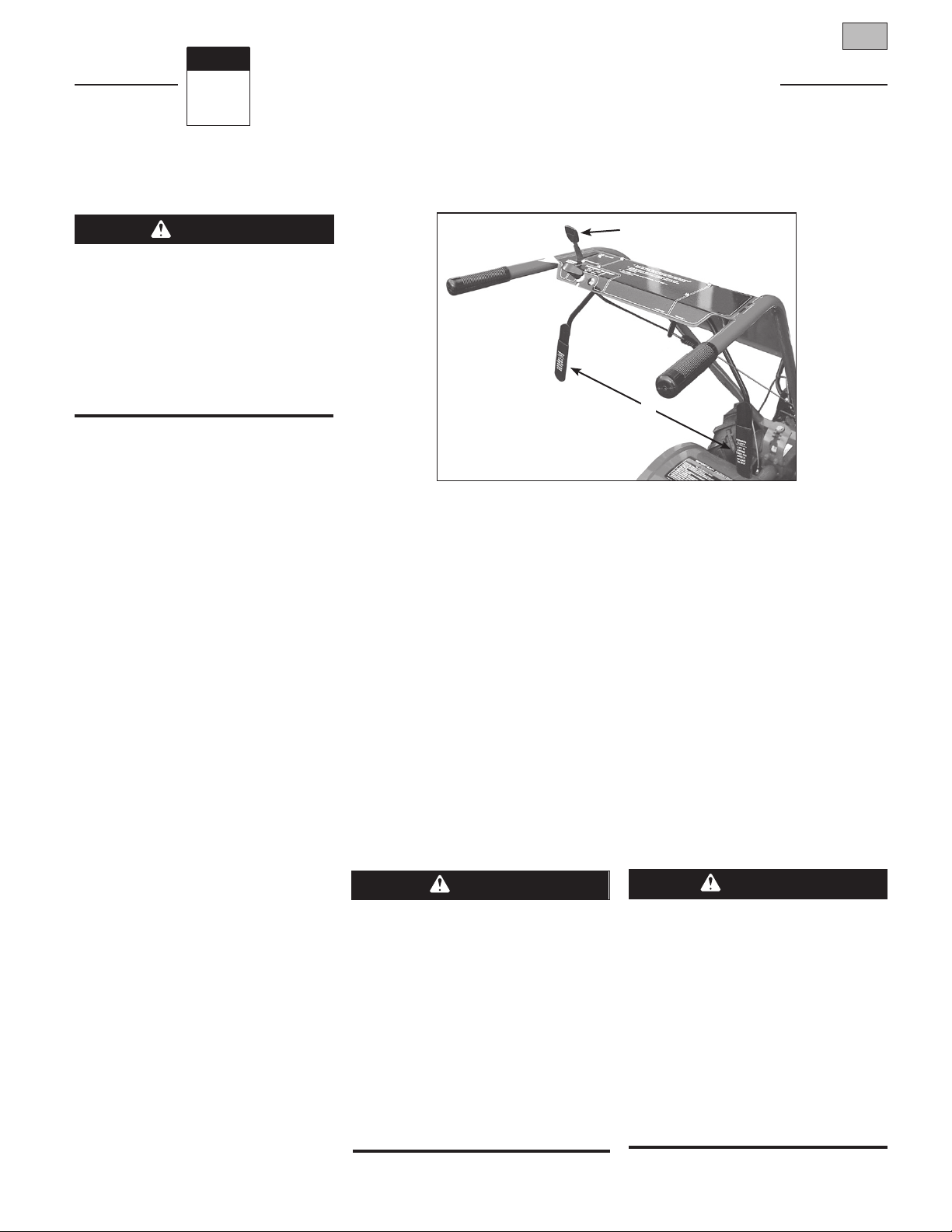

WHEEL GEAR LEVER

This lever (A, Figure 3-1) has two positions: ENGAGE and DISENGAGE.

In the ENGAGE position, the wheels will

start turning when either the Forward

Clutch Control or the Reverse Clutch

Control is engaged (the tines will also

start turning when either clutch is

engaged).

C

Figure 3-1: Controls located on handlebar.

The DISENGAGE position places the

wheels in the freewheeling mode to allow

the unit to be moved without the engine

running. Use the DISENGAGE position

only when the engine is not running. See

“DANGER” statement that follows.

