Page 1

Safety • Assembly • Operation • Tips & Techniques • Maintenance • Troubleshooting • Parts Lists • Warranty

A O A AL

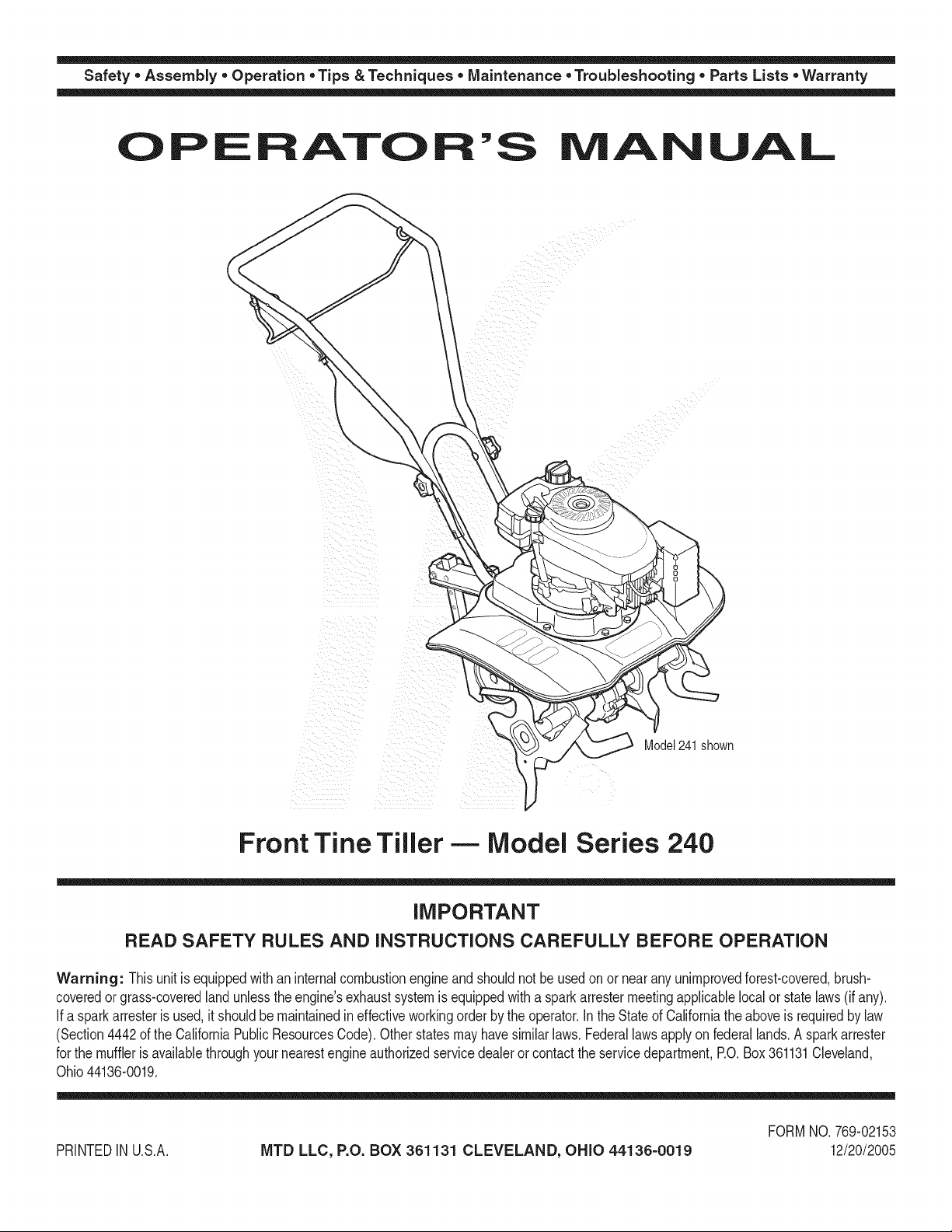

Model241shown

Front Tine Tiller -- Model Series 240

IMPORTANT

READ SAFETY RULES AND INSTRUCTIONS CAREFULLY BEFORE OPERATION

Warning: Thisunit isequippedwithaninternalcombustionengineandshouldnot beusedonornearanyunimprovedforest-covered,brush-

coveredor grass-coveredlandunlesstheengine'sexhaustsystemisequippedwitha sparkarrestermeetingapplicablelocalorstatelaws(if any).

If a sparkarresterisused,it shouldbemaintainedineffectiveworkingorderbytheoperator.IntheStateofCaliforniatheaboveisrequiredbylaw

(Section4442oftheCaliforniaPublicResourcesCode).Otherstatesmayhavesimilarlaws.Federallawsapplyonfederallands.Asparkarrester

forthe mufflerisavailablethroughyournearestengineauthorizedservicedealeror contacttheservicedepartment,RO.Box361131Cleveland,

Ohio44136-0019.

FORMNO.769-02153

PRINTEDIN U.S.A.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

12/20/2005

Page 2

This Operator's Manual is an important part of your new tiller, it will help you assemble,

prepare, and maintain the unit for best performance. Please read and understand what it says.

Table of Contents

Safety Labels ...................................................... 3

Safety ................................................................... 4

Assembly ............................................................. 6

Operation ............................................................. 8

Adjustments ...................................................... 12

Finding and Recording Model Number

BEFOREYOU ASSEMBLINGYOUR NEW EQUIPMENT,

please locatethe modelplate onthe equipmentandcopythe

informationtothe sample model plate provided tothe right.

Youcan locatethe modelplateby looking at the rear of the

tineshield.This informationis importantfor usewhen visiting

the manufacturer'sweb site,obtainingassistance from the

CustomerSupportDepartment,orwhencommunicatingwith

an authorizedservice dealer.

Maintenance ...................................................... 13

Troubleshooting ................................................ 14

Off-Season Storage .......................................... 15

Parts List ........................................................... 16

Warranty ............................................ Back Cover

f

Model Number

www.mtdproducts.com

Serial Number

MTD LLC

P.O. BOX 361131

CLEVELAND, OH 44136

330=220=4683

800-800-731 0

Customer Support

Please do IVOTretum the unit to the retailer from which it was

purchased, without first contacting Customer Support.

Ifyou have difficultyassemblingthis productorhave anyquestions regardingthe controls, operation,or maintenanceof this

unit,youcanseek helpfromthe experts.Choosefrom the options below:

• Visit www.mtdproducts.com. Click on the Service & Supportmenuoption.

• Phonea Customer Support Representative at 1-800-800-7310.

• The engine manufacturer is responsiblefor all engine-relatedissueswith regardsto performance, power-rating,specifica-

tions,warranty and service. Pleasereferto the engine manufacturer'sOwner's/Operator's Manual,packedseparatelywith

your unit, for moreinformation.

MTD _er_afio_a_ Aw®_8Wi_mir_@_r®d_cf_ O¢_rCompa_y

Product Menu

S,'.::hr_,iceS ,::_Jpp,._rt

Produd: Registration

Coa_ad__J_ ?riwcy Porky

2

Page 3

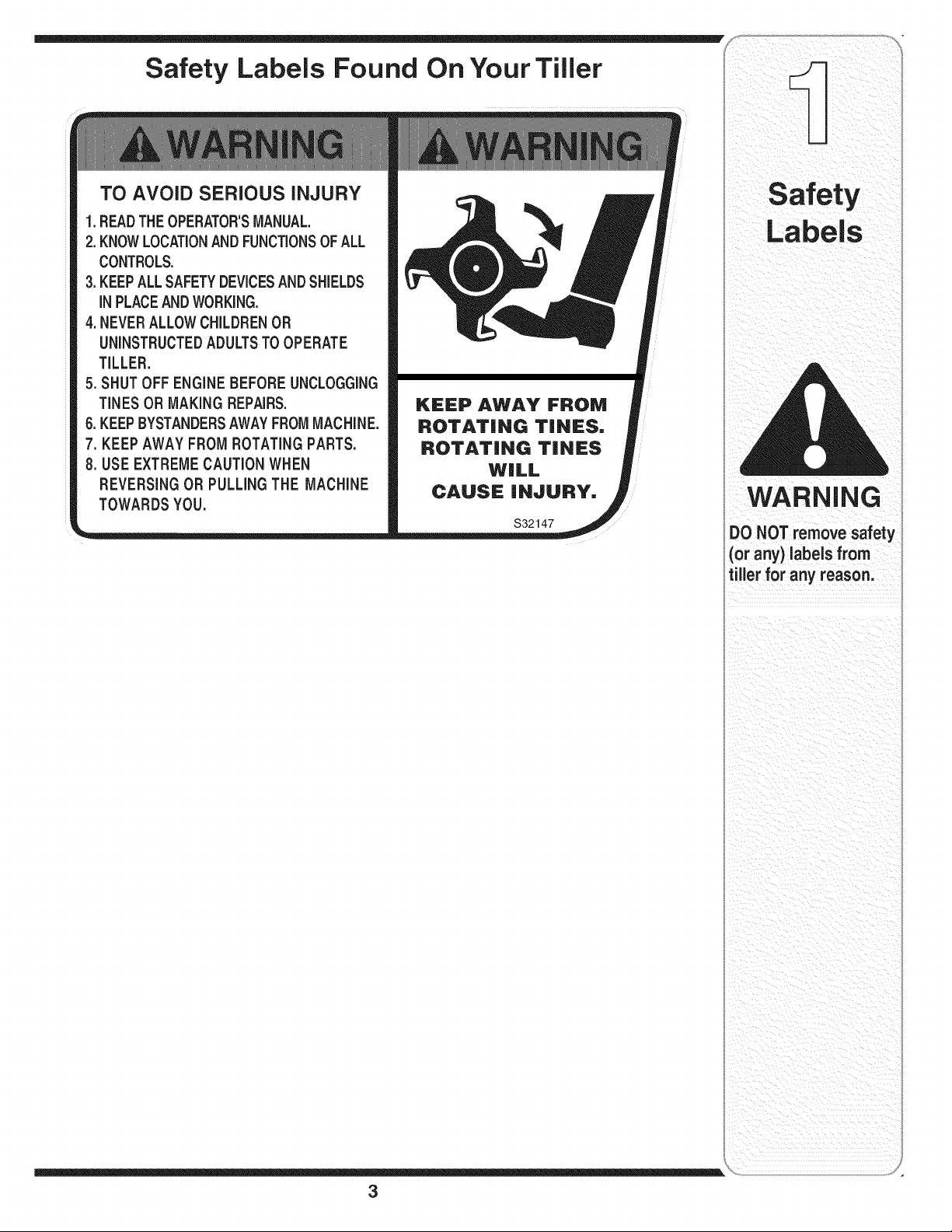

Safety Labels Found On Your Tiller

TO AVOID SERIOUS iNJURY

i_ii__iii_iI i__ii_

1.READTHEOPERATOR'SMANUAL.

2.KNOWLOCATIONANDFUNCTIONSOFALL

CONTROLS.

3.KEEPALLSAFETYDEVICESANDSHIELDS

iNPLACEANDWORKING.

4.NEVERALLOWCHILDRENOR

UNINSTRUCTEDADULTSTOOPERATE

TILLER.

5. SHUT OFF ENGINE BEFOREUNCLOGGING

TINES OR MAKING REPAIRS.

6.KEEPBYSTANDERSAWAYFROMMACHINE.

7,KEEP AWAY FROM ROTATING PARTS.

8.USE EXTREME CAUTION WHEN

REVERSING OR PULLING THE MACHINE

TOWARDS YOU.

Labels

WARNING

S32147

DONOT remove safety

(or any) labels from

tiller for any reason.

3

Page 4

Operat on

WARNING

Thissymbol points

outimportant safety

instructionswhich, if

notfollowed,could

endangerthe personal

safetyand/or property

of yourself and others.

Readand follow all

instructionsinthis man-

ualbeforeattempting to

operatethis machine.

Failureto complywith

these instructions

mayresult in personal

injury.When you see

i this symbol, HEED ITS

WARNING!

WARNING: EngineExhaust,some of its constituents, andcertain vehicle compo-

nentscontain or emit chemicals knownto Stateof Californiato cause cancer and

birth defects or other reproductiveharm.

DANGER: This machinewas built to beoperatedaccording to the rulesforsafe operationin this

manual.As with any type of powerequipment,carelessness or error on the part ofthe operatorcan

result in seriousinjury.This machine is capable of amputatinghands andfeet andthrowing objects.

Failureto observethe followingsafety instructionscould resultinserious injury ordeath.

Training

1. Read,understand,andfollow all instructionsonthemachine

andinthe manual(s)beforeattemptingto assembleand

operate.Keepthismanualina safeplaceforfutureand

regularreferenceand fororderingreplacementparts.

2. Befamiliarwithall controlsand theirproperoperation.Know

howtostopthe machine.

3. Neverallowchildrenunder14yearsoldto operatethis

machine.Children14yearsold andovershouldreadand

understandthe operationinstructionsand safetyrules in

this manualandshouldbe trainedand supervisedby a

parent.

4. Neverallowadultsto operatethis machinewithoutproper

instruction.

5. Keepbystanders,helpers,petsandchildrenatleast75feet

fromthe machinewhileitis inoperation.Stopmachineif

anyoneentersthearea.

Preparation

1. Thoroughlyinspectthe areawheretheequipmentisto be

used.Removeallstones,sticks,wire, andotherforeign

objectswhichcouldbetrippedoverandcausepersonal

injury.

2 Wearsturdy,rough-soledworkshoesand closefitting

slacksandshirt.Loosefittingclothesor jewelrycan be

caughtin movableparts.Neveroperatethis machinein bare

feetorsandals.

3. Disengageclutchleversand shift(if provided)intoneutral

("N")beforestartingthe engine.

4. Neverleavethis machineunattendedwiththe engine

running.

5. Neverattemptto makeanyadjustmentswhile engineis

running,exceptwherespecificallyrecommendedinthe

operator'smanual.

6. Toavoid personalinjury orpropertydamageuseextreme

carein handlinggasoline.Gasolineis extremelyflammable

andthevaporsare explosive.Seriouspersonalinjurycan

occurwhengasolineisspilledonyourselforyourclothes

whichcanignite.Washyourskin andchangeclothes

immediately.

7. Useonly anapprovedgasolinecontainer.

8. Extinguishallcigarettes,cigars,pipesand othersourcesof

ignition.

9. Neverfuelmachineindoors.

10.Neverremovegascapor addfuel whiletheengineishot or

running.

11.Allowenginetocool at leasttwo minutesbeforerefueling

12.Neveroverfillfueltank.Filltankto nomorethanY2inch

belowbottomof fillerneckto providespacefor fuel

expansion.

13. Replacegasolinecapandtightensecurely.

14. Ifgasolineisspilled,wipeit offtheengineand

equipment.Movemachinetoanotherarea.Wait5

minutesbeforestartingthe engine.

15. Neverstorethe machineorfuelcontainerinside nearan

openflame,spark or pilotlight(e.g.furnace,wateror

spaceheater,clothesdryer,etc.).

16. Allowmachineto cool 5minutesbeforestoring.

Operation

1. Do notput handsor feetnear rotatingparts.Contactwith

the rotatingpartscanamputatehandsandfeet.

2. Do notoperatemachinewhileunderthe influenceofalcohol

or drugs.

3. Neveroperatethismachinewithoutgoodvisibility orlight.

Alwaysbe sureof yourfootingand keepafirm hold onthe

handles.

4. Keepbystanders,helpers,pets,and childrenat least75feet

fromthe machinewhileitis inoperation.Stopthe machineif

anyoneentersthearea.

5. Becarefulwhentillingin hardground.Thetines maycatch

in thegroundandpropelthe tillerforward. Ifthis occurs,let

goof the handlebars anddo notrestrainthe machine.

6. Exerciseextremecautionwhenoperatingonor crossing

gravelsurfaces.Stayalertfor hiddenhazardsor traffic.

7. Neveroperatethe machineat hightransportspeedson hard

or slipperysurfaces.

8. Exercisecautionto avoidslippingorfalling.

9. Lookdownand behindandusecarewhenin reverseor

pullingmachinetowardsyou.

10.Startthe engineaccordingtotheinstructionsfoundin this

manualandkeepfeet wellawayfromthetinesat alltimes.

11.Afterstrikingaforeignobject,stoptheengine,disconnect

the sparkplugwireandgroundagainstthe engine

Thoroughlyinspectthe machinefor anydamage.Repairthe

damagebeforestarting andoperating.

12.Disengageallclutchlevers(if fitted)andstopenginebefore

youleavetheoperatingposition(behindthe handles).Wait

untilthetinescometoa completestopbeforeunclogging

thetines, makinganyadjustments,orinspections.

13.Neverrun anengineindoorsor inapoorlyventilatedarea.

Engineexhaustcontainscarbonmonoxide,an odorlessand

deadlygas.

14.Mufflerand enginebecomehotandcancausea burn.Do

nottouch.

15.Usecautionwhentillingnearfences,buildingsand

undergroundutilities.Rotatingtinescancauseproperty

damageor personalinjury.

4

Page 5

16.Donotoverloadmachinecapacityby attemptingtotill soilto

deepattoofast of arate.

17.Ifthe machineshouldstartmakinganunusualnoiseor

vibration,stopthe engine,disconnectthe sparkplugwire

andgroundit againstthe engine.Inspectthoroughlyfor

damage.Repairanydamagebeforestartingandoperating.

18.Keepallshields,guards,andsafetydevicesin placeand

operatingproperly.

19.Neverpick upor carrymachinewhiletheengineis running.

20.Use onlyattachmentsandaccessoriesapprovedbythe

manufacturer.Failuretodoso can resultinpersonalinjury.

21. Ifsituationsoccur whichare notcoveredinthis manual,use

careandgoodjudgment.Contactyourdealerortelephone

1-800-800-7310forassistanceandthe nameof your

nearestservicingdealer.

Maintenance & Storage

1. Nevertamperwith safetydevices.Checktheirproper

operationregularly.

2. Checkboltsandscrewsfor propertightnessatfrequent

intervalsto keepthe machineinsafe workingcondition.

Also,visuallyinspectmachineforany damage.

3. Beforecleaning,repairing,orinspecting,stopthe engine

andmakecertainthe tinesand all movingpartshave

stopped.Disconnectthesparkplugwireandgroundit

againstthe engineto preventunintendedstarting.

4. Do notchangethe enginegovernorsettings orover-speed

the engine.Thegovernorcontrolsthe maximumsafe

operatingspeedofthe engine.

5. Maintainor replacesafetyand instructionlabels,as

necessary.

6. Followthismanualfor safeloading,unloading,transporting,

andstorageofthis machine.

7. Neverstorethemachineor fuelcontainerinsidewhere

there isanopenflame,sparkorpilotlightsuchas awater

heater,furnace,clothesdryer,etc.

8. Alwaysrefertothe operator'smanualfor properinstructions

on off-seasonstorage.

9. Ifthe fueltank hasto bedrained,dothis outdoors.

10.Observeproperdisposallawsand regulationsforgas,oil,

etc.to protectthe environment.

Your Responsibility

1. Restrictthe useofthispowermachineto personswhoread,

understand,andfollowthe warningsandinstructionsinthis

manualandonthemachine.

2. Thesafetylabelsonthetillerareshowninthe "Safety

Labels"section.Toensuresafeoperationofthe tiller,follow

theinstructionsonalllabelsclosely.

ces

WARNING

Thissymbol points

out importantsafety

instructionswhich, if

notfollowed,could

endangerthe personal

safety and/or property

ofyourselfand others.

Readandfollowall

instructions inthisman-

ual before attemptingto

operatethis machine.

Failureto complywith

these instructions

mayresult in personal

njury.Whenyou see

this symbol, HEED ITS

WARNING!

5

Page 6

NOTE: Stand behind

the tilleras if you were

goingto operate it. Your

righthand corresponds

to the right sideof the

tiller; your left hand

correspondsto the left

sideof the tiller.

NOTE:This operator's

manualmay cover

various modelsof tillers.

The unitsillustrated

mayvary slightlyfrom

your unit. Followonly

those instructionswhich

pertainto your model

number.

Assembly

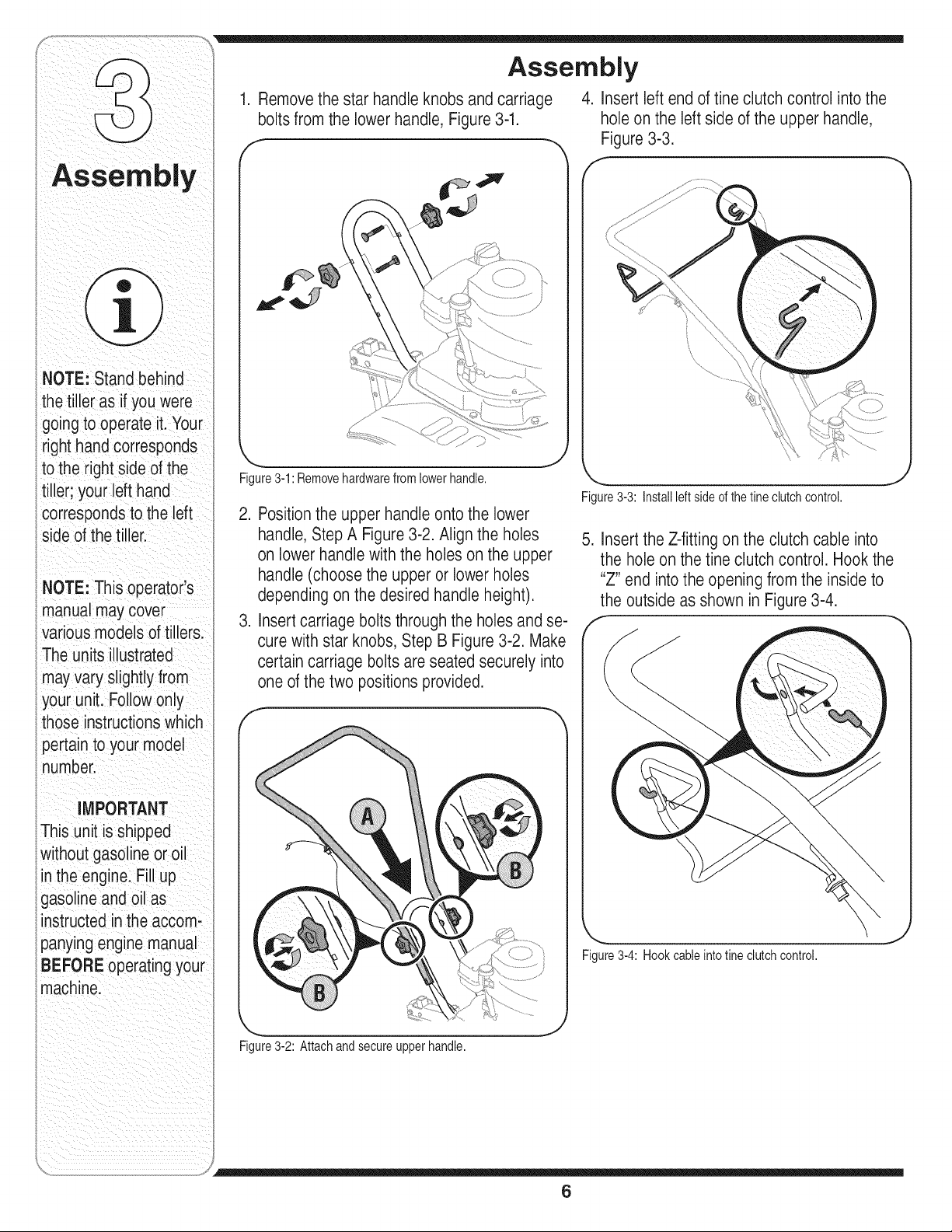

1. Removethe star handle knobs andcarriage

boltsfrom the lowerhandle, Figure3-1.

J

Figure3-1:Removehardwarefrom lowerhandle.

2. Positionthe upper handleontothe lower

handle,Step A Figure3-2.Alignthe holes

onlowerhandlewith the holes on the upper

handle(choosethe upper or lower holes

dependingon the desired handleheight).

3. Insertcarriage boltsthroughtheholesand se-

cure with star knobs,Step B Figure 3-2. Make

certain carriageboltsare seated securely into

one ofthetwo positions provided.

f

4. Insert leftendof tine clutch control into the

holeon the leftside of the upper handle,

Figure3-3.

f

\

J

Figure3-3: Installleftsideofthe tineclutchcontrol.

5. InserttheZ-fittingon the clutch cable into

the hole on the tine clutch control. Hook the

"Z" end into the opening from the insideto

theoutside as shown in Figure3-4.

iMPORTANT

::Thisunit is shipped

without gasoline or oi

iinthe engine. Fillup

igasolineand oil as

instructedintheaccom-

panyingenginemanual

iBEFOREoperatingyour

machine.

'_ _j

Figure3-2:Attachandsecureupperhandle.

....... J

Figure3-4: Hookcableintotineclutchcontrol.

6

\

Page 7

6.Squeezethetineclutchcontrolinward.

Insertrightendintotheholeontherightside

oftheupperhandle,Figure3-5.

f

,,_ .y

Figure3-5: Installrightend oftineclutchcontrol.

NOTE: Stand behind

thetiller as if you were

goingto operate it. Your

ighthand corresponds

to the rightside ofthe

tiller; your left hand

correspondstothe left

side of the tiller.

NOTE: This operator's

manualmay cover

various modelsoftillers.

The units illustrated

mayvary slightlyfrom

our unit. Followonly

those instructionswhich

)ertain to your mode[

number.

7

Page 8

You rTiller

WARNING

Thetine clutch control

isasafetydevice.

Neverattempt to

bypass its operation.

Rec0il

Starter

Clutch Cable

Rear Wheel

with Depth

Stake

Useextremecare

when handling

gasoline.Gasoline is

extremely flammable

and the vapors are

explosive.Neverfuel

the machine indoors

i orwhilethe engine

ishot or running.

Extinguishcigarettes,

cigars, pipes, and

other sources of

ignition.

Keephandsand feet

awayfrom the tines.

Referto warning label

on the unit.

Figure4-1:The majorpartsofthetiller (model241shown).

_ ARNING:Read,understand, and

follow ail instructionsandwarnings

postedonthe machine and inthis

manualbefore operating.

Tine Clutch Control

Theclutchcontrolleverislocatedontheupperhandle.

Squeezingthe leveragainstthe handleengagesthefine

drive.Releasetheleverto stopthe tinesfromturning.

Rear Wheel with Depth Stake

Thedepthstakeandwheelare locatedatthe rearof

thetiller.Bothmaybeadjusted.Refertothe "Wheel

Position"and"DepthStake"sectionsfor instructions.

Handle Knobs

Thehandleheightmaybeadjusted.Loosentheknobs

andremovethecarriageboltstochangetheposition.

Reinstallandtightenthe hardwarewhencomplete.

Engine Controls

NOTE:Seetheseparateenginemanualforadditional

engineinformationand functions.

Throttle Control

Thethrottlecontrolleveris locatedon theengine,it

controlstheengine'sspeedandstopstheengine.

* Withthe throttlecontrolmovedcompletelyto theleft,

thecarburetorisin STARTor FASTposition.Use

maximumenginespeedfor deeptilling.

* Movethe throttlecontrollevertotherightto reduce

enginespeed.ThrottlecontrolshouldbeatIDLEfor

transportingthe tiller.

Movethethrottleallthewaytothe rightto stopthe

engine.

Primer

Theprimer,locatedonthe engine,is usedto pumpgas

intothe carburetorandaid instartingthe engine.Useit

tostarta coldengine,butdonotuseitto restartawarm

engineaftera shortshutdown.

Recoil Starter

Therecoilstarteris locatedon theengineandisusedto

manuallystartthe engine.

8

Page 9

_ ARNING:Read,understand,and

follow all instructionsandwarnings

postedonthe machine and in this

manualbefore operating.

manyotherusefullaborsavingtasksinthe garden.After

engineis runningandappropriatespeedseton throttle,

squeezefineclutchcontrol(seeFigure4-1)against

upperhandleto engagethefinedrive.Releasethelever

tostopthetinesfromturning.

Before Starting

Gas And Oil Fill-Up

Servicetheenginewithgasolineandoil asinstructedin

theseparateenginemanualpackedwithyourtiller.Read

instructionscarefully.

_._|1_ ARNING:Useextremecarewhen

handlinggasoline. Gasolineisex-

tremely flammable and thevaporsare

explosive.Neverfuel machine indoors

or while the engineishot or running.

Starting Engine

_ WARNING:Besureno one is standing

1. Attachsparkplugwireto sparkplug. Makesurethe

metalcapontheendofthesparkplugisfastened

securelyoverthemetaltip on thesparkplug.

2. Makesurethatthefineclutchcontrolisdisengaged.

3. PlacethethrottlecontrolintheFASTposition.

4. Forfirsttimestart-up,firmlypressengineprimerfive

(5)times.Forallfuturestarts,pressthree(3) times.

Waitabouttwo secondsbetweeneachpress.

5. Placelefthandongas tank.Grasprecoilstarterand

pullropeoutslowlyuntilenginereachesthebeginning

ofitscompressioncycle(ropewillpull slightlyharder

atthispoint).

6. Pullropewitharapid,continuous,fullarmstroke.

Keepa firmgripon handle.Letroperewindslowly.Do

notlet recoilstartersnapbackagainstengine.Repeat

untilenginestarts.

infront of the tiller while the engineis

runningor being started.

Wheel Position

Thetiller isshippedwiththewheeladjustedsuchthat the

unitsitslevel.Beforetilling,thewheelmustberaised.To

dothis,removethe clevisandcotterpins,raisethewheel

tothe desiredposition,thenreattachpinsto secure,

Figure4-2.Fortransportingthetiller,reversethestepsto

lowerthewheel.

Figure4-2:WheelAdjustment

Depth Stake

Thedepth stakeactsasabrakeforthetillerandcontrols

thedepthand speedat whichthemachinewilloperate,

Figure4-3. Removethe clevisandcotterpins,raiseor

lowerthedepthstake,thenreattachpinstosecure.

Your Tiller

WARNING

Besorenooneother

thanthe operator :is

standing near the tiller

while starting engine

or operating the unit.

Never run engine

indoorsor in enclosed,

poorly ventilated

areas. Engine exhaust

contains carbon

monoxide, an odorless

and deadly

hands, feet, hair and

loose clothing away

fromanymo. ngparts

Stopping Engine

1. MovethrottlecontrollevertoSTOPor OFFposition.

2. Disconnectsparkplugwirefromsparkplugand

groundagainsttheengine.

Using Your Tiller

Yourtiller(alsoknownasacultivator)isa precisionbuilt

machinedesignedforseedbedpreparation,cultivating,

furrowing,andmulching.It isengineeredto minimize

thehardestworkinthevegetableor flowergarden,to

till thesoilforplantingandcultivating,andto perform

See your engine

manual packaged with

your unit for detailed

instructions pertaining

to starting the engine,

Figure4-3:The DepthStake

_ii_i_;i/;I_I:_I_I_I_I_I_I_I_I_I_I_I_I!!il

9

Page 10

i ¸

Fortilling,thedepthstakemustbeloweredandthe

wheelmustbe raised,Figure4-4.

Byincreasingthedepthof thedepthstake,theforward

speedof themachineis reducedandthe workingdepth

isincreased.Whenthe depthstakeis raised,theworking

depthof themachineis reducedandthe forwardspeed

isincreased.Theworkingdepthofthemachinemay

bepredeterminedbysettingthedepthstakesothatthe

wheelsareaboutfourinchesfromthegroundwhenthe

tinesanddepthstakearerestingonthe ground.This

settingwill permitaworkingdepthof aboutfourinches.

Whenpresettingtheworkingdepth,the handlesshould

beadjustedsothehandgripsarea littleabovewaist.

Thetiller willbelowerwhenthe tinesand depthstake

penetratetheground.

Figure4-4:Lowerthedepthstakeandraisethe wheelwhen

tilling.

Controlling Speed and Tilling Depth

Whentilling,leaveapproximately8 inchesof untilledsoil

betweenthefirst andsecondtillingpaths,thenmake

thethirdpathbetweenthefirstandsecond,Figure4-5.

Insomesoils,thedesireddepthis obtainedthefirst

timeoverthe garden.Inothersoils,thedesireddepth

isobtainedbygoingoverthegardentwoorthreetimes.

Passesshouldbemadeacrossthelengthandwidth

ofthe gardenalternately.Rockswhichareturnedup

shouldberemovedfromthe gardenarea.

J

Figure4-5:Recommendedtillerpaths.

Thetypeof soilandworkingconditionswilldeterminethe

actualsettingof thedepthstakeandthehandlepressure

required.

Cultivating

Forcultivating,a twotothreeinchdepth isdesirable.The

throttleshouldbe settocontrolforwardmovementto a

slowwalkingspeed.Withtheoutertinesinstalled,the

workingwidthofthe machineis22 or24inches.

Forcultivation,thismaybereducedto 13inchesby

removingtheoutertines,refertotheAdjustmentSection.

Whenlayingoutplant rows,besuretoallowenough

widthto permitcultivationbetweentherows.Ingrowing

cornor similarcrops,check-rowplantingwillpermitcross

cultivationandpracticallyeliminatehandhoeing,Figure

4-6.

Handle Pressure

Furthercontroloftillingdepthandtravelspeedcanbe

obtainedbyvariationofpressureonthe handles.

A downwardpressureon thehandleswillreducethe

workingdepthandincreasetheforwardspeed.An

upwardpressureon the handleswillincreasethe

workingdepthandreducetheforwardspeed.

Figure4-6:Allowenoughareabetweenrows.

Thetiller hasmanyusesotherthantillingandcultivating

a garden.Oneof theseisthepreparationoflawnarea

forseeding.Thetillerwillprepareadeepseedbedwhich

10

Page 11

willbefreeofharduntilledspots,allowingabetterstandofgrassto grow.Thetillerisveryusefulforlooseninghard

soilfor excavationwitha shovel;Notedioushandworkwillbenecessary.Yourtillermaybe usedformixingcompost

in thepileorfor mixingitwiththesoil inyourgarden.Thisshouldbedoneafterthesoil hasbeenbrokentothefull

workingdepth.Thecompostshouldbe workedin toadepthofsix to seveninches.Thismaybedonebyworkingthe

lengthof thegardenandthenbymakingseparatepassesacrossits width.Theadditionofdecayedorganicmatterwill

substantiallyincreasethefertilityofyourgarden.Forproperdecayingaction,fertilizershouldbeappliedandworkedin

withthemulchmaterials.Breakingupleavesandstrawandmixingitwithseveralinchesof soilallowsproperaeration

ofthe plantrootsystemandretardsthe growthofweeds.

Transporting and Storing the Tiller

Totransportthetiller,lowerthewheeland movethe Tostorethe tiller,lowerthe wheelandorientthedepth

depthstaketothehighestposition,Figure4-7. stakeso botharetouchingthe ground,Figure4-8.

J _ J

Figure4-7:Fortransport,lowerwheelandraisedepthstake. Figure4-8:Forstorage,lowerwheelanddepthstake.

Your Tiller

Besurenooneother

than the operator is

standing near the tiller

while starting engine

or operating the unit;

Never engine

indoorsOrinenclosed,

poorlyventilated

areas. Engine exhaust

containscarbo

monoxide, anodorless

and deadly gas:Keep

hands, feet, hair and

looseclothingaway

from any moving parts

11

See your engine

manual packaged with

your unit for detailed

instructions pertaining

to starting the enginei

Page 12

Making Adjustments

i¸ : / i:!

NOTEi This operator,s

manual may coverVari_

ous modelsoftillerS:

The unts illuStrated

mayVaryslightlyfrom

your unit.Followon!y

those instructions

Whichpertain to your

model numberl ...........

Warning: Disconnectthe spark

plugwire and ground it against

the engine before performing

any adjustments.

Engine Adjustment

Referto the separateengine manualfor engine

adjustmentinstructions.

Tine Width Adjustment

The tilling width ofthe unit is22 inches.Tilling

width can increaseto 24 inchesby removing

the clevis and cotter pins, sliding each outer

tine out one inch, and securingin this position

with the pins. Forcultivation, reduce thetine

width to 13inches byremovingthe outer tines

completely,Figure 5-1.

f

,€ 24-inch

2-inch •

NOTE: Stand behind

thetiller as if you were

goingto operate it.

Yourrighthand cor-

respondsto the right

side of the tiller; your

left hand corresponds

:othe left side of the

:iller.

J

Figure5-1:Tinewidthadjustment.

12

Page 13

nect sparkplug,andgroundagainst

performingany maintenanceon your

machine.

Engine

Refertothe separateenginemanualforenginemainte-

nanceinstructions.

• Maintainengineoilas instructedintheseparate

enginemanualpackedwithyourunit.Readandfollow

instructionscarefully.

• Serviceair cleanereveryten hoursundernormal

conditions.Cleaneveryhourunderextremelydusty

conditions.Poorengineperformanceandflooding

usuallyindicatesthattheair cleanershouldbe

serviced.Toservicetheaircleaner,refertothe

separateenginemanualpackedwithyourunit.

'_,'_) MPORTANT:Neverrunyourenginewithout

air cleanercompletely assembled.

• Thesparkplugshouldbecleanedandthegap reset

every25hoursofengineoperation.Sparkplug

replacementis recommendedat thestartofeachtiller

season;checkenginemanualforcorrectplugtype

andgap specification.

• Cleantheengineregularlywitha clothor brush.

Keepthecoolingsystem(blowerhousingarea)clean

to permitproperaircirculationwhichisessentialto

engineperformanceand life.Becertainto removeall

dirtandcombustibledebrisfrommufflerarea.

Lubrication

Transmission

Thetransmissionispre-lubricatedandsealedatthefac-

tory.It requiresnochecking.Seean authorizedservice

dealerforany serviceissues.

Tine Shafts

Removetine assembliesand lubricatethetine shaftsat

leastoncea season.

Wheel Shaft

Removewheelassemblyandlubricatetheaxleshaftat

leastoncea season.

Yourtillerhas beenengineeredwitha beltmadeof

specialmaterialforlongerlifeand betterperformance.

It shouldnotbe replacedwithanoff-the-shelfbelt.See

theretailerfromwhichyoupurchasedyourtiller,an

authorizedMTDServiceDealer,orcall 1-800-800-7310

forinformationregardingpriceandavailability.

1. Removetheframeandenginebyremovingthesix

screwsandlocknutsholdingtheengineandframeto

theshield,Figure6-1.

Figure6-1:Removeengineandframetogainaccesstothebelt.

(Model241shown)

2. Loosenthelocknut showninStepAFigure6-2.

3. Unloopthebeltfromthepulleys,StepB Figure6-2.

4. Reassemblethe newbelt andtightenthelocknut.

5. Reattachframeandengineusingthehardware

removedearlier.

Alwaysstop engine,

disconnectspark

plugland ground

ga nstenginebefore

cleaningl lubricat-

mgor performing

maintenance on your

machine:

IMPORTANT:Never

usea pressurewasher

to clean yourtiller.

Water can penetrate

tightareas ofthetiller

causing serious damage

to the unit.

Cleaning Tine Area

Cleanthe undersideofthefineshieldaftereach use.

Thedirt washesoffthetineseasierifrinsedoff im-

mediatelyinsteadof afteritdries.Alwaystoweldrythe

tillerafterwardsandapplya lightcoatofoil or siliconeto

preventrustingorwaterdamage.

(]_,_j) IMPORTANT:Neveruse a "pressure washer"

to clean your tiller. Water can penetratetight

areasof the tiller causing serious damage.

IMPORTANT:Never run

your engine withoutthe

aircleaner completely

assembled.

Figure6-2:Loosenthenuttoremovethebelt.

13

Page 14

Problem Cause Remedy

Engine fa! s tOstart wi!ed ! connect wireto spa[k

I 2 Fue tankemptyorstaefue 2 F tankwthcean freshgaso ne

3. Throttle control!evernotincorrect 3, Movethrottlelevertostart position.

sta_ingPosition(i!equipped)position I

4, Chokenot n ON post on. 5: clean fuelline.

&Blocked fue! 6 C!ean:adjustgaROr[epiace:

Fau!tysPa[k wait afew rninutesto restartlbutdo

7, Engnefood ng. . not prme(f equpped)

For repairs beyond

the minor adjust.

merits listed here,

contact an authorized

service dealer.

Engineruns erratic

1. Sparkplugwireloose.

2. Unitrunningon CHOKE.

3. Blockedfuellineor stalefuel.

4. Ventplugged.

5. Waterordirtin fuelsystem.

6. Dirtyair cleaner.

7. Carburetorout ofadjustment.

1. Connectandtightenspark

plugwire.

2. MovechokelevertoOFE

3. Cleanfuelline;filltankwithclean,

freshgasoline.

4. Clearvent.

5. Drainfueltank. Refillwith

freshfuel.

6. Cleanfollowingenginemanual.

7. Referto enginemanual.

I

Engineoverheats !; Engineoi!!eve!low: 1; E!!crankcasew thProPeroi!:

2 Di!tYa[fi!ter: 2 c!eanai[C!eaiei:

Ai[f!ow iest[cte& Removeblowerhousingandc!eanr

4. Carburetornotadjustedproperly. 4. Referto enginemanual.

Tines do no engage

1. Foreignobjectlodgedintines.

2. Tineclevispin(s)missing.

3. Beltwornand/orstretched.

4. Pulleyandidlernotincorrectadjust-

ment.

1. Stop tillercompletely,checkand

discardforeignobject.

2. Replacefineclevispin(s).

3. Replacebelt.

4. Takeunit toauthorizedservice

14

Page 15

Off-Season Storage

ifthe tillerwill notbeusedforaperiodlongerthan30

days,the followingstepsshouldbetakentopreparethe

tillerfor storage.

Cleantheexteriorofengineandthe entiretiller

thoroughly.Lubricatethetillerasdescribedin the

lubricationinstructions.

Wedonotrecommendtheuseof pressurewashersto

cleanyour unit.Theymaycausedamageto spindles,

pulleys,bearings,orthe engine.Theuseofpressure

washerswill resultin shortenedlifeand reduce

serviceability.

Refertothe enginemanualforcorrectenginestorage

instructions.

Wipetineswithoiledragto preventrust.

Storetillerin aclean,dryarea.Donotstorenextto

corrosivematerials,suchas fertilizer.

Whenstoringanytypeofpowerequipmentinan

unventilatedor metalstorageshed,careshouldbe

takentorustprooftheequipment.Usinga lightoil

or silicone,coatthe equipmentandespeciallyany

springs,bearings,andcables.

NOTE: When storing

anytype of power

equipment inan unven-

tilatedor metalstorage

shed.careshould be

takento rustproofthe

equipment.Usinga

Ight oil or silicone,coat

theequipmentand

especiallyany springs,

bearings,and cables.

15

Page 16

16

Page 17

1 749-04282 UpperHandle

2 720-04072 StarHandle Knob

3 749-04281 LowerHandle

4 710-04398 FlangeScrew5/16-18x7.5

5 754-04123 Belt

6 756-04163 idlerPulley

7 748-04125 ShoulderSpacer

8 686-04080 IdlerBracket

9 712-04065 FlangeLockNut:3/8-16

10 710-0654A TT Screw3/8-16x 1.00

11 786-04303 Frame

Parts List

12 710-0514 HHCapScrew3/8-16x 1.00

13 732-0418 ExtensionSpring

14 738-04139 Stud33x 1.5x 3/8-16

15 756-04217 FlywheelPulley

16 710-0591 HHCapScrew3/8-24x 1.00

17 710-0520 HHCapScrew3/8-16x 1.50

18 786-04256 TineShield61cm

19 711-0415 ClevisPin

20 642-0005 OuterTineAssemblyLH

21 642-0003 InnerTineAssemblyLH

22 714-0149B internalCotterPin

23 710-0809 TT Screw1/4-20x 1.25

24 GW-9727 PipePlug3/8 NPT

25 642-0002 InnerTineAssemblyRH

26 642-0004 OuterTineAssemblyRH

27 618-04276A CaseAssembly

28 721-04157 Gasket

29 726-0299 PushCap

30 734-0973 Wheel5 x 1.38

31 749-04265 DepthStakeTube

32 711-04520 Axle Shaft

33 710-1007 TT Screw3/8-16x 1.50

34 786-04296 WheelBracket

35 749-04266 RearWheelTube

36 714-3020 internalCotterPin

37 712-04063 FlangeLockNut:5/16-18

38 710-0487 CarriageBolt

39 731-05385 ClutchCableFitting

40 746-04247 ClutchCable

41 710-0599 TT Screw1/4-20x.50

42 786-04307 Cable MountBracket

43 747-04508 Clutch Bail

44 736-0300 FiatWasher.406x .875x .059

_FACTORY PARTS

To order

replacement parts, call

1-800-800-7310

or visit

www.mtdproducts.com

Fora properworking

machine,use Fac-

tory Approved Parts.

V-BELTSare specially

designed to engageand

disengagesafely. A

substitute (nomOEM)

V-Belt canbe danger-

ous by not disengaging

completely.

Tiller features/compo-

nentsvarybymodel.

Someparts listed may

not be availableonyour

unit.

17

Page 18

Notes

Use this page to take notes.

_ ii_ _ i_ill i_ii i_iii_ _ I_

Page 19

Use this page to take notes.

Notes

19

Page 20

MANUFACTURER'S LiMiTED WARRANTY FOR

ThelimitedwarrantysetforthbelowisgivenbyMTDLLCwithrespect

tonewmerchandisepurchasedandusedin theUnitedStates,its

possessionsandterritories.

"MTD"warrantsthisproductagainstdefectsinmaterialandworkman-

shipfor a periodoftwo (2)yearscommencingonthedateoforiginal

purchaseandwill,at itsoption,repairor replace,freeof charge,any

partfoundto bedefectiveinmaterialsorworkmanship.Thislimitedwar-

rantyshallonlyapplyifthisproducthasbeenoperatedandmaintained

inaccordancewiththe Operator'sManualfurnishedwiththeproduct,

andhasnotbeensubjectto misuse,abuse,commercialuse,neglect,

accident,impropermaintenance,alteration,vandalism,theft,fire,water,

ordamagebecauseofotherperilor naturaldisaster.Damageresulting

fromthe installationor useof anypart,accessoryor attachmentnot

approvedby MTDforusewiththeproduct(s)coveredbythis manual

willvoid yourwarrantyasto anyresultingdamage.

Normalwearpartsarewarrantedto befreefromdefectsinmaterialand

workmanshipfora periodof thirty(30)daysfromthedateof purchase.

Normalwearpartsinclude,butare notlimitedto itemssuchas: batter-

ies,belts,blades,bladeadapters,grassbags,riderdeckwheels,seats,

snowthrowerskidshoes,shaveplates,augerspiralrubberandtires.

NOW TO OBTAIN SERVICE: Warrantyservice isavailable,WITH

PROOFOF PURCHASE, throughyour localauthorizedservice

dealer.To locate the dealer in your area, check yourYellowPages,

or contact MTDLLCat RO.Box361131,Cleveland,Ohio44136-

0019,or call 1-800-800-7310or 1-330-220-4683 or log on to our

Website at www.mtdproducts.com.

Thislimitedwarrantydoesnotprovidecoverageinthefollowingcases:

a. Theengineor componentpartsthereof.Theseitemsmaycarrya

separatemanufacturer'swarranty.Refertoapplicablemanufacturer's

warrantyfortermsandconditions.

b. Logsplitterpumps,valves,andcylindershavea separateoneyear

warranty.

c. Routinemaintenanceitemssuchaslubricants,filters,blade

sharpening,tune-ups,brakeadjustments,clutchadjustments,deck

adjustments,andnormaldeteriorationof theexteriorfinishdueto

useor exposure.

d. Servicecompletedbysomeoneotherthananauthorizedservice

dealer.

e. MTDdoesnotextendanywarrantyforproductssoldor exported

outsideofthe UnitedStates,its possessionsandterritories,except

thosesoldthroughMTD'sauthorizedchannelsofexportdistribution.

f. ReplacementpartsthatarenotgenuineMTDparts.

g. Transportationchargesandservicecalls.

Noimpliedwarranty,includingany impliedwarrantyof mer-

chantabilityof fitness for a particular purpose,appliesafter the

applicable periodof express written warranty aboveasto the

partsasidentified.Nootherexpresswarranty, whetherwritten or

oral, except as mentioned above,givenby any personor entity,

includinga dealeror retailer, withrespect to any product,shall

bindMTD.Duringthe periodof the warranty,the exclusiveremedy

isrepairor replacementof the productassetforth above.

Theprovisionsas set forth inthis warrantyprovidethesoleand

exclusiveremedy arising from the sale.MTDshallnot be liable

for incidentalor consequentiallossor damageincluding,without

limitation, expensesincurredfor substituteor replacementlawn

careservicesor for rentalexpensesto temporarily replacea

warranted product.

Somestatesdo notallowthe exclusionor limitationofincidentalor

consequentialdamages,orlimitationsonhowlongan impliedwarranty

lasts,sothe aboveexclusionsor limitationsmaynotapplytoyou.

Innoeventshallrecoveryofanykindbegreaterthantheamountofthe

purchasepriceof theproductsold.Alterationof safetyfeaturesof

the product shallvoid this warranty. Youassumethe riskand liability

forloss,damage,or injuryto youandyourpropertyand/ortoothersand

theirpropertyarisingoutofthemisuseor inabilitytousethe product.

Thislimitedwarrantyshallnotextendtoanyoneotherthantheoriginal

purchaserorto the personforwhomitwaspurchasedasa gift.

HOWSTATELAWRELATESTOTHISWARRANTY:Thislimited

warrantygivesyouspecificlegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

IMPORTANT:OwnermustpresentOriginalProofof Purchaseto obtain

warrantycoverage.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136=0019; Phone: 1=800=800=7310, 1=330=220=4683

Loading...

Loading...