MTD 21A-342-062 Owner’s Manual

YARDMACHINES

OPERATOR'S MANUAL

FRONT TINE

TILLERS

Models

340 Thru 390

Model 340 Shown

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warnlng: This unit =s equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine's exhaust system _s equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P O Box 368022 Cleveland, Ohio 44136-9722.

MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A.

FORM NO. 770-10135

(10/98)

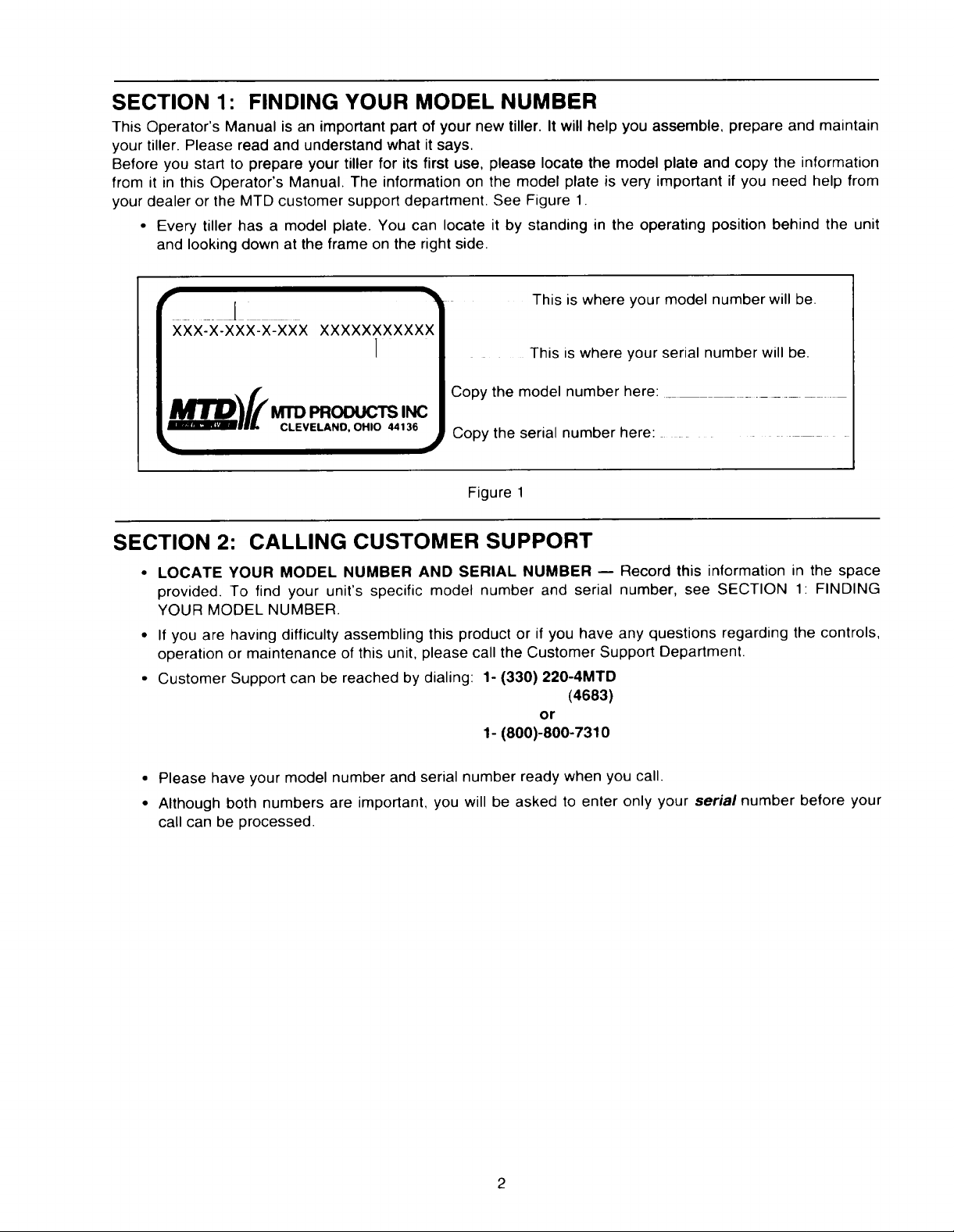

SECTION 1: FINDING YOUR MODEL NUMBER

This Operator's Manual is an important part of your new tiller. It will help you assemble, prepare and maintain

your tiller. Please read and understand what it says.

Before you start to prepare your tiller for its first use, please locate the model plate and copy the information

from it in this Operator's Manual. The information on the model plate is very important if you need help from

your dealer or the MTD customer support department. See Figure 1.

• Every tiller has a model plate. You can locate it by standing in the operating position behind the unit

and looking down at the frame on the right side.

This is where your model number will be.

_,XX-)(-X_Xi-X-,XX-X XXXXXXXXXX_

]

CLEVELAND, OHIO 44136

_ This is where your serial number will be.

Copy the model number here: ............

Copy the serial number here:

Figure 1

SECTION 2: CALLING CUSTOMER SUPPORT

• LOCATE YOUR MODEL NUMBER AND SERIAL NUMBER m Record this information in the space

provided. To find your unit's specific model number and serial number, see SECTION 1: FINDING

YOUR MODEL NUMBER.

• If you are having difficulty assembling this product or if you have any questions regarding the controls,

operation or maintenance of this unit, please call the Customer Support Department.

• Customer Support can be reached by dialing: 1- (330) 220-4MTD

(4683)

or

1- (800)-800-7310

• Please have your model number and serial number ready when you call.

• Although both numbers are important, you will be asked to enter only your serial number before your

call can be processed.

SECTION 3: IMPORTANT SAFE OPERATION PRACTICES

WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF

&

1. GENERAL OPERATION

NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF

YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE YOUR TILLER. FAILURE TO COMPLY WITH THESE

INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL-- HEED

ITS WARNING.

WARNING: The Engine Exhaust from this product contains chemicals known to

the State of California to cause cancer, birth defects or other reproductive harm.

DANGER: Your tiller was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This tiller is capable of amputating hands and feet. Failure to observe the

following safety instructions could result in serious injury or death.

• Read this operator's manual carefully in its entirety

before attempting to assemble this machine. Read,

understand, and follow all instructions on the

machine and in the manual(s) before operation. Be

completely familiar with the controls and the proper

use of the machine before operating it. Keep this

manual in a safe place for future and regular

reference and for ordering replacement parts.

• Your tiller is a powerful tool, not a plaything.

Therefore, exercise extreme caution at all times.

Your unit has been designed to perform one job: to

till soil. Do not use it for any other purpose.

• Never allow children under age 14 to operate the

unit. Children 14 years and older should only

operate the unit under close parental superwsion

Only responsible individuals who are familiar with

these rules of safe operation should be allowed to

use your unit.

• Do not operate tiller while under the influence of

alcohol or drugs.

• Keep the area of operation clear of all persons,

particularly small children and pets. Stop the

engine when they are in the vicinity of your tiller.

• Wear sturdy, rough-soled work shoes and close

fitting slacks and shirt. Shirt and slacks that cover

the arms and legs and steel-toed shoes are

recommended. Do not wear loose fitting clothes or

jewelry and secure hair so it is above shoulder

length. They can be caught in moving parts. Never

operate a unit in bare feet, sandals or sneakers.

• Operate tiller only in daylight or good artificial light.

• Do not start tiller unless the shift lever (if provided)

is in the neutral (N) position.

• Do not allow anyone to stand or walk in front of

tiller when starting or running engine.

• Do not place feet or hands on or near the tines

when starting the engine or while the engine is

running.

• Never attempt to make depth bar, tine width, cable,

handle, or wheel adjustments while the engine is

running

• Do not leave the tiller unattended with the engine

running

• Before attempting to remove rocks, bricks and

other objects from tines, stop the engine and be

sure the tines have stopped completely. Disconnect

the spark plug wire and move it away from the

spark plug.

• If your machine should start making an unusual

noise or vibration, immediately stop the engine and

allow the machine to come to a complete stop.

Disconnect the spark plug wire and move it away

from the spark plug. Take the following steps:

• Inspect for damage.

• Repair or replace any damaged parts.

• Check for any loose parts and tighten to

assure continued safe operation.

• Muffler and engine become hot and can cause a

burn. Do not touch.

• Keep all shields, guards and safety devices in

place and operating properly.

• Use caution when tilling near fences, buildings and

underground utilities. Rotating tines can cause

damage or injury.

• Do not operate engine if air cleaner or cover over

carburetor air intake is removed, except for

adjustment. Removal of such parts could create a

fire hazard.

• Only use accessories approved for this machine by

the manufacturer. Read, understand, and follow all

instructions provided with the approved accessory.

• If situations occur which are not covered by this

manual, use care and good judgment. Contact your

dealer for assistance.

2. CHILDREN

• Tragic accidents can occur if the operator is not

alert to the presence of small children. Children are

often attracted to the tilling activity. Never assume

that children will remain where you last saw them.

• Keep children out of the work area and under the

watchful eye of a responsible adult other than the

operator.

• Be alert and turn the unit off if a child enters the

area.

• Never allow children under the age of 14 to operate

the tiller.

3. SERVICE

• Use extreme care in handling gasoline and other

fuels. They are extremely flammable and the

vapors are explosive.

• Store fuel and oil in approved containers, away

from heat and open flame, and out of the reach of

children. Check and add fuel before starting the

engine. Never remove gas cap or add fuel while the

engine is running. Allow engine to cool at least two

m_nutes before refueling.

• Replace gasoline cap securely and wipe off any

spilled gasoline before starting the engine as it may

cause a fire or explosion.

• Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

• Never refuel unit indoors because flammable

vapors will accumulate in the area.

• Never store the machine or fuel container inside

where there _s an open flame or spark such as a

gas hot water heater, space heater, clothes dryer

or furnace.

• Never run your machine =nan enclosed area as the

exhaust from the engine contains carbon

monoxide, which is a odorless, tasteless and

deadly poisonous gas.

• To reduce fire hazard, keep engine and muffler free

of leaves, grass, and other debris build-up. Clean

up fuel and oil spillage. Allow unit to cool at least 5

minutes before storing.

• Before cleaning, repairing, or inspecting, make

certain the tines and all moving parts have stopped.

Disconnect the spark plug wire and keep wire away

from spark plug to prevent accidental starting. Do

not use flammable solutions to clean air filter.

• Keep all nuts, bolts, and screws tight to be sure the

equipment is in safe working condition.

• Never tamper with safety devices. Check their

proper operation regularly.

• Do not alter or tamper with the engine's governor

setting. The governor controls the maximum safe

operating speed of the engine. Overspeeding the

engine is dangerous and will cause damage to the

engine and to other moving parts of the machine.

_ ARNING m YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who

read, understand and follow the warnings and instructions in this manual and on the machine.

TO AVOID INJURY

• READTHEOPERATOR"SMANUAL

• KNOWLOCATIONAND

FUNCTIONSOFALLCONTROLS

• KEEPALLSAFETYDEVICESAND

SHIELDSIN PLACE,

• NEVERALLOWCHILDRENOR

UNINSTRUCTEDADULTSTO

OPERATE"nLLER.

• SHUTOFFENGINEBEFORE

UNCLOGGING11NESORMAKING

REPAIRS.

• KEEPBYSTANDERSAWAYFROM

MACHINE.

• KEEPAWAYFROMROTATING

PARTS.

• USEEXTREMECAUTIONWHEN

REVERSINGORPULLINGTHE

MACHINETOWARDSYOU

Figure 2 Safety labels found on your unit

4

SECTION 4: UNPACKING INSTRUCTIONS

1. Remove staples, break glue on top flaps, or cut

tape at carton end and peel along top flap to

open carton.

2. Remove all loose parts included with unit.

3. Cut along dotted lines and lay carton down flat.

4. Remove packing material.

5. Roll or slide unit out of carton. Check carton

thoroughly for loose parts.

SECTION 5: ASSEMBLY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL. After assembly, see separate

engine manual for proper fuel and engine oil

recommendations.

NOTE: Left and right is determined from the

operator's position, standing behind the tiller.

TOOLS REQUIRED FOR ASSEMBLY

(1)-1/2" Wrench or Socket*

(1)-Pair of Pliers

(1)-3/8" Wrench*

*An adjustable wrench may be used.

This owner's guide covers three different model

tillers. Models 340 thru 345 have forward tine

drive only. Model 390 has both forward and

reverse tine drive. Follow only the instructions

which pertain to your model tiller. See the model

plate on your tiller for the correct model number.

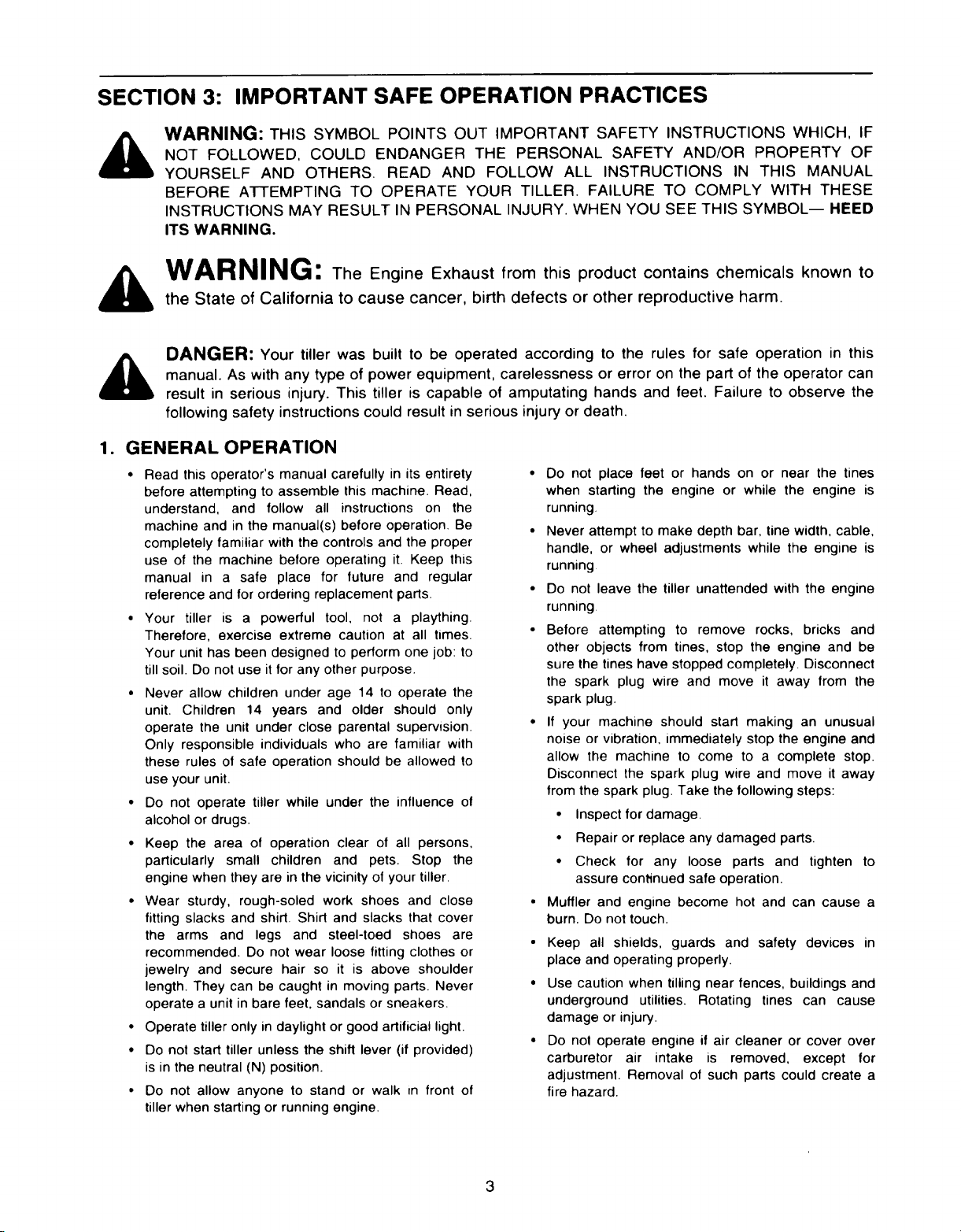

ATrACHING THE TAILPIECE AND DEPTH

STAKE

Remove the two self-tapping screws on the frame.

Slide the tailpiece into the frame, with the lower hole

in the tailpiece toward the front. Secure with screws

just removed. (See Figure 3.)

6. Extend control cable(s) to the rear of the tiller

and lay them on the floor. Be careful not to bend

or kink control cable(s).

All hardware required for assembly has been placed

in position on the tiller.

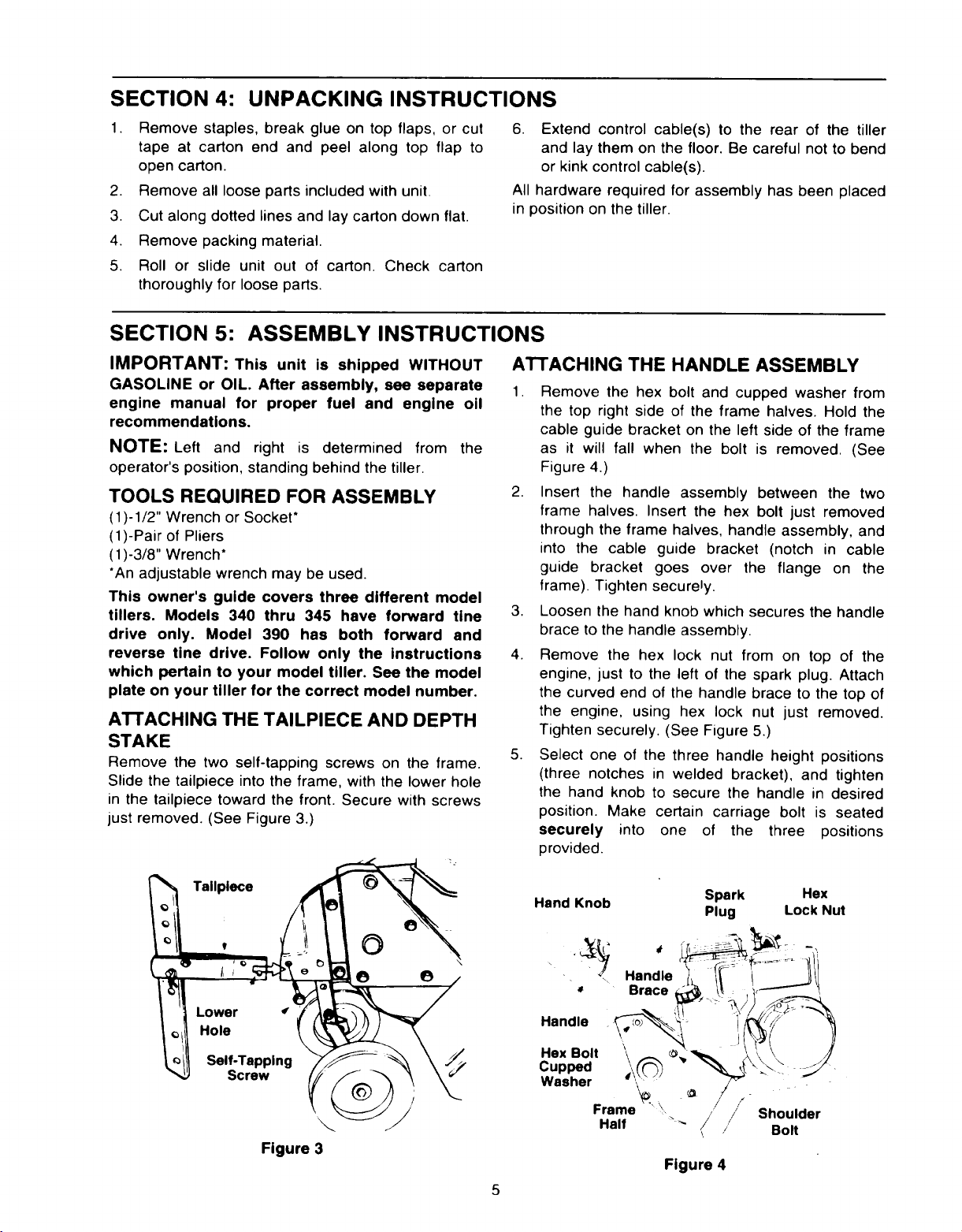

ATTACHING THE HANDLE ASSEMBLY

1. Remove the hex bolt and cupped washer from

the top right side of the frame halves. Hold the

cable guide bracket on the left side of the frame

as it will fall when the bolt is removed. (See

Figure 4.)

2. Insert the handle assembly between the two

frame halves. Insert the hex bolt just removed

through the frame halves, handle assembly, and

into the cable guide bracket (notch in cable

guide bracket goes over the flange on the

frame). Tighten secureJy.

3. Loosen the hand knob which secures the handle

brace to the handle assembly.

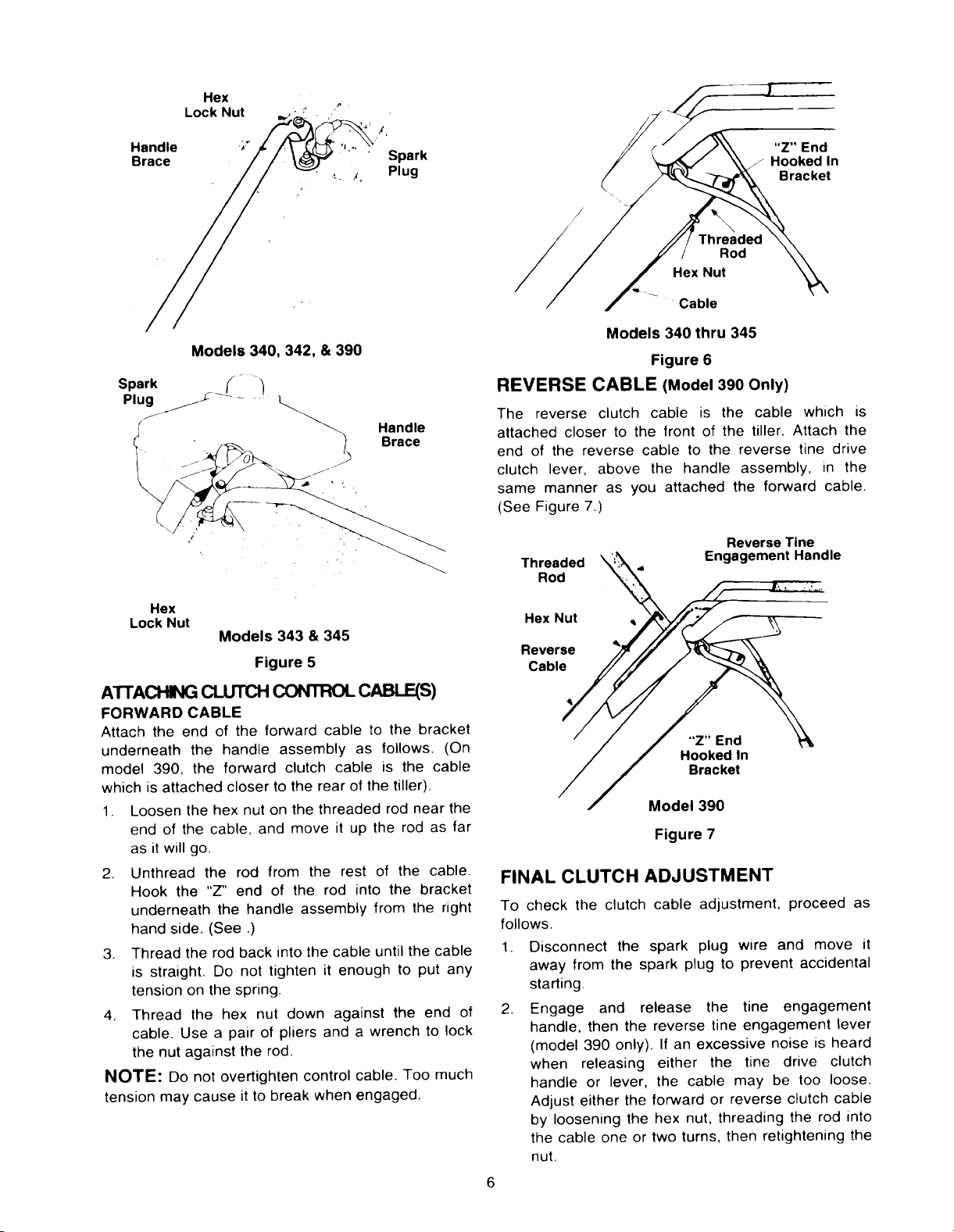

4. Remove the hex lock nut from on top of the

engine, just to the left of the spark plug. Attach

the curved end of the handle brace to the top of

the engine, using hex lock nut just removed.

Tighten securely. (See Figure 5.)

5. Select one of the three handle height positions

(three notches in welded bracket), and tighten

the hand knob to secure the handle in desired

position. Make certain carriage bolt is seated

securely into one of the three positions

provided.

Tailpiece

Lower •

Hole

Self-Tapping

Screw

Figure 3

Hand Knob Spark Hex

Plug Lock Nut

.

-. , Handle

Handle

Hex Bolt "\

Cupped j\_'

Washer

5

Brace

_.\ _ / ,/-

Frame " / /

Half _-- / //

Figure 4

Shoulder

Bolt

Hex

Lock Nut

Handle _/

Brace

Models 340, 342, & 390

Spark _ "_

Spark

Plug

Threaded

Rod

Hex Nut

Cable

"Z" End

Hooked In

Bracket

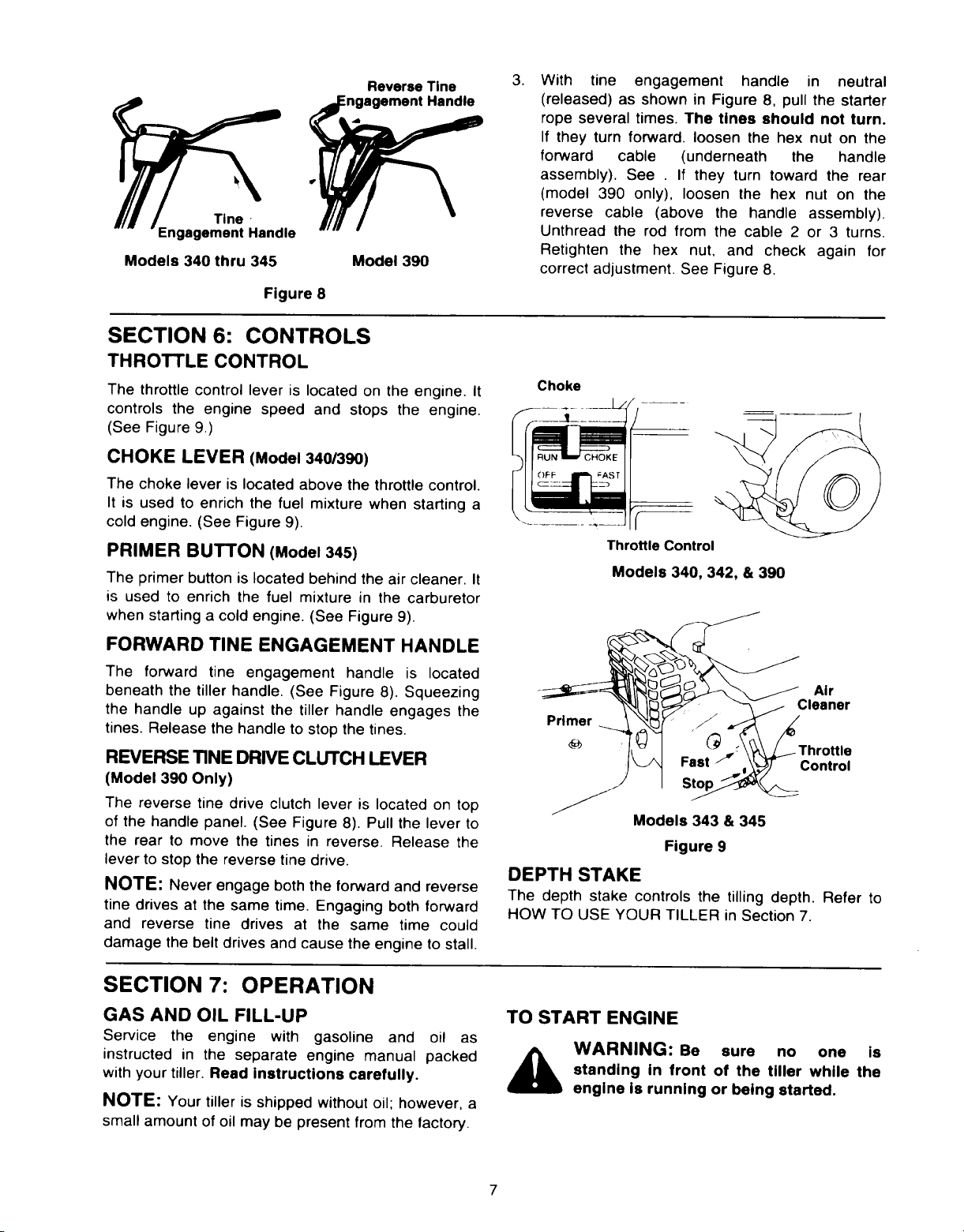

Models 340 thru 345

Figure 6

REVERSE CABLE (Model 390 Only)

Handle

Brace

f

The reverse clutch cable is the cable which is

attached closer to the front of the tiller. Attach the

end of the reverse cable to the reverse tine drive

clutch lever, above the handle assembly, in the

same manner as you attached the forward cable.

(See Figure 7.)

Reverse Tine

Threaded \

Rod

Engagement Handle

Hex

Lock Nut

Models 343 & 345

Figure 5

ATI"AQ-IIt_ CLUTCH _ CABLE(S)

FORWARD CABLE

Attach the end of the forward cable to the bracket

underneath the handle assembly as follows. (On

model 390, the forward clutch cable is the cable

which is attached closer to the rear of the tiller).

1. Loosen the hex nut on the threaded rod near the

end of the cable, and move it up the rod as far

as it will go.

2. Unthread the rod from the rest of the cable.

Hook the "Z" end of the rod into the bracket

underneath the handle assembly from the right

hand side. (See .)

3. Thread the rod back into the cable until the cable

is straight. Do not tighten it enough to put any

tension on the spring.

4. Thread the hex nut down against the end of

cable. Use a pair of pliers and a wrench to lock

the nut against the rod.

NOTE: Do not overtighten control cable. Too much

tension may cause it to break when engaged.

Hex Nut •

Reverse

Cable

"Z" End

Hooked In

Bracket

Model 390

Figure 7

FINAL CLUTCH ADJUSTMENT

To check the clutch cable adjustment, proceed as

follows.

1. Disconnect the spark plug wire and move it

away from the spark plug to prevent accidental

starting.

2. Engage and release the tine engagement

handle, then the reverse tine engagement lever

(model 390 only). If an excessive noise is heard

when releasing either the tine drive clutch

handle or lever, the cable may be too loose.

Adjust either the forward or reverse clutch cable

by loosening the hex nut, threading the rod into

the cable one or two turns, then retightening the

nut.

Reverse Tine

._Engagement Handle

Engagement Handle

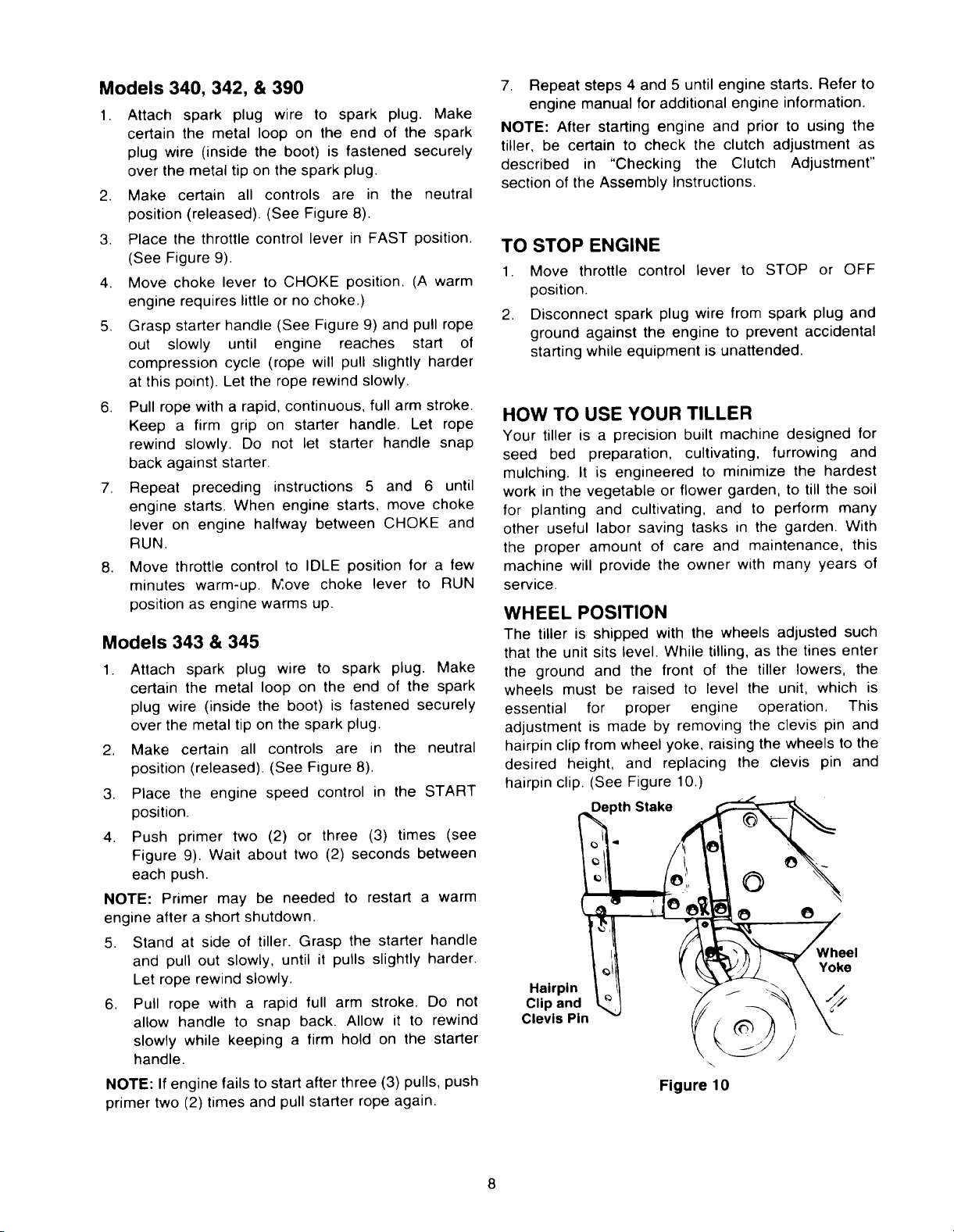

Models 340 thru 345 Model 390

Figure 8

SECTION 6: CONTROLS

THROTTLE CONTROL

The throttle control lever is located on the engine. It

controls the engine speed and stops the engine.

(See Figure 9.)

CHOKE LEVER (Model 3401390)

The choke lever is located above the throttle control.

It is used to enrich the fuel mixture when starting a

cold engine. (See Figure 9).

PRIMER BUTTON (Model 345)

The primer button is located behind the air cleaner. It

is used to enrich the fuel mixture in the carburetor

when starting a cold engine. (See Figure 9).

FORWARD TINE ENGAGEMENT HANDLE

.

With tine engagement handle in neutral

(released) as shown in Figure 8, pull the starter

rope several times. The tines should not turn.

If they turn forward, loosen the hex nut on the

forward cable (underneath the handle

assembly). See . If they turn toward the rear

(model 390 only), loosen the hex nut on the

reverse cable (above the handle assembly).

Unthread the rod from the cable 2 or 3 turns.

Retighten the hex nut, and check again for

correct adjustment. See Figure 8.

Choke

Throttle Control

Models 340, 342, & 390

J

The forward tine engagement handle is located

beneath the tiller handle. (See Figure 8). Squeezing

the handle up against the tiller handle engages the

tines. Release the handle to stop the tines.

REVERSE TINE DRIVE CLUTCH LEVER

(Model 390 Only)

The reverse tine drive clutch lever is located on top

of the handle panel. (See Figure 8). Pull the lever to

the rear to move the tines in reverse Release the

lever to stop the reverse tine drive.

NOTE: Never engage both the forward and reverse

tine drives at the same time. Engaging both forward

and reverse tine drives at the same time could

damage the belt drives and cause the engine to stall.

SECTION 7: OPERATION

GAS AND OIL FILL-UP

Service the engine with gasoline and oil as

instructed in the separate engine manual packed

with your tiller. Read instructions carefully.

NOTE: Your tiller is shipped without oil; however, a

small amount of oil may be present from the factory.

___ _ Air

Primer

_,_.q_ Cleaner

'o,

Models 343 & 345

Figure 9

DEPTH STAKE

The depth stake controls the tilling depth. Refer to

HOW TO USE YOUR TILLER in Section 7.

TO START ENGINE

standing in front of the tiller while the

WARNING: Be sure no one is

engine is running or being started.

Models 340, 342, & 390

1. Attach spark plug wire to spark plug. Make

certain the metal loop on the end of the spark

plug wire (inside the boot) is fastened securely

over the metal tip on the spark plug.

2. Make certain all controls are in the neutral

position (released). (See Figure 8).

3. Place the throttle control lever in FAST position.

(See Figure 9).

4. Move choke lever to CHOKE position. (A warm

engine requires little or no choke.)

5. Grasp starter handle (See Figure 9) and pull rope

out slowly until engine reaches start of

compression cycle (rope will pull slightly harder

at this point). Let the rope rewind slowly.

6. Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on starter handle. Let rope

rewind slowly. Do not let starter handle snap

back against starter.

7. Repeat preceding instructions 5 and 6 until

engine starts. When engine starts, move choke

lever on engine halfway between CHOKE and

RUN.

8. Move throttle control to IDLE position for a few

minutes warm-up. Move choke lever to RUN

position as engine warms up.

Models 343 & 345

1. Attach spark plug wire to spark plug. Make

certain the metal loop on the end of the spark

plug wire (inside the boot) is fastened securely

over the metal tip on the spark plug.

2. Make certain all controls are in the neutral

position (released). (See Figure 8).

3. Place the engine speed control in the START

position.

4. Push primer two (2) or three (3) times (see

Figure 9). Wait about two (2) seconds between

each push.

NOTE: Primer may be needed to restart a warm

engine after a short shutdown.

5. Stand at side of tiller. Grasp the starter handle

and pull out slowly, until it pulls slightly harder.

Let rope rewind slowly.

6. Pull rope with a rapid full arm stroke. Do not

allow handle to snap back. Allow it to rewind

slowly while keeping a firm hold on the starter

handle.

NOTE: If engine fails to start after three (3) pulls, push

primer two (2) times and pull starter rope again.

7. Repeat steps 4 and 5 until engine starts. Refer to

engine manual for additional engine information.

NOTE: After starting engine and prior to using the

tiller, be certain to check the clutch adjustment as

described in "Checking the Clutch Adjustment"

section of the Assembly Instructions.

TO STOP ENGINE

1. Move throttle control lever to STOP or OFF

position.

2. Disconnect spark plug wire from spark plug and

ground against the engine to prevent accidental

starting while equipment is unattended.

HOW TO USE YOUR TILLER

Your tiller is a precision built machine designed for

seed bed preparation, cultivating, furrowing and

mulching. It is engineered to minimize the hardest

work in the vegetable or flower garden, to till the soil

for planting and cultivating, and to perform many

other useful labor saving tasks in the garden. With

the proper amount of care and maintenance, this

machine will provide the owner with many years of

service.

WHEEL POSITION

The tiller is shipped with the wheels adjusted such

that the unit sits level. While tilling, as the tines enter

the ground and the front of the tiller lowers, the

wheels must be raised to level the unit, which is

essential for proper engine operation. This

adjustment is made by removing the clevis pin and

hairpin clip from wheel yoke, raising the wheels to the

desired height, and replacing the clevis pin and

hairpin clip. (See Figure 10.)

Depth Stake

Yoke

Hairpin \

Clevis Pin

c,p.

Figure 10

8

Loading...

Loading...