To shift to ENGAGE, gently (do not force)

move the lever forward while also rolling

the tiller a few inches forward or backward. Moving the tiller helps to align the

shift mechanism with the transmission

wheel drive gears.

To shift to DISENGAGE (freewheel), move

the lever rearward, without rolling the

tiller. The wheels will roll freely

when the lever is properly set in the

DISENGAGE position.

Never place the Wheel Gear Lever in

DIS E N G A GE (Fr e e w h eel) wh e n the

engine is running.

Having t h e Whee l Gear L e v e r in

DISENGAGE and then engaging the tines/

wheels with either the Forward Clutch

Control or the Reverse Clutch Control

could allow the tines to propel the tiller

rapidly forward or backward.

Failure to follow this instruction could

result in personal injury or property

damage.

A

B

FORWARD CLUTCH CONTROL

The two interconnected levers (B, Figure

3-1) control the engagement of forward

drive to the wheels and tines.

To Operate the Forward Clutch Control:

1. Before engaging the Forward Clutch

Control, put the Wheel Gear Lever in

the ENGAGE position (see “WARNING”

below).

2. Pull up and hold one or both of the

levers against the handlebar grips to

engage the wheels and tines.

3. Release BOTH levers to disengage

(stop) the wheels and tines. All forward

motion will stop (the engine will continue

to run).

Never engage the wheels and tines

with the Forward Clutch Control or the

Reverse Clutch Control unless the Wheel

Gear Lever is in ENGAGE.

Engaging the Forward Clutch Control

or the Reverse Clutch Control when the

wheels are not engaged could allow the

tines to rapidly propel the tiller forward

or backward.

Failure to follow this warning could

result in personal injury or property

damage.

www.mymowerparts.com

www.mymowerparts.com

WARNING

WARNING

STOP

For Parts Call 606-678-9623 or 606-561-4983

For Parts Call 606-678-9623 or 606-561-4983

10 Section 3: Features and Controls

REVERSE CLUTCH CONTROL

The Reverse Clutch Control (C, Figure

3-1) controls the engagement of reverse

drive to the wheels and tines. The revers-

ing feature is used for maneuvering the

tiller only – never engage the tines in

the ground while going in the reverse

direction.

• Use extreme caution when reversing

or pulling the machine towards you.

Look behind to avoid obstacles.

• Never attempt to till in reverse.

Failure to follow this warning could

result in personal injury or property

damage.

To Operate the Reverse Clutch Control:

1. Put the Wheel Gear Lever in the

ENGAGE position (see the “WARNING”

statement on previous page).

2. Stop all tiller motion by releasing the

Forward Clutch Control levers.

3. Lift up the handlebars until the tines

clear the ground, look behind you to avoid

any obstacles, and then pull the Reverse

Clutch Control knob out. The tines and

wheels will rotate in a reverse direction.

4. Release the Reverse Clutch Control

knob to disengage (stop) the wheels and

tines. All reverse motion will stop (the

engine will continue to run).

D

Figure 3-2: Depth Regulator Lever.

The highest notch (lever all the way down)

raises the tines approximately

1-1/2 inches off the ground. This “travel”

position allows the tiller to be moved

without the tines digging into the ground.

Moving the lever up increases the tilling

depth. The lowest notch allows a tilling

depth of approximately six to eight inches,

depending on soil conditions.

For best results, always begin tilling at

a very shallow depth setting and gradually increase the tilling depth. Complete

details on using the Depth Regulator are

found in the “Operation” Section of this

manual.

HANDLEBAR HEIGHT ADJUSTMENT

The handlebar height is adjustable to

four different settings. Set the handlebar

height to a comfortable setting, but keep

in mind that the handlebars will be lower

when the tines are engaged in the soil.

To Adjust the Handlebar Height:

F

E

keyed washer into the slot. Tighten the

height adjustment screw securely.

5. Retighten the two screws at the ends

of the handlebar.

ENGINE CONTROLS

Refer to the engine manufacturer’s Engine

Owner’s Manual (included in the tiller

literature package) to identify the controls

on your engine. The following two controls are used when stopping or starting

the engine.

IMPORTANT:

the recoil start engine is located on the

engine.

ENGINE THROTTLE CONTROL LEVER

The Engine Throttle Control Lever (located

on engine--see Figure 4-1) is used to

regulate the engine speed. On the recoil

start model only, it is also used to stop

the engine (on the electric start model, the

electric start keyswitch is used to stop the

engine). The throttle settings are shown

below.

IMPORTANT:

the Engine” in the “Operation” Section

for detailed engine starting and stopping

instructions.

The control for stopping

See “Starting and Stopping

FAST - Use for most tilling and

cultivating projects.

- Use when idling engine

SLOW

or when slower tilling and cultivating speeds are needed.

• Do not attempt to till too deeply too

quickly. Gradually work down to deeper

tilling depths.

• Place the Depth Regulator Lever in

the “travel” position before starting

the engine. This position prevents the

tines from touching the ground until

you are ready to begin tilling.

Failure to follow this warning could

result in personal injury or property

damage.

DEPTH REGULATOR

The Depth Regulator lever (D, Figure 3-2)

controls the tilling depth of the tines. Pull

the lever straight back and slide it up or

down to engage the notched height settings.

www.mymowerparts.com

www.mymowerparts.com

Figure 3-3: Handlebar height adjustment.

1. Stop the engine, wait for all parts to

stop moving and then disconnect the

spark plug wire. Remove the ignition key

on electric start models.

2. Loosen the two screws at the lower

ends of the handlebar.

3. Loosen the height adjustment screw

(E, Figure 3-3) and pull the keyed washer

(F) free of the slots in the curved height

adjustment bracket.

4. Move the handlebars to the new slot

setting and insert the raised keys on the

- Stops the engine (on

STOP

recoil start models only).

ELECTRIC START KEYSWITCH

(MODEL E663E)

The ignition keyswitch on the electric

start model is used to start and stop

the engine. The keyswitch settings are

described below.

IMPORTANT:

the Engine” in the “Operation” Section for

detailed instructions.

OFF - Stops engine.

RUN - After starting, key returns to run

position.

START - Starts engine. Release key when

engine starts (avoid cranking engine for

longer than 15 seconds for each attempt).

See “Starting and Stopping

WARNING

DANGER

CAUTION

For Parts Call 606-678-9623 or 606-561-4983

For Parts Call 606-678-9623 or 606-561-4983

Section

11

Before operating your machine, carefully read and understand all safety

(Section 1), controls (Section 3) and

operating instructions (Section 4) in

this Manual, in the separate Engine

Owner’s Manual, and on the decals on

the machine.

Failure to follow these instructions can

result in serious personal injury.

INTRODUCTION

Read this Section of the manual thoroughly before you start the engine. Then,

take the time to familiarize yourself with

the basic operation of the tiller before

using it in the garden.

Find an open, level area and practice

using the tiller controls without the tines

engaging the soil (put tines in “travel”

setting). Only after you’ve become completely familiar with the tiller should you

begin using it in the garden.

BREAK-IN OPERATION

Perform the following maintenance after

the first two hours of new operation (see

“Maintenance” in this manual and the

Engine Owner’s Manual).

1. Change engine oil.

2. Check for loose or missing hardware

on unit. Tighten or replace as needed.

3. Check transmission gear oil level.

4. Check tension on forward clutch belt.

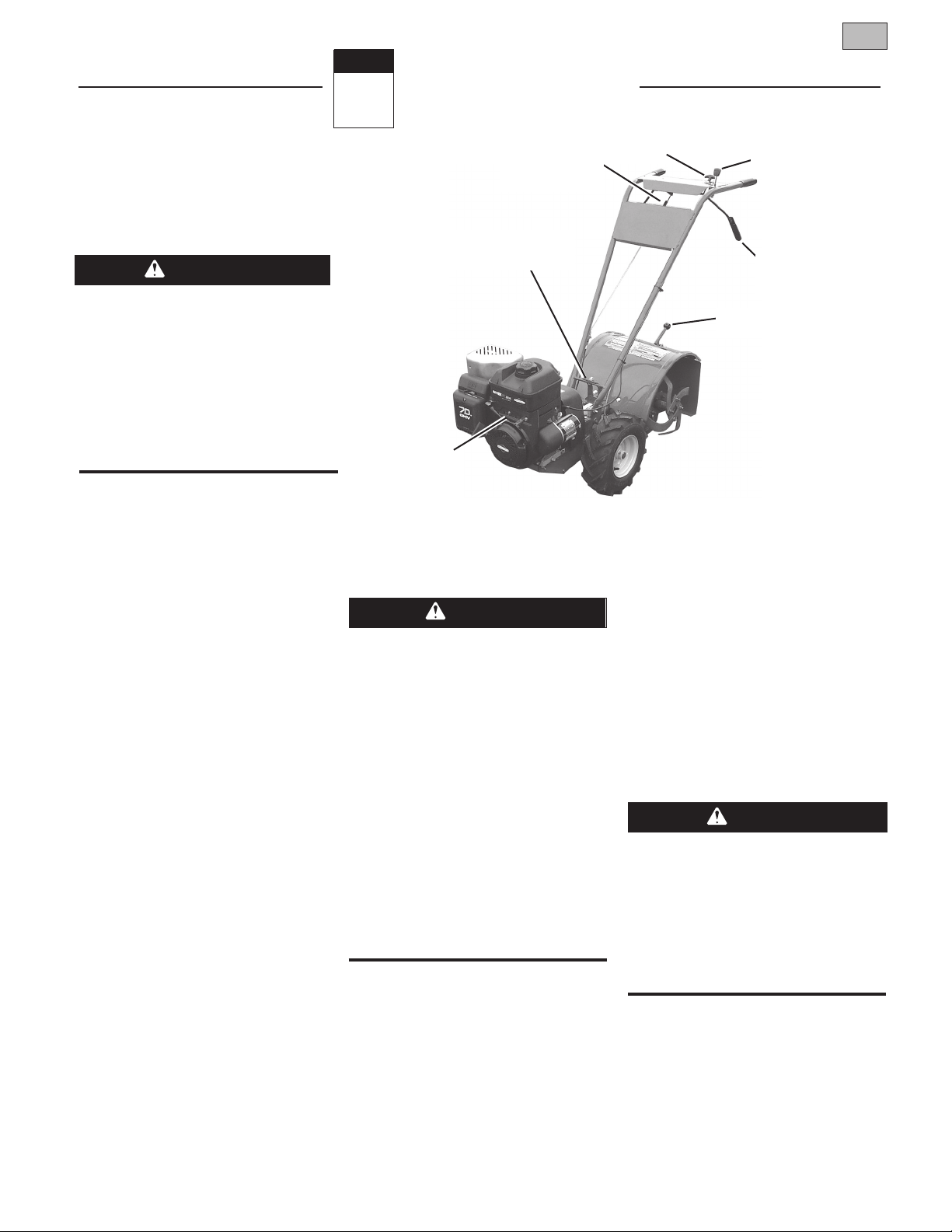

4

Engine Throttle

Control Lever

Operation

Forward Clutch

Control Lever

Handlebar Height

Adjustment Screw

Figure 4-1: Location of main tiller controls.

STARTING AND STOPPING

THE ENGINE

To help prevent serious personal injury

or damage to equipment:

• Before starting engine, put Wheel Gear

Lever in ENGAGE position.

• Before starting engine, put Forward

Clutch Control levers and Reverse

Clutch Control in neutral (disengaged)

positions by releasing controls.

• Ne v e r run engine in d o o rs or in

enclosed, poorly ventilated areas.

Engine exhaust contains carbon monoxide, an odorless and deadly gas.

• Avoi d e ngine muff ler and nearb y

areas. Temperatures in these areas

may exceed 150oF.

Reverse Clutch

Control

1. Read Sections 1 and 3 in this Manual.

Read the separate Engine Owner’s

Manual.

2. Check unit for loose or missing hardware. Service as required.

3. Check engine oil level. See Engine

Owner’s Manual.

4. Check that all safety guards and

covers are in place.

5. Check air cleaner and engine cooling

system. See Engine Owner’s Manual.

6. Attach spark plug wire to spark plug.

GASOLINE IS HIGHLY FLAMMABLE AND

ITS VAPORS ARE EXPLOSIVE.

Follow gasoline safety rules in this

manual (see Section 1) and in the separate Engine Owner’s Manual.

Failure to follow gasoline safety instructions can result in serious personal

injury and property damage.

Wheel Gear Lever

Forward Clutch

Control Lever

Depth Regulator Lever

PRE-START CHECKLIST:

Make the following checks and perform

the following services before starting the

engine.

www.mymowerparts.com

www.mymowerparts.com

7. Fill the fuel tank with gasoline according to the directions in the separate

Engine Owner’s Manual. Follow all

instructions and safety rules carefully.

WARNING

WARNING

For Parts Call 606-678-9623 or 606-561-4983

For Parts Call 606-678-9623 or 606-561-4983

12 Section 4: Operation

STARTING THE ENGINE

The following steps describe how to start

and stop the engine. Do not attempt to

engage the tines or wheels until you

have read all of the operating instructions in this Section. Also review

the safety rules in Section 1: “Safety”

and the tiller and engine controls

information in Section 3: “Features and

Controls.”

1. Complete the “Pre-Start Checklist” on

the previous page.

2. Put the Wheel Gear Lever (Figure 4-1)

in the ENGAGE position.

3. Put the Depth Regulator Lever in the

“travel” position (lever all the way down)

so that the tines are clear of the ground.

4. Release all controls on the tiller.

5. Put the Engine Throttle Control Lever

(Figure 4-1) in the “FAST” setting.

6. On engines equipped with a fuel valve,

turn valve to open position as instructed

in the separate engine manual.

7. Choke or prime engine as instructed in

the separate Engine Owner’s Manual.

8. For recoil (non-electric) starting

models:

(a) Place one hand on fuel tank to sta-

bilize unit when you pull the starter

handle.

(b) Use the recoil starter rope to start

the engine as instructed in the

separate Engine Owner’s Manual.

When the engine starts, gradually

move the choke lever (on engines

so equipped) to the “NO CHOKE”,

“CHOKE OFF” or “RUN” position.

(c) Leave

9. For electric starting models (E663E):

(a) Turn the engine ignition key to

the Engine Throttle Control

Lever in the “FAST” setting.

the “START” setting and allow the

starter motor to crank the engine for

several seconds. Avoid cranking the

engine longer than 15 seconds at a

time as doing so could damage the

starter motor. NOTE: Refer to the

Engine Owner’s Manual for detailed

starting instructions.

(b) When the engine starts, release the

key and it will return to the “RUN”

setting.

(c) Gradually move choke lever

(on engines so equipped) to

“NO CHOKE”, “CHOKE OFF” or

“RUN” position.

(d) Leave the Engine Throttle Control

Lever in the “FAST” setting.

To Start the Electric Start Engine With

the Recoil Starter Rope

If necessary, the electric start engine can

be started with the recoil starter rope by

following the steps below:

1. If the battery is not “dead” or

damaged, leave it connected to the tiller

so it will be recharged during engine

operation. Make sure the battery cells

are filled to the UPPER LEVEL line with

electrolyte.

2. If the battery is “dead” or damaged,

remove it (refer to “Battery Removal and

Installation” in Section 5) and have it

tested. Before starting engine, cover the

terminal on the loose end of the positive (+) cable with the insulated boot and

secure it in place with electrical tape to

prevent electrical sparks.

3. Put the ignition key in the “RUN”

position and then follow Steps 1-8 of

“Starting the Engine.”

STOPPING THE ENGINE

1. To stop the wheels and tines, release

the Forward Clutch Control levers or the

Reverse Clutch Control knob (whichever

control is engaged).

2. To stop the engine on the recoil start

model, move the Engine Throttle Control

Lever to the “STOP” position.

3. To stop the engine on an electric start

model, move the ignition key to “OFF”.

IMPORTANT:

start engine, remove the ignition key from

the switch to reduce the possibility of

unauthorized starting of the engine.

After stopping an electric

OPERATING THE TILLER

The following pages provide guidelines to

using your tiller effectively and safely in

various gardening applications. Be sure

to read “Tilling Tips & Techniques” in this

Section before you actually put the tines

into the soil.

This is a traditional “standard rotating

tine” tiller with forward rotating tines. It

operates completely differently from CRT

(Counter Rotating Tines) tillers or from

low-cost front tine tillers.

1. Follow the “Pre-Start Checklist” on the

previous page. Be sure that the Wheel

Gear Lever is in the ENGAGE position.

2. Put the Depth Regulator Lever in the

“travel” position (lever all the way down)

so that the tines are clear of the ground.

Use this position when practicing with

your tiller or when moving to or from the

garden. When you are ready to begin

tilling, you must move the Depth Regulator Lever to the desired depth setting (see

“Tilling Tips & Techniques”).

3. Start the engine and allow it to warm

up. When warm, put Engine Throttle

Control Lever in “FAST” speed setting.

Keep away from rotating tines.

Rotating tines will cause injury.

4. For forward motion of the wheels and

tines:

(a) Pull one or both of the Forward

Clutch Control Levers up and hold

them against the handlebars. To

stop forward motion of the wheels

and tines, release the levers.

www.mymowerparts.com

www.mymowerparts.com

Loading...

Loading...