MTD 218-402-000 User Manual

$1.00

owners GUIDE

OUTDOOR POWER EQUIPMENT

for all seasons

REAR TINE

TILLERS

IMPORTANT:

Read Safety Rules and

Instructions Carefully

PRINTED IN U.S.A.

Model Numbers

218-402-000

218-404-000

218-405-000

Thank you for purchasing

an American-built product.

FORM NO. 770-5250C

INDEX

Safe Operation Practices

Assembiy

Controis

Operation...................................................................8

How To Use Your Tilier

Adjustments....................................................

Lubrication......................................................

Maintenance...................................................

Off-Season Storage........................................

Trouble Shooting Chart ..................................

lilustrated Parts

Parts List

Parts Information

...................................................................

.....................................................................

.....................................

...............................................

.......................................

........................................

.............................................

.. .9

. .10

. .11

. .13

. .14

16, 18, 20, 21

17, 19, 20, 21

Bad Cover

Dear Customer,

So often throughout the year we are all In a

3

4

7

8

rush to meet our daily obligations.

However, we at MTD Products Inc are tak

ing a quick moment out to say...

“Thank you for your business.’’

Sincerely,

MTD PRODUCTS INC

INSTRUCTIONS GIVEN WITH THIS SYM

BOL ARE FOR PERSONAL SAFETY. BE

A

SURE TO FOLLOW THEM.

r

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

LIMITED WARRANTY

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm, any

part or parts found to be defective ii material or workmanship. Transportation charges for

the movement of any power equipment unit or attachment are the responsibility of the pur

chaser. Transportation charges foriimy parts submitted for replacement under this warran

ty must be paid by the purchaser unless such return is requested by MTD PRODUCTS INC.

This warranty will not apply to any eart which has become inoperative due to misuse, ex

cessive use, accident, neglect, improper maintenance, alterations, or unless the unit has

been operated and maintained in ac cordance with the instructions furnished. This warran

ty does not apply to the engine, mot^r, battery, battery charger or component parts thereof.

Please refer to the applicable manufacturer’s warranty on these items.

This warranty will not apply where the unit has been used commercially.

Warranty service is available throuj h your local authorized service dealer or distributor. If

you do not know the dealer or distril)utor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will not be accepted by the factory unless prior written per

mission has been extended by MTD.

This warranty gives you specific legal rights. You may also have other rights which vary

from state to state.

♦

♦

♦

♦

♦

♦

♦

t

♦

♦

♦

♦

♦

♦

J

WARNING: This unit is equipped with an interrial combustion engine and should not be used on or near any unim

proved forest-covered, brush-covered or grass -covered land unless the engine’s exhaust system is equipped with

a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal lav ^s apply on federal lands. A spark arrester for the muffler is available

through your nearest engine authorized service center.

^ *waVn*nV^J

To reduce the potential for any injury, comply with the following safety instructions. Failure to comply

with the instructions may result in personal injury.

SAFE OPERATION PRACTICES FOR TILLERS

1. It is suggested that this manual be read in its

entirety before attempting to assemble or

operate this unit. Keep this manual in a safe

place for future and regular reference and for

ordering replacement parts.

2. Your tiller is a precision piece of power equip

ment, not a plaything. Therefore, exercise ex

treme caution at all times.

3. Read this Owner’s Manual carefully. Be

thoroughly familiar with the controls and the

proper use of the equipment.

4. Never allow children to operate a power tiller.

Only persons well acquainted with these rules

of safe operation should be allowed to use

your tiller.

5. No one should operate this unit while intoxi

cated or while taking medication that impairs

the senses or reactions.

6. Keep the area of operation ciear of ail per

sons, particularly small children and pets.

14. Do not walk in front of the tiller while the

engine is running.

15. Check the fuel before starting the engine.

Gasoline is an extremely flammable fuel. Do

not fill gasoline tank indoors, while the engine

is running, or while the engine is still hot.

Replace gasoline cap securely, and wipe off

any spilled gasoline before starting the

engine as it may cause a fire or explosion.

16. Do not run the engine while indoors. Exhaust

gases are deadly poisonous.

17. Be careful not to touch the muffler after the

engine has been running. It is hot.

18. Do not change the engine governor settings

or overspeed the engine. Excessive engine

speeds are dangerous.

19. Before any maintenance work is performed or

adjustments are made, remove the spark plug

wire and ground it on the engine block for

added safety.

7. Do not operate equipment when barefoot or

wearing open sandals. Always wear substan

tial footwear.

8. Do not wear loose fitting clothing that could

get caught on the tiller.

9. Do not start the engine unless the shift lever

is in the neutral (N) position.

10. Do not stand in front of the tiller while starting

the engine.

11. Do not place feet and hands on or near the

tines when starting the engine or while the

engine is running.

12. Never attempt to make a wheel or depth bar

adjustment while the engine is running.

13. Do not leave the tiller unattended with the

engine running.

20. Use caution when tilling near buildings and

fences. Rotating tines can cause damage or

injury.

21. Before attempting to remove rocks, bricks and

other objects from tines, stop the engine and

be sure the tines have stopped completely.

Disconnect the spark plug wire and ground to

prevent accidental starting.

22. Check the tine and engine mounting bolts at

frequent intervals for proper tightness.

23. Keep all nuts, bolts and screws tight to be

sure the equipment is in safe working condi

tion.

24. Never store the equipment with gasoline in

the tank inside of a building where fumes may

reach an open flame or spark. Allow the

engine to cool before storing in any

enclosure.

FIGURE 1.

«

o

ASSEMBLY

NOTE

This unit is shipped WITHOUT GAS

OLINE or OIL. After assembly, see

separate engine manual for proper

fuel and engine oil recommenda

tions.

----

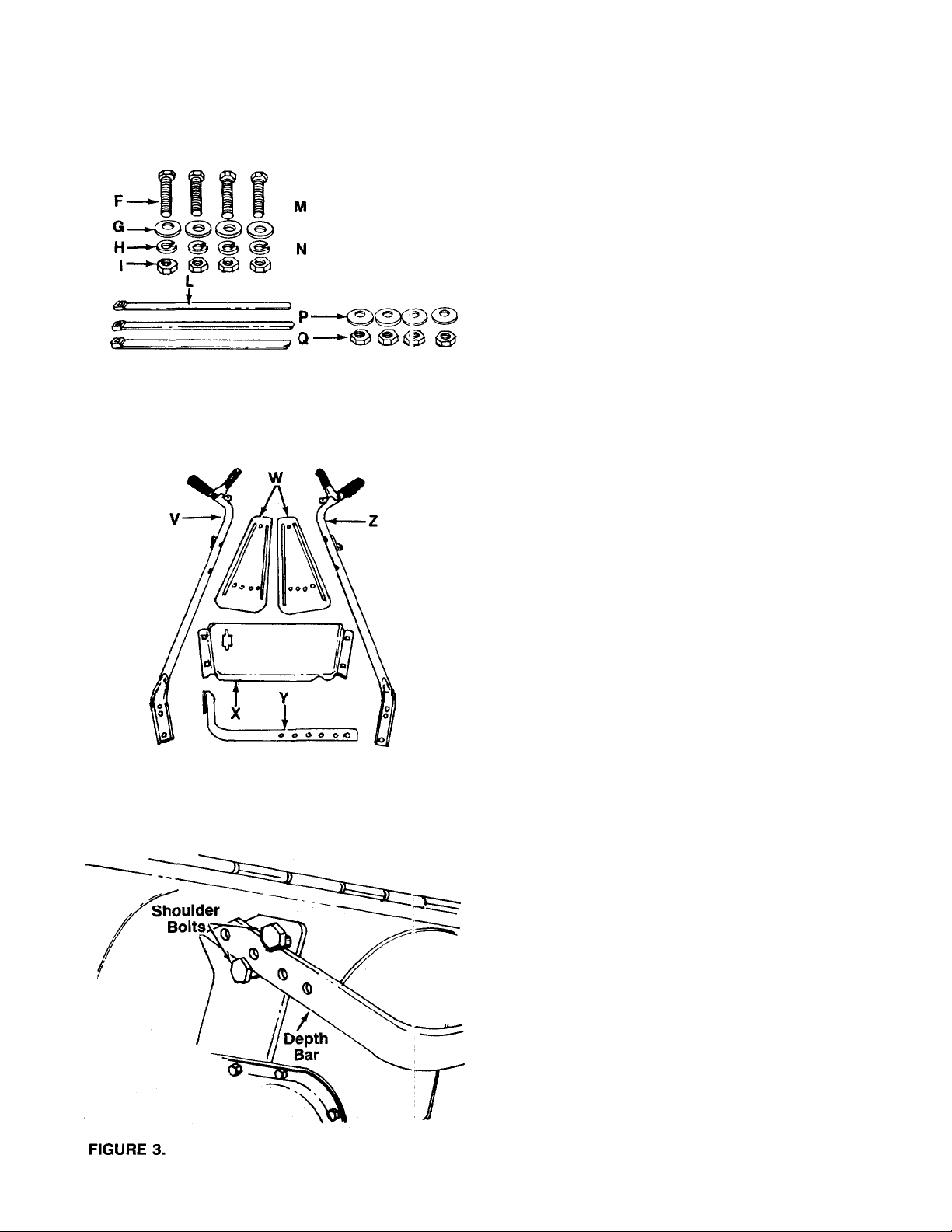

-Contents of Hardware Pack: (See Figure 1)

A (1) Hex Bolt 3/8-16 x 3/4" Long

B (1) Flat Washer 3/8" I.D.

C Ò) Ball Knob

D Ò) Clevis Pin

E Ò) Hairpin Cotter

F (4) Hex Bolts 3/8-16 x 1.0" Long

G (4) Belleville Washers 3/8" I.D.

H (4) Lock Washers 3/8" I.D.

I (4) Hex Nuts 3/8-16 Thread

L (3) Cable Ties

M (4) Carriage Bolts 5/16-18 x 1.75" Long

N (4) Lock Washers 5/16" I.D.

O (4) Hex Nuts 5/16-18 Thread

P (4) Belleville Washers 5/16" I.D.

Q (4) Hex Nuts 5/16-18 Thread

R (1) Self-Tapping Screw (Not Shown)

FIGURE 2.

-Loose Parts in Carton: (See Figure 2)

V (1) Handle—R.H.

W (2) Side Shields

X 0) Handle Panel

Y 0) Depth Bar Assembly

Z (1) Handle—LH.

This owners manual covers various models of

tillers. The units illustrated may vary from your unit.

Follow the instructions which pertain to your unit.

1. Remove tiller, loose parts and hardware pack from

carton. Make certain all parts and literature have

been removed from the carton before the carton

is discarded.

2. Extend the control cables attached to the tiller and

place on the floor. Be careful not to bend or kink

the cables.

DEPTH BAR INSTALLATION

/

1. Raise the tine shield hinge flap assembly. Insert

the depth bar assembly (Y) between the two

shoulder bolts and up through the tine shield

------

assembly as shown in figure 3.

NOTE

For clarity, figure 3 was taken with

tiller raised on end. It is not neces

sary to raise the tiller.

End Cover

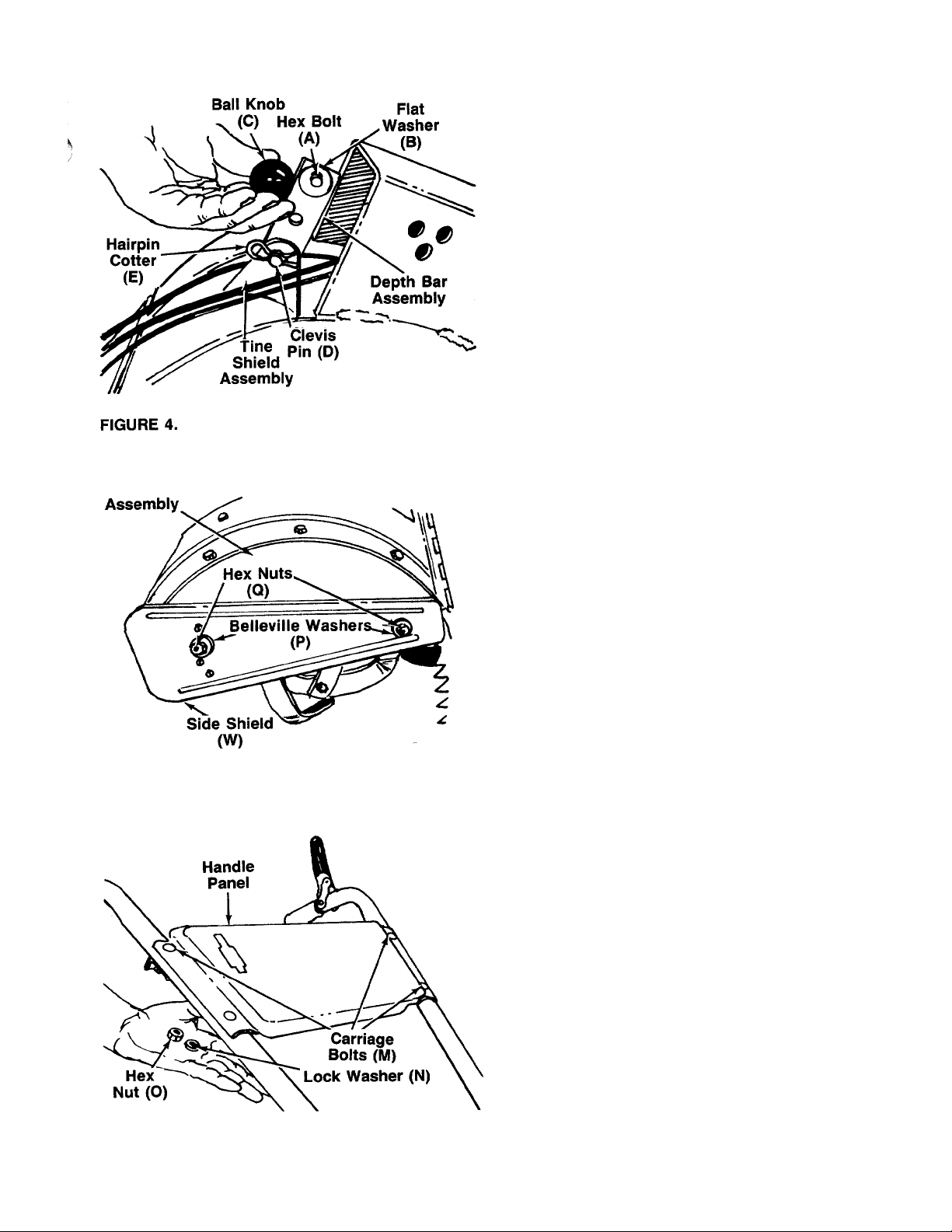

2. Insert clevis pin (D) through the tine shield and

depth bar assemblies. Secure with hairpin cotter

—(E). See figure 4.

3. Insert hex bolt (A) into the upper hole of the depth

bar assembly. Place flat washer (B) onto the hex

bolt and thread ball knob (C) onto the hex bolt. See

figure 4. Tighten secureiy.

SIDE SHIELD INSTALLATION

Mount side shields (W) over the weld bolts on the end

cover assemblies. Secure with belleville washers (P)

-and hex nuts (Q). See figure 5.

FIGURE 5.

FIGURE 6.

HANDLE ASSEMBLY

1. Attach the handle panel to the handles using carrige bolts (M), lock washer (W) and hex nuts (O).

------

See figure 6. Do not tighten.

NOTE

To align the holes in the handle panel

and the handle, it may be necessary to

loosen the cable brackets which are

mounted to the back of the handles with

self-tapping screws.

NOTE

On Models 402 and 404, handle height

is determined by the three mounting

holes in the handle mounting bracket.

Refer to the adjustment section in your

owner’s manual.

FIGURE 7—Model 405 Shown.

Belleville

Washers (3)

2. Place handle assembly in position on the tiller.

Working on one side of the unit, insert one hex bolt

(F) through belleville washer (G) (crowned side of

washer goes against head of bolt), then through

bottom hole of handle and handle mounting

bracket. Secure loosely with lock washer (H) and

-hex nut (I). See figure 7.

3. Align the other side of the handle with the handle

mounting bracket. It may be necessary to use force

to spring the handle over the handle mounting

bracket. Secure loosely with hex bolt, belleville

washer, lock washer and hex nut.

4. Secure upper hole in handle to handle mounting

bracket (both sides) in the same manner.

5. Tighten securely all four nuts and bolts which

secure the handles to the handle mounting

brackets. Then tighten the four nuts at the handle

panel.

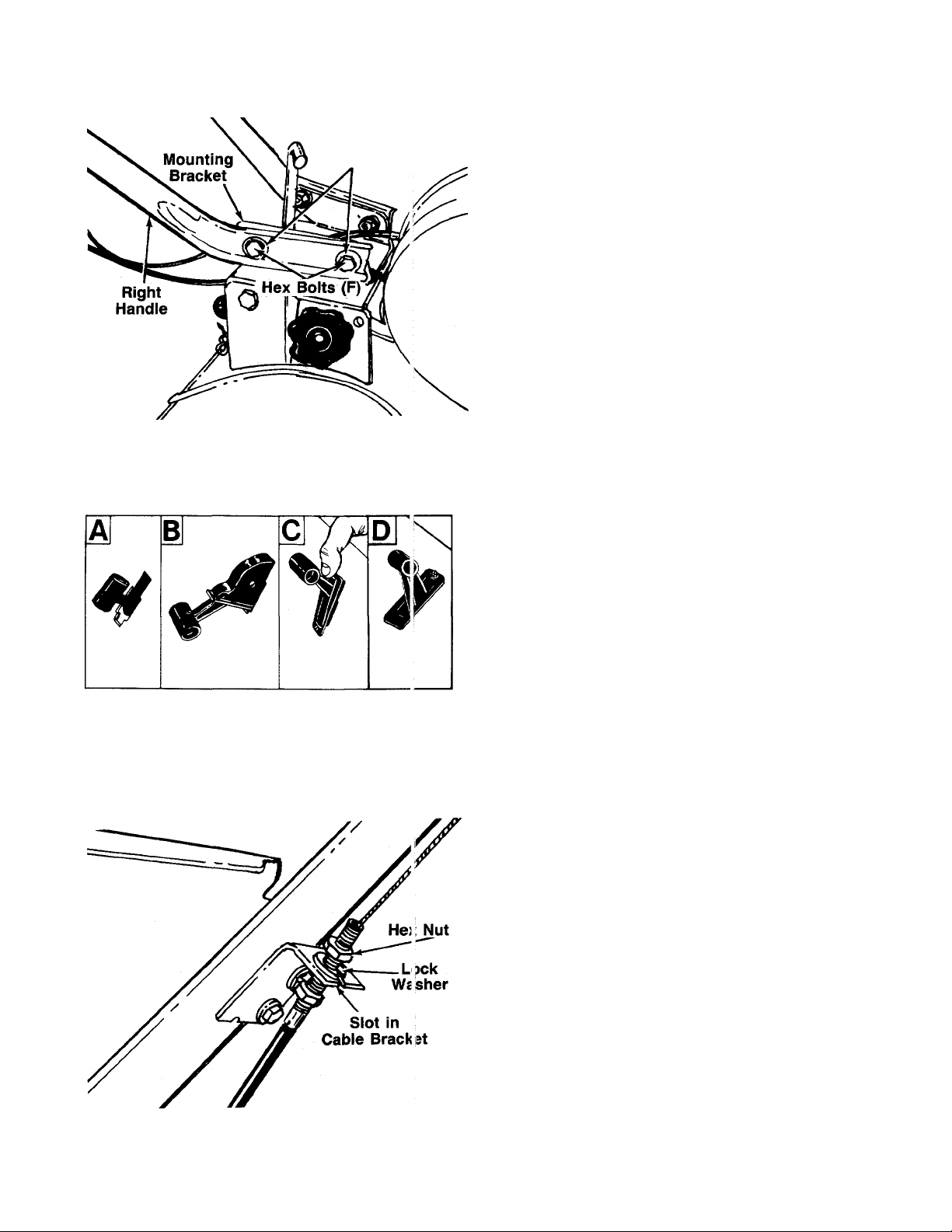

THROTTLE CONTROL INSTALLATION

Assemble the throttle control to the handle panel as

follows.

1. Hold the throttle control assembly beneath the han

dle panel. Turn the control sideways and insert the

lever up through the wide portion of the slot on the

------

handle panel. See figure 8A.

2. After the end of the lever is through the slot, turn

and then tip the control forward as shown in figure

8B to slide it through the slot.

FIGURE 8.

FIGURE 9.

NOTE

The lever must be all the way to the

back of the control housing as

shown in figure 8B.

3. Push the control back into the slot in the handle

panel and press in place. Be certain the control is

locked securely into the slot.

4. Secure the throttle control to the handle panel

using the self-tapping screw (R). See figure 8D.

ATTACHING THE CLUTCH CONTROL CABLES

The drive clutch and tine clutch control cables are

already attached to the unit. There is a tag attached

to the drive clutch cable (cable which appears to be

shorter). This cable attaches to the right handle.

NOTE

Both the drive clutch cable and the

tine clutch cable are attached to

springs, which are hooked to weld

-bolts as shown in figure 9. If either

the cable or spring has come loose

in shipping, it must be reassembled.

Refer to page 18, reference numbers

1, 2, 89 and 98.

Control Wire

FIGURE 10.

Hole in

Clutch Lever

1. Remove one nut and the lock washer from the end

of the drive clutch cable (short cable). Slip the

cable up through the slot on the cable bracket on

the right handle. Rethread hex nut and lock washer

on the end of the cable. See figure 9. Do not tighten

at this time.

2. Hook the “Z” end of drive clutch cable into the hole

in drive clutch lever.

-3. With the clutch lever released (in the “up” posi

tion), adjust the bottom nut at the cable bracket so

there is only a slight amount of slack in the control

wire. Tighten the upper nut against the bracket.

Squeeze the clutch lever against the handle. The

control wire should now be straight. See figure 10.

NOTE

Do not overtighten control wire.

Too much tension may cause it to

break.

H. Attach the tine clutch cable (cable which appears

to be longer) to the tine clutch lever on the left han

dle in the same manner as the drive clutch cable.

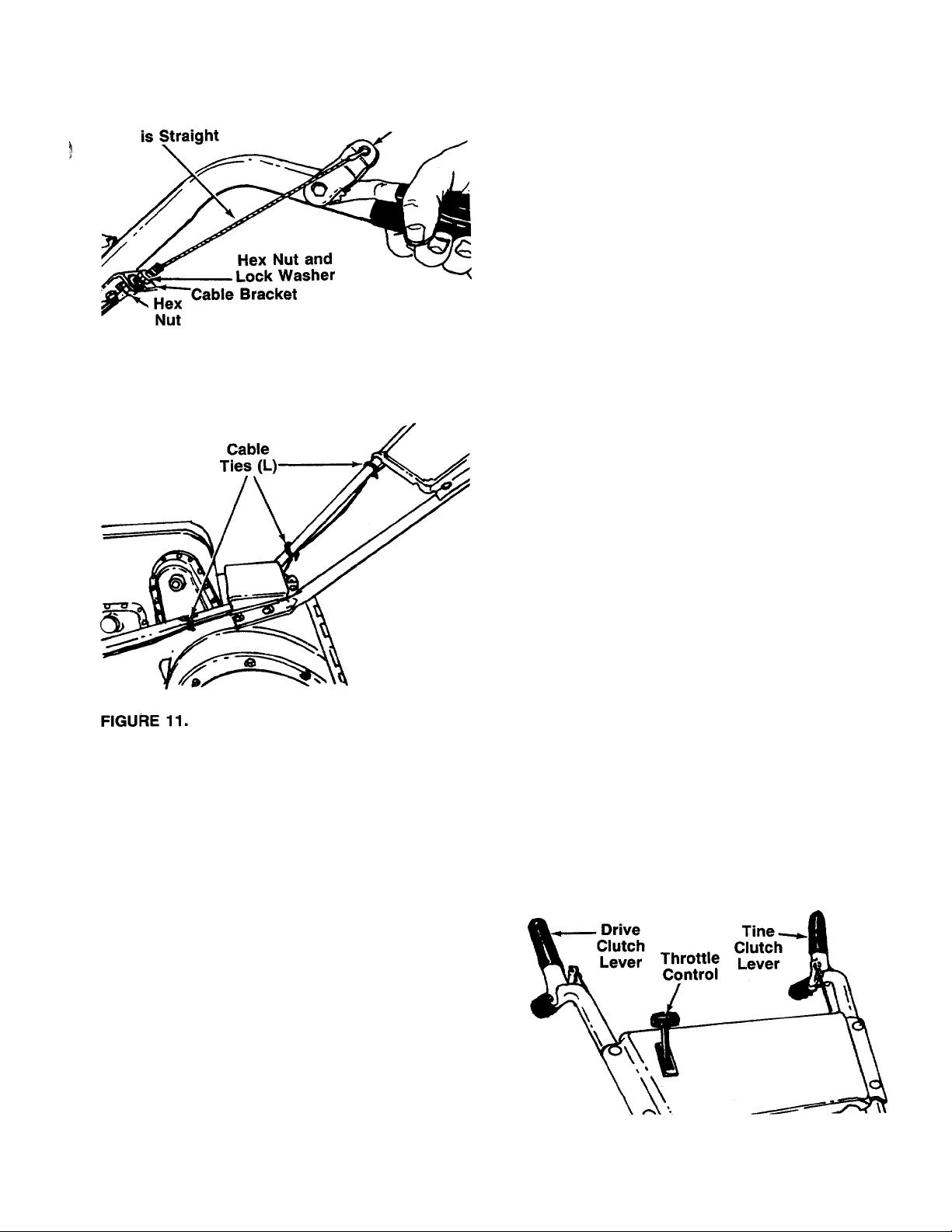

5. Secure all the cables to the right handle as shown

-----

in figure 11 with cable ties (L). In addition, secure

the throttle cable directly to the tiller frame with

cable tie.

CONTROLS-

Throttle Control

The throttle control lever is located on the right hand

side of handle panel and controls the engine speed.

See figure 12.

1. Start—Push throttle control lever forward (down)

to start position.

2. Stop—Pull lever back (upward) to stop the engine.

Tine Clutch Lever

The tine clutch lever is located on the left handle. See

figure 12.

Squeeze the lever down to engage the tines. Release

the lever to disengage the tines.

-Location and Use

Drive Clutch Lever

The drive clutch lever is located on the right handle.

See figure 12.

Squeeze the lever down to engage the wheels. Release

the lever to disengage the wheels.

FIGURE 12.

Loading...

Loading